Understanding the Influencing Factors of Enterprise Transformation and Upgrading Capability: A Case Study of the National Innovation Demonstration Zones, China

Abstract

:1. Introduction

2. Literature Review

2.1. Studies of Enterprises’ Transformation and Upgrading

2.2. Studies of Influencing Factors

2.3. Studies of National Innovation Demonstration Zones

3. Data and Indicator System Establishment

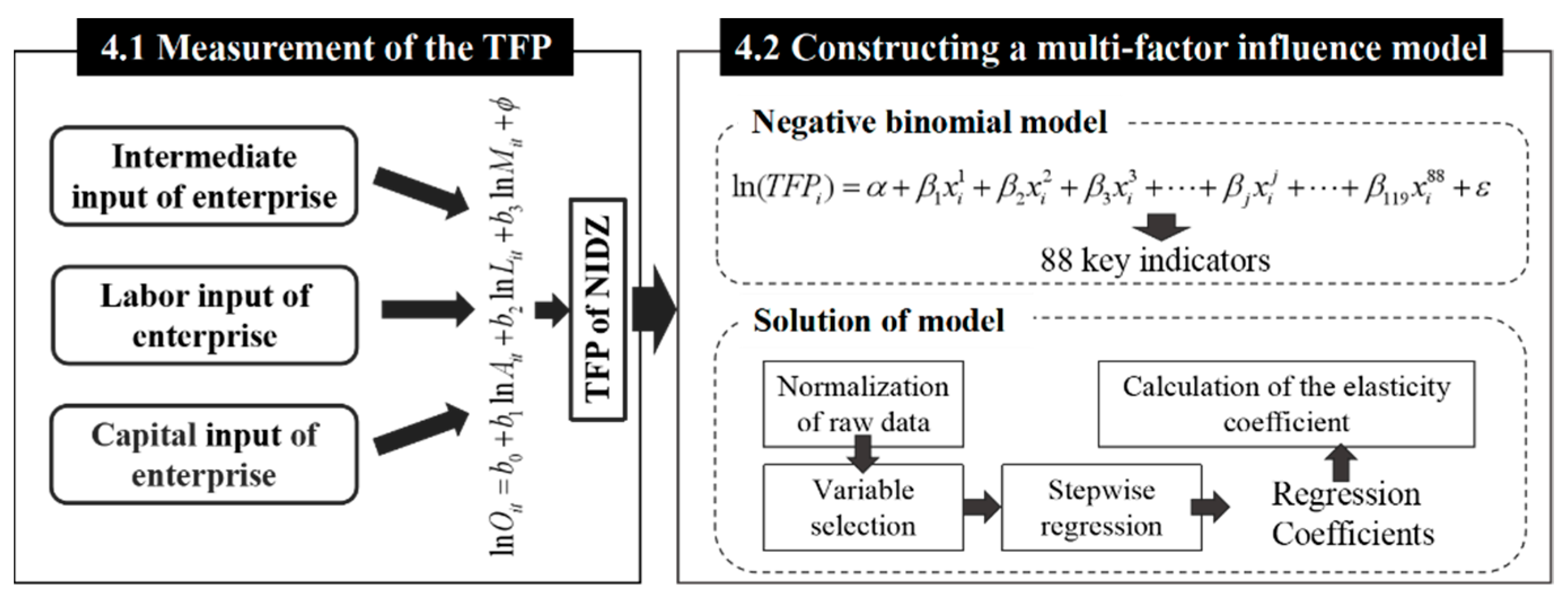

4. Methodology

4.1. Measurement of Enterprises’ Transformation and Upgrading Capabilities

4.2. Constructing a Multi-Factor Influence Model for Enterprises’ Transformation and Upgrading Capabilities

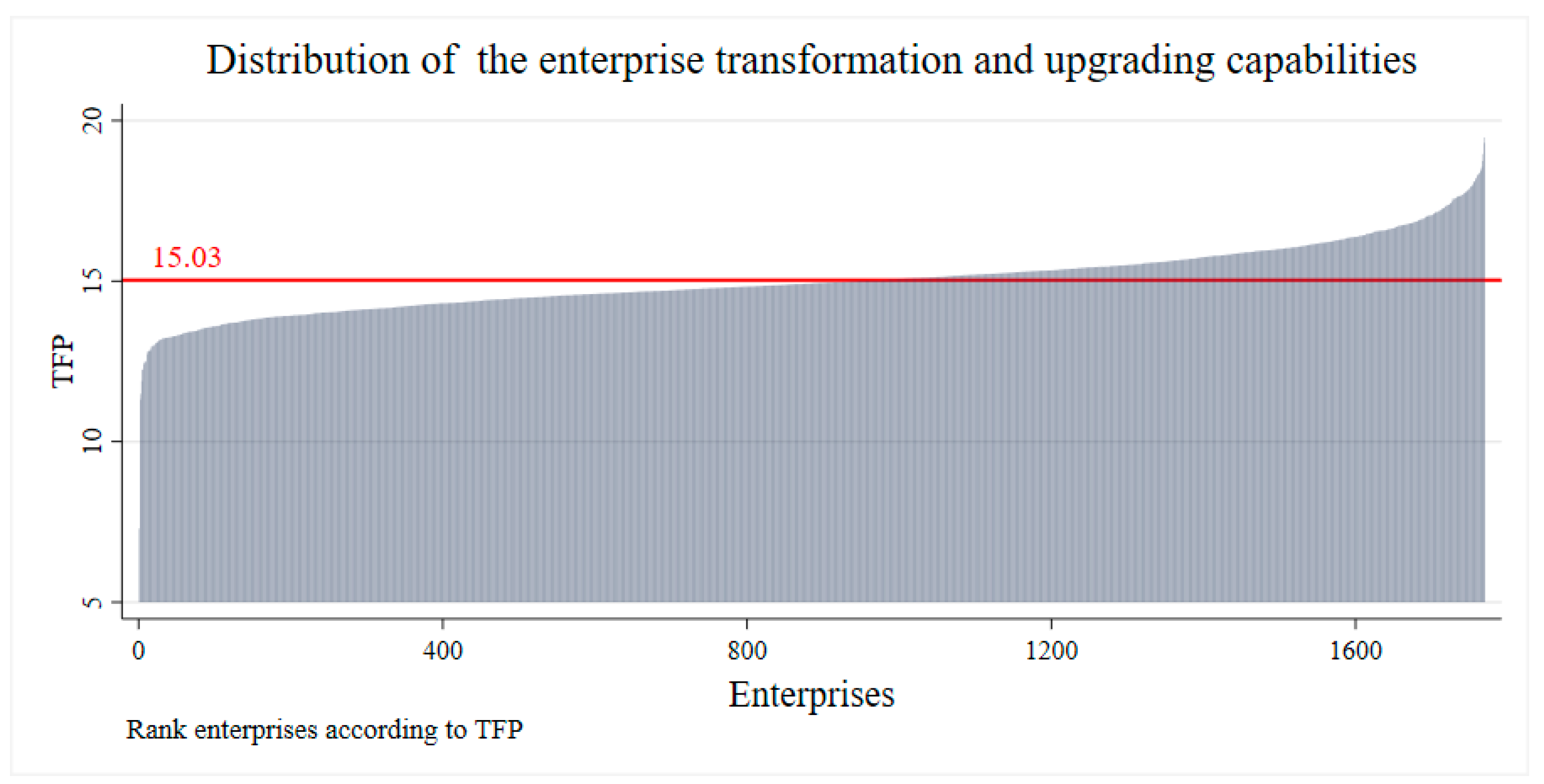

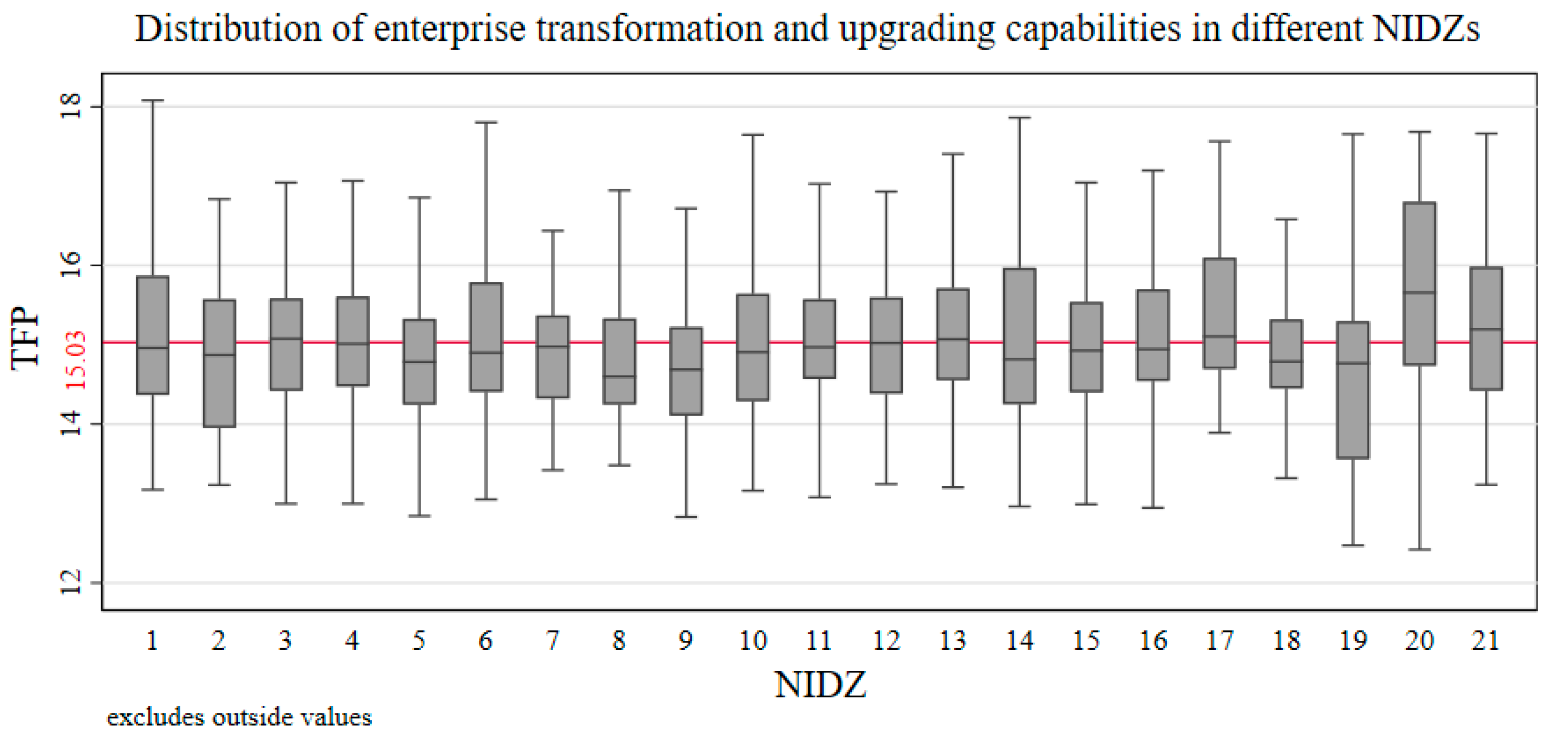

5. Results and Discussion

5.1. Analysis of Enterprises’ Transformation and Upgrading Capabilities in National Innovation Demonstration Zones

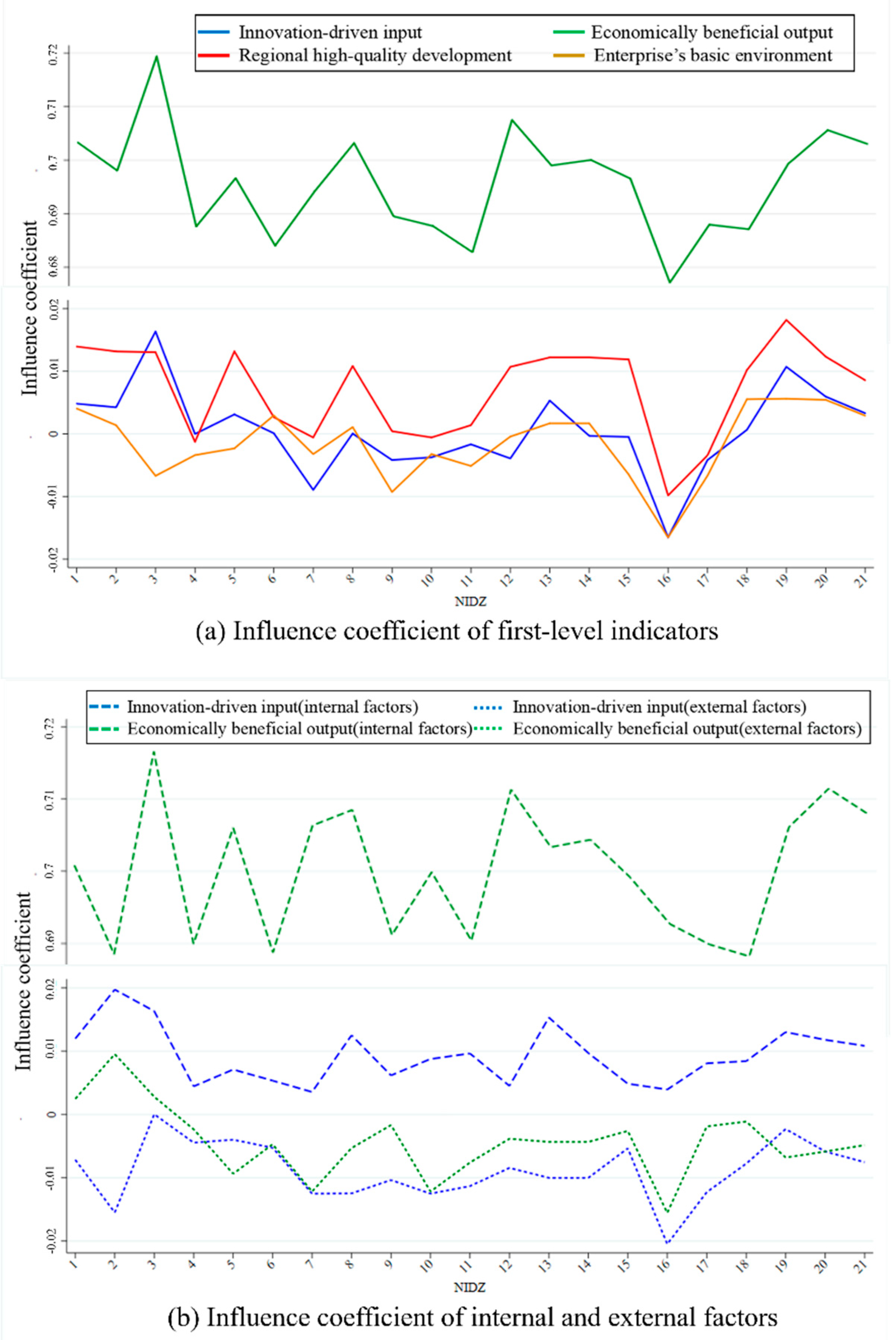

5.2. Analysis of Factors Influencing Enterprises’ Transformation and Upgrading Capabilities

- (1)

- The amount of enterprise R&D investment, expenditure on new product development, and S&T institutions of industrial enterprises above the designated size (secondary indicators of IDI). Among them, the amount of enterprise R&D investment (one of the internal factors) has the greatest impact on enterprises’ transformation and upgrading capabilities (regression coefficient 0.5894), which indicates that such R&D investment can significantly affect these capabilities. Generally speaking, higher R&D investment provides financial support for manufacturing enterprises to engage in independent R&D. Enterprises prefer to upgrade and transform their existing processes through independent R&D in order to take the lead in completing “process upgrade, product upgrade, function upgrade and industry chain upgrade” and gain a core competitive advantage over the industry’s development. Among the external factors, expenditure on the new product development of industrial enterprises above a designated size has the greatest impact on enterprises’ transformation and upgrading capabilities with an elasticity coefficient of 0.0172. This indicates that for every 1% increase in expenditure on the new product development of industrial enterprises above the designated