China’s Embodied Copper Flow from the Demand-Side and Production-Side Perspectives

Abstract

1. Introduction

2. Methods and Data

2.1. Environmentally Extended Input-Output Model

2.2. Structural Path Analysis

2.3. Complex Network Theory

2.3.1. Network Centrality

2.3.2. Community Structure

2.4. Data Source

3. Results and Discussion

3.1. Embodied Copper in the Final Demand

3.1.1. Embodied Copper in the Final Demand of Each Industry

3.1.2. Critical Path Analysis

3.2. Copper Embodied in the Production Process

3.2.1. Critical Sectors of the Embodied Copper Network

Role Analysis Based on the Weighted Degree Centrality

Role Analysis Based on the SP Betweenness

Role Analysis Based on the Downstream Closeness

Role Analysis Based on the Upstream Closeness

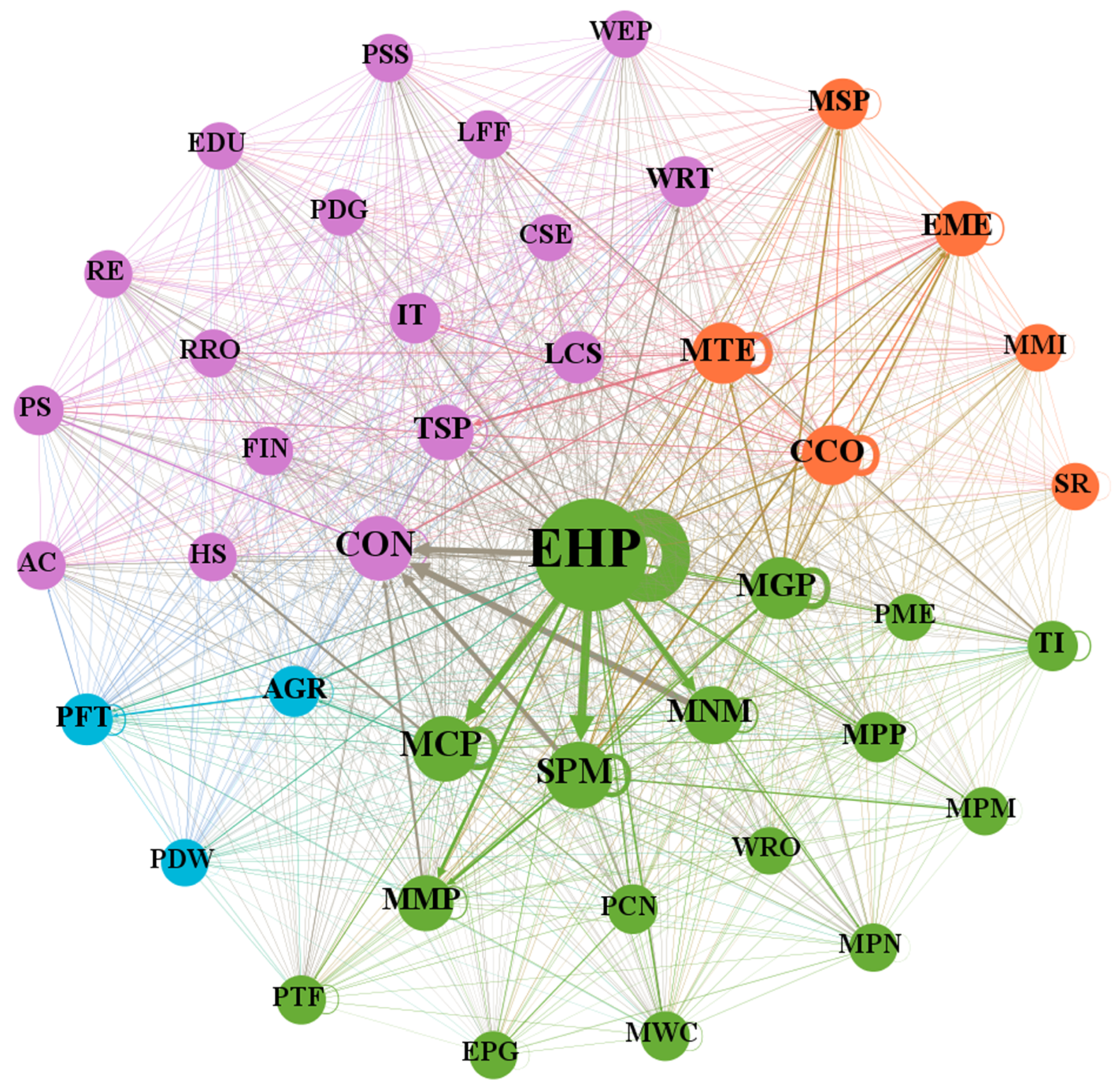

3.2.2. Community Structure of the Embodied Copper Network

4. Conclusions and Policy Implications

- From the perspective of final demand, different from the direct consumption, the Construction sector is the largest driver of copper consumption, contributing 3.27 Mt in 2020, followed by the Manufacture of General Purpose Machinery sector (1.31 Mt), and the Manufacture of Transport Equipment sector (1.16 Mt), the Manufacture of Communication Equipment, Computers and Other Electronic Equipment sector (1.05 Mt), and the Production and Distribution of Electric Power and Heat Power sector (0.76 Mt).

