Application of Digital Technologies Tools for Social and Sustainable Construction in a Developing Economy

Abstract

:1. Introduction

2. Understanding the Concept of Digital Technologies (DTs)

2.1. The Emergence of Digital Technologies (DTs)

2.2. Adoption of Digital Technologies (DTs) in the Construction Industry

2.2.1. Design Phase

2.2.2. Construction and Engineering Phase

2.2.3. Operation and Management Phase

3. Research Methodology

4. Results

4.1. Background Information of Respondents

4.2. Application Areas of Digital Technologies (DTs)

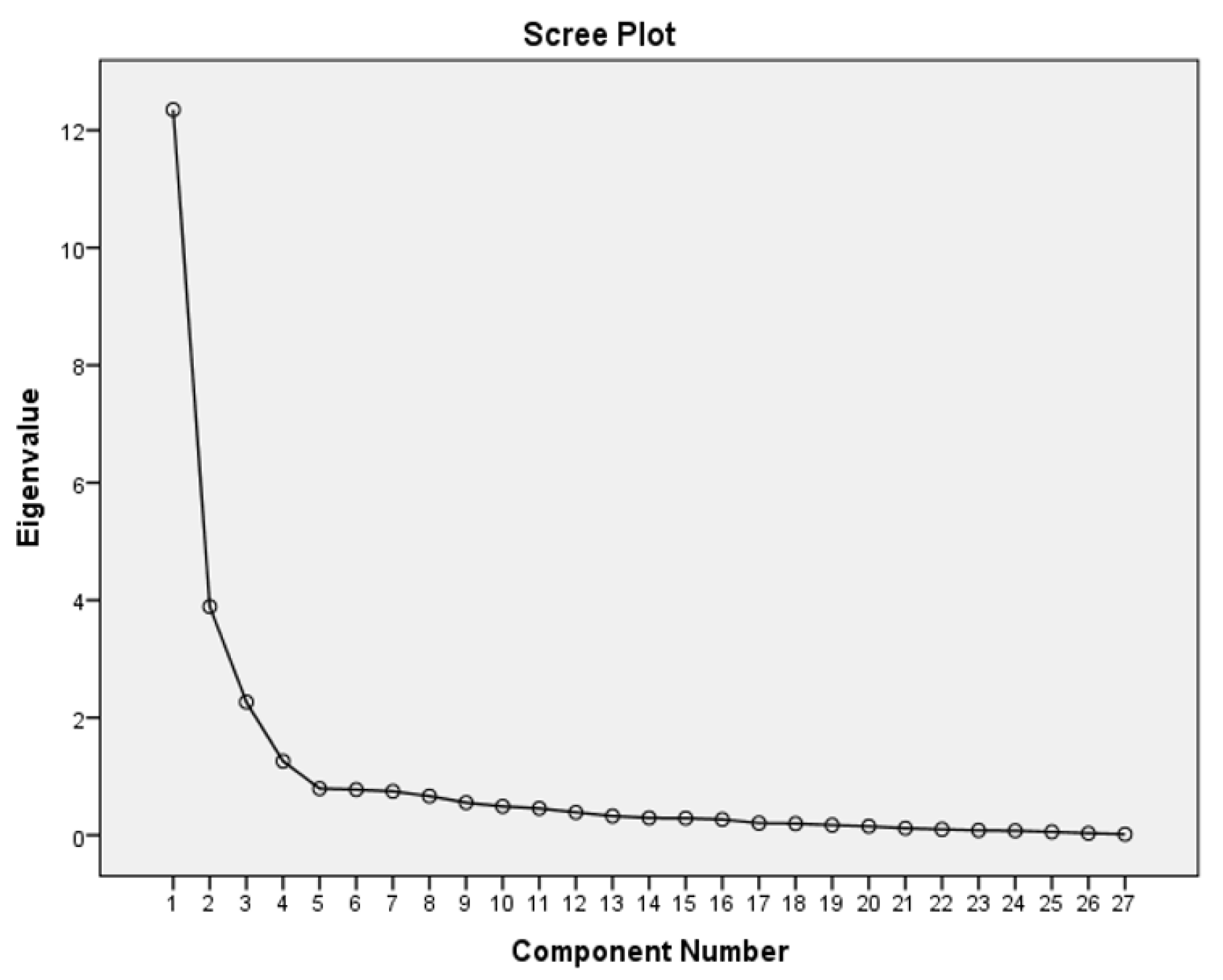

4.3. Factor Analysis of the Areas of Application of Digital Technologies (DTs)

5. Discussion of Findings

- Component 1—Pre-contract stage

- Component 2—Construction stage

- Component 3—Post contract stage

- Component 4—Modelling stage

6. Conclusions and Recommendations

- (1)

- The study provides construction organizations with insights into innovative ways in which digital technologies (DTs) can enhance various stages of construction projects.

