Comparative Assessment of Environmental/Energy Performance under Conventional Labor and Collaborative Robot Scenarios in Greek Viticulture

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Study Area and Selected Vineyards’ Description

2.2. Collaborative Robots in Agriculture

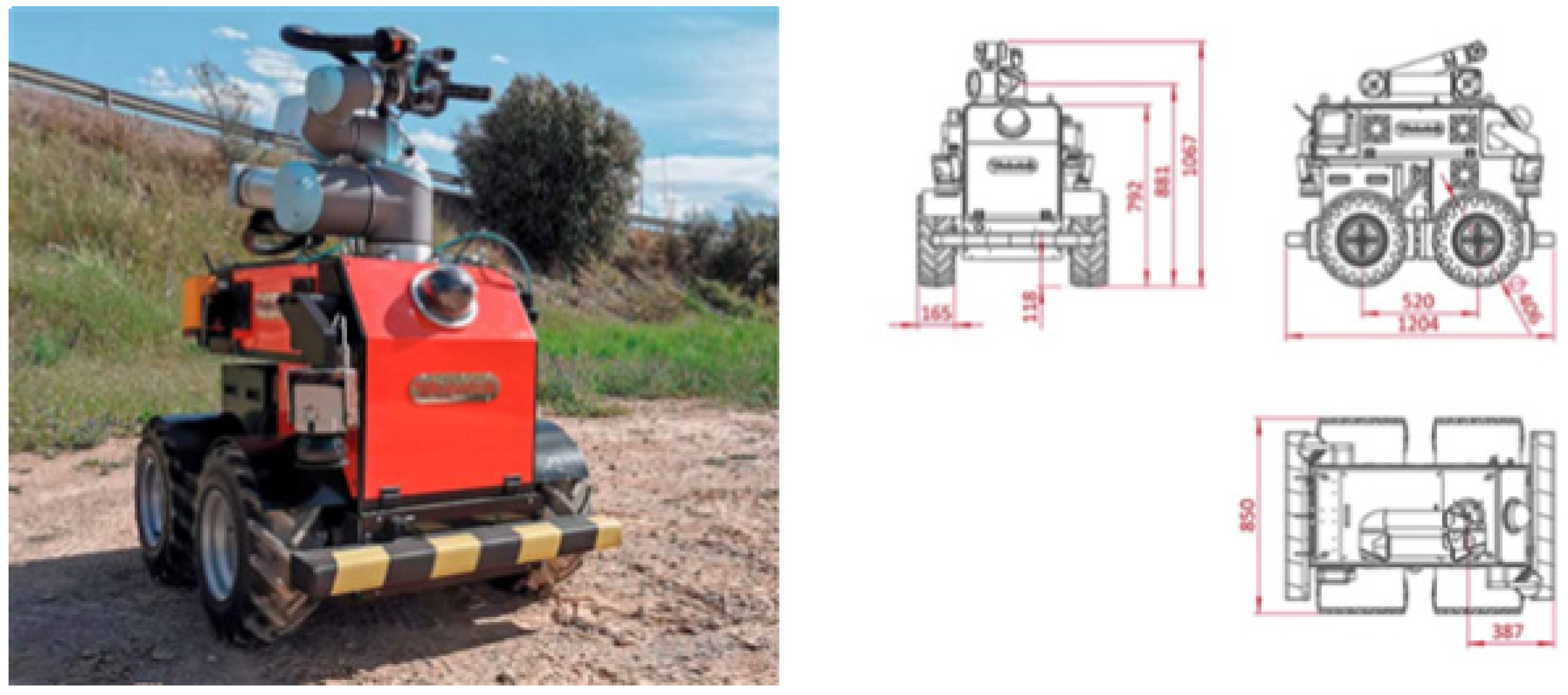

2.3. Selected Cobots’ Description

2.4. Goal and Scope Definition

2.5. Inventory Analysis

2.6. Carbon Footprint and Energy Consumption Impact Assessment

2.7. Energy Efficiency and Emission Intensity of the Investigated System

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Porter, J.; Xie, L.; Challinor, A.; Cochrane, K.; Howden, M.; Iqbal, M.; Lobell, D.; Travasso, M. Food Security and Food Production Systems. In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- FAO. Climate Change and Food Security: Risks and Responses; FAO: Rome, Italy, 2015; ISBN 978-92-5-108998-9. [Google Scholar]

- Jones, G.V.; White, M.A.; Cooper, O.R.; Storchmann, K. Climate Change and Global Wine Quality. Clim. Change 2005, 73, 319–343. [Google Scholar] [CrossRef]

- Kurtural, S.K.; Gambetta, G.A. Global Warming and Wine Quality: Are We Close to the Tipping Point? Oeno One 2021, 55, 353–361. [Google Scholar] [CrossRef]

- Duchêne, E.; Huard, F.; Dumas, V.; Schneider, C.; Merdinoglu, D. The Challenge of Adapting Grapevine Varieties to Climate Change. Clim. Res. 2010, 41, 193–204. [Google Scholar] [CrossRef]

- Ferrara, C.; De Feo, G. Life Cycle Assessment Application to the Wine Sector: A Critical Review. Sustainability 2018, 10, 395. [Google Scholar] [CrossRef]

- Eurostat Wine-Grower Holdings by Production. Total Area under Vines (in/Not yet in Production). Available online: https://ec.europa.eu/eurostat/databrowser/view/vit_t1/default/table?lang=en (accessed on 28 July 2022).

