Measurement and Analysis of Light Leakage in Plastic Optical Fiber Daylighting System

Abstract

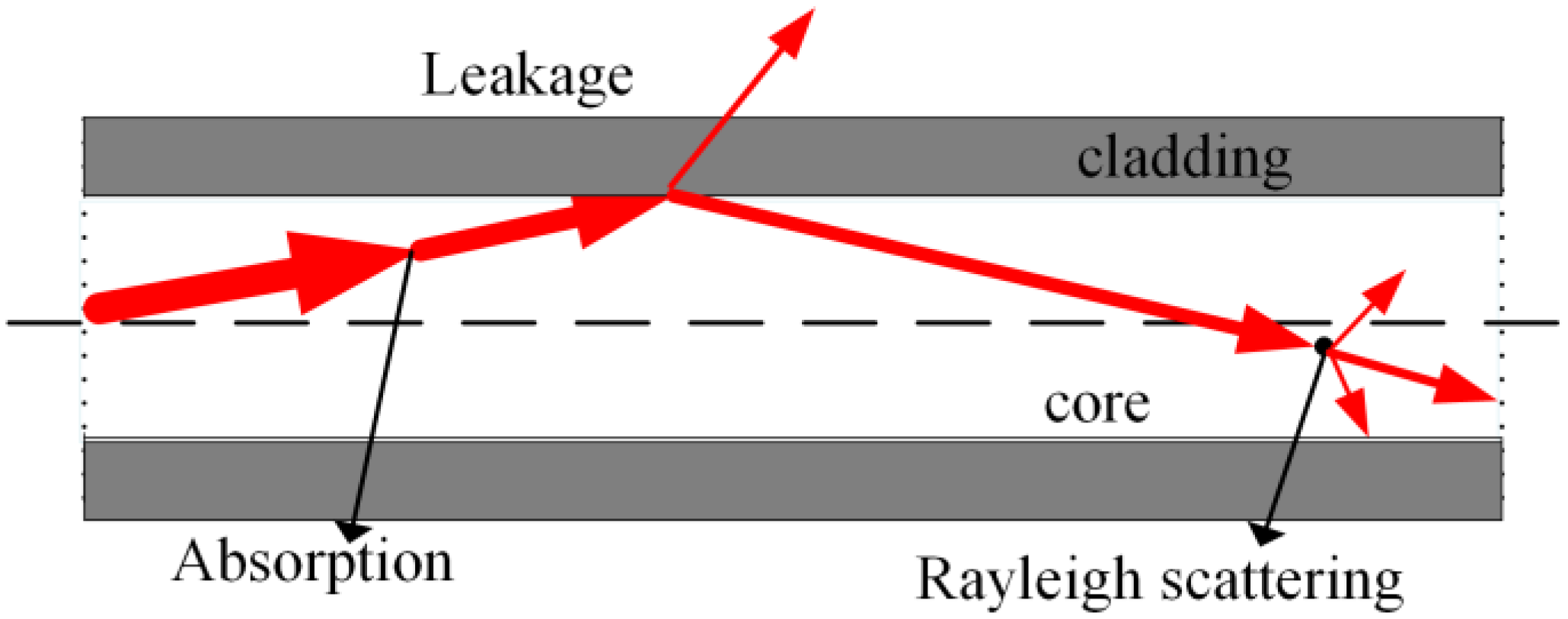

1. Introduction

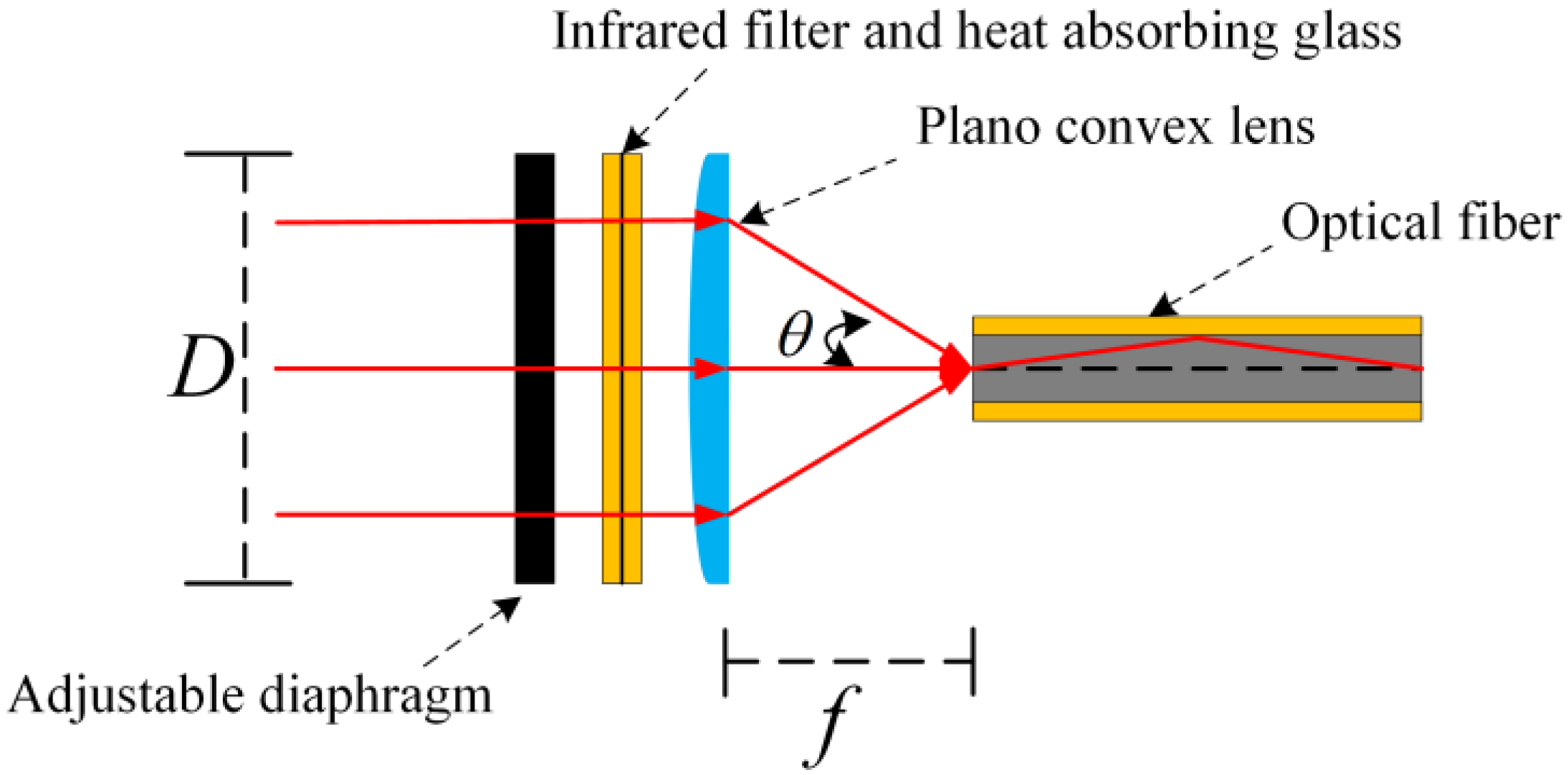