- From the perspective of final demand, the SPA method shows that the Construction sector mainly drives copper consumption from the Production and Distribution of Electric Power and Heat Power sector, followed by the Manufacture of Non-metallic Mineral Products sector, the Smelting and Processing of Metals sector, the Manufacture of General Purpose Machinery sector, and so on. On the other hand, the Production and Distribution of Electric Power and Heat Power sector is the main initial sector in the supply chain, driven by the Construction sector, the Manufacture of Non-metallic Mineral Products sector, the Smelting and Processing of Metals sector and so on.

- From the perspective of production, the sectors including the Transport, Storage, and Postal Services sector and the Processing of Petroleum, Coking, Processing of Nuclear Fuel sector are important transfer stations, transforming resources from the upstream sectors to the downstream sectors along with transfers of embodied copper. The sectors including the Production and Distribution of Electric Power and Heat Power sector and the Manufacture of General Purpose Machinery sector are important suppliers for the downstream sectors. The sectors including the Construction sector and the Manufacture of Electrical Machinery and Equipment sector are important consumers for the upstream sectors.It is also worth noting that the sectors including the Smelting and Processing of Metals sector, the Manufacture of Chemical Products sector, and the Manufacture of Non-metallic Mineral Products sector perform very well in all the five lists including weighted degree, SP betweenness, downstream closeness and upstream closeness, indicating that they function well as transformers, suppliers and consumers in the process of embodied copper transfers.

- From the perspective of production, there are four industrial communities derived from the embodied copper flow network. The E and C community is the core member of the whole embodied copper flow system, both as a critical supplier and as an important transmission center of the embodied copper resources. The C and S community is the main consumer of embodied copper resources in the network, exporting a great deal of embodied copper from other communities. What is more, there is quite a strong self-circulating flow in each community.

5. Limitations of This Study and Further Research

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Number | Industry | Abbreviation | Direct Consumption /Mt | Number | Industry | Abbreviation | Direct Consumption /Mt |

|---|---|---|---|---|---|---|---|

| 1 | Agriculture, Forestry, Animal Husbandry and Fishery | AGR | 0 | 22 | Other manufacturing and waste resources | WRO | 0 |

| 2 | Mining and washing of coal | MWC | 0 | 23 | Repair of metal products, machinery and equipment | PME | 0 |

| 3 | Extraction of petroleum and natural gas | EPG | 0 | 24 | Production and distribution of electric power and heat power | EHP | 5.81 |

| 4 | Mining and processing of metal ores | MPM | 0 | 25 | Production and distribution of gas | PDG | 0 |

| 5 | Mining and processing of nonmetal and other ores | MPN | 0 | 26 | Production and distribution of tap water | PDW | 0 |

| 6 | Food and tobacco processing | PFT | 0 | 27 | Construction | CON | 0.975 |

| 7 | Textile industry | TI | 0 | 28 | Wholesale and retail trades | WRT | 0 |

| 8 | Manufacture of leather, fur, feather and related products | LFF | 0 | 29 | Transport, storage, and postal services | TSP | 0 |

| 9 | Processing of timber and furniture | PTF | 0 | 30 | Accommodation and catering | AC | 0 |

| 10 | Manufacture of paper, printing and articles for culture, education and sport activity | MPP | 0 | 31 | Information transfer, software and information technology services | IT | 0 |

| 11 | Processing of petroleum, coking, processing of nuclear fuel | PCN | 0 | 32 | Finance | FIN | 0 |

| 12 | Manufacture of chemical products | MCP | 0 | 33 | Real estate | RE | 0 |

| 13 | Manuf. of non-metallic mineral products | MNM | 0 | 34 | Leasing and commercial services | LCS | 0 |

| 14 | Smelting and processing of metals | SPM | 0 | 35 | Scientific research | SR | 0 |

| 15 | Manufacture of metal products | MMP | 0 | 36 | Polytechnic services | PS | |

| 16 | Manufacture of general purpose machinery | MGP | 1.86 | 37 | Administration of water, environment, and public facilities | WEP | 0 |

| 17 | Manufacture of special purpose machinery | MSP | 0 | 38 | Resident, repair and other services | RRO | 0 |

| 18 | Manufacture of transport equipment | MTE | 1.11 | 39 | Education | EDU | 0 |

| 19 | Manufacture of electrical machinery and equipment | EME | 0 | 40 | Health care and social work | HS | 0 |

| 20 | Manufacture of communication equipment, computers and other electronic equipment | CCO | 1.18 | 41 | Culture, sports, and entertainment | CSE | 0 |

| 21 | Manufacture of measuring instruments | MMI | 0 | 42 | Public administration, social insurance, and social organizations | PSS | 0 |

