Abstract

The combination of red mud (RM) and phosphogypsum (PG) can exert the alkalinity of RM and the acidity of PG as a calcium source to promote the gel hardening of composite cementitious material, which effectively improves the reutilization efficiency of RM and. In this study, the effects of the ratio and content of pretreated RM and PG on the non-evaporated water, porosity, hydration products, mechanical properties, pore size distribution, and microstructure of composite cementitious materials were investigated. The results show that, with the incorporation of PG, RM, PG, and RM, the non-evaporable water content, reaction degree, compressive strength, and flexural strength show a downward trend after rising first, and their values reach the maximum with 10% PG and 10% RM, which are higher than a pure cement system, while 70% PG, 70% RM, 70% RM + 10% PG, and 70% PG + 10% RM have the reverse effect. The results of hydration products, pore size distributions, and microstructure indicate that adding an appropriate dosage of RM and PG can efficaciously improve the compactness of cement systems. Nevertheless, the research results can contribute to using the combination of PG and RM to manufacture sustainable cementitious materials with good performance, and achieve the purpose of environmental protection and industrial solid waste resource recycling.

1. Introduction

In today’s construction industry, concrete is a traditional building material. However, cement, as the basic material of concrete, produces carbon dioxide. Hence, finding an economic and environmental protection mode of production is an urgent problem to be solved. Based on the concept of sustainable development, many scholars have proposed a great deal of ways to reduce CO2 by means of using different waste materials [1]. The application of industrial waste and by-products in the construction industry can not only cut down the cost, but also serve to protect the environment [2,3].

Red mud (RM), as a by-product of the Bayer process, is an alkaline leaching waste [4]. It is estimated that the global RM accumulation exceeds 4 billion tons and about 120 million tons of RM are generated per year in China [5,6]. RM contains the oxides Fe2O3, Al2O3, SiO2, TiO2, CaO, and Na2O, a small amount of trace elements (F, Cr, Cu, Pb, V and Zn), and radionuclides (226Ra, 232Th, and 40K) [7]. Meanwhile, due to the use of sodium hydroxide solution in the production process, RM is highly alkaline (pH value is 9.2–12.2) [8]. However, RM is generally treated by burial and deposition into the sea, which will contaminate water, soil, and other sources [9]. Therefore, the recycling and rational utilization of RM is extraordinarily significant. In recent years, researchers have been looking for economic and environmentally-protective methods to deal with RM. It has been widely used in the fields of cement, concrete, glass, ceramics [10], adsorbents [11], geopolymers, catalysts [12], composite materials, sewage treatment, waste gas treatment [13], soil improvement, and valuable element recovery [14,15]. RM has the characteristics of porous materials and strong adsorption capacity; therefore, it can be used to prepare water treatment adsorption materials [16]. As a substitutable filler, RM is also used in roadbed construction [17,18]. The use of RM is mainly concentrated in the field of construction, which is also the most effective method to consume it. It can be used as a substitute for fly ash to prepare self-compacting concrete, thus improving the mechanical properties of concrete [19,20]. In addition, RM can also be used as an additive in materials to enhance their physico-mechanical properties [21,22]. Because RM can cut down the porosity of hydration products of binary blends, it can be used to prepare unfired bricks [23]. Moreover, adding a certain amount of RM into mortar improves its fluidity and prolongs the setting time [24]. At present, red mud is mainly used to prepare cementitious materials [25]. As a new type of cementitious material, geopolymer has entered the public eye. The gelling property of RM-based geopolymer alone is poor [26]. Nonetheless, geopolymers prepared from RM and other wastes can be used in the construction industry. For example, RM and slag are mixed in different proportions to examine the mechanical properties [27]. RM and fly ash can also be used as raw materials for geopolymers [28,29]. Meanwhile, using municipal solid waste incineration fly ash and RM to prepare geopolymer is a method to activate RM [30]. Tang et al. [31] also showed that the compressive strength of fly ash mixer using 50% RM to replace fly ash was higher.

As a by-product of phosphoric acid production, phosphogypsum (PG) is a kind of waste gypsum. It is reported that approximately five tons of PG are generated in the production of one ton of phosphoric acid [32]. Every year, from 100 to 280 million tons of PG are produced in the world [33]. Nevertheless, only 15% of PG is utilized effectively and a large amount of PG remains in areas near rivers or seas and in open-air piles without any special treatments [34]. PG contains CaSO4·2H2O and small amounts of phosphorus, fluorine, heavy metal, organic matters, and radioactive elements [35]. Due to the effect of harmful impurities, the accumulation of PG causes serious environmental pollution such as waste of land, pollution of atmosphere, water bodies, and so on [36]. Although the cost of PG is low, it requires water washing, chemical neutralization by basic solutions, calcination, and other pre-treatment processes before using, which not only produces a high concentration of environmental pollutant, but also increases the cost [37,38]. Based on this, the large-scale application of PG in the construction industry is restricted [39]. At present, PG is recycled as raw materials of building materials [40]. In road construction, PG stimulates the pozzolanic characteristics of fly ash. Thus, it is can be beneficial to utilize PG and fly ash as raw materials in road base construction [41]. Besides, the treated PG can be used as an additive in cement production to control the hydration reaction rate of cement [42,43,44]. Using PG to prepare self-leveling mortar is also a method to consume it [45]. Nowadays, using PG to produce a green cementitious material with good performance is found to be a scientific method for PG disposal [46]. Owing to the hydration of PG-based cementitious material being complex, PG incorporation increases the mechanical property of paste and the setting time [47,48]. Sun et al. [49] also proved that PG could obviously prolong setting time and decrease compressive strength as well as density due to the water-soluble phosphorus, fluoride, and sulfate compounds in PG. Zhang et al. [50] thought that 10% wet-grinded PG could improve the compressive strength of mortar, which increased by 193%; however, the compressive strength of mortar could not unceasingly increase with a content of wet-grinded PG over 10%.

The above research shows that RM and PG can be used as a binder or supplementary cementitious material in cement systems. Simultaneously, recent research has studied the properties of RM or PG incorporated into cement-based materials, involving mainly material composition and mix proportion optimization. A key challenge related to cementitious material combined with RM and PG is the present absence of research on its hydration hardening characteristics, as there are few studies in the literature about this issue. Nevertheless, the hydration hardening characteristics of cementitious material combined with RM and PG will be discussed in this study.

In the present manuscript, the aim is to evaluate the hydration and hardening characteristics of cementitious material with RM as an alkaline activator and acidic PG as a calcium source. However, RM, having a high pH value, and PG, having high gypsum content, are used; thus, the focus of this research is on whether cementitious material combined with RM and PG can be manufactured. The novelty of this study is that the use of Ordinary Portland cement is small because 80% of the Ordinary Portland cement was replaced by industrial by-product, and the difference between RM and PG as supplementary cementitious materials is investigated. Nevertheless, three types of mortar/paste with RM, PG, and RM and PG coexistence are appraised for an effect contrast with pure cement mortar/paste. The following performances of cementitious material were evaluated: the non-evaporable water, porosity, hydration product, mechanical property, pore size distribution, and microstructure.

2. Materials and Methods

2.1. Experimental Materials

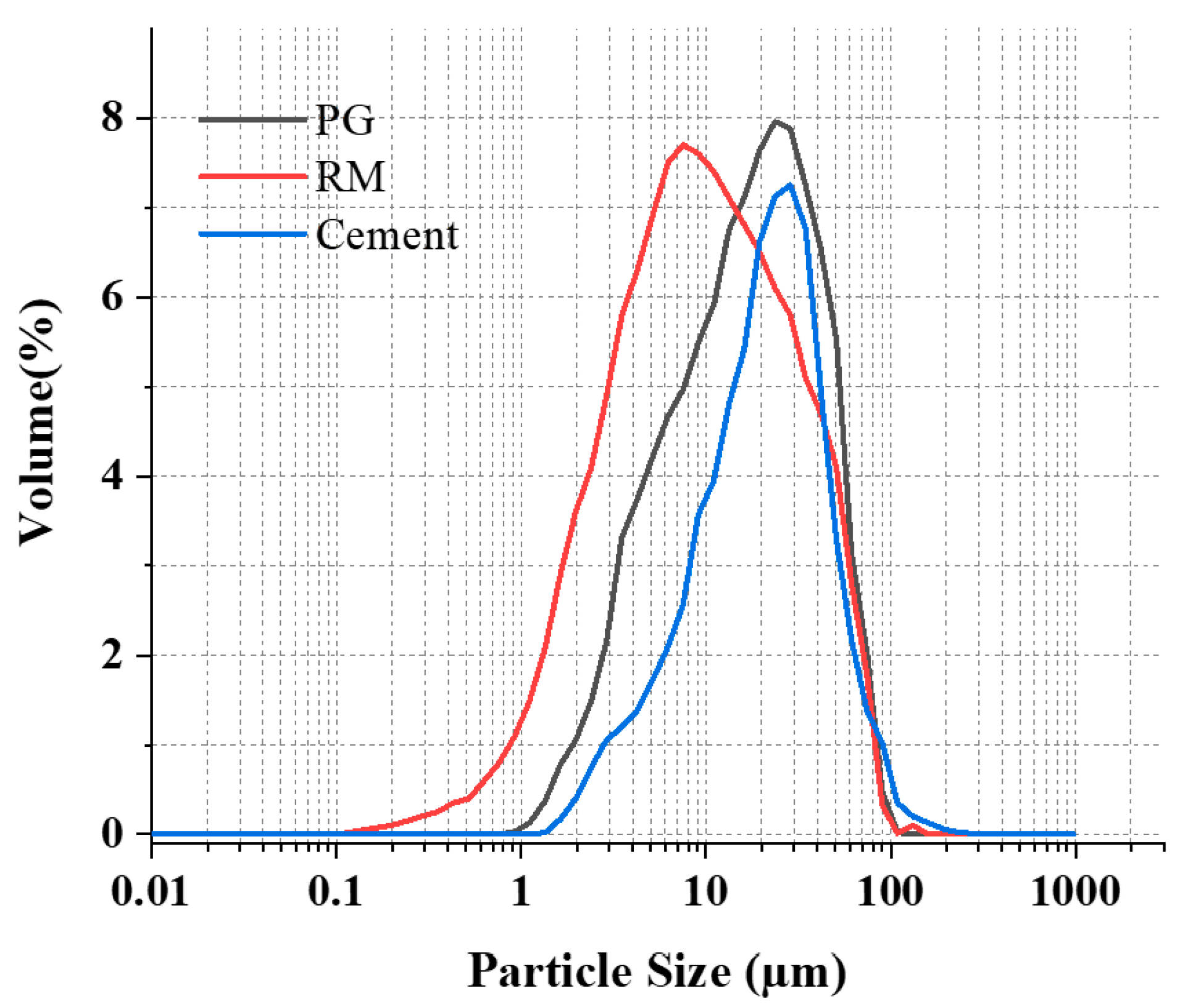

Ordinary Portland cement (Level 42.5 R) came from China’s XiNan cement factory. Its specific surface area is 380 m2/kg and density is 3.11 g/cm3, and the compressive strengths are 18.7 MPa at 3 days, 29.8 MPa at 7 days, and 44.5 MPa at 28 days, respectively, according to Chinese standard GB175-2007. Ultrasonic circulating water pretreatment of combined process RM was employed, which came from a bauxite factory in Guizhou of China. Its specific surface and density are 540 m2/kg and 2.81 g/cm3, respectively. Ultrasonic circulating water pretreatment PG was employed, which came from Kailin Chemical Fertilizer Co., Ltd. of China. It has a water content of 5.23%, a density of 2.37 g/cm3, a specific surface of 450 m2/kg, and initial and final setting times of 35.4 min and 42.6 min, according to Chinese standard GB/T23456-2018. The chemical composition and particle size distribution of Ordinary Portland cement, PG, and RM are illustrated in Table 1 and Figure 1, respectively. Superplasticizer was employed to provide a satisfactory workability, which came from Laiyang Hongyang construction admixture factory of China. The particle sizes of the standard sand which was employed remain below 2.35, the sand came from Xia Men ISO standard sand Co., Ltd. of China (Xiamen, China).

Table 1.

Chemical composition of Ordinary Portland cement, PG, and RM (wt.%).

Figure 1.

Particle size distribution of cement, PG, and RM.