- OIV. World Wine Production Outlook—OIV First Estimates—31.10.2022; OIV: Dijon, France, 2022. [Google Scholar]

- ISO 14040 International Standard. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization (ISO): Geneva. Switzerland, 2006. [Google Scholar]

- ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006.

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook: Analysing of Existing Environmental Impact Assessment Methodologies for Use in Life Cycle Assessment. European Commission 2010, 115. [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Matthews, H.S.; Hendrickson, C.T.; Weber, C.L. The Importance of Carbon Footprint Estimation Boundaries. Environ. Sci. Technol. 2008, 42, 5839–5842. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Van Der Voet, E. A Greenhouse Gas Indicator for Bioenergy: Some Theoretical Issues with Practical Implications. Int. J. Life Cycle Assess. 2009, 14, 328–339. [Google Scholar] [CrossRef]

- Sheehan, J.J. Biofuels and the Conundrum of Sustainability. Curr. Opin. Biotechnol. 2009, 20, 318–324. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life Cycle Assessment: Part 1: Framework, Goal and Scope Definition, Inventory Analysis, and Applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Jensen, A.; J., E.; Christiansen, K.; Hoffman, L.; Moller, B.T.; Schmidt, A. Life Cycle Assessment (LCA)—A Guide to Approaches. Exp. Inf. Sources 1998. [Google Scholar]

- Sala, S.; Reale, F.; Cristobal-Garcia, J.; Marelli, L.; Pant, R. Life Cycle Assessment for the Impact Assessment of Policies; Publications Office of the European Union: Luxemburg, 2016. [Google Scholar]

- De Luca, A.I.; Iofrida, N.; Leskinen, P.; Stillitano, T.; Falcone, G.; Strano, A.; Gulisano, G. Life Cycle Tools Combined with Multi-Criteria and Participatory Methods for Agricultural Sustainability: Insights from a Systematic and Critical Review. Sci. Total Environ. 2017, 595, 352–370. [Google Scholar] [CrossRef] [PubMed]

- Tziolas, E.; Bournaris, T.; Manos, B.; Nastis, S. Life Cycle Assessment and Multi-Criteria Analysis in Agriculture: Synergies and Insights BT—Multicriteria Analysis in Agriculture: Current Trends and Recent Applications; Berbel, J., Bournaris, T., Manos, B., Matsatsinis, N., Viaggi, D., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 289–321. ISBN 978-3-319-76929-5. [Google Scholar]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Muralikrishna, I.V.; Manickam, V. Chapter Five—Life Cycle Assessment. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; ISBN 978-0-12-811989-1. [Google Scholar]

- Canaj, K.; Morrone, D.; Roma, R.; Boari, F.; Cantore, V.; Todorovic, M. Reclaimedwater for Vineyard Irrigation in a Mediterranean Context: Life Cycle Environmental Impacts, Life Cycle Costs, and Eco-Efficiency. Water 2021, 13, 2242. [Google Scholar] [CrossRef]

- Kalboussi, N.; Biard, Y.; Pradeleix, L.; Rapaport, A.; Sinfort, C.; Ait-mouheb, N. Life Cycle Assessment as Decision Support Tool for Water Reuse in Agriculture Irrigation. Sci. Total Environ. 2022, 836, 155486. [Google Scholar] [CrossRef]

- Quinteiro, P.; Dias, A.C.; Pina, L.; Neto, B.; Ridoutt, B.G.; Arroja, L. Addressing the Freshwater Use of a Portuguese Wine (’vinho Verde’) Using Different LCA Methods. J. Clean. Prod. 2014, 68, 46–55. [Google Scholar] [CrossRef]

- Borsato, E.; Giubilato, E.; Zabeo, A.; Lamastra, L.; Criscione, P.; Tarolli, P.; Marinello, F.; Pizzol, L. Comparison of Water-Focused Life Cycle Assessment and Water Footprint Assessment: The Case of an Italian Wine. Sci. Total Environ. 2019, 666, 1220–1231. [Google Scholar] [CrossRef]

- Gazulla, C.; Raugei, M.; Fullana-I-Palmer, P. Taking a Life Cycle Look at Crianza Wine Production in Spain: Where Are the Bottlenecks? Int. J. Life Cycle Assess. 2010, 15, 330–337. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T.; Feijoo, G. Environmental Analysis of Ribeiro Wine from a Timeline Perspective: Harvest Year Matters When Reporting Environmental Impacts. J. Environ. Manag. 2012, 98, 73–83. [Google Scholar] [CrossRef]

- Laca, A.; Gancedo, S.; Laca, A.; Díaz, M. Assessment of the Environmental Impacts Associated with Vineyards and Winemaking. A Case Study in Mountain Areas. Environ. Sci. Pollut. Res. 2021, 28, 1204–1223. [Google Scholar] [CrossRef]

- Masotti, P.; Zattera, A.; Malagoli, M.; Bogoni, P. Environmental Impacts of Organic and Biodynamic Wine Produced in Northeast Italy. Sustainability 2022, 14, 6281. [Google Scholar] [CrossRef]

