Performance Analysis and Identification of an Indirect Photovoltaic Thermal Dryer with Aluminum Oxide Nano-Embedded Thermal Energy Storage Modification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Nano-Integrated Latent Heat Storage Unit

2.2. Experimental Setup

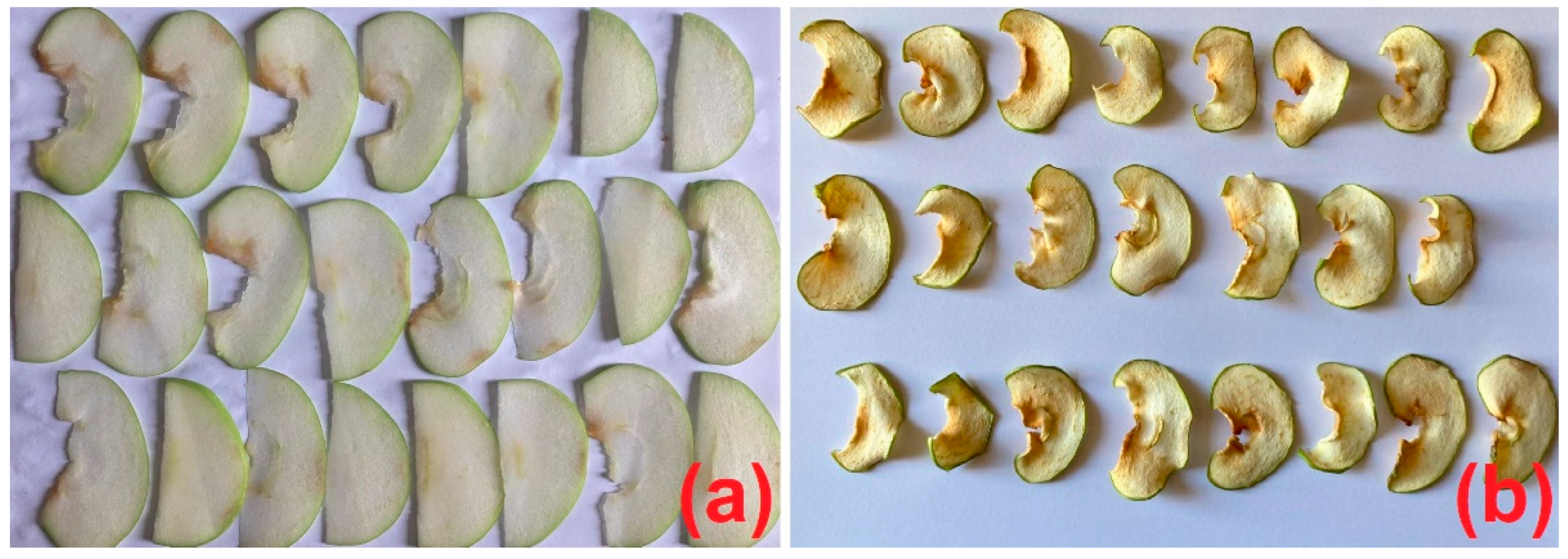

2.3. Experimental Procedure

3. Theoretical Analysis

3.1. Energy Evaluation of the PVT Collector

3.2. Exergy Evaluation of the PVT Collector

3.3. Exergy Evaluation of the Drying Room

3.4. Evaluation of Drying Parameters

3.5. Analysis of Exergy-Based Sustainability Parameters

3.6. Uncertainty Analysis

4. Dynamic Model with MIMO System Identification

5. Results and Discussion