- (2)

- Policymakers and government entities can leverage the study’s findings to make informed decisions about investing in DT for the benefit of the broader community.

- (3)

- The study encourages governments to support the digitalization of the construction industry by subsidizing the acquisition of DT, facilitating their widespread adoption in construction organizations.

- (4)

- Emphasizing the significant safety and productivity benefits of DT, the study advocates for developing countries to embrace and implement DT across various sectors to stimulate economic growth. These sectors include finance, health, energy, aviation, education, and others.

- (5)

- The study highlights the potential for construction organizations to achieve improved safety measures and enhanced productivity by integrating DT into their operations, which can lead to better outcomes for both workers and the industry as a whole.

- (6)

- It underscores the importance of staying current with technological advancements in the construction sector, as failing to adopt DT may result in missed opportunities for efficiency and competitiveness.

- (7)

- The study’s findings also emphasize the role of collaboration between construction organizations, technology providers, and government bodies to create an environment conducive to the successful implementation of DTs in the industry.

- (8)

- Policymakers can consider incentivizing research and development in DT tailored for the construction sector, as this can lead to the creation of specialized solutions that address industry-specific challenges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aghimien, D.; Ikuabe, M.; Aliu, J.; Aigbavboa, C.; Oke, A.E.; Edwards, D.J. Empirical scrutiny of the behavioral intention of construction organizations to use unmanned aerial vehicles. Constr. Innov. 2022, 23, 1075–1094. [Google Scholar] [CrossRef]

- Sajjad, M.; Hu, A.; Waqar, A.; Falqi, I.I.; Alsulamy, S.H.; Bageis, A.S.; Alshehri, A.M. Evaluation of the Success of Industry 4.0 Digitalization Practices for Sustainable Construction Management: Chinese Construction Industry. Buildings 2023, 13, 1668. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Ngo, J.; Teo, J.Z.K. Challenges and Strategies for the Adoption of Smart Technologies in the Construction Industry: The Case of Singapore. J. Manag. Eng. 2022, 38, 05021014. [Google Scholar] [CrossRef]

- Oke, A.E.; Arowoiya, V.A. An analysis of the application areas of augmented reality technology in the construction industry. Smart Sustain. Built Environ. 2021, 11, 1081–1098. [Google Scholar] [CrossRef]

- Okafor, C.C.; Aigbavboa, C.; Thwala, W.D. A bibliometric evaluation and critical review of the smart city concept—Making a case for social equity. J. Sci. Technol. Policy Manag. 2022, 14, 487–510. [Google Scholar] [CrossRef]

- Bodenko, E.M.; Slesarev, M.Y.; Shershneva, M.V.; Perepechenov, A.M. Reducing the Negative Impact of Harmful Factors on the Environment in the Process of Transporting Waste from Demolition of Buildings and Structures. IOP Conf. Series Earth Environ. Sci. 2022, 988, 052063. [Google Scholar] [CrossRef]

- Ibrahim, F.S.B.; Ebekozien, A.; Khan, P.A.M.; Aigbedion, M.; Ogbaini, I.F.; Amadi, G.C. Appraising fourth industrial revolution technologies’ role in the construction sector: How prepared is the construction consultants? Facilities 2022, 40, 515–532. [Google Scholar] [CrossRef]

- Yahya, M.Y.; Abba, W.A.; Mohamed, S.; Yassin, A.M. Contributing factors of poor construction project performance in Nigeria. Int. J. Prop. Sci. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Botha, C.P. Determining the Human Factors Influencing RFID Technology Adoption in the South African Wholesale Distribution Industry. Doctoral Dissertation, North-West University, Potchefstroom, South Africa, 2023. [Google Scholar]

