Construction and Application of an Intelligent Roof Stability Evaluation System for the Roof-Cutting Non-Pillar Mining Method

Abstract

1. Introduction

2. Key Problems in Roof Stability Evaluation

3. Evaluation of Roof Stability in the Roof-Cutting Non-Pillar Mining Method

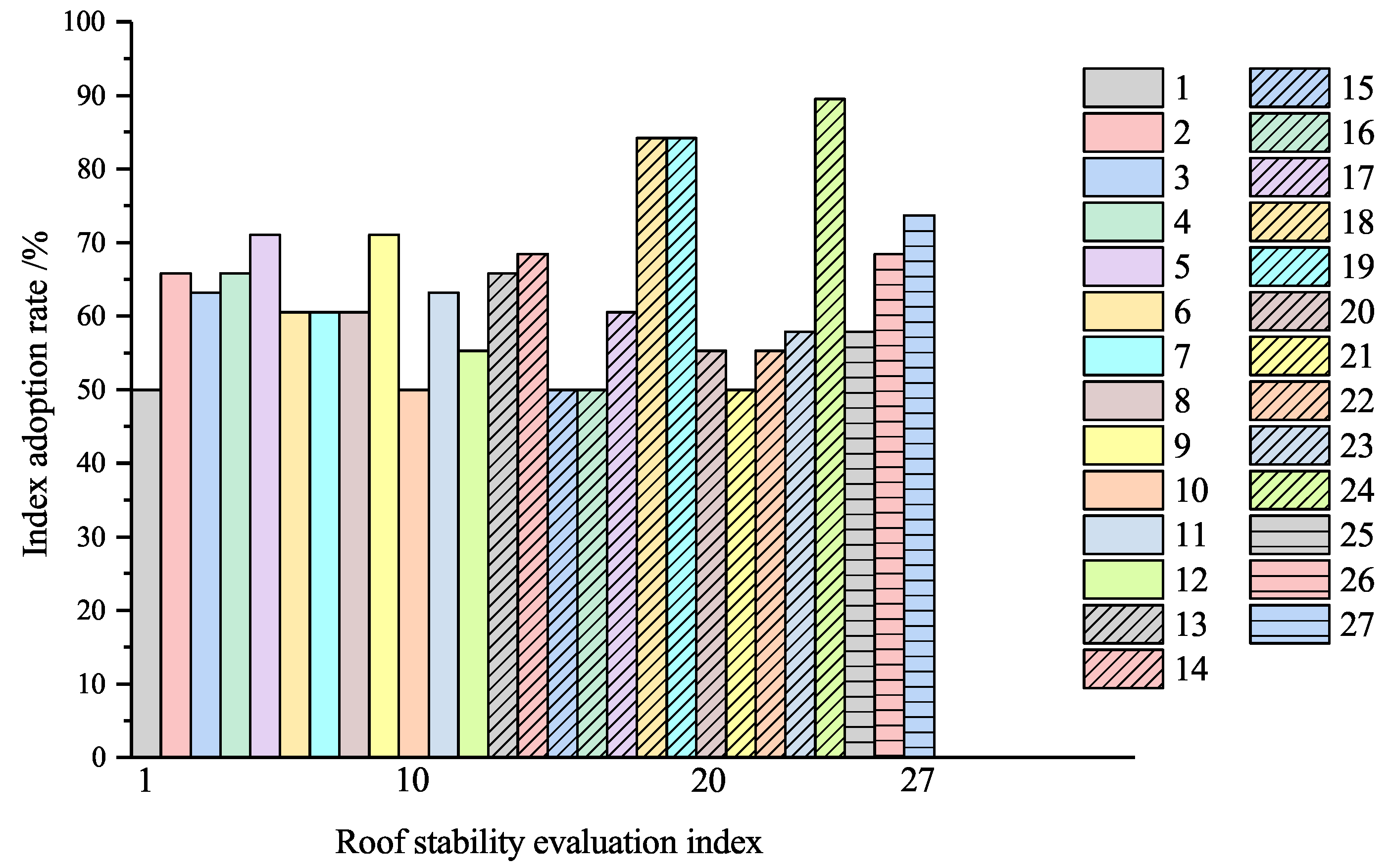

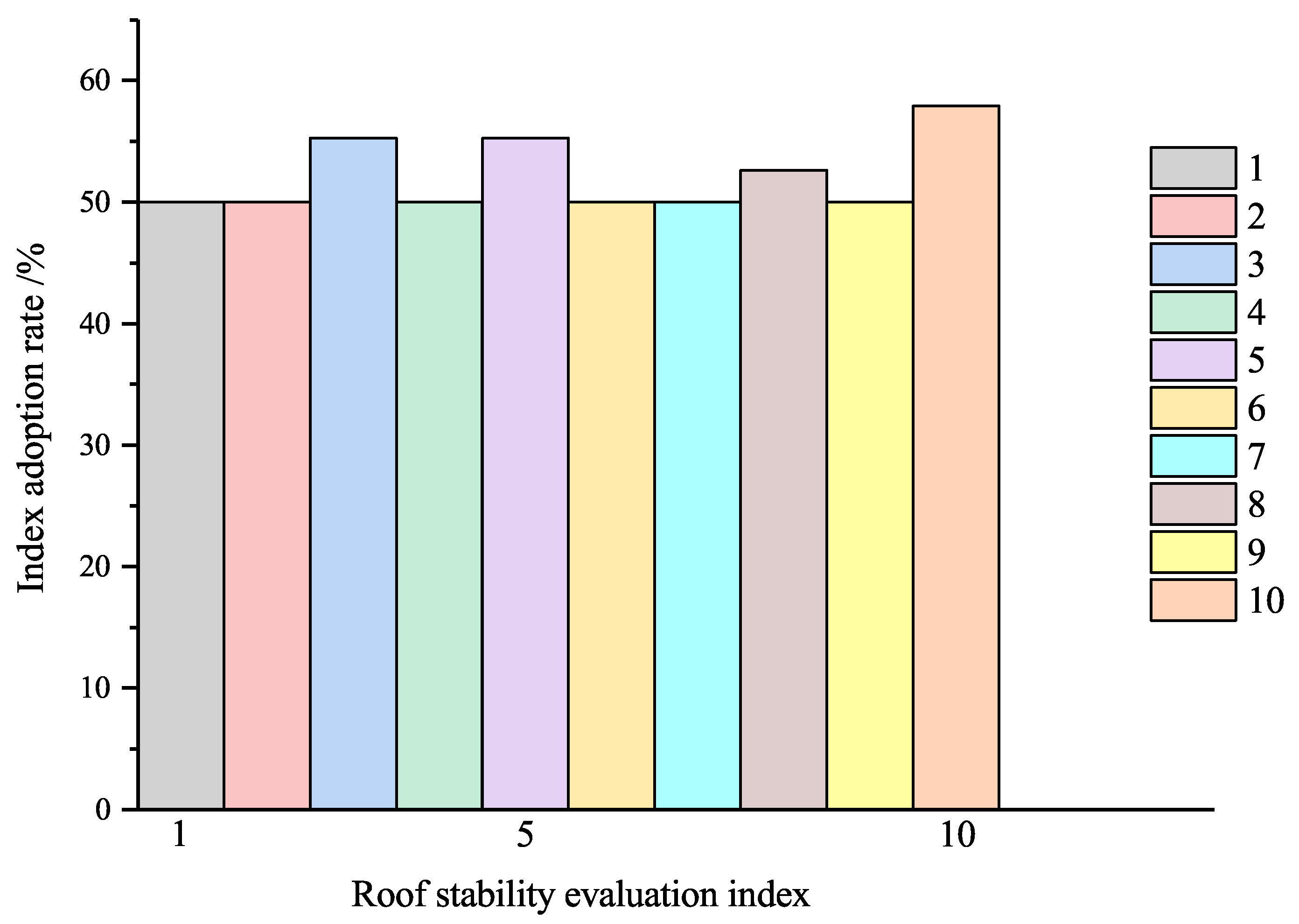