2. System Configuration

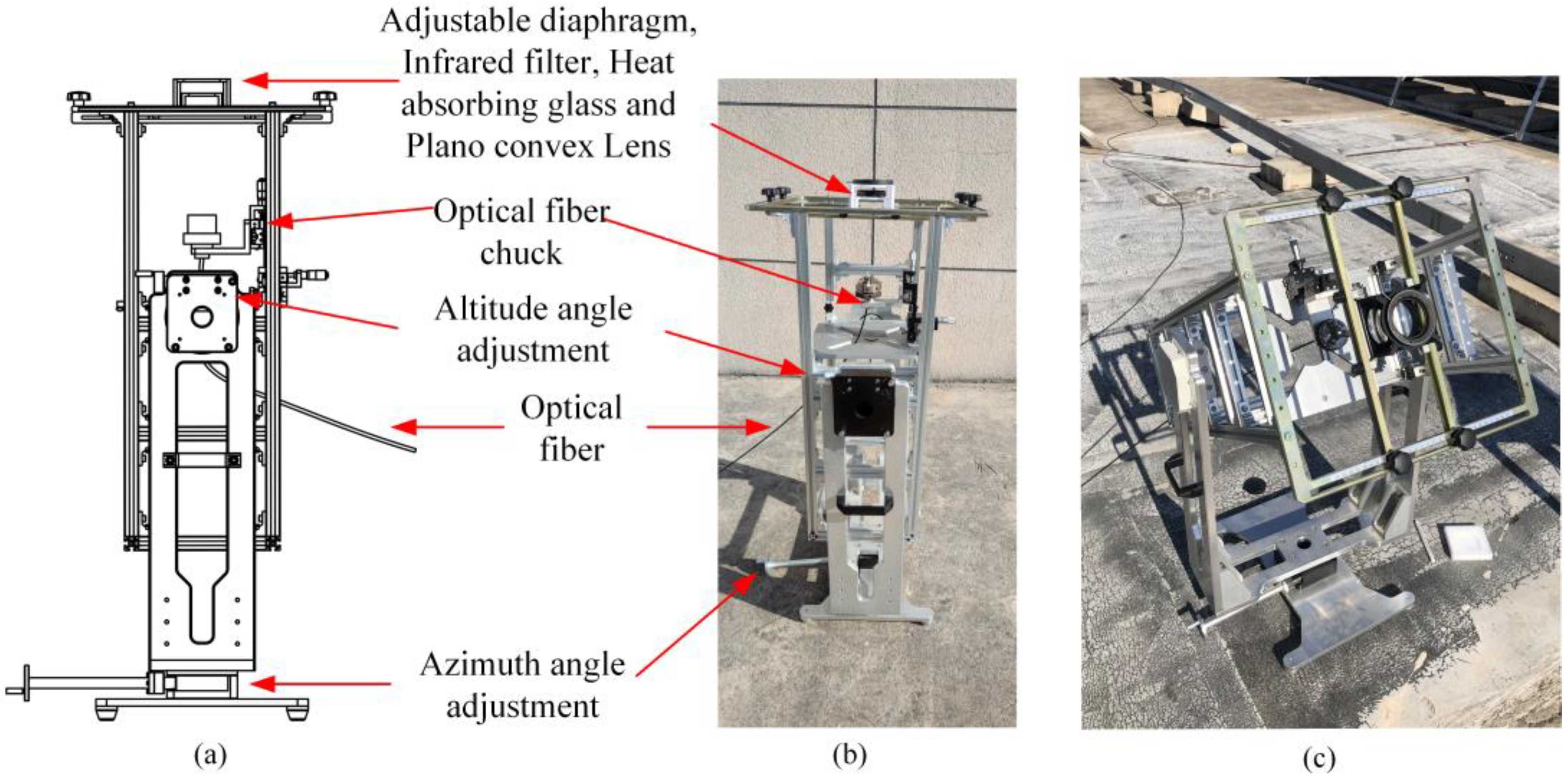

2.1. Platform