- Ebekozien, A.; Aigbavboa, C.; Aigbedion, M. Construction industry post-COVID-19 recovery: Stakeholders perspective on achieving sustainable development goals. Int. J. Constr. Manag. 2021, 23, 1376–1386. [Google Scholar] [CrossRef]

- Adekunle, S.A.; Ejohwomu, O.; Aigbavboa, C.O. Building Information Modelling Diffusion Research in Developing Countries: A User Meta-Model Approach. Buildings 2021, 11, 264. [Google Scholar] [CrossRef]

- Perera, U.D.S.; Kulatunga, U.; Abdeen, F.N.; Sepasgozar, S.M.E.; Tennakoon, M. Application of building information modelling for fire hazard management in high-rise buildings: An investigation in Sri Lanka. Intell. Build. Int. 2022, 14, 207–221. [Google Scholar] [CrossRef]

- Oke, A.E.; Arowoiya, V.A.; Akomolafe, O.T. Influence of the Internet of Things’ application on construction project performance. Int. J. Constr. Manag. 2020, 22, 2517–2527. [Google Scholar] [CrossRef]

- Ali, M.H.; Issayev, G.; Shehab, E.; Sarfraz, S. A critical review of 3D printing and digital manufacturing in construction engineering. Rapid Prototyp. J. 2022, 28, 1312–1324. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0: Introduction and overview. In Construction 4.0; Routledge: London, UK, 2020; pp. 3–22. [Google Scholar]

- Petrov, I.; Hakimov, A. Digital technologies in construction monitoring and construction control. IOP Conf. Ser. Mater. Sci. Eng. 2019, 497, 012016. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Costin, A.M.; Karimi, R.; Shirowzhan, S.; Abbasian, E.; Li, J. BIM and Digital Tools for State-of-the-Art Construction Cost Management. Buildings 2022, 12, 396. [Google Scholar] [CrossRef]

- Manzoor, B.; Othman, I.; Pomares, J.C. Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities. Int. J. Environ. Res. Public Health 2021, 18, 6135. [Google Scholar] [CrossRef]

- Cao, D.; Li, H.; Wang, G. Impacts of building information modeling (BIM) implementation on design and construction performance: A resource dependence theory perspective. Front. Eng. Manag. 2017, 4, 20–34. [Google Scholar] [CrossRef]

- Ismail, S.A.; Bandi, S.; Maaz, Z.N. An Appraisal into the Potential Application of Big Data in the Construction Industry. Int. J. Built Environ. Sustain. 2018, 5, 145–154. [Google Scholar] [CrossRef]

- Ustinovičius, L.; Puzinas, A.; Starynina, J.; Vaišnoras, M.; Černiavskaja, O.; Kontrimovičius, R. Challenges of BIM technology application in project planning. Eng. Manag. Prod. Serv. 2018, 10, 15–28. [Google Scholar] [CrossRef]

- Ikuabe, M.; Aghimien, D.; Aigbavboa, C.; Oke, A. Exploring the adoption of digital technology at the different phases of construction projects in South Africa. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020; pp. 10–12. [Google Scholar]

- Sharma, S.; Mitra, S.; Adesina, A.; Das, S. Construction Industry with 3D Printer: A New Era. In Recent Advances in Computational and Experimental Mechanics, Vol II; Springer: Singapore, 2022; pp. 311–324. [Google Scholar]

- Gan, Y.; Yin, H.; Chen, X. Application of BIM and RFID Technologies in Power Construction Industry. IOP Conf. Series Earth Environ. Sci. 2020, 558, 052069. [Google Scholar] [CrossRef]

- Naranje, V.; Swarnalatha, R. Design of Tracking System for Prefabricated Building Components using RFID Technology and CAD Model. Procedia Manuf. 2019, 32, 928–935. [Google Scholar] [CrossRef]

- Boulos, T.; Sartipi, F.; Khoshaba, K. Bibliometric analysis on the status quo of robotics in construction. J. Constr. Mater. 2020, 1, 2–3. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Haghighi, A. Large-Scale Automated Additive Construction: Overview, Robotic Solutions, Sustainability, and Future Prospect. Sustainability 2022, 14, 9782. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Ge, J.; He, S.X. Digitization in facilities management: A literature review and future research directions. Autom. Constr. 2018, 92, 312–326. [Google Scholar] [CrossRef]