3.1. Roof Stability Evaluation Index Data Acquisition

3.2. Establishment of Roof Stability Evaluation Index System

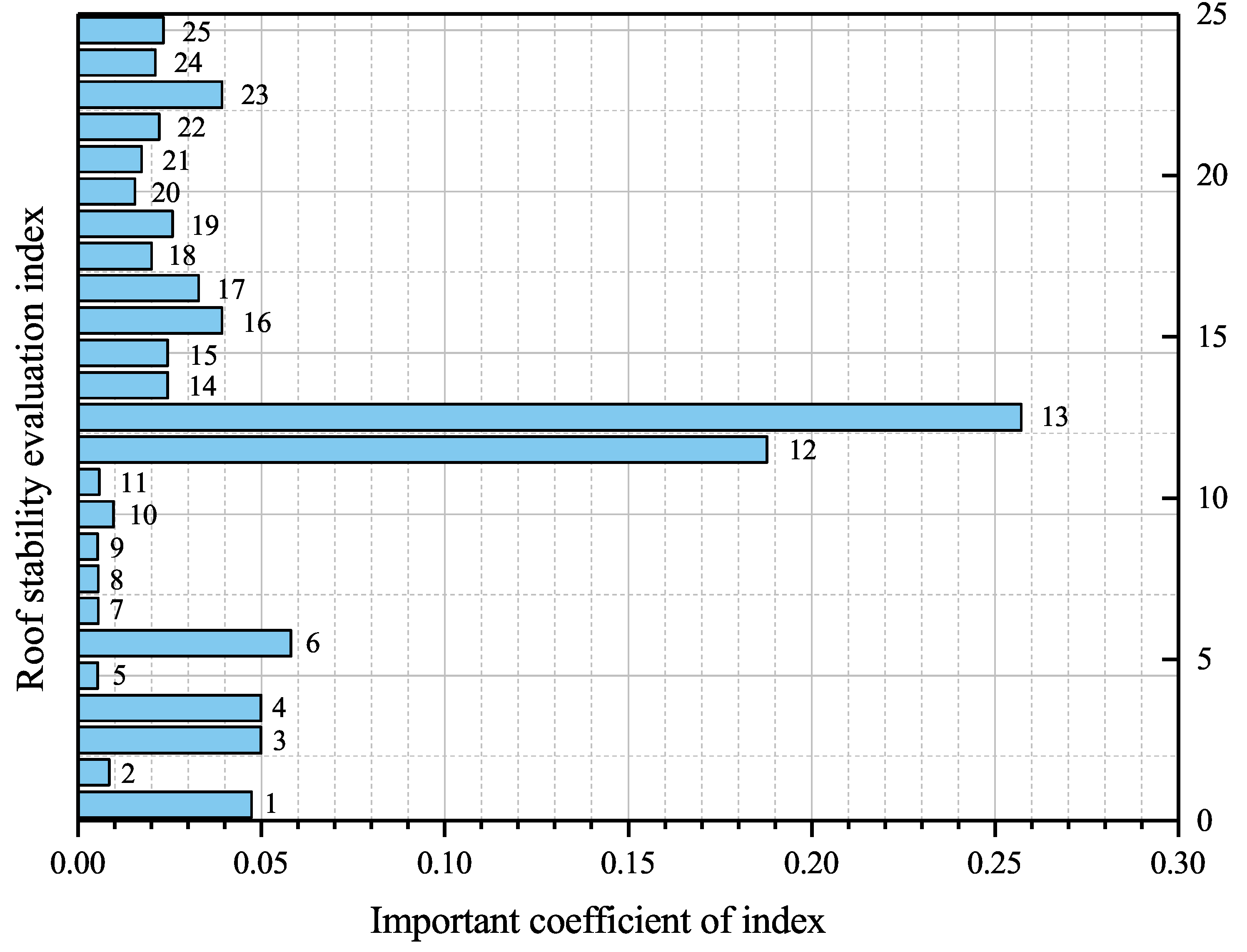

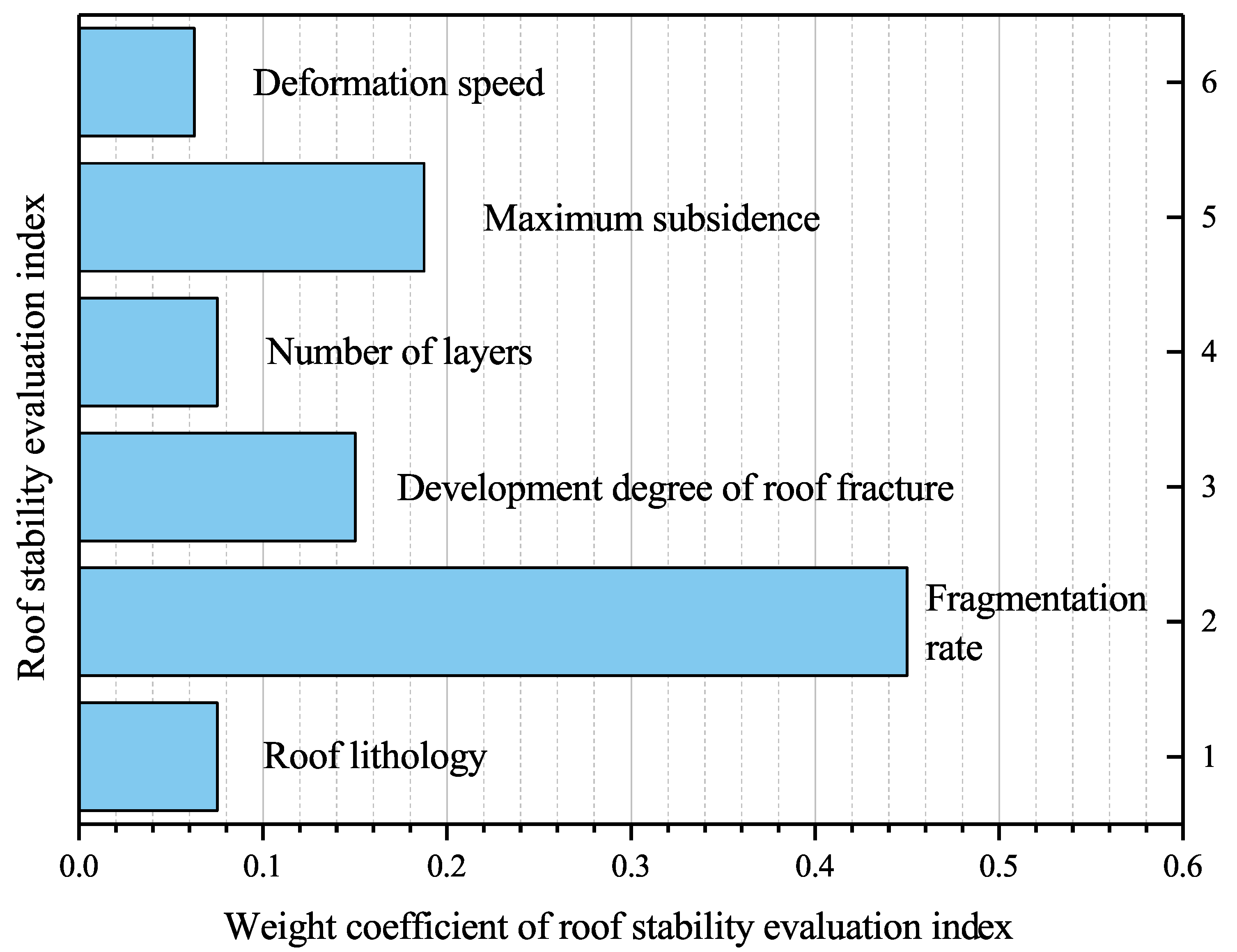

3.3. Weight Calculation of Roof Stability Evaluation Index

3.4. Comprehensive Evaluation Model of Roof Stability Grade

3.5. Roof Stability Evaluation Index Classification Standard

