Geothermal Pavements: Experimental Testing, Prototype Testing, and Numerical Analysis of Recycled Demolition Wastes

Abstract

:1. Introduction

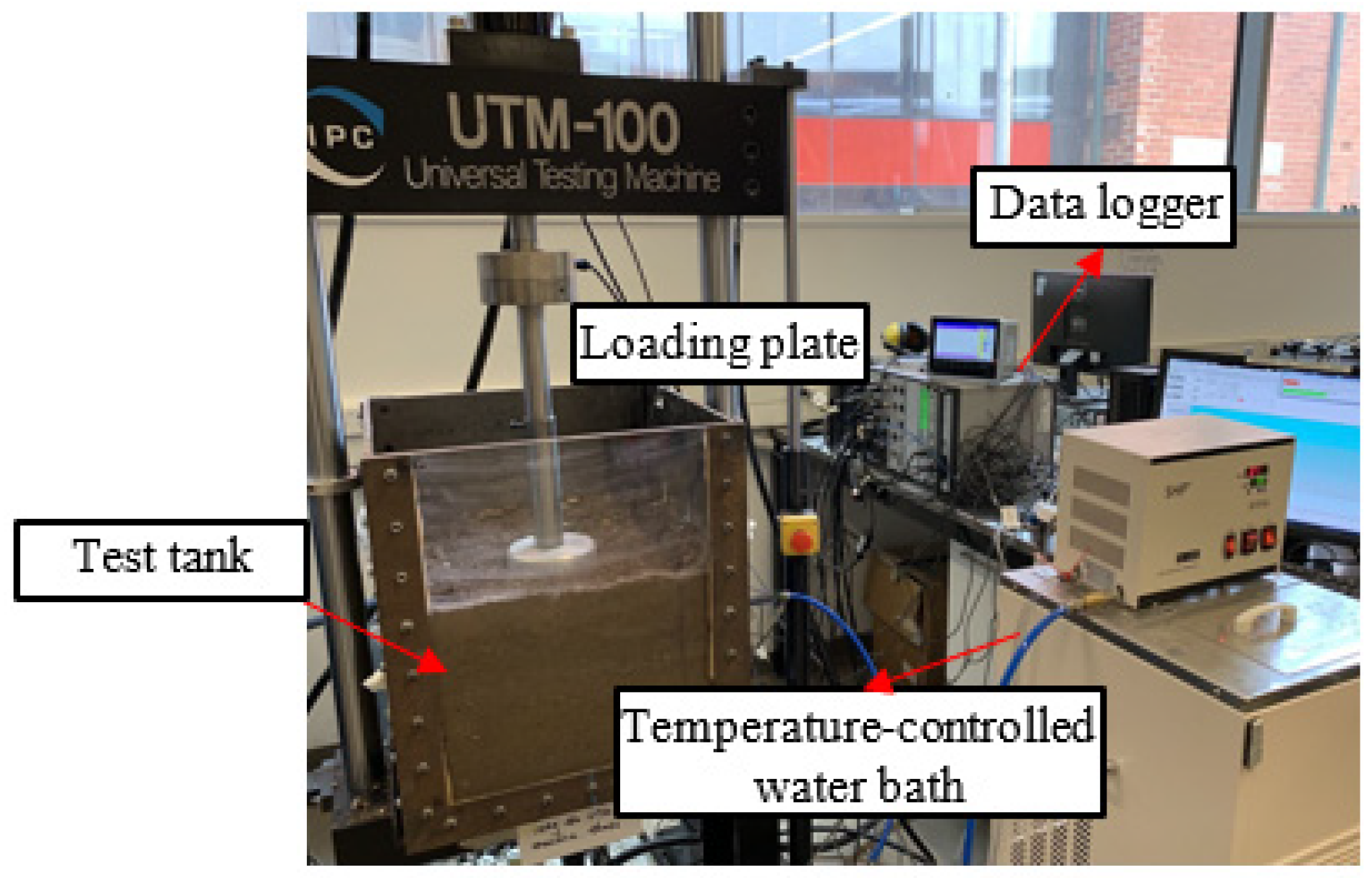

2. Materials and Methods

2.1. Experimental Investigation

2.2. Thermal Performance

3. Results

3.1. Experimental Characterization

3.2. Numerical Simulation

4. Conclusions

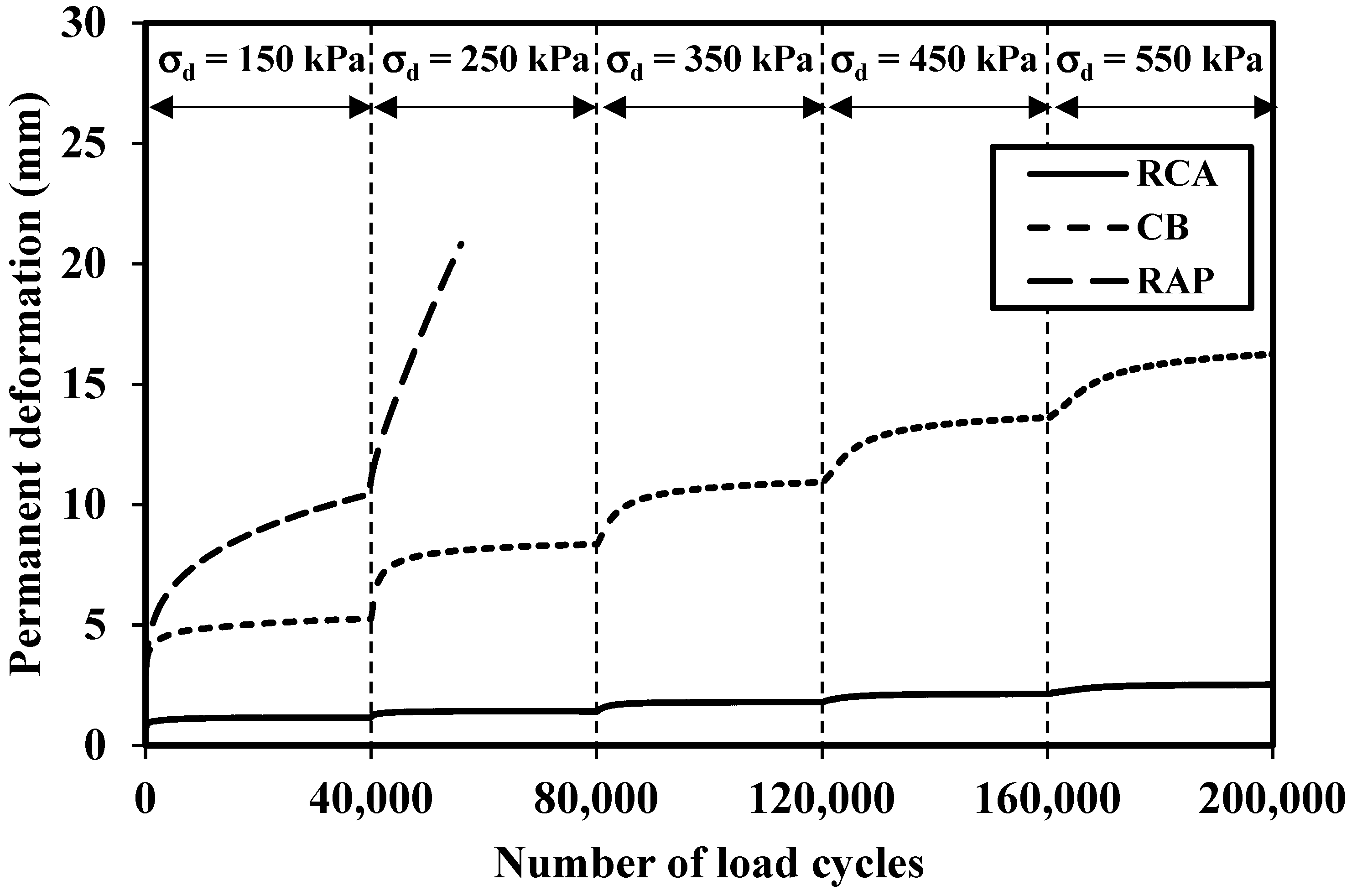

- The deeper pipe-embedded layer can reduce the stress concentration on the pipe, leading to lower permanent deformation after the same number of cycles. The inclusion of pipes in the pavement base layer was found to have negligible detrimental effects on the deformation behavior of RCA. Regardless of the pipe type and inclusion depth, the permanent strain values of all RCA samples were lower than 0.86%. It can be concluded that the pipes can be inserted in unbound granular layers without causing excessive deformations.

