Towards the Sustainable Intensification of Aquaculture: Exploring Possible Ways Forward

Abstract

:1. Introduction

Aquaculture and the EU

- Aquaculture systems—the most appropriate farming method;

- Technological solutions for aquaculture systems;

- Technological solutions—future perspectives;

- Development of the aquaculture sector through good management practices.

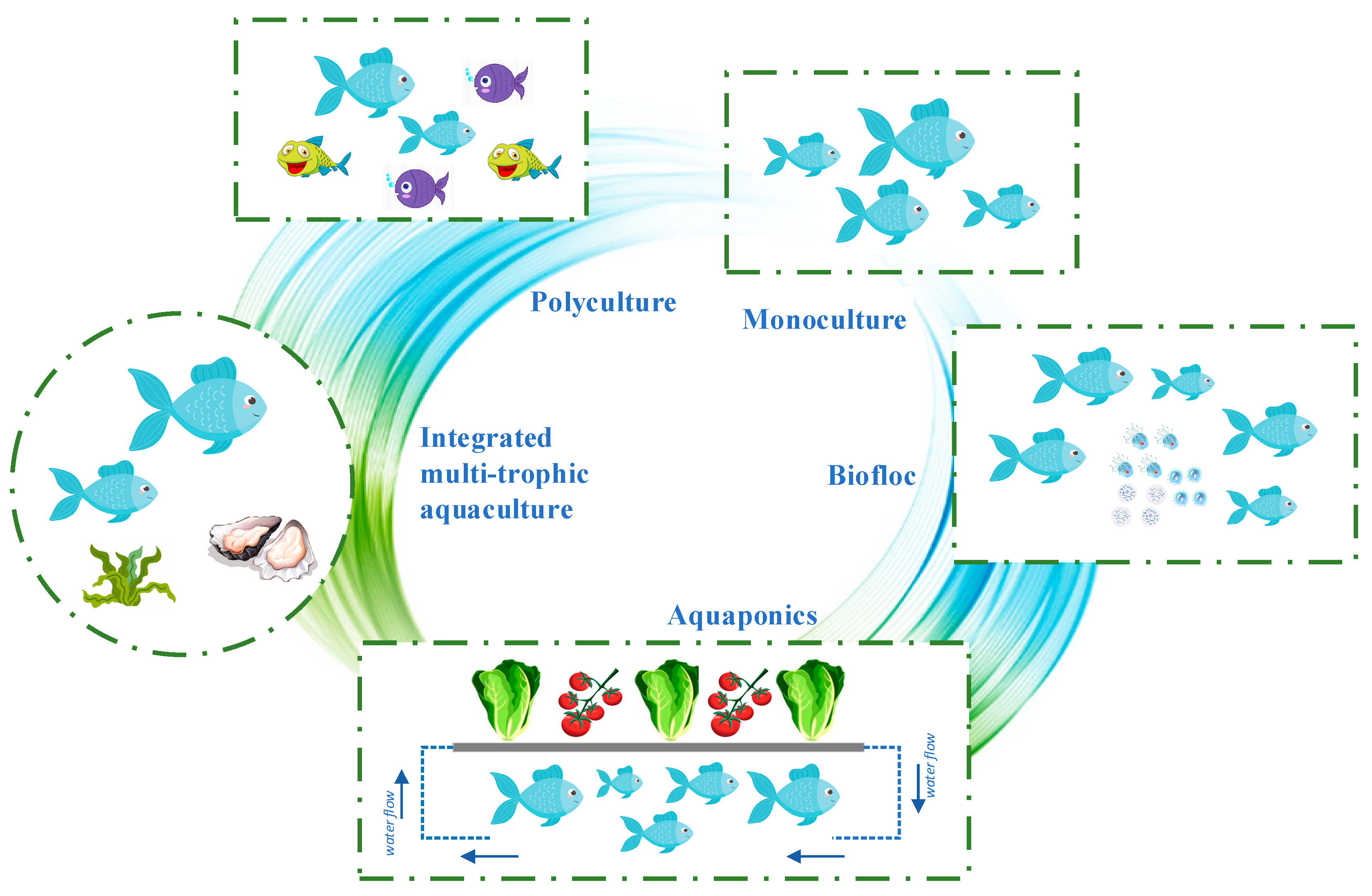

2. Aquaculture Systems

2.1. Intensively Fed Monoculture and Polyculture

2.2. Integrated Multitrophic Aquaculture

2.3. Aquaponics

2.4. Bioflocs

- ◾

- minimal or no external water exchange;

- ◾

- less feed is needed, which reduces feed costs by 30%;

- ◾

- natural microbial biomass improves water purification;

- ◾

- enhanced growth, performance, and immunity of cultured aquatic organisms;

- ◾

- some bacterial species are useful in sequestering atmospheric CO2.