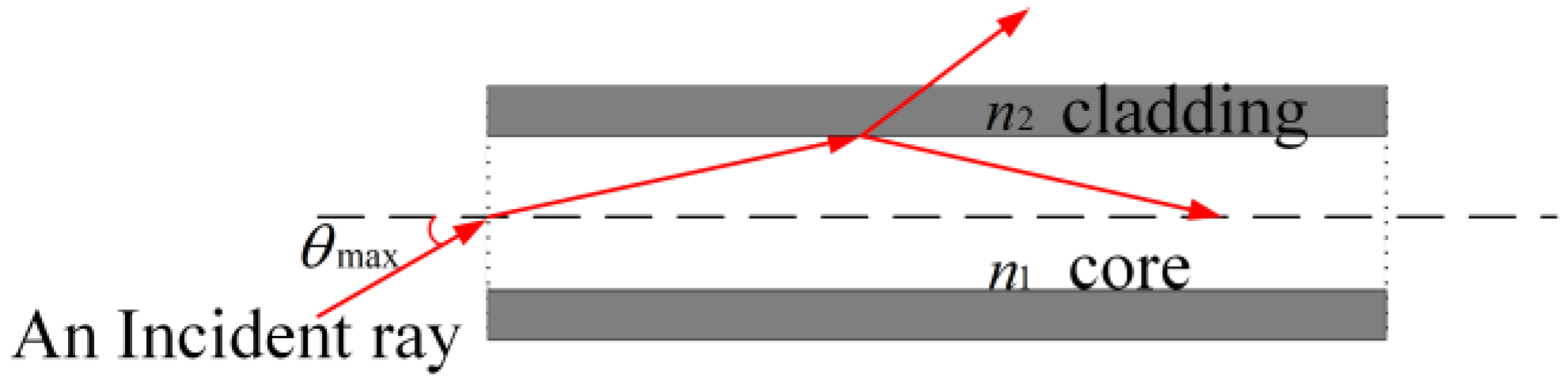

2.2. Plastic Optical Fibers

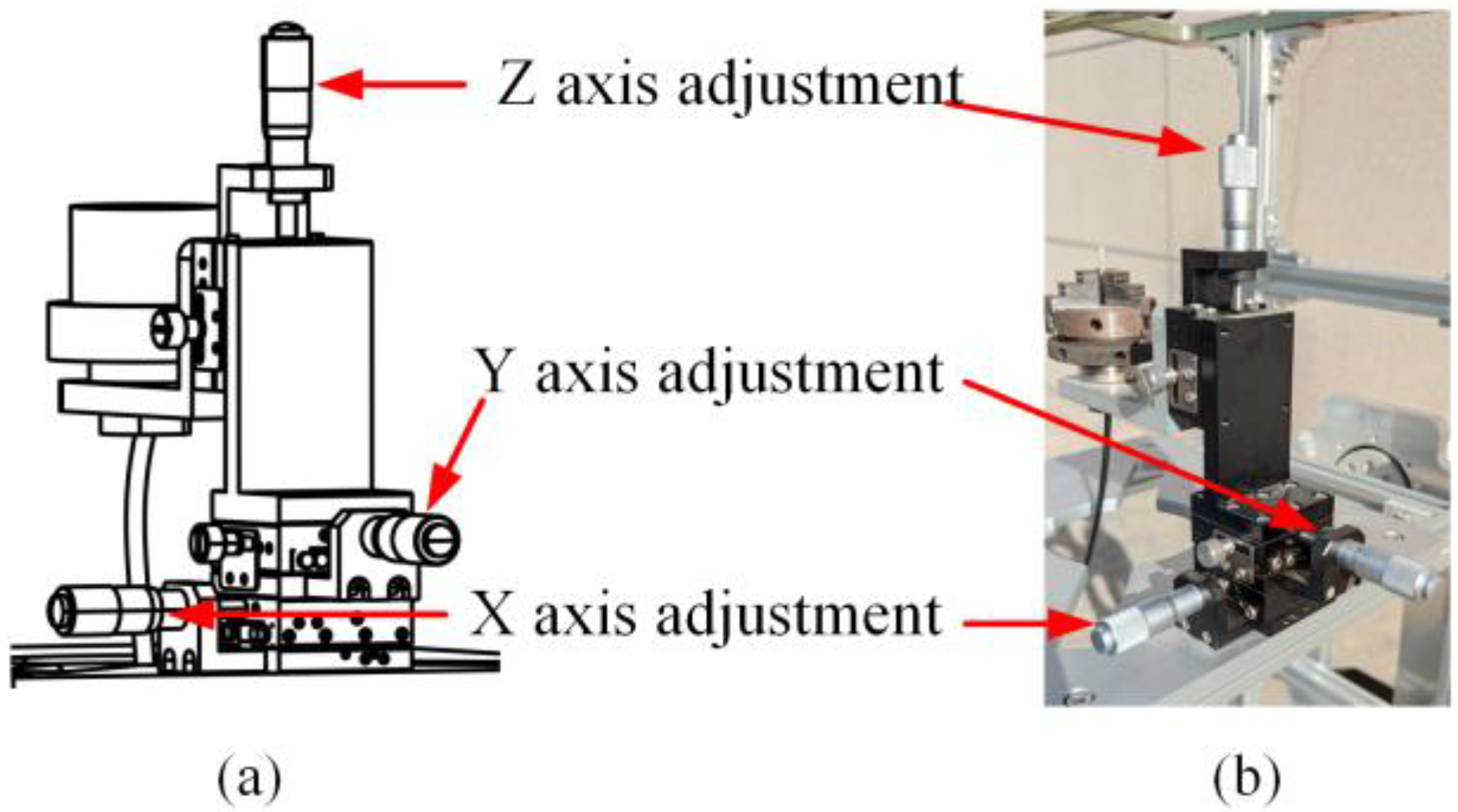

