Conceptual Design of a Semi-Automatic Process Line for Recycling Photovoltaic Panels as a Way to Ecological Sustainable Production

Abstract

1. Introduction

2. Literature Review of the Problem

2.1. The Essence of the Research Problem

2.2. Literature Review of the Analyzed Problem

3. Materials and Methods

3.1. Formulation of Design Assumptions and SWOT Analysis

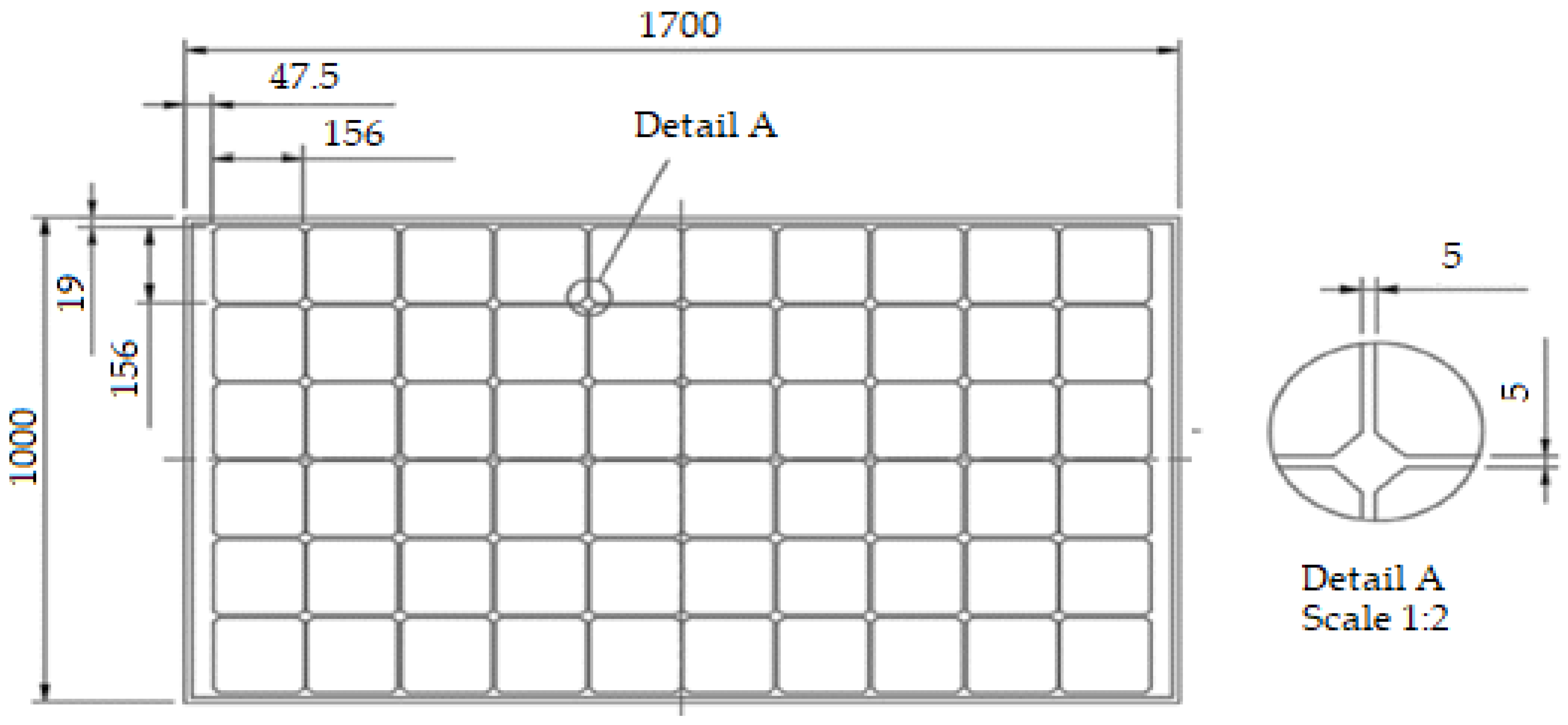

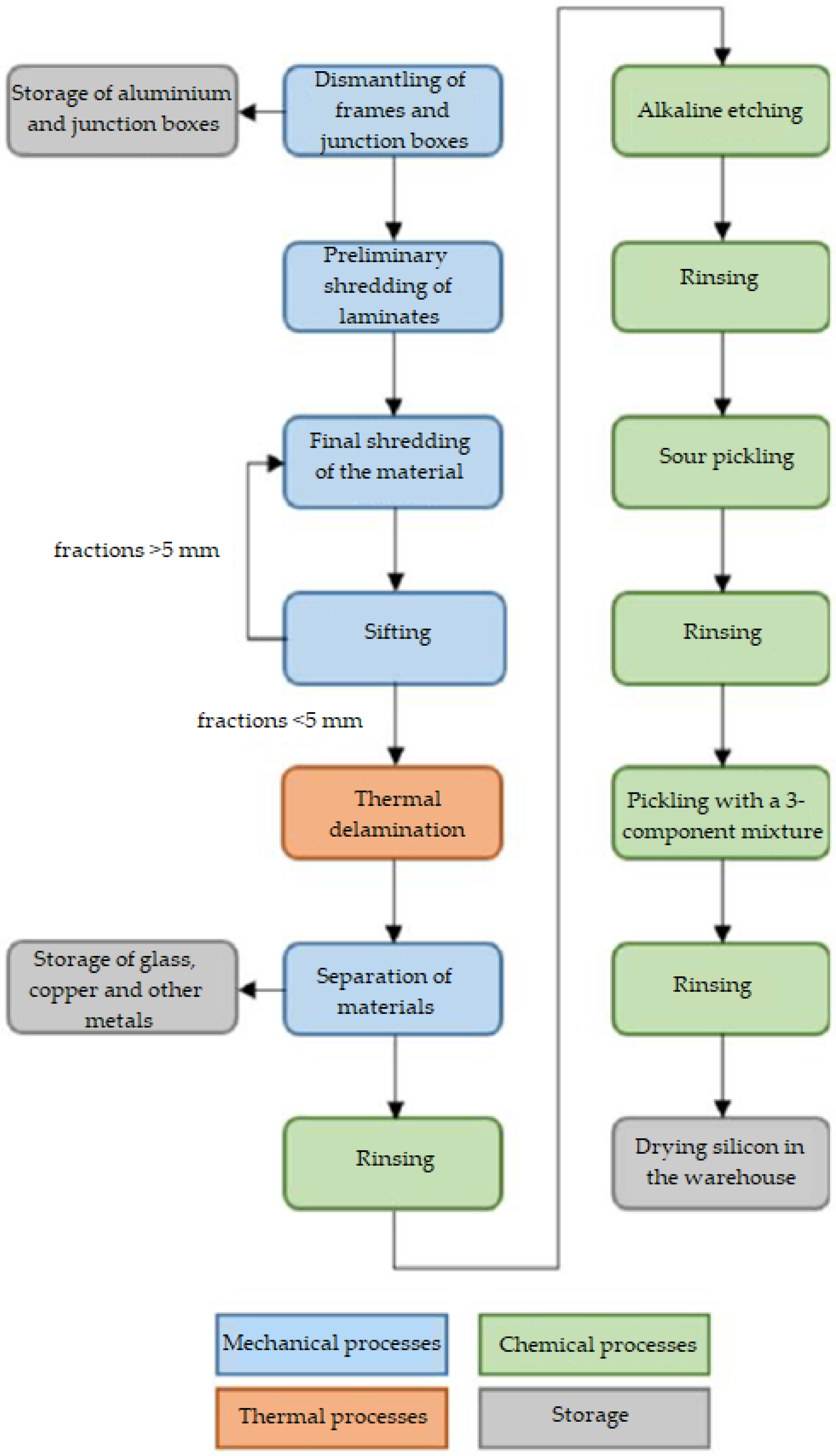

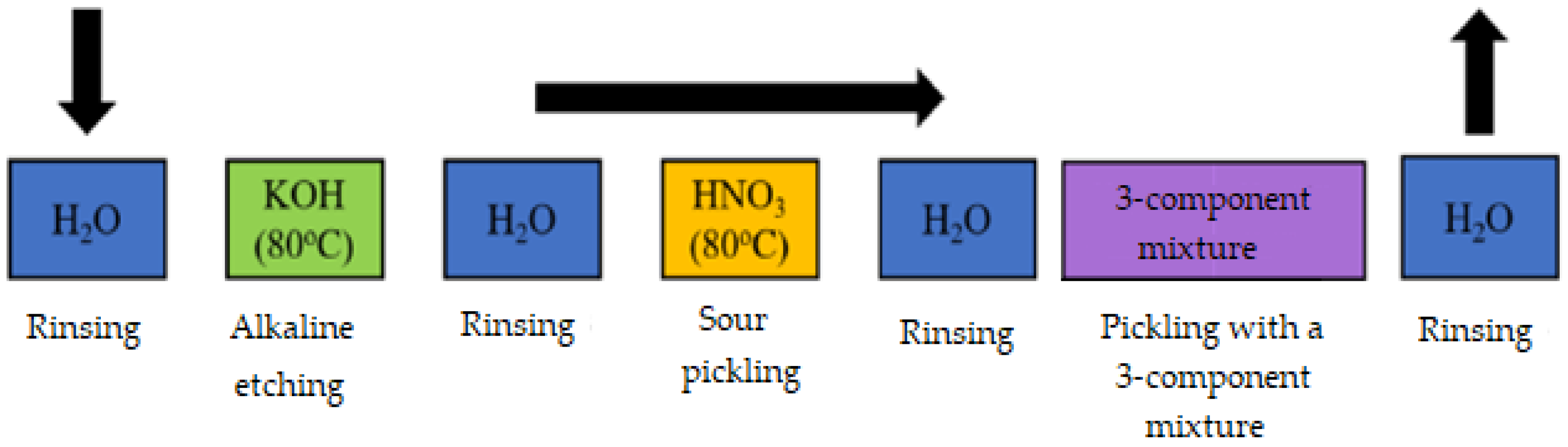