3. Engineered Ponds and Tanks for Increased Productivity

3.1. Traditional Pond Aquaculture Systems

3.2. Partitioned Aquaculture Systems

3.2.1. Split Ponds

3.2.2. In-Pond Raceway Systems

3.3. Recirculating Aquaculture Systems

3.4. Land-Based Mariculture

4. Technological Improvements—Energy Efficiency and Renewable Energy Resources

4.1. Technological Solutions—Aeration

4.2. Energy from Renewable Sources

4.3. High Technologies and Aquaculture

5. Towards Best Management Practices

5.1. Traceability and Transparency

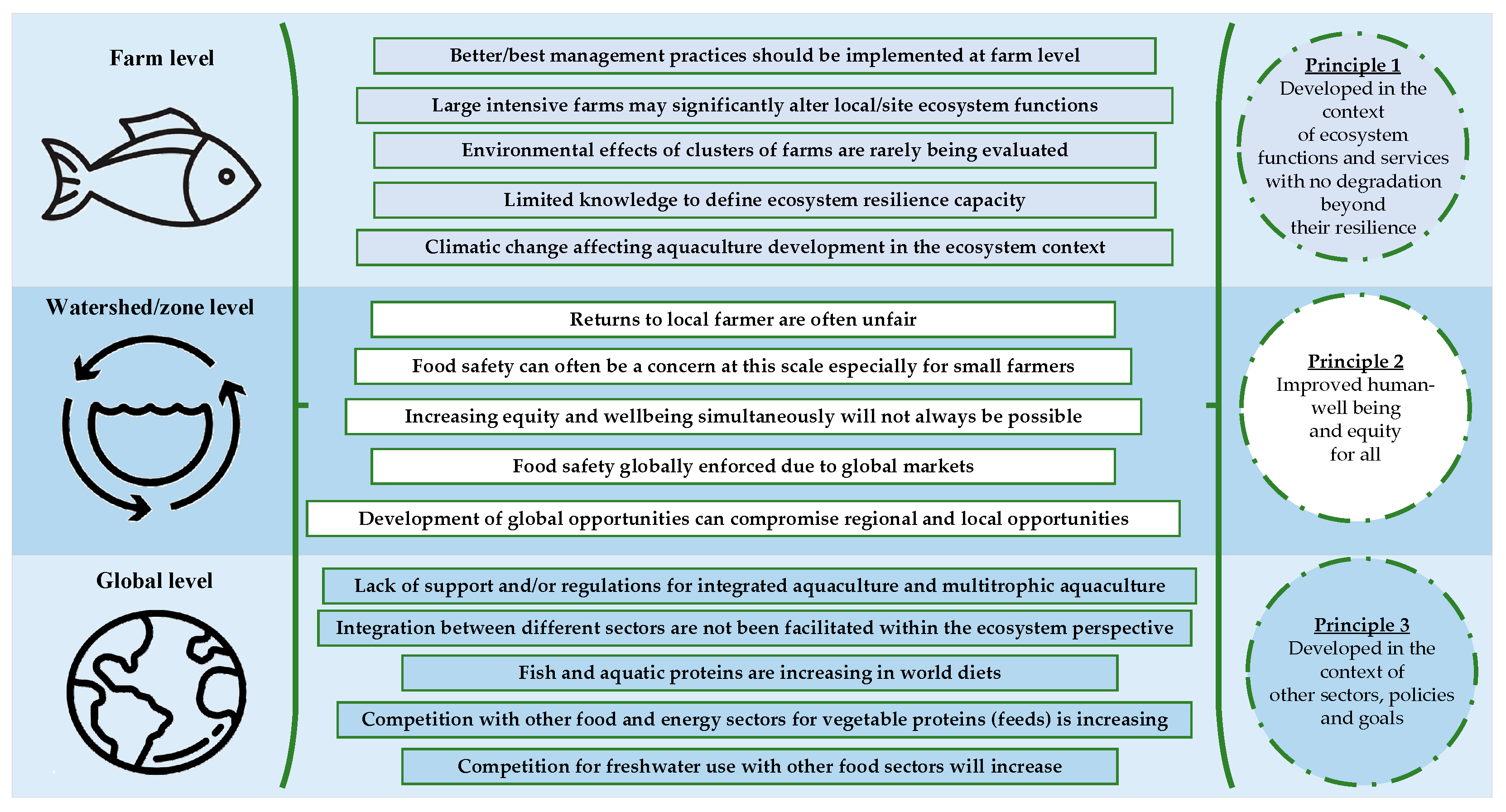

5.2. Ecosystem Approach to Aquaculture

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ScienceDirect.com. Science, Health and Medical Journals, Full Text Articles and Books. Available online: https://www-sciencedirect-com.resursi.rtu.lv/ (accessed on 23 November 2023).

- Boyd, C.E.; D’Abramo, L.R.; Glencross, B.D.; Huyben, D.C.; Juarez, L.M.; Lockwood, G.S.; McNevin, A.A.; Tacon, A.G.J.; Teletchea, F.; Tomasso, J.R., Jr.; et al. Achieving sustainable aquaculture: Historical and current perspectives and future needs and challenges. J. World Aquac. Soc. 2020, 51, 578–633. [Google Scholar] [CrossRef]

- Edwards, P. Aquaculture environment interactions: Past, present and likely future trends. Aquaculture 2015, 447, 2–14. [Google Scholar] [CrossRef]

- Valenti, W.C.; Kimpara, J.M.; de Lima Preto, B.; Moraes-Valenti, P. Indicators of sustainability to assess aquaculture systems. Ecol. Indic. 2018, 88, 402–413. [Google Scholar] [CrossRef]

- Henares, M.N.P.; Medeiros, M.V.; Camargo, A.F.M. Overview of strategies that contribute to the environmental sustainability of pond aquaculture: Rearing systems, residue treatment, and environmental assessment tools. Rev. Aquac. 2020, 12, 453–470. [Google Scholar] [CrossRef]

- Jennings, S.; Stentiford, G.D.; Leocadio, A.M.; Jeffery, K.R.; Metcalfe, J.D.; Katsiadaki, I.; Auchterlonie, N.A.; Mangi, S.C.; Pinnegar, J.K.; Ellis, T.; et al. Aquatic food security: Insights into challenges and solutions from an analysis of interactions between fisheries, aquaculture, food safety, human health, fish and human welfare, economy and environment. Fish Fish. 2016, 17, 893–938. [Google Scholar] [CrossRef]

- Willot, P.-A.; Aubin, J.; Salles, J.-M.; Wilfart, A. Ecosystem service framework and typology for an ecosystem approach to aquaculture. Aquaculture 2019, 512, 734260. [Google Scholar] [CrossRef]

- Ponte, S.; Kelling, I.; Jespersen, K.S.; Kruijssen, F. The Blue Revolution in Asia: Upgrading and Governance in Aquaculture Value Chains. World Dev. 2014, 64, 52–64. [Google Scholar] [CrossRef]

- European Commission Areas of EU Action. Available online: https://commission.europa.eu/about-european-commission/what-european-commission-does/law/areas-eu-action_en (accessed on 7 August 2023).

- European Commission Aquaculture Policy. Available online: https://oceans-and-fisheries.ec.europa.eu/policy/aquaculture-policy_en (accessed on 7 August 2023).

- Carter, C. Actor intentions implementing ‘ecosystem Europe’: The contested case of aquaculture. Environ. Sci. Policy 2021, 124, 305–312. [Google Scholar] [CrossRef]

- Communication from the Commission to the European Parliament; The Council; The European Economic and Social Committee and the Committee of the Regions. Strategic Guidelines for a More Sustainable and Competitive EU Aquaculture for the Period 2021 to 2030. 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2021:236:FIN (accessed on 7 August 2023).