size, the enterprises’ transformation and upgrading capacity increases by 0.0172%. Enterprises’ new product expenditure includes capital investment in new product design and new technology development, which is usually the main source of enhancements in enterprises’ transformation and upgrading capabilities. Therefore, any increase in expenditure on the new product development of industrial enterprises above the designated size provides development impetus for the improvement of such capabilities.

- (2)

- Business revenue, operating profit margin, rate of return on common stockholders’ equity, return on assets, and general public budget revenue (secondary indicators of EBO). The internal factors of return on assets, return on equity, and operating profit margin are three indicators used to reflect enterprises’ profitability. Among them, the operating profit margin has the greatest impact on enterprises’ transformation and upgrading capabilities (the regression coefficient is 0.7398), and every 1% increase in an enterprise’s return on equity increases its transformation and upgrading capabilities by 0.1758%. Good profitability for an enterprise means continuous cash flow growth, which is an important source of finance for various expenditures needed in the process of transformation and upgrading. Companies with a good return on equity will thus be better able to transform and upgrade their businesses. Among the external factors, for every 1% increase in local general public budget revenue, the regional enterprises’ transformation and upgrading capabilities will increase by 0.0022%. Higher local general public budget revenue means a social environment where development is more modern and people’s livelihood needs are fully protected. These regions are more dynamic in terms of business development, which is conducive to local enterprises’ transformation and upgrading.

- (3)

- E-commerce sales, green covered area as % of completed area, and the number of parks (secondary indicators of RHD). Among these, regional E-commerce sales have the greatest degree of influence on enterprises’ transformation and upgrading capabilities (regression coefficient 0.0455). On the one hand, an increase of E-commerce sales promotes the widespread