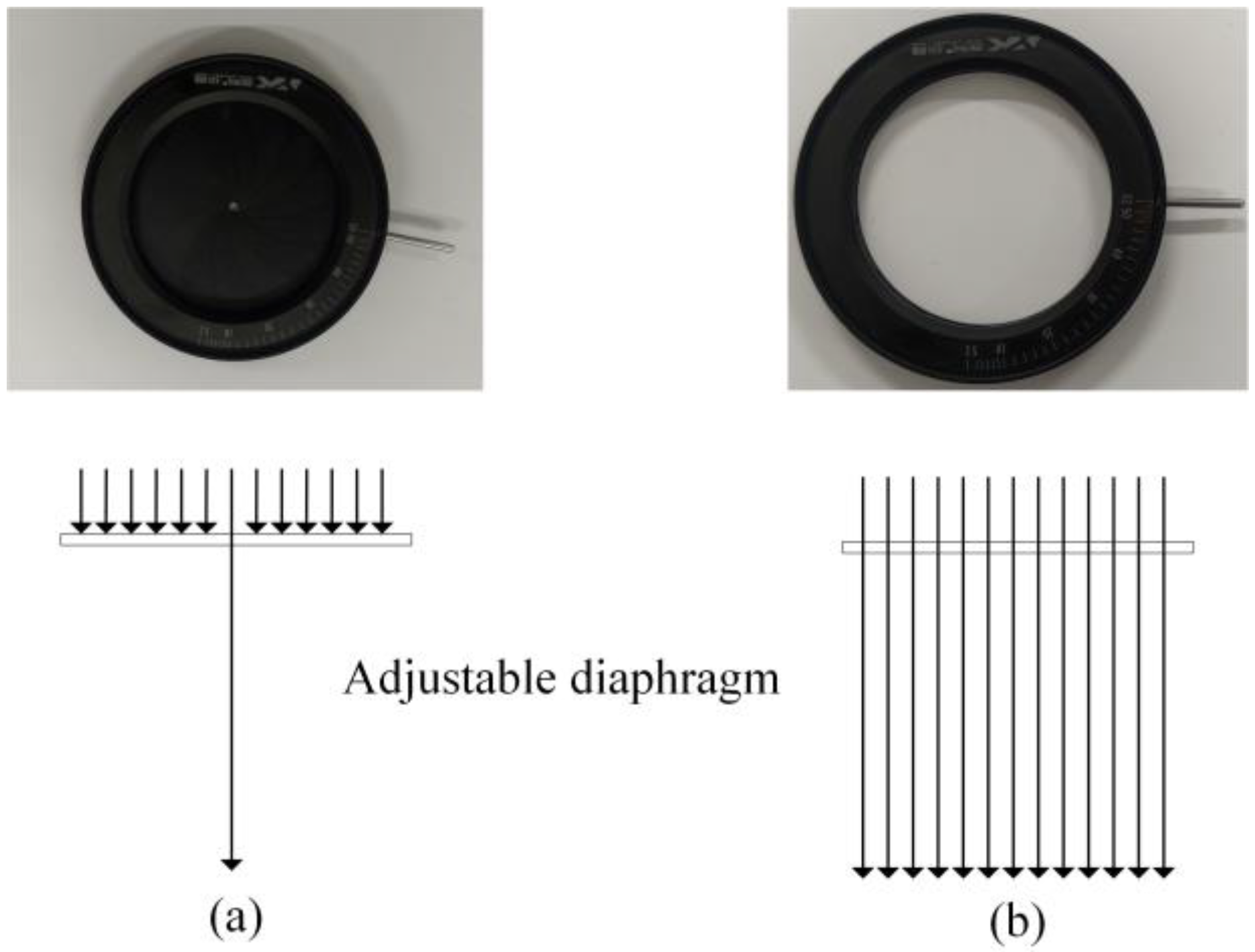

2.3. Light Path Adjustment