- Communication from the Commission to the European Parliament; The Council; The European Economic and Social Committee and the Committee of the Regions. Strategic Guidelines for the Sustainable Development of EU Aquaculture. 2013. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1477555805378&uri=CELEX%3A52013DC0229 (accessed on 7 August 2023).

- EUMOFA. The EU Fish Market. 2023. Available online: https://www.eumofa.eu/documents/20178/566349/EFM2023_EN.pdf/95612366-79d2-a4d1-218b-8089c8e7508c?t=1699352554122 (accessed on 23 November 2023).

- Boyd, C.E.; Martinson, D.J. Evaluation of propeller-aspirator-pump aerators. Aquaculture 1984, 36, 283–292. [Google Scholar] [CrossRef]

- Boyd, C.E.; Torrans, E.L.; Tucker, C.S. Dissolved Oxygen and Aeration in Ictalurid Catfish Aquaculture. J. World Aquac. Soc. 2018, 49, 7–70. [Google Scholar] [CrossRef]

- Cheatham, M.; Kumar, G.; Tucker, C.; Rutland, B. Research verification of four commercial scale split-pond designs. Aquac. Eng. 2023, 103, 102349. [Google Scholar] [CrossRef]

- Schrader, K.K.; Tucker, C.S.; Brown, T.W.; Torrans, E.L.; Whitis, G.N. Comparison of Phytoplankton Communities in Catfish Split-Pond Aquaculture Systems with Conventional Ponds. N. Am. J. Aquac. 2016, 78, 384–395. [Google Scholar] [CrossRef]

- Afewerki, S.; Osmundsen, T.; Olsen, M.S.; Størkersen, K.V.; Misund, A.; Thorvaldsen, T. Innovation policy in the Norwegian aquaculture industry: Reshaping aquaculture production innovation networks. Mar. Policy 2023, 152, 105624. [Google Scholar] [CrossRef]

- Dong, S.; Shan, H.; Yu, L.; Liu, X.; Ren, Z.; Wang, F. An ecosystem approach for integrated pond aquaculture practice: Application of food web models and ecosystem indices. Ecol. Indic. 2022, 141, 109154. [Google Scholar] [CrossRef]

- Polovina, J.J. An overview of the ECOPATH model. Fishbyte 1984, 2, 5–7. [Google Scholar]

- Varga, M.; Berzi-Nagy, L.; Csukas, B.; Gyalog, G. Long-term dynamic simulation of environmental impacts on ecosystem-based pond aquaculture. Environ. Model. Softw. 2020, 134, 104755. [Google Scholar] [CrossRef]

- Das, S.K.; Mondal, B.; Sarkar, U.K.; Das, B.K.; Borah, S. Understanding and approaches towards circular bio-economy of wastewater reuse in fisheries and aquaculture in India: An overview. Rev. Aquac. 2023, 15, 1100–1114. [Google Scholar] [CrossRef]

- Amoussou, N.; Lecocq, T.; Fourrier, C.; Nivelle, R.; Fleck, C.; Fontaine, P.; Pasquet, A.; Thomas, M. A multi-trait evaluation framework to assess the consequences of polyculture in fish production: An application for pikeperch in recirculated aquaculture systems. Aquac. Rep. 2022, 27, 101349. [Google Scholar] [CrossRef]

- Park, M.; Shin, S.K.; Do, Y.H.; Yarish, C.; Kim, J.K. Application of open water integrated multi-trophic aquaculture to intensive monoculture: A review of the current status and challenges in Korea. Aquaculture 2018, 497, 174–183. [Google Scholar] [CrossRef]

- Stickney, R.R. Polyculture in Aquaculture. In Sustainable Food Production; Christou, P., Savin, R., Costa-Pierce, B.A., Misztal, I., Whitelaw, C.B.A., Eds.; Springer: New York, NY, USA, 2013; pp. 1366–1368. [Google Scholar] [CrossRef]

- Sanz-Lazaro, C.; Sanchez-Jerez, P. Regional Integrated Multi-Trophic Aquaculture (RIMTA): Spatially separated, ecologically linked. J. Environ. Manag. 2020, 271, 110921. [Google Scholar] [CrossRef] [PubMed]

- Nissar, S.; Bakhtiyar, Y.; Arafat, M.Y.; Andrabi, S.; Mir, Z.A.; Khan, N.A.; Langer, S. The evolution of integrated multi-trophic aquaculture in context of its design and components paving way to valorization via optimization and diversification. Aquaculture 2023, 565, 739074. [Google Scholar] [CrossRef]

- Sumbing, M.V.; Al-Azad, S.; Estim, A.; Mustafa, S. Growth performance of spiny lobster Panulirus ornatus in land-based Integrated Multi-Trophic Aquaculture (IMTA) system. Trans. Sci. Technol. 2016, 3, 143–149. [Google Scholar]

- Kleitou, P.; Kletou, D.; David, J. Is Europe ready for integrated multi-trophic aquaculture? A survey on the perspectives of European farmers and scientists with IMTA experience. Aquaculture 2018, 490, 136–148. [Google Scholar] [CrossRef]

- Granada, L.; Sousa, N.; Lopes, S.; Lemos, M.F.L. Is integrated multitrophic aquaculture the solution to the sectors’ major challenges?—A review. Rev. Aquac. 2016, 8, 283–300. [Google Scholar] [CrossRef]

- Alexander, K.A.; Freeman, S.; Potts, T. Navigating uncertain waters: European public perceptions of integrated multi trophic aquaculture (IMTA). Environ. Sci. Policy 2016, 61, 230–237. [Google Scholar] [CrossRef]

- Hughes, A.; Black, K. Going beyond the search for solutions: Understanding trade-offs in European integrated multi-trophic aquaculture development. Aquacult. Environ. Interact. 2016, 8, 191–199. [Google Scholar] [CrossRef]