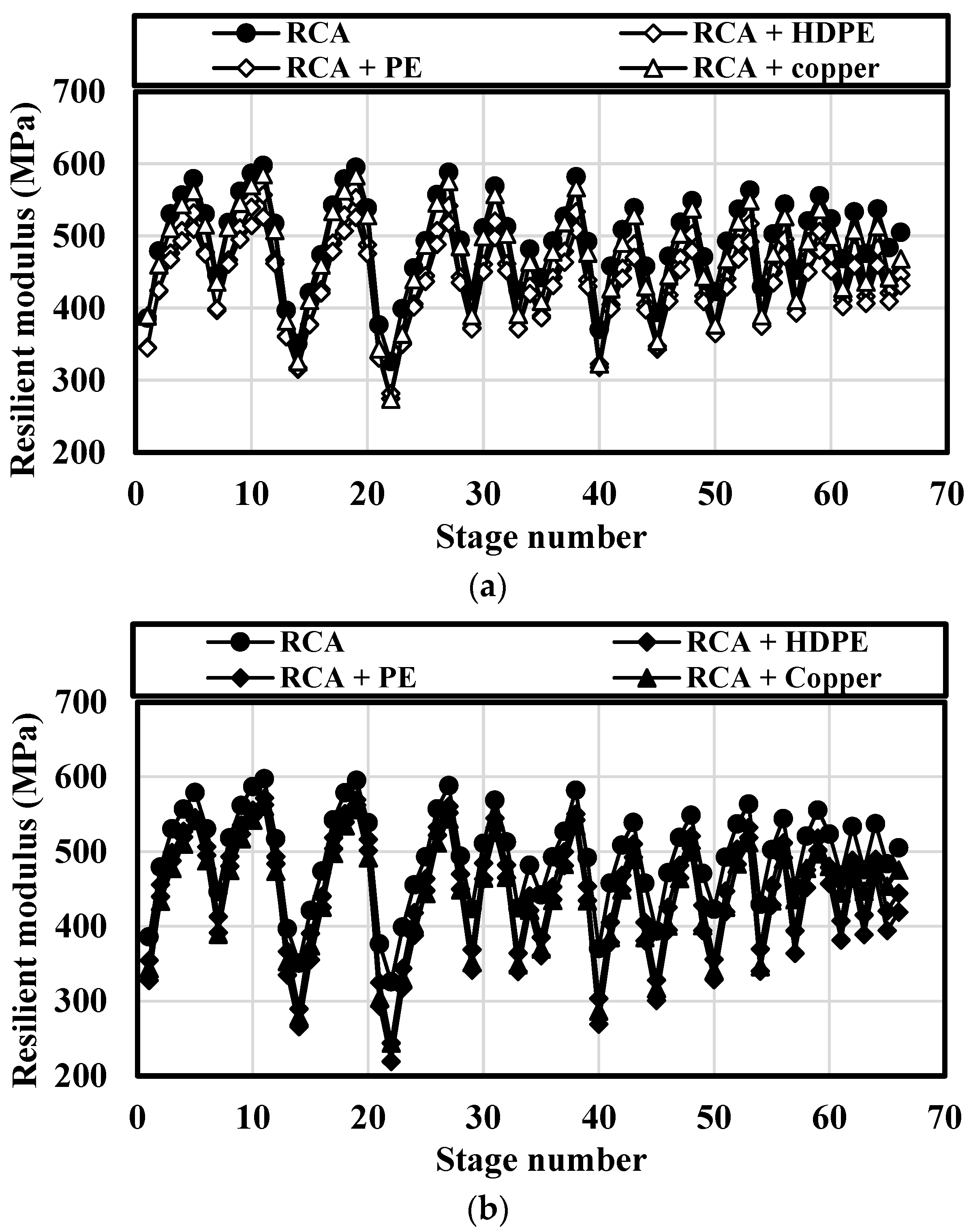

- Due to the higher permanent deformation, the MR of RCA samples slightly decreased with the inclusion of pipes. The RCA + copper sample exhibited MR values equivalent to those of RCA because of its adequate stiffness, and the RCA + PE and RCA + HDPE samples exhibited slightly lower MR values. Similar to the permanent deformation results, the inclusion of the pipes had no significant detrimental effects on the resilient modulus of RCA.

- The results of the RL-CBR test indicated that the inclusion of the HDPE pipe reduced the peak load of the stiffness of the RCA + HDPE mix due to the loss of stiffness. On the other hand, the high stiffness of the copper pipe improved the strength of the mix and resulted in a higher peak load. The total deformation for the RCA + copper mix was the highest due to the brittle response of the copper pipe and the significant deformations once the failure point was reached under monotonic loading.

- A numerical analysis was developed to evaluate the effects of pipe materials and flow rates on the surface temperature. The numerical model was calibrated using the experimental data. The parametric study indicated that the flow rate had negligible effects on the surface temperature for both the HDPE and copper pipes. Copper pipes were slightly more efficient in reducing the surface temperature compared to HDPE pipes. At a constant flow rate of 2000 mL/min, using a copper pipe resulted in an approximately 4% further decrease in the surface temperature compared to the HDPE pipe. It was also noted that varying flow rates during testing had small effects on the surface temperature profile.