2.2. Samples Preparation

According to the research of references [49,50,51,52,53], it was found that 10% RM- and 10% PG-replaced cement can improve the quality of cement system. In the present study, in order to analyze the difference in hydration between PG and RM in cement systems, the water-binder ratio was fixed at 0.5, 10%, and 70% of PG and RM replaced an equal weight of cement. On this basis, cement was fixed at 20%, PG and RM were 10 wt% and 70 wt% or 70 wt% and 10 wt%, respectively. Then, the differences between the single admixtures were analyzed, and the mixture ratio is shown in Table 2. These mortars, after mixing evenly, were poured for 63 mortar specimens (the size was 160 mm × 40 mm × 40 mm), then demolded after curing at room temperature for 1 day, and then cured at room constant temperature (20 ± 1 °C) and relative humidity over 95% for 3 days, 7 days, and 28 days. Then, the mechanical property, pore size distribution, microstructure, and porosity of mortar specimens were examined in pure cement system, cement PG system, cement RM system, and cement PG–RM system.

Table 2.

Mix of mortar /g.

The paste specimens were prepared according to the mix of paste shown in Table 3. These pastes, after mixing evenly, were put into 63 centrifuge tubes of 10 mL and sealed, then cured at room temperature (20 ± 1 °C) and relative humidity over 95% for 3, 7, and 28 days. The non-evaporable water, reaction degree, and hydration product of composite binder paste specimens were measured in cement system, cement PG system, cement RM system, and cement PG–RM system.

Table 3.

Mix of paste/g.

2.3. Test Methods

2.3.1. The Non-Evaporable Water

The non-evaporable water of paste in cement system, cement PG system, cement RM system, and cement PG–RM system were evaluated by calcination. First, the sample was finely ground, then passed through a 0.16 mm square hole sieve and calcined in an oven at 105 °C and 1000 °C for 4 h to keep it at a constant weight. Then, the non-evaporable water of paste was calculated by the difference in mass between 105 °C and 1000 °C, 3 experimental results were used as the final value.

2.3.2. Reaction Degree

The reaction degree of PG and RM in cement PG system, cement RM system, and cement PG–RM system was evaluated by solution selective dissolution method according to the Chinese national standard GB/T 12960-2007. Taking cement PG system as an example, it weighed about 0.5 g (m1) of the ground sample (through the sieve aperture of 0.08 mm), and was put in a 150 mL beaker, 80 mL of distilled water was added, it was stirred on a magnetic stirrer for 5 min (rotating speed of 200 r/min, temperature of (20 ± 1) °C), 40 mL (1 + 2) hydrochloric acid solution was added, stirring continued for 25 min on a magnetic stirrer with a rotating speed of 200 r/min, then it was taken off and a sand-core glass funnel (m2) which has been dried in an oven at (105 ± 5) °C in advance for pumping and filtering was used. After that, the insoluble residue was washed with distilled water 5–6 times, and then washed with anhydrous ethanol (analytically pure) 2–3 times. After washing, we placed the glass funnel with sand core into an oven at 105 ± 5 °C, dried it to a constant weight (more than 4 h), and then weighed it after drying and cooling (m3). After hydrochloric acid dissolution, the residual mass fraction (RPG) of cement–PG paste was calculated by Formula (1), and the reaction degree of PG was calculated according to Formula (2):

where Wne was the non-evaporable water of cement–PG paste, %. RC was the residual mass fraction of cement, %. fPG and fC were the mass fraction of PG, and cement in cement PG system, %.

The reaction degree of PG and RM in the cement PG–RM system was evaluated by calcination, and the specific implementation process was as follows: the paste was molded in a centrifugal tube according to the mass ratio of water to PG of 1:1, and its non-evaporable water content was measured after curing at 60 °C for 120 days. The measured value (n0) was regarded as the approximate total non-evaporable water content of fully-hydrated PG, and the non-evaporable water content (nt) at a specific curing age was measured, then the reaction degree of PG (η) at a specific curing age was calculated according to Formula (3) and 3 experimental results were used as the final value.

η = nt/n0 × 100%

2.3.3. Phase Analysis of Paste/Mortar with PG and RM

After mortar/ paste was cured for 3 days and 28 days, samples were taken by crushing and placed in alcohol to stop hydration; they were then used for X-ray diffractometer, scanning electron microscope, and mercury intrusion porosimeter investigation. Hydration products of paste with PG and RM were investigated by X-ray diffractometer (XRD) with copper palladium. Implementation voltage and current were 40 KV and 40 mA, respectively. The various chemicals were identified by the Made Jade software using the PDF-2 database as a reference. Scanning rate was 10° per minute and 0.02° per step, and experimental range wase 10–50°. Microstructure of mortar with PG and RM was investigated by the TM4000 series scanning electron microscope (SEM) after spraying gold in vacuum, its resolution is 1.2 nm@30 keV and 3.5 nm@1 keV, acceleration voltage was 200 eV–30 keV, and probe beam current is 3 pA–20 nA, the stability is better than 0.2%/h.

2.3.4. Mechanical Property and Pore Size Distribution of Mortar with PG and RM

The compressive strength and flexural strength of mortar with PG and RM were investigated by YAW-300C experiment machine according to the Chinese national standard GB/T 17671-2005, its loading ratios were 2.4 and 0.5 kN/s, respectively, and the average of 6 compressive strength and 3 flexural strength experimental results were used as the final value, respectively. The porosity and the pore size distribution of mortar with PG and RM were investigated by mercury intrusion porosimeter (MIP, model is auto pore II 9220), and the maximum mercury intrusion pressure was 300 MPa.

3. Results and Discussion

3.1. Reaction Degree of PG and RM

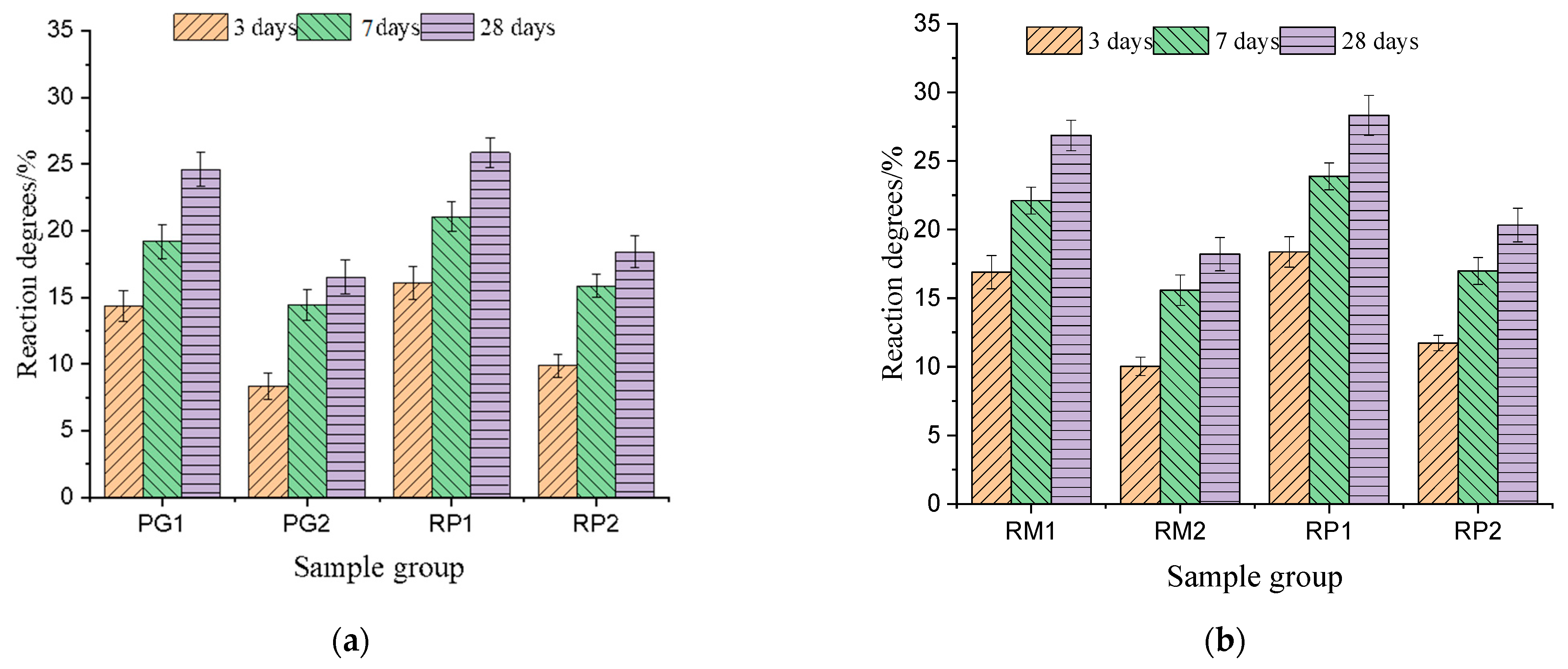

The reaction degrees of PG and RM in a cement PG system, cement RM system, and cement PG–RM system are shown in Figure 2. From Figure 2a, it can be seen that the reaction degree of PG in the PG2 group was about 41.78% at 3 days, 24.77% at 7 days, and 32.79% at 28 days compared with PG1 group. Unlike the cement PG system, the RM in the RM group had a reaction degree of 9.88% at 3 days, 15.88% at 7 days, and 18.43% at 28 days in RP1 group, which is a decrease of 38.67%,24.60% and 28.79%, respectively, compared with RP2 group. Therefore, the reaction degree of PG decreases with increases in the replacement ratio of PG in a cement PG system, while it increases in a cement PG–RM system. Compared with the PG2 group, when adding 10% RM, the reaction degree of PG in the RP1 group increased by 92.70% at 3 days, 45.95% at 7 days, and 56.47% at 28 days. When adding 70% RM, the reaction degree of PG in RP2 group decreased by 31.20% at 3 days, 17.21% at 7 days, and 25.11% at 28 days, compared with the PG1 group. Therefore, RM alkalinity has an obvious stimulating effect, and the excitation effect of RM alkalinity is relatively small. The literature [54] also found that the reactivity of PG can be not sufficiently excited because of its low activity under the excitation of cement and RM. Nevertheless, the filling action of PG plays a vital role at the early stage of hydration of composite cementitious material [55]. Unlike the change trend of PG, the reaction degree of RM also decreases with increases in the replacement ratio of RM in a cement RM system and cement PG–RM system. Compared with the cement RM system, the reaction degree of RM increased in the cement PG–RM system with increases in the replacement of PG and RM; however, it was no more than 3%. Besides, compared with the RM2 group, it is not difficult to find that, when adding 10% PG, the reaction degree of PG in the RP2 group increased by 14.42% at 3 days, 8.25% at 7 days, and 10.43% at 28 days. Adding 70% PG, the reaction degree of PG in the RP1 group increased by 8.70% at 3 days, 7.96% at 7 days, and 5.44% at 28 days, compared with the RM1 group. Obviously, the excitation effect of gypsum in PG is relatively small. Comparing with the reaction degree of PG, it is not difficult to find that the reaction degree of RM is relatively higher; even in the cement RM system and the cement RM-PG system, the curing period was prolonged from 3 days to 28 days, and it still showed the same variation tendency, although it was no more than 3%. Nevertheless, it is beneficial to exert the alkalinity of RM and the excitation of gypsum in PG in a cement RM-PG system.

Figure 2.

Reaction degree of paste with (a) PG and (b) RM.

