Abstract

In the 21st century, numerous economic and environmental initiatives have significantly increased paper recycling, which continues to expand due to environmental awareness. With increasing recycling rate, low-quality paper fractions may be included in the process, leading to the overproduction of very low-value papers that cannot be reprocessed. Moreover, the production of paper from poor-quality wastepaper can result in the introduction of chemicals from the recycled paper into the recycling loop and unintended spread of chemical substances. Therefore, reliable and conscious selection of recycled pulp is imperative. To this end, the present study verified the properties of recycled pulp critical for the assessment of its papermaking ability for the production of high-quality sanitary paper. Following an examination of samples, it was found that the key parameters that influence the papermaking ability of wastepaper include presence of impurities, content of extractive substances, freeness, and length of fiber. On this basis, types of wastepaper that, at the very beginning, did not portend well for obtaining paper products with high potential for utility were eliminated.

1. Introduction

Recovered fibrous raw materials from paper products have long been used for secondary pulp production [1,2,3,4]. For several centuries, products of inadequate quality, unsuitable for further use or with dry breaks, have been used as input materials. With growing demand for paper, however, the processing of used paper products, called wastepaper, has become increasingly significant for obtaining fibrous raw materials. Currently, the pulp and paper industry uses secondary pulp as an indispensable production input. The global paper recycling rate stands at approximately 58% [5,6,7,8]. In some of the more developed countries, the recycling rate of wastepaper has reached as high as 70–75% of the total amount of wastepaper generated at the national scale [9]. In particular, Europe stands out with the highest paper recycling rate in the world (72%), followed by North America, whereas Asia, Latin America, and Africa have the lowest recycling rates [10]. Many countries have unceasingly sought to increase this rate by implementing measures to optimize activities from the beginning of paper production until its use, collection, and recycling.

Paper and its waste are easily degradable, and the resulting cellulose fibers can be recycled up to seven times [11,12]. Therefore, useful paper waste must be recycled. Efficient wastepaper recycling plays a significant role in building a sustainable environment, offering several benefits over the paper life cycle [13,14]. Sensible paper recycling saves energy, water, and landfill areas. Moreover, wastepaper recycling saves virgin fiber input during paper production. As opposed to chemical pulping of wood from virgin pulp, wastepaper pulping generates no wood waste or dissolved chemicals for energy generation [15]. Moreover, paper recycling reduces the emissions of CO2, NO2, and SO2 in the air and decreases water pollution caused by chlorine compounds from bleaching and chemicals [16]. In general, recycling and retreatment of paper impact sustainability, particularly the economy, environment, and society.

Whilst the paper recycling rate can undoubtedly be further increased in most countries, the quality of wastepaper may eventually decrease as increasing numbers of marginal paper fractions are gathered for recycling. However, increasing the paper recycling rate requires the use of recycled fibers from high-quality paper. This is crucial since the mechanical and printing properties of the material deteriorate every time it is recycled owing to the limited number of recycling rounds [17,18,19,20,21]. These fibers are shortened and their swelling and flexibility properties deteriorate. Poor-quality wastepaper not only reduces the papermaking ability of pulp but is also associated with increased use of chemical additives and fillers, which produce large quantities of by-products, creating major environmental and economic challenges [22]. Moreover, poor-quality recycled fibers increase the content of injurious substances in paper [23,24,25]. In this context, systematic analysis of paper pulp is essential to provide a basis for further evaluation of the quality of wastepaper as a resource as well as to identify appropriate processing methods for ensuring that the resulting recycled pulp meets the expectations of papermakers and, ultimately, consumers. This is particularly applicable to sanitary papers, which must be not only strong but also absorbent and soft. In addition, consumers require a certain quality of whiteness and brightness. Thus, recyclable wastepaper can be segregated into various grades to facilitate the production of high-quality products. By dividing the recyclable paper waste according to its properties and comparing them with the characteristics of the desired final product, paper waste can be recycled more efficiently. In addition, a highly sorted paper stream facilitates the production of high-quality end products; saves processing chemicals, water, and energy; and reduces the amount of sludge and rejects generated during wastepaper processing. Removing contaminants from wastepaper, ensuring papermaking ability, and maintaining consistent quality whilst limiting the environmental footprint of products have become a major goal and challenge in the industry.

These goals and challenges were explored by many studies on paper recycling at the turn of the last decade [26,27,28,29,30]. Previous research mainly focused on the development of technologies that enable the reuse of fibers from wastepaper, such as bleaching methods [31,32,33,34,35] of fibers and deinking technologies [36,37,38,39]. Publications on paper recycling peaked in 2000, which may have been dictated by the European declaration on paper recovery issued in that year [40]. During the next decade, publications continued to focus on fiber recovery issues [41,42,43,44,45]. In recent publications, the topic of recovery of biomaterials and bio-refinery feedstock from wastepaper prevailed [46,47,48,49] since, considering the principles of circular economy, this is strategic for mitigating the ongoing climate change.

However, the available literature lacks thorough analyses of the papermaking ability of specific types of wastepaper, along with the verification of the possibility of using them for the production of specific types of paper. All of this is more significant since, in practice, the quality and composition of wastepaper delivered to paper mills often differ from expectations, and the specific types of wastepaper do not meet the requirements in the respective standards. Therefore, in the present study, we determined the papermaking ability of a wide range of wastepaper processed in a selected paper mill and verified the possibility of using them for the production of high-quality sanitary paper. The research in the article contributes further to the methods of assessment of wastepaper for the paper production.

2. Materials and Methods

2.1. Materials

The following materials were selected from the paper mill for research:

- White wastepaper, including products of bleached pulps, scraps of wood-free paper, little printed, no glue, no waterproof paper, and no colored paper (ranked 3.04 according to the EN643 ‘List of European standard types of wastepaper’ [50]) (seven samples).

- Mixed wastepaper composed of unsorted wastepaper, formally classified as the entire spectrum of the second type of paper, that is medium-sized varieties. These included newspapers and printed office wastepaper, among others (ranked 3.19 according to theEN643 ‘List of European standard types wastepaper’) (five samples).

The wastepaper was crushed manually (pieces of approximately 2–5 cm) and mixed to ensure that the sample was mixed homogeneously. The wastepaper prepared in this way was placed in the described PP foil bags, which were subsequently stored in barrels with tight covers to protect the samples from moisture and contamination. After mechanical shredding, the wastepaper samples were packed in tight containers and stored at a constant temperature of approximately 15 °C.