application of the Internet in business. On the other hand, the E-commerce platform provides enterprises with a broad space for online marketing and promotion, which is conducive to promoting their intelligent transformation. In addition, for every 1% increase in the green covered area as % of completed area, enterprises’ transformation and upgrading capabilities will increase by 0.0168%, because in areas with an excellent environment and a high level of greening, local enterprises are also likely to be more aware of green innovation in their transformation and upgrading process, which is conducive to long-term sustainable development.

- (4)

- Construction area of S&T museums, the number of secondary vocational schools, and the number of students enrolled in secondary vocational schools (secondary indicators of EBE). Among all the external factors in the EBE category, the construction area of S&T museums has the greatest impact on enterprises’ transformation and upgrading capabilities (regression coefficient 0.0223). Meanwhile, for every 1% increase in the number of regional secondary vocational schools and the number of students enrolled in them, enterprises’ transformation and upgrading capabilities increase by 0.0132% and 0.0.0061%, respectively. This is due to an increase in high-quality young innovative talent for local enterprises.

- (1)

- The number of national university science parks, the number of mass maker spaces, and projects for the new product development of industrial enterprises above the designated size (secondary indicators of IDI). The three factors mentioned above are all external indicators. For every 1% increase in the number of national university science parks and mass maker spaces, local companies’ enterprise transformation and upgrading capabilities decrease by 0.0006% and 0.0208%, respectively. This is mainly due to the fact that, compared with local enterprises, national university science parks and mass maker spaces will enjoy preferential government subsidies and preferential policies, which reduces the policy and financial support for enterprise transformation. This reduces the inflow of innovation resources from the “supply” side of transformation and upgrading, somewhat reducing enterprises’ capabilities.