- Chiriacò, M.V.; Belli, C.; Chiti, T.; Trotta, C.; Sabbatini, S. The Potential Carbon Neutrality of Sustainable Viticulture Showed through a Comprehensive Assessment of the Greenhouse Gas (GHG) Budget of Wine Production. J. Clean. Prod. 2019, 225, 435–450. [Google Scholar] [CrossRef]

- Neto, B.; Dias, A.C.; Machado, M. Life Cycle Assessment of the Supply Chain of a Portuguese Wine: From Viticulture to Distribution. Int. J. Life Cycle Assess. 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Martins, A.A.; Araújo, A.R.; Graça, A.; Caetano, N.S.; Mata, T.M. Towards Sustainable Wine: Comparison of Two Portuguese Wines. J. Clean. Prod. 2018, 183, 662–676. [Google Scholar] [CrossRef]

- Roselli, L.; Casieri, A.; de Gennaro, B.C.; Sardaro, R.; Russo, G. Environmental and Economic Sustainability of Table Grape Production in Italy. Sustainability 2020, 12, 3670. [Google Scholar] [CrossRef]

- Falcone, G.; Strano, A.; Stillitano, T.; De Luca, A.I.; Iofrida, N.; Gulisano, G. Integrated Sustainability Appraisal of Wine-Growing Management Systems through LCA and LCC Methodologies. Chem. Eng. Trans. 2015, 44, 223–228. [Google Scholar] [CrossRef]

- Falcone, G.; De Luca, A.I.; Stillitano, T.; Strano, A.; Romeo, G.; Gulisano, G. Assessment of Environmental and Economic Impacts of Vine-Growing Combining Life Cycle Assessment, Life Cycle Costing and Multicriterial Analysis. Sustainability 2016, 8, 793. [Google Scholar] [CrossRef]

- Rouault, A.; Beauchet, S.; Renaud-Gentie, C.; Jourjon, F. Life Cycle Assessment of Viticultural Technical Management Routes (TMRs): Comparison between an Organic and an Integrated Management Route. Journal International des Sciences de la Vigne et du Vin 2016, 50. [Google Scholar] [CrossRef]

- Tsangas, M.; Gavriel, I.; Doula, M.; Xeni, F.; Zorpas, A.A. Life Cycle Analysis in the Framework of Agricultural Strategic Development Planning in the Balkan Region. Sustainability 2020, 12, 1813. [Google Scholar] [CrossRef]

- Dede, D.; Didaskalou, E.; Bersimis, S.; Georgakellos, D. A Statistical Framework for Assessing Environmental Performance of Quality Wine Production. Sustainability 2020, 12, 10246. [Google Scholar] [CrossRef]

- Vantarakis, G.C.; Abeliotis, K.; Karathanos, V.T. Environmental Impact Assessment of Protected Designation of Origin (PDO) Foods: The Case of Vostizza Corinthian Currants in Greece. Euro-Mediterr. J. Environ. Integr. 2022, 7, 131–140. [Google Scholar] [CrossRef]

- Balafoutis, A.T.; Koundouras, S.; Anastasiou, E.; Fountas, S.; Arvanitis, K. Life Cycle Assessment of Two Vineyards after the Application of Precision Viticulture Techniques: A Case Study. Sustainability 2017, 9, 997. [Google Scholar] [CrossRef]

- Fountas, S.; Mylonas, N.; Malounas, I.; Rodias, E.; Santos, C.H.; Pekkeriet, E. Agricultural Robotics for Field Operations. Sensors 2020, 20, 2672. [Google Scholar] [CrossRef] [PubMed]

- VINEROBOT Deliverable 2.3: First Field Demonstration. Basic Mobility and Navigation of the Robot. Available online: https://www.vinerobot.eu/wp-content/uploads/2015/12/Deliverable-2_3_First-demo-report.pdf (accessed on 15 January 2023).

- Álvarez Fernández, S.; Prieto López, D.; Nistal Freije, V.; González Cueva, M.; Ribeiro, Á.; Bengochea, J.M.; Todeschini, M.; Andujar, D.; Valente, J.; Ariza Sentís, M.; et al. D4.1 Pilot 1 Objectives, Requirements and Design. 2021. Available online: https://flexigrobots-h2020.eu/sites/flexig/files/public/content-files/deliverables/FLEXIGROBOTS_D4.1.%20Pilot%201%20objectives%2C%20requirements%20and%20design_v1.0.pdf (accessed on 19 January 2023).

- Thayer, T.C.; Vougioukas, S.; Goldberg, K.; Carpin, S. Multi-Robot Routing Algorithms for Robots Operating in Vineyards. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Munich, Germany, 20–24 August 2018. [Google Scholar]

- Thayer, T.C.; Vougioukas, S.; Goldberg, K.; Carpin, S. Bi-Objective Routing for Robotic Irrigation and Sampling in Vineyards. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Vancouver, BC, Canada, 22–26 August 2019. [Google Scholar]

- Lacotte, V.; NGuyen, T.; Sempere, J.D.; Novales, V.; Dufour, V.; Moreau, R.; Pham, M.T.; Rabenorosoa, K.; Peignier, S.; Feugier, F.G.; et al. Pesticide-Free Robotic Control of Aphids as Crop Pests. AgriEngineering 2022, 4, 903–921. [Google Scholar] [CrossRef]