3.2. Development of a Technology for Recycling Photovoltaic Panels

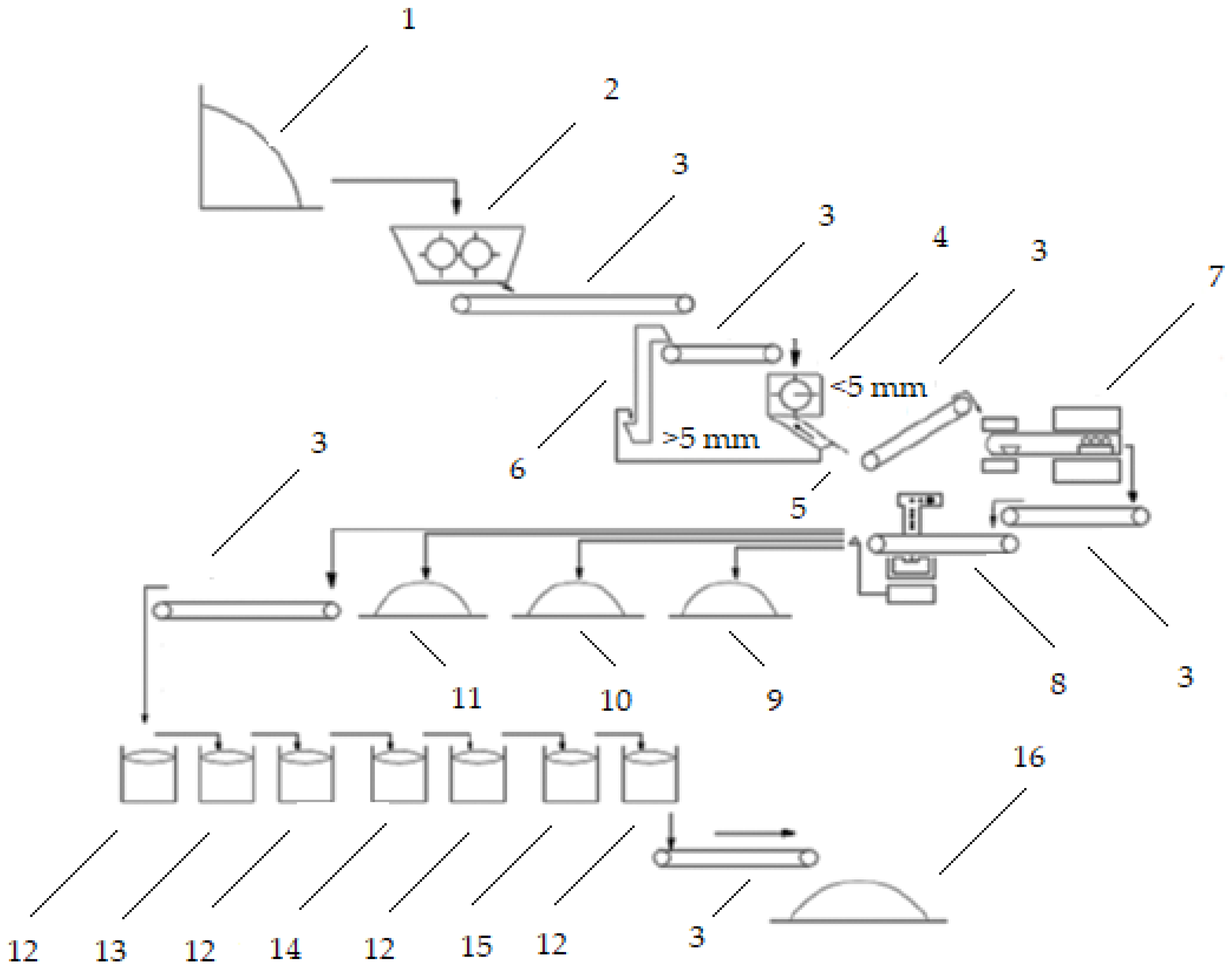

4. Results and Discussion

4.1. Analysis of the Energy Effects

4.2. Development of a Technology for Recycling Photovoltaic Panels

5. Conclusions

- The dynamics of the development of the photovoltaic market in Poland is very high and it will definitely increase in the coming years. Micro and small prosumer installations constitute a large part of the market.

- The amount of electro-waste from photovoltaics will increase significantly in the next 20–30 years. Currently, there are not many companies in the world dealing with the recycling of used PV panels, which creates a good chance for the success of the project.

- Legal regulations concerning the disposal of photovoltaic panels are not sufficiently developed. Legal regulations should be introduced at the government level to facilitate the creation of PV recycling companies.