- Gbadamosi, A.Q.; Oyedele, L.; Mahamadu, A.M.; Kusimo, H.; Olawale, O. The role of Internet of Things in delivering smart construction. In Proceedings of the CIB World Building Congress, Hong Kong, China, 17–21 July 2019. [Google Scholar]

- Gamil, Y.; Abdullah, M.A.; Rahman, I.A.; Asad, M.M. Internet of things in construction industry revolution 4.0: Recent trends and challenges in the Malaysian context. J. Eng. Des. Tech. 2020, 18, 1091–1102. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and trends in Internet of Things (IoT) research: Future applications in the construction industry. Eng. Constr. Arch. Manag. 2020, 28, 457–481. [Google Scholar] [CrossRef]

- Asadzadeh, S.; de Oliveira, W.J.; Filho, C.R.d.S. UAV-based remote sensing for the petroleum industry and environmental monitoring: State-of-the-art and perspectives. J. Pet. Sci. Eng. 2022, 208, 109633. [Google Scholar] [CrossRef]

- Kanan, R.; Elhassan, O.; Bensalem, R. An IoT-based autonomous system for workers’ safety in construction sites with real-time alarming, monitoring, and positioning strategies. Autom. Constr. 2018, 88, 73–86. [Google Scholar] [CrossRef]

- Elghaish, F.; Matarneh, S.; Talebi, S.; Kagioglou, M.; Hosseini, M.R.; Abrishami, S. Toward digitalization in the construction industry with immersive and drones technologies: A critical literature review. Smart Sustain. Built Environ. 2021, 10, 345–363. [Google Scholar] [CrossRef]

- Keskin, B.; Salman, B.; Ozorhon, B. Airport project delivery within BIM-centric construction technology ecosystems. Eng. Constr. Arch. Manag. 2020, 28, 530–548. [Google Scholar] [CrossRef]

- Setaki, F.; van Timmeren, A. Disruptive technologies for circular building industry. Build. Environ. 2022, 223, 109394. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Bosch-Sijtsema, P.; Claeson-Jonsson, C.; Johansson, M.; Roupe, M. The hype factor of digital technologies in AEC. Constr. Innov. 2021, 21, 899–916. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Pelosi, A.; Jia, Y.; Shen, X.; Siddiqui, M.K.; Yang, N. Implementation of technologies in the construction industry: A systematic review. Eng. Constr. Arch. Manag. 2021, 29, 3181–3209. [Google Scholar] [CrossRef]

- Henriksson, F.; Johansen, K. Integrated Product and Production Research on Introducing Internet of Things in Swedish Wood Industry Products. Procedia Manuf. 2018, 25, 10–16. [Google Scholar] [CrossRef]

- Bajpai, A.; Misra, S.C. A framework for the continuation of digitalization in construction: A PLS-SEM approach. Eng. Constr. Archit. Manag. 2022, 30, 4715–4734. [Google Scholar] [CrossRef]

- Ikuabe, M.; Aigbavboa, C.; Anumba, C.; Oke, A.; Aghimien, L. Confirmatory Factor Analysis of Performance Measurement Indicators Determining the Uptake of CPS for Facilities Management. Buildings 2022, 12, 466. [Google Scholar] [CrossRef]

- Masoetsa, T.G.; Ogunbayo, B.F.; Aigbavboa, C.O.; Awuzie, B.O. Assessing Construction Constraint Factors on Project Performance in the Construction Industry. Buildings 2022, 12, 1183. [Google Scholar] [CrossRef]

- Akinradewo, O.; Aigbavboa, C.; Oke, A.; Edwards, D.; Kasongo, N. Key requirements for effective implementation of building information modelling for maintenance management. Int. J. Constr. Manag. 2021, 23, 1902–1910. [Google Scholar] [CrossRef]

- Pallant, J. SPSS Survival Manual: A Step by Step Guide to Data Analysis Using IBM SPSS; McGraw-Hill Education: Maidenhead, UK, 2020. [Google Scholar]

- Phakiti, A. Likert-type scale construction. In The Routledge Handbook of Second Language Acquisition and Language Testing; Routledge: London, UK, 2020; pp. 102–144. [Google Scholar]