- Urdal, F.; Utstumo, T.; Vatne, J.K.; Ellingsen, S.A.A.; Gravdahl, J.T. Design and Control of Precision Drop-on-Demand Herbicide Application in Agricultural Robotics. In Proceedings of the 2014 13th International Conference on Control Automation Robotics and Vision, ICARCV, Singapore, 10–12 December 2014. [Google Scholar]

- Pradel, M.; de Fays, M.; Séguineau, C. Comparative Life Cycle Assessment of Intra-Row and Inter-Rows Weeding Practices Using Autonomous Robot Systems in French Vineyards. SSRN Electron. J. 2022, 838, 156441. [Google Scholar] [CrossRef]

- Saidani, M.; Pan, Z.; Kim, H.; Wattonville, J.; Greenlee, A.; Shannon, T.; Yannou, B.; Leroy, Y.; Cluzel, F. Comparative Life Cycle Assessment and Costing of an Autonomous Lawn Mowing System with Human-Operated Alternatives: Implication for Sustainable Design Improvements. Int. J. Sustain. Eng. 2021, 14, 704–724. [Google Scholar] [CrossRef]

- Lagnelöv, O.; Larsson, G.; Larsolle, A.; Hansson, P.A. Life Cycle Assessment of Autonomous Electric Field Tractors in Swedish Agriculture. Sustainability 2021, 13, 11285. [Google Scholar] [CrossRef]

- Lowenberg-DeBoer, J.; Huang, I.Y.; Grigoriadis, V.; Blackmore, S. Economics of Robots and Automation in Field Crop Production. Precis. Agric. 2020, 21, 278–299. [Google Scholar] [CrossRef]

- Lytridis, C.; Kaburlasos, V.G.; Pachidis, T.; Manios, M.; Vrochidou, E.; Kalampokas, T.; Chatzistamatis, S. An Overview of Cooperative Robotics in Agriculture. Agronomy 2021, 11, 1818. [Google Scholar] [CrossRef]

- Choset, H.; Lynch, M.K.; Hutchinson, S.; Kantor, A.G.; Burgard, W.; Kavraki, E.L.; Thrun, S. Principles of Robot Motion Theory, Algorithms, and Implementations; MIT Press: Cambridge, MA, USA, 2005; ISBN 9780262033275. [Google Scholar]

- Delmerico, J.; Mueggler, E.; Nitsch, J.; Scaramuzza, D. Active Autonomous Aerial Exploration for Ground Robot Path Planning. IEEE Robot. Autom. Lett. 2017, 2, 664–671. [Google Scholar] [CrossRef]

- Guzman, R.; Arino, J.; Navarro, R.; Lopes, C.; Graça, J.; Reyes, M.; Barriguinha, A.; Braga, R. Autonomous Hybrid Gps/Reactive Navigation of an Unmanned Ground Vehicle for Precision Viticulture—VINBOT; University of Lisbon: Lisbon, Portugal, 2016. [Google Scholar]

- Duffy, B.; Joue, G. Intelligent Robots: The Question of Embodiment. In Proceedings of BRAIN-MACHINE 2000 Workshop; University College Dublin: Dublin, Ireland, 2000. [Google Scholar]

- Kaburlasos, V.G.; Pachidis, T. A Lattice-Computing Ensemble for Reasoning Based on Formal Fusion of Disparate Data Types, and an Industrial Dispensing Application. Inf. Fusion 2014, 16, 68–83. [Google Scholar] [CrossRef]

- Kaburlasos, V.G. Lattice Computing: A Mathematical Modelling Paradigm for Cyber-Physical System Applications. Mathematics 2022, 10, 271. [Google Scholar] [CrossRef]

- Kaburlasos, V.G. The Lattice Computing (LC) Paradigm. In CEUR Workshop Proceedings; International Hellenic University: Kavala, Greece, 2020. [Google Scholar]

- Robotnik RB-EKEN 5 Technical Specifications Datasheet. Available online: https://robotnik.eu/wp-content/uploads/2022/02/Robotnik-DATASHEET-RB-EKEN-5-EN-220209.pdf (accessed on 30 December 2022).

- Robotnik RB-VOGUI MOBILE ROBOT Technical Specifications Datasheet. Available online: https://robotnik.eu/wp-content/uploads/2022/02/Robotnik-RB-VOGUIDatasheet-211212-EN.pdf (accessed on 30 December 2022).

- Svinartchuk, T.; Hunziker, P.; Novello, V.; Tonni, M.; Corbet-Milward, J.; de la Fuente, M.; Costa, D. Methodological Recommendations for Accounting for GHG Balance in the Vitivinicultural Sector. Available online: https://www.oiv.int/public/medias/5519/methodological-ghg-balance.pdf (accessed on 8 December 2022).

- Tziolas, E.; Ispikoudis, S.; Mantzanas, K.; Koutsoulis, D.; Pantera, A. Economic and Environmental Assessment of Olive Agroforestry Practices in Northern Greece. Agriculture 2022, 12, 851. [Google Scholar] [CrossRef]

- Vaskan, P.; Pachón, E.R.; Gnansounou, E. Life Cycle Assessment of Sugar Crops and Starch-Based Integrated Biorefineries. In Life-Cycle Assessment of Biorefineries; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 9780444635860. [Google Scholar]

- Brentrup, F.; Küsters, J.; Kuhlmann, H.; Lammel, J. Environmental Impact Assessment of Agricultural Production Systems Using the Life Cycle Assessment Methodology: I. Theoretical Concept of a LCA Method Tailored to Crop Production. Eur. J. Agron. 2004, 20, 247–264. [Google Scholar] [CrossRef]

- Corrado, S.; Castellani, V.; Zampori, L.; Sala, S. Systematic Analysis of Secondary Life Cycle Inventories When Modelling Agricultural Production: A Case Study for Arable Crops. J. Clean. Prod. 2018, 172, 3990–4000. [Google Scholar] [CrossRef] [PubMed]

- Biograce II Harmonised Greenhouse Gas Calculations for Electricity, Heating and Cooling from Biomass, Calculation Rules 4a; Biograce: Delhi, India, 2021.