References

- Yang, S.; Xiao, N.; Wang, J.; Zhang, B.; Huang, J.J. Development of miniature self-powered single-chamber microbial fuel cell and its response mechanism to copper ions in high and trace concentration. Sci. Total Environ. 2022, 834, 155367. [Google Scholar] [CrossRef]

- Cross, N.R.; Rau, M.J.; Lvov, S.N.; Gorski, C.A.; Logan, B.E.; Hall, D.M. Power and energy capacity tradeoffs in an all-aqueous copper thermally regenerative ammonia battery. J. Power Sources 2022, 531, 231339. [Google Scholar] [CrossRef]

- Ma, Z.-X.; Ning, J.; Yu, B.; Zhang, L.-J.; Fan, J.-H.; Yuan, L.-G. Effects of process parameters and scanning patterns on quality of thin-walled copper flanges manufactured by selective laser melting. J. Manuf. Process. 2021, 72, 419–430. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Goossens, L.R.; Kinds, Y.; Hooreweder, B.V.; Vanmeensel, K. Laser-based powder bed fusion additive manufacturing of pure copper. Addit. Manuf. 2021, 42, 101990. [Google Scholar] [CrossRef]

- Zhou, Q.; Luo, D.; Hua, D.; Ye, W.; Li, S.; Zou, Q.; Chen, Z.; Wang, H. Design and characterization of metallic glass/graphene multilayer with excellent nanowear properties. Friction 2022, 10, 1913–1926. [Google Scholar] [CrossRef]

- Martis, P.; Venugopal, B.R.; Seffer, J.F.; Delhalle, J.; Mekhalif, Z. Infrared irradiation controlled decoration of multiwalled carbon nanotubes with copper/copper oxide nanocrystals. Acta Mater. 2011, 59, 5040–5047. [Google Scholar] [CrossRef]

- Idrisi, H.; Kolbesen, B.O. Copper decoration and etching of crystal defects in SOI materials. Mater. Sci. Eng. B 2009, 159–160, 350–354. [Google Scholar] [CrossRef]

- Jia, Q.; He, W.; Hua, D.; Zhou, Q.; Du, Y.; Ren, Y.; Lu, Z.; Wang, H.; Zhou, F.; Wang, J. Effects of structure relaxation and surface oxidation on nanoscopic wear behaviors of metallic glass. Acta Mater. 2022, 232, 117934. [Google Scholar] [CrossRef]

- Bhardwaj, V.; Zhou, Q.; Zhang, F.; Han, W.; Du, Y.; Hua, K.; Wang, H. Effect of Al addition on the microstructure, mechanical and wear properties of TiZrNbHf refractory high entropy alloys. Tribol. Int. 2021, 160, 107031. [Google Scholar] [CrossRef]

- Zhang, X. Peaking carbon neutrality requires an uphill battle for natural resource governance. Nat. Resour. Econ. China 2022, 35, 1. [Google Scholar]

- Song, J.; Wang, G. Thoughts on Securing the Supply Chain for Critical Minerals under Carbon Peaking and Carbon Neutrality. Nat. Resour. Econ. China 2022, 35, 4–9. [Google Scholar]

- De Leon, M.; Shin, H.-S. Review of the advancements in aluminum and copper ultrasonic welding in electric vehicles and superconductor applications. J. Mater. Process. Technol. 2022, 307, 117691. [Google Scholar] [CrossRef]

- Nguyen, R.T.; Eggert, R.G.; Severson, M.H.; Anderson, C.G. Global Electrification of Vehicles and Intertwined Material Supply Chains of Cobalt, Copper and Nickel. Resour. Conserv. Recycl. 2020, 167, 105198. [Google Scholar] [CrossRef]

- International Copper Study Group. The World Copper Factbook; International Copper Study Group: Lisbon, Portugal, 2021. [Google Scholar]

- Beijing Antaike Information Company, Ltd. China’s Copper Market Development Report in 2020; Beijing Antaike Information Company, Ltd.: Beijing, China, 2020. [Google Scholar]

- Li, Y.; Brooks, R. Evidence of arbitrage trading activity: The case of Chinese metal futures contracts. Emerg. Mark. Rev. 2022, 51, 100885. [Google Scholar] [CrossRef]

- Wang, C.; Huang, X.; Lim, M.K.; Tseng, M.L.; Ghadimi, P. Mapping the structural evolution in the global scrap copper trade network. J. Clean. Prod. 2020, 275, 122934. [Google Scholar] [CrossRef]