- Adepoju, O.O.; Aigbavboa, C.O. Assessing knowledge and skills gap for construction 4.0 in a developing economy. J. Public Aff. 2021, 21, e2264. [Google Scholar] [CrossRef]

- Gunasekara, D.M.H.; Indikatiya, I.H.P.R.; Perera, B.A.K.S.; Senaratne, S. Managing intragroup conflicts within project design teams during the pre-contract stage that affect the project deliverables in Sri Lanka. Constr. Innov. 2022, 23, 406–424. [Google Scholar] [CrossRef]

- Rajaratnam, D.; Weerasinghe, D.; Abeynayake, M.; Perera, B.A.K.S.; Ochoa, J.J. Potential use of Augmented Reality in pre-contract design communication in construction projects. Intell. Build. Int. 2021, 14, 661–678. [Google Scholar] [CrossRef]

- Daniotti, B.; Gianinetto, M.; Della Torre, S. Digital Transformation of the Design, Construction, and Management Processes of the Built Environment; Springer: Berlin/Heidelberg, Germany, 2020; p. 400. [Google Scholar]

- Re Cecconi, F.; Dejaco, M.C.; Moretti, N.; Mannino, A.; Blanco Cadena, J.D. Digital asset management. In Digital Transformation of the Design, Construction and Management Processes of the Built Environment; Springer: Cham, Switzerland, 2020; pp. 243–253. [Google Scholar]

- Yevu, S.K.; Ann, T.W.; Darko, A. Digitalization of construction supply chain and procurement in the built environment: Emerging technologies and opportunities for sustainable processes. J. Clean. Prod. 2021, 322, 129093. [Google Scholar] [CrossRef]

- Bello, S.A.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Delgado, J.M.D.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud computing in the construction industry: Use cases, benefits, and challenges. Autom. Constr. 2021, 122, 103441. [Google Scholar] [CrossRef]

- Nagitta, P.O.; Mugurusi, G.; Obicci, P.A.; Awuor, E. Human-centered artificial intelligence for the public sector: The gatekeeping role of the public procurement professional. Procedia Comput. Sci. 2022, 200, 1084–1092. [Google Scholar] [CrossRef]

- García de Soto, D.B.; Streule, T.; Klippel, M.; Bartlomé, O.; Adey, B.T. Improving the planning and design phases of construction projects by using a Case-Based Digital Building System. Int. J. Constr. Manag. 2020, 20, 900–911. [Google Scholar] [CrossRef]

- Chaurasia, S.S.; Verma, S. Strategic determinants of big data analytics in the AEC sector: A multi-perspective framework. Constr. Econ. Build. 2020, 20, 63–81. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Lim, J.H.; Weng, Y.; Tay, Y.W.D.; Pham, H.; Pham, Q.-C. Large-scale 3D printing by a team of mobile robots. Autom. Constr. 2018, 95, 98–106. [Google Scholar] [CrossRef]

- Bumgardner, M.; Buehlmann, U. A Preliminary Assessment of Industry 4.0 and Digitized Manufacturing in the North American Woodworking Industry. For. Prod. J. 2022, 72, 67–73. [Google Scholar] [CrossRef]

- Chea, C.P.; Bai, Y.; Pan, X.; Arashpour, M.; Xie, Y. An integrated review of automation and robotic technologies for structural prefabrication and construction. Transp. Saf. Environ. 2020, 2, 81–96. [Google Scholar] [CrossRef]

- Igwe, U.S.; Mohamed, S.F.; Azwarie, M.B.M.D.; Eberechukwu, N.P. Recent Developments in Construction Post Contract Cost Control Systems. J. Comput. Theor. Nanosci. 2020, 17, 1236–1241. [Google Scholar] [CrossRef]

- Jafari, K.G.; Noorzai, E.; Hosseini, M.R. Assessing the capabilities of computing features in addressing the most common issues in the AEC industry. Constr. Innov. 2021, 21, 875–898. [Google Scholar]

- Ormiston, R.; Belman, D.; Erlich, M. An Empirical Methodology to Estimate the Incidence and Costs of Payroll Fraud in the Construction Industry. Report. 2020. Available online: http://stoptaxfraud.net/wp-content/uploads/2020/03/National-Carpenters-Study-Methodology-for-Wage-and-Tax-Fraud-Report-FINAL.pdf (accessed on 10 October 2023).