- EC Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Official Journal of the European Union. 2018. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjqrtu1wfb8AhWDrVYBHT8qAFsQFnoECBgQAQ&url=https%3A%2F%2Feur-lex.europa.eu%2Flegal-content%2FEN%2FTXT%2FPDF%2F%3Furi%3DCELEX%3A32018L2001&usg=AOvVaw28E3vJb4j-I3mDMed04_C (accessed on 21 December 2018).

- ASAE American Society of Agricultural and Biological Engineers. D497.7 MAR2011 Agricultural Machinery Management Data. Test 2011, 9. [Google Scholar]

- Rozakis, S.; Haque, M.I.; Natsis, A.; Borzecka-Walker, M.; Mizak, K. Cost-Effectiveness of Bioethanol Policies to Reduce Carbon Dioxide Emissions in Greece. Int. J. Life Cycle Assess. 2013, 18, 306–318. [Google Scholar] [CrossRef]

- Diacono, M.; Persiani, A.; Testani, E.; Montemurro, F.; Ciaccia, C. Recycling Agricultural Wastes and By-Products in Organic Farming: Biofertilizer Production, Yield Performance and Carbon Footprint Analysis. Sustainability 2019, 11, 3824. [Google Scholar] [CrossRef]

- Taxidis, E.T.; Menexes, G.C.; Mamolos, A.P.; Tsatsarelis, C.A.; Anagnostopoulos, C.D.; Kalburtji, K.L. Comparing Organic and Conventional Olive Groves Relative to Energy Use and Greenhouse Gas Emissions Associated with the Cultivation of Two Varieties. Appl. Energy 2015, 149, 117–124. [Google Scholar] [CrossRef]

- Genitsariotis, M.; Chlioumis, G.; Tsarouhas, B.; Tsatsarelis, K.; Sfakiotakis, E. Energy and Nutrient Inputs and Outputs of a Typical Olive Orchard in Northern Greece. Acta Hortic. 2000, 525, 455–458. [Google Scholar] [CrossRef]

- White, R.; Taiganides, E. Pyrolysis of Livestock Manure, Livestock Manure Management. In Proceedings of the 2nd International Symposium on Livestock Manure; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1971; pp. 190–191. [Google Scholar]

- Zhu, Z.; Li, L.; Dong, H.; Wang, Y. Ammonia and Greenhouse Gas Emissions of Different Types of Livestock and Poultry Manure during Storage. Trans. ASABE 2020, 63, 1723–1733. [Google Scholar] [CrossRef]

- Cech, R.; Leisch, F.; Zaller, J.G. Pesticide Use and Associated Greenhouse Gas Emissions in Sugar Beet, Apples, and Viticulture in Austria from 2000 to 2019. Agriculture 2022, 12, 879. [Google Scholar] [CrossRef]

- Kaltsas, A.M.; Mamolos, A.P.; Tsatsarelis, C.A.; Nanos, G.D.; Kalburtji, K.L. Energy Budget in Organic and Conventional Olive Groves. Agric. Ecosyst. Environ. 2007, 122, 243–251. [Google Scholar] [CrossRef]

- Kavargiris, S.E.; Mamolos, A.P.; Tsatsarelis, C.A.; Nikolaidou, A.E.; Kalburtji, K.L. Energy Resources’ Utilization in Organic and Conventional Vineyards: Energy Flow, Greenhouse Gas Emissions and Biofuel Production. Biomass Bioenergy 2009, 33, 1239–1250. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Brzozowska, A.; Stebila, J. Life Cycle Energy Consumption and Carbon Dioxide Emissions of Agricultural Residue Feedstock for Bioenergy. Appl. Sci. 2021, 11, 2009. [Google Scholar] [CrossRef]

- Soni, P.; Sinha, R.; Perret, S.R. Energy Use and Efficiency in Selected Rice-Based Cropping Systems of the Middle-Indo Gangetic Plains in India. Energy Rep. 2018, 4, 554–564. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Čipliene, A. Estimation of Carbon-Oxide Emissions of Tractors during Operation and Correlation with the Not-to-Exceed Zone. Biosyst. Eng. 2016, 147, 117–129. [Google Scholar] [CrossRef]

- Sørensen, C.G.; Halberg, N.; Oudshoorn, F.W.; Petersen, B.M.; Dalgaard, R. Energy Inputs and GHG Emissions of Tillage Systems. Biosyst. Eng. 2014, 120, 2–14. [Google Scholar] [CrossRef]

- Mantoam, E.J.; Romanelli, T.L.; Gimenez, L.M. Energy Demand and Greenhouse Gases Emissions in the Life Cycle of Tractors. Biosyst. Eng. 2016, 151, 158–170. [Google Scholar] [CrossRef]