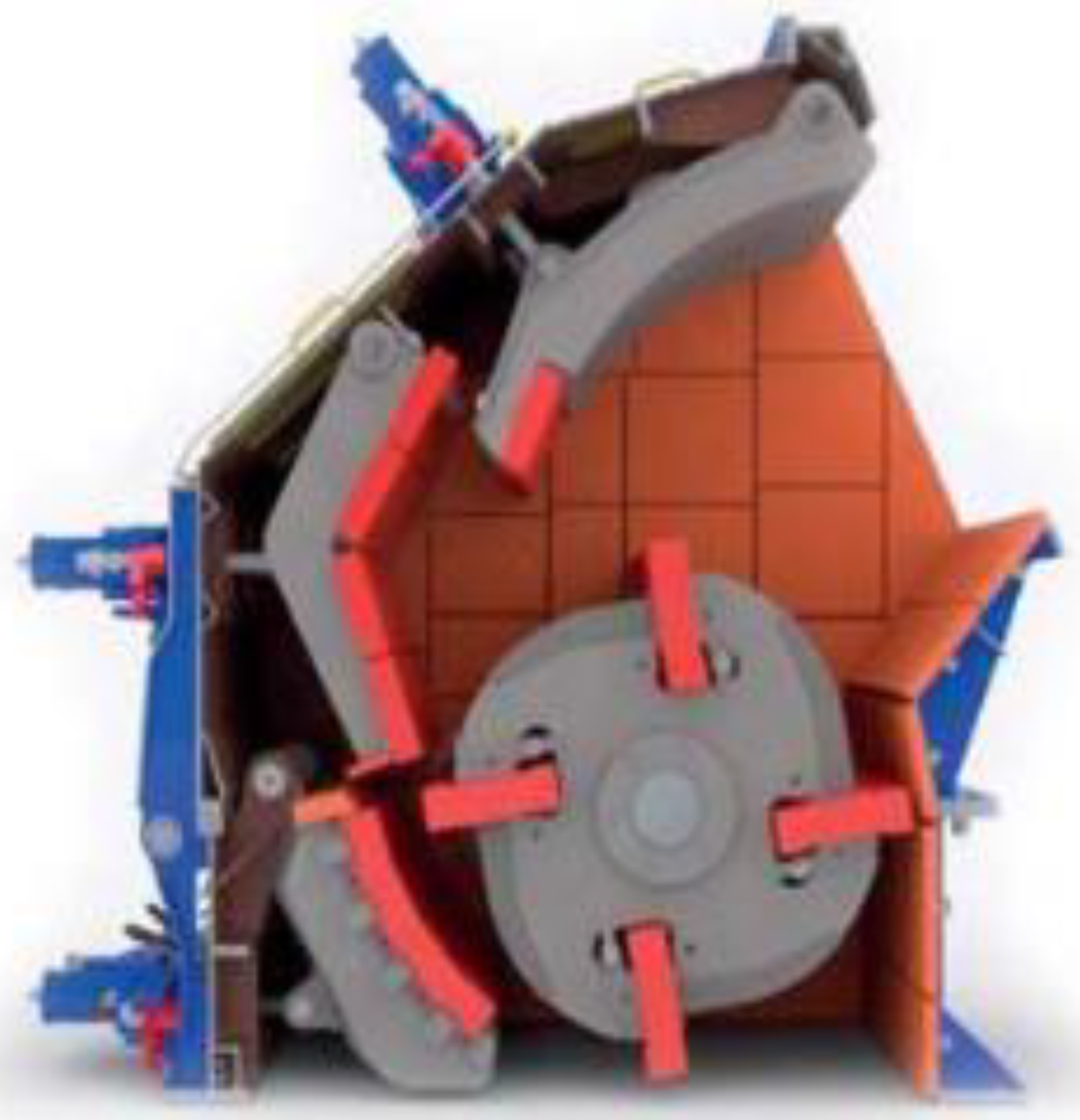

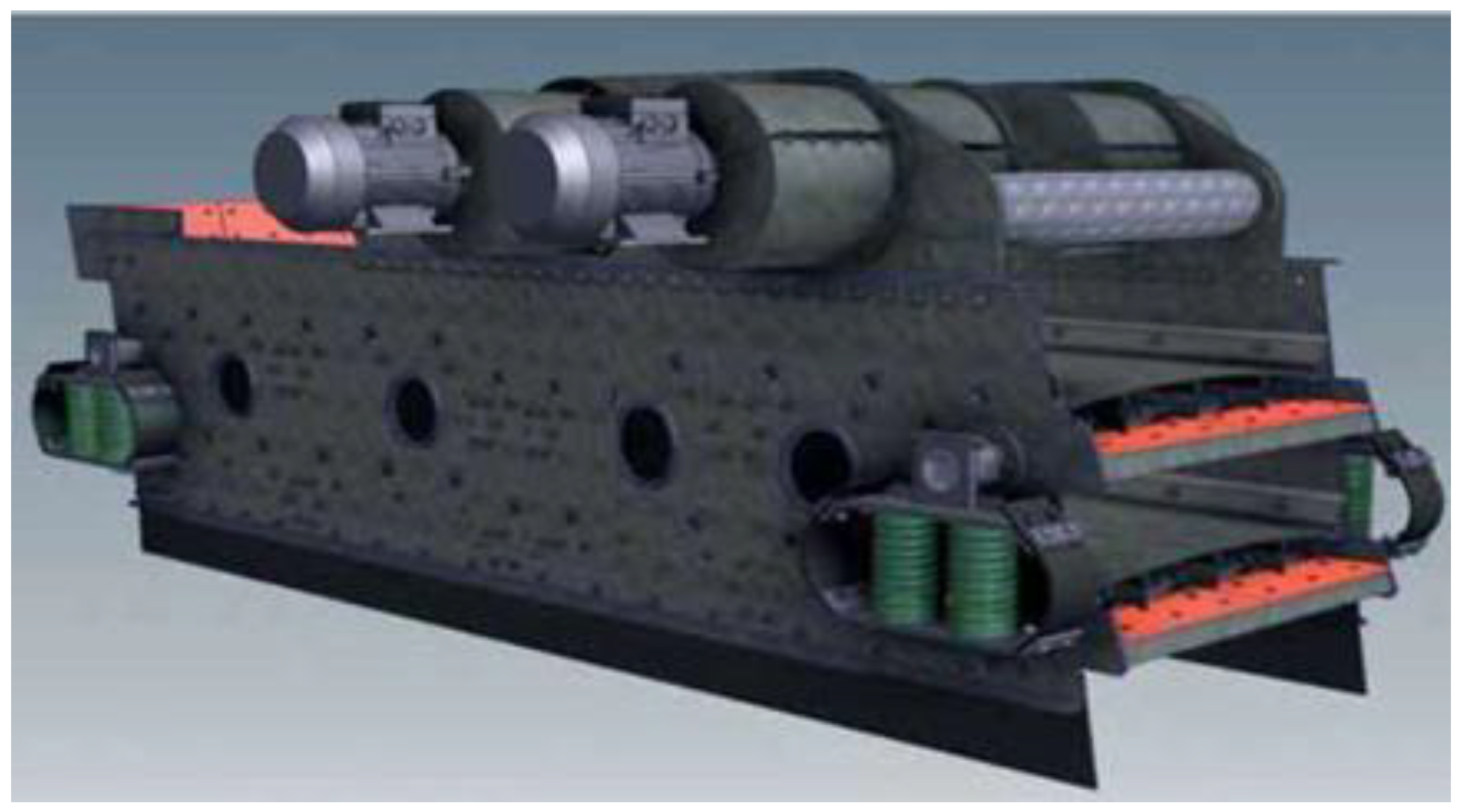

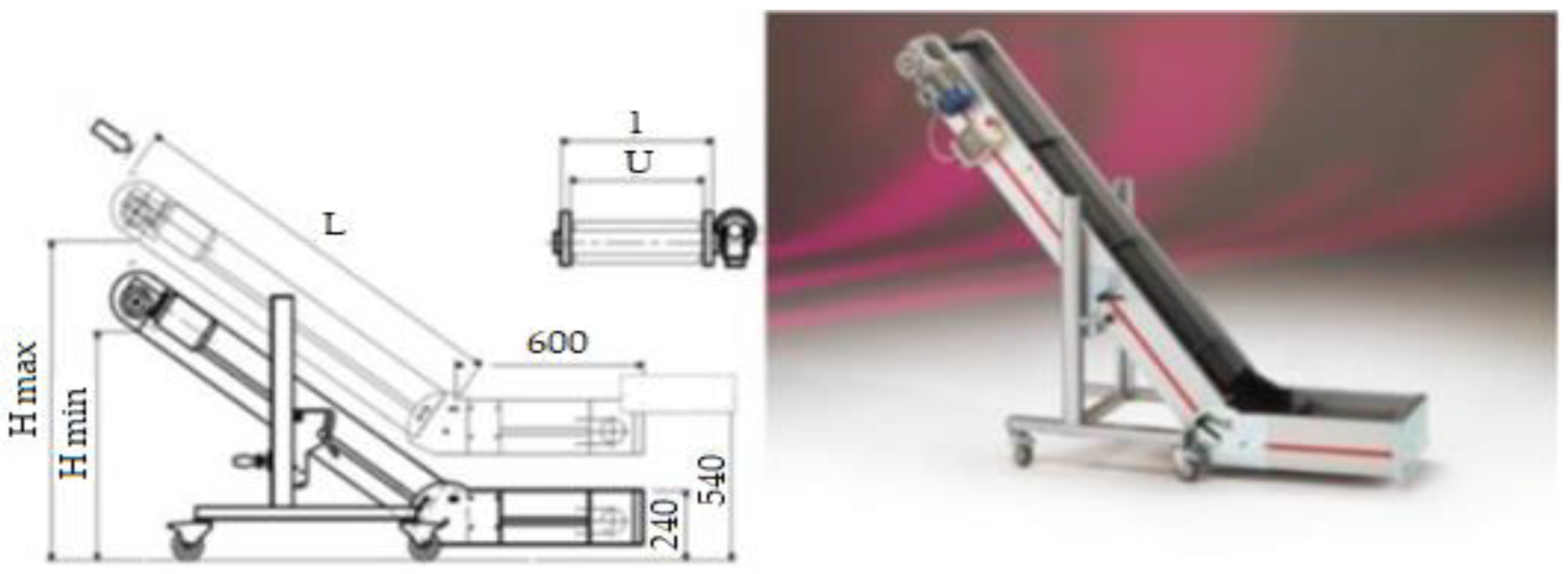

- The process of recycling used photovoltaic panels is a complex and complicated process. The best results in terms of efficiency and environmental friendliness are achieved by recycling the components using mechanical, thermal and chemical processes.

- The tests of separating PV cells from damaged and worn PV modules, and then removing subsequent layers from PV cells in order to recover a clean silicon substrate, on the basis of which it is possible to produce new cells with good parameters, performed as part of the research, have shown that recycling of PV modules is possible. As a result of the tests, it was possible to separate the cells from the PV module and remove the unwanted layers.

- The optimal solution is to use thermal treatment to separate cells from PV modules and chemical treatment to remove metallization, contacts, ARC layer and connector p-n from PV cells. A series of tests made it possible to determine the optimal parameters of the stages of recycling silicon modules and PV cells.

- The proposed concept of a semi-automatic installation for recycling silicon PV cells enables implementation of recycling on a semi-industrial scale. Purpose of building the presented installation has been confirmed by high parameters of PV cells, produced on a silicon substrate recovered from used PV modules.

- Maximum efficiency of the designed technological line for recycling of PV panels is 45 t/h. To process 1 ton of photovoltaic laminates with the use of selected machines, without taking into account the energy used in thermal processes, 16.49 kWh of energy is needed. The developed concept of the line is characterized by the possibility of development and adaptation to the market requirements that may arise in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SWOT | S—strengths, W—weaknesses, O—opportunities, T—threats |