- Zimmermann, S.; Kiessling, A.; Zhang, J. The future of intensive tilapia production and the circular bioeconomy without effluents: Biofloc technology, recirculation aquaculture systems, bio-RAS, partitioned aquaculture systems and integrated multitrophic aquaculture. Rev. Aquac. 2023, 15, 22–31. [Google Scholar] [CrossRef]

- Tom, A.P.; Jayakumar, J.S.; Biju, M.; Somarajan, J.; Ibrahim, M.A. Aquaculture wastewater treatment technologies and their sustainability: A review. Energy Nexus 2021, 4, 100022. [Google Scholar] [CrossRef]

- Ogello, E.O.; Outa, N.O.; Obiero, K.O.; Kyule, D.N.; Munguti, J.M. The prospects of biofloc technology (BFT) for sustainable aquaculture development. Sci. Afr. 2021, 14, e01053. [Google Scholar] [CrossRef]

- Mugwanya, M.; Dawood, M.A.O.; Kimera, F.; Sewilam, H. Biofloc Systems for Sustainable Production of Economically Important Aquatic Species: A Review. Sustainability 2021, 13, 7255. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Sharifinia, M.; Emerenciano, M.G.C. A detailed look at the impacts of biofloc on immunological and hematological parameters and improving resistance to diseases. Fish Shellfish Immunol. 2023, 137, 108796. [Google Scholar] [CrossRef]

- Crab, R.; Defoirdt, T.; Bossier, P.; Verstraete, W. Biofloc technology in aquaculture: Beneficial effects and future challenges. Aquaculture 2012, 356–357, 351–356. [Google Scholar] [CrossRef]

- Luo, G.; Wang, J.; Ma, N.; Liu, Z.; Tan, H. Effects of Inoculated Bacillus subtilis on Geosmin and 2-Methylisoborneol Removal in Suspended Growth Reactors Using Aquacultural Waste for Biofloc Production. J. Microbiol. Biotechnol. 2016, 26, 1420–1427. [Google Scholar] [CrossRef] [PubMed]

- Green, B.W.; Schrader, K.K.; Perschbacher, P.W. Effect of stocking biomass on solids, phytoplankton communities, common off-flavors, and production parameters in a channel catfish biofloc technology production system. Aquac. Res. 2014, 45, 1442–1458. [Google Scholar] [CrossRef]

- FAO. Simple Methods for Aquaculture—Handbook on Fish Farming. Available online: https://www.fao.org/fishery/docs/CDrom/FAO_Training/FAO_Training/General/t0581e/Index.htm (accessed on 17 August 2023).

- Boyd, C.E.; Chainark, S. Advances in technology and practice for land-based aquaculture systems: Ponds for finfish production. In New Technologies in Aquaculture; Elsevier: Amsterdam, The Netherlands, 2009; pp. 984–1009. [Google Scholar] [CrossRef]

- Boyd, C.E.; Davis, R.P. Lentic Freshwater: Ponds—Aquaculture Ponds. In Encyclopedia of the World’s Biomes; Goldstein, M.I., DellaSala, D.A., Eds.; Elsevier: Oxford, UK, 2020; pp. 316–324. [Google Scholar] [CrossRef]

- Brune, D.E. Tilapia in High-Rate Aquaculture Processes. In Tilapia in Intensive Co-Culture; Perschbacher, P.W., Stickney, R.R., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2016; pp. 186–210. [Google Scholar] [CrossRef]

- Turker, H.; Eversole, A.G.; Brune, D.E. Filtration of green algae and cyanobacteria by Nile tilapia, Oreochromis niloticus, in the Partitioned Aquaculture System. Aquaculture 2003, 215, 93–101. [Google Scholar] [CrossRef]

- Tucker, C.S.; Brune, D.E.; Torrans, E.L. Partitioned pond aquaculture systems. World Aquac. Mag. 2014, 45, 9–17. [Google Scholar]

- Brown, T.W.; Tucker, C.S.; Rutland, B.L. Performance evaluation of four different methods for circulating water in commercial-scale, split-pond aquaculture systems. Aquac. Eng. 2016, 70, 33–41. [Google Scholar] [CrossRef]

- Jescovitch, L.N.; Boyd, C.E.; Whitis, G.N. Effects of mechanical aeration in the waste-treatment cells of split-pond aquaculture systems on water quality. Aquaculture 2017, 480, 32–41. [Google Scholar] [CrossRef]

- Jescovitch, L.N.; Boyd, C.E. A case study: Impacts of deviating from model research design to the commercial industry for split-pond aquaculture. Aquac. Eng. 2017, 79, 35–41. [Google Scholar] [CrossRef]

- Schrader, K.K.; Tucker, C.S.; Brown, T.W.; Whitis, G.N. Earthy and Musty Off-Flavor Episodes in Catfish Split-Pond Aquaculture Systems. N. Am. J. Aquac. 2018, 80, 26–41. [Google Scholar] [CrossRef]

- Brown, T.W.; Chappell, J.A.; Boyd, C.E. A commercial-scale, in-pond raceway system for Ictalurid catfish production. Aquac. Eng. 2011, 44, 72–79. [Google Scholar] [CrossRef]

- Masser, M.P. 17 Cages and in-pond raceways. In Biology and Culture of Channel Catfish; Tucker, C.S., Hargreaves, J.A., Eds.; Developments in Aquaculture and Fisheries Science; Elsevier: Amsterdam, The Netherlands, 2004; Volume 34, pp. 530–544. [Google Scholar] [CrossRef]

- Nagy, Z.; Ardó, L.; Demény, F.; Gál, D.; Sándor, Z.J.; Ljubobratović, U. Case study on the aptness of in-pond raceways for pikeperch, Sander lucioperca, grow-out. Aquac. Rep. 2022, 27, 101356. [Google Scholar] [CrossRef]

- Smith, B.; Dvorak, J.; Semmens, K.; Colliver, D. Using a computer based selection model for sizing of solar panels and battery back-up systems for use in a floating in-pond raceway. Aquac. Eng. 2022, 97, 102238. [Google Scholar] [CrossRef]

- Masser, M.P.; Lazur, A. In-Pond Raceways. South. Reg. Aquac. Cent. 1997, 1–8. [Google Scholar]