- Gemtos, T.A.; Cavalaris, C.; Karamoutis, C.; Tagarakis, A.; Fountas, S. Energy Analysis of Three Energy Crops in Greece. Agric. Eng. Int. CIGR J. 2013, 15, 52–66. [Google Scholar]

- Smart Freight Centre. Cefic Calculating GHG Transport and Logistics Emissions for the European Chemical Industry; Smart Freight Center: Amsterdam, The Netherlands, 2021. [Google Scholar]

- World Resources Institute GHG Protocol Agricultural Guidance Interpreting the Corporate Accounting and Reporting Standard for the Agricultural Sector. Available online: https://ghgprotocol.org/sites/default/files/standards/GHG%20Protocol%20Agricultural%20Guidance%20%28April%2026%29_0.pdf (accessed on 15 August 2022).

- Lynch, J.; Cain, M.; Pierrehumbert, R.; Allen, M. Demonstrating GWP: A Means of Reporting Warming-Equivalent Emissions That Captures the Contrasting Impacts of Short—A Nd Long-Lived Climate Pollutants. Environ. Res. Lett. 2020, 15, 044023. [Google Scholar] [CrossRef] [PubMed]

- Blancard, S.; Martin, E. Energy Efficiency Measurement in Agriculture with Imprecise Energy Content Information. Energy Policy 2014, 66, 198–208. [Google Scholar] [CrossRef]

- Patterson, M.G. What Is Energy Efficiency? Concepts, Indicators and Methodological Issues. Energy Policy 1996, 24, 377–390. [Google Scholar] [CrossRef]

- Mahmoud, M.; Cheikh, N.; Cerny, O.; Gerard, F.; Lemoin, P. The Road to Energy Efficiency. Available online: https://www.europarl.europa.eu/RegData/etudes/STUD/2021/695480/IPOL_STU(2021)695480_EN.pdf (accessed on 15 August 2022).

- Laborde, D.; Mamun, A.; Martin, W.; Piñeiro, V.; Vos, R. Agricultural Subsidies and Global Greenhouse Gas Emissions. Nat. Commun. 2021, 12, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Mrówczyńska-Kamińska, A.; Bajan, B.; Pawłowski, K.P.; Genstwa, N.; Zmyślona, J. Greenhouse Gas Emissions Intensity of Food Production Systems and Its Determinants. PLoS ONE 2021, 16, e0250995. [Google Scholar] [CrossRef]

- RStudio Team RStudio: Integrated Development Environment for R 2020. Available online: https://www.r-project.org/conferences/useR-2011/abstracts/180111-allairejj.pdf (accessed on 15 August 2022).

- Petti, L.; Arzoumanidis, I.; Benedetto, G.; Bosco, S.; Cellura, M.; De Camillis, C.; Fantin, V.; Masotti, P.; Pattara, C.; Raggi, A.; et al. Life Cycle Assessment in the Wine Sector. In Life Cycle Assessment in the Agri-food Sector; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Steenwerth, K.L.; Strong, E.B.; Greenhut, R.F.; Williams, L.; Kendall, A. Life Cycle Greenhouse Gas, Energy, and Water Assessment of Wine Grape Production in California. Int. J. Life Cycle Assess. 2015, 20, 1243–1253. [Google Scholar] [CrossRef]

- Marras, S.; Masia, S.; Duce, P.; Spano, D.; Sirca, C. Carbon Footprint Assessment on a Mature Vineyard. Agric. For. Meteorol. 2015, 214–215, 350–356. [Google Scholar] [CrossRef]

- Gierling, F.; Blanke, M. Lower Carbon Footprint from Grapevine Cultivation on Steep Slopes Compared with Flat Terrain? A Case Study. Acta Hortic. 2021, 1327, 703–706. [Google Scholar] [CrossRef]

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Comparative Life Cycle Assessment in the Wine Sector: Biodynamic vs. Conventional Viticulture Activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- Litskas, V.D.; Irakleous, T.; Tzortzakis, N.; Stavrinides, M.C. Determining the Carbon Footprint of Indigenous and Introduced Grape Varieties through Life Cycle Assessment Using the Island of Cyprus as a Case Study. J. Clean. Prod. 2017, 156, 418–425. [Google Scholar] [CrossRef]

- Rashidov, N.; Chowaniak, M.; Niemiec, M.; Mamurovich, G.S.; Gufronovich, M.J.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Sikora, J.; Kuboń, M.; Komorowska, M. Assessment of the Multiannual Impact of the Grape Training System on GHG Emissions in North Tajikistan. Energies 2021, 14, 6160. [Google Scholar] [CrossRef]

- Pedersen, S.M.; Fountas, S.; Blackmore, S. Agricultural Robots—Applications and Economic Perspectives. In Service Robot Applications; InTech: Houston, TX, USA, 2008; p. 16. [Google Scholar]

- Pedersen, S.M.; Fountas, S.; Have, H.; Blackmore, B.S. Agricultural Robots—System Analysis and Economic Feasibility. Precis. Agric. 2006, 7, 295–308. [Google Scholar] [CrossRef]

- Romero Schmidt, J.; Auat Cheein, F. Assessment of Power Consumption of Electric Machinery in Agricultural Tasks for Enhancing the Route Planning Problem. Comput. Electron. Agric. 2019, 163, 104868. [Google Scholar] [CrossRef]