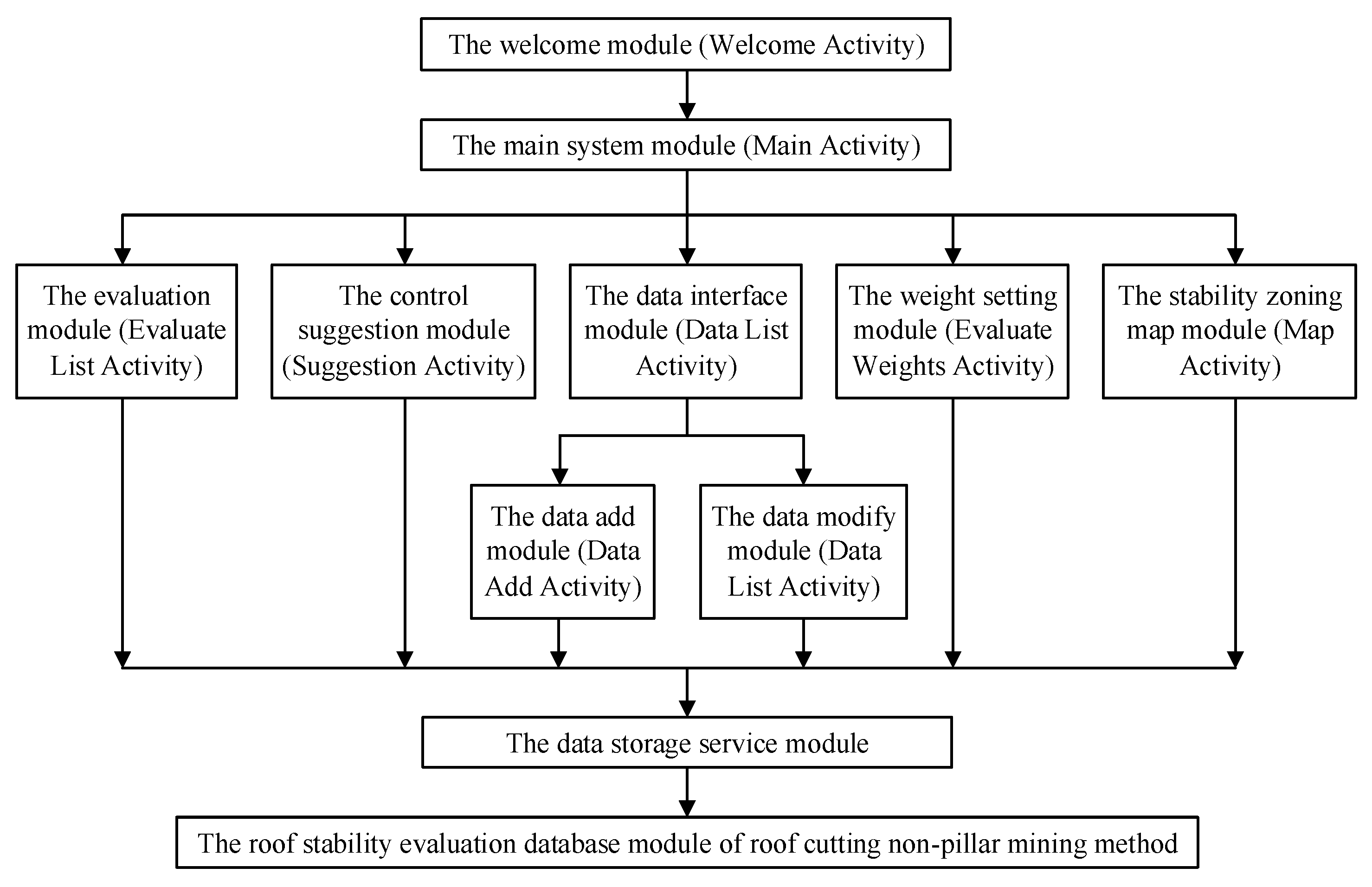

4. Mobile Intelligent Computing System Development

4.1. System Function Design

4.2. System Module Design

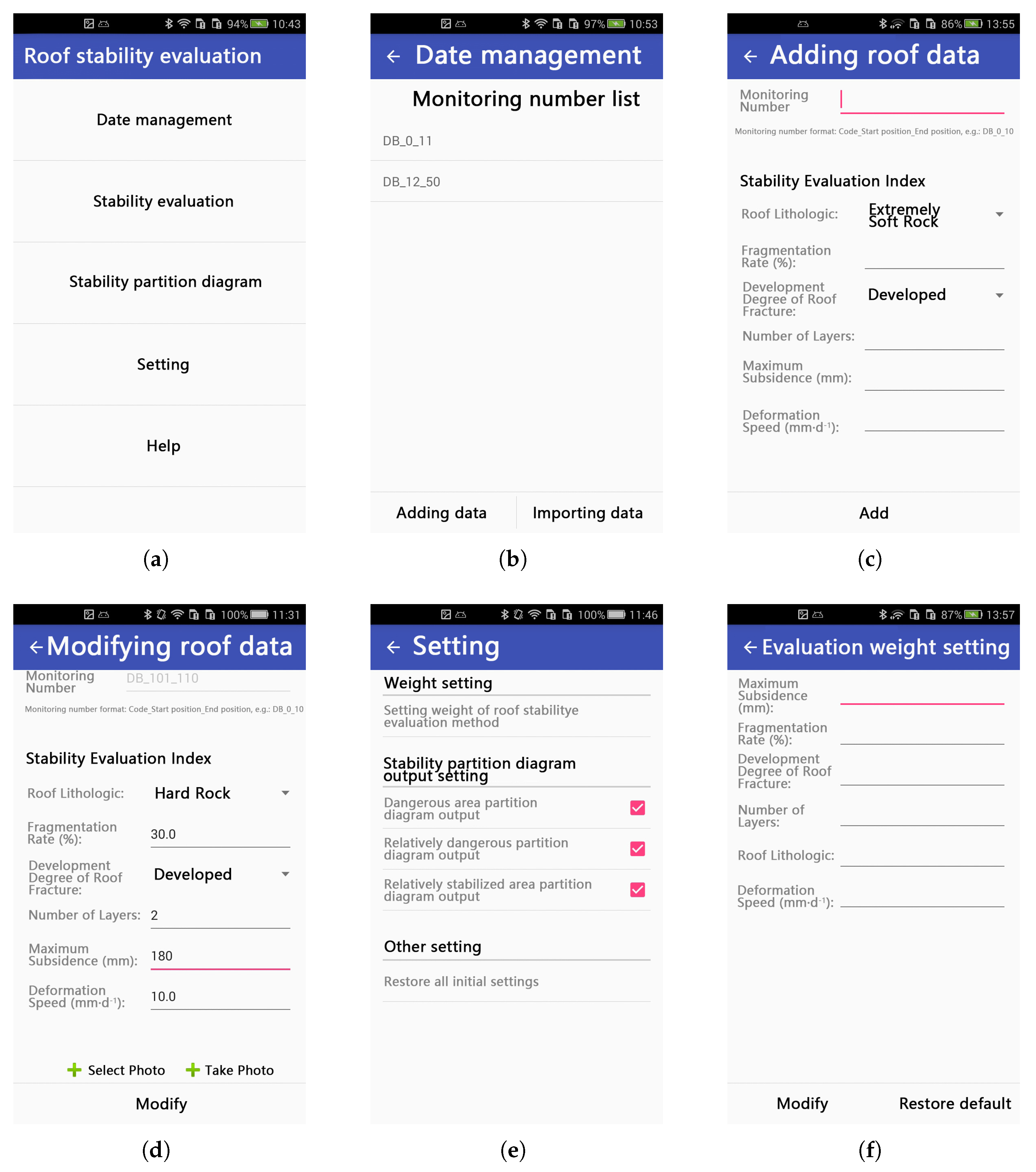

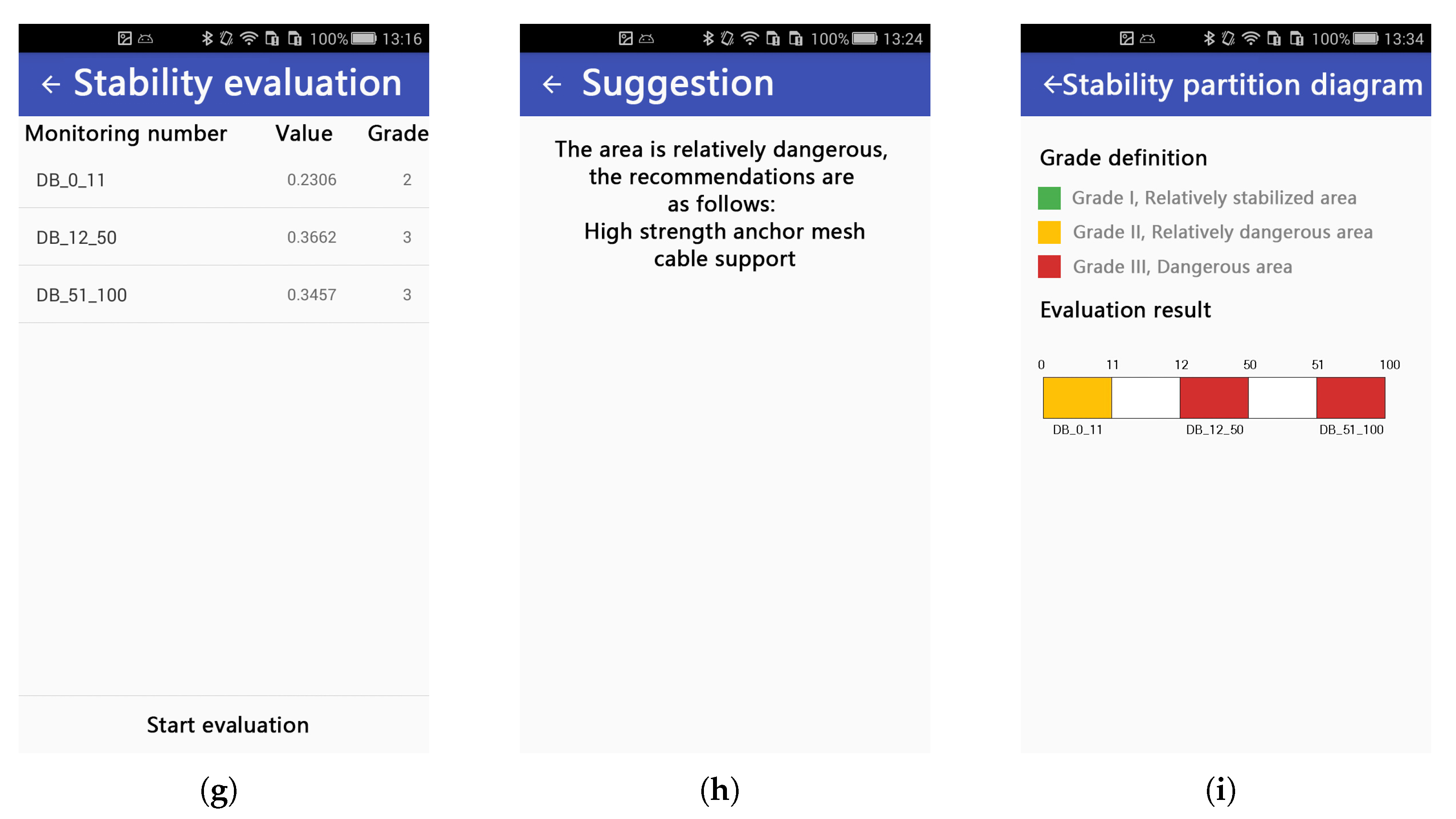

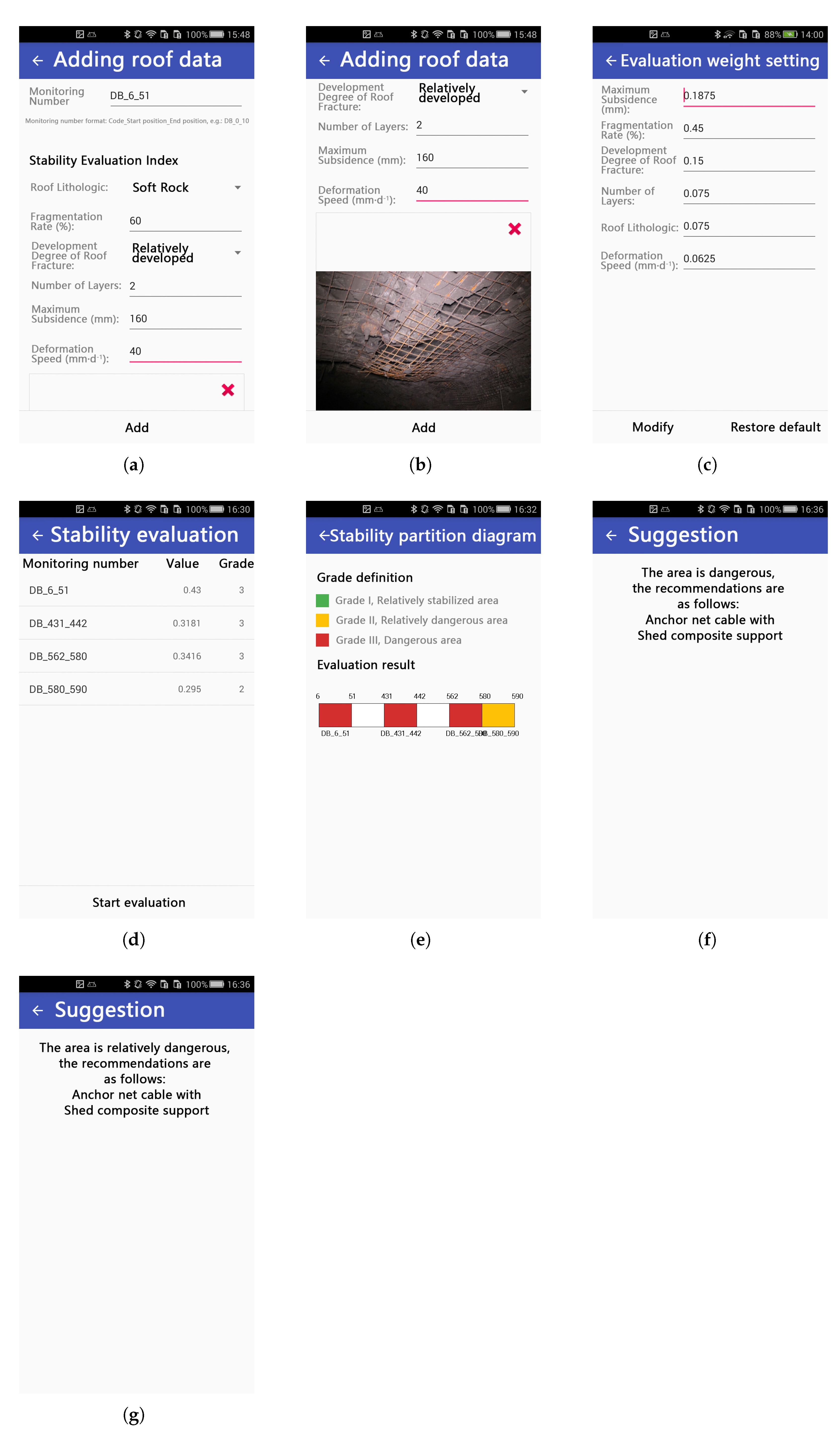

4.3. System User Interface Design

5. Engineering Application