- The installation of plastic pipes (HDPE and PE) and copper pipes in the unbound base layer can effectively reduce the pavement’s surface temperature without a large effect of excessive deformation. At the same temperature, the copper pipe had a high potential to transfer the surface heat with lower permanent strain compared to the RCA without a pipe. Meanwhile, the plastic pipes caused slightly higher permanent deformation than the RCA layer without a pipe and had a slightly lower potential to reduce the surface temperature compared to RCA with a copper pipe but at a much-reduced material cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pascual-Muñoz, P.; Castro-Fresno, D.; Serrano-Bravo, P.; Alonso-Estébanez, A. Thermal and hydraulic analysis of multilayered asphalt pavements as active solar collectors. Appl. Energy 2013, 111, 324–332. [Google Scholar] [CrossRef]

- Chiarelli, A.; Dawson, A.; Garcia, A. Field evaluation of the effects of air convection in energy harvesting asphalt pavements. Sustain. Energy Technol. Assess. 2017, 21, 50–58. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S. Experimental and ANN analysis of temperature effects on the permanent deformation properties of demolition wastes. Transp. Geotech. 2020, 24, 100365. [Google Scholar] [CrossRef]

- Guldentops, G.; Nejad, A.M.; Vuye, C.; Rahbar, N. Performance of a pavement solar energy collector: Model development and validation. Appl. Energy 2016, 163, 180–189. [Google Scholar] [CrossRef]

- Mallick, R.B.; Chen, B.-L.; Bhowmick, S. Harvesting heat energy from asphalt pavements: Development of and comparison between numerical models and experiment. Int. J. Sustain. Eng. 2012, 5, 159–169. [Google Scholar] [CrossRef]