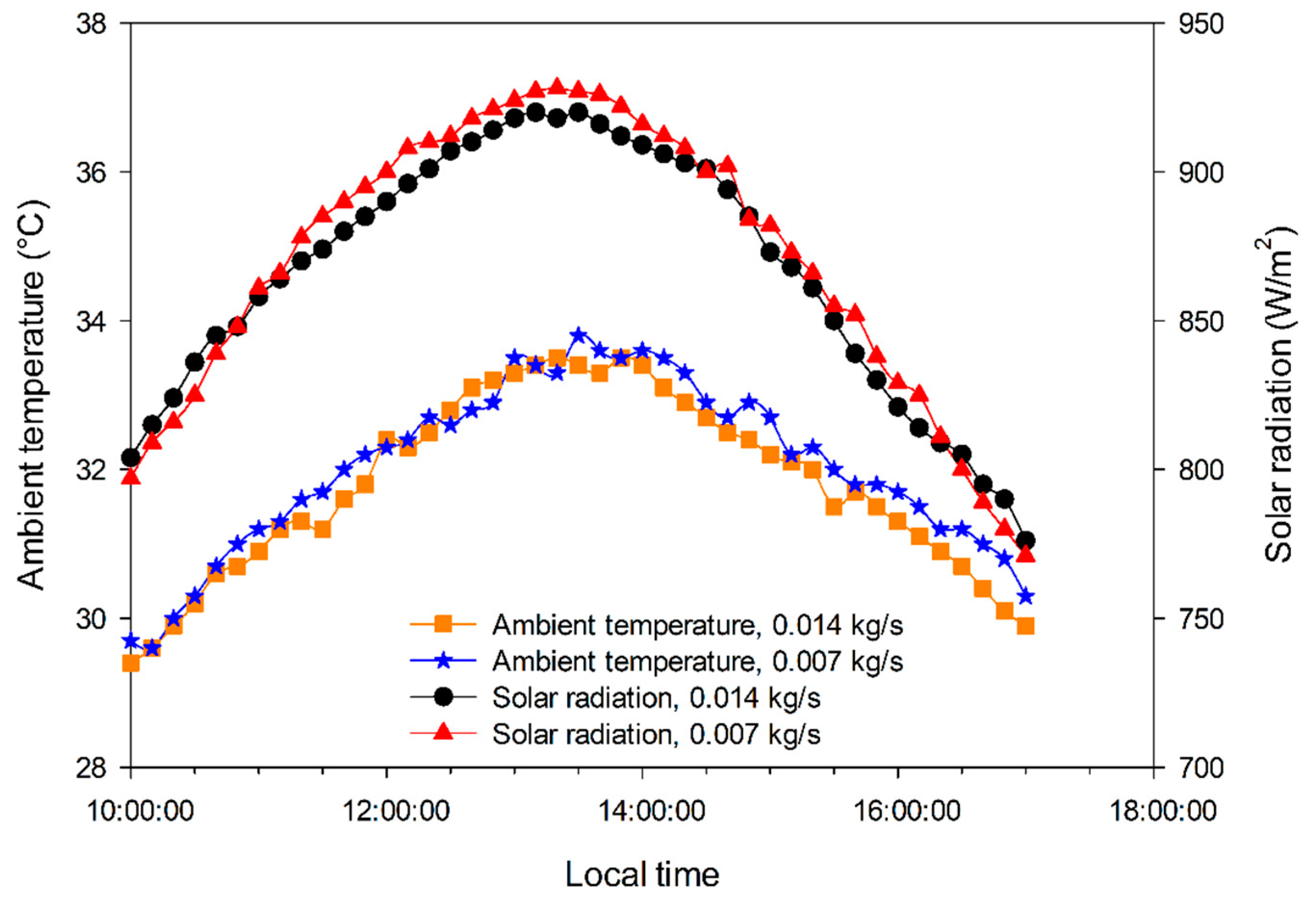

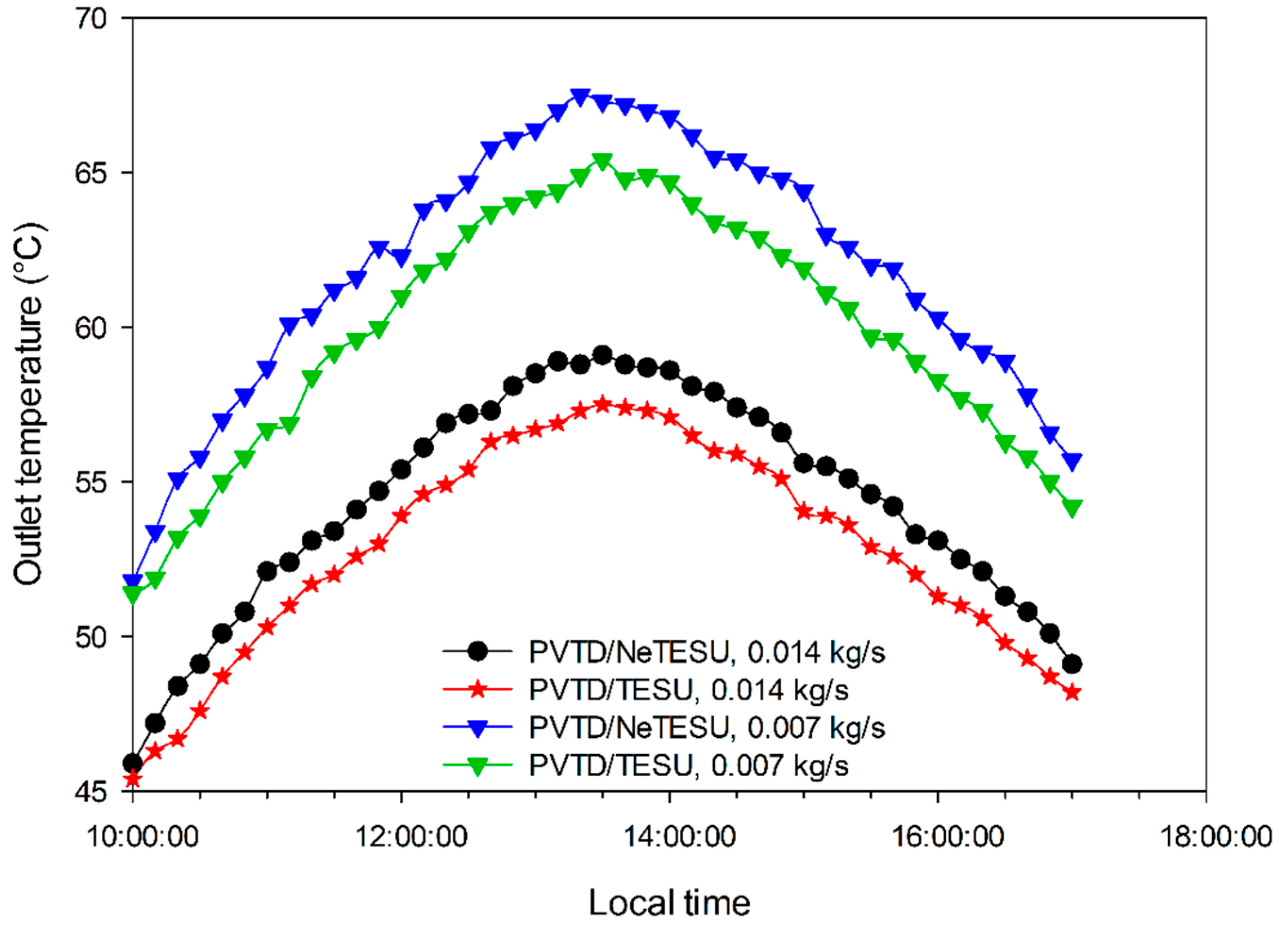

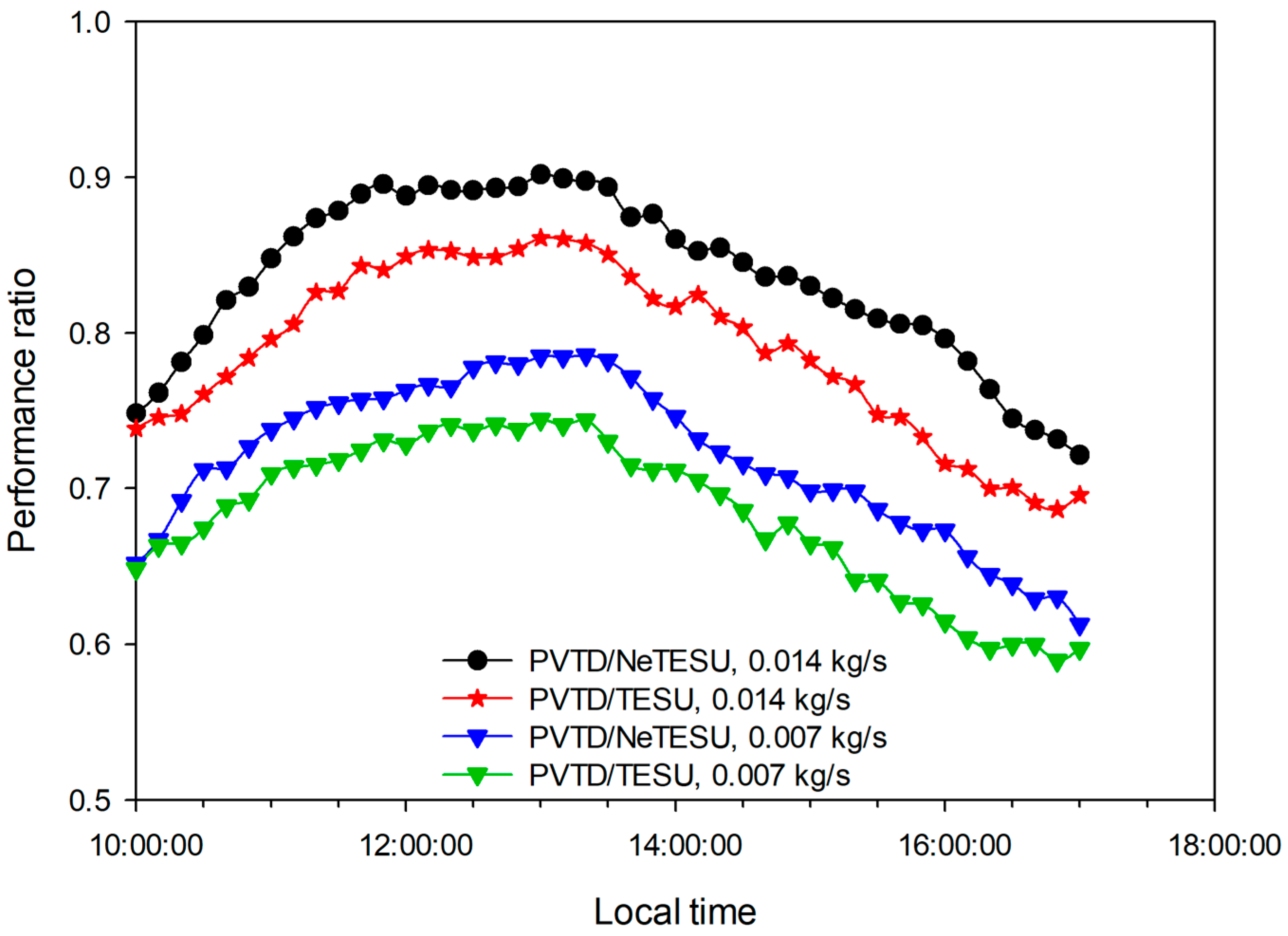

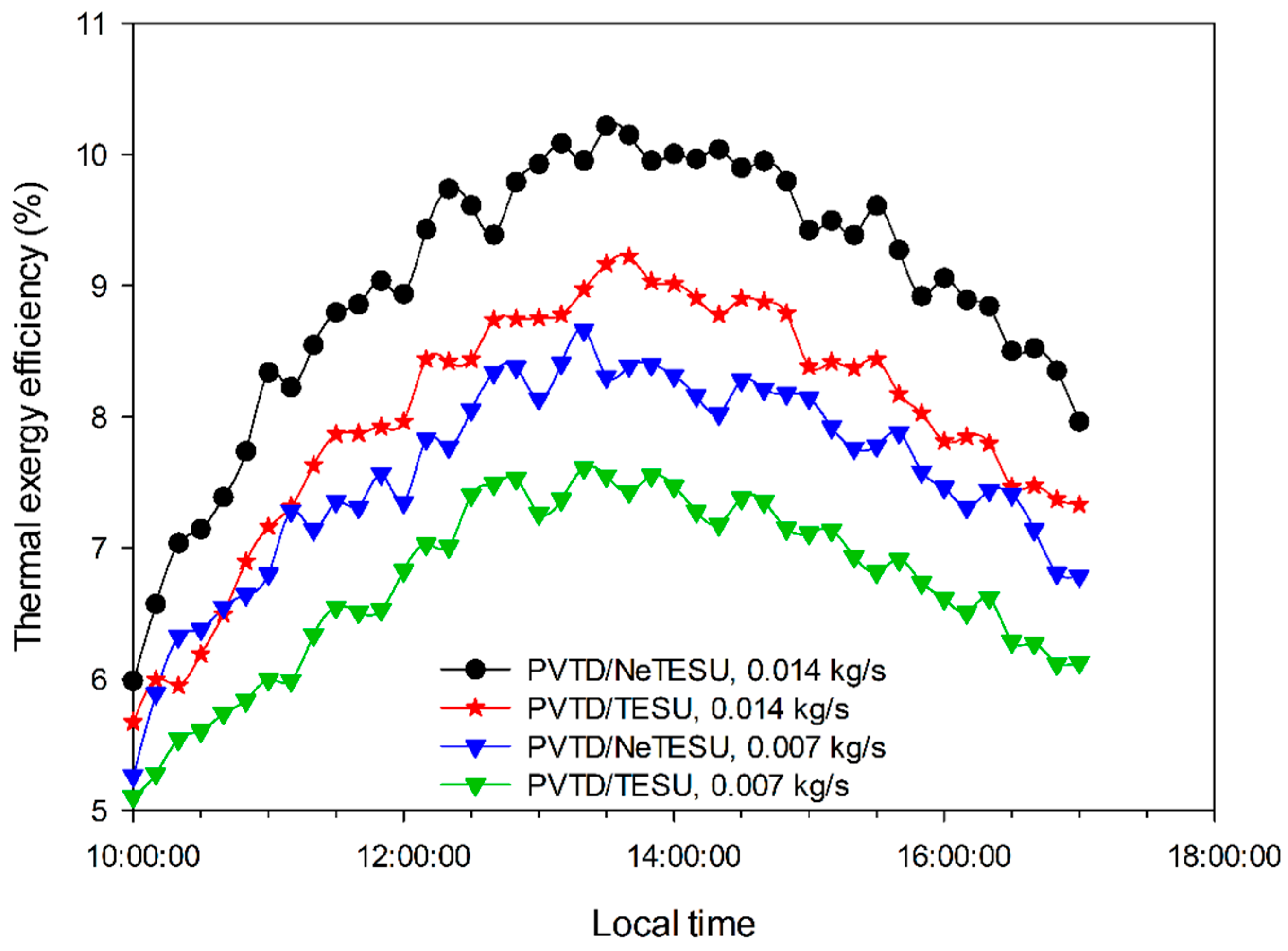

5.1. Experimental Results

5.2. System Identification Results

6. Conclusions

- The drying time was decreased by 5–22% by employing a nano-integrated thermal storage unit.

- The mean electrical efficiency was raised by 22.32% by upgrading the air velocity and adding nano-sized particles into the thermal storage unit.

- By using nanoparticles in the TESU, the overall energetic efficiency values of the PVT air collector were improved by 6.91% and 6.97%, respectively, in the tests performed at higher and lower flow rates. Both modifying the TESU with nanoparticles and enhancing the flow rate improved the overall energetic efficiency by 40.07%.

- The total exergy efficiencies for the PVT collector with TESU and PVT air collector with NeTESU were obtained in the ranges of 12.49–14.67% and 13.64–16.06%, respectively. In addition, mean electrical exergy yield values were achieved as 6.68% and 7.06%, respectively, in the test performed at a higher velocity value.

- The average sustainability index and waste exergy ratio of the drying chamber for PVTD/TESU were found to be between 2.26 and 2.57 and 0.48 and 0.51, respectively. These values for PVTD/NeTESU were obtained as 2.44–2.64 and 0.45–0.50, respectively.