- Gil, G.; Casagrande, D.E.; Cortés, L.P.; Verschae, R. Why the Low Adoption of Robotics in the Farms? Challenges for the Establishment of Commercial Agricultural Robots. Smart Agric. Technol. 2023, 3, 100069. [Google Scholar] [CrossRef]

- Ryan, M.; van der Burg, S.; Bogaardt, M.-J. Identifying Key Ethical Debates for Autonomous Robots in Agri-Food: A Research Agenda. AI Ethics 2022, 2, 493–507. [Google Scholar] [CrossRef]

- FAO. Brief to The State of Food and Agriculture 2022; FAO: Rome, Italy, 2022; ISBN 978-92-5-137005-6. [Google Scholar]

- Vrochidou, E.; Pachidis, T.; Manios, M.; Papakostas, G.A.; Kaburlasos, V.G.; Theocharis, S.; Koundouras, S.; Karabatea, K.; Bouloumpasi, E.; Pavlidis, S.; et al. Identifying the Technological Needs for Developing a Grapes Harvesting Robot: Operations and Systems. In CEUR Workshop Proceedings; International Hellenic University: Kavala, Greece, 2020. [Google Scholar]

- Vrochidou, E.; Bazinas, C.; Mavridou, E.; Pachidis, T.; Mamalis, S.; Koundouras, S.; Gkrimpizis, T.; Kaburlasos, V.G. Considerations for a Multi-Purpose Agrobot Design toward Automating Skillful Viticultural Tasks: A Study in Northern Greece Vineyards. In Proceedings of the 10th International Conference on Information and Communication Technologies in Agriculture, Food & Environment (HAICTA 2022), Athens, Greece, 22–25 September 2022; p. 7. [Google Scholar]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wäger, P.; Stamp, A.; Zah, R.; Althaus, H.J. Contribution of Li-Ion Batteries to the Environmental Impact of Electric Vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef]

| Cultivar/Rootstock | Tempranillo/110 Richter | Asyrtiko/1103 Paulsen | Cabernet Sauvignon/SO4 | Merlot/SO4 |

|---|---|---|---|---|

| Winery | LOC1 Ktima Pavlidis winery | LOC1 Ktima Pavlidis winery | LOC2 Nico Lazaridi winery | LOC2 Nico Lazaridi winery |

| Coordinates (HGRS87/EGSA87) (Lat, Lon) | 41.200400 N, 23.953084 E | 41.127832 Ν, 24.275972 Ε | ||

| Elevation | 200 m | 190 m | ||

| Planting distance/orientation | 2.2 X 1.2/NE–SW | 2.2 X 1.2/NW–SE | 2.2 X 1.2/N–S | |