- Wang, L.; Jia, S.; Zhang, L.; Ma, F.; Zhang, M.; Yu, M.; Jiang, H.; Qiao, Z.; Li, X. Comparative study on nutritional quality and volatile flavor compounds of muscle in Cyprinus carpio haematopterus under wild, traditional pond and in-pond raceway system culture. Aquac. Rep. 2022, 25, 101194. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Chin, J.Y.; Mohd Harun, M.H.Z.; Low, S.C. Environmental impacts and imperative technologies towards sustainable treatment of aquaculture wastewater: A review. J. Water Process Eng. 2022, 46, 102553. [Google Scholar] [CrossRef]

- Badiola, M.; Mendiola, D.; Bostock, J. Recirculating Aquaculture Systems (RAS) analysis: Main issues on management and future challenges. Aquac. Eng. 2012, 51, 26–35. [Google Scholar] [CrossRef]

- Martins, C.I.M.; Eding, E.H.; Verdegem, M.C.J.; Heinsbroek, L.T.N.; Schneider, O.; Blancheton, J.P.; d’Orbcastel, E.R.; Verreth, J.A.J. New developments in recirculating aquaculture systems in Europe: A perspective on environmental sustainability. Aquac. Eng. 2010, 43, 83–93. [Google Scholar] [CrossRef]

- Kamali, S.; Ward, V.C.A.; Ricardez-Sandoval, L. Dynamic modeling of recirculating aquaculture systems: Effect of management strategies and water quality parameters on fish performance. Aquac. Eng. 2022, 99, 102294. [Google Scholar] [CrossRef]

- Yu, Y.-B.; Lee, J.-H.; Choi, J.-H.; Choi, Y.J.; Jo, A.-H.; Choi, C.Y.; Kang, J.-C.; Kim, J.-H. The application and future of biofloc technology (BFT) in aquaculture industry: A review. J. Environ. Manag. 2023, 342, 118237. [Google Scholar] [CrossRef]

- Xu, W.; Yang, Q.; Wang, Y.; Tang, R.; Li, D. The growth performance, antioxidative status and muscle quality of grass carp (Ctenopharyngodon idellus) cultured in the recirculating pond aquaculture system (RPAS). Aquaculture 2023, 562, 738829. [Google Scholar] [CrossRef]

- Shpigel, M. Mariculture systems, integrated land-based. In Encyclopedia of Sustainability Science and Technology; Springer: New York, NY, USA, 2013; pp. 1111–1120. Available online: https://acikders.ankara.edu.tr/pluginfile.php/203440/mod_resource/content/1/Angel2013ReferenceWorkEntry_MarineAquacultureAquacultureIn.pdf (accessed on 23 November 2023).

- Neori, A.; Chopin, T.; Troell, M.; Buschmann, A.H.; Kraemer, G.P.; Halling, C.; Shpigel, M.; Yarish, C. Integrated aquaculture: Rationale, evolution and state of the art emphasizing seaweed biofiltration in modern mariculture. Aquaculture 2004, 231, 361–391. [Google Scholar] [CrossRef]

- Webb, J.M.; Quintã, R.; Papadimitriou, S.; Norman, L.; Rigby, M.; Thomas, D.N.; Le Vay, L. Halophyte filter beds for treatment of saline wastewater from aquaculture. Water Res. 2012, 46, 5102–5114. [Google Scholar] [CrossRef] [PubMed]

- Ridwan; Irawan, R.; Mubarok, M.A. Number of holes and blades to control the performance of aquaculture aerator. Aquac. Fish. 2023, 8, 672–680. [Google Scholar] [CrossRef]

- Summerfelt, R.C. Water Quality Considerations for Aquaculture. Dep. Anim. Ecol. 2000, 2–7. [Google Scholar]

- Huan, J.; Cao, W.; Qin, Y. Prediction of dissolved oxygen in aquaculture based on EEMD and LSSVM optimized by the Bayesian evidence framework. Comput. Electron. Agric. 2018, 150, 257–265. [Google Scholar] [CrossRef]

- Dean, T.L.; Richardson, J. Responses of seven species of native freshwater fish and a shrimp to low levels of dissolved oxygen. N. Z. J. Mar. Freshw. Res. 1999, 33, 99–106. [Google Scholar] [CrossRef]

- Franklin, P. Dissolved oxygen criteria for freshwater fish in New Zealand: A revised approach. N. Z. J. Mar. Freshw. Res. 2014, 48, 112–126. [Google Scholar] [CrossRef]

- Roy, S.M.; P, J.; Machavaram, R.; Pareek, C.M.; Mal, B.C. Diversified aeration facilities for effective aquaculture systems—A comprehensive review. Aquac. Int. 2021, 29, 1181–1217. [Google Scholar] [CrossRef]

- Mahmoud, A.; Quang, T.N.; Pavlov, E.; Bilton, A. Development of a solar updraft aeration system for pond aquaculture in resource-constrained environments. In Proceedings of the 2015 IEEE Global Humanitarian Technology Conference (GHTC), Seattle, WA, USA, 8–10 October 2015; pp. 306–313. [Google Scholar] [CrossRef]

- Roy, S.M.; Tanveer, M.; Gupta, D.; Pareek, C.M.; Mal, B.C. Prediction of standard aeration efficiency of a propeller diffused aeration system using response surface methodology and an artificial neural network. Water Supply 2021, 21, 4534–4547. [Google Scholar] [CrossRef]

- Roy, S.M.; Moulick, S.; Mukherjee, C.K. Design characteristics of perforated pooled circular stepped cascade (PPCSC) aeration system. Water Supply 2020, 20, 1692–1705. [Google Scholar] [CrossRef]

- Roshan, R.U.; Harini, R.; Anand, T. Development of Integrated Aerator combining Paddlewheel and Propeller Aspirator Aerators for Shrimp Farming. In Next Generation Materials and Processing Technologies; Bag, S., Paul, C.P., Baruah, M., Eds.; Springer Proceedings in Materials; Springer: Singapore, 2021; pp. 67–79. [Google Scholar] [CrossRef]

- Jamroen, C. Optimal techno-economic sizing of a standalone floating photovoltaic/battery energy storage system to power an aquaculture aeration and monitoring system. Sustain. Energy Technol. Assess. 2022, 50, 101862. [Google Scholar] [CrossRef]