- A multi-input multi-output dynamic model was obtained by using the system identification method for the developed PVT collectors considering energetic and exergetic efficiencies as multiple outputs of systems. The dynamic characteristics of the systems were well captured with dynamic models, and a modeling accuracy above 85% was achieved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| area (m2) | |

| specific heat capacity (kJ·kg−1·K−1) | |

| hydraulic diameter of the air channel (m) | |

| drying rate (gwater.gdry matter−1·min−1) | |

| energy (W) | |

| exergy (W) | |

| solar irradiation intensity (W·m−2) | |

| effective solar irradiance (W) | |

| heat transfer coefficient (W·m−2·K−1) | |

| enthalpy (kJ·kg−1) | |

| electrical current (A) | |

| conductivity (W·m−1·K−1) | |

| moisture ratio (%) | |

| mass flow rate (kg·s−1) | |

| Nusselt number | |

| electrical power (W) | |

| the function uncertainty | |

| Reynolds number | |

| entropy (kJ·kg−1·K−1) | |

| temperature (°C) | |

| electrical voltage (V) | |

| uncertainty values in the independent metrics | |

| total uncertainty (%) | |

| moisture content (gwater/gdry matter) | |

| initial moisture content (gwater/gdry matter) | |

| final dry weight (g) | |

| moisture content on dry basis (gwater/gdry matter) | |

| equilibrium moisture content (gwater/gdry matter) | |

| beginning wet weight (g) | |

| moisture content at time “t” (gwater/gdry matter) | |

| moisture content at time “t + dt” (gwater/gdry matter) | |

| Greek symbols | |

| autoregressive with exogenous input | |

| fill factor | |

| finite impulse response | |

| multi-input multi-output | |

| output error | |

| performance ratio | |

| photovoltaic thermal collector | |

| sustainability index | |

| transmission electron microscopy | |

| X-ray diffraction | |

| waste exergy ratio | |

| Greek letters | |

| absorptivity | |

| air velocity (m·s−1) | |

| transmissivity | |

| density (kg·m−3) | |

| viscosity (Pa·s) | |

| stream exergy | |

| electrical efficiency (%) | |

| normalized power output efficiency (%) | |

| thermal efficiency (%) | |

| exergy efficiency (%) | |

| Subscripts | |

| a | ambient |

| ai | air |

| c | convection |

| d | destruction |

| dc | drying chamber |

| e | effective |

| el | electrical |

| f | friction |

| i | inflow |

| l | loss |

| m | mass |

| mx | maximum |

| ms | measured |

| o | outflow |

| ov | total |

| r | radiation |

| stc | standard test conditions |

| t | thermal |

References

- Li, G. Sensible heat thermal storage energy and exergy performance evaluations. Renew. Sustain. Energy Rev. 2016, 53, 897–923. [Google Scholar] [CrossRef]

- Sezen, K.; Tuncer, A.D.; Akyuz, A.O.; Gungor, A. Effects of ambient conditions on solar assisted heat pump systems: A review. Sci. Total Environ. 2021, 778, 146362. [Google Scholar] [CrossRef]

- Ali, H.M. Recent advancements in PV cooling and efficiency enhancement integrating phase change materials based systems—A comprehensive review. Sol. Energy 2020, 197, 163–198. [Google Scholar] [CrossRef]

- Oztop, H.F.; Bayrak, F.; Hepbasli, A. Energetic and exergetic aspects of solar air heating (solar collector) systems. Renew. Sustain. Energy Rev. 2013, 21, 59–83. [Google Scholar] [CrossRef]

- Bayrak, F.; Oztop, H.F.; Selimefendigil, F. Effects of different fin parameters on temperature and efficiency for cooling of photovoltaic panels under natural convection. Sol. Energy 2019, 188, 484–494. [Google Scholar] [CrossRef]

- Khanlari, A.; Güler H, Ö.; Tuncer, A.D.; Şirin, C.; Bilge, Y.C.; Yılmaz, Y.; Güngör, A. Experimental and numerical study of the effect of integrating plus-shaped perforated baffles to solar air collector in drying application. Renew. Energy 2020, 145, 1677–1692. [Google Scholar] [CrossRef]

- Fan, W.; Kokogiannakis, G.; Ma, Z. A multi-objective design optimisation strategy for hybrid photovoltaic thermal collector (PVT)-solar air heater (SAH) systems with fins. Sol. Energy 2018, 163, 315–328. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Rukman NS, B.; Nazri, N.S.; Mustapha, M.; Yen, C.H.; Mohammad, M.; Sopian, K. Exergy and sustainability index of photovoltaic thermal (PVT) air collector: A theoretical and experimental study. Renew. Sustain. Energy Rev. 2019, 100, 44–51. [Google Scholar] [CrossRef]

- Li, G.; Hwang, Y.; Radermacher, R. Cold thermal energy storage materials and applications toward sustainability. In Energy Solutions to Combat Global Warming; Springer: Cham, Switzerland, 2017; pp. 67–117. [Google Scholar]

- Li, G. Energy and exergy performance assessments for latent heat thermal energy storage systems. Renew. Sustain. Energy Rev. 2015, 51, 926–954. [Google Scholar] [CrossRef]

- Li, G.; Zheng, X. Thermal energy storage system integration forms for a sustainable future. Renew. Sustain. Energy Rev. 2016, 62, 736–757. [Google Scholar] [CrossRef]

- Tuncer, A.D.; Khanlari, A.; Aytaç, İ.; Çiftçi, E.; Sözen, A.; Variyenli H, İ. Passive thermal management of photovoltaic panel by using phase change material-filled aluminum cans: An experimental study. Heat Transf. Res. 2022, 53, 73–86. [Google Scholar] [CrossRef]

- Fiorentini, M.; Cooper, P.; Ma, Z.; Robinson, D.A. Hybrid model predictive control of a residential HVAC system with PVT energy generation and PCM thermal storage. Energy Procedia 2015, 83, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Ahmadi, R.; Monadinia, F.; Maleki, M. Passive/active photovoltaic-thermal (PVT) system implementing infiltrated phase change material (PCM) in PS-CNT foam. Sol. Energy Mater. Sol. Cells 2021, 222, 110942. [Google Scholar] [CrossRef]

- Carmona, M.; Bastos, A.P.; García, J.D. Experimental evaluation of a hybrid photovoltaic and thermal solar energy collector with integrated phase change material (PVT-PCM) in comparison with a traditional photovoltaic (PV) module. Renew. Energy 2021, 172, 680–696. [Google Scholar] [CrossRef]

- Fu, Z.; Liang, X.; Li, Y.; Li, L.; Zhu, Q. Performance improvement of a PVT system using a multilayer structural heat exchanger with PCMs. Renew. Energy 2021, 169, 308–317. [Google Scholar] [CrossRef]

- Li, G.; Hwang, Y.; Radermacher, R. Review of cold storage materials for air conditioning application. Int. J. Refrig. 2012, 35, 2053–2077. [Google Scholar] [CrossRef]

- Li, G.; Hwang, Y.; Radermacher, R.; Chun, H.H. Review of cold storage materials for subzero applications. Energy 2013, 51, 1–17. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.; Chaichan, M.T.; Sopian, K.; Kazem, H.A.; Mahood, H.B.; Khadom, A.A. Modeling and experimental validation of a PVT system using nanofluid coolant and nano-PCM. Sol. Energy 2019, 177, 178–191. [Google Scholar] [CrossRef]