6. Conclusions

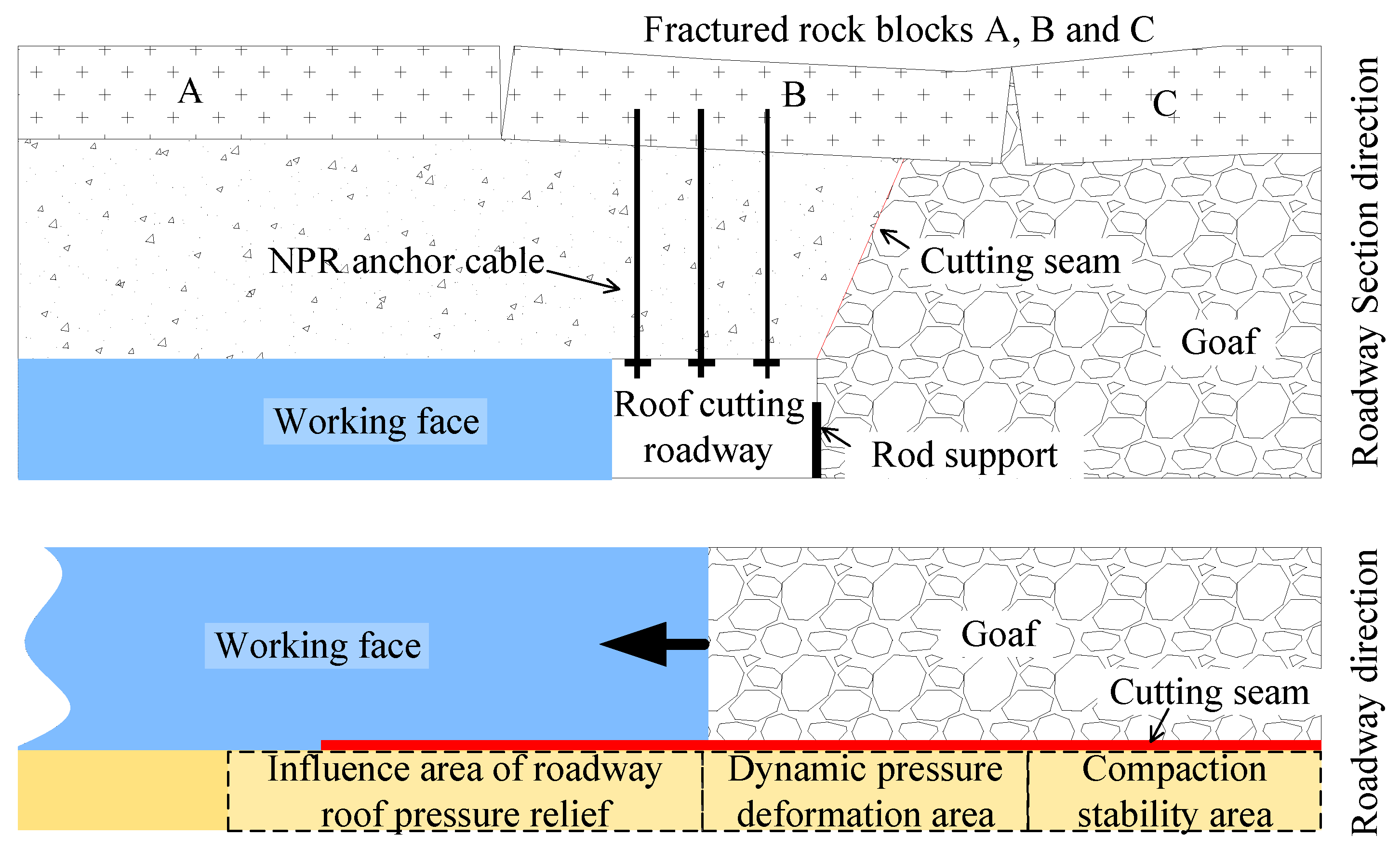

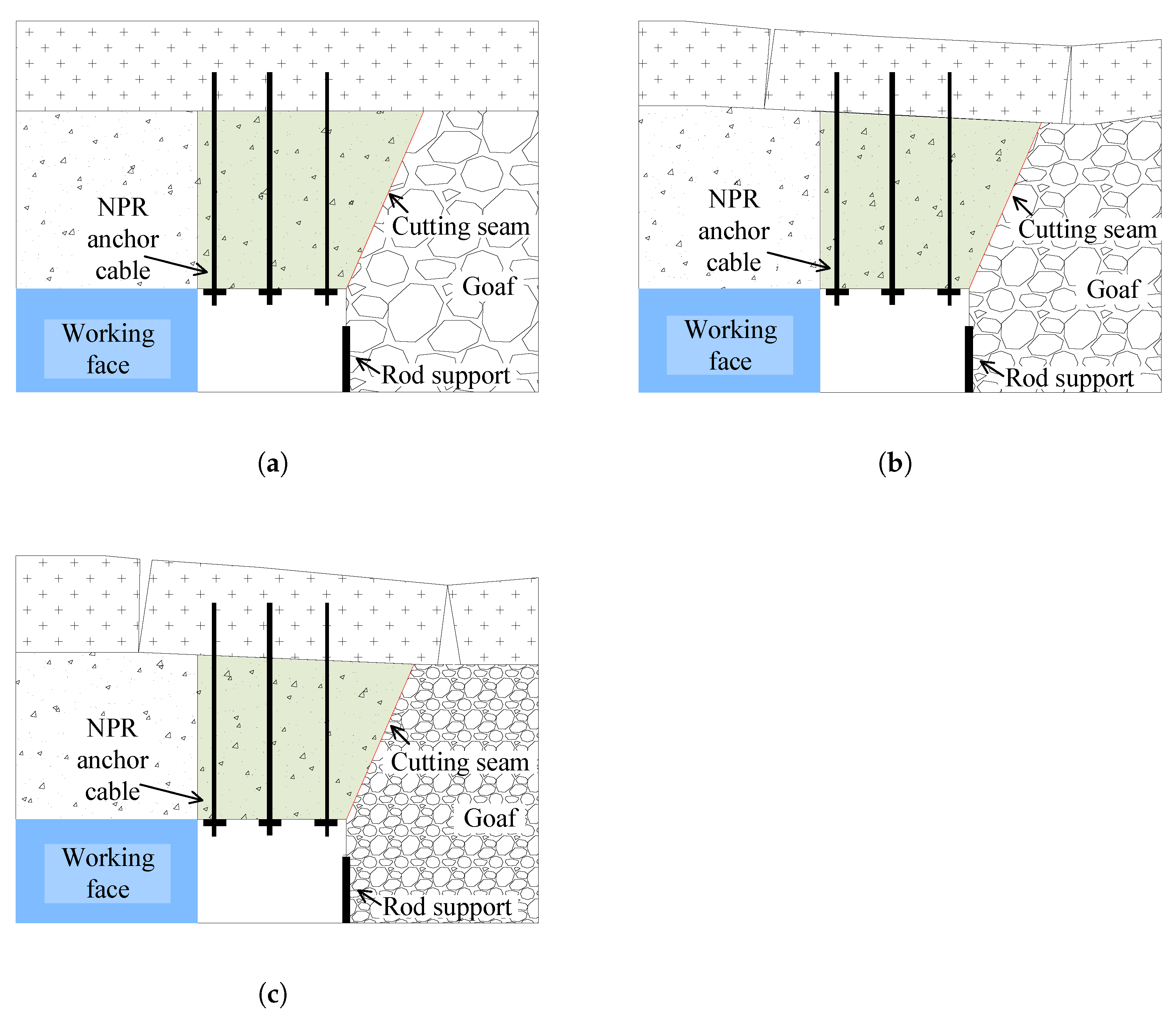

- In view of the deformation characteristics of the roof of the roadway behind the working face of the self-formed roadway without a coal pillar, this paper proposed that different roof deformation sections should be distinguished in the evaluation of roof stability, and the roof of the mining roadway should be divided into the influence area of roadway roof pressure relief, the dynamic pressure deformation area of the roadway roof, and the compaction stability area of the roadway roof.

- The roof stability evaluation index system for the roof-cutting non-pillar mining method is established, which includes the integrity of the roof strata and the displacement characteristics of the roof-surrounding rock. A comprehensive evaluation method of the roof stability grade of the roof-cutting non-pillar mining method is proposed, which integrates the classification standard of the roof stability evaluation index and the index weight assignment of the improved AHP method.