- Tien, N.N.; Matsuhashi, R.; Bich Chau, V.T.T. A Sustainable Energy Model for Shrimp Farms in the Mekong Delta. Energy Procedia 2019, 157, 926–938. [Google Scholar] [CrossRef]

- Vo, T.T.E.; Ko, H.; Huh, J.-H.; Park, N. Overview of Solar Energy for Aquaculture: The Potential and Future Trends. Energies 2021, 14, 6923. [Google Scholar] [CrossRef]

- Jamroen, C.; Kotchprapa, P.; Chotchuang, S.; Phoket, R.; Vongkoon, P. Design and performance analysis of a standalone floating photovoltaic/battery energy-powered paddlewheel aerator. Energy Rep. 2023, 9, 539–548. [Google Scholar] [CrossRef]

- Kumar, A.; Moulick, S.; Mal, B.C. Performance evaluation of propeller-aspirator-pump aerator. Aquac. Eng. 2010, 42, 70–74. [Google Scholar] [CrossRef]

- Timmerhaus, G.; Lazado, C.C.; Cabillon, N.A.R.; Reiten, B.K.M.; Johansen, L.-H. The optimum velocity for Atlantic salmon post-smolts in RAS is a compromise between muscle growth and fish welfare. Aquaculture 2021, 532, 736076. [Google Scholar] [CrossRef]

- Solstorm, F.; Solstorm, D.; Oppedal, F.; Olsen, R.E.; Stien, L.H.; Fernö, A. Not too slow, not too fast: Water currents affect group structure, aggression and welfare in post-smolt Atlantic salmon Salmo salar. Aquac. Environ. Interact. 2016, 8, 339–347. [Google Scholar] [CrossRef]

- Duarte, S.; Reig, L.; Masaló, I.; Blanco, M.; Oca, J. Influence of tank geometry and flow pattern in fish distribution. Aquac. Eng. 2011, 44, 48–54. [Google Scholar] [CrossRef]

- Wiranto, G.; Kurniawan, D.; Maulana, Y.; Hermida, I.D.P.; Oktaviandi, D. Design and Implementation of Wireless Sensors and Android Based Application for Highly Efficient Aquaculture Management System. EMITTER Int. J. Eng. Technol. 2020, 8, 355–371. [Google Scholar] [CrossRef]

- Hongpin, L.; Guanglin, L.; Weifeng, P.; Jie, S.; Qiuwei, B. Real-time remote monitoring system for aquaculture water quality. Int. J. Agric. Biol. Eng. 2015, 8, 136–143. [Google Scholar] [CrossRef]

- Ma, Y.; Ding, W. Design of Intelligent Monitoring System for Aquaculture Water Dissolved Oxygen. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 414–418. [Google Scholar] [CrossRef]

- Kusumah, B.R.; Kostajaya, A.; Supriadi, D.; Nugraha, E.H.; Siskandar, R. Engineering of Automatically Controlled Energy Aeration Systems for Fisheries Cultivation Pools. Aquac. Indones. 2020, 21, 74. [Google Scholar] [CrossRef]

- Pringle, A.M.; Handler, R.M.; Pearce, J.M. Aquavoltaics: Synergies for dual use of water area for solar photovoltaic electricity generation and aquaculture. Renew. Sustain. Energy Rev. 2017, 80, 572–584. [Google Scholar] [CrossRef]

- Matulić, D.; Andabaka, Ž.; Radman, S.; Fruk, G.; Leto, J.; Rošin, J.; Rastija, M.; Varga, I.; Tomljanović, T.; Čeprnja, H.; et al. Agrivoltaics and Aquavoltaics: Potential of Solar Energy Use in Agriculture and Freshwater Aquaculture in Croatia. Agriculture 2023, 13, 1447. [Google Scholar] [CrossRef]

- Haas, J.; Khalighi, J.; Chen, P.J.; De La Fuente, A.; Nowak, W. Save the Lake! Floating Solar Photovoltaic to Avoid Algae Blooms? H13R-2020; American Geophysical Union: Washington, DC, USA, 2018. [Google Scholar]

- Badiola, M.; Basurko, O.C.; Piedrahita, R.; Hundley, P.; Mendiola, D. Energy use in Recirculating Aquaculture Systems (RAS): A review. Aquac. Eng. 2018, 81, 57–70. [Google Scholar] [CrossRef]

- Guerra, C.R.; Resh, R.E.; Godfriaux, B.L.; Stephens, C.A. Venture Analyses for a Proposed Commercial Waste Heat Aquaculture Facility. Proc. World Maric. Soc. 1979, 10, 28–38. [Google Scholar] [CrossRef]

- Yee, W.C. Thermal aquaculture. Engineering and economics. Environ. Sci. Technol. 1972, 6, 232–237. [Google Scholar] [CrossRef]

- Olszewski, M.; Wilson, J.V. Analysis of Economic and Energy Utilization Aspects for Waste Heat Aquaculture. In Proceedings of the 2. Waste Heat Aquaculture Workshop, New Brunswick, NJ, USA, 29 March 1978; Available online: https://www.osti.gov/biblio/6647334 (accessed on 11 August 2023).

- Parker, T.; Kiessling, A. Low-grade heat recycling for system synergies between waste heat and food production, a case study at the European Spallation Source. Energy Sci. Eng. 2016, 4, 153–165. [Google Scholar] [CrossRef]

- Xiao, R.; Wei, Y.; An, D.; Li, D.; Ta, X.; Wu, Y.; Ren, Q. A review on the research status and development trend of equipment in water treatment processes of recirculating aquaculture systems. Rev. Aquac. 2019, 11, 863–895. [Google Scholar] [CrossRef]

- Lund, J.W.; Toth, A.N. Direct utilization of geothermal energy 2020 worldwide review. Geothermics 2021, 90, 101915. [Google Scholar] [CrossRef]

- Xuan, B.B.; Sandorf, E.D. Potential for Sustainable Aquaculture: Insights from Discrete Choice Experiments. Environ. Resour. Econ. 2020, 77, 401–421. [Google Scholar] [CrossRef]