2.2. Non-Fibrised Substances and Chemical Analysis of Pulp

To determine the amount of non-fiberized substances in the tested wastewater, the rewetted pulp samples (22.5 g dry weight samples soaked in water for 24 h) were subjected to disintegration using a laboratory JAC SHPD28D propeller pulp disintegrator (Danex, Katowice, Poland) with 23,000 revolutions following ISO 5263-1 (2004). Non-defibered substances versus fibers and water were removed using a membrane screener (PS-114; Danex, Katowice, Poland) at an amplitude of 25 mm and a frequency of 2 Hz. The screener is equipped with a gap screen (gap width = 0.50 mm).

To identify the dissolved substances in the tested wastepaper samples, the association between the amount of oxygen required for the oxidation of organic substances in the tested samples and that of soluble substances was used. The MERCK COD test was applied to quantify these substances. Organic compounds were oxidized following the manufacturer’s instructions. The amount of oxygen consumed to oxidize these substances was determined using a spectrophotometer (UV-1280; Shimadzu, Japan) at 620 nm.

Analyses of the chemical composition of cellulosic pulp included the quantification of ash, extractives, holocellulose, and lignin. Ash content was determined using a gravimetric method in compliance with the Tappi T211 standard (ash in wood, pulp, paper, and paperboard; combustion at 525 °C). The amounts of extractives were determined according to the Tappi T204 standard (solvent extractives from wood and pulp). Holocellulose content was determined according to Tappi Useful Method 249 (cellulose in pulp). As indicators of lignin content in the pulp, kappa numbers for dried pulps were examined according to ISO 302 (2015). The average polymerization degree of cellulose (DP) in the pulp was determined using viscometry following ISO 5351 (2010). All chemical analyses were performed in triplicate for each pulp sample.

2.3. Analysis of Fibre and Pulp Properties

Pulps were characterized in terms of fiber dimension, fine content, water retention value (WRV), and freeness. The dimensions of fibers were measured according to ISO 16065-2:2014 using the Morfi Compact Black Edition apparatus (Techpap, Grenoble, France). WRV was determined according to ISO 23714:2014. Freeness was measured using the Schopper–Riegler apparatus (Thwing-Albert Instrument Company, West Berlin, NJ, USA), according to PN-EN ISO 5267-1 (2002). All analyses were performed on both unbeaten and refined pulp samples.

2.4. Pulp Refining

Before processing, the pulp was soaked in water for 24 h. Then, wastewater was treated in the Danex JAC SHPD28D propeller pulp disintegrator (Danex, Katowice, Poland) according to PN EN ISO 5263-1 (2006) with 23,000 revolutions. The refining process was performed in the Danex JAC PFID12X PFI mill (Danex, Katowice, Poland), with a single batch of dried pulp (22.5 g), according to PN-EN ISO 5264-2 (2011). Pulp was refined to 30 ± 1 °SR.

2.5. Preparation of Paper Sheets

Laboratory paper sheets were prepared from unbeaten and refined pulp samples that had been previously disintegrated, as described in Section 2.4 Sheets of paper were formed using the Rapid–Koethen apparatus in accordance with PN-EN ISO 5269-2 (2007). Each paper sheet had the basis weight of 80 g·m−2 (ISO 536:2012). Only sheets with base weights between 79 and 81 g·m−2 were used for further investigation.

The paper samples were conditioned at 23 °C and 50% relative humidity according to ISO 187:1990 for a minimum of 24 h before examination.

2.6. Analysis of Paper Properties

Contaminants on the tested paper surfaces were assessed using the Keyence VHX-6000 microscope (Keyence, Belgium) equipped with the VH-Z20UT lens (20/200× magnification). The OP-72402 adapter (ring shape) was used for sample illumination. Image analysis-based measurements of elements was performed using the microscope software. The surface texture of samples was tested under a microscope in accordance with ISO 25178:2016 Geometrical Product Specifications (GPS). Briefly, based on three-dimensional microscopic photographs of coated surface papers, roughness profiles were prepared. Specifically, roughness profiles were obtained from the surface profiles by separating the long-wave components (waviness and shape deviations) with an λc profile filter. The λc profile filter determines the transition from roughness to waviness, that is, random or close-to-periodic inequalities. The basic roughness parameters (Sa and Sz) describing surface microgeometry and those related to specific profile features were obtained from the roughness profile photographs. For roughness profiles, Sa represents the arithmetic mean deviation of the roughness profile along the sampling length, whilst Sz represents the maximum roughness (the maximum height of the profile indicates the absolute vertical distance between the maximum profile peak height and maximum profile valley depth along the sampling length).

Furthermore, the roughness of paper surface was determined in accordance with ISO 8791-2:2013 with the TMI 58-27 Bendtsen Roughness Tester (Kontech, Lodz, Poland). Air permeability was determined according to the ISO 5636-3:2013 with the TMI 58-27 Bendtsen Roughness Tester (Kontech, Lodz, Poland). Optical parameters were determined using the X-rite Exact spectro-densitometer in accordance with ISO 2470-1:2016.

The priority strength properties of papers were determined using the Zwick 005 ProLine testing machine (ZwickRoell, Ulm, Germany) coupled with the testXpert III software in accordance with ISO 1924-2:2010. The following tensile properties of paper were examined:

- IB: breaking length [m]

- FB: tensile force at break [N]

- σTb: width-related force at break [N·m−1]

- σTW: force at break index [Nm·g−1]

- εT: strain at break [%]

- WTb: energy absorption [J·m−2]

- WTW: energy absorption index [J·g−1]

- Eb: tensile stiffness [N·m−1]

- Ew: tensile stiffness index [Nm·g−1]

- E*: Young’s modulus [MPa]

Detailed statistical analysis was performed on individual research series to determine the following basic indicators: arithmetic mean, extended deviation, and percentage relative error.

3. Results and Discussion

Contents of non-fiberized substances in wastepaper pulp samples are summarized in Table 1. White wastepaper, described as number 3.04 in accordance with the PN-EN 643:2004 standard, contains scraps of wood-free paper with little print, no glue, no waterproof paper, and no colored paper. Cursory analysis of wastepaper revealed that most of the tested samples did not meet the assumed requirements to a greater or lesser extent. Specifically, this wastepaper contained certain amounts of wood paper and paper colored in mass, and most of them contained a significant amount of heavily printed paper. Based on the results of these analyses, the delivered wastepaper to the mill should be formally characterized under category 3.02, that is, mixed wastepaper with scraps of printing and writing paper, slightly dyed in mass, containing at least 90% of wood-free paper, or under category 3.03, that is, wastepaper containing bookbinding scraps of wood-free paper (it may contain 10% wood paper at the most), with little print and glue but no paper colored in mass. In summary, the treatment of white wastepaper as purely type 3 or 04 is a simplification used in the trade of wastepaper. In fact, this type of paper exhibits a spectrum of properties.