- (2)

- Sales revenue of new products of industrial enterprises above the designated size (secondary indicator of EBO). In the secondary indicators of economically beneficial output, it is mainly external factors that have a negative impact on enterprises’ transformation and upgrading capabilities. For every 1% increase in such sales revenue, enterprises’ transformation and upgrading capability will decrease by 0.0309%. If an enterprise spends too much on the design, production, and sales of new products, instead of promoting transformation and upgrading according to its business and operational characteristics, it will cause a lot of waste, which is not conducive to good transformation and upgrading capabilities.

- (3)

- Websites per 100 enterprises, the amount of informatization and E-commerce of enterprises, value-added by tertiary industry, and income from software-related businesses (secondary indicators of RHD). With 1% more websites per 100 enterprises and informatization and E-commerce of enterprises in the region, enterprises’ transformation and upgrading capabilities fall by 0.0116% and 0.0068%, respectively. This is probably because, in the initial stages of transformation, putting a lot of capital investment into intelligent transformation may mean enterprises are ignoring the key issues of transformation and upgrading. Accumulating high costs is not conducive to such capabilities. Income from software-related businesses has a regression coefficient of −0.0462 (significant). The software business belongs to the tertiary industry. The results show that the tertiary industry also has a negative impact on the ability of enterprises to transform and upgrade. For every 1% increase in the value-added by tertiary industry, enterprises’ transformation and upgrading capabilities decrease by 0.0046%. Emerging industries such as new energy, energy conservation, environmental protection, electric vehicles, new materials, new medicines, and software development are all tertiary industries, providing enterprises with a direction for transformation and upgrading. However, if some enterprises flock to these emerging industries without thinking, although the tertiary industry’s value-added is increased, in the long run, this is not conducive to the economic growth of enterprises, and will also undermine healthy competition in the industrial chain.

- (4)

- The number of S&T museums and the number of public libraries (secondary indicators of EBE). Compared with the three other categories, EBE indicators have less of an overall impact on enterprises’ transformation and upgrading capabilities in NIDZs. The number of S&T museums and the number of public libraries affect such capabilities to the greatest extent, with regression coefficients of 0.026 and 0.018, respectively. For every 1% increase in the number of S&T museums and public libraries, enterprises’ transformation and upgrading capabilities decrease by 0.0222% and 0.0134%, respectively. We speculate that a large increase in the number of S&T museums and public libraries in the short term will incur a lot of capital and labor costs, which will slow down enterprises’ transformation and upgrading in a certain sense.

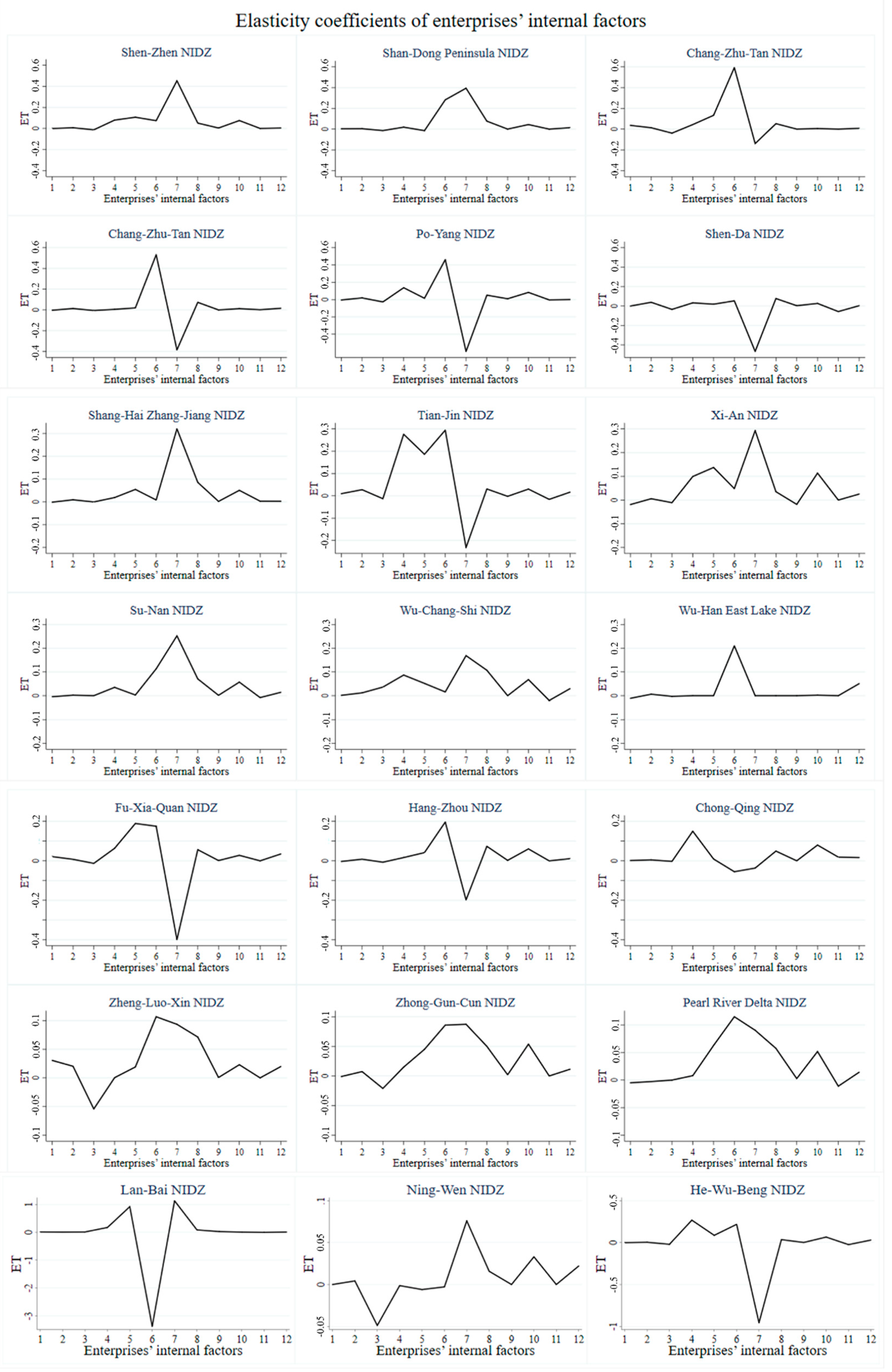

5.3. Analysis of Factors Influencing Enterprises’ Transformation and Upgrading Capabilities in the Different National Innovation Demonstration Zones

6. Conclusions

- (1)

- Improve the supportive policy system for enterprises’ transformation and upgrading at the national level and accelerate the layouts of differentiated industrial chains in NIDZs. The NIDZs represent the highland for promoting regional technological innovation and accelerating the flow of innovation resources in China, but the results show that there is a problem in terms of large differences in the development of enterprises’ transformation and upgrading capabilities in different NIDZs. On the one hand, NIDZs should make full use of innovation platforms such as universities and research institutes to smooth the flow of innovation resources between enterprises and the outside world, in order to form a long-term synergistic cooperation mechanism. On the other hand, enterprises should seize the major opportunity of regional differentiation and transformation and clarify the key development industries and the division of labor in the industrial chain in NIDZs, so as to achieve the goal of value chain climbing.