- Bernal-Higuita, F.; Acosta-Coll, M.; Ballester-Merelo, F.; De-la-Hoz-Franco, E. Implementation of information and communication technologies to increase sustainable productivity in freshwater finfish aquaculture—A review. J. Clean. Prod. 2023, 408, 137124. [Google Scholar] [CrossRef]

- Shen, Y.; Ma, K.; Yue, G.H. Status, challenges and trends of aquaculture in Singapore. Aquaculture 2021, 533, 736210. [Google Scholar] [CrossRef]

- Akhter, F.; Siddiquei, H.R.; Alahi, M.E.E.; Mukhopadhyay, S.C. Recent Advancement of the Sensors for Monitoring the Water Quality Parameters in Smart Fisheries Farming. Computers 2021, 10, 26. [Google Scholar] [CrossRef]

- Rowan, N.J. The role of digital technologies in supporting and improving fishery and aquaculture across the supply chain—Quo Vadis? Aquac. Fish. 2023, 8, 365–374. [Google Scholar] [CrossRef]

- Janssen, K.; Chavanne, H.; Berentsen, P.; Komen, H. Impact of selective breeding on European aquaculture. Aquaculture 2017, 472, 8–16. [Google Scholar] [CrossRef]

- Spalvins, K.; Raita, S.; Valters, K.; Blumberga, D. Improving single cell protein yields and amino acid profile via mutagenesis: Review of applicable amino acid inhibitors for mutant selection. Agron. Res. 2021, 19, 1285–1307. [Google Scholar] [CrossRef]

- Asche, F. Farming the Sea. Mar. Resour. Econ. 2008, 23, 527–547. [Google Scholar] [CrossRef]

- Edler, J.; Fagerberg, J. Innovation policy: What, why, and how. Oxf. Rev. Econ. Policy 2017, 33, 2–23. [Google Scholar] [CrossRef]

- Osmundsen, T.C.; Amundsen, V.S.; Alexander, K.A.; Asche, F.; Bailey, J.; Finstad, B.; Olsen, M.S.; Hernández, K.; Salgado, H. The operationalisation of sustainability: Sustainable aquaculture production as defined by certification schemes. Glob. Environ. Chang. 2020, 60, 102025. [Google Scholar] [CrossRef]

- Rector, M.E.; Filgueira, R.; Bailey, M.; Walker, T.R.; Grant, J. Sustainability outcomes of aquaculture eco-certification: Challenges and opportunities. Rev. Aquac. 2023, 15, 840–852. [Google Scholar] [CrossRef]

- Ntiri, P.; Ragasa, C.; Anang, S.A.; Kuwornu, J.K.M.; Torbi, E.N. Does ICT-based aquaculture extension contribute to greater adoption of good management practices and improved incomes? Evidence from Ghana. Aquaculture 2022, 557, 738350. [Google Scholar] [CrossRef]

- Jaiswal, S.; Kiran, R.D.; Chandra, T.; Prabha, R.; Iquebal, M.A.; Rai, A.; Kumar, D. Proteomics in fish health and aquaculture productivity management: Status and future perspectives. Aquaculture 2023, 566, 739159. [Google Scholar] [CrossRef]

- Freitas, J.; Vaz-Pires, P.; Câmara, J.S. From aquaculture production to consumption: Freshness, safety, traceability and authentication, the four pillars of quality. Aquaculture 2020, 518, 734857. [Google Scholar] [CrossRef]

- Osmundsen, T.C.; Olsen, M.S. The imperishable controversy over aquaculture. Mar. Policy 2017, 76, 136–142. [Google Scholar] [CrossRef]

- Directorate-General for Maritime Affairs and Fisheries (European Commission). Facts and Figures on the Common Fisheries Policy: Basic Statistical Data: 2022; Publications Office of the European Union: Luxembourg, 2022; Available online: https://data.europa.eu/doi/10.2771/737237 (accessed on 28 August 2023).

- Tolentino-Zondervan, F.; Ngoc, P.T.A.; Roskam, J.L. Use cases and future prospects of blockchain applications in global fishery and aquaculture value chains. Aquaculture 2023, 565, 739158. [Google Scholar] [CrossRef]

- FAO. Ecosystem Approach to Aquaculture Management; FAO: Yangon, Myanmar, 2021. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations; FAO Fisheries and Aquaculture Department (Eds.) Aquaculture Development; FAO Technical Guidelines for Responsible Fisheries No. 5; Suppl. 1–3, Food and Agriculture Organization of the United Nations: Rome, Italy, 2001; ISBN 978-92-5-104613-5. [Google Scholar]

- Soto, D.; Aguilar-Manjarrez, J.; Bermudez, J.; Brugere, C.; Angel, D.; Bailey, C.; Black, K.; Edwards, P.; Costa-Pierce, B.; Chopin, T.; et al. Applying an ecosystem-based approach to aquaculture: Principles, scales and some management measures. In Building an Ecosystem Approach to Aquaculture; FAO: Palma de Mallorca, Spain, 2008; pp. 15–35. [Google Scholar]

- Rector, M.E.; Filgueira, R.; Grant, J. From farm sustainability to ecosystem sustainability: Exploring the limitations of farm-applied aquaculture eco-certification schemes. J. Environ. Manag. 2023, 339, 117869. [Google Scholar] [CrossRef] [PubMed]

- Brugère, C.; Aguilar-Manjarrez, J.; Beveridge, M.C.M.; Soto, D. The ecosystem approach to aquaculture 10 years on—A critical review and consideration of its future role in blue growth. Rev. Aquac. 2019, 11, 493–514. [Google Scholar] [CrossRef]

- Bohvalovs, Ģ.; Kalnbaļķīte, A.; Pakere, I.; Vanaga, R.; Kirsanovs, V.; Lauka, D.; Prodaņuks, T.; Laktuka, K.; Doļģe, K.; Zundāns, Z.; et al. Driving Sustainable Practices in Vocational Education Infrastructure: A Case Study from Latvia. Sustainability 2023, 15, 10998. [Google Scholar] [CrossRef]