- Kazemian, A.; Khatibi, M.; Maadi, S.R.; Ma, T. Performance optimization of a nanofluid-based photovoltaic thermal system integrated with nano-enhanced phase change material. Appl. Energy 2021, 295, 116859. [Google Scholar] [CrossRef]

- Manigandan, S.; Kumar, V. Comparative study to use nanofluid ZnO and CuO with phase change material in photovoltaic thermal system. Int. J. Energy Res. 2019, 43, 1882–1891. [Google Scholar] [CrossRef]

- Siahkamari, L.; Rahimi, M.; Azimi, N.; Banibayat, M. Experimental investigation on using a novel phase change material (PCM) in micro structure photovoltaic cooling system. Int. Commun. Heat Mass Transf. 2019, 100, 60–66. [Google Scholar] [CrossRef]

- Veeramanipriya, E.; Sundari, A.R.U. Performance evaluation of hybrid photovoltaic thermal (PVT) solar dryer for drying of cassava. Sol. Energy 2021, 215, 240–251. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N.; Al-Helal, I.M. Performance analysis of photovoltaic–thermal (PVT) mixed mode greenhouse solar dryer. Sol. Energy 2016, 133, 421–428. [Google Scholar] [CrossRef]

- Mortezapour, H.; Ghobadian, B.; Minaei, S.; Khoshtaghaza, M.H. Saffron drying with a heat pump–assisted hybrid photovoltaic–thermal solar dryer. Dry. Technol. 2012, 30, 560–566. [Google Scholar] [CrossRef]

- Nayak, S.; Kumar, A.; Mishra, J.; Tiwari, G.N. Drying and testing of mint (Mentha piperita) by a hybrid photovoltaic-thermal (PVT)-based greenhouse dryer. Dry. Technol. 2011, 29, 1002–1009. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N. Energy and exergy analysis of a mixed-mode greenhouse-type solar dryer, integrated with partially covered N-PVT air collector. Energy 2017, 128, 183–195. [Google Scholar] [CrossRef]

- Çiftçi, E.; Khanlari, A.; Sözen, A.; Aytaç, İ.; Tuncer, A.D. Energy and exergy analysis of a photovoltaic thermal (PVT) system used in solar dryer: A numerical and experimental investigation. Renew. Energy 2021, 180, 410–423. [Google Scholar] [CrossRef]

- Gupta, A.; Das, B.; Biswas, A.; Mondol, J.D. Sustainability and 4E analysis of novel solar photovoltaic-thermal solar dryer under forced and natural convection drying. Renew. Energy 2022, 188, 1008–1021. [Google Scholar] [CrossRef]

- Tiwari, S.; Sahdev, R.K.; Kumar, M.; Chhabra, D.; Tiwari, P.; Tiwari, G.N. Environmental and economic sustainability of PVT drying system: A heat transfer approach. Environ. Prog. Sustain. Energy 2021, 40, e13535. [Google Scholar] [CrossRef]

- Gupta, A.; Biswas, A.; Das, B.; Reddy, B.V. Development and testing of novel photovoltaic-thermal collector-based solar dryer for green tea drying application. Sol. Energy 2022, 231, 1072–1091. [Google Scholar] [CrossRef]

- Hao, W.; Zhang, H.; Liu, S.; Lai, Y. Design and prediction method of dual working medium solar energy drying system. Appl. Therm. Eng. 2021, 195, 117153. [Google Scholar] [CrossRef]

- Gürel, A.E.; Ağbulut, Ü.; Ergün, A.; Ceylan, İ.; Sözen, A.; Tuncer, A.D.; Khanlari, A. A detailed investigation of the temperature-controlled fluidized bed solar dryer: A numerical, experimental, and modeling study. Sustain. Energy Technol. Assess. 2022, 49, 101703. [Google Scholar] [CrossRef]

- Kırbaş, İ.; Tuncer, A.D.; Şirin, C.; Usta, H. Modeling and developing a smart interface for various drying methods of pomelo fruit (Citrus maxima) peel using machine learning approaches. Comput. Electron. Agric. 2019, 165, 104928. [Google Scholar] [CrossRef]

- Dhalsamant, K. Development, validation, and comparison of FE modeling and ANN model for mixed-mode solar drying of potato cylinders. J. Food Sci. 2021, 86, 3384–3402. [Google Scholar] [CrossRef]

- Abdenouri, N.; Zoukit, A.; Salhi, I.; Doubabi, S. Model identification and fuzzy control of the temperature inside an active hybrid solar indirect dryer. Sol. Energy 2022, 231, 328–342. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C. Energy and exergy analysis of a hybrid photovoltaic/thermal-air collector modified with nano-enhanced latent heat thermal energy storage unit. J. Energy Storage 2022, 45, 103467. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C.; Ghachem, K.; Kolsi, L. Exergy and environmental analysis of an active greenhouse dryer with Al2O3 nano-embedded latent heat thermal storage system: An experimental study. Appl. Therm. Eng. 2022, 217, 119167. [Google Scholar] [CrossRef]

- Loni, R.; Asli-Ardeh, E.A.; Ghobadian, B.; Najafi, G.; Bellos, E. Effects of size and volume fraction of alumina nanoparticles on the performance of a solar organic Rankine cycle. Energy Convers. Manag. 2019, 182, 398–411. [Google Scholar] [CrossRef]

- Schuller, M.; Shao, Q.; Lalk, T. Experimental investigation of the specific heat of a nitrate–alumina nanofluid for solar thermal energy storage systems. Int. J. Therm. Sci. 2015, 91, 142–145. [Google Scholar] [CrossRef] [Green Version]

- Mondragón, R.; Sánchez, D.; Cabello, R.; Llopis, R.; Juliá, J.E. Flat plate solar collector performance using alumina nanofluids: Experimental characterization and efficiency tests. PLoS ONE 2019, 14, e0212260. [Google Scholar] [CrossRef] [Green Version]

- Malik, D.R. Evaluation of Composite Alumina Nanoparticle and Nitrate Eutectic Materials for Use in Concentrating Solar Power Plants. Ph.D. Thesis, Texas A & M University, College Station, TX, USA, 2010. [Google Scholar]

- Kanti, P.K.; Chereches, E.I.; Minea, A.A.; Sharma, K.V. Experiments on thermal properties of ionic liquid enhanced with alumina nanoparticles for solar applications. J. Therm. Anal. Calorim. 2022, 147, 13027–13038. [Google Scholar] [CrossRef]