- Dong, D.; Espinoza, L.A.T.; Loibl, A.; Pfaff, M.; Tukker, A.; Van der Voet, E. Scenarios for anthropogenic copper demand and supply in China: Implications of a scrap import ban and a circular economy transition. Resour. Conserv. Recycl. 2020, 161, 104943. [Google Scholar] [CrossRef]

- Wang, J.; Shi, X.; Niu, L.; Zhang, H. Cooper Resources Demand Forecasting by Scenario Analysis in China. Nat. Resour. Econ. China 2015, 28, 53–57. [Google Scholar]

- Ma, Z.; Yu, L. Analysis on China’s Copper Resources Situation, Mine Capacity and Some Countermeasures. Nat. Resour. Econ. China 2010, 23, 27–55. [Google Scholar]

- Soulier, M.; Gloser-Chahoud, S.; Goldmann, D.; Espinoza, L.A.T. Dynamic analysis of European copper flows. Resour. Conserv. Recycl. 2018, 129, 143–152. [Google Scholar] [CrossRef]

- Wang, M.X.; Chen, W.; Li, X. Substance flow analysis of copper in production stage in the US from 1974 to 2012. Resour. Conserv. Recycl. 2015, 105, 36–48. [Google Scholar] [CrossRef]

- Hao, M.; Wang, P.; Song, L.; Dai, M.; Ren, Y.; Chen, W.-Q. Spatial distribution of copper in-use stocks and flows in China: 1978–2016. J. Clean. Prod. 2020, 261, 121260. [Google Scholar] [CrossRef]

- Tian, X.; Zheng, J.X.; Hu, L.; Liu, Y.; Wen, H.W.; Dong, X.S. Impact of China’s waste import policy on the scrap copper recovery pattern and environmental benefits. Waste Manag. 2021, 135, 287–297. [Google Scholar] [CrossRef]

- Liao, M.-I.; Chen, P.-C.; Ma, H.-W.; Nakamura, S. Identification of the driving force of waste generation using a high-resolution waste input–output table. J. Clean. Prod. 2015, 94, 294–303. [Google Scholar] [CrossRef]

- Sverdrup, H.U.; Ragnarsdottir, K.V.; Koca, D. On modelling the global copper mining rates, market supply, copper price and the end of copper reserves. Resour. Conserv. Recycl. 2014, 87, 158–174. [Google Scholar] [CrossRef]

- Aruga, K.; Managi, S. Price linkages in the copper futures, primary, and scrap markets. Resour. Conserv. Recycl. 2011, 56, 43–47. [Google Scholar] [CrossRef]

- Brown, M.T.; Herendeen, R.A. Embodied energy analysis and EMERGY analysis: A comparative view. Ecol. Econ. 1996, 19, 219–235. [Google Scholar] [CrossRef]

- IFIAS. Energy Analysis Workshop on Methodology and Conventions; International Federation of Institutes for Advanced Study: Stockholm, Sweden, 1974; p. 89. [Google Scholar]

- Chen, B.; Li, J.S.; Wu, X.F.; Han, M.Y.; Zeng, L.; Li, Z.; Chen, G.Q. Global energy flows embodied in international trade: A combination of environmentally extended input–output analysis and complex network analysis. Appl. Energy 2018, 210, 98–107. [Google Scholar] [CrossRef]

- Jiang, M.M.; Chen, B.; Zhou, S.Y. Embodied Energy Account of Chinese Economy 2002. Procedia Environ. Sci. 2011, 5, 184–198. [Google Scholar] [CrossRef]

- Wei, W.; Li, J.; Chen, B.; Wang, M.; Zhang, P.; Guan, D.; Meng, J.; Qian, H.; Cheng, Y.; Kang, C.; et al. Embodied greenhouse gas emissions from building China’s large-scale power transmission infrastructure. Nat. Sustain. 2021, 4, 739–747. [Google Scholar] [CrossRef]

- Liang, S.; Yang, X.; Qi, J.; Wang, Y.; Xie, W.; Muttarak, R.; Guan, D. CO2 Emissions Embodied in International Migration from 1995 to 2015. Environ. Sci. Technol. 2020, 54, 12530–12538. [Google Scholar] [CrossRef]

- Duarte, R.; Pinilla, V.; Serrano, A. Factors driving embodied carbon in international trade: A multiregional input-output gravity model. Econ. Syst. Res. 2018, 30, 545–566. [Google Scholar] [CrossRef]

- Zhao, H.; Qu, S.; Liu, Y.; Gu, O.S.; Xu, M. Virtual water scarcity risk in China. Resour. Conserv. Recycl. 2020, 160, 104886. [Google Scholar] [CrossRef]

- Chen, W.; Wu, S.; Lei, Y.; Li, S. China’s water footprint by province, and inter-provincial transfer of virtual water. Ecol. Indic. 2017, 74, 321–333. [Google Scholar] [CrossRef]