- (2)

- Invest innovation funds to tackle technical problems and improve the efficiency of innovation resource allocation. We have found that the internal IDI and EBO factors can significantly promote the improvement of enterprises’ transformation and upgrading capabilities, especially the internal EBO factors. Enterprises are the main implementers of innovation activities in NIDZs and the key to continuously improving the efficiency of innovation resource allocation. On the one hand, enterprises can reduce the waste of resources by improving the innovative capital investment mechanism and increasing special capital investment in basic research and key core technology fields, so as to achieve the goal of optimizing resource allocation. On the other hand, enterprises can attract outstanding talent at home and abroad through preferential conditions such as bonuses and resettlement allowances. Based on their actual development and future strategic directions, they can build a team to tackle technical problems, solve the technical problems that restrict their transformation and upgrading, and accelerate the breakthrough of core technologies.

- (3)

- Optimize the soft environment of the innovation ecosystem in the NIDZs, so as to promote high-quality enterprise transformation and upgrading. The soft environment of the innovation ecosystem refers to the innovation policy, service ecology, and innovation culture in the location of the NIDZs. Cultivating a good soft environment of the innovation ecosystem is very important for NIDZs’ innovation development. On the one hand, NIDZs should actively promote the construction of an open innovation environment. In line with the construction standards of foreign high-tech industrial parks, the NIDZs should continuously strengthen the awareness of open innovation and promote their innovation capabilities and independent R&D capabilities. On the other hand, NIDZs should actively cultivate a cultural atmosphere that stimulates innovation vitality and promotes the efficient allocation of innovation resources. The soft environment of an open, innovative, and collaborative innovation ecosystem for enterprises will promote the NIDZs’ high-quality transformation and upgrading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cevik, E.I.; Yıldırım, D.Ç.; Dibooglu, S. Renewable and Non-Renewable Energy Consumption and Economic Growth in the US: A Markov-Switching VAR Analysis. Energy Environ. 2021, 32, 519–541. [Google Scholar] [CrossRef]

- Armstrong, B. Industrial Policy and Local Economic Transformation: Evidence from the U.S. Rust Belt. Econ. Dev. Q. 2021, 35, 181–196. [Google Scholar] [CrossRef]

- Li, K.; Kim, D.J.; Lang, K.R.; Kauffman, R.J.; Naldi, M. How Should We Understand the Digital Economy in Asia? Critical Assessment and Research Agenda. Electron. Commer. Res. Appl. 2020, 44, 101004. [Google Scholar] [CrossRef]

- Chen, F.H.; Liu, H.R. Evaluation of Sustainable Development in Six Transformation Fields of the Central Taiwan Science Park. Sustainability 2021, 13, 4336. [Google Scholar] [CrossRef]

- Liu, F.; Fan, Y.; Yang, S. Environmental Benefits of Innovation Policy: China’s National Independent Innovation Demonstration Zone Policy and Haze Control. J. Environ. Manag. 2022, 317, 115465. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Siraj, A.; Jiang, H.; Zhu, Y.; Li, J. Chinese-Style Innovation and Its International Repercussions in the New Economic Times. Sustainability 2020, 12, 1859. [Google Scholar] [CrossRef]

- Rupeika-Apoga, R.; Petrovska, K. Barriers to Sustainable Digital Transformation in Micro-, Small-, and Medium-Sized Enterprises. Sustainability 2022, 14, 3558. [Google Scholar] [CrossRef]

- Shen, L.; Fan, R.; Wang, Y.; Yu, Z.; Tang, R. Impacts of Environmental Regulation on the Green Transformation and Upgrading of Manufacturing Enterprises. Int. J. Environ. Res. Public Health 2020, 17, 7680. [Google Scholar] [CrossRef] [PubMed]

- Gereffi, G. International Trade and Industrial Upgrading in the Apparel Commodity Chain. J. Int. Econ. 1999, 48, 37–70. [Google Scholar] [CrossRef]

- Bhupendra, K.V.; Sangle, S. Product Stewardship Strategy: A Study of Indian Firms. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 124–134. [Google Scholar] [CrossRef]

- Skare, M.; de las Mercedes de Obesso, M.; Ribeiro-Navarrete, S. Digital Transformation and European Small and Medium Enterprises (SMEs): A Comparative Study Using Digital Economy and Society Index Data. Int. J. Inf. Manag. 2023, 68, 102594. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, Q.; Zhang, X.; Li, C. Can Digital Transformation Promote Green Technology Innovation? Sustainability 2022, 14, 7497. [Google Scholar] [CrossRef]

- Lamin, A.; Livanis, G. Agglomeration, Catch-up and the Liability of Foreignness in Emerging Economies. J. Int. Bus. Stud. 2013, 44, 579–606. [Google Scholar] [CrossRef]

- Horbach, J.; Rammer, C. Energy Transition in Germany and Regional Spill-Overs: The Diffusion of Renewable Energy in Firms. Energy Policy 2018, 121, 404–414. [Google Scholar] [CrossRef]

- Khan, M.A.; Stoll, O.; West, S.; Wuest, T. Equipment Upgrade Service Provision in the Context of Servitization: Drivers, Capabilities, and Resources. Prod. Plan. Control 2022, 1–19. [Google Scholar] [CrossRef]

- Han, X.; Zheng, Y. Driving Elements of Enterprise Digital Transformation Based on the Perspective of Dynamic Evolution. Sustainability 2022, 14, 9915. [Google Scholar] [CrossRef]

- Liu, Y.; Lee, H.; Ham, D.; Westervelt, R.M. CMOS-Based Magnetic Cell Manipulation System. Technovation 2007, 2, 103–144. [Google Scholar] [CrossRef]

- Ho, Y.P.; Ruan, Y.; Hang, C.C.; Wong, P.K. Technology Upgrading of Small-and-Medium-Sized Enterprises (SMEs) through a Manpower Secondment Strategy—A Mixed-Methods Study of Singapore’s T-Up Program. Technovation 2016, 57–58, 21–29. [Google Scholar] [CrossRef]