- Tariq, S.L.; Ali, H.M.; Akram, M.A.; Janjua, M.M.; Ahmadlouydarab, M. Nanoparticles enhanced Phase Change Materials (NePCMs)-A Recent Review. Appl. Therm. Eng. 2020, 176, 115305. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Sopian, K.; Chaichan, M.T.; Kazem, H.A.; Ibrahim, A.; Mat, S.; Ruslan, M.H. Evaluation of the nanofluid and nano-PCM based photovoltaic thermal (PVT) system: An experimental study. Energy Convers. Manag. 2017, 151, 693–708. [Google Scholar] [CrossRef]

- Singh, D.K.; Suresh, S.; Singh, H.; Rose, B.A.J.; Tassou, S.; Anantharaman, N. Myoinositol based nano-PCM for solar thermal energy storage. Appl. Therm. Eng. 2017, 110, 564–572. [Google Scholar] [CrossRef] [Green Version]

- Teng, T.P.; Yu, C.C. Characteristics of phase-change materials containing oxide nano-additives for thermal storage. Nanoscale Res. Lett. 2012, 7, 611. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karaağaç, M.O.; Ergün, A.; Ağbulut, Ü.; Gürel, A.E.; Ceylan, İ. Experimental analysis of CPV/T solar dryer with nano-enhanced PCM and prediction of drying parameters using ANN and SVM algorithms. Sol. Energy 2021, 218, 57–67. [Google Scholar] [CrossRef]

- Ansari, S.A.; Husain, Q. Immobilization of Kluyveromyces lactis β galactosidase on concanavalin A layered aluminium oxide nanoparticles—Its future aspects in biosensor applications. J. Mol. Catal. B Enzym. 2011, 70, 119–126. [Google Scholar] [CrossRef]

- Khanlari, A.; Sözen, A.; Afshari, F.; Tuncer, A.D. Energy-exergy and sustainability analysis of a PV-driven quadruple-flow solar drying system. Renew. Energy 2021, 175, 1151–1166. [Google Scholar] [CrossRef]

- Afshari, F.; Tuncer, A.D.; Sözen, A.; Çiftçi, E.; Khanlari, A. Experimental and numerical analysis of a compact indirect solar dehumidification system. Sol. Energy 2021, 226, 72–84. [Google Scholar] [CrossRef]

- Kazemian, A.; Taheri, A.; Sardarabadi, A.; Ma, T.; Passandideh-Fard, M.; Peng, J. Energy, exergy and environmental analysis of glazed and unglazed PVT system integrated with phase change material: An experimental approach. Sol. Energy 2020, 201, 178–189. [Google Scholar] [CrossRef]

- Zare, D.; Minaei, S.; Zadeh, M.M.; Khoshtaghaza, M.H. Computer simulation of rough rice drying in a batch dryer. Energy Convers. Manag. 2006, 47, 3241–3254. [Google Scholar] [CrossRef]

- Granstrom, M.; Petritsch, K.; Arias, A.C.; Lux, A.; Andersson, M.R.; Friend, R.H. Laminated fabrication of polymeric photovoltaic diodes. Nature 1998, 395, 257–260. [Google Scholar] [CrossRef]

- Abuşka, M.; Şevik, S. Energy, exergy, economic and environmental (4E) analyses of flat-plate and V-groove solar air collectors based on aluminium and copper. Sol. Energy 2017, 158, 259–277. [Google Scholar] [CrossRef]

- Wongwuttanasatian, T.; Sarikarin, T.; Suksri, A. Performance enhancement of a photovoltaic module by passive cooling using phase change material in a finned container heat sink. Sol. Energy 2020, 195, 47–53. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Hosseinzadeh, M.; Kazemian, A.; Passandideh-Fard, M. Experimental investigation of the effects of using metal-oxides/water nanofluids on a photovoltaic thermal system (PVT) from energy and exergy viewpoints. Energy 2017, 138, 682–695. [Google Scholar] [CrossRef]

- Park, S.R.; Pandey, A.K.; Tyagi, V.V.; Tyagi, S.K. Energy and exergy analysis of typical renewable energy systems. Renew. Sustain. Energy Rev. 2014, 30, 105–123. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Fong, K.F.; Lin, Z.; Chan AL, S.; Ji, J. Energy and exergy analysis of photovoltaic–thermal collector with and without glass cover. Appl. Energy 2009, 86, 310–316. [Google Scholar] [CrossRef]

- Kuzgunkaya, E.H.; Hepbasli, A. Exergetic evaluation of drying of laurel leaves in a vertical ground-source heat pump drying cabinet. Int. J. Energy Res. 2007, 31, 245–258. [Google Scholar] [CrossRef]

- Akpinar, E.K. Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analyses. Energy Convers. Manag. 2010, 51, 2407–2418. [Google Scholar] [CrossRef]

- Mugi, V.R.; Chandramohan, V.P. Energy and exergy analysis of forced and natural convection indirect solar dryers: Estimation of exergy inflow, outflow, losses, exergy efficiencies and sustainability indicators from drying experiments. J. Clean. Prod. 2021, 282, 124421. [Google Scholar] [CrossRef]

- Ghasemkhani, H.; Keyhani, A.; Aghbashlo, M.; Rafiee, S.; Mujumdar, A.S. Improving exergetic performance parameters of a rotating-tray air dryer via a simple heat exchanger. Appl. Therm. Eng. 2016, 94, 13–23. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Praveen, P.; Gupta, S.; Saikiran, J.; Bharj, R.S. Performance evaluation of photovoltaic module integrated with phase change material-filled container with external fins for extremely hot climates. J. Energy Storage 2020, 32, 101876. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C.; Öztop, H.F. Improving the performance of an active greenhouse dryer by integrating a solar absorber north wall coated with graphene nanoplatelet-embedded black paint. Sol. Energy 2022, 231, 140–148. [Google Scholar] [CrossRef]

- Ceylan, İ.; Gürel, A.E. Solar-assisted fluidized bed dryer integrated with a heat pump for mint leaves. Appl. Therm. Eng. 2016, 106, 899–905. [Google Scholar] [CrossRef]

- Tuncer, A.D.; Sözen, A.; Afshari, F.; Khanlari, A.; Şirin, C.; Gungor, A. Testing of a novel convex-type solar absorber drying chamber in dehumidification process of municipal sewage sludge. J. Clean. Prod. 2020, 272, 122862. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C. Experimental investigation of a parabolic greenhouse dryer improved with copper oxide nano-enhanced latent heat thermal energy storage unit. Int. J. Energy Res. 2022, 46, 3647–3662. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Applications of artificial neural-networks for energy systems. Appl. Energy 2020, 67, 17–35. [Google Scholar] [CrossRef]

- Mellit, A.; Kalogirou, S.A. ANFIS-based modelling for photovoltaic power supply system: A case study. Renew. Energy 2011, 36, 250–258. [Google Scholar] [CrossRef]

- Varol, Y.; Koca, A.; Oztop, H.F.; Avci, E. Forecasting of thermal energy storage performance of Phase Change Material in a solar collector using soft computing techniques. Expert Syst. Appl. 2010, 37, 2724–2732. [Google Scholar] [CrossRef]