- Dolge, K.; Kubule, A.; Rozakis, S.; Gulbe, I.; Blumberga, D.; Krievs, O. Towards Industrial Energy Efficiency Index. Environ. Clim. Technol. 2020, 24, 419–430. [Google Scholar] [CrossRef]

- Diaz, F.; Vignati, J.A.; Marchi, B.; Paoli, R.; Zanoni, S.; Romagnoli, F. Effects of Energy Efficiency Measures in the Beef Cold Chain: A Life Cycle-based Study. Environ. Clim. Technol. 2021, 25, 343–355. [Google Scholar] [CrossRef]

- Yoo, K.H.; Masser, M.P.; Hawcroft, B.A. An in-pond raceway system incorporating removal of fish wastes. Aquac. Eng. 1995, 14, 175–187. [Google Scholar] [CrossRef]

| Mechanical Aeration Systems | Aerator Types | Basic Information about Aerator Type | Pros | Cons |

|---|---|---|---|---|

| Splash aeration | Vertical turbines/pumps | Basic configuration consists of an impeller connected to a shaft and a submersible motor [72]. Water is splashed into the air from the center of the float through an opening [72]. Photovoltaic panels can be used for power supply [72]. | useful in aeration of hatcheries [72] | improved DO concentration in aerator proximity and near the surface [78] |

| Pump-sprayer | Submerged propeller in a vertical tube attached to an electric motor suspended by floats. Propeller draws water into the vertical tube and pumps it upwards. Water is then discharged at high velocity, deflected radially through orifices, and falls back on the water surface in an umbrella-like pattern. [72,77,78]. | very effective in aerating the bottom part of the pond [77] simple and do not require much maintenance [72,77] | increase the DO in a small area, but a large area cannot be aerated [72]; horizontal influence is very limited [72] | |

| Paddlewheel aerator | Surface aerators, can be divided into 2 broad groups: electrical floating and power takeoff driven [72]. Consists of a frame, motor, floats, coupling, speed reduction mechanism, bearing, and paddle wheel [72]. The most commonly used type of aerator for ponds larger than 0.5 ha [43]. | the most effective surface aerators performance−wise [72] high standard oxygen transfer rate, suitable for use in emergency situations [72]; solar−powered aerators are a result of recent research [80] | high purchase and operating costs of a tractor impeller-powered aerator [16] sometimes powered by a diesel generator, which releases emissions and increases operating costs [80] | |

| Spiral aerator | Aeration obtained by constant splashing of water into the atmosphere by the spiral rotation (tangential) of the impeller. Consists of an electric motor, a reduction gearbox or a reducer, handles, cups, connecting shaft, a base frame, movable joints, cover spines, and floats [72]. | can be used in intensive and semi−intensive cultures [72]; solar−powered aerators are a result of recent research [80] | sometimes powered by a diesel generator, which releases emissions and increases operating costs [80] | |

| Bubbling aeration | Diffused-air systems/diffused aerator | Releases air bubbles to affect aeration near the bottom or top of a water body using a blower or compressor to supply air to diffusers [72]. High oxygenation rates can be achieved if diffusers use pure oxygen [72]. | energy-efficient and with lower operating costs compared to other aerators [72] can be used for sensitive cultured animals as it has no moving parts [72] | pipelines installed at the pond bottom hinder pond management [72]; high cost if pure oxygen is used [72]; not suitable for shallow ponds [74] |

| Propeller-aspirator | Consists of a frame, air suction pipe, propeller, and a motor [72,81]. The pump draws in atmospheric air through a rotating hollow shaft connected to an electric motor at one end and a propeller at the other end submerged under water [15,81]. Propeller accelerates the water to create a pressure drop across the diffuser surface [15,81]. This forces air to pass through a diffuser in the hollow shaft and enter the water as fine bubbles [15,81]. | used in small water bodies [72]; one of the most often used aerator type [74]; suitable for use in intensive aquacultures [74] | performance depends on the shaft submergence depth, positional angle, propeller design, and rotational speed [72] | |

| Submersible aerators | Consists of a hollow pipe above the water, a submersible pump attached to the propeller [72]. As the propeller rotates in the water, it sucks in air and mixes it with the water, which facilitates aeration [72]. | efficiency depends on angular position and submergence depth of the propellers [72] | ||

| Gravity aeration— Cascade aeration | Weir aerator | Aeration takes place above a dam by splashing, where gravity breaks up the water droplets, which then flow over various screens [72]. These water droplets are sucked under the dam in a current, creating a large inflow of air [72]. Used for general water treatment, fish hatcheries, and flowing water or in raceways [72]. | no additional power supply needed [72] | feasible for small ponds [72] |

| Circular stepped cascade | The system consists of a circular stepped cascade and a pump. The pump lifts the water to the top of the cascade and drops it over the steps of the aerator. This creates turbulence in the water, breaking the air-water interface and resulting in aeration [75]. Used to treat wastewater before or after filtration [72]. | no pumping is required if natural elevation is available for gravity flow [72]; very economical [72]; most economical for ponds with less than 1000 m3 capacity [76] | low efficiency, has to be combined with other aerator types [72] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laktuka, K.; Kalnbalkite, A.; Sniega, L.; Logins, K.; Lauka, D. Towards the Sustainable Intensification of Aquaculture: Exploring Possible Ways Forward. Sustainability 2023, 15, 16952. https://doi.org/10.3390/su152416952

Laktuka K, Kalnbalkite A, Sniega L, Logins K, Lauka D. Towards the Sustainable Intensification of Aquaculture: Exploring Possible Ways Forward. Sustainability. 2023; 15(24):16952. https://doi.org/10.3390/su152416952

Chicago/Turabian StyleLaktuka, Krista, Antra Kalnbalkite, Liga Sniega, Kalvis Logins, and Dace Lauka. 2023. "Towards the Sustainable Intensification of Aquaculture: Exploring Possible Ways Forward" Sustainability 15, no. 24: 16952. https://doi.org/10.3390/su152416952

APA StyleLaktuka, K., Kalnbalkite, A., Sniega, L., Logins, K., & Lauka, D. (2023). Towards the Sustainable Intensification of Aquaculture: Exploring Possible Ways Forward. Sustainability, 15(24), 16952. https://doi.org/10.3390/su152416952