- Gaglio, C.; Kraemer-Mbula, E.; Lorenz, E. The Effects of Digital Transformation on Innovation and Productivity: Firm-Level Evidence of South African Manufacturing Micro and Small Enterprises. Technol. Forecast. Soc. Change 2022, 182, 121785. [Google Scholar] [CrossRef]

- Wen, H.; Lee, C.C.; Zhou, F. Green Credit Policy, Credit Allocation Efficiency and Upgrade of Energy-Intensive Enterprises. Energy Econ. 2021, 94, 105099. [Google Scholar] [CrossRef]

- Matsuzaki, T.; Shigeno, H.; Ueki, Y.; Tsuji, M. Innovation Upgrading of Local Small and Medium-Sized Enterprises and Regional Innovation Policy: An Empirical Study. Ind. Mark. Manag. 2021, 94, 128–136. [Google Scholar] [CrossRef]

- Xiao, S.; Yang, J. Does the Executive Equity Incentive Promote the Up- Grading of Enterprises: Empirical Evidence from Chi- Nese Listed Companies. Explor. Econ. Hist. 1993, 24, ETG 5-1–ETG 5-17. [Google Scholar] [CrossRef]

- Ai, H.; Hu, S.; Li, K.; Shao, S. Environmental Regulation, Total Factor Productivity, and Enterprise Duration: Evidence from China. Bus. Strateg. Environ. 2020, 29, 2284–2296. [Google Scholar] [CrossRef]

- Zhu, L. Research on the Impact of Environmental Regulation on Global Value Chain Upgrading of Enterprises: From the Perspective of Export Domestic Added Value. J. Int. Bus. Stud. 2011, 1, 137–140. [Google Scholar] [CrossRef]

- Yang, F.; Sun, Y.; Zhang, Y.; Wang, T. Factors Affecting the Manufacturing Industry Transformation and Upgrading: A Case Study of Guangdong–Hong Kong–Macao Greater Bay Area. Int. J. Environ. Res. Public Health 2021, 18, 7157. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Liu, X.; Wang, W.; Gong, Z. Behavioral DEA Model and Its Application to the Efficiency Evaluation of Manufacturing Transformation and Upgrading in the Yangtze River Delta. Soft Comput. 2020, 24, 10721–10738. [Google Scholar] [CrossRef]

- Song, C.; Yin, G.; Lu, Z.; Chen, Y. Industrial Ecological Efficiency of Cities in the Yellow River Basin in the Background of China’s Economic Transformation: Spatial-Temporal Characteristics and Influencing Factors. Environ. Sci. Pollut. Res. 2022, 29, 4334–4349. [Google Scholar] [CrossRef] [PubMed]

- Mao, W.; Wang, W.; Sun, H.; Yao, P.; Wang, X.; Luo, D. Urban Industrial Transformation Patterns under Natural Resource Dependence: A Rule Mining Technique. Energy Policy 2021, 156, 112383. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Shi, F. Factors Influencing Mechanism of Construction Development Transformation in China Based on SEM. Discret. Dyn. Nat. Soc. 2015, 2015, 9865. [Google Scholar] [CrossRef]

- Meng, F.; Xu, Y.; Zhao, G. Environmental Regulations, Green Innovation and Intelligent Upgrading of Manufacturing Enterprises: Evidence from China. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef]

- Zhai, X.; An, Y. Analyzing Influencing Factors of Green Transformation in China’s Manufacturing Industry under Environmental Regulation: A Structural Equation Model. J. Clean. Prod. 2020, 251, 119760. [Google Scholar] [CrossRef]

- Wang, Z.; Shou, M.; Wang, S.; Dai, R.; Wang, K. An Empirical Study on the Key Factors of Intelligent Upgrade of Small and Medium-Sized Enterprises in China. Sustainability 2019, 11, 619. [Google Scholar] [CrossRef]

- Li, C.; Wan, J.; Xu, Z.; Lin, T. Impacts of Green Innovation, Institutional Constraints and Their Interactions on High-Quality Economic Development across China. Sustainability 2021, 13, 5277. [Google Scholar] [CrossRef]

- Sheng, Z.; Yuan, G.; Xiru, D.; Minglong, Z.; Yi, W.; Yu, H. Research on High Quality Evaluation and Influencing Factors of China Energy Finance: Evidence From A-Share New Energy Companies. Front. Environ. Sci. 2021, 9, 1–15. [Google Scholar] [CrossRef]

- Xin, G. Research on Curriculum System of Electrical Engineering Based on Innovation and Entrepreneurship Education. In Proceedings of the 2021 6th International Conference on Social Sciences and Economic Development (ICSSED 2021), Nanjing, China, 12–14 March 2021; Volume 543, pp. 985–989. [Google Scholar] [CrossRef]

- Borrás, S.; Laatsit, M. Towards System Oriented Innovation Policy Evaluation? Evidence from EU28 Member States. Res. Policy 2019, 48, 312–321. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Z.; Ma, C. Chinese Innovation-Driving Factors: Regional Structure, Innovation Effect, and Economic Development—Empirical Research Based on Panel Data. Ann. Reg. Sci. 2017, 59, 43–68. [Google Scholar] [CrossRef]

- Zaharia, A.; Diaconeasa, M.C.; Maehle, N.; Szolnoki, G.; Capitello, R. Developing Sustainable Food Systems in Europe: National Policies and Stakeholder Perspectives in a Four-Country Analysis. Int. J. Environ. Res. Public Health 2021, 18, 7701. [Google Scholar] [CrossRef]

- Yong, Z. Research on the Effect of National Independent Innovation Demonstration Zone Policy on Regional Economy. Am. J. Res. Commun. 2021, 1, 1–7. [Google Scholar]

- Aisaiti, G.; Xie, J.; Zhang, T. National Innovation Demonstration Zone Policy and City Innovation Capability—A Quasi-Natural Experimental Analysis. Ind. Manag. Data Syst. 2022, 122, 1246–1267. [Google Scholar] [CrossRef]

- Wei, L.; Bu, W. Research on the Economic Growth Promoting Effect of National Innovation Demonstration Zone. Sci. Technol. Prog. Policy 2018, 35, 48–56. [Google Scholar]

- Ma, Z.; Ding, C. Evaluation on the Innovation Ecosystem of National Independent Innovation Demonstration Zone Based on RJVs. Am. J. Res. Commun. 2009, 5, 12–42. [Google Scholar]

- Zhang, W. Position, Construction Strategy and the Orientation of National Independent Innovation Demonstration Zones. Innov. Dev. Coord. Dev. 2019, 1, 9–25. [Google Scholar]

- Wang, S. Evolution Track and Expectation of National Independent Innovation Demon-Stration Zone. Complexity 2017, 297, 82–94. [Google Scholar]