- Voyant, C.; Notton, G.; Kalogirou, S.; Nivet, M.L.; Paoli, C.; Motte, F.; Fouilloy, A. Machine learning methods for solar radiation forecasting: A review. Renew. Energy 2017, 105, 569–582. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Oztop, H.F. Identification of pulsating flow effects with CNT nanoparticles on the performance enhancements of thermoelectric generator (TEG) module in renewable energy applications. Renew. Energy 2020, 162, 1076–1086. [Google Scholar] [CrossRef]

- Ljung, L. Perspectives on system identification. Annu. Rev. Control. 2010, 34, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Giannakis, G.B.; Serpedin, E. A bibliography on nonlinear system identification. Signal Process. 2001, 81, 533–580. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Sujith, R.I.; Polifke, W. Identification of heat transfer dynamics for non-modal analysis of thermoacoustic stability. Appl. Math. Comput. 2011, 217, 5134–5150. [Google Scholar] [CrossRef]

- Chaibi, Y.; Malvoni, M.; El Rhafiki, T.; Kousksou, T.; Zeraouli, Y. Artificial neural-network based model to forecast the electrical and thermal efficiencies of PVT air collector systems. Clean. Eng. Technol. 2021, 4, 100132. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Brinkley, J.; Hota, S.K.; Ferry, J.; Diaz, G.; Winston, R. Experimental performance of an ultra-low-cost solar photovoltaic-thermal (PVT) collector using aluminum minichannels and nonimaging optics. Appl. Energy 2020, 268, 114894. [Google Scholar] [CrossRef]

- Gholampour, M.; Ameri, M.; Sheykh Samani, M. Experimental study of performance of Photovoltaic–Thermal Unglazed Transpired Solar Collectors (PV/UTCs): Energy, exergy, and electrical-to-thermal rational approaches. Sol. Energy 2014, 110, 636–647. [Google Scholar] [CrossRef]

- Tiwari, A.; Dubey, S.; Sandhu, G.S.; Sodha, M.S.; Anwar, S.I. Exergy analysis of integrated photovoltaic thermal solar water heater under constant flow rate and constant collection temperature modes. Appl. Energy 2009, 86, 2592–2597. [Google Scholar] [CrossRef]

- Evola, G.; Marletta, L. Exergy and thermoeconomic optimization of a water-cooled glazed hybrid photovoltaic/thermal (PVT) collector. Sol. Energy 2014, 107, 12–25. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Effect of climate on electrical performance of finned phase change material integrated solar photovoltaic. Sol. Energy 2018, 174, 593–605. [Google Scholar] [CrossRef]

- Velmurugan, K.; Karthikeyan, V.; Korukonda, T.B.; Poongavanam, P.; Nadarajan, S.; Kumarasamy, S.; Wongwuttanasatian, T.; Sandeep, D. Experimental studies on photovoltaic module temperature reduction using eutectic cold phase change material. Sol. Energy 2020, 209, 302–315. [Google Scholar] [CrossRef]

- Téllez, M.C.; Figueroa, I.P.; Téllez, B.C.; Vidaña, E.C.L.; Ortiz, A.L. Solar drying of Stevia (Rebaudiana bertoni) leaves using direct and indirect technologies. Sol. Energy 2018, 159, 898–907. [Google Scholar] [CrossRef]

- Lakshmi, D.V.N.; Muthukumar, P.; Layek, A.; Nayak, P.K. Performance analyses of mixed mode forced convection solar dryer for drying of stevia leaves. Sol. Energy 2019, 188, 507–518. [Google Scholar] [CrossRef]

- Lakshmi, D.V.N.; Muthukumar, P.; Nayak, P.K. Experimental investigations on active solar dryers integrated with thermal storage for drying of black pepper. Renew. Energy 2021, 167, 728–739. [Google Scholar] [CrossRef]

- Nayak, S.; Tiwari, G.N. Energy and exergy analysis of photovoltaic/thermal integrated with a solar greenhouse. Energy Build. 2008, 40, 2015–2021. [Google Scholar] [CrossRef]

- Jahromi, S.N.; Vadiee, A.; Yaghoubi, M. Exergy and economic evaluation of a commercially available PV/T collector for different climates in Iran. Energy Procedia 2015, 75, 444–456. [Google Scholar] [CrossRef] [Green Version]

- Kesavan, S.; Arjunan, T.V.; Vijayan, S. Thermodynamic analysis of a triple-pass solar dryer for drying potato slices. J. Therm. Anal. Calorim. 2019, 136, 159–171. [Google Scholar] [CrossRef]

- Panwar, N.L. Experimental investigation on energy and exergy analysis of coriander (Coriadrum sativum L.) leaves drying in natural convection solar dryer. Appl. Sol. Energy 2014, 50, 133–137. [Google Scholar] [CrossRef]

- Karthikeyan, A.K.; Murugavelh, S. Thin layer drying kinetics and exergy analysis of turmeric (Curcuma longa) in a mixed mode forced convection solar tunnel dryer. Renew. Energy 2018, 128, 305–312. [Google Scholar] [CrossRef]

- Madhankumar, S.; Viswanathan, K.; Wu, W. Energy, exergy and environmental impact analysis on the novel indirect solar dryer with fins inserted phase change material. Renew. Energy 2021, 176, 280–294. [Google Scholar] [CrossRef]

- Tagnamas, Z.; Lamsyehe, H.; Moussaoui, H.; Bahammou, Y.; Kouhila, M.; Idlimam, A.; Lamharrar, A. Energy and exergy analyses of carob pulp drying system based on a solar collector. Renew. Energy 2021, 163, 495–503. [Google Scholar] [CrossRef]

- Bhardwaj, A.K.; Kumar, R.; Kumar, S.; Goel, B.; Chauhan, R. Energy and exergy analyses of drying medicinal herb in a novel forced convection solar dryer integrated with SHSM and PCM. Sustain. Energy Technol. Assess. 2021, 45, 101119. [Google Scholar] [CrossRef]

- Rabha, D.K.; Muthukumar, P.; Somayaji, C. Energy and exergy analyses of the solar drying processes of ghost chilli pepper and ginger. Renew. Energy 2017, 105, 764–773. [Google Scholar] [CrossRef]

- Ndukwu, M.C.; Simo-Tagne, M.; Abam, F.I.; Onwuka, O.S.; Prince, S.; Bennamoun, L. Exergetic sustainability and economic analysis of hybrid solar-biomass dryer integrated with copper tubing as heat exchanger. Heliyon 2020, 6, e03401. [Google Scholar] [CrossRef] [PubMed]

- Akpinar, E.K. The effects of some exergetic indicators on the performance of thin layer drying process of long green pepper in a solar dryer. Heat Mass Tran. 2019, 55, 299–308. [Google Scholar] [CrossRef]