3.2. The Non-Evaporable Water of Paste with RM and PG

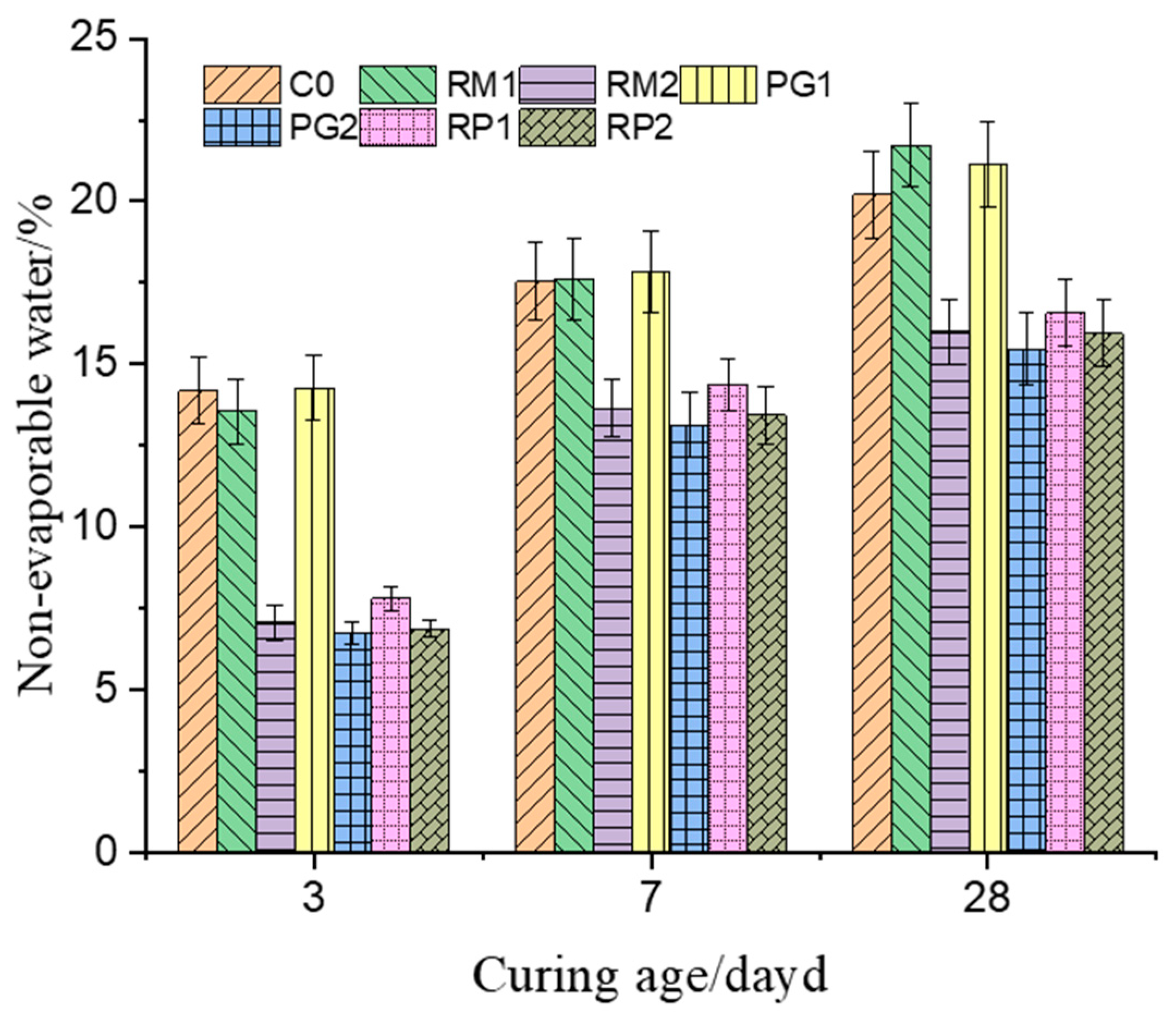

The non-evaporable water content can usually be used as the relative hydration degree. The effect of PG and RM on the cement PG system, cement RM system, and cement PG–RM system are presented in Figure 3. Compared with pure cement paste, the non-evaporable water content of paste with 10% PG is the higher, being more than 2% at 3, 7, and 28 days. Similarly, the non-evaporable water content of paste with 10% RM is higher than that of pure cement paste at 7 and 28 days. Compared with the effects of PG and RM on the non-evaporable water content of composite cementitious material paste, it was found that the effect of RM is higher than that of PG, especially in the later stage. What is more, compared with the PG2 group, when adding 10% RM, the non-evaporation water content of the RP1 group increased by 15.53% at 3 days, 9.37% at 7 days, and 7.04% at 28 days. When adding 70% RM, the non-evaporation water content of RP2 group decreased by 51.82% at 3 days, 24.72% at 7 days, and 24.51% at 28 days, compared with the PG1 group. The reason for this is mainly that the gypsum in PG had a certain retarding effect, which hindered the setting and hardening of paste [47,48], while RM had a certain stimulating effect due to the alkali in RM [16]. Compared with the non-evaporable water content of the cement PG system, the non-evaporable water content of the cement PG–RM system paste had a certain enhancing effect; however, by no more than 2%w While RM also showed similar experimental results. In addition, compared with the RM2 group, when adding 10% PG, the non-evaporation water content of the RP2 group showed a decrease of 43.40% at 3 days, 18.46% at 7 days, and 23.75% at 28 days. Adding 70% PG, the RP1 group decreased by 2.55% at 3 days, 1.61% at 7 days, and 0.25% at 28 days, compared with RM1 group. This shows that PG and RM can a exert superposition effect to increase the non-evaporation water content of paste. Therefore, adding a certain proportion of RM and PG can improve the non-evaporated water of cement paste, which is also similar to the change rule for reaction degree.

Figure 3.

The non-evaporable water of paste with RM and PG.

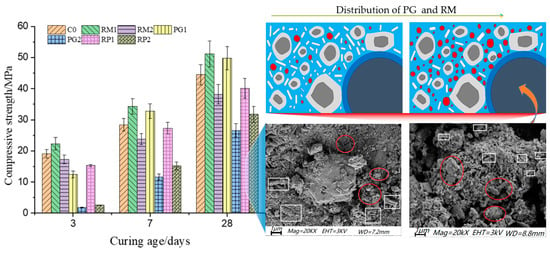

3.3. Mechanical Property of Mortar with PG and RM

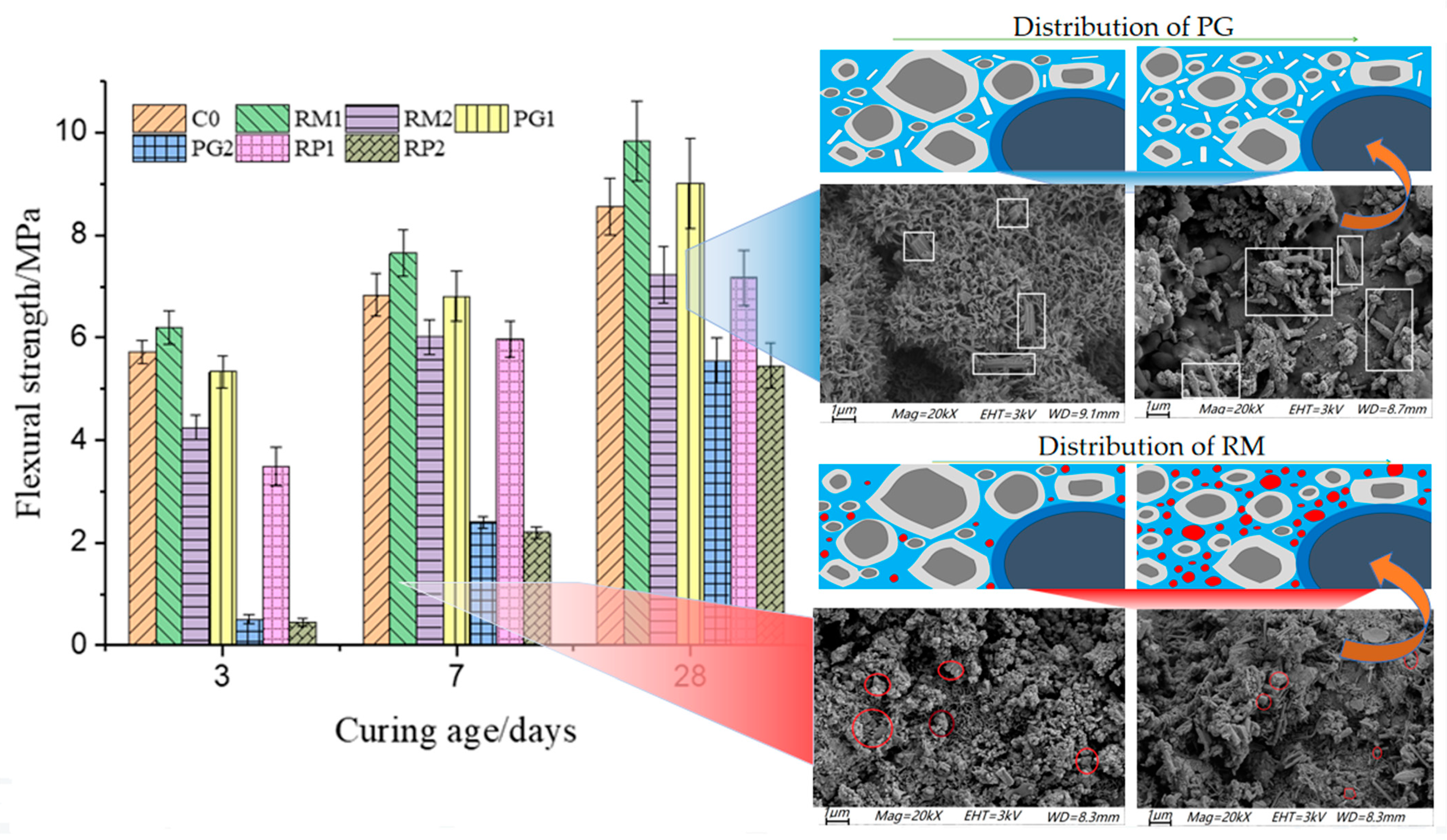

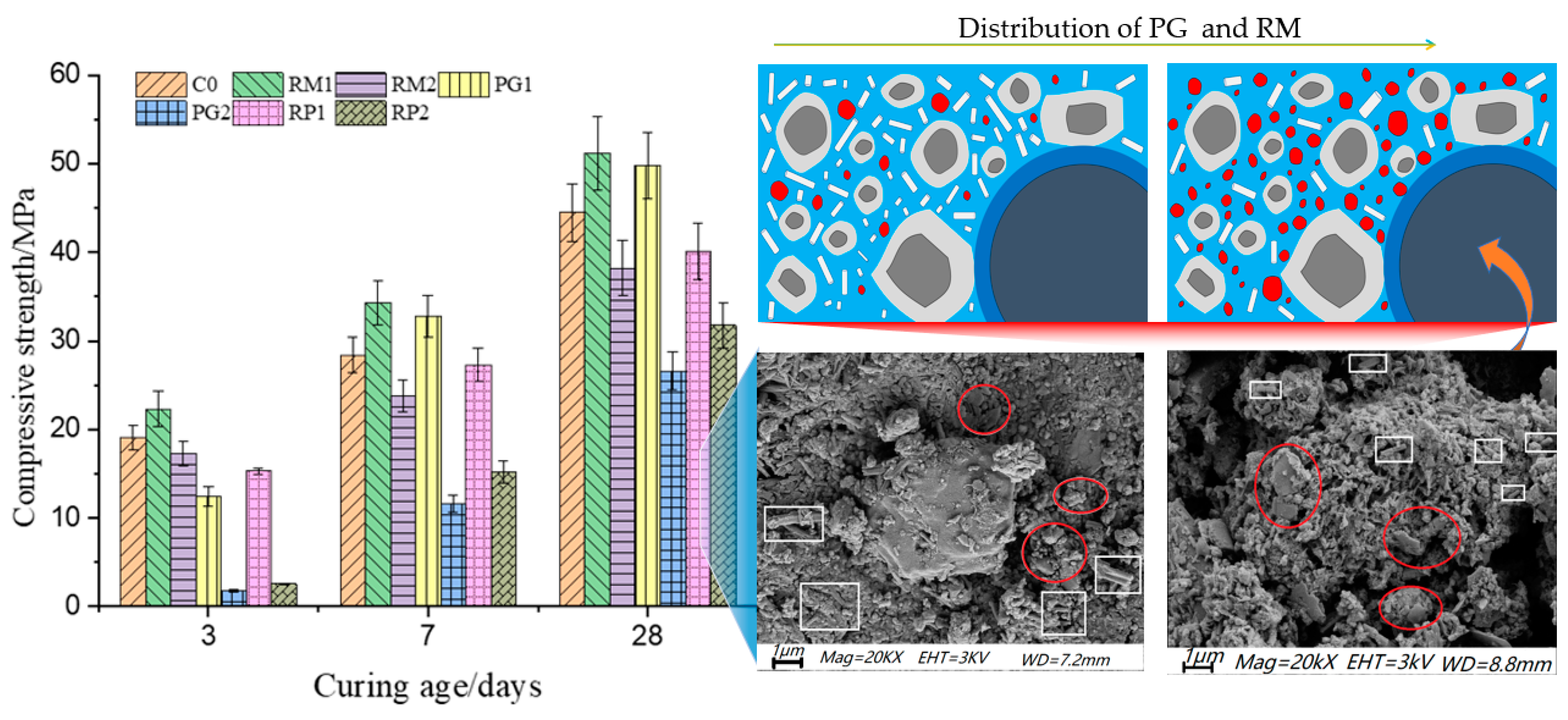

Mechanical properties are accepted as one of the main parameters for cement mortar. In the present research, the effects of PG, RM, PG, and RM on the mechanical properties of cement PG system, cement RM system, and cement PG–RM system at 3, 7, and 28 days are presented in Figure 4. Compared with pure cement mortar, 10% RM can obviously improve the flexural strength of mortar at 3, 7, and 28 days, while 10% PG can decrease the flexural strength of mortar at 3 and 7 days; however, the flexural strength increases at 28 days. For example, at 3 days, the flexural strength in the PG1 group was 5.34 MPa, in the PG2 group it was 0.51 MPa, in the RM1 group it was 6.21 MPa, and in the RM2 group it was 4.25 MPa, increases of −6.64%, −91.08%, 8.57%, and −25.70%, compared with the flexural strength of the pure cement mortar group, which was 5.72 MPa. At 28 days the flexural strength in the PG1 group was 9.02 MPa, in the PG2 group was 5.56 MPa, in the RM1 group was 9.84 MPa, and in the RM2 group was 7.23 MPa, increases of 5.37%, −35.05%, 14.95%, and −15.54%, compared with the flexural strength of the pure cement mortar group, which was 8.56 MPa. It is mainly the gypsum component in PG that prevents the hydration of cement, which further decreases the early mechanical properties of mortar [18,19,20]. The alkaline substance in RM has a stimulating effect [16,21] which further improves the early mechanical properties of mortar. Nevertheless, it is beneficial to improve the mechanical properties of mortar at 28 days with 10% RM and 10% PG, while it shows obvious deterioration with 70% RM and 70% PG. In addition, compared with the PG2 group, it is not difficult to find that, in adding 10% RM, the flexural strength of the RP1 group increases by 584.31% at 3 days, 149.17% at 7 days, and 28.96% at 28 days. When adding 70% RM, the flexural strength of the RP2 group decreased by 91.57% at 3 days, 67.69% at 7 days, and 39.47% at 28 days, compared with the PG1 group. Thus, after RM and PG replace cement together, their respective characteristics can be brought into play and the flexural strength of mortar can be improved; however, this effect is relatively small when the dosage is 80%. The main reason for this is that the activity of RM and PG is limited, and the reduction in cement content it further decreases the excitation effect of cement on RM and PG. This is also confirmed by the research results of hydration degree and non-evaporation water.