- Jiang, M.; Behrens, P.; Yang, Y.; Tang, Z.; Chen, D.; Yu, Y.; Liu, L.; Gong, P.; Zhu, S.; Zhou, W.; et al. Different Material Footprint Trends between China and the World in 2007–2012 Explained by Construction- and Manufacturing-associated Investment. One Earth 2022, 5, 109–119. [Google Scholar] [CrossRef]

- Wiedmann, T.O.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The material footprint of nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef]

- Defourny, J.; Thorbecke, E. Structural path analysis and multiplier decomposition within a social accounting matrix framework. Econ. J. 1984, 94, 111–136. [Google Scholar] [CrossRef]

- Chen, J.; Shi, Q.; Zhang, W. Structural path and sensitivity analysis of the CO2 emissions in the construction industry. Environ. Impact Assess. Rev. 2022, 92, 106679. [Google Scholar] [CrossRef]

- Peng, J.; Xie, R.; Lai, M. Energy-related CO2 emissions in the China’s iron and steel industry: A global supply chain analysis. Resour. Conserv. Recycl. 2018, 129, 392–401. [Google Scholar] [CrossRef]

- Zhong, Q.; Li, H.; Liang, S.; Wu, X.; Qi, J.; Wang, S. Changes of production and consumption structures in coastal regions lead to mercury emission control in China. J. Ind. Ecol. 2022, 26, 1760–1770. [Google Scholar] [CrossRef]

- He, K.; Mi, Z.; Chen, L.; Coffman, D.M.; Liang, S. Critical transmission sectors in embodied atmospheric mercury emission network in China. J. Ind. Ecol. 2021, 25, 1644–1656. [Google Scholar] [CrossRef]

- Qi, J.; Wang, Y.; Liang, S.; Li, Y.; Li, Y.; Feng, C.; Xu, L.; Wang, S.; Chen, L.; Wang, D.; et al. Primary Suppliers Driving Atmospheric Mercury Emissions through Global Supply Chains. One Earth 2019, 1, 254–266. [Google Scholar] [CrossRef]

- Li, W.; Xu, D.; Li, G.; Su, B. Structural path and decomposition analysis of aggregate embodied energy intensities in China, 2012–2017. J. Clean. Prod. 2020, 276, 124185. [Google Scholar] [CrossRef]

- Shi, J.; Li, H.; An, H.; Guan, J.; Ma, N. What Induces the Energy–Water Nexus in China’s Supply Chains? Environ. Sci. Technol. 2020, 54, 372–379. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Liang, S. Input–output networks offer new insights of economic structure. Phys. A Stat. Mech. Its Appl. 2019, 527, 121178. [Google Scholar] [CrossRef]

- James, M.; Brian, D.F.; Gerald, S. Network structure of inter-industry flows. Phys. A Stat. Mech. Its Appl. 2013, 392, 6427–6441. [Google Scholar]

- Lenzen, M.; Kanemoto, K.; Moran, D.; Geschke, A. Mapping the Structure of the World Economy. Environ. Sci. Technol. 2012, 46, 8374–8381. [Google Scholar] [CrossRef]

- Owen, A.; Wood, R.; Barrett, J.; Evans, A. Explaining value chain differences in MRIO databases through structural path decomposition. Econ. Syst. Res. 2016, 28, 243–272. [Google Scholar] [CrossRef]

- Qi, Z.; Song, J.; Yang, W.; Duan, H.; Liu, X. Revealing contributions to sulfur dioxide emissions in China: From the dimensions of final demand, driving effect and supply chain. Resour. Conserv. Recycl. 2020, 160, 104864. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, C.; Gao, J.; Wu, X.; Zhang, B. Mapping the changes of CH4 emissions in global supply chains. Sci. Total Environ. 2022, 832, 155019. [Google Scholar] [CrossRef]

- Fan, Y.; Ren, S.; Cai, H.; Cui, X. The state’s role and position in international trade: A complex network perspective. Econ. Model. 2014, 39, 71–81. [Google Scholar] [CrossRef]

- Leicht, E.A.; Newman, M.E.J. Community Structure in Directed Networks. Phys. Rev. Lett. 2008, 100, 118703. [Google Scholar] [CrossRef] [PubMed]

- Blondel, V.D.; Guillaume, J.-L.; Lambiotte, R.; Lefebvre, E. Fast unfolding of communities in large networks. J. Stat. Mech. Theory Exp. 2008, 2008, P10008. [Google Scholar] [CrossRef]

- Sun, X.; An, H.; Liu, X. Network analysis of Chinese provincial economies. Phys. A Stat. Mech. Its Appl. 2018, 492, 1168–1180. [Google Scholar] [CrossRef]

- Interdonato, R.; Magnani, M.; Perna, D.; Tagarelli, A.; Vega, D. Multilayer network simplification: Approaches, models and methods. Comput. Sci. Rev. 2020, 36, 100246. [Google Scholar] [CrossRef]