- Feng, C.; Liao, X. An Overview of “Energy + Internet” in China. J. Clean. Prod. 2020, 1, 258. [Google Scholar] [CrossRef]

- Yu, F.; Wang, L.; Li, X. The Effects of Government Subsidies on New Energy Vehicle Enterprises: The Moderating Role of Intelligent Transformation. Energy Policy 2020, 141, 111463. [Google Scholar] [CrossRef]

- Boeing, P.; Eberle, J.; Howell, A. The Impact of China’s R&D Subsidies on R&D Investment, Technological Upgrading and Economic Growth. Technol. Forecast. Soc. Change 2022, 174, 121212. [Google Scholar] [CrossRef]

- Lan, F.; Wang, W.; Cao, Q. Tax Cuts and Enterprises’ R&D Intensity: Evidence from a Natural Experiment in China. Econ. Model. 2020, 89, 304–314. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Li, H.; Li, X. Research on Financing Efficiency and Influencing Factors of Equipment Manufacturing Industry-Regression Model Based on SFA Panel Data. J. Intell. Fuzzy Syst. 2021, 40, 8117–8126. [Google Scholar] [CrossRef]

- Kolaj, M.; Smith, R.S. A Multiple Transmitter and Receiver Electromagnetic System for Improved Target Detection. Geophysics 2015, 80, E247–E255. [Google Scholar] [CrossRef]

- Dong, T. The Evaluation System of Publishing Industry’s Competitiveness in Overseas Market; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 9789811686597. [Google Scholar]

- Cao, H.; Chen, Z. The Driving Effect of Internal and External Environment on Green Innovation Strategy-The Moderating Role of Top Management’s Environmental Awareness. Nankai Bus. Rev. Int. 2019, 10, 342–361. [Google Scholar] [CrossRef]

- Li, H.; Graham, D.J.; Majumdar, A. The Effects of Congestion Charging on Road Traffic Casualties: A Causal Analysis Using Difference-in-Difference Estimation. Accid. Anal. Prev. 2012, 49, 366–377. [Google Scholar] [CrossRef] [PubMed]

- Xia, P.; Wei, L.; Ma, Z. Negative Binomial Regression Model Based Analysis for Influential Factors of Expressway Traffic Accidents. Shandong Sci. 2013, 26, 80–84. [Google Scholar] [CrossRef]

| Regional Distribution | NIDZ | Affiliated Province | Establishment Date | Number of Companies |

|---|---|---|---|---|

| Eastern coastal areas | Zhong-Guan-Cun NIDZ | Beijing | 2009.3 | 136 |

| Shang-Hai Zhang-Jiang NIDZ | Shanghai | 2011.3 | 173 | |

| Shen-Zhen NIDZ | Guangdong | 2014.6 | 203 | |

| Su-Nan NIDZ | Jiangsu | 2014.11 | 285 | |

| Tian-Jin NIDZ | Tianjin | 2015.2 | 33 | |

| Hang-Zhou NIDZ | Zhejiang | 2015.9 | 97 | |

| Pearl River Delta NIDZ | Guangdong | 2015.9 | 197 | |

| Shan-Dong Peninsula NIDZ | Shandong | 2016.4 | 133 | |

| Shen-Da NIDZ | Liaoning | 2016.4 | 23 | |

| Fu-Xia-Quan NIDZ | Fujian | 2016.6 | 68 | |

| Ning-Wen NIDZ | Zhejiang | 2018.2 | 97 | |

| Central area | Wu-Han East Lake NIDZ | Hubei | 2009.12 | 33 |

| Chang-Zhu-Tan NIDZ | Hunan | 2015.1 | 50 | |

| Zheng-Luo-Xin NIDZ | Henan | 2016.4 | 30 | |

| He-Wu-Beng NIDZ | Anhui | 2016.6 | 48 | |

| Chong-Qing NIDZ | Chongqing | 2016.7 | 28 | |

| Po-Yang Lake NIDZ | Jiangxi | 2019.8 | 31 | |

| Western area | Cheng-Du NIDZ | Sichuan | 2015.6 | 49 |

| Xi-An NIDZ | Shanxi | 2015.9 | 25 | |

| Lan-Bai NIDZ | Gansu | 2018.2 | 14 | |

| Wu-Chang-Shi NIDZ | Xinjiang | 2018.11 | 17 |

| First-Level Indicator | Second-Level Indicator | |

|---|---|---|

| Innovation-driven input | Internal factors | Proportion of corporate R&D personnel (x1), Amount of enterprise R&D investment (x2), Enterprise R&D investment intensity (x3) |

| External factors | Full time equivalent of R&D personnel (x4), R&D expenditure input intensity (x5), Expenditure on science and technology (S&T) (x6), Number of patent applications (x7), Number of patents granted (x8), Number of enterprises with R&D institutions (x9), Number of R&D institutions in industrial enterprises above designated size (x10), Expenditure on S&T institutions of industrial enterprises above designated size (x11), Expenditure on technical renovation in industrial enterprises above designated size (x12), Projects for new product development of industrial enterprises above designated size (x13), Expenditure on new product development of industrial enterprises above designated size (x14), Number of foreign technology import contracts (x15), Transaction value in technical markets (x16), Scientific papers issued (x17), Publications on S&T (x18), Number of technical formed national and industrial standards (x19), Number of R&D institutions (x20), Number of mass maker spaces (x21), Number of national university science parks (x22) | |

| Economically beneficial output | Internal factors | Return on assets (x23), Profit rate of total assets (x24), Return on equity (x25), Operating profit margin (x26), Turnover of total assets (x27), Accounts receivable turnover (x28), Asset-liability ratio (x29), Total assets growth rate (x30), Business revenue (x31) |

| External factors | Per capita gross regional product (x32), General public budget revenue (x33), Per capita disposable income of households (x34), Per capita disposable expenditure of households (x35), General consumer price index (x36), Growth rate of total investment in fixed assets (x37), Proportion of urban population (x38), Total wages bill of employed persons in urban non-private units (x39), Number of employed persons in urban non-private units (x40), Per capita consumption expenditure of urban households (x41), Sales revenue of new products of industrial enterprises above designated scale (x42), Business revenue of high-tech industry (x43), Profits of high-tech industry (x44) | |