- The intelligent evaluation, risk partition, and control suggestion portable mobile application for the stability evaluation of the roof-cutting non-pillar mining method is developed based on Android. In the application, functions of data input including photos, data modification, data deletion, evaluation index weight setting, roof stability evaluation, roof stability control, roof stability partition diagram output, and other integrated functions of roof stability for the roof-cutting non-pillar mining method are realized.

- Taking the No. 1107 working face of Hecaogou No. 2 Coal Mine in Yan’an City as an example, the stability evaluation and intelligent calculation control of the roof-cutting non-pillar mining method were carried out. The evaluation results include roof stability grade, stability partition diagram, and control suggestions corresponding to different stability grades, which provide a theoretical basis for the partition support of roadway roofs. This successful engineering application can provide a basis for the sustainable utilization of coal resources in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, M.; Gao, Y.; Yang, J.; Guo, Z.; Wang, E.; Wang, Y. An energy-gathered roof cutting technique in no-pillar mining and its impact on stress variation in surrounding rocks. Chin. J. Rock Mech. Eng. 2017, 36, 1314–1325. [Google Scholar]

- He, M.; Li, C.; Gong, W.; Sousa, L.; Li, S. Dynamic tests for a Constant-Resistance-Large-Deformation bolt using a modified SHTB system. Tunn. Undergr. Space Technol. 2017, 64, 103–116. [Google Scholar] [CrossRef]

- He, M.; Gao, Y.; Yang, J.; Wang, J.; Wang, Y.; Zhu, Z. Engineering experimentation of gob-side entry retaining formed by roof cutting and pressure release in a thick-seam fast-extracted mining face. Rock Soil Mech. 2018, 39, 254–264. [Google Scholar]

- He, M.; Wang, Y.; Yang, J.; Zhou, P.; Gao, Q.; Gao, Y. Comparative analysis on stress field distributions in roof cutting non-pillar mining method and conventional mining method. J. China Coal Soc. 2018, 43, 626–637. [Google Scholar]

- He, M.; Song, Z.; Wang, A.; Yang, H.; Qi, H.; Guo, Z. Theory of longwall mining by using roof cutting shortwall team and 110 method. Coal Sci. Technol. Mag. 2017, 11, 1–9. [Google Scholar]

- Wang, Y.; Gao, Y.; Wang, E.; He, M.; Yang, J. Roof deformation characteristics and preventive techniques using a novel non-pillar mining method of gob-side entry retaining by roof cutting. Energies 2018, 11, 627. [Google Scholar] [CrossRef]

- He, M.; Wang, Q.; Wu, Q. Innovation and future of mining rock mechanics. J. Rock Mech. Geotech. Eng. 2021, 13, 1–21. [Google Scholar] [CrossRef]

- He, M.; Wang, Y.; Yang, J.; Gao, Y.; Gao, Q.; Wang, S. Zonal characteristics and its influence factors of working face pressure using roof cutting and pressure-relief mining method with no pillar and roadway formed automaticly. J. China Univ. Min. Technol. 2018, 47, 1157–1165. [Google Scholar]

- He, M.; Ma, Z.; Guo, Z.; Chen, S. Key parameters of the gob-side entry retaining formed by roof cutting and pressure release in deep medium-thickness coal seams. J. China Univ. Min. Technol. 2018, 47, 468–477. [Google Scholar]

- He, M.; Ma, X.; Niu, F.; Wang, J.; Liu, Y. Adaptability research and application of rapid gob-side entry retaining formed by roof cutting and pressure releasing with composite roof and medium thick coal seam. Chin. J. Rock Mech. Eng. 2018, 37, 2641–2654. [Google Scholar]

- Gao, Y.; He, M.; Yang, J.; Ma, X. Experimental study of caving and distribution of gangues influenced by roof fracturing in pillarless mining with gob-side entry retaining. J. China Univ. Min. Technol. 2018, 47, 21–31. [Google Scholar]

- Wang, Y.; He, M.; Zhang, K.; Yang, J.; Zhen, E.; Zhu, Z.; Gao, Y.; Ma, Z. Strata behavior characteristics and control countermeasures for the gateroad surroundings in innovative non-pillar mining method with gateroad formed automatically. J. Min. Saf. Eng. 2018, 35, 677–685. [Google Scholar]

- Yang, J.; Fu, Q.; Gao, Y.; Gao, H.; Qiao, B. Surrounding rock movement and pressure distribution laws of non-pillar mining with entry automatically retained by roof cutting influenced by faults. J. China Univ. Min. Technol. 2019, 48, 1238–1247. [Google Scholar]

- Gao, Y.; Wang, J.; Gao, H.; Yang, J.; Zhang, Y.; He, M. Mine pressure distribution and surrounding rock control of gob-side entry formed by roof cutting and pressure release under the influence of faults. Chin. J. Rock Mech. Eng. 2019, 38, 2182–2193. [Google Scholar]

- Wang, Y.; He, M.; Yang, J.; Fu, Q.; Gao, Y. The structure characteristics and deformation of “short cantilever beam” using a non-pillar mining method with gob-side entry formed automatically. J. China Univ. Min. Technol. 2019, 48, 718–726. [Google Scholar]

- Tao, Z.; Song, Z.; He, M.; Meng, Z.; Pang, S. Principles of the roof cut short-arm beam mining method (110 method) and its mining-induced stress distribution. Int. J. Min. Sci. Technol. 2018, 28, 391–396. [Google Scholar]

- Jiang, X.x.; Li, C.x. Statistical analysis on coal mine accidents in China from 2013 to 2017 and discussion on the countermeasures. Coal Eng. 2019, 51, 101–105. [Google Scholar]

- He, Y.; Huang, Q.; Wei, Y.; Du, J. Research on Roof Load Transfer by Passing Coal Pillar of Working Face in Shallow Buried Closely Multiple-Seam. Minerals 2023, 13, 118. [Google Scholar] [CrossRef]

- Zhu, Z.; Du, M.; Xi, C.; Yuan, H.; He, W. Mechanics Principle and Implementation Technology of Surrounding Rock Pressure Release in Gob-Side Entry Retaining by Roof Cutting. Processes 2022, 10, 2629. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, D.; Zhang, X.; He, M. Analysis and optimization of entry stability in underground longwall mining. Sustainability 2017, 9, 2079. [Google Scholar] [CrossRef]

- Yang, X.; Wang, E.; Wang, Y.; Gao, Y.; Wang, P. A study of the large deformation mechanism and control techniques for deep soft rock roadways. Sustainability 2018, 10, 1100. [Google Scholar] [CrossRef]

- Xiong, X.; Dai, J.; Wang, X. Comprehensive analysis of stability of coal seam composite roof based on analytic hierarchy process. Adv. Civ. Eng. 2019, 2019, 2042460. [Google Scholar] [CrossRef]