Table 1.

Non-fiberized substances and chemical composition of wastepaper pulps.

These results confirmed the chemical composition of the examined wastepaper pulp, without simple dependencies on the type of wastepaper. The degree of polymerization affects the strength properties of paper; this is due to the fact that with a decrease in polymerization degree, the mechanical strength of cellulose decreases. Based on the results of our analyses, despite the high degree of cellulose polymerization, the selected wastepaper pulps did not achieve the highest strength properties. Therefore, presence of impurities and many other factors may affect the strength of paper derived from recycled pulp.

To determine the critical parameters for obtaining high-quality recycled pulp and ensuring suitability for the production of specific types of paper, papermaking ability was assessed. This analysis covers a wide spectrum of tests aimed at determining whether a given fibrous raw material is suitable for use in paper production. Papermaking ability is determined based on multiple parameters of pulp, including the chemical composition and properties of the finished paper. The assessment of papermaking ability allows comprehensive comparison of the properties of recycled pulps and determination of the types of wastepaper that may be useful. Most importantly, this assessment identifies the types that cannot certainly be used to obtain products of high utility value.

To assess papermaking ability, pulp was refined, the primary purpose of which is the maximum development of surface area bound in the paper. Refining increases the elasticity of cellulose fibers, thereby improving the strength and structural-dimensional properties of the finished paper. Simultaneously, however, it contributes to the reduction of pulp dewatering, which adversely affects the efficiency of the papermaking machine. Moreover, the refining process is highly energy intensive, accounting for nearly 50% of the electricity consumption of the paper mill. Previous studies and industrial experiments have established that the optimum cost, efficiency, and paper product properties could be obtained at a lubricity of approximately 30 °SR. Therefore, the papermaking ability of the selected pulps was determined after refining for the Schopper–Riegler freeness of 30 ± 1 °SR, which was expected to ensure the maximum strength of pulps and contribute to easy dehydration. In further analyses of papermaking ability, the pulp samples that did not promise products with excellent functional properties due to their characteristics at the very beginning were rejected. Therefore, from amongst all considered wastepaper types, the pulps that were characterized by a freeness of >30 °SR in the unrefined state were rejected. In addition, pulp samples in which the content of extractive substances exceeded 1.30% were excluded. Owing to their high chemical reactivity as well as the significant viscosity and adhesion of their components, extractives may hinder the papermaking process in the form of so-called resin difficulties and may create resin stains, visible as spots in the finished products. In addition, pulp samples with fiber length of <900 µm were excluded as they increase static strength but decrease tear resistance. In contrast, the intermediate fraction lowers the static strength but improves he dynamic strength. Meanwhile, the long-fiber fraction improves all strength properties of the paper. A longer fiber length increases the tear resistance and extensibility of the paper, which are particularly desirable in the case of sanitary papers. In the present study, white wastepaper 1.3, 1.4, 2.1 and 3.2 and mixed wastepaper 1.5 met the above criteria.

Considering the practical technological aspects of subsequent processes on a paper machine, the most important changes occurring as a result of the refining process, in addition to from freeness, include the development of swelling degree (WRV) of the recycled pulp. The greater the degree of pulp swelling, the greater the compactness of the structure of the obtained paper, which significantly improves its properties but reduces its dynamic strength. After refining, WRV of the tested pulps increased by 28–61% (Table 2), achieving the highest values for white wastepaper. Mixed wastepaper 1.5 was much more keratinized and achieved a much lower degree of pulp swelling. Similarly, regarding fiber length, higher values were recorded for white wastepaper (Table 3), suggesting that the paper obtained from these types will achieve higher strength parameters at the outset. To date, the highest content of the fine fraction amongst refined pulps has been recorded for white 2.1 and mixed 1.5 wastepaper (Table 2), which is conducive to the quality paper derived from these pulps as well as to the process economy resulting from the saving of bulk additives. Overall, our analyses of unrefined and refined pulps showed that the type of wastepaper (impurity content), similar to chemical composition, does significantly affect fiber and pulp properties.

Table 2.

Characteristics of wastepaper pulps.

Table 3.

Fiber properties.