- Ma, N.; Li, H.; Tang, R.; Dong, D.; Shi, J.; Wang, Z. Structural analysis of indirect carbon emissions embodied in intermediate input between Chinese sectors: A complex network approach. Environ. Sci. Pollut. Res. 2019, 26, 17591–17607. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Xiao, S.; Yan, J.; Zhang, P. Regional and sectoral structures of the Chinese economy: A network perspective from multi-regional input–output tables. Phys. A Stat. Mech. Its Appl. 2021, 581, 126196. [Google Scholar] [CrossRef]

- He, X.; Dong, Y.; Wu, Y.; Wei, G.; Xing, L.; Yan, J. Structure analysis and core community detection of embodied resources networks among regional industries. Phys. A Stat. Mech. Its Appl. 2017, 479, 137–150. [Google Scholar] [CrossRef]

- Newman, M.E. Fast algorithm for detecting community structure in networks. Phys. Rev. E Stat. Nonlin. Soft. Matter. Phys. 2004, 69, 066133. [Google Scholar] [CrossRef]

- Defays, D. An efficient algorithm for a complete link method. Comput. J. 1977, 4, 364–366. [Google Scholar] [CrossRef]

- Newman, M.E.J. Modularity and community structure in networks. Proc. Natl. Acad. Sci. USA 2006, 103, 8577–8582. [Google Scholar] [CrossRef]

- Girvan, M.; Newman, M.E.J. Community structure in social and biological networks. Proc. Natl. Acad. Sci. USA 2002, 99, 7821–7826. [Google Scholar] [CrossRef] [PubMed]

| Rank | Industry | Embodied Copper/Mt | Proportion | Embodied Intensity */g/ CNY | Rank | Industry | Embodied Copper/Mt | Proportion | Embodied Intensity/g/ CNY |