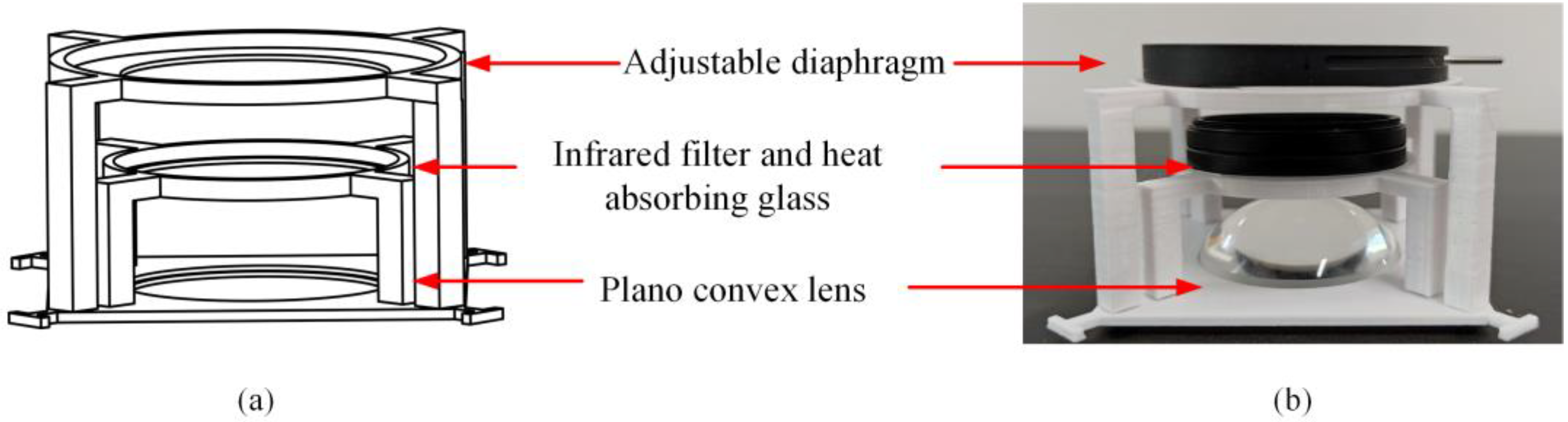

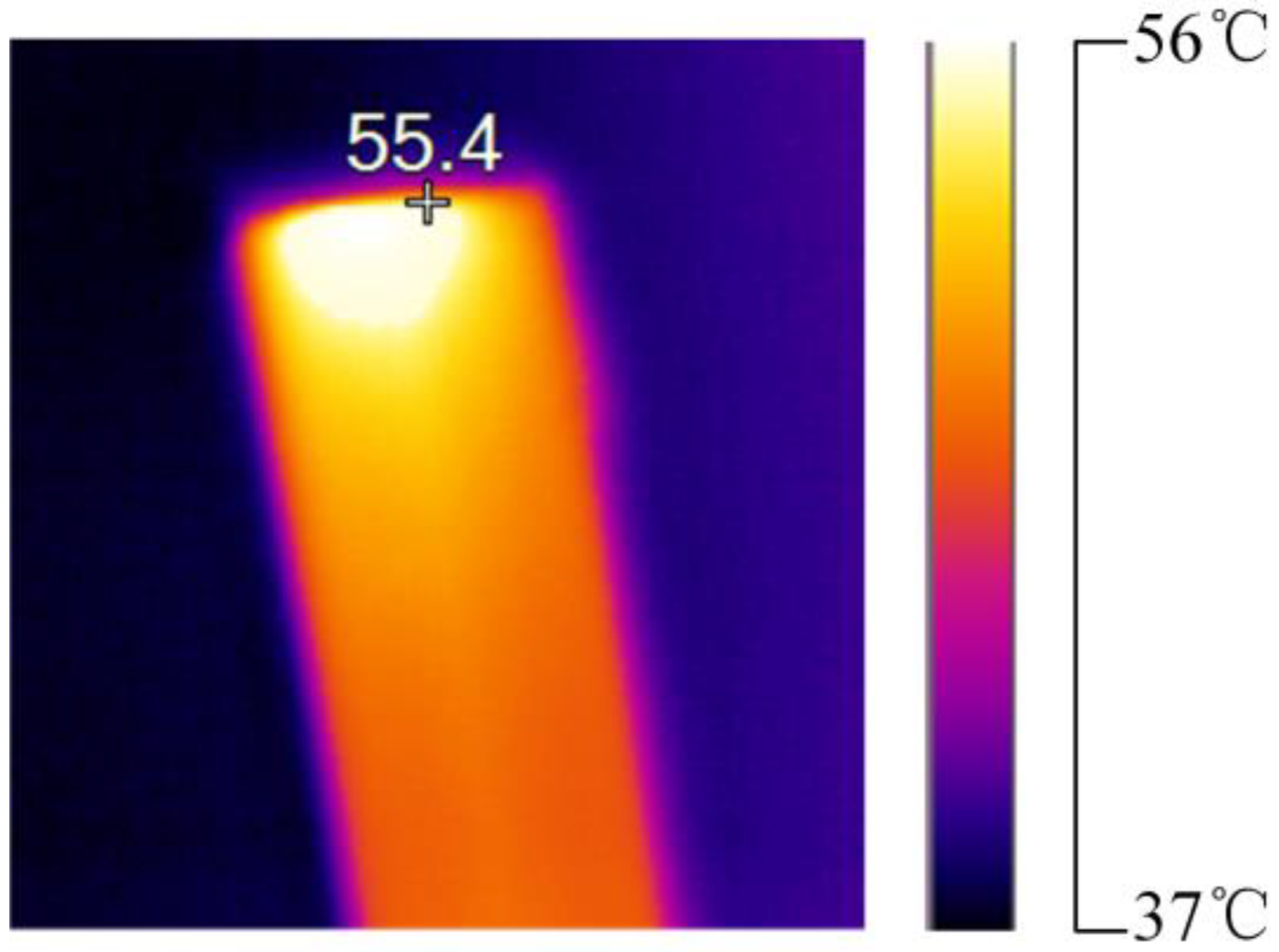