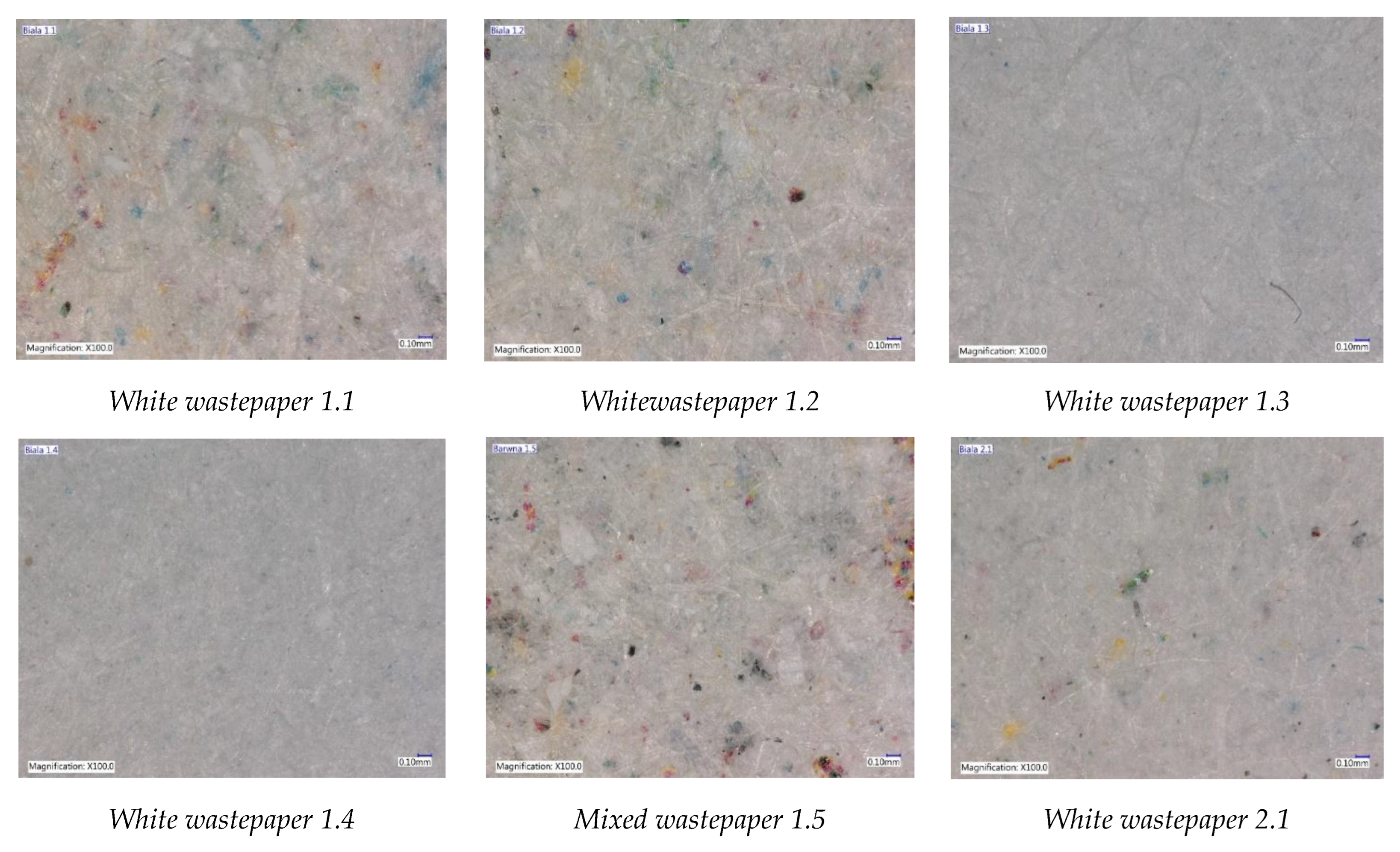

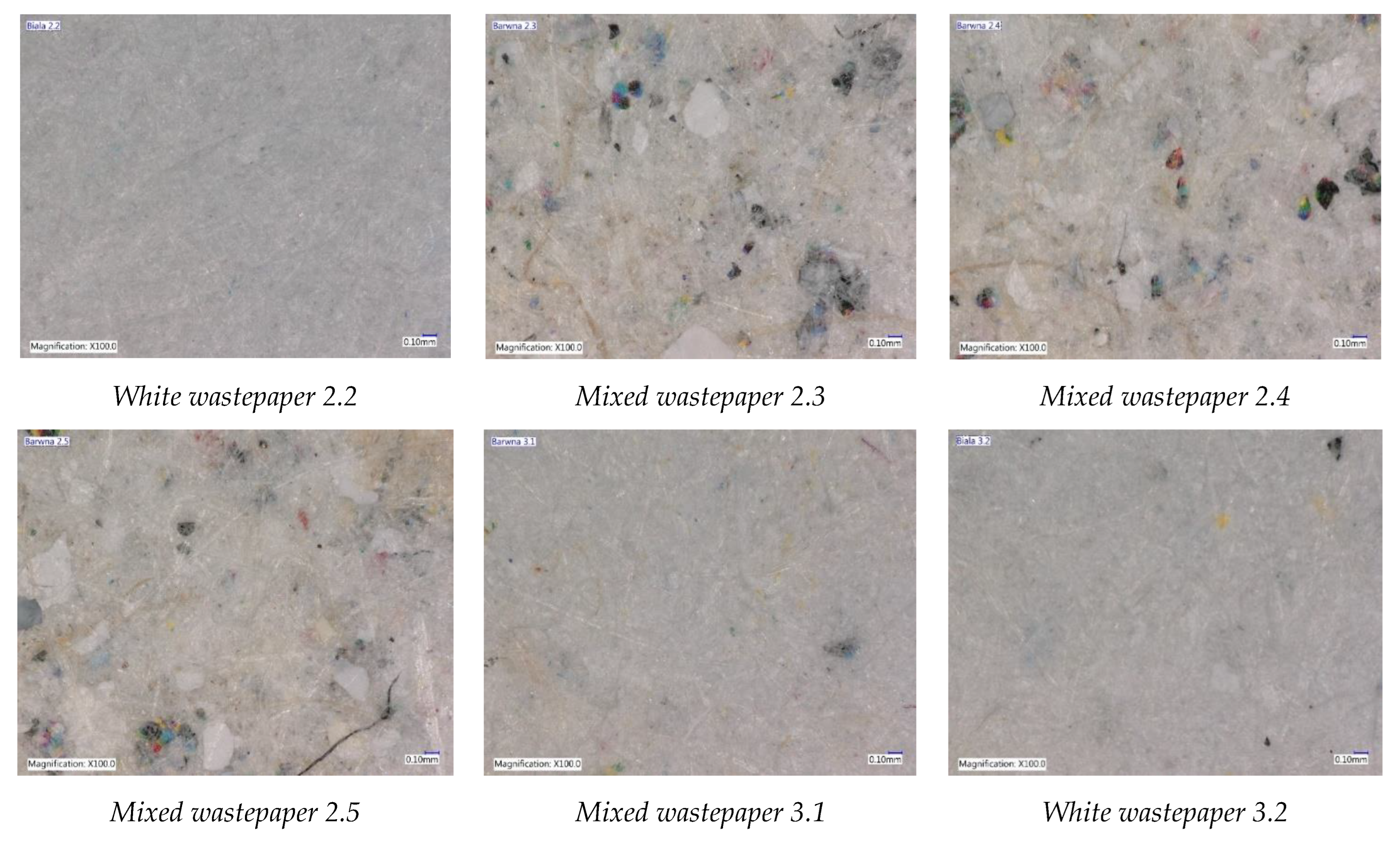

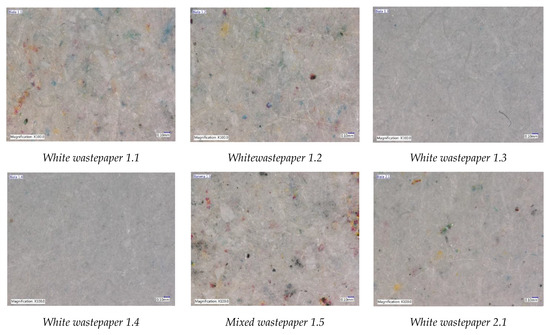

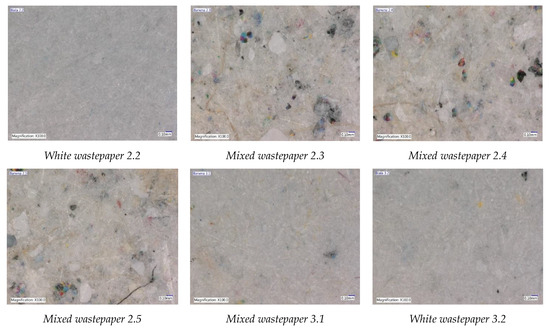

Results of microscopic analysis of impurities on the surface of the tested paper are presented in Figure 1. Significant amounts of impurities were observed on the surface of papers produced from mixed wastepaper due to the higher content of impurities in the pulp.

Figure 1.