| WEEE | Waste from Electrical and Electronic Equipment |

| EVA | Ethylene-Vinyl Acetate |

| Toddler | Cell sealing foil |

| PEP2040 | Poland’s Energy Policy until 2040 |

| KOH | Potassium hydroxide solution |

| HNO3 | Nitric acid solution |

| XRF | X-ray fluorescence |

| GaAs | Gallium arsenide |

| CdTe | Cadmium telluride |

| CIGS | Copper Indium Gallium Selenide |

References

- Casteleiro-Roca, J.-L.; Vivas, F.J.; Segura, F.; Barragán, A.J.; Calvo-Rolle, J.L.; Andújar, J.M. Hybrid Intelligent Modeling in Renewable Energy Sources-Based Microgrid. A Variable Estimation of the Hydrogen Subsystem Oriented to the Energy Management Strategy. Sustainability 2020, 12, 10566. [Google Scholar] [CrossRef]

- Marinakis, V.; Flamos, A.; Stamtsis, G.; Georgizas, I.; Maniatis, Y.; Doukas, H. The Efforts towards and Challenges of Greece’s Post-Lignite Era: The Case of Megalopolis. Sustainability 2020, 12, 10575. [Google Scholar] [CrossRef]

- Bogacka, M.; Potempa, M.; Milewicz, B.; Lewandowski, D.; Pikoń, K.; Klejnowska, K.; Sobik, P.; Misztal, E. PV Waste Thermal Treatment According to the Circular Economy Concept. Sustainability 2020, 12, 10562. [Google Scholar] [CrossRef]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Niekurzak, M. The Potential of Using Renewable Energy Sources in Poland Taking into Account the Economic and Ecological Conditions. Energies 2021, 14, 7525. [Google Scholar] [CrossRef]

- Kousar, S.; Ahmed, F.; López García, M.D.L.N.; Ashraf, N. Renewable Energy Consumption, Water Crises, and Environmental Degradation with Moderating Role of Governance: Dynamic Panel Analysis under Cross-Sectional Dependence. Sustainability 2020, 12, 10308. [Google Scholar] [CrossRef]