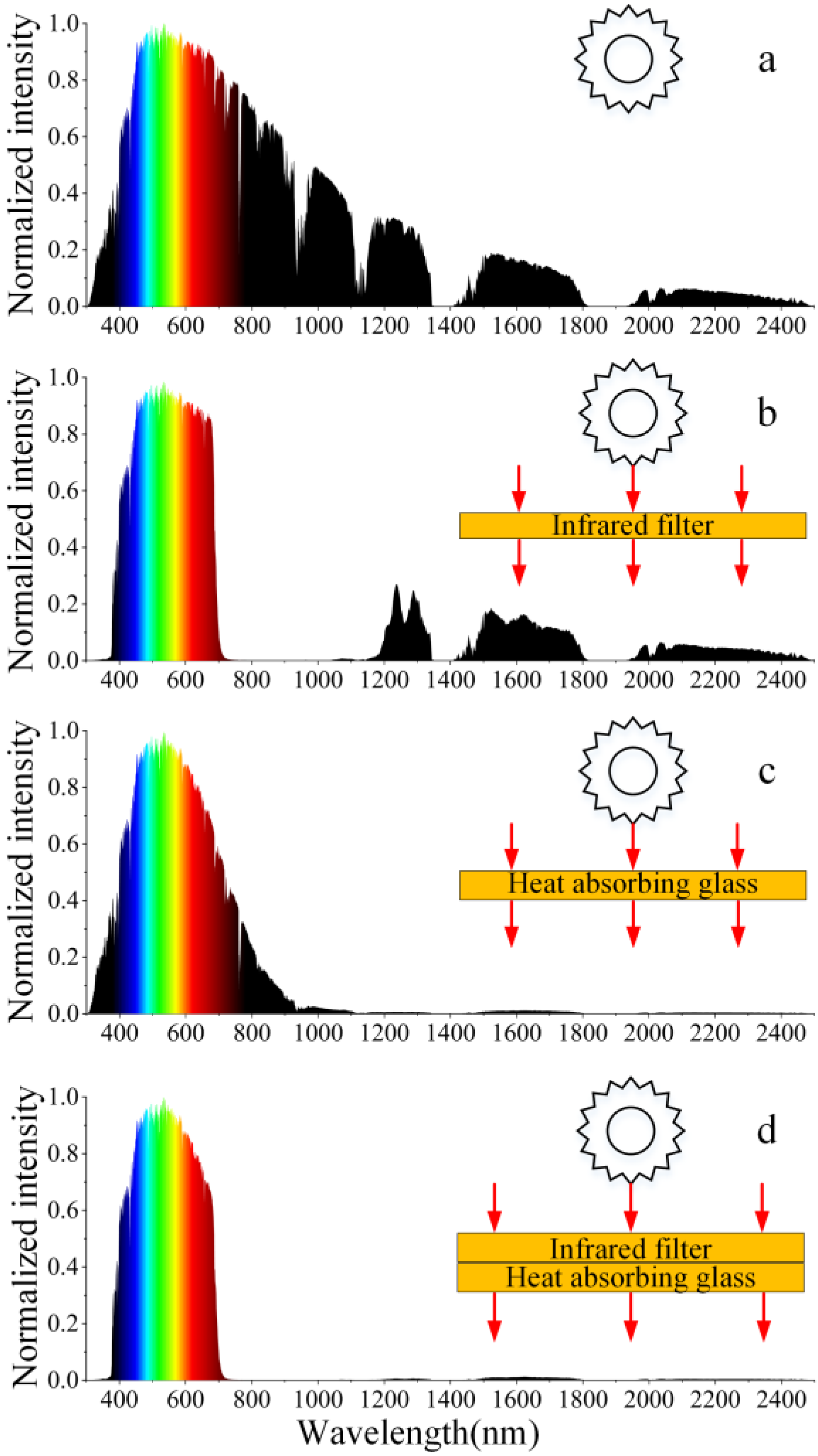

2.4. Filters

3. Experiments and Analysis

3.1. Experiments