Figure 4.

Flexural strength of mortar with PG and RM. (White frame represents phosphogypsum, which is rod-shaped in microstructure, and red frame represents that the red mud is displayed as particles in the microstructure.).

The compressive strength of mortar in the cement PG system, cement RM system and cement PG–RM system at 3, 7 and 28 days is presented in Figure 5. Form Figure 5, it can be seen that the compressive strength of cement mortar shows a downward trend after rising first in the cement RM system and cement PG system at 7 and 28 days, while it shows a downward trend in the cement PG–RM system and cement PG system at 3 days, and the change in their peak compressive strength depends on the content of RM and PG. For the pure cement mortar, the compressive strength is 19.1 MPa at 3 days, 28.4 MPa at 7 days, and 44.5 MPa at 28 days. The peak value of compressive strength of the cement PG system appeared at 10%, which was 12.5 MPa at 3 days, 32.8 MPa at 7 days, and 49.8 MPa at 28 days, a decrease by 34.55%, and an increase by 15.49% and 11.91% compared with pure cement mortar. The peak value of compressive strength of the cement RM system appeared at 10%, which was 22.3 MPa at 3 days, 34.3 MPa at 7 days, and 51.2 MPa at 28 days, an increase by 16.75%, 20.77%, and 15.06% compared with the pure cement mortar. Therefore, adding 10% RM and PG is beneficial to improve the compressive strength of mortar at 28 days. Besides, the compressive strength of the cement RM system was higher than that of the cement PG system. Compared with the PG2 group, it is not difficult to find that, when adding 10% RM, the compressive strength of the RP1 group increases by 750.00% at 3 days, 135.34% at 7 days, and 50.75% at 28 days. When adding 70% RM, the compressive strength of the RP2 group decreases by 79.20% at 3 days, 53.66% at 7 days, and 36.18% at 28 days, compared with the PG1 group. Meanwhile, compared with the RM2 group, when adding 10% PG, the compressive strength of the RP2 group decreases by 85.64% at 3 days, 43.28% at 7 days, and 22.86% at 28 days. When adding 70% PG, the compressive strength of PG in the RP1 group decreases by 31.39% at 3 days, 20.41% at 7 days, and 21.68% at 28 days, compared with the RM1 group. Similarly, the flexural strength, when adding RM and PG to replace cement together, the compressive strength of mortar can be improved; however, this effect is relatively small when the dosage is 80%. According to the research, the appropriate amount of PG and RM can improve the mechanical properties of cement-based materials, Ortega et al. [51] and Zhang et al. [50] also found a similar result. Combining the existing literature and the experimental results of this paper, it can be seen that the replacement rate of RM and PG is less than 10%, and is beneficial to improve the mechanical properties of composite cementitious material. Generally speaking, after adding RM and PG, their 28-day compressive strengths were not less than 25 MPa in all experimental groups, which meets the requirements of M25 in China standard JGJ/T70—2009. Therefore, it can be used in masonry wall, mortar brick, wall decoration, and other projects.

Figure 5.

Compressive strength of mortar with PG and RM. (White frame represents phosphogypsum, which is rod-shaped in microstructure, and red frame represents that the red mud is displayed as particles in the microstructure.).

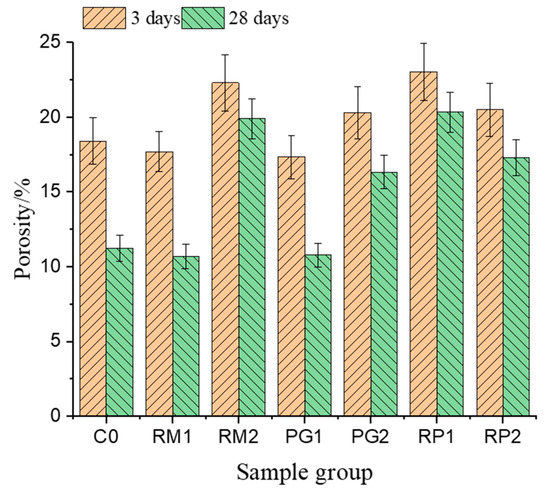

3.4. Porosity of Mortar with PG and RM

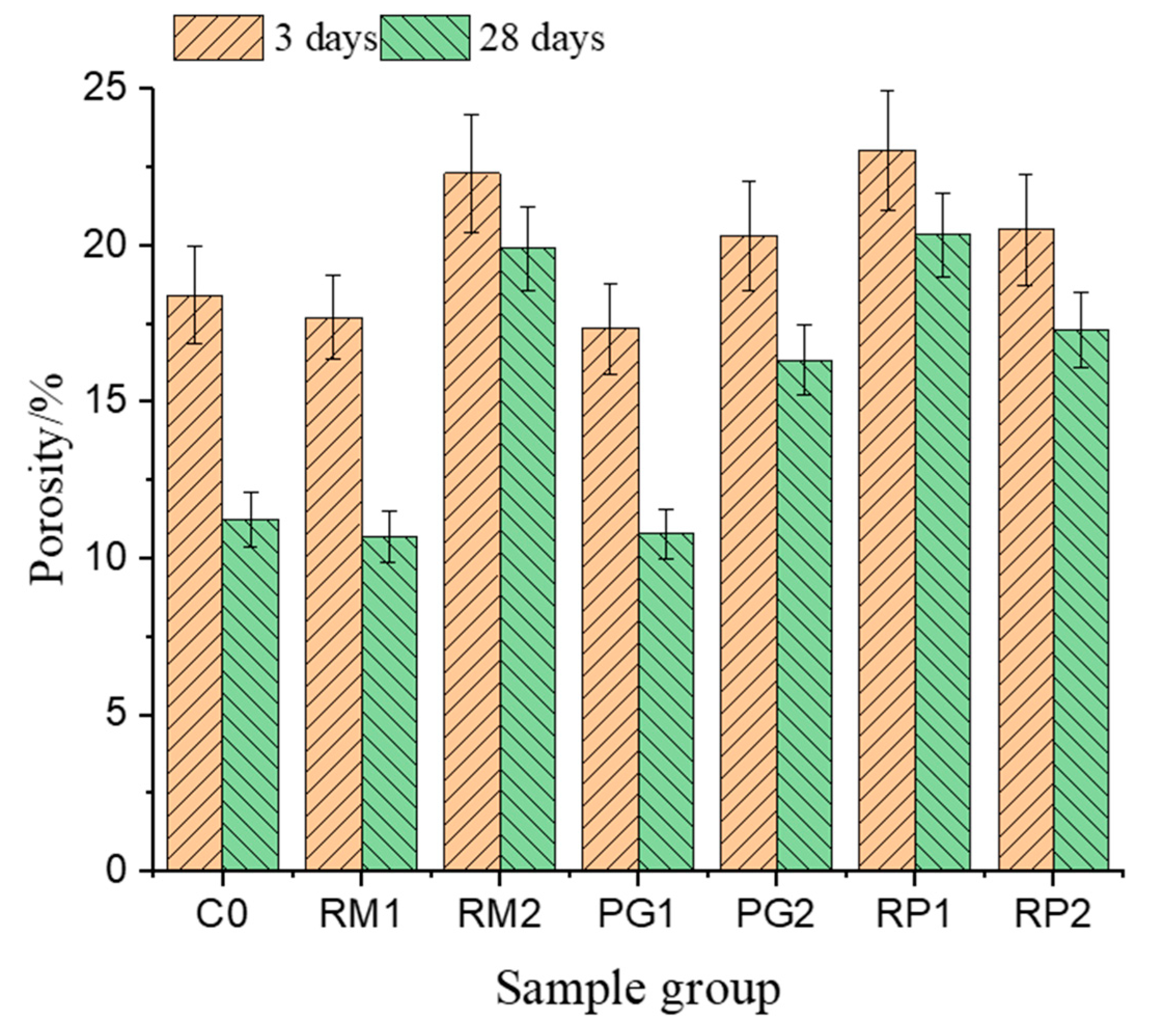

The porosities of mortar in the cement PG system, cement RM system, and cement PG–RM system at 3 and 28 days are presented in Figure 6. Obviously, curing age, single-doped content, and compound-doped content can significantly change the porosity of mortar. For example, the porosities of the samples C0, RM1, RM2, PG1, PG2, RP1, and RP2 were 18.4%, 17.7%, 22.3%, 17.3%, 20.3%, 23.0%, and 20.5% at three days, respectively, which prove that 10% RM and 10% PG can effectively improve the porosity of mortar, while 70% RM, 70% PG, 70% RM + 10% PG, 70% PG + 10% RM showed a negative effect. Even compound-doped PG and RM do not have a good modification effect on the porosity of mortar, which can be attributed to the high replacement rate and low reaction degree of RM and PG that fail to give full play to pozzolanic activity [52]. After the curing period was prolonged, the mortar become denser due to the hydration of the cement; nevertheless, the porosity of mortar decreased by 38.9% at 28 days in the C0 group, and sample RM1 and sample PG1 decreased by 39.7% and 37.9%, respectively, which are both lower than that of pure cement mortar. The samples RM2, PG2, RP1, and RP2 reduced no more than 20%, which are all higher than that of pure cement mortar. Comparing RM1, PG1, RM2, PG2, RP1, and RP2, it is found that PG can more effectively refine the pore structure of mortar than RM. There is a certain amount of ettringite that can be generated due to the existence of gypsum in PG. In addition, ettringite can grow effectively without affecting the stability of mortar due to the retarding effect of PG. Nevertheless, PG has a good function of refining the pore structure of mortar. What is more, many studies have also confirmed that single-doped RM and PG can improve the pore structure of mortar. For example, Yang et al. [12] thought that mortar became denser, and the porosity decreased with 0–9% RM. Venkatesh et al. [53,56] also thought that the porosity of concrete decreased with 10% RM, and exhibited higher strength and durability compared with pure cement concrete. Li et al. [47] compared unmodified PG, 500 °C burnt PG, and neutralized PG with 4% lime, and thought that the porosity of mortar with 15% PG burnt at 500 °C was the smaller, and the differences in others were less than 1%.

Figure 6.

Porosity of mortar with PG and RM.