- Zaim, E.H.; Farzan, H.; Ameri, M. Assessment of pipe configurations on heat dynamics and performance of pavement solar collectors: An experimental and numerical study. Sustain. Energy Technol. Assess. 2020, 37, 100635. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ghorbani, B.; Narsilio, G.; Horpibulsuk, S.; Leong, M. Thermal performance of geothermal pavements constructed with demolition wastes. Geomech. Energy Environ. 2021, 28, 100253. [Google Scholar] [CrossRef]

- Gabr, A.; Cameron, D. Properties of recycled concrete aggregate for unbound pavement construction. J. Mater. Civ. Eng. 2012, 24, 754–764. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Bo, M. Thermal and mechanical properties of demolition wastes in geothermal pavements by experimental and machine learning techniques. Constr. Build. Mater. 2021, 280, 122499. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Disfani, M.M.; Arulrajah, A.; Kodikara, J. Development of a void ratio-moisture ratio-net stress framework for the prediction of the volumetric behavior of unsaturated granular materials. Soils Found. 2019, 59, 443–457. [Google Scholar] [CrossRef]

- Sustainability Victoria. Victorian Recycling Industries Annual Report 2008–2009; Sustainability Victoria: Melbourne, VIC, Australia, 2010; ISSN 1836-9902.

- Jankovic, K.; Nikolic, D.; Bojovic, D. Concrete paving blocks and flags made with crushed brick as aggregate. Constr. Build. Mater. 2012, 28, 659–663. [Google Scholar] [CrossRef]

- Gayarre, F.L.; López-Colina, C.; Serrano, M.A.; López-Martínez, A. Manufacture of concrete kerbs and floor blocks with recycled aggregate from C and DW. Constr. Build. Mater. 2013, 40, 1193–1199. [Google Scholar] [CrossRef]

- Liu, H.J.; Li, P.X.; Cao, S.G.; Zhao, F.Q. Preparation of high-performance brick from construction and demolition waste. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2012; Volume 391, pp. 180–183. [Google Scholar]

- Gregory, R.J.; Hughes, T.G.; Kwan, A.S.K. Brick recycling and reuse. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; No. 3; Thomas Telford Ltd.: London, UK, 2004; Volume 157, pp. 155–161. [Google Scholar]

- Yaghoubi, E.; Sudarsanan, N.; Arulrajah, A. Stress-strain response analysis of demolition wastes as aggregate base course of pavements. Transp. Geotech. 2021, 30, 100599. [Google Scholar] [CrossRef]

- Taha, R.; Al-Harthy, A.; Al-Shamsi, K.; Al-Zubeidi, M. Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J. Mater. Civ. Eng. 2002, 14, 239–245. [Google Scholar] [CrossRef]

- Hoyos, L.R.; Puppala, A.J.; Ordonez, C.A. Characterization of cement-fiber treated reclaimed asphalt pavement aggregates: Preliminary investigation. J. Mater. Civ. Eng. 2011, 23, 977–989. [Google Scholar] [CrossRef]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

- Yaghoubi, E.; Ahadi, M.R.; Sheshpoli, M.A.; Pahlevanloo, H.J. Evaluating the performance of hot mix asphalt with reclaimed asphalt pavement and heavy vacuum slops as rejuvenator. Int. J. Transp. 2013, 1, 115–124. [Google Scholar]

- Melbouci, B. Compaction and shearing behavior study of recycled aggregates. Constr. Build. Mater. 2009, 23, 2723–2730. [Google Scholar] [CrossRef]

- Sivakumar, V.; McKinley, J.D.; Ferguson, D. Reuse of construction waste: Performance under repeated loading. Proc. Inst. Civ. Eng. Geotech. Eng. 2004, 157, 91–96. [Google Scholar] [CrossRef]

- Azam, A.; Cameron, D. Geotechnical properties of blends of recycled clay masonry and recycled concrete aggregates in unbound pavement construction. J. Mater. Civ. Eng. 2013, 25, 788–798. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Leong, M. Resilient moduli of demolition wastes in geothermal pavements: Experimental testing and ANFIS modelling. Transp. Geotech. 2021, 29, 100592. [Google Scholar] [CrossRef]