Microscopic images of wastepaper surfaces.

When processing paper, the roughness of the material’s surface is a very important parameter since it affects many properties of the material as well as various other characteristics of the product such as appearance, aesthetics, and functional value, which are particularly important in the case of sanitary papers. Hence, based on the three-dimensional microscopic analysis of different papers, roughness profiles were prepared. Specifically, profiles were obtained by separating the long-wave components of the surface profile (waviness and shape deviations) with a λc profile filter. The λc profile filter determines the transition from roughness to waviness, that is, random or close-to-periodic inequalities. Therefore, the basic roughness parameters (Sa and Sz) describe the surface microgeometry and link it to specific profile features (Table 4). In roughness profiles, Sa represents the arithmetic mean deviation of the roughness profile along the sampling length, whilst Sz represents the maximum roughness (the maximum height of the profile indicates the absolute vertical distance between the maximum profile peak height and maximum profile valley depth along the sampling length).

Table 4.

Structural and optical properties of papers.

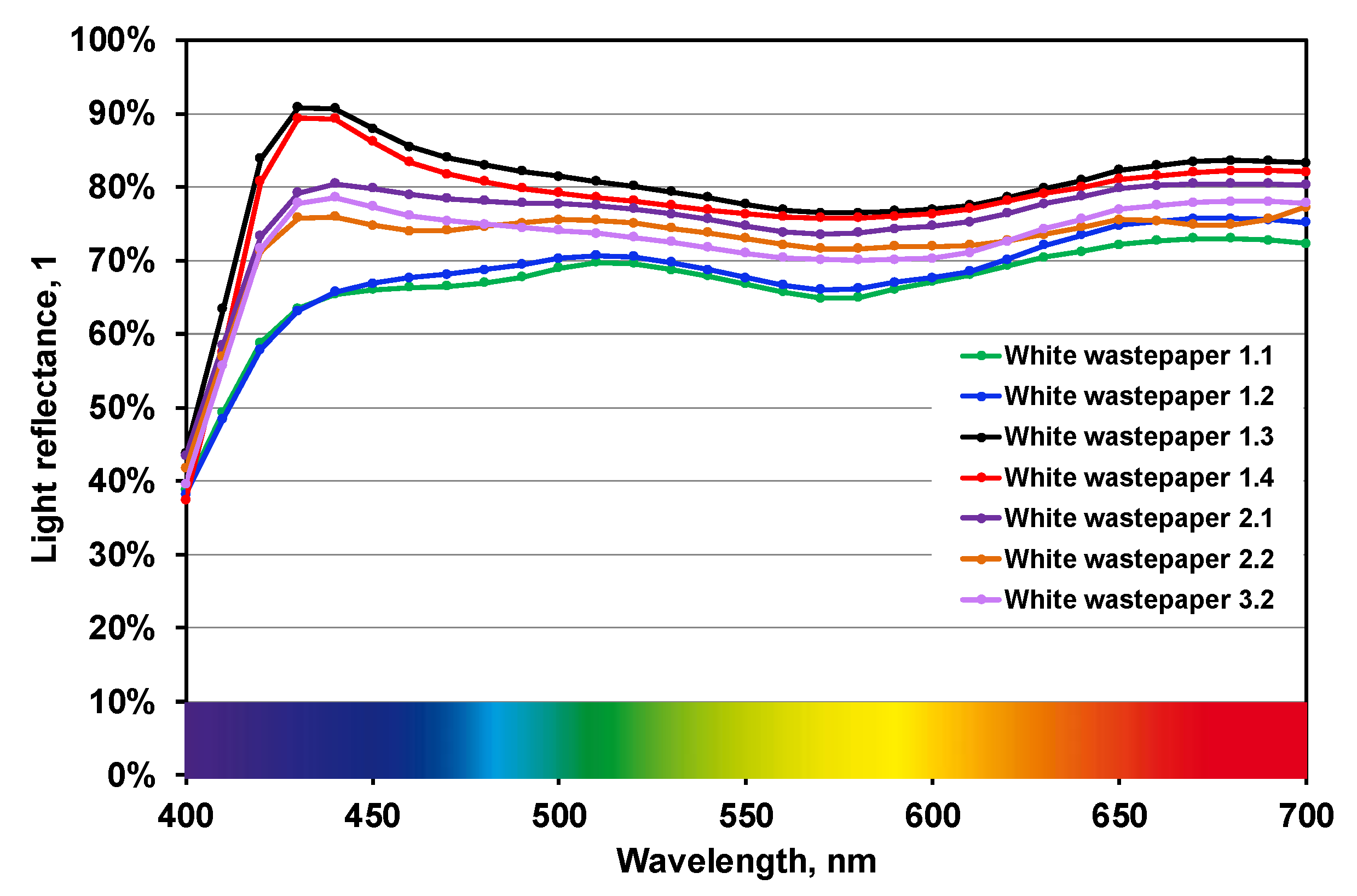

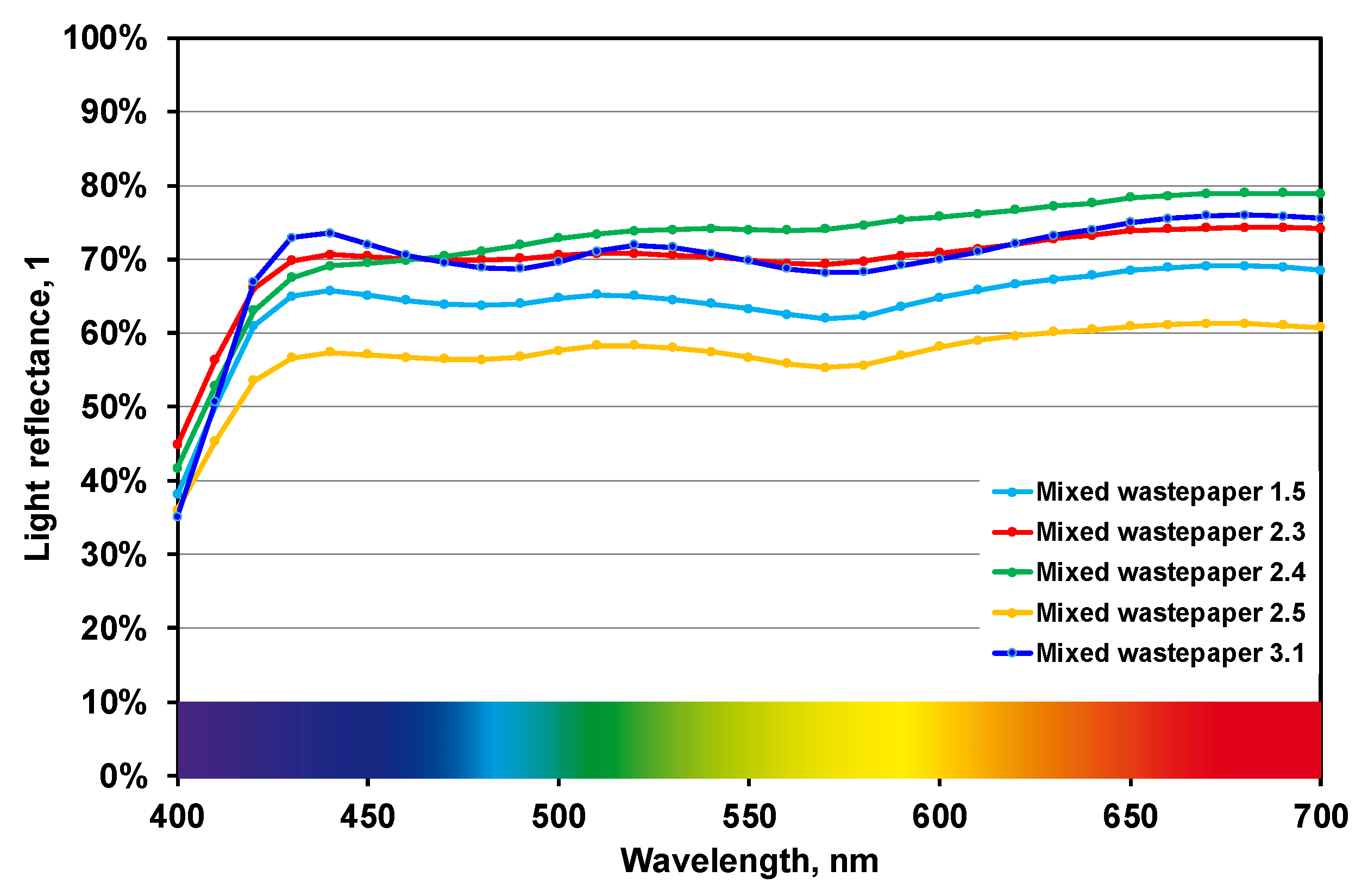

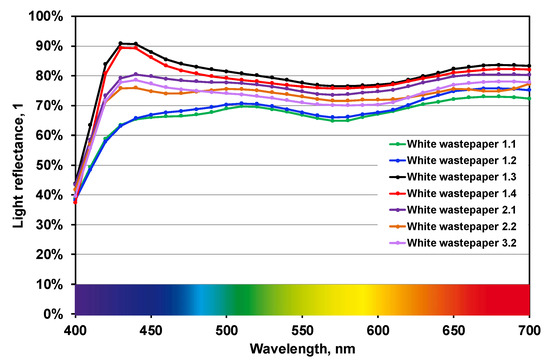

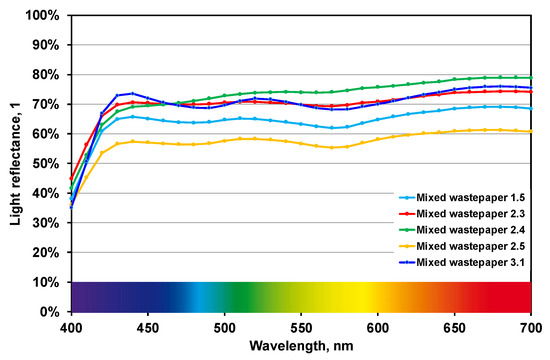

Microscopic analysis of paper roughness showed no significant differences depending on the type of wastepaper used to produce paper sheets, despite the differences in the amount of impurities between white and mixed wastepaper (Table 4). Additional roughness measurements, performed following the Bendtsen procedure (Table 4), confirmed that the type of wastepaper used did not alter roughness parameters. Notably, in most cases, the process of refining smoothed the surface of the papers produced only to a small extent. This was also true for optical parameters. Interestingly, compared to mixed wastepaper, white wastepaper did not exhibit higher whiteness indices. The optical characteristics are presented in Table 4 and Figure 2 and Figure 3.

Figure 2.

Light reflection curve of white wastepaper.

Figure 3.

Light reflection curve of mixed wastepaper.

Another important property that contributes significantly to the functional properties of paper is air permeability. Moreover, air permeability is an important indicator for the production process control of sanitary papers, since it reflects the porosity of the product and thus its absorbance and tensile properties. Most of the studied papers produced from unrefined pulps were characterized by high air permeability, which decreased significantly after refining (Table 4). However, whether this is disadvantageous depends on the purpose of application.