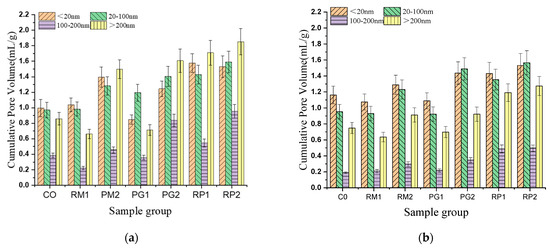

3.5. Pore Size Distribution of Mortar with PG and RM

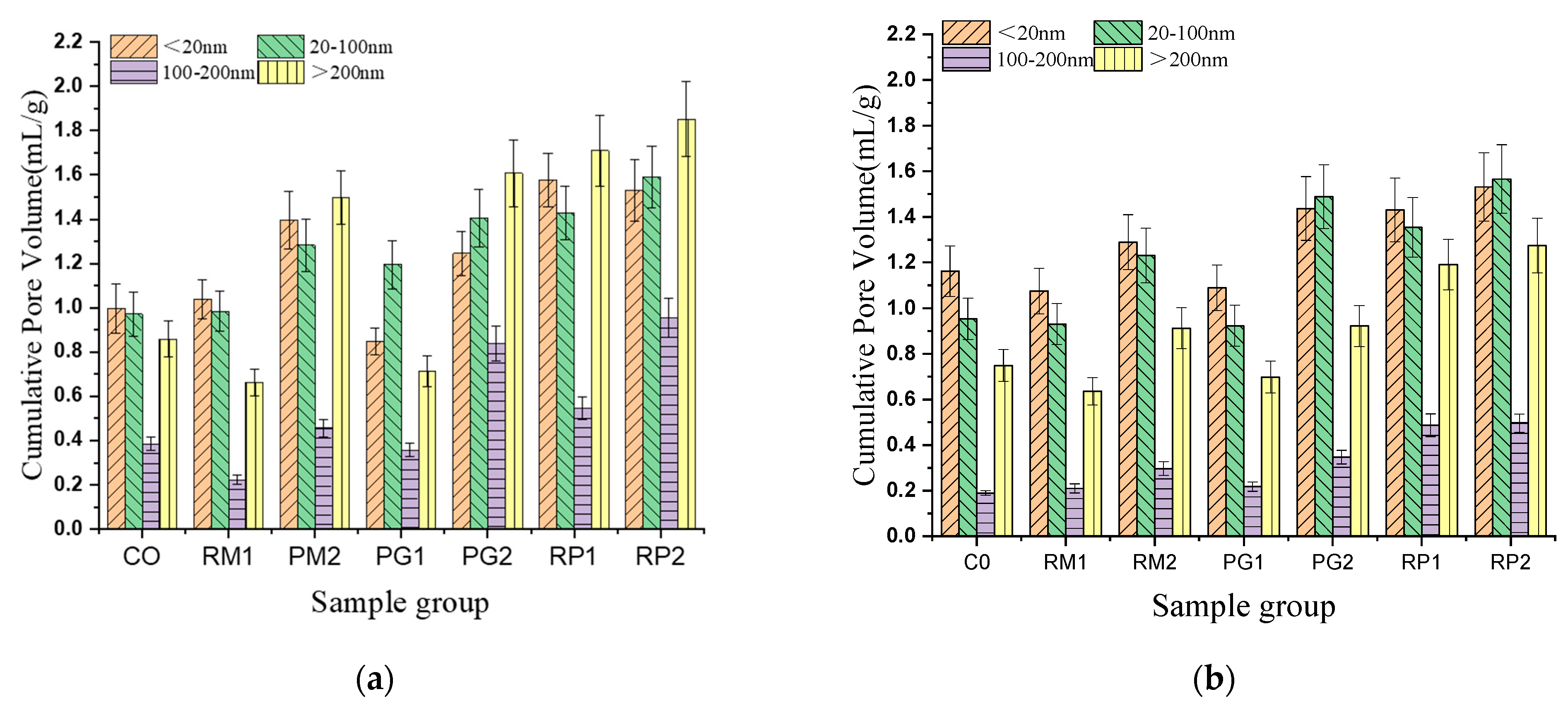

Pore size distributions have been naturalized as one of the primary factors affecting strength and permeability; the effect of PG, RM, PG, and RM on the pore size distributions of mortar is monitored by MIP and the experimental results are shown in Figure 7. From Figure 7a, it can be seen that the pore size distributions of mortar are greatly influenced by single-doped content and compound-doped content. For example, the volume of capillary pores of >200 nm for mortar with 0% PG and RM is approximately 27% of the total gel pore volume. A total of 10% PG and 10% RM reduce by approximately 25%, and the volumes of capillary pore of 100~200 nm are similar. The volume of capillary pores of >200 nm, 100~200 nm, 20~100 nm, and <20 nm in mortar with 70% PG, 70% RM, 70% RM + 10% PG, and 70% PG + 10% RM significantly increase, and the volume of capillary pore of >200 nm in the RM2 group, PG2 group, RP1 group, and RP2 group increase by approximately two times compared with the pure cement mortar. Nevertheless, the larger the incorporation of PG and RM, the larger the volume content of mortar gel pores.

Figure 7.

Pore size distributions of mortar with PG and RM; (a) 3 days, (b) 28 days.

The curing period was prolonged from 3 days to 28 days (seen Figure 7b), most of the cement particles have been hydrated, which stimulates the activity of PG and RM and promotes the refinement of the pore structure of mortar; nevertheless, the volume of capillary pores of <20 nm for mortar without PG and RM significantly increases, while the volume of capillary pores of >200 nm and 100~200 nm significantly decreases. Similarly, the volume of capillary pores of >200 nm significantly decreases among all mixers. Based on the above experiment results, the prolongation of curing age and the addition of appropriate admixtures are beneficial to the refinement of mortar pore structure, and many studies have also confirmed this point. In general, a pore size of more than 50 nm has an important impact on strength [47]; according to the pore size distributions of mortar in Figure 7, which are in response to the experimental results of the strength as shown in Figure 4 and Figure 5, the capillary pore of mortar could be filled with the secondary hydration reaction between cement and RM [24].

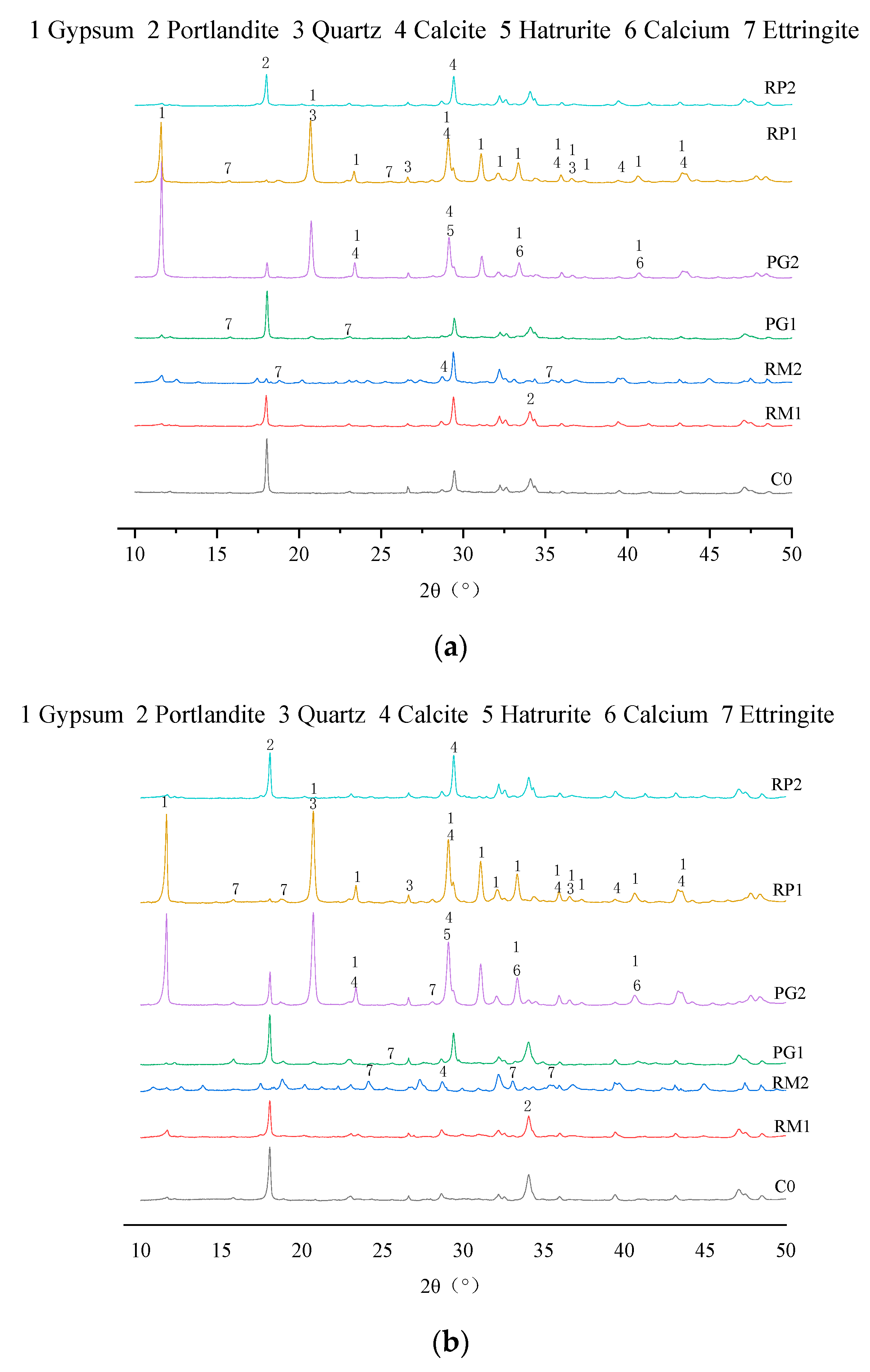

3.6. Hydration Products of Paste Samples with PG and RM

To analyze the hydration product of paste in the cement PG system, cement RM system, and cement PG–RM system at 3 and 28 days, the method of XRD analysis was carried out and the experimental results are shown in Figure 8.

Figure 8.

Hydration products of paste with PG and RM; (a) 3 days, (b) 28 days.

Generally, hydration products in cement paste are mainly portlandite, hydrated calcium silicate, ettringite, hydrated calcium aluminate, unhydrated particles, etc. [5,32], while portlandite has a strong peak, other peaks are weak or undetected in ample C0. The characteristic peak of portlandite significantly decreases in ample RM1 and PG1 compared with ample C0; this proves that PG and RM have a certain pozzolanic activity and can consume a part of portlandite [35,38]. Besides, the cement content in these mixes has been decreased to 90%, which can also reduce the amount of portlandite formed; therefore, the characteristic peak of portlandite is significantly decreased. Compared with the PG2 group, it is not difficult to find that, when adding 10% RM, the characteristic peak of portlandite significantly decreases in the RP1 group. When adding 70% RM, the characteristic peak of portlandite decreases in the RP2 group; however, it is higher than that of the RP1 group. Similarly, compared with the RM1 group, adding 10% RM, the characteristic peak of portlandite is also decreased in the RP1 group; however, it is abnormal in the RP2 group compared with the RM1 group. It is worth noting that the characteristic peak of portlandite is also significantly decreased in ample RP2 and disappears in ample RP1, which further proves that it is beneficial to stimulate the activity of PG and RM with a ratio of PG to RM of 7: 1; it is similar to the experimental results of the reaction degree. The curing period was prolonged from 3 days to 28 days, the hydration products of paste are not changed in 3 kinds of composite cementitious material systems, and the strength of the hydration characteristic peak has a certain change. In general, the octahedral [Al (OH)6)]3− ion and alkaline oxides (Al2O3, CaO, Fe2O3, K2O, and Na2O) in RM will prompt the formation of ettringite and hatrurite [57,58], and can exert amicro-aggregate effect, improving the compactness, microstructure, and strength [3,59]. There are no less than 90% CaSO4·2H2O in waste PG, with the presence of C3A in cement, which will form ettringite [60,61]; however, their characteristic peak intensity in three kinds of composite cementitious material systems is not obvious. It can be summarized that portlandite in hydrates is detected due to the presence of low activity PG and RM, and its amount is significantly decreased as time goes on and can even disappear, which indicates that the hydration of cement can be stimulated by PG and RM. Nevertheless, the greater the amount of portlandite consumed, the higher the reaction degree of PG and RM.