- Remund, C.; Carda, R.; Rawlings, P.; Bose, J. Ground Source Heat Pump Residential and Light Commercial Design and Installation Guide; International Ground Source Heat Pump Association, Oklahoma State University: Stillwater, OK, USA, 2009. [Google Scholar]

- Gu, X.; Makasis, N.; Motamedi, Y.; Narsilio, G.A.; Arulrajah, A.; Horpibulsuk, S. Geothermal pavements: Field observations, numerical modelling and long-term performance. Géotechnique 2022, 72, 832–846. [Google Scholar] [CrossRef]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Brandl, H. Energy foundations and other thermo-active ground structures. Géotechnique 2006, 56, 81–122. [Google Scholar] [CrossRef]

- Laloui, L.; Di Donna, A. Understanding the behaviour of energy geo-structures. In Proceedings of the Institution of Civil Engineers-Civil Engineering; Thomas Telford Ltd.: London, UK, 2011. [Google Scholar]

- Loveridge, F.; McCartney, J.S.; Narsilio, G.A.; Sanchez, M. Energy geostructures: A review of analysis approaches, in situ testing and model scale experiments. Geomech. Energy Environ. 2020, 22, 100173. [Google Scholar]

- Amatya, B.L.; Soga, K.; Bourne-Webb, P.J.; Amis, T.; Laloui, L. Thermo-mechanical behaviour of energy piles. Géotechnique 2012, 62, 503–519. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sustain. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Van Bijsterveld, W.; De Bondt, A. Structural aspects of asphalt pavement heating and cooling systems. In Proceedings of the 3rd International Symposium on 3D Finite Element Modelling, Amsterdam, The Netherlands, 2–5 April 2002. [Google Scholar]

- He, X.; Abdelaziz, S.; Chen, F.; Yin, H. Finite element simulation of self-heated pavement under different mechanical and thermal loading conditions. Road Mater. Pavement Des. 2019, 20, 1807–1826. [Google Scholar] [CrossRef]

- Bobes-Jesus, V.; Pascual-Muñoz, P.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Asphalt solar collectors: A literature review. Appl. Energy 2013, 102, 962–970. [Google Scholar] [CrossRef]

- AG:PT/T053; Determination of Permanent Deformation and Resilient Modulus Characteristics of Unbound Granular Materials under Drained Conditions. AustRoads: Sydney, NSW, Australia, 2000.

- Araya, A.; Molenaar, A.; Houben, L. Characterization of unbound granular materials using repeated load CBR and triaxial testing. In Paving Materials and Pavement Analysis; Geotechnical Special Publication: Shanghai, China, 2010; pp. 355–363. [Google Scholar]

- Haghighi, H.; Arulrajah, A.; Mohammadinia, A.; Horpibulsuk, S. A new approach for determining resilient moduli of marginal pavement base materials using the staged repeated load CBR test method. Road Mater. Pavement Des. 2018, 19, 1848–1867. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghorbani, B.; Arulrajah, A.; Narsilio, G.A.; Horpibulsuk, S.; Buritatum, A. Geothermal Pavements: Experimental Testing, Prototype Testing, and Numerical Analysis of Recycled Demolition Wastes. Sustainability 2023, 15, 2680. https://doi.org/10.3390/su15032680

Ghorbani B, Arulrajah A, Narsilio GA, Horpibulsuk S, Buritatum A. Geothermal Pavements: Experimental Testing, Prototype Testing, and Numerical Analysis of Recycled Demolition Wastes. Sustainability. 2023; 15(3):2680. https://doi.org/10.3390/su15032680

Chicago/Turabian StyleGhorbani, Behnam, Arul Arulrajah, Guillermo A. Narsilio, Suksun Horpibulsuk, and Apinun Buritatum. 2023. "Geothermal Pavements: Experimental Testing, Prototype Testing, and Numerical Analysis of Recycled Demolition Wastes" Sustainability 15, no. 3: 2680. https://doi.org/10.3390/su15032680