- Winn, K.; Wong, L.N.Y.; Alejano, L.R. Multi-approach stability analyses of large caverns excavated in low-angled bedded sedimentary rock masses in Singapore. Eng. Geol. 2019, 259, 105164. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Sahu, S.P.; Kushwaha, A.; Bhattacharjee, R.; Tewari, S. Evaluation of the effect of fault on the stability of underground workings of coal mine through DEM and statistical analysis. J. Geol. Soc. India 2018, 92, 732–742. [Google Scholar] [CrossRef]

- Wang, T.; Yang, C.; Chen, J.; Daemen, J. Geomechanical investigation of roof failure of China’s first gas storage salt cavern. Eng. Geol. 2018, 243, 59–69. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Bhattacharjee, R.; Tiwari, S.; Kushwaha, A.; Roy, L. Evaluation of stability of underground workings for exploitation of an inclined coal seam by the ubiquitous joint model. Int. J. Rock Mech. Min. Sci. 2017, 93, 101–114. [Google Scholar] [CrossRef]

- Feng, J.; Xu, H.; Zheng, Y.; Peng, R.; Ma, H. Distinguishing Method of Strata Instability and Classification of Roof Fall Hidden Danger of Coal Roadway Composite Roof. Coal Eng. 2019, 8, 78–83. [Google Scholar]

- Qin, W. Early warning system design of roof disaster based on MATLAB data analysis. Coal Chem. Ind. 2018, 41, 100–103. [Google Scholar]

- Liu, S.W.; Zhang, H.; Li, Y.H.; Zhang, X.; Yao, B.Z. Realization and engineering application of classification of coal roof stability. J. China Coal Soc. 2013, 38, 1531–1536. [Google Scholar]

- Teramachi, H.; Komada, N.; Tanizawa, K.; Kuzuya, Y.; Tsuchiya, T. Development of skill scale for communication skill measurement of pharmacist. Yakugaku Zasshi J. Pharm. Soc. Jpn. 2011, 131, 587–595. [Google Scholar] [CrossRef]

- Meshram, S.G.; Alvandi, E.; Singh, V.P.; Meshram, C. Comparison of AHP and fuzzy AHP models for prioritization of watersheds. Soft Comput. 2019, 23, 13615–13625. [Google Scholar] [CrossRef]

- He, M.C.; Qian, Q.H. The Basis of Deep Rock Mechanics; Science Press: Beijing, China, 2010. [Google Scholar]

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Study on rock mechanics in deep mining engineering. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- He, M. Progress and challenges of soft rock engineering in depth. J. China Coal Soc. 2014, 39, 1409–1417. [Google Scholar]

| Target Layer | Criterion Layer | Index Layer (Unit) |

|---|---|---|

| Index system for roof stability evaluation of non-pillar mining A | Roof rock integrity | Roof lithology |

| Fragmentation rate (%) | ||

| Development degree of roof fracture | ||

| Number of layers | ||

| Displacement characteristics of roof surrounding rock | Maximum subsidence (mm) | |

| Deformation speed (mm/d) |

| Index System for Roof Stability Evaluation of None-Pillar Mining | Roof Rock Integrity | Displacement Characteristics of Roof Surrounding Rock | |

|---|---|---|---|

| Roof rock integrity | 1 | 3 | 0.75 |

| Displacement characteristics of roof-surrounding rock | 0.3333 | 1 | 0.25 |

| Roof Rock Integrity | Roof Lithology | Fragmentation Rate | Development Degree of Roof Fracture | Number of Layers | |

|---|---|---|---|---|---|

| Roof lithology | 1 | 0.1667 | 0.5 | 1 | 0.1 |

| Fragmentation rate | 6 | 1 | 3 | 6 | 0.6 |

| Development degree of roof fracture | 2 | 0.3333 | 1 | 2 | 0.2 |

| Number of layers | 1 | 0.1667 | 0.5 | 1 | 0.1 |

| Displacement Characteristics of Roof Surrounding Rock | Maximum Subsidence | Deformation Speed | |

|---|---|---|---|

| Maximum subsidence | 1 | 3 | 0.75 |

| Deformation speed | 0.3333 | 1 | 0.25 |

| Roof Stability Classification | Roof Rock Integrity | Displacement Characteristics of Roof Surrounding Rock | ||||

|---|---|---|---|---|---|---|

| Roof Lithology | Fragmentation Rate (%) | Development Degree of Roof Fracture | Number of Layers | Maximum Subsidence (mm) | Deformation Speed (mm/d) | |

| III | Extremely soft rock | >30% | Developed | >3 | >150 | >30 |

| II | Soft rock | 20–30% | Relatively developed | 2 | 100–150 | 20–30 |

| I | Hard rock | <20% | Not developed | 1 | <100 | <20 |

| Roof Stability Evaluation Index () | Roof Stability Partition (Grade) |

|---|---|

| Dangerous area (Grade III) | |

| Relatively dangerous area (Grade II) | |

| Relatively stabilized area (Grade I) |

| Roof Stability Evaluation Index | Measurement Value of Evaluation Index | |||

|---|---|---|---|---|

| 6–51 m Interval | 431–442 m Interval | 562–580 m Interval | 580–590 m Interval | |

| Roof lithology | Soft rock | Soft rock | Soft rock | Soft rock |

| Fragmentation rate (%) | 60 | 45 | 38 | 44 |

| Development degree of roof fracture | Relatively developed | Not developed | Relatively developed | Not developed |

| Number of layers | 2 | 2 | 2 | 2 |

| Maximum subsidence (mm) | 160 | 110 | 180 | 82 |

| Deformation speed (mm/d) | 40 | 23 | 45 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Zou, B.; Tao, Z.; He, M.; Hu, B. Construction and Application of an Intelligent Roof Stability Evaluation System for the Roof-Cutting Non-Pillar Mining Method. Sustainability 2023, 15, 2670. https://doi.org/10.3390/su15032670

Chen Q, Zou B, Tao Z, He M, Hu B. Construction and Application of an Intelligent Roof Stability Evaluation System for the Roof-Cutting Non-Pillar Mining Method. Sustainability. 2023; 15(3):2670. https://doi.org/10.3390/su15032670

Chicago/Turabian StyleChen, Qizhi, Baoping Zou, Zhigang Tao, Manchao He, and Bo Hu. 2023. "Construction and Application of an Intelligent Roof Stability Evaluation System for the Roof-Cutting Non-Pillar Mining Method" Sustainability 15, no. 3: 2670. https://doi.org/10.3390/su15032670

APA StyleChen, Q., Zou, B., Tao, Z., He, M., & Hu, B. (2023). Construction and Application of an Intelligent Roof Stability Evaluation System for the Roof-Cutting Non-Pillar Mining Method. Sustainability, 15(3), 2670. https://doi.org/10.3390/su15032670