- Khanlari, A.; Afshari, F.; Sözen, A.; Tuncer, A.D.; Kusun, B. Numerical and experimental investigation of a solar absorber extension tube with turbulators for upgrading the performance of a solar dryer. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 3104–3131. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Azam, M.M.; Alghannam, A.O. Solar PV powered mixed-mode tunnel dryer for drying potato chips. Renew. Energy 2018, 116, 594–605. [Google Scholar] [CrossRef]

- Rani, P.; Tripathy, P.P. Drying characteristics, energetic and exergetic investigation during mixed-mode solar drying of pineapple slices at varied air mass flow rates. Renew. Energy 2021, 167, 508–519. [Google Scholar] [CrossRef]

| Material | Specification | Value |

|---|---|---|

| Nanoparticles | Manufacturing company | Nanografi Co., Turkey |

| CAS No. | 1344-28-1 | |

| Mean particle size | 78 nm | |

| Color | white | |

| Purity | 99.5+% | |

| Morphology | almost spherical | |

| Crystallographic structure | rhombohedral | |

| Specific heat capacity | 880 J·kg−1·K−1 | |

| Specific surface area | >20,000 m2/kg | |

| Phase change material | Manufacturer | RUBITHERM |

| Model | RT42 | |

| Thermal conductivity | 0.2 W·m−1·K−1 (both phases) | |

| Specific heat capacity | 2 kJ·kg−1·K−1 | |

| Heat storage capacity | 250 kJ·kg−1 | |

| Density | 8 kg·L−1 (solid), 7 kg·L−1 (liquid) |

| Metric | Unit | Uncertainty |

|---|---|---|

| Temperature | °C | ±0.58 |

| Electrical power | W | ±0.37 |

| Solar radiation | W/m2 | ±16.54 |

| Velocity of air | m/s | ±0.41 |

| Ref. | Dryer Type | Modification | Flow Rate (kg·s−1) | Thermal Efficiency of Collector (%) | Exergy Yield of Collector (%) | Exergy Yield of Drying Chamber (%) | SI of Drying Chamber | WER of Drying Chamber |

|---|---|---|---|---|---|---|---|---|

| [28] | Indirect PVT dryer | Vertically placed PVT collector, baffles | 0.010, 0.012, 0.014 | 47.46–58.16 (a) | 2.32–2.86 (a) | 41.85–56.11 (a) | 2.16–3.25 (a) | 0.43–0.58 (a) |

| [50] | Indirect solar dryer | Quadruple-flow solar air collector, PV panel assistance | 0.007, 0.010, 0.013 | 73.27–78.19 (a) | 3.56–4.40 (a) | 44.16–58.38 (a) | 1.93–2.73 (a) | 0.52–0.56 (a) |

| [51] | Indirect solar dryer | Compact geometry, obstacles | 0.011, 0.014 | 38.49–49.30 (a) | - | 44.91–55.28 (a) | 2.23–3.06 (a) | - |

| [62] | Indirect solar dryer | Corrugated absorber, PV panel assistance | 0.0429–0.0690 | 61.49–74.98 (a) | 2.03–2.44 (a) | 55.45–59.32 (a) | 3.69–5.1 (a) | 0.41–0.445 (a) |

| [91] | Indirect solar dryer | Mixed mode, tunnel geometry | - | - | - | 49.12 (a) | - | - |

| [92] | Indirect solar dryer | Grooved absorber, thermal energy storage, PV panel assistance | 0.06 | - | - | 8.66- 79.02 (i) | - | - |

| [93] | Indirect solar dryer | Shelved drying chamber | - | - | - | 21.35–80.5 (i) | - | - |

| [94] | Indirect solar dryer | Sensible and latent heat thermal storage | - | 9.8–26.10 (a) | 0.14–0.81 (a) | 30.28 (a) | - | - |

| [95] | Indirect solar dryer | Parallel-flow drying chamber | - | 9.64–40.24 (a) | - | 47 (a) | - | - |

| [96] | Indirect solar dryer | Biomass furnace, copper tubing as a heat exchanger | - | - | - | 5.6–95.13 (i) | 2.3–6.11 (i) | 0.05–0.94 (i) |

| [97] | Indirect solar dryer | Finned solar heating system | - | - | - | 28.22–86.02 (i) | 0.393–6.156 (i) | 0.13–0.71 (i) |

| [98] | Indirect solar dryer | Solar absorber extension tube with ball-shaped turbulators | 0.008, 0.0012 | 45.26–64.71 (a) | - | - | - | - |

| [99] | Direct solar dryer | Auxiliary solar heater, PV panel assistance, black thermal curtain | 0.0572–0.0998 | 35.93–52.70 (a) | - | - | - | - |

| [100] | Direct solar dryer | Drying chamber with transparent cover | 0.006, 0.01, 0.015 | 8.18–28.87 (a) | 0.38–1.65 (a) | 1.09–7.49 (a) | - | - |

| This study | Indirect PVT dryer (PVTD-TESU) | Thermal energy storage unit | 0.007, 0.014 | 45.6–65.2 (a) | 12.49–14.67 (a) | 48.33–51.26 (a) | 2.20–2.57 (a) | 0.48–0.51 (a) |

| Model Coefficient | System Type | |

|---|---|---|

| PVTD-TESU | PVTD-NeTESU | |

| A0 | ||

| B0 | ||

| B1 | ||

| B2 | ||

| B3 | ||

| B4 | ||

| B5 | ||

| B6 | ||

| B7 | ||

| B8 | ||

| B9 | ||

| B10 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şirin, C.; Selimefendigil, F.; Öztop, H.F. Performance Analysis and Identification of an Indirect Photovoltaic Thermal Dryer with Aluminum Oxide Nano-Embedded Thermal Energy Storage Modification. Sustainability 2023, 15, 2422. https://doi.org/10.3390/su15032422

Şirin C, Selimefendigil F, Öztop HF. Performance Analysis and Identification of an Indirect Photovoltaic Thermal Dryer with Aluminum Oxide Nano-Embedded Thermal Energy Storage Modification. Sustainability. 2023; 15(3):2422. https://doi.org/10.3390/su15032422

Chicago/Turabian StyleŞirin, Ceylin, Fatih Selimefendigil, and Hakan Fehmi Öztop. 2023. "Performance Analysis and Identification of an Indirect Photovoltaic Thermal Dryer with Aluminum Oxide Nano-Embedded Thermal Energy Storage Modification" Sustainability 15, no. 3: 2422. https://doi.org/10.3390/su15032422

APA StyleŞirin, C., Selimefendigil, F., & Öztop, H. F. (2023). Performance Analysis and Identification of an Indirect Photovoltaic Thermal Dryer with Aluminum Oxide Nano-Embedded Thermal Energy Storage Modification. Sustainability, 15(3), 2422. https://doi.org/10.3390/su15032422