The tensile properties of paper sheets are important for manufacturing and processing [51,52]. Therefore, the effects of specific pulp parameters and impurity contents on the strength of papers were analyzed, and the results are summarized in Table 5 and Table 6. Regarding strength properties, papers produced from unrefined white wastepaper 2.1 and 3.2 achieved the best results in the conducted tests (Table 5). Refining significantly improves the papermaking ability of wastepaper pulp, increasing the strength of the obtained papers. From refined pulp, the best results were recorded for white recycled papers 1.3 and 3.2 (Table 6), which was expected considering their excellent pulp and fiber properties (Table 2 and Table 3). High tear resistance and elasticity render these papers the most attractive for use in the production of sanitary paper. The lowest strength was recorded from recycled paper1.5, which may be due to the lowest fiber length of its pulp.

Table 5.

Tensile properties of paper produced from unrefined pulp.

Table 6.

Tensile properties of paper produced from refined pulps.

Of note, in a few cases, pulps with similar properties in the unrefined state exhibited markedly different properties in the refined state, such as wastepaper 1.4 and 1.5. Therefore, thorough estimation of the papermaking ability is essential.

4. Conclusions

Analyses conducted in the present work were aimed at verifying the specific properties of wastepaper pulp on the basis of which their suitability to produce a product with satisfactory usability characteristics can be initially assessed. However, although the present work does not allow for identifying the pulp that is reliable in terms of papermaking, it allows for revealing the pulp that is not suitable. In other words, the usefulness of recycled pulp can be assessed at high probability by determining the freeness and content of extractive substances. Based on the obtained data, it was conducted that, samples containing large amounts of extractives (above 1.30%) and dissolved substances cannot yield products with a high added value. Also, samples with very high initial Schopper–Riegler freeness should not be introduced into the system, as they do not allow for achieving the expected results and may induce a number of technological difficulties. Similarly, pulp samples with fiber length of <900 µm do not allow good paper strength, and especially satisfactory tear resistance, so essential to sanitary papers. Moreover, strength properties cannot be determined without the refining process. Overall, comprehensive evaluation of the papermaking ability of wastepaper is imperative. Undeniably, our findings will be helpful to further analyze the validity of recycled materials and reduce the impact of wastepaper on the environment.