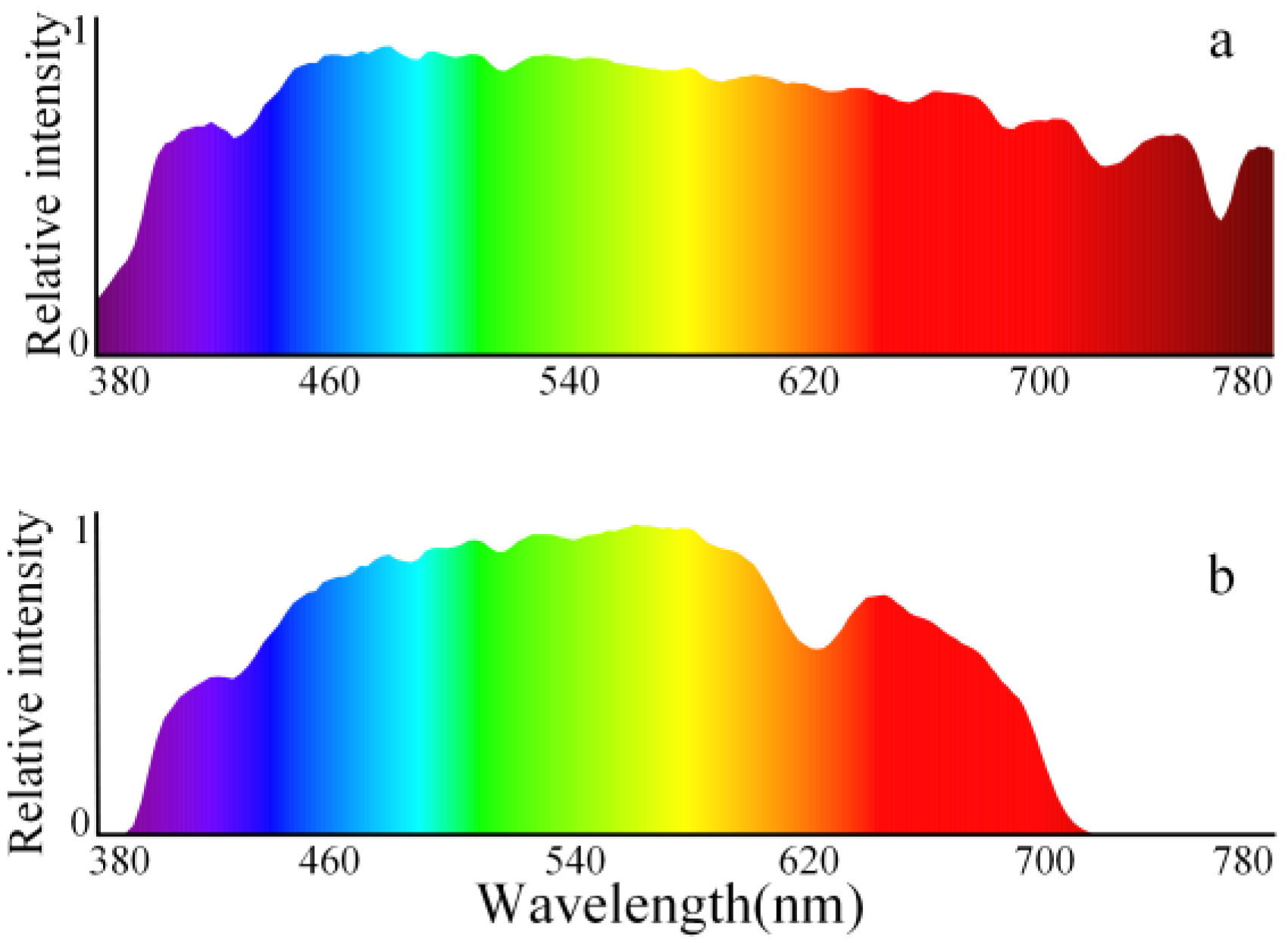

3.2. Spectrum

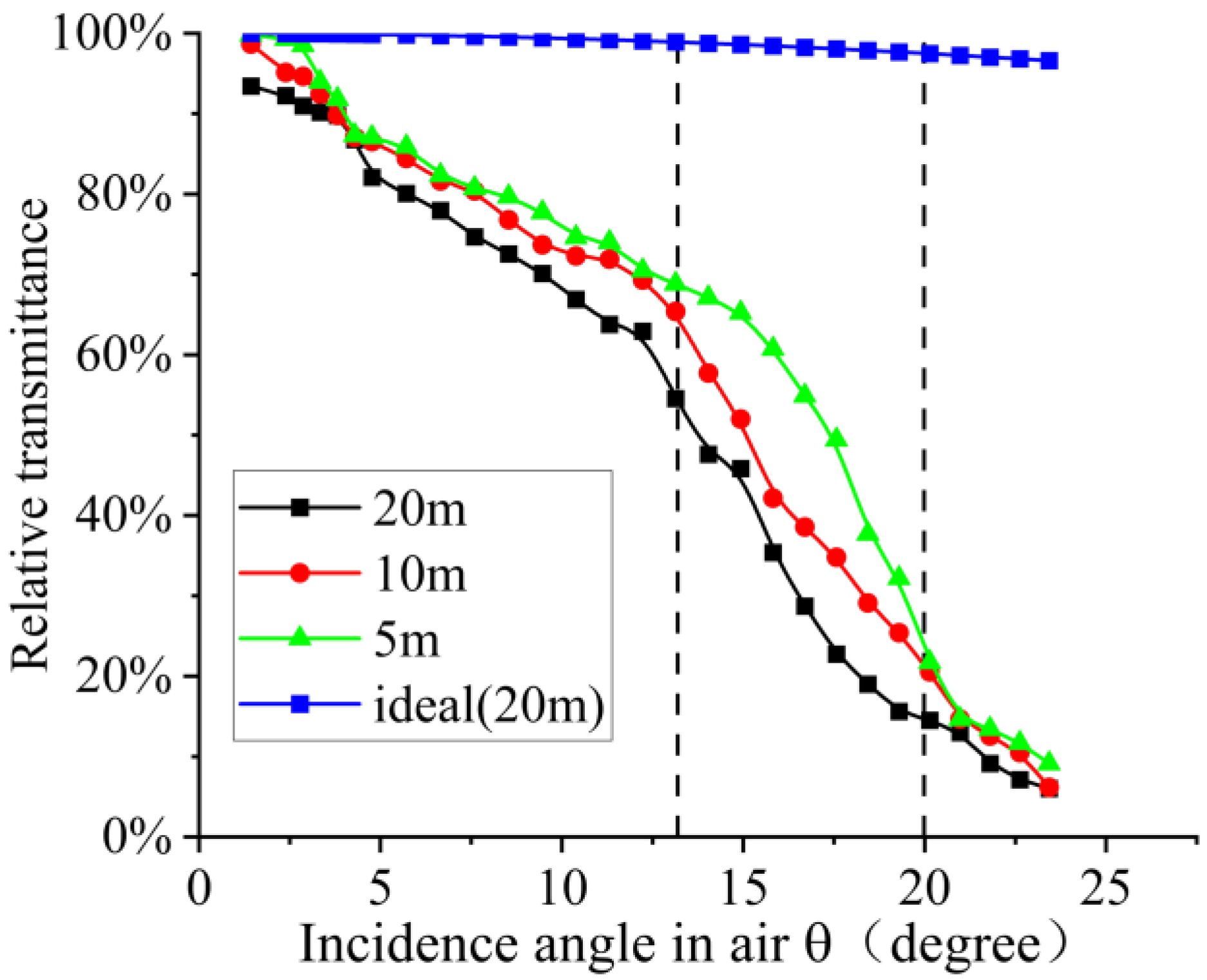