| Regional high-quality development | External factors | Amount of informatization and E-commerce of enterprises (x45), Computers used per 100 persons (x46), Websites per 100 enterprises (x47), Sales through E-commerce (x48), Number of persons employed in information transmission software and information technology (x49), Business volume of telecommunication services (x50), Revenue from express delivery services (x51), Broadband subscribers by Internet ports (x52), Mobile internet subscribers (x53), Qualification rate of products (x54), Income from software-related business (x55), Area of green space (x56), Number of parks (x57), Forest coverage rate (x58), Forest area (x59), Investment in gardening and greening (x60), Green area as % of completed area (x61), Integrated reuse of common industrial solid waste (x62), Daily disposal capacity of city sewage (x63), Harmless treatment capacity of garbage (x64), International trade in goods (x65), Number of foreign-invested enterprises (x66), Total investment of foreign-invested enterprises (x67), Value-added by tertiary industry (x68), Tertiary industry’s share of GDP (x69), Proportion of employed persons in tertiary industry (x70) |

| Enterprise’s basic environment | External factors | Number of regular higher education institutions (x71), Number of education personnel in regular senior secondary schools (x72), Number of students enrolled in general senior secondary schools (x73), Number of secondary vocational schools (x74), Number of students enrolled in secondary vocational schools (x75), Educational finance (x76), Number of health care institutions (x77), Number of licensed physicians and physicians’ assistants (x78), Number of public libraries (x79), Collections of public libraries per person (x80), Number of museums (x81), Full-time S&T popularization personnel (x82), Number of S&T museums (x83), Construction area of S&T museums (x84), Number of people participating in basic medical insurance (x85), Number of buses and trolly buses (x86), Number of motor vehicles (x87), Electricity consumption (x88) |

| Paramaters | Regression Coefficients | Elastic Coefficients | Paramaters | Regression Coefficients | Elastic Coefficients | Paramaters | Regression Coefficients | Elastic Coefficients |

|---|---|---|---|---|---|---|---|---|

| R2 | 0.1895 | β29 | 0.1840 | 0.0781 | β59 | 0.0007 | 0.0003 | |

| β0 | 0.4608 | β30 | −0.0266 | −0.0043 | β60 | −0.0001 | 0.0000 | |

| β1 | −0.1089 | −0.0017 | β31 | 0.7398 | 0.0093 | β61 | 0.0209 | 0.0168 |

| β2 | 0.5894 | 0.0149 | β32 | 0.0009 | 0.0007 | β62 | 0.0046 | 0.0025 |

| β3 | −0.4128 | −0.0002 | β33 | 0.0024 | 0.0022 | β63 | 0.0000 | 0.0000 |

| β4 | −0.0029 | −0.0025 | β34 | 0.0008 | 0.0006 | β64 | 0.0000 | 0.0000 |

| β5 | 0.0000 | 0.0000 | β35 | −0.0002 | −0.0001 | β65 | −0.0041 | −0.0033 |

| β6 | 0.0009 | 0.0007 | β36 | −0.0093 | −0.0077 | β66 | 0.0001 | 0.0000 |

| β7 | 0.0000 | 0.0000 | β37 | 0.0018 | 0.0019 | β67 | 0.0001 | 0.0000 |

| β8 | 0.0000 | 0.0000 | β38 | 0.0003 | 0.0003 | β68 | −0.0048 | −0.0046 |

| β9 | −0.0001 | −0.0001 | β39 | 0.0234 | 0.0191 | β69 | 0.0006 | 0.0003 |

| β10 | 0.0000 | 0.0000 | β40 | 0.0119 | 0.0093 | β70 | 0.0027 | 0.0016 |

| β11 | 0.0035 | 0.0022 | β41 | −0.0062 | −0.0049 | β71 | −0.0109 | −0.0112 |

| β12 | 0.0016 | 0.0011 | β42 | −0.0362 | −0.0309 | β72 | −0.0008 | −0.0006 |

| β13 | −0.0005 | −0.0004 | β43 | 0.0006 | 0.0004 | β73 | 0.0078 | 0.0057 |

| β14 | 0.0233 | 0.0172 | β44 | 0.0008 | 0.0006 | β74 | 0.0198 | 0.0132 |

| β15 | 0.0004 | 0.0002 | β45 | −0.0076 | −0.0068 | β75 | 0.0082 | 0.0061 |

| β16 | 0.0006 | 0.0003 | β46 | 0.0008 | 0.0004 | β76 | −0.0172 | −0.0137 |

| β17 | −0.0167 | −0.0167 | β47 | −0.0089 | −0.0116 | β77 | 0.0037 | 0.0025 |

| β18 | 0.0001 | 0.0001 | β48 | 0.0455 | 0.0394 | β78 | −0.0016 | −0.0015 |

| β19 | 0.0002 | 0.0001 | β49 | −0.0001 | 0.0000 | β79 | −0.0177 | −0.0134 |

| β20 | 0.0000 | 0.0000 | β50 | 0.0001 | 0.0001 | β80 | −0.0005 | −0.0002 |

| β21 | −0.0229 | −0.0208 | β51 | −0.0028 | −0.0019 | β81 | −0.0006 | −0.0004 |

| β22 | −0.0008 | −0.0006 | β52 | −0.0018 | −0.0017 | β82 | −0.0024 | −0.0018 |

| β23 | 0.1055 | 0.0812 | β53 | 0.0032 | 0.0025 | β83 | −0.0263 | −0.0222 |

| β24 | 0.0715 | 0.0536 | β54 | 0.0103 | 0.0081 | β84 | 0.0223 | 0.0234 |

| β25 | 0.1921 | 0.1758 | β55 | −0.0462 | −0.0390 | β85 | 0.0017 | 0.0015 |

| β26 | 0.4216 | 0.6729 | β56 | 0.0011 | 0.0008 | β86 | −0.0034 | −0.0030 |

| β27 | 0.2062 | 0.0461 | β57 | 0.0137 | 0.0079 | β87 | 0.0137 | 0.0111 |

| β28 | 0.0702 | 0.0007 | β58 | −0.0021 | −0.0018 | β88 | 0.0003 | 0.0003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Fan, X.; Zhang, Y.; Hu, B. Understanding the Influencing Factors of Enterprise Transformation and Upgrading Capability: A Case Study of the National Innovation Demonstration Zones, China. Sustainability 2023, 15, 2711. https://doi.org/10.3390/su15032711

Ma Z, Fan X, Zhang Y, Hu B. Understanding the Influencing Factors of Enterprise Transformation and Upgrading Capability: A Case Study of the National Innovation Demonstration Zones, China. Sustainability. 2023; 15(3):2711. https://doi.org/10.3390/su15032711

Chicago/Turabian StyleMa, Zongguo, Xueai Fan, Yanli Zhang, and Beibei Hu. 2023. "Understanding the Influencing Factors of Enterprise Transformation and Upgrading Capability: A Case Study of the National Innovation Demonstration Zones, China" Sustainability 15, no. 3: 2711. https://doi.org/10.3390/su15032711