Author Contributions

Conceptualization, E.M. and P.P.; methodology, A.L., M.D. and E.M.; data processing, M.D. and A.L.; literature review, M.D.; writing—original draft preparation, E.M.; writing—review and editing, E.M.; supervision, P.P.; funding acquisition, P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Center of Research and Development in Poland, grant number POIR.01.01.01-00-0084/17.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Aue, J.; Picard, K.; Grabner, K. Fiber recovery from waste paper: A breakthrough in re-pulping technology. TAPPI Fall Technol. Conf. 2003, 273–280. [Google Scholar]

- Scott, G.M. Chapter 10—Recovered paper. In Waste, A Handbook for Management; Academic Press: Cambridge, MA, USA, 2011; pp. 137–149. [Google Scholar] [CrossRef]

- Scott, G.M. Chapter 14—Recovered paper. In Waste, A Handbook for Management, 2nd ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 291–305. [Google Scholar] [CrossRef]

- Key Statistics 2021. European Pulp & Paper Industry. Available online: https://www.cepi.org/wp-content/uploads/2022/07/Key-Statistics-2021-Final.pdf (accessed on 22 November 2022).

- Paper Recycling Rate at about 66 Percent in 2020. Recycling Today. Available online: https://www.recyclingtoday.com/article/paper-recycling-rate-66-percent-2020/ (accessed on 22 November 2022).

- European Paper Recycling Council Monitoring Report 2020. European Declaration on Paper Recycling 2016–2020. Available online: https://www.cepi.org/wp-content/uploads/2021/07/WEB-PAGES_EPRC-Monitoring-Report-2020_20210716.pdf (accessed on 22 November 2022).

- Unpacking Continuously High Paper Recycling Rate. American Forest & Paper Association. Available online: https://www.afandpa.org/news/2022/unpacking-continuously-high-paper-recycling-rates (accessed on 25 July 2022).

- Global Paper Recycling Market (2021–2026) by Source of Collection, Type, Application, Collection & Segregation Channel, End-Use, Geography, Competitive Analysis and the Impact of COVID-19 with Ansoff Analysis. Research and Markets the World’s Largest Market Research Store. Available online: https://www.researchandmarkets.com/reports/5317165/global-paper-recycling-market-2021-2026-by (accessed on 25 September 2022).

- Global Forest and Paper Industry Releases Policy Statement on Paper Recycling. CEPI. Available online: https://www.cepi.org/global-forest-and-paper-industry-releases-policy-statement-on-paper-recycling/ (accessed on 13 November 2022).

- Recycling Facts. IMPACTPapeRec. Available online: https://impactpaperec.eu/en/facts-figures/recycling-facts/ (accessed on 13 November 2022).

- Circular Economy, Renewable and Recyclable: Our Essence. CEPI. Available online: https://sustainability.cepi.org/policy-blocks/circular-economy/# (accessed on 25 July 2022).

- How Many Times Can Paper Be Recycled? Myth Vs. Fact—Can Recycled Paper be Used Indefinitely? FSSI Document Outsourcing Specialists. Available online: https://www.fssi-ca.com/myths-vs-facts-we-can-use-recycled-paper-until-its-all-gone/ (accessed on 22 November 2022).

- Laurijssen, J.; Marsidi, M.; Westenbroek, A.; Worrell, E.; Faaij, A. Paper and biomass for energy?: The impact of paper recycling on energy and CO2 emissions. Resour. Conserv. Recycl. 2010, 54, 1208–1218. [Google Scholar] [CrossRef]

- Villanueva, A.; Wenzel, H. Paper waste—Recycling, incineration or landfilling? A review of existing life cycle assessments. Waste Manag. 2007, 27, S29–S46. [Google Scholar] [CrossRef]

- Rahman, M.O.; Hussain, A.; Basri, H. A critical review on waste paper sorting techniques. Int. J. Environ. Sci. Technol. 2013, 11, 551–564. [Google Scholar] [CrossRef]

- Ozola, Z.U.; Vesere, R.; Kalnins, S.N.; Blumberga, D. Paper waste recycling. Circular economy aspects. Environ. Clim. Technol. 2019, 23, 260–273. [Google Scholar] [CrossRef]

- Cabalova, I.; Kacik, F.; Geffert, A.; Kacikova, D. The Effects of paper recycling and its environmental impact. Environ. Manag. Pract. 2011, 329–350. [Google Scholar] [CrossRef]

- Potček, F.; Češek, B.; Milichovský, M. Effect of adding secondary fibers to kraft pulp on strength properties and air resistance. Cellul. Chem. Technol. 2013, 47, 425–441. [Google Scholar]

- Yilmaz, U.; Tutus, A.; Sönmez, S. Fiber classification, physical and optical properties of recycled paper. Cellul. Chem. Technol. 2021, 55, 689–696. [Google Scholar] [CrossRef]

- Ghais, A.; Mutwly, M. Effect of recycling process on paper properties. Int. J. Sci. Eng. Res. 2014, 5, 401–403. [Google Scholar]

- Obradovic, D.; Mishra, L.N. Mechanical properties of recycled paper and cardboard. J. Eng. Exact Sci. 2020, 6, 0429–0434. [Google Scholar] [CrossRef]

- Faubert, P.; Barnabé, S.; Bouchard, S.; Côté, R.; Villeneuve, C. Pulp and paper mill sludge management practices: What are the challenges to assess the impacts on greenhouse gas emissions? Resour. Conserv. Recycl. 2016, 108, 107–133. [Google Scholar] [CrossRef]

- Liao, C.; Kannan, K. Widespread occurrence of bisphenol A in paper and paper products: Implications for human exposure. Environ. Sci. Technol. 2011, 45, 9372–9379. [Google Scholar] [CrossRef] [PubMed]

- Pivnenko, K.; Eriksson, E.; Astrup, T.F. Waste paper for recycling: Overview and identification of potentially critical substances. Waste Manag. 2015, 45, 134–142. [Google Scholar] [CrossRef]

- Geens, T.; Goeyens, L.; Kannan, K.; Neels, H.; Covaci, A. Levels of bisphenol-A in thermal paper receipts from Belgium and estimation of human exposure. Sci. Total Environ. 2012, 435–436, 30–33. [Google Scholar] [CrossRef]

- Ervasti, I.; Miranda, R.; Kauranen, I. A global, comprehensive review of literature related to paper recycling: A pressing need for a uniform system of terms and definitions. Waste Manag. 2016, 48, 64–71. [Google Scholar] [CrossRef]