|---|---|---|---|---|---|---|---|---|---|

| 1 | CON | 32.72 × 10−1 | 29.92% | 0.121 | 22 | AC | 6.37 × 10−2 | 0.58% | 0.036 |

| 2 | MGP | 13.06 × 10−1 | 11.94% | 0.524 | 23 | PTF | 6.28 × 10−2 | 0.57% | 0.071 |

| 3 | MTE | 11.58 × 10−1 | 10.59% | 0.262 | 24 | MPP | 6.01 × 10−2 | 0.55% | 0.067 |

| 4 | CCO | 10.49 × 10−1 | 9.60% | 0.196 | 25 | TI | 5.78 × 10−2 | 0.53% | 0.066 |

| 5 | EHP | 76.30 × 10−2 | 6.98% | 1.221 | 26 | WEP | 5.49 × 10−2 | 0.50% | 0.070 |

| 6 | MSP | 28.50 × 10−2 | 2.61% | 0.124 | 27 | FIN | 5.33 × 10−2 | 0.49% | 0.015 |

| 7 | EME | 27.16 × 10−2 | 2.48% | 0.103 | 28 | MNM | 5.19 × 10−2 | 0.47% | 0.126 |

| 8 | HS | 24.20 × 10−2 | 2.21% | 0.050 | 29 | SPM | 4.95 × 10−2 | 0.45% | 0.121 |

| 9 | PSS | 23.46 × 10−2 | 2.15% | 0.031 | 30 | PS | 4.89 × 10−2 | 0.45% | 0.050 |

| 10 | TSP | 20.31 × 10−2 | 1.86% | 0.066 | 31 | LCS | 4.49 × 10−2 | 0.41% | 0.046 |

| 11 | PFT | 19.66 × 10−2 | 1.80% | 0.033 | 32 | PDW | 4.04 × 10−2 | 0.37% | 0.186 |

| 12 | IT | 19.52 × 10−2 | 1.78% | 0.042 | 33 | CSE | 3.24 × 10−2 | 0.30% | 0.034 |

| 13 | MCP | 16.91 × 10−2 | 1.55% | 0.090 | 34 | PCN | 2.32 × 10−2 | 0.21% | 0.061 |

| 14 | MMP | 13.70 × 10−2 | 1.25% | 0.137 | 35 | MMI | 2.15 × 10−2 | 0.20% | 0.092 |

| 15 | SR | 12.87 × 10−2 | 1.18% | 0.056 | 36 | PDG | 2.13 × 10−2 | 0.19% | 0.061 |

| 16 | WRT | 12.56 × 10−2 | 1.15% | 0.026 | 37 | PME | 0.85 × 10−2 | 0.08% | 0.143 |

| 17 | AGR | 11.62 × 10−2 | 1.06% | 0.027 | 38 | WRO | 0.48 × 10−2 | 0.04% | 0.036 |

| 18 | LFF | 11.32 × 10−2 | 1.04% | 0.055 | 39 | MPN | 0.41 × 10−2 | 0.04% | 0.123 |

| 19 | EDU | 10.85 × 10−2 | 0.99% | 0.021 | 40 | MPM | 0.16 × 10−2 | 0.01% | 0.116 |

| 20 | RE | 8.39 × 10−2 | 0.77% | 0.014 | 41 | MWC | −0.10 × 10−2 | −0.01% | 0.083 |

| 21 | RRO | 7.59 × 10−2 | 0.69% | 0.050 | 42 | EPG | −0.41 × 10−2 | −0.04% | 0.077 |

| Rank | Supply Chain Paths | Path Value | Order | Contribution Rate |

|---|---|---|---|---|

| 1 | CON | 92.39 | 0 | 8.45% |

| 2 | MGP | 86.99 | 0 | 7.96% |

| 3 | CCO | 57.90 | 0 | 5.30% |

| 4 | MTE | 56.82 | 0 | 5.20% |

| 5 | EHP | 51.92 | 0 | 4.75% |

| 6 | EHP→CON | 32.89 | 1 | 3.01% |

| 7 | EHP→MNM→CON | 17.77 | 2 | 1.63% |

| 8 | MGP→MGP | 16.82 | 1 | 1.54% |

| 9 | MTE→MTE | 15.96 | 1 | 1.46% |

| 10 | CCO→CCO | 15.57 | 1 | 1.42% |

| 11 | EHP→EHP | 15.42 | 1 | 1.41% |

| 12 | EHP→SPM→CON | 11.90 | 2 | 1.09% |

| 13 | EHP→EHP→CON | 9.77 | 2 | 0.89% |

| 14 | MGP→CON | 6.71 | 1 | 0.61% |

| 15 | MGP→MSP | 6.41 | 1 | 0.59% |

| 16 | EHP→PSS | 5.77 | 1 | 0.53% |

| 17 | EHP→MCP | 5.40 | 1 | 0.49% |

| 18 | EHP→EHP→MNM→CON | 5.28 | 3 | 0.48% |

| 19 | MGP→MTE | 4.79 | 1 | 0.44% |

| 20 | EHP→MMP→CON | 4.72 | 2 | 0.43% |

| 21 | EHP→EHP→EHP | 4.58 | 2 | 0.42% |

| 22 | EHP→MCP→HS | 4.54 | 2 | 0.42% |

| 23 | MTE→MTE→MTE | 4.48 | 2 | 0.41% |

| 24 | CCO→CCO→CCO | 4.19 | 2 | 0.38% |

| 25 | EHP→CCO | 4.18 | 1 | 0.38% |

| 26 | EHP→MMP | 3.78 | 1 | 0.35% |

| 27 | EHP→IT | 3.76 | 1 | 0.34% |

| 28 | EHP→EHP→SPM→CON | 3.53 | 3 | 0.32% |

| 29 | EHP→MGP | 3.51 | 1 | 0.32% |

| 30 | EHP→TSP | 3.51 | 1 | 0.32% |

| Sector | SP Betweenness | Rank | Sector | SP Betweenness | Rank |

|---|---|---|---|---|---|

| SPM | 118,296 | 1 | TI | 6626 | 22 |

| TSP | 107,424 | 2 | IT | 4530 | 23 |

| MCP | 92,048 | 3 | CCO | 2885 | 24 |

| MNM | 61,293 | 4 | MPN | 1829 | 25 |

| PCN | 58,075 | 5 | FIN | 1502 | 26 |

| LCS | 53,300 | 6 | WRO | 1320 | 27 |

| AGR | 38,982 | 7 | RE | 932 | 28 |

| EPG | 30,678 | 8 | PDG | 728 | 29 |

| PS | 30,265 | 9 | MMI | 611 | 30 |

| EHP | 28,485 | 10 | WEP | 148 | 31 |

| EME | 25,160 | 11 | PTF | 97 | 32 |