- Waqar, A.; Skrzypkowski, K.; Almujibah, H.; Zagórski, K.; Khan, M.B.; Zagórska, A.; Benjeddou, O. Success of Implementing Cloud Computing for Smart Development in Small Construction Projects. Appl. Sci. 2023, 13, 5713. [Google Scholar] [CrossRef]

- Babatunde, S.O.; Ekundayo, D.; Adekunle, A.O.; Bello, W. Comparative analysis of drivers to BIM adoption among AEC firms in developing countries: A case of Nigeria. J. Eng. Des. Technol. 2020, 18, 1425–1447. [Google Scholar] [CrossRef]

- Mikhailov, S.; Mikhailova, A.; Nadyrshine, N.; Nadyrshine, L. BIM-technologies and digital modeling in educational architectural design. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012168. [Google Scholar] [CrossRef]

- Garbett, J.; Hartley, T.; Heesom, D. A multi-user collaborative BIM-AR system to support design and construction. Autom. Constr. 2021, 122, 103487. [Google Scholar] [CrossRef]

- Babatunde, S.O.; Ekundayo, D.O.; Adekunle, A.O. Analysis of BIM maturity level among AEC firms in developing countries: A case of Nigeria. In Proceedings of the 35th Annual ARCOM Conference, Leeds, UK, 2–4 September 2019; pp. 225–234. [Google Scholar]

| Areas of Application | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Architectural design | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Cost planning | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Prefabrication | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Cost estimating | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Feasibility study | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Construction cost control | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Structural analysis | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Contract documentation | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| Supervision and surveying | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| Building system analysis | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Facility management | ✓ | ✓ | ✓ | |||||||||||||

| Dispute resolution | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| Procurement management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Asset management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Property management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Construction supply | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| Contract management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Chain management | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| Project management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Fabrication | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Concrete making | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| Carpentry | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| Excavation | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Drilling | ✓ | ✓ | ✓ | |||||||||||||

| Painting | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Maintenance schedule | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Existing condition modeling | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Areas of Application | Mean () | Std. Deviation (SD) | Rank |

|---|---|---|---|

| Architectural design | 4.35 | 0.954 | 1 |

| Cost planning | 3.85 | 1.152 | 2 |

| Building system analysis | 3.84 | 1.091 | 3 |

| Structural analysis | 3.81 | 1.022 | 4 |

| Contract documentation | 3.78 | 1.180 | 5 |

| Construction cost control | 3.74 | 1.096 | 6 |

| Feasibility study | 3.74 | 1.124 | 7 |

| Contract management | 3.71 | 1.158 | 8 |

| Payroll | 3.66 | 1.166 | 10 |

| Supervision and surveying | 3.66 | 1.166 | 11 |

| Property management | 3.66 | 1.218 | 9 |

| Chain management | 3.63 | 1.213 | 12 |

| Project management | 3.61 | 1.313 | 13 |

| Asset management | 3.60 | 1.199 | 14 |

| Construction supply | 3.58 | 1.175 | 15 |

| Prefabrication | 3.55 | 1.159 | 16 |

| Procurement management | 3.45 | 1.202 | 17 |

| Dispute resolution | 3.42 | 1.175 | 18 |

| Existing condition modeling | 3.37 | 1.287 | 19 |

| Maintenance schedule | 3.26 | 1.311 | 20 |

| Excavation | 3.11 | 1.331 | 21 |

| Carpentry | 3.06 | 1.322 | 22 |

| Painting | 3.04 | 1.315 | 23 |

| Drilling | 2.98 | 1.316 | 24 |

| Concrete making | 2.98 | 1.324 | 25 |

| Bricklaying | 2.96 | 1.392 | 26 |

| Fabrication | 2.94 | 1.353 | 27 |

| Component | Initial Eigenvalues | Rotation Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 12.349 | 45.739 | 45.739 | 6.711 | 24.854 | 24.854 |