- Grossmann, H.; Handke, T.; Brenner, T. Paper recycling. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Elsevier: Amsterdam, The Netherlands, 2014; pp. 165–178. [Google Scholar] [CrossRef]

- Technologies for paper recycling. In Lead Markets for Environmental Innovations. ZEW Economic Studies; Physica-Verlag Heidelberg: Heidelberg, Germany, 2005; Volume 27, pp. 205–2016. [CrossRef]

- Jin, H.; Kose, R.; Akada, N.; Okayama, T. Relationship between wettability of pulp fibers and tensile strength of paper during recycling. Sci. Rep. 2022, 12, 1560. [Google Scholar] [CrossRef]

- Ali, I. Study of the mechanical behavior of recycled fibers. Applications to papers and paperboards. In Contribution à l’ Étude Du Comportement Mécanique Des Fibres Recyclées; Applications Aux Support; Université de Grenoble: Grenoble, France, 2013. [Google Scholar]

- Valchev, I.V.; Bikov, P.I.; Blyahovski, V.N.; Tsekova, P.B. New Possibilities for Recycled Paper Bleaching. In Proceedings of the 16th International Symposium Wood, Fiber Pulping Chemistry, Tianjin, China, 8–10 June 2011; Volume 1, pp. 677–681. [Google Scholar]

- Optimization of Bleaching and Deinking of Waste Paper for Strength and Brightness Improvement. European Commission CORDIS EU Research Result. Available online: https://cordis.europa.eu/project/id/MP2B0006/pl (accessed on 20 August 2022).

- Kopania, E.; Stupińska, H.; Palenik, J. Susceptibility of deinked waste paper mass to peroxide bleaching. Fibres Text. East. Eur. 2008, 16, 112–116. [Google Scholar]

- Peşman, E.; Parlak, M. Recycling of colored office paper. Part II: Postbleaching with formamidine sulfinic acid and hydrogen peroxide. BioResources 2019, 13, 4841–4855. [Google Scholar] [CrossRef]

- Zeb, H.; Hussain, M.A.; Ahmed, I.; Akram, M.S.; Haider, B.; Haider, R.; Babar, Z.B.; Saleem, R.M.; Ahsan, A.; Aziz, I.; et al. Study of bleaching of old newsprint recycled paper: Reproduction of newspaper material. Mater. Res. Express 2021, 8, 085305. [Google Scholar] [CrossRef]

- Bajpai, P. Deinking with enzymes. Recycl. Deinking Recover. Pap. 2014, 139–153. [Google Scholar] [CrossRef]

- Kumar, A.; Dutt, D. A Comparative study of conventional chemical deinking and environment-friendly bio-deinking of mixed office wastepaper. Sci. African 2021, 12, e00793. [Google Scholar] [CrossRef]

- Hasanin, M.S.; Hashem, A.H.; Abd El-Sayed, E.S.; El-Saied, H. Green ecofriendly bio-deinking of mixed office waste paper using various enzymes from Rhizopus microsporus AH3: Efficiency and characteristics. Cellulose 2020, 27, 4443–4453. [Google Scholar] [CrossRef]

- Lasheva, V.; Todorova, D.; Kotlarova, S.; Kamburov, M. Deinking of Waste Offset Printed Paper by the Use of Enzymes. Int. Sci. J. Sci. Business, Soc. 2016, 1, 26–28. [Google Scholar]

- Paper Recycling. Monitoring Report 2011, ERPC European Declaration on Paper Recycling 2011–2015; Paper Recycling: Brussel, Belgium, 2011; pp. 1–8. Available online: http://www.cobelpa.be/pdf/Monitoring%20report%20final.pdf (accessed on 30 November 2022).

- Li, S.; Wu, Z.; Wu, Z.; Liu, G. Enhancing fiber recovery from wastewater may require toilet paper redesign. J. Clean. Prod. 2020, 261, 121138. [Google Scholar] [CrossRef]

- Su, Z.H.; Fan, S.J.; Zhang, Y.; Tian, C.; Gong, C.; Ni, J.P.; Yang, B.; Peng, F.; Korkko, M.; Mahmoud, M.S. Industrial scale-up of fiber recovery technology from mixed office waste fine screen rejects. BioResources 2020, 15, 6420–6430. [Google Scholar] [CrossRef]

- Cortright, A. Paper Recycling Fiber Recapture. Honors Thesis, Western Michigan University, Kalamazoo, MI, USA, 2020. [Google Scholar]

- Small-Scale Paper Fiber Recovery. Final Report. 1995. Available online: https://p2infohouse.org/ref/17/16804.pdf (accessed on 23 November 2022).

- Barber, S.D. Analysis and Prevention of Usable Fiber Loss from a Fine Paper Mill. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1998. [Google Scholar]

- Adu, C.; Jolly, M.; Thakur, V.K. Exploring new horizons for paper recycling: A review of biomaterials and biorefinery feedstocks derived from wastepaper. Curr. Opin. Green Sustain. Chem. 2018, 13, 21–26. [Google Scholar] [CrossRef]

- Haile, A.; Gelebo, G.G.; Tesfaye, T.; Mengie, W.; Mebrate, M.A.; Abuhay, A.; Limeneh, D.Y. Pulp and paper mill wastes: Utilizations and prospects for high value-added biomaterials. Bioresour. Bioprocess. 2021, 8, 35. [Google Scholar] [CrossRef]

- Al-Battashi, H.; Annamalai, N.; Al-Kindi, S.; Nair, A.S.; Al-Bahry, S.; Verma, J.P.; Sivakumar, N. Production of bioplastic (poly-3-hydroxybutyrate) using waste paper as a feedstock: Optimization of enzymatic hydrolysis and fermentation employing burkholderia sacchari. J. Clean. Prod. 2019, 214, 236–247. [Google Scholar] [CrossRef]

- Absorbing Research Produces Aerogels from Waste Paper. Materials Today. Available online: https://www.materialstoday.com/biomaterials/news/research-produces-aerogels-from-waste-paper/ (accessed on 23 November 2022).

- PN-EN 643:2014-03. Available online: https://sklep.pkn.pl/pn-en-643-2014-03e.html (accessed on 13 November 2022).

- Kamel, S.; El-Sakhawy, M.; Nada, A.M.A. Mechanical properties of the paper sheets treated with different polymers. Thermochim. Acta 2004, 421, 81–85. [Google Scholar] [CrossRef]

- Nada, A.M.A.; El-Sakhawy, M.; Kamel, S.; Eid, M.A.M.; Adel, A.M. Mechanical and electrical properties of paper sheets treated with chitosan and its derivatives. Carbohydr. Polym. 2006, 63, 113–121. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).