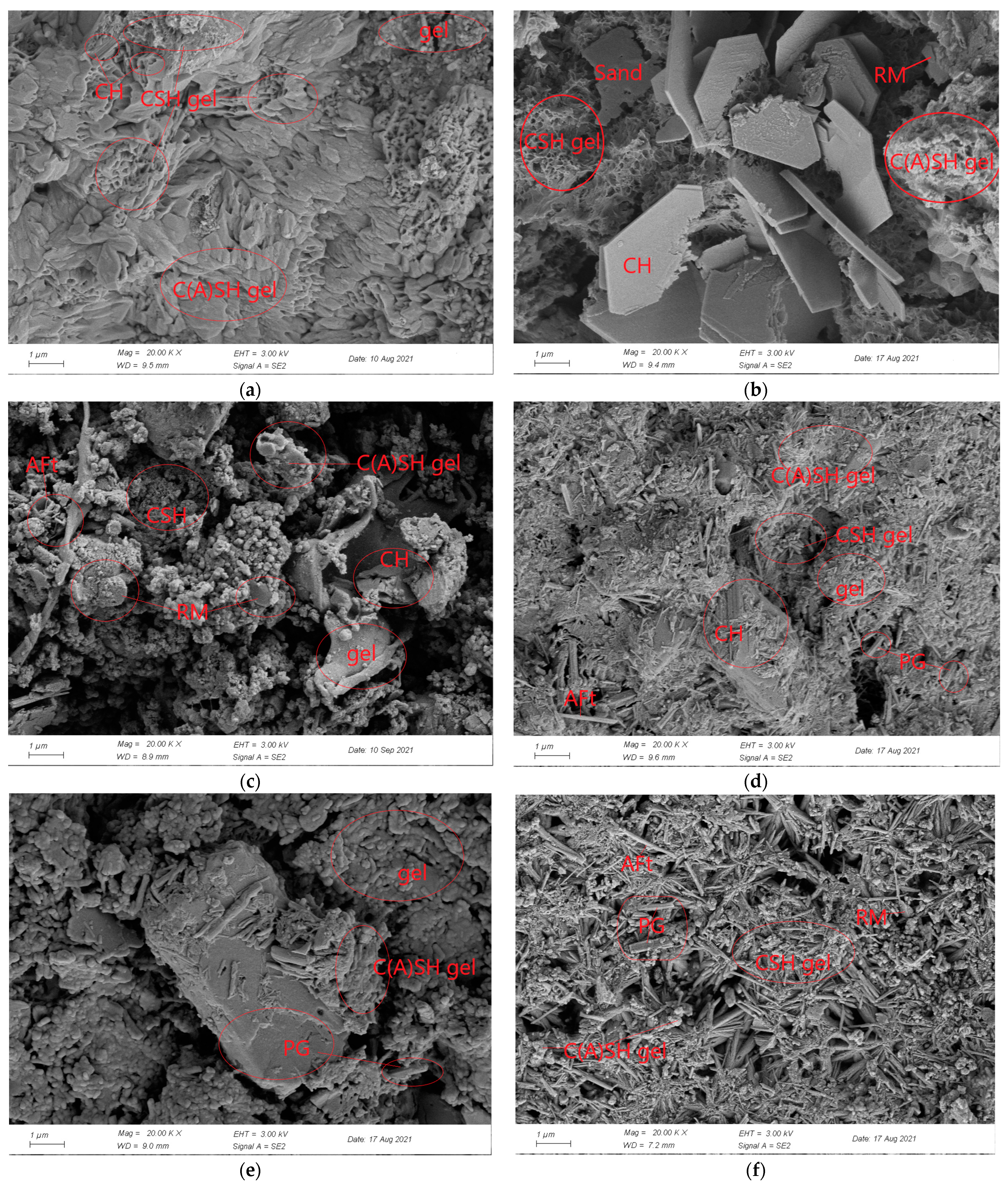

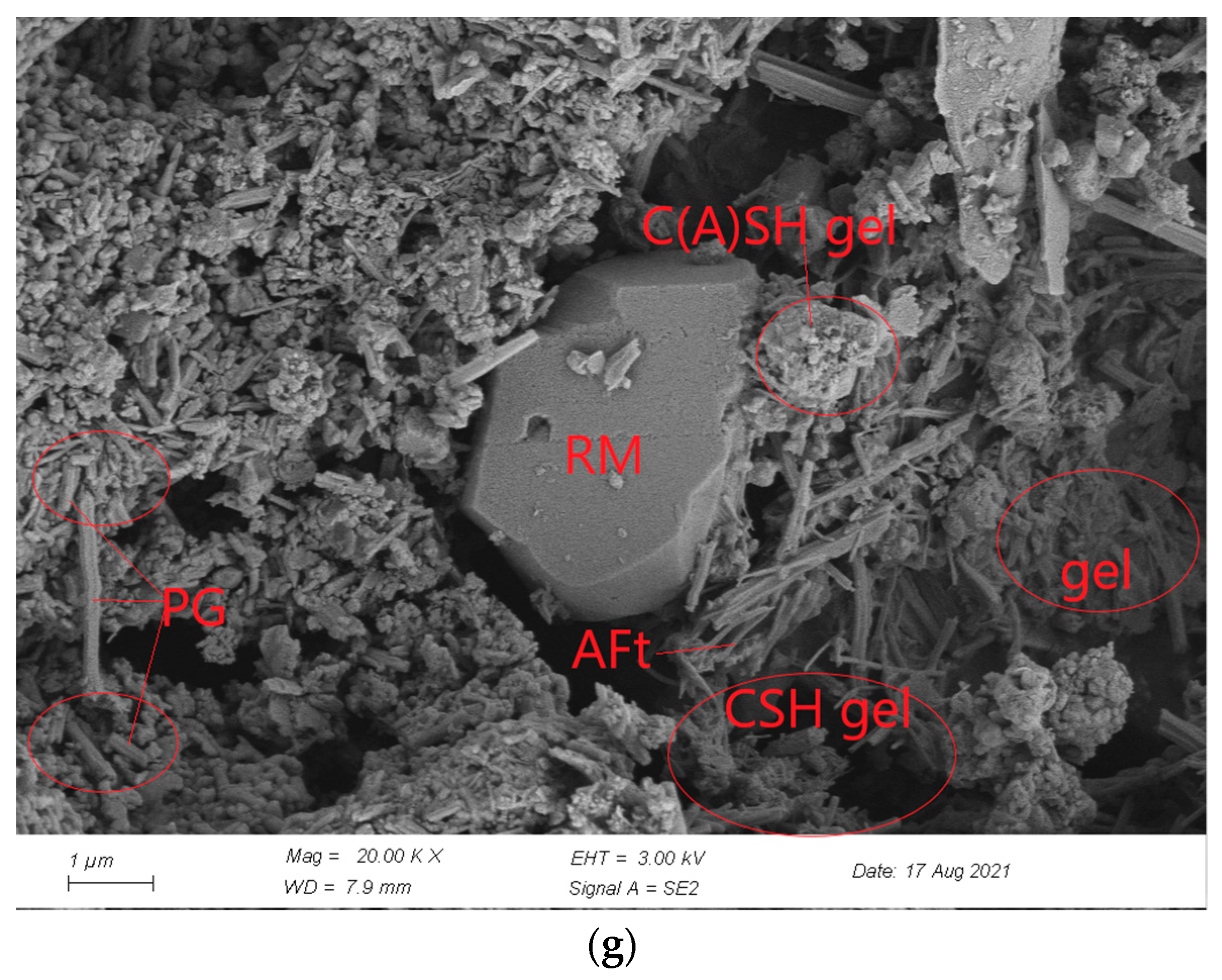

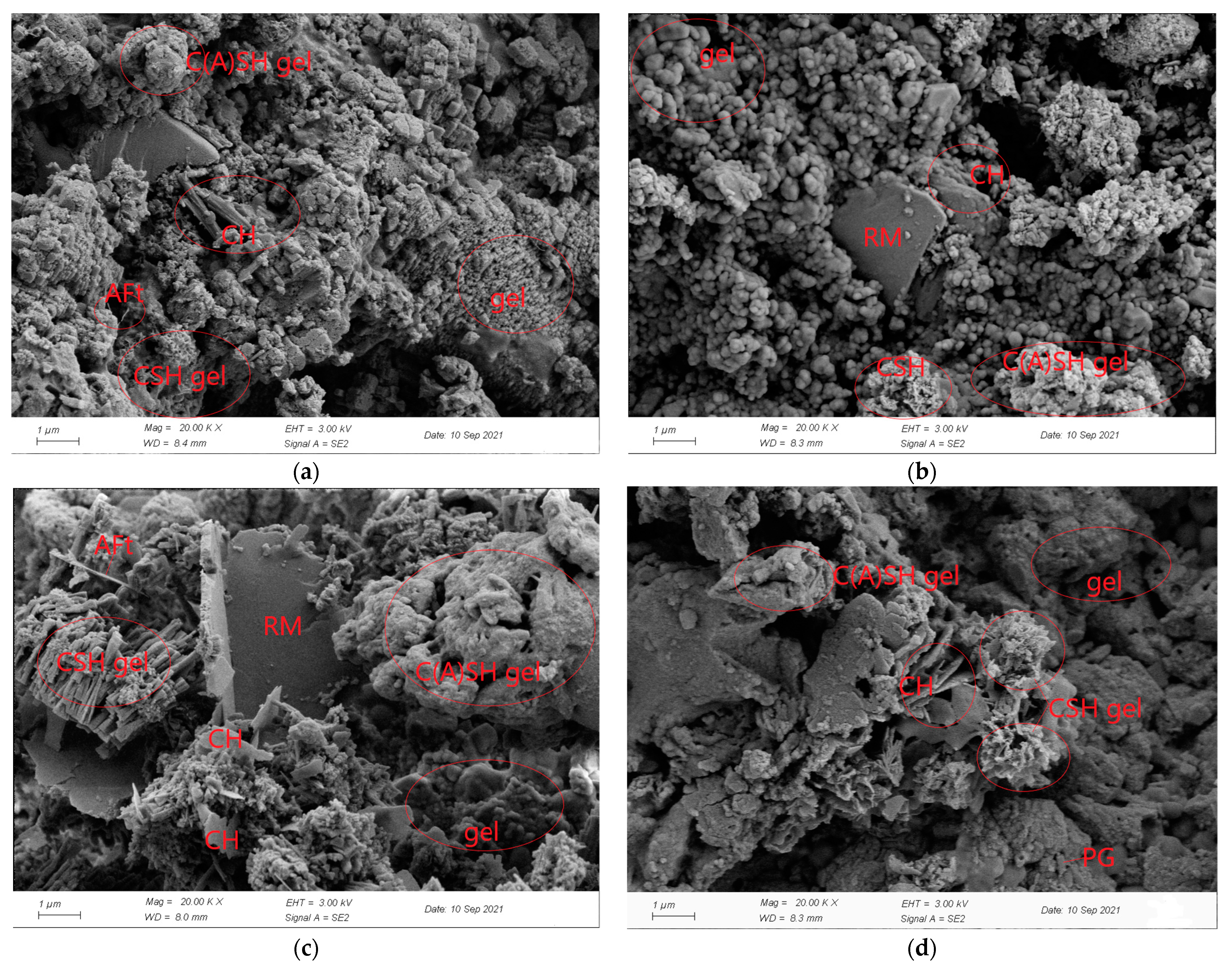

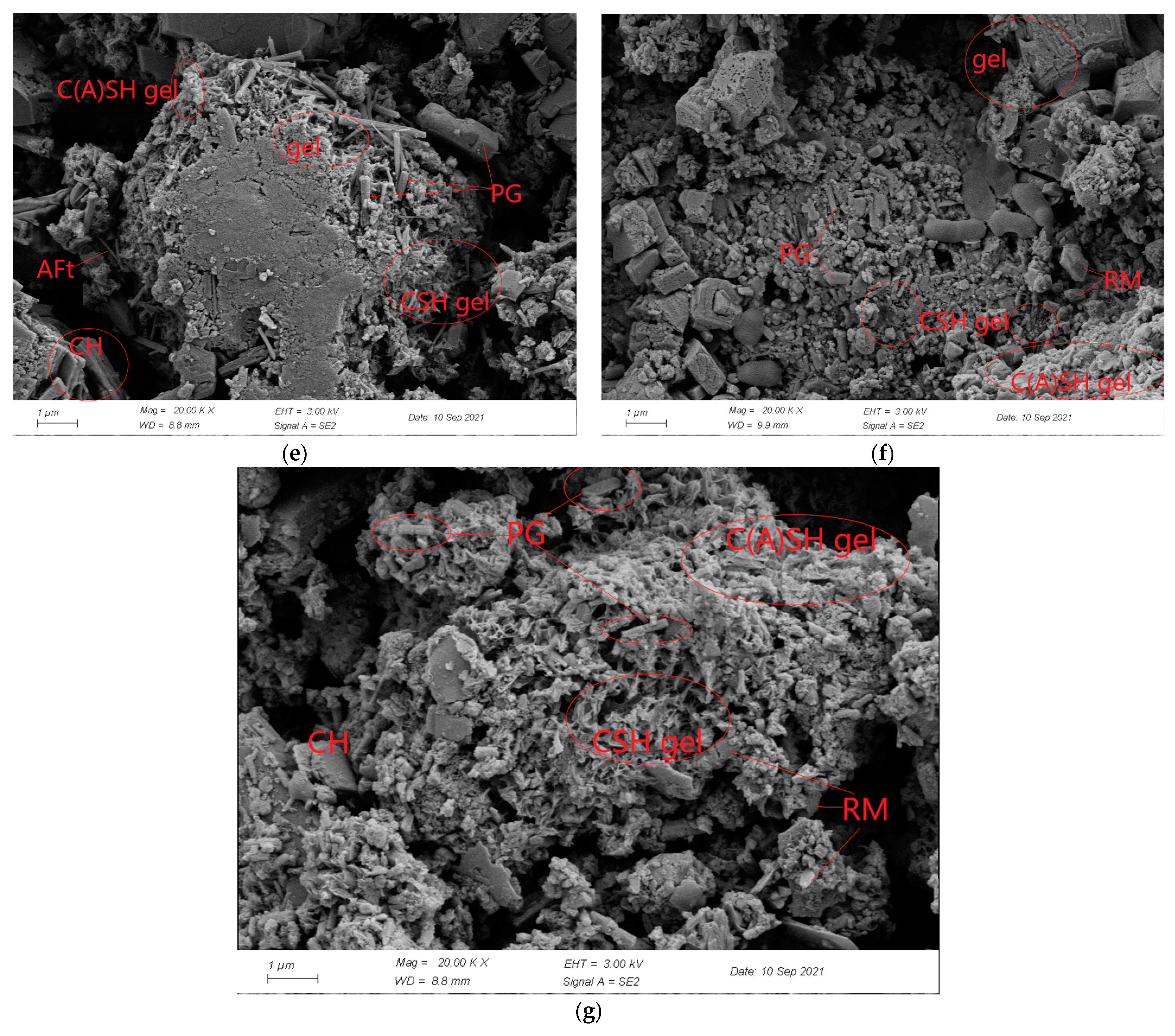

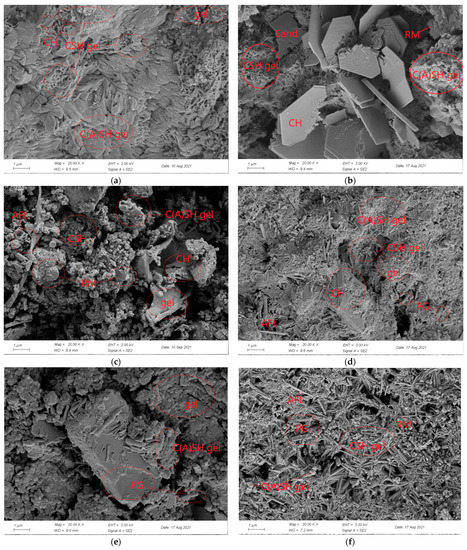

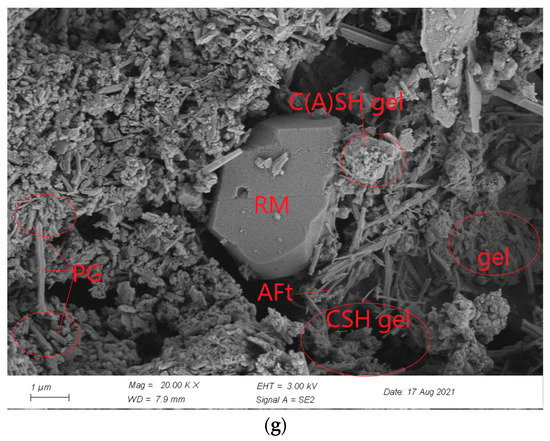

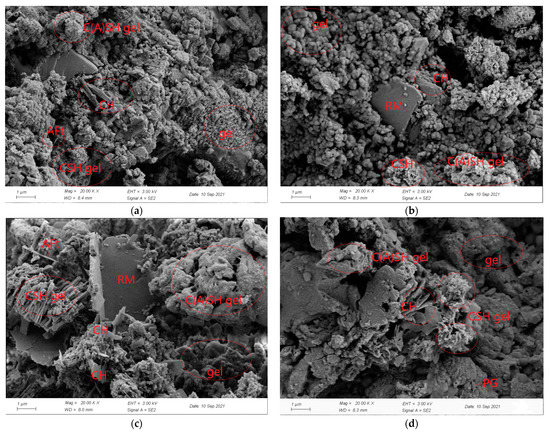

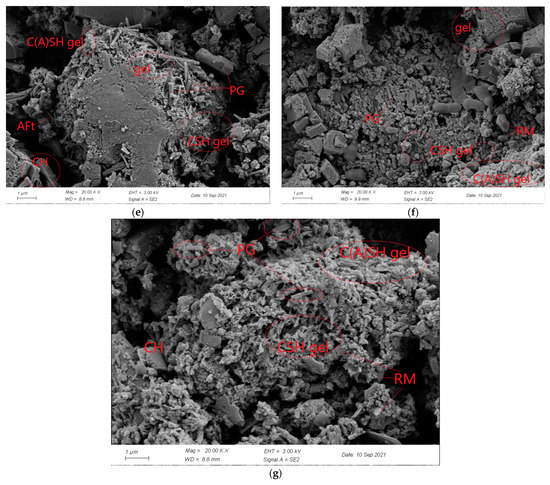

3.7. Microstructure of Mortar with PG and RM

In order to observe the microstructure of mortar in the cement PG system, cement RM system, and cement PG–RM system, the SEM images of three kinds of systems are obtained at 3 days and 28 days, as shown in Figure 9 and Figure 10. In general, the solid phase in cement consists of fibrous hydrated calcium silicate, hexagonal sheet-like portlandite, needle-like ettringite, and unhydrated particles. It is similarly shown, in Figure 9a, and these hydration products are wrapped together, indicating that the interface structure of pure cement mortar is relatively dense. In comparison with ample C0, there is typical hexagonal sheet-like portlandite and a certain amount of hydrated calcium silicate in RM1 and a certain amount of needle-like ettringite and unhydrated particles in RM2. After the cement was replaced by PG, there was typical cluster hydrated calcium silicate interleaved by needle-like ettringite and column-like gypsum in PG1 and short column-like gypsum and unhydrated particles in PG2. After the cement was replaced by PG and RM, there is a typical fibrous hydrated calcium silicate, a small quantity of needle-like ettringite, fine column-like gypsum, and unhydrated particles in RP1, while there is a certain amount of portlandite in RP2. These experimental results indicate that continuous incorporation of RM, PG, RM, and PG can notably reduce the content of cement hydration products and the compactness of microstructures [39]. Comparatively speaking, 10% RM and 10% PG can strikingly improve the microstructure of mortar, which can promote the hydration of cement, and RM and PG, to participate in the hydration reaction [40]. The larger the amount of hydration, the looser the structure, and the hydration products pile up with each other, thus reducing their mechanical properties. The curing period was prolonged from 3 days to 28 days, and hydration products in three kinds of cement systems are relatively abundant and closely connected together; however, the pore size is relatively large and loose, with the replacement rates being 70% and 80%. It can be deduced that the incorporation of PG, RM, and PG and RM can obviously transform the porous microstructure of cement mortar due to the hydration reaction of cement in three kinds of cement systems along with the pozzolanic reaction of PG, RM, and PG and RM, which produces more hydration products such as hydrated calcium silicate and ettringite. The first parameter mainly comes from the reaction of portlandite in cement with pozzolanic activity Al2O3 and SiO2 in PG and RM [35,62], and the second parameter mainly comes from the reaction of calcium aluminate hydrate with SO42− in PG [63]. Additionally, it can be found that the pozzolanic activity of PG and RM is low from the experiment of reaction degree (Seen Figure 2) and the non-evaporable water (Seen Figure 3), and most of the PG and RM particles can fill the pores and cracks because PG and RM are finer than cement, which can improve the compactness of mortar [50,61]. For this reason, the combination of PG and RM can efficaciously improve the interfacial transition zone and mechanical properties of mortar [49,53,56,62]. This is attributed to the fact that RM and PG have experienced pretreatment processes by ultrasonic circulating water instead of calcination and lime neutralization, etc., which can favorably manufacture sustainable cementitious materials.

Figure 9.

Microstructure of mortar with PG and RM at three days. (a) C0; (b) RM1; (c) RM2; (d) PG1; (e) PG2; (f) RP1; (g) RP2.

Figure 10.

Microstructure of mortar with PG and RM at 28 days. (a) C0; (b) RM1; (c) RM2; (d) PG1; (e) PG2; (f) RP1; (g) RP2.

4. Conclusions

In this work, the effect of PG and RM on the hydration properties of a cement PG system, cement RM system, and cement PG–RM system were studied. The main experimental results can be drawn as follows:

- (1)

- The non-evaporable water content, reaction degree, compressive strength, and flexural strength of cement systems show a downward trend after rising first when increasing the incorporation of PG, RM, and PG and RM, whose values reach the maximum with 10% PG and 10%RM, which are higher than a pure cement system, and the others have the reverse effect on cement systems.

- (2)

- The XRD, MIP, and SEM analyses revealed that the incorporation of PG, RM, and PG and RM can obviously transform the porous microstructure and produce more hydration products of cement systems.

- (3)

- The combination of PG and RM can efficaciously improve the interfacial transition zone as RM with high pH value and PG with high gypsum content are used, and PG and RM are finer than cement. The first mainly promotes the pozzolanic reaction of PG, RM, and PG and RM, and the second mainly improves the compactness of cement systems.

Author Contributions

Conceptualization, S.D. and F.W.; methodology, Q.Z.; software, L.X.; vali dation, Q.Z., L.X. and L.C.; formal analysis, L.X.; investigation, L.X.; resources, L.X.; data curation, F.W.; writing—original draft preparation, S.D.; writing—review and editing, S.D.; visualization, F.W.; supervision, Q.Z.; project administration, F.W.; funding acquisition, F.W. and L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This study is supported by Guizhou Provincial Department of Education General undergraduate University Scientific Re-search Project (Youth Project Qian Jiaoji [2022] 128), Guizhou Science and Technology support Plan Project (Qianke Joint Support [2021] General 486), the Special Project of Scientific Research on the Introduction of Talents in Huzhou Vocational and Technical College (No.2022GY04). The authors are extremely grateful to the support of school of materials and architectural engineering, Guizhou normal university.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors appreciate the aid provided by the reviewers and editors to improve the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghalehnovi, M.; Roshan, N.; Hakak, E.; Shamsabadi, A.E.; Brito, J.D. Effect of red mud (bauxite residue) as cement replacement on the properties of self-compacting concrete-incorporating various fillers. J. Clean Prod. 2019, 240, 118213. [Google Scholar] [CrossRef]

- Chandru, P.; Natarajan, C.; Karthikeyan, J. Influence of sustainable materials in strength and durability of self-compacting concrete: A review. J. Build. Pathol. Rehabil. 2018, 3, 8. [Google Scholar] [CrossRef]

- Jiang, Y.; Ahmad, M.; Chen, B. Properties of magnesium phosphate cement containing steel slag powder. Construct. Build. Mater. 2019, 195, 140–147. [Google Scholar] [CrossRef]

- Moreira, M.A.N.S.; Heitmann, A.P.; Bezerra, A.C.S.; Patrício, P.S.O.; Souza, P.P.D. Photocatalytic performance of cementitious materials with addition of red mud and Nb2O5 particles. Constr. Build. Mater. 2020, 259, 119851. [Google Scholar] [CrossRef]

- Nenadović, S.S.; Mucsi, G.; Kljajević, M.L.; Mirković, M.M.; Nenadović, T.M.; Kristaly, F.; Vukanac, S.I. Physicochemical, mineralogical and radiological properties of red mud samples as secondary raw materials. Nucl. Technol. Radiat. Prot. 2017, 32, 261–266. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Liu, S.J.; Yao, Z.Y.; Wu, S.P.; Jiang, H.G.; Liang, M.; Qiao, Y.N. Environmentalaspects and pavement properties of red mud waste as the replacement of mineral filler in asphaltmixture. Constr. Build. Mater. 2018, 178, 288–300. [Google Scholar]

- Zhao, H.; Gou, H. Unfired bricks prepared with red mud and calcium sulfoaluminate cement: Properties and environmental impact. J. Build. Eng. 2021, 38, 102238. [Google Scholar] [CrossRef]

- Chen, X.; Guo, Y.G.; Ding, S.; Zhang, H.Y.; Yue, F. Utilization of red mud ingeopolymer-based pervious concrete with function of adsorption of heavy metal ions. J. Clean Prod. 2019, 207, 789–800. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, J.; Li, H.; Zhao, P.; Chen, Q. Reclycling red mud from the production of aluminium as a red cement-based mortar. Waste Manag. Res. 2017, 35, 500–507. [Google Scholar] [CrossRef]