- López Gómez, J.; Ogando Martínez, A.; Troncoso Pastoriza, F.; Febrero Garrido, L.; Granada Álvarez, E.; Orosa García, J.A. Photovoltaic Power Prediction Using Artificial Neural Networks and Numerical Weather Data. Sustainability 2020, 12, 10295. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, H. Regional Security Assessment of Integrated Energy Systems with Renewables in China: A Grid-Connected Perspective. Sustainability 2020, 12, 10299. [Google Scholar] [CrossRef]

- KPEiK, 2019, Krajowy Plan na Rzecz Energii i Klimatu na Lata 2021–2030, Założenia i Cele Oraz Polityki i Działania, Ministerstwo Aktywów Państwowych. 18 December 2019. Available online: https://www.gov.pl/ (accessed on 18 September 2022). (In Polish)

- PEP. Polityka Energetyczna Polski do 2040; Ministerstwo Klimatu i Środowiska: Warsaw, Poland, 2021. (In Polish)

- SROR. Strategia na Rzecz Odpowiedzialnego Rozwoju do Roku 2020 (z Perspektywą do 2030r); Uchwała Rady Ministrów: Warszawa, Poland, 2017. (In Polish)

- PSE. Plan Rozwoju w Zakresie Zaspokojenia Obecnego i Przyszłego Zapotrzebowania na Energie Elektryczną na Lata 2021–2030; Polskie Sieci Elektroenergetyczne: Konstancin-Jeziorna, Poland, 2020. (In Polish) [Google Scholar]

- Niekurzak, M.; Kubińska-Jabcoń, E. Analysis of the Return on Investment in Solar Collectors on the Example of a Household: The Case of Poland. Front. Energy Res. 2021, 9, 660140. [Google Scholar] [CrossRef]

- KRIE. Kierunki Rozwoju Innowacji Energetycznej; Ministerstwo Energii: Warsaw, Poland, 2017. (In Polish)

- Ahmadi, M.H.; Baghban, A.; Sadeghzadeh, M.; Zamen, M.; Mosavi, A.; Shamshirband, S.; Kumar, R.; Mohammadi-Khanaposhtani, M. Evaluation of electrical efficiency of photovoltaic thermal solar collector. Eng. Appl. Comput. Fluid Mech. 2020, 14, 545–565. [Google Scholar]

- Niekurzak, M.; Lewicki, W.; Drożdż, W.; Miązek, P. Measures for assessing the effectiveness of investments for electricity and heat generation from the hybrid cooperation of a photovoltaic installation with a heat pump on the example of a household. Energies 2022, 16, 6089. [Google Scholar] [CrossRef]

- Preet, S.; Bhushan, B.; Mahajan, T. Experimental investigation of water based photovoltaic/thermal (PV/T) system with and without phase change material (PCM). Sol. Energy 2017, 155, 1104–1120. [Google Scholar] [CrossRef]

- D’Adamo, I.; Miliacca, M.; Rosa, P. Economic Feasibility for Recycling of Waste Crystalline Silicon Photovoltaic Modules. Int. J. Photoenergy 2017, 2017, 4184676. [Google Scholar] [CrossRef]

- Chen, W.-S.; Chen, Y.-J.; Lee, C.-H.; Cheng, Y.-J.; Chen, Y.-A.; Liu, F.-W.; Wang, Y.-C.; Chueh, Y.-L. Recovery of Valuable Materials from the Waste Crystalline Silicon Photovoltaic Cell and Ribbon. Processes 2021, 9, 712. [Google Scholar]

- Van Opstal, W.; Smeets, A. Circular economy strategies as enablers for solar PV adoption in organizational market segments. Sustain. Prod. Consum. 2023, 35, 40–54. [Google Scholar] [CrossRef]

- Koval, V.; Arsawan, I.W.E.; Suryantini, N.P.S.; Kovbasenko, S.; Fisunenko, N.; Aloshyna, T. Circular Economy and Sustainability-Oriented Innovation: Conceptual Framework and Energy Future Avenue. Energies 2023, 16, 243. [Google Scholar] [CrossRef]

- Moon, H.E.; Ha, Y.H.; Kim, K.N. Comparative Economic Analysis of Solar PV and Reused EV Batteries in the Residential Sector of Three Emerging Countries—The Philippines, Indonesia, and Vietnam. Energies 2023, 16, 311. [Google Scholar] [CrossRef]

- Hernández-López, D.A.; Rasikh, T.; El Mekaoui, A.; Bassam, A.; Vega De Lille, M.; Ricalde, L.J.; Riech, I. Does recycling solar panels make this renewable resource sustainable? Evidence supported by environmental, economic, and social dimensions. Sustain. Cities Soc. 2022, 77, 103539. [Google Scholar] [CrossRef]

- Torrubia, J.; Valero, A.; Valero, A.; Lejuez, A. Challenges and Opportunities for the Recovery of Critical Raw Materials from Electronic Waste: The Spanish Perspective. Sustainability 2023, 15, 1393. [Google Scholar] [CrossRef]

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage: A review. Appl. Energy 2019, 235, 846–873. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar]

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Atia, T.A.; Altimari, P.; Havlik, T.; Toro, L. Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies. Waste Manag. 2017, 59, 422–431. [Google Scholar] [CrossRef]

- Celik, I.; Lunardi, M.; Frederickson, A.; Corkish, R. Sustainable End Life Management of Crystalline Silicon and Thin Film Solar Photovoltaic Waste: The Impact of Transportation. Appl. Sci. 2020, 10, 5465. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez-Gaitan, J.P.; Bilbao, J.I.; Corkish, R. Comparative Life Cycle Assessment of End of Life Silicon Solar Photovoltaic Modules. Appl. Sci. 2018, 8, 1396. [Google Scholar] [CrossRef]

- Kuczyńska-Łażewska, A.; Klugmann-Radziemska, E. Key issues of the recycling process of used photovoltaic modules of the 1st and 2nd generation. Scientific Papers of the Institute of Mineral and Energy Economy. Pol. Acad. Sci. 2018, 102, 329–342. Available online: https://9lib.org/document/yr3k66oy-key-issues-recycling-process-generation-lifephotovoltaic-modules.html (accessed on 19 October 2022).