| MMP | 21,750 | 12 | MPM | 0 | 33 |

| MTE | 18,191 | 13 | MGP | 0 | 34 |

| LFF | 16,993 | 14 | PME | 0 | 35 |

| MPP | 16,009 | 15 | PDW | 0 | 36 |

| MSP | 10,978 | 16 | SR | 0 | 37 |

| WRT | 10,857 | 17 | RRO | 0 | 38 |

| CON | 9962 | 18 | EDU | 0 | 39 |

| AC | 9907 | 19 | HS | 0 | 40 |

| PFT | 9362 | 20 | CSE | 0 | 41 |

| MWC | 7926 | 21 | PSS | 0 | 42 |

| Sector | Downstream Closeness | Rank | Sector | Downstream Closeness | Rank |

|---|---|---|---|---|---|

| EHP | 128,533 | 1 | IT | 3240 | 22 |

| SPM | 26,880 | 2 | EPG | 3214 | 23 |

| MGP | 23,417 | 3 | TI | 3000 | 24 |

| MCP | 19,211 | 4 | FIN | 2959 | 25 |

| MNM | 17,273 | 5 | AC | 2200 | 26 |

| MTE | 13,472 | 6 | PTF | 1778 | 27 |

| CCO | 12,754 | 7 | RRO | 1771 | 28 |

| MMP | 12,080 | 8 | RE | 1732 | 29 |

| TSP | 11,722 | 9 | MMI | 1692 | 30 |

| LCS | 8614 | 10 | LFF | 1528 | 31 |

| EME | 8537 | 11 | CON | 1403 | 32 |

| WRT | 6239 | 12 | WRO | 1321 | 33 |

| PCN | 5590 | 13 | PDW | 770 | 34 |

| AGR | 5256 | 14 | PDG | 628 | 35 |

| MPM | 5036 | 15 | WEP | 532 | 36 |

| MWC | 4974 | 16 | PME | 521 | 37 |

| PS | 4258 | 17 | CSE | 432 | 38 |

| MPP | 4157 | 18 | HS | 120 | 39 |

| MPN | 3892 | 19 | EDU | 105 | 40 |

| MSP | 3729 | 20 | PSS | 87 | 41 |

| PFT | 3569 | 21 | SR | 0 | 42 |

| Sector | Upstream Closeness | Rank | Sector | Upstream Closeness | Rank |

|---|---|---|---|---|---|

| CON | 60,866 | 1 | EHP | 5413 | 22 |

| SPM | 28,065 | 2 | FIN | 4870 | 23 |

| MCP | 23,784 | 3 | LFF | 4613 | 24 |

| MNM | 18,904 | 4 | TI | 4319 | 25 |

| TSP | 17,865 | 5 | MWC | 4185 | 26 |

| EME | 15,890 | 6 | RE | 4075 | 27 |

| MMP | 15,878 | 7 | AC | 3927 | 28 |

| MTE | 13,213 | 8 | RRO | 3792 | 29 |

| MSP | 10,857 | 9 | PTF | 3424 | 30 |

| LCS | 10,488 | 10 | MPM | 3215 | 31 |

| WRT | 10,481 | 11 | SR | 3207 | 32 |

| MGP | 10,100 | 12 | MPN | 3165 | 33 |

| CCO | 9800 | 13 | EDU | 2917 | 34 |

| PFT | 9051 | 14 | EPG | 2137 | 35 |

| IT | 8563 | 15 | MMI | 2078 | 36 |

| AGR | 8008 | 16 | WEP | 1934 | 37 |

| HS | 7472 | 17 | PDW | 1829 | 38 |

| PCN | 6435 | 18 | CSE | 1332 | 39 |

| PSS | 6226 | 19 | PDG | 1205 | 40 |

| MPP | 5809 | 20 | WRO | 1202 | 41 |

| PS | 5769 | 21 | PME | 746 | 42 |

| A & F | E & C | E & R | C & S | |

|---|---|---|---|---|

| Sectors number (percentage) | 3 (7.1%) | 16 (38.1%) | 6 (14.3%) | 17 (40.5%) |

| Sum of embodied copper flow (percentage) | 1.68 × 106 (3.8%) | 26.2 × 106 (58.7%) | 6.98 × 106 (15.6%) | 9.79 × 106 (21.9%) |

| Sum of SP betweenness | 4.8 × 104 (6.1%) | 4.4 × 105 (55.8%) | 5.8 × 104 (7.3%) | 2.5 × 105 (30.9%) |

| Sum of downstream closeness | 9.6 × 103 (2.7%) | 2.6 × 105 (72.8%) | 4.0 × 104 (11.2%) | 4.8 × 104 (13.3%) |

| Sum of upstream closeness | 1.9 × 104 (5.1%) | 1.4 × 105 (37.3%) | 5.5 × 104 (15.0%) | 1.6 × 105 (42.6%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Fang, M.; Zhou, X. China’s Embodied Copper Flow from the Demand-Side and Production-Side Perspectives. Sustainability 2023, 15, 2199. https://doi.org/10.3390/su15032199

Ma S, Fang M, Zhou X. China’s Embodied Copper Flow from the Demand-Side and Production-Side Perspectives. Sustainability. 2023; 15(3):2199. https://doi.org/10.3390/su15032199

Chicago/Turabian StyleMa, Shaoqiang, Min Fang, and Xin Zhou. 2023. "China’s Embodied Copper Flow from the Demand-Side and Production-Side Perspectives" Sustainability 15, no. 3: 2199. https://doi.org/10.3390/su15032199

APA StyleMa, S., Fang, M., & Zhou, X. (2023). China’s Embodied Copper Flow from the Demand-Side and Production-Side Perspectives. Sustainability, 15(3), 2199. https://doi.org/10.3390/su15032199