- Kaya, K.; Soyer-Uzun, S. Evolution of structural characteristics and compressive strength in red mud-metakaolin based geopolymer systems. Ceram. Int. 2016, 42, 7406–7413. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Vilar, V.J.P.; Botelho, C.M.S.; Boaventura, R.A.R. A review of the use of red mud as adsorbent for the removal of toxic pollutants from water and wastewater. Environ. Technol. 2011, 32, 231–249. [Google Scholar] [CrossRef] [PubMed]

- Guangtao, W.; Luhua, S.; Jihua, M.; Zhongming, L.; Linye, Z. Preparation of a new Fenton-like catalyst from red mud using molasses wastewater as partial acidifying agent. Environ. Sci. Pollut. Res. Int. 2017, 24, 15067–15077. [Google Scholar]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive Utilization Status of Red Mud in China: A critical review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- Qu, Y.; Li, H.; Tian, W.J. Leaching of valuable metals from red mud via batch and continuous processes by using fungi. Miner. Eng. 2015, 81, 1–4. [Google Scholar] [CrossRef]

- Liu, Y.; Naidu, R. Hidden values in bauxite residue (red mud): Recovery of metals. Waste Manag. 2014, 34, 2662–2673. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, S.; Hu, D.; Sheng, Y.; Lv, H.; Cheng, L.; Cheng, Y.D.; Sun, J. Paraffin/red mud phase change energy storage composite incorporated gypsum based and cement-based materials: Microstructures, thermal and mechanical properties. J. Hazard. Mater. 2019, 364, 608–620. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C. Experimental study on lime and fly ash stabilized sintered red mud in road base. J. Test. Eval. 2018, 46, 1539–1547. [Google Scholar] [CrossRef]

- Chen, R.; Cai, G.; Dong, X.; Mi, D.; Puppala, A.J.; Duan, W. Mechanical properties and micro-mechanism of loess roadbed filling using by-product red mud as a parti-al alternative. Constr. Build. Mater. 2019, 216, 188–201. [Google Scholar] [CrossRef]

- Ghalehnovi, M.; Shamsabadi, E.A.; Khodabakhshian, A.; Sourmeh, F.; Brito, J.D. Self-compacting architectural concrete production using red mud. Constr. Build. Mater. 2019, 226, 418–427. [Google Scholar] [CrossRef]

- Tang, W.C.; Wang, Z.; Liu, Y.; Cui, H.Z. Influence of red mud on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 2018, 178, 288–300. [Google Scholar] [CrossRef]

- Krivenko, P.; Kovalchuk, O.; Pasko, A.; Croymans, T.; Hult, M. Development of alkali activated cements and concrete mixture design with high volumes of red mud. Constr. Build. Mater. 2017, 151, 819–826. [Google Scholar] [CrossRef]

- Hou, D.; Wua, D.; Wang, X.; Yu, S.; Li, R.; Wang, M.M.; Wang, P.; Shuai, Y. Sustainable use of red mud in ultra-high-performance concrete (UHPC): Design and performance evaluation. Cem. Concr. Compos. 2021, 115, 103862. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, N.; Chen, H.; Yuan, L.I. Preparation and properties of sintering red mud unburned road brick using orthogonal experiments. Constr. Build. Mater. 2020, 238, 117739. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Z.; Chen, B. Experimental research on magnesium phosphate cements modified by red mud. Constr. Build. Mater. 2020, 231, 117131. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.; Li, Z. Investigation the synergistic effects in quaternary binder containing red mud, blast furnace slag, steel slag and flue gas desulfurization gypsum based on artificial neural networks. J. Clean. Prod. 2020, 273, 122972. [Google Scholar] [CrossRef]

- Alam, S.; Das, S.K.; Rao, B.H. Strength and durability characteristic of alkali activated GGBS stabilized red mud as geomaterial. Construct. Build. Mater. 2019, 211, 932–942. [Google Scholar] [CrossRef]

- Garanayak, L. Strength effect of alkali activated red mud slag cement in ambient condition. Mater. Today Proc. 2021, 44, 1437–1443. [Google Scholar] [CrossRef]

- Yang, Z.; Mocadlo, R.; Zhao, M.; Sisson, R.D.J.; Tao, M.; Liang, J. Preparation of a geopolymer from red mud slurry and class F fly ash and its behavior at ele-vated temperatures. Constr. Build. Mater. 2019, 221, 308–317. [Google Scholar] [CrossRef]

- Canbek, O.; Shakouri, S.; Sinan, T. Laboratory production of calcium sulfoaluminate cements with high industrial waste content. Cem. Concr. Compos. 2019, 106, 103475. [Google Scholar] [CrossRef]

- Li, Y.; Min, X.; Ke, Y.; Liu, D.; Tang, C. Preparation of red mud-based geopolymer materials from MSWI fly ash and red mud by mechanical activation. Waste Manag. 2019, 83, 202–208. [Google Scholar] [CrossRef]

- Tang, W.; Wang, Z.; Donne, S.; Forghani, M.; Liu, Y. Influence of red mud on mechanical and durability performance of self-compacting concrete. J. Hazard. Mater. 2019, 379, 120802. [Google Scholar] [CrossRef]

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Jiang, G.; Wu, A.; Wang, Y.; Li, J. The rheological behavior of paste prepare-d from hemihydrate phosphogypsum and tailing. Constr. Build. Mater. 2019, 229, 116870. [Google Scholar] [CrossRef]

- da Silva Calderón Morales Antonio García-Martínez, B.R.; Pineda, P.; García-Tenório, R. Valorization of phosphogypsum in cement-based materials: Limits and potential in eco-efficient construction. J. Build. Eng. 2021, 44, 102506. [Google Scholar]

- Holanda, F.C.; Schmidt, H.; Quarcioni, V.A. Influence of phosphorus from phosphogypsum on the initial hydration of Portland cement in the presence of superplasticcizers. Cem. Concr. Compos. 2017, 83, 384–393. [Google Scholar] [CrossRef]

- Xue, S.G.; Li, M.; Jiang, J.; Graeme, M.J.; Li, C.X.; Kong, X.F. Phosphogypsum stabilization of bauxite residue: Conversion of its alkaline characteristics. J. Environ. Sci. 2018, 77, 1–10. [Google Scholar] [CrossRef]

- Costa, A.R.D.; Matos, S.R.C.; Camarini, G.; Gonçalves, J.P. Hydration of sustainable ternary cements containing phosphogypsum. Sustain. Mater. Technol. 2021, 28, 280. [Google Scholar] [CrossRef]

- Chen, X.; Gao, J.; Zhao, Y. Investigation on the hydration of hemihydrate phosphogypsum after posttreatment. Constr. Build. Mater. 2019, 229, 116864. [Google Scholar] [CrossRef]

- Gijbels, K.; Nguyen, H.; Kinnunen, P.; Schroeyers, W.; Illikainen, M. Feasibility of incorporating phosphogypsum in ettringite-based binder from ladle slag. J. Clean. Prod. 2019, 237, 117793. [Google Scholar] [CrossRef]

- Campos, M.P.; Costa, L.J.P.; Nisti, M.B.; Mazzilli, B.P. Phosphogypsum recycling in the building materials industry: Assessment of the radon exhalation rate. J. Environ. Radioact. 2017, 172, 232–236. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, B.; Shen, W.; Wu, M.; Zhu, J. High industrial solid waste road base course binder: Performance regulation, hydration characteristics and practical application. J. Clean. Prod. 2021, 313, 127879. [Google Scholar] [CrossRef]

- Sadiqul Islam, G.M.; Chowdhury, F.H.; Raihan, M.T.; Amit, S.K.S.; Islam, M.R. Effect of phosphogypsum on the properties of portland cement. Procedia. Eng. 2017, 171, 744–751. [Google Scholar] [CrossRef]

- Huang, Y.; Qian, J.; Kang, X.; Yu, J.; Fan, Y.; Dang, Y.; Zhang, W.; Wang, S. Belite-calcium sulfoaluminate cement prepared with phosphogypsum: Influence of P2O5 and F on the clinker formation and cement performances. Constr. Build. Mater. 2019, 203, 432–442. [Google Scholar] [CrossRef]

- Liu, S.; Wang, L.; Yu, B. Effect of modified phosphogypsum on the hydration properties of the phosphogypsum-based supersulfated cement. Constr. Build. Mater. 2019, 214, 9–16. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, R. A novel gypsum-based self-leveling mortar produced by phosphorus building gypsum. Constr. Build. Mater. 2019, 226, 11–20. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B.; Bi, W.; Guan, Y. Recycling of waste gypsum in preparation of magnesium oxychloride cement (MOC). J. Clean. Prod. 2021, 313, 127958. [Google Scholar] [CrossRef]

- Li, M.; Chen, Z. Strength properties of phosphogypsum based composite filling materials. Adv. Energy Environ. Mater. 2018, 555–567. [Google Scholar] [CrossRef]

- Jin, Z.; Ma, B.; Su, Y.; Lu, W.; Hu, P. Effect of calcium sulphoaluminate cement on mechanical strength and waterproof properties of beta-hemihydrate phosphogypsum. Constr. Build. Mater. 2020, 242, 118198. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, C.; Zhou, W.B.; Zhu, J.Z. Influence of phosphogypsum on physical properties and hydration process of Portland cement (in Chinese). World Build. Mater. 2010, 31, 4–7. [Google Scholar]

- Zhang, J.; Tan, H.; He, X.; Yang, W.; Yang, J. Compressive strength and hydration process of ground granulated blast furnace slag-waste gypsum system managed by wet grinding. Constr. Build. Mater. 2019, 228, 116777. [Google Scholar] [CrossRef]

- Ortega, J.M.; Cabeza, M.; Tenza-Abril, A.J.; Real-Herraiz, T.; Climent, M.Á.; Sánchez, I. Effects of red mud addition in the microstructure, durability and mechanical performance of cement mortars. Appl. Sci. 2019, 9, 984. [Google Scholar] [CrossRef]

- Liu, R.-X.; Poon, C.-S. Utilization of red mud derived from bauxite in self-compacting concrete. J. Clean. Prod. 2016, 112, 384–391. [Google Scholar] [CrossRef]

- Venkatesh, C.; Chand, M.; Nerella, R. Experimental investigation of strength, durability, and microstructure of red-mud concrete. J. Korean Ceram. Soc. 2020, 57, 167–174. [Google Scholar] [CrossRef]

- Kang, S.-P.; Kwon, S.-J. Effects of red mud and alkali-activated slag cement on efflorescence in cement mortar. Constr. Build. Mater. 2017, 133, 459–467. [Google Scholar] [CrossRef]

- Jothilingam, M.; Preethi, V. Feasibility, compressive strength and utilization of red mud in geopolymer concrete for sustainable constructions. Mater. Today Proc. 2021, 45, 7016–7022. [Google Scholar] [CrossRef]

- Venkatesh, C.; Chand, M.; Nerella, R. Red mud as an additive in concrete: Comprehensive characterization. J. Korean Ceram. Soc. 2020, 57, 281–289. [Google Scholar] [CrossRef]

- Luo, S.; Liu, M.; Yang, L.; Chang, J.; Yang, W.; Yan, X.; Yu, H.; Shen, Y. Utilization of waste from alumina industry to produce sustainable cement-based materials. Constr. Build. Mater. 2019, 229, 116795. [Google Scholar] [CrossRef]

- Zhang, N.; Li, H.; Liu, X. Hydration mechanism and leaching behavior of bauxite calcination-metho-d red mud-coal gangue based cementitious materials. J. Hazard. Mater. 2016, 314, 172–180. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, H.; Li, Y.; Bi, W.; Yao, X. The effect of slag on the properties of magnesium potassium phosphate cement. Constr. Build. Mater. 2016, 126, 313–320. [Google Scholar] [CrossRef]

- Guo, T.; Malone, R.F.; Rusch, K.A. Stabilized phosphogypsum: Class C fly ash: Portland type II cement composites for potential marine application. Environ. Sci. Technol. 2001, 35, 3967–3973. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B.; Pan, Y. Utilization of untreated-phosphogypsum as filling and binding material in preparing grouting materials. Constr. Build. Mater. 2020, 265, 120749. [Google Scholar] [CrossRef]

- Neto, J.S.A.; Bersch, J.D.; Silva, T.S.; Rodríguez, E.D.; Kirchheim, A.P. Influence of phosphogypsum purification with lime on the properties of cementitious matrices with and without plasticizer. Constr. Build. Mater. 2021, 299, 123935. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Fourie, A.; Chen, X. Utilization of phosphogypsum and phosphate tailings for cemented paste backfill. J. Environ. Manag. 2017, 201, 19–27. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).