- Wróblewski, P.; Niekurzak, M. Assessment of the possibility of using various types of renewable energy sources installations in single-family buildings as part of saving final energy consumption in Polish conditions. Energies 2022, 15, 1329. [Google Scholar] [CrossRef]

- Cerchier, P.; Brunelli, K.; Pezzato, L.; Audoin, C.; Rakotoniaina, J.P.; Sessa, T.; Tammaro, M.; Sabia, G.; Attanasio, A.; Forte, C.; et al. Innovative recycling of end of life silicon PV panels: Resielp. Detritus 2021, 16, 41–47. [Google Scholar] [CrossRef]

- Selvi, A.; Rajasekar, A.; Theerthagiri, J.; Ananthaselvam, A.; Sathishkumar, K.; Madhavan, J.; Rahman, P.K. Rahman6Integrated Remediation Processes Towards Heavy Metal Removal/Recovery from Various Environments: A Review. Front. Environ. Sci. 2019, 7, 66. [Google Scholar] [CrossRef]

- Pandey, A.K.; Hossain, M.S.; Tyagi, V.V.; Abd Rahim, N.; Jeyraj, A.; Selvaraj, L.; Sari, A. Novel approaches and recent developments on potential applications of phase change materials in solar energy. Renew Sustain. Energy Rev. 2018, 82, 281–323. [Google Scholar]

- Sultan, S.M.; Ervina Efzan, M.N. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Sol. Energy 2018, 173, 939–954. [Google Scholar]

- Azeumo, M.F.; Germana, C.; Ippolito, N.M.; Franco, M.; Luigi, P.; Settimio, S. Photovoltaic module recycling, a physical and a chemical recovery process. Sol. Energy Mater. Sol. Cells 2019, 193, 314–319. [Google Scholar] [CrossRef]

- Fiandra, V.; Sanino, L.; Andreozzi, C.; Corcelli, F.; Graditi, G. Silicon photovoltaic modules at end of life: Removal of polymers layers and separation of materials. Waste Manag. 2019, 87, 97–107. [Google Scholar] [CrossRef]

- Xu, Y.P.; Ouyang, P.; Xing, S.M.; Qi, L.Y.; Jafari, H. Optimal structure design of a PV/FC HRES using amended Water Strider Algorithm. Energy Rep. 2021, 7, 2057–2067. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels ’end of life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Chai, J.; Xue, B.; Zhao, F.; Wang, X. Environmental influence assessment of China’s multi-crystalline silicon (multi-Si) photovoltaic modules considering recycling process. Sol. Energy 2017, 143, 132–141. [Google Scholar] [CrossRef]

- Adewole, B.Z.; Malomo, B.O.; Olatunji, O.P.; Ikobayo, A.O. Simulation and Experimental Verification of Electrical Power Output of a Microcontroller Based Solar Tracking Photovoltaic Module. Int. J. Sustain. Energy Environ. Res. 2020, 9, 34–45. [Google Scholar] [CrossRef]

- Franco, M.; Groesser, S. A Systematic Literature Review of the Solar Photovoltaic Value Chain for a Circular Economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Huang, W.H.; Shin, W.J.; Wang, L.; Sun, W.C.; Tao, M. Strategy and technology to recycle wafer-silicon solar modules. Sol. Energy 2017, 144, 22–31. [Google Scholar]

- IRENA. Future of Solar Photovoltaic: Deployment, Investment, Technology, Grid Integration, and Socioeconomic Aspects. 2019. Available online: https://www.irena.org/publications/2019/Nov/Future-of-Solar-Photovoltaic (accessed on 2 November 2022).

- EC 2020a—European Commission, Critical Materials for Strategic Technologies and Sectors in the EU—A Foresight Study, 2020. EU 2020. Available online: https://rmis.jrc.ec.europa.eu (accessed on 5 November 2022).

- Niekurzak, M. Determining the Unit Values of the Allocation of Greenhouse Gas Emissions for the Production of Biofuels in the Life Cycle. Energies 2021, 14, 8394. [Google Scholar] [CrossRef]

- Fuentes, M.; Vivar, M.; de la Casa, J.; Aguilera, J. An experimental comparison between commercial hybrid PV-T and simple PV systems intended for PIPV. Renew. Sustain. Energy Rev. 2018, 93, 110–120. [Google Scholar]

- Ozdarski, W.T.; Witkowska-Dąbrowska, M.; de Jesus, I.M. Feasibility Study of the Use of Renewable Energy Sources in Households. Olszt. Econ. J. 2021, 16, 251–262. [Google Scholar] [CrossRef]

- Niekurzak, M.; Kubińska-Jabcoń, E. Assessment of the Impact of Wear of the Working Surface of Rolls on the Reduction of Energy and Environmental Demand for the Production of Flat Products: Methodological Approach. Materials 2022, 15, 2334. [Google Scholar] [CrossRef]

- Farrell, C.; Osman, A.I.; Zhang, X.; Murphy, A.; Doherty, R.; Morgan, K.; Rooney, D.W.; Harrison, J.; Coulter, R.; Shen, D. Assessment of the energy recovery potential of waste Photovoltaic (PV) modules. Sci. Rep. 2019, 9, 5267. [Google Scholar] [CrossRef]

- Niekurzak, M.; Mikulik, J. Modeling of Energy Consumption and Reduction of Pollutant Emissions in a Walking Beam Furnace Using the Expert Method—Case Study. Energies 2021, 14, 8099. [Google Scholar] [CrossRef]