| 2 | 3.889 | 14.405 | 60.144 | 6.010 | 22.258 | 47.113 |

| 3 | 2.266 | 8.391 | 68.535 | 5.407 | 20.028 | 67.140 |

| 4 | 1.259 | 4.662 | 73.197 | 1.635 | 6.057 | 73.197 |

| 5 | 0.793 | 2.938 | 76.135 | |||

| 6 | 0.775 | 2.870 | 79.005 | |||

| 7 | 0.746 | 2.764 | 81.769 | |||

| 8 | 0.664 | 2.460 | 84.229 | |||

| 9 | 0.554 | 2.051 | 86.280 | |||

| 10 | 0.490 | 1.814 | 88.094 | |||

| 11 | 0.455 | 1.686 | 89.780 | |||

| 12 | 0.388 | 1.437 | 91.217 | |||

| 13 | 0.325 | 1.204 | 92.421 | |||

| 14 | 0.294 | 1.088 | 93.509 | |||

| 15 | 0.288 | 1.065 | 94.574 | |||

| 16 | 0.267 | 0.987 | 95.561 | |||

| 17 | 0.206 | 0.762 | 96.323 | |||

| 18 | 0.197 | 0.729 | 97.052 | |||

| 19 | 0.172 | 0.635 | 97.688 | |||

| 20 | 0.150 | 0.557 | 98.244 | |||

| 21 | 0.117 | 0.435 | 98.679 | |||

| 22 | 0.098 | 0.365 | 99.044 | |||

| 23 | 0.081 | 0.301 | 99.345 | |||

| 24 | 0.074 | 0.274 | 99.619 | |||

| 25 | 0.055 | 0.203 | 99.822 | |||

| 26 | 0.032 | 0.118 | 99.940 | |||

| 27 | 0.016 | 0.060 | 100.000 | |||

| Kaiser–Meyer–Olkin Measure of Sampling Adequacy | 0.820 | |||||

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 2714.281 | ||||

| Df | 351 | |||||

| Sig. | 0.000 | |||||

| Application Areas | Component | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Pre-contract stage | ||||

| Contract management | 0.852 | |||

| Property management | 0.845 | |||

| Asset management | 0.832 | |||

| Procurement management | 0.811 | |||

| Construction supply | 0.725 | |||

| Chain management | 0.716 | |||

| Building system analysis | 0.674 | |||

| Contract documentation | 0.607 | |||

| Dispute resolution | 0.575 | |||

| Supervision and surveying | 0.574 | |||

| Construction stage | ||||

| Concrete making | 0.855 | |||

| Fabrication | 0.852 | |||

| Carpentry | 0.839 | |||

| Painting | 0.835 | |||

| Bricklaying | 0.795 | |||

| Drilling | 0.775 | |||

| Excavation | 0.731 | |||

| Maintenance schedule | 0.656 | |||

| Post contract stage | ||||

| Feasibility study | 0.813 | |||

| Payroll | 0.810 | |||

| Cost planning | 0.768 | |||

| Construction cost control | 0.764 | |||

| Structural analysis | 0.679 | |||

| Prefabrication | 0.632 | |||

| Building system analysis | 0.573 | |||

| Modelling stage | ||||

| Architectural design | 0.866 | |||

| Existing condition modeling | 0.689 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oke, A.E.; Aliu, J.; Jamir Singh, P.S.; Onajite, S.A.; Kineber, A.F.; Samsurijan, M.S. Application of Digital Technologies Tools for Social and Sustainable Construction in a Developing Economy. Sustainability 2023, 15, 16378. https://doi.org/10.3390/su152316378

Oke AE, Aliu J, Jamir Singh PS, Onajite SA, Kineber AF, Samsurijan MS. Application of Digital Technologies Tools for Social and Sustainable Construction in a Developing Economy. Sustainability. 2023; 15(23):16378. https://doi.org/10.3390/su152316378

Chicago/Turabian StyleOke, Ayodeji Emmanuel, John Aliu, Paramjit Singh Jamir Singh, Solomon A. Onajite, Ahmed Farouk Kineber, and Mohamad Shaharudin Samsurijan. 2023. "Application of Digital Technologies Tools for Social and Sustainable Construction in a Developing Economy" Sustainability 15, no. 23: 16378. https://doi.org/10.3390/su152316378

APA StyleOke, A. E., Aliu, J., Jamir Singh, P. S., Onajite, S. A., Kineber, A. F., & Samsurijan, M. S. (2023). Application of Digital Technologies Tools for Social and Sustainable Construction in a Developing Economy. Sustainability, 15(23), 16378. https://doi.org/10.3390/su152316378