| Vines/ha | 3780 | 3330 | ||

| Inputs | Unit | Energy Content | GHG Unit | GHGs | Remarks |

|---|---|---|---|---|---|

| Agrochemicals | |||||

| Ν | MJ/kg | 48.99 | gCO2eq/kg | 4524.41 | [68] |

| Ρ | MJ/kg | 15.23 | gCO2eq/kg | 541.67 | [68] |

| Κ | MJ/kg | 9.68 | gCO2eq/kg | 416.67 | [68] |

| Olive pomace res | MJ/kg | 20.75 | gCO2eq/kg | 67.00 | [72,73,74] |

| Poultry manure | MJ/kg | 8.40 | gCO2eq/kg | 148.62 | [73,75,76] |

| Fungicides | MJ/kg | 99.00 | gCO2eq/kg | 3,900.00 | [77,78] |

| Herbicides | MJ/kg | 418.00 | gCO2eq/kg | 9,100.00 | [77,79] |

| Energy | |||||

| Lubricants | MJ/kg | 53.28 | gCO2eq/kg | 947.00 | [68] |

| Diesel | MJ/kg | 56.80 | gCO2eq/MJ | 95.10 | [68,80] |

| Petrol | MJ/kg | 60.20 | gCO2eq/MJ | 93.30 | [68,80] |

| Electricity | MJ/MJ | 2.73 | gCO2eq/MJ | 243.49 | [68] |

| Operations, maintenance, and manufacturing | |||||

| Tractor | MJ/h | 16.42 | gCO2eq/h | 9800 | [81,82] |

| Human | MJ/h | 1.80 | gCO2eq | - | [81] |

| Machinery | MJ/h | 0.10–35.05 | gCO2eq/h | 0.10–190 | [73,83,84] |

| RB-EKEN | MJ/h | 2.59 | gCO2eq | - | - |

| RB-VOGUI | MJ/h | 0.65 | gCO2eq | - | - |

| Irrigation system | MJ/ha | 373.7 | gCO2eq | - | [85] |

| Use of diesel | MJ | - | gCO2eq/MJ | 0.9 | [68] |

| Transportation | |||||

| Supplies | MJ/t.km | 0.87 | gCO2eq/t.km | 71 | [68,86] |

| Biomass | MJ/t.km | 0.81 | gCO2eq/t.km | 71 | [68,86] |

| Inputs | Unit | Asyrtiko | Tempranillo | Cabernet Sauvignon | Merlot |

|---|---|---|---|---|---|

| Acreage | ha | 2.9 | 2.2 | 2.4 | 1.9 |

| Crop yield | t/ha | 9.63 | 8.02 | 5.32 | 5.05 |

| Irrigation (energy) | MJ/ha | 884.52 | 884.52 | 442.26 | 442.26 |

| Borehole depth | m | 180 | 180 | 90 | 90 |

| N-based fertilizers | kg/ha | 33 | 3 | 15 | 10.5 |

| P-based fertilizers | kg/ha | 3 | 3 | 15 | 10.5 |

| K-based fertilizers | kg/ha | 3 | 3 | 21.5 | 14.88 |

| Poultry manure | kg/ha | - | - | 244 | 940 |

| Olive pomace res | kg/ha | - | - | 1100 | - |

| Fungicides | kg/ha | 25 | 25 | 15.44 | 8 |

| Herbicides | kg/ha | - | - | - | 3.5 |

| Diesel | lt/ha | 255 | 238 | 111.8 | 142 |

| Petrol | lt/ha | 40 | 40 | 20 | 20 |

| Residues | t/ha | 4.2 | 3.9 | 1.5 | 1.5 |

| Human labor | h/ha | 447.5 | 450 | 308.66 | 401.25 |

| Tractor | h/ha | 32.5 | 30 | 23.7 | 32.75 |

| Scenario | Unit | AC | ACB | CC | CCB | MC | MCB | TC | TCB |

|---|---|---|---|---|---|---|---|---|---|

| Consumed energy | MJ ha−1 | 27,281.80 | 16,304.33 | 25,643.95 | 21,642.95 | 25,014.93 | 18,633.65 | 25,648.47 | 14,703.07 |

| GHG emissions | kg CO2-eq ha−1 | 2570.57 | 1456.57 | 1428.74 | 980.16 | 1678.68 | 1125.43 | 2308.90 | 1210.23 |

| Scenario | Agrochemicals | Electric Energy | Fossil Fuels | Machinery | Other |

|---|---|---|---|---|---|

| AC | 9.71% | 8.38% | 62.32% | 14.60% | 4.98% |

| ACB | 17.14% | 18.21% | 44.13% | 12.35% | 8.18% |

| CC | 17.85% | 7.54% | 50.13% | 18.87% | 5.62% |

| CCB | 26.02% | 15.17% | 37.97% | 12.94% | 7.90% |

| MC | 15.62% | 6.41% | 52.38% | 22.15% | 3.43% |

| MCB | 23.29% | 13.02% | 26.64% | 32.44% | 4.61% |

| TC | 4.94% | 9.33% | 69.39% | 15.05% | 1.29% |

| TCB | 9.42% | 21.38% | 54.01% | 13.46% | 1.74% |

| Scenario | Agrochemicals | Electric Energy | Fossil Fuels | Machinery | Other |

|---|---|---|---|---|---|

| AC | 15.27% | 8.85% | 61.92% | 10.14% | 3.82% |

| ACB | 25.55% | 18.24% | 41.46% | 11.48% | 3.28% |

| CC | 54.54% | 4.71% | 29.46% | 8.43% | 2.86% |

| CCB | 64.63% | 7.70% | 18.08% | 6.94% | 2.65% |

| MC | 43.85% | 4.83% | 37.06% | 11.40% | 2.86% |

| MCB | 58.87% | 8.82% | 16.92% | 13.28% | 2.11% |

| TC | 10.51% | 9.41% | 65.86% | 10.34% | 3.87% |

| TCB | 18.34% | 19.73% | 46.74% | 11.83% | 3.36% |

| Scenario | kg CO2 eq kg−1 | Deviation (%) | MJ kg−1 | Deviation (%) |

|---|---|---|---|---|

| AC | 0.267 | −43.34% | 2.833 | −40.24% |

| ACB | 0.151 | 1.693 | ||

| CC | 0.269 | −31.40% | 4.820 | −15.60% |

| CCB | 0.184 | 4.068 | ||

| MC | 0.332 | −32.96% | 4.953 | −25.51% |

| MCB | 0.223 | 3.690 | ||

| TC | 0.288 | −47.58% | 3.198 | −42.67% |

| TCB | 0.151 | 1.833 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tziolas, E.; Karapatzak, E.; Kalathas, I.; Lytridis, C.; Mamalis, S.; Koundouras, S.; Pachidis, T.; Kaburlasos, V.G. Comparative Assessment of Environmental/Energy Performance under Conventional Labor and Collaborative Robot Scenarios in Greek Viticulture. Sustainability 2023, 15, 2753. https://doi.org/10.3390/su15032753

Tziolas E, Karapatzak E, Kalathas I, Lytridis C, Mamalis S, Koundouras S, Pachidis T, Kaburlasos VG. Comparative Assessment of Environmental/Energy Performance under Conventional Labor and Collaborative Robot Scenarios in Greek Viticulture. Sustainability. 2023; 15(3):2753. https://doi.org/10.3390/su15032753

Chicago/Turabian StyleTziolas, Emmanouil, Eleftherios Karapatzak, Ioannis Kalathas, Chris Lytridis, Spyridon Mamalis, Stefanos Koundouras, Theodore Pachidis, and Vassilis G. Kaburlasos. 2023. "Comparative Assessment of Environmental/Energy Performance under Conventional Labor and Collaborative Robot Scenarios in Greek Viticulture" Sustainability 15, no. 3: 2753. https://doi.org/10.3390/su15032753