- Dias, P.; Schmidt, L.; Lunardi, M.M.; Chang, N.L.; Spier, G.; Corkish, R.; Veitb, H. Comprehensive recycling of silicon photovoltaic modules incorporating organic solvent delamination—Technical, environmental and economic analyses. Resour. Conserv. Recycl. 2021, 165, 105241. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez-Gaitan, J.P.; Bilbao, J.I.; Corkish, R. A Review of Recycling Processes for Photovoltaic Modules, in Solar Panels and Photovoltaic Materials; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Herceg, S.; Pinto Bautista, S.; Weiß, K.A. Influence of Waste Management on the environmental Footprint of Electricity Produced by Photivoltaic Systems. Energies 2020, 13, 2146. [Google Scholar] [CrossRef]

- Mulazzani, A.; Eleftheriadis, P.; Leva, S. Recycling c-Si PV Modules: A Review, a Proposed Energy Model and a Manufacturing Comparison. Energies 2022, 15, 8419. [Google Scholar] [CrossRef]

- Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79. [Google Scholar] [CrossRef]

- Schnatmann, A.K.; Schoden, F.; Schwenzfeier-Hellkamp, E. Sustainable PV Module Design—Review of State-of-the-Art Encapsulation Methods. Sustainability 2022, 14, 9971. [Google Scholar] [CrossRef]

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A.; Amin, N.; Nor Adzman, N. Global Challenges and Prospects of Photovoltaic Materials Disposal and Recycling: A Comprehensive Review. Sustainability 2022, 14, 8567. [Google Scholar] [CrossRef]

- Calì, M.; Hajji, B.; Nitto, G.; Acri, A. The Design Value for Recycling End of Life Photovoltaic Panels. Appl. Sci. 2022, 12, 9092. [Google Scholar] [CrossRef]

- Papamichael, I.; Voukkali, I.; Jeguirim, M.; Argirusis, N.; Jellali, S.; Sourkouni, G.; Argirusis, C.; Zorpas, A.A. End of Life Management and Recycling on PV Solar Energy Production. Energies 2022, 15, 6430. [Google Scholar] [CrossRef]

- Senán-Salinas, J.; Landaburu-Aguirre, J.; García-Pacheco, R.; García-Calvo, E. Recyclability Definition of Recycled Nanofiltration Membranes through a Life Cycle Perspective and Carbon Footprint Indicator. Membranes 2022, 12, 854. [Google Scholar] [CrossRef]

- Abramczyk, N.; Drewing, S.; Panasiuk, K.; Żuk, D. Application of Statistical Methods to Accurately Assess the Effect of Gamma Aluminum Oxide Nanopowder on the Hardness of Composite Materials with Polyester–Glass Recyclate. Materials 2022, 15, 5957. [Google Scholar] [CrossRef]

- Isherwood, P.J.M. Reshaping the Module: The Path to Comprehensive Photovoltaic Panel Recycling. Sustainability 2022, 14, 1676. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M. Technoeconomic appraisal of a ground source heat pump system for a heating season in eastern Turkey. Energy Convers. Manag. 2006, 47, 1281–1297. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M. A techno-economic comparison of ground-coupled and air-coupled heat pump system for space cooling. Build. Environ. 2007, 42, 1955–1965. [Google Scholar] [CrossRef]

- Esen, M.; Yuksel, T. Experimental evaluation of using various renewable energy sources for heating a greenhouse. Energy Build. 2013, 65, 340–351. [Google Scholar] [CrossRef]

- Helms, M.M.; Nixon, J. Exploring SWOT analysis where are we now? A review of academic research from the last decade. J. Strategy Manag. 2010, 3, 215–251. [Google Scholar] [CrossRef]

- Glass, J.R.; Kruse, G.H.; Miller, S.A. Socioeconomic considerations of the commercial weathervane scallop fishery off Alaska using SWOT analysis. Ocean. Coast. Manag. 2015, 105, 154–165. [Google Scholar] [CrossRef]

- DeCarb. Reference Case Study and SWOT Analysis Identifying the Most Advantageous Growth Areas in Relation to the Existing Workforce and Territorial Specificities in Order to Create Alternative to Coal-Driven Activities; Final Report; DeCarb—Supporting the Clean Energy Transition of Coal-Intensive EU Regions: Stara Zagora, Bulgaria, 2019. [Google Scholar]

| Type | Positive | Negative |

|---|---|---|

| Inside | Strengths | Weaknesses |

|

| |

| Outside | Chances | Threats |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niekurzak, M.; Lewicki, W.; Coban, H.H.; Brelik, A. Conceptual Design of a Semi-Automatic Process Line for Recycling Photovoltaic Panels as a Way to Ecological Sustainable Production. Sustainability 2023, 15, 2822. https://doi.org/10.3390/su15032822

Niekurzak M, Lewicki W, Coban HH, Brelik A. Conceptual Design of a Semi-Automatic Process Line for Recycling Photovoltaic Panels as a Way to Ecological Sustainable Production. Sustainability. 2023; 15(3):2822. https://doi.org/10.3390/su15032822

Chicago/Turabian StyleNiekurzak, Mariusz, Wojciech Lewicki, Hasan Huseyin Coban, and Agnieszka Brelik. 2023. "Conceptual Design of a Semi-Automatic Process Line for Recycling Photovoltaic Panels as a Way to Ecological Sustainable Production" Sustainability 15, no. 3: 2822. https://doi.org/10.3390/su15032822

APA StyleNiekurzak, M., Lewicki, W., Coban, H. H., & Brelik, A. (2023). Conceptual Design of a Semi-Automatic Process Line for Recycling Photovoltaic Panels as a Way to Ecological Sustainable Production. Sustainability, 15(3), 2822. https://doi.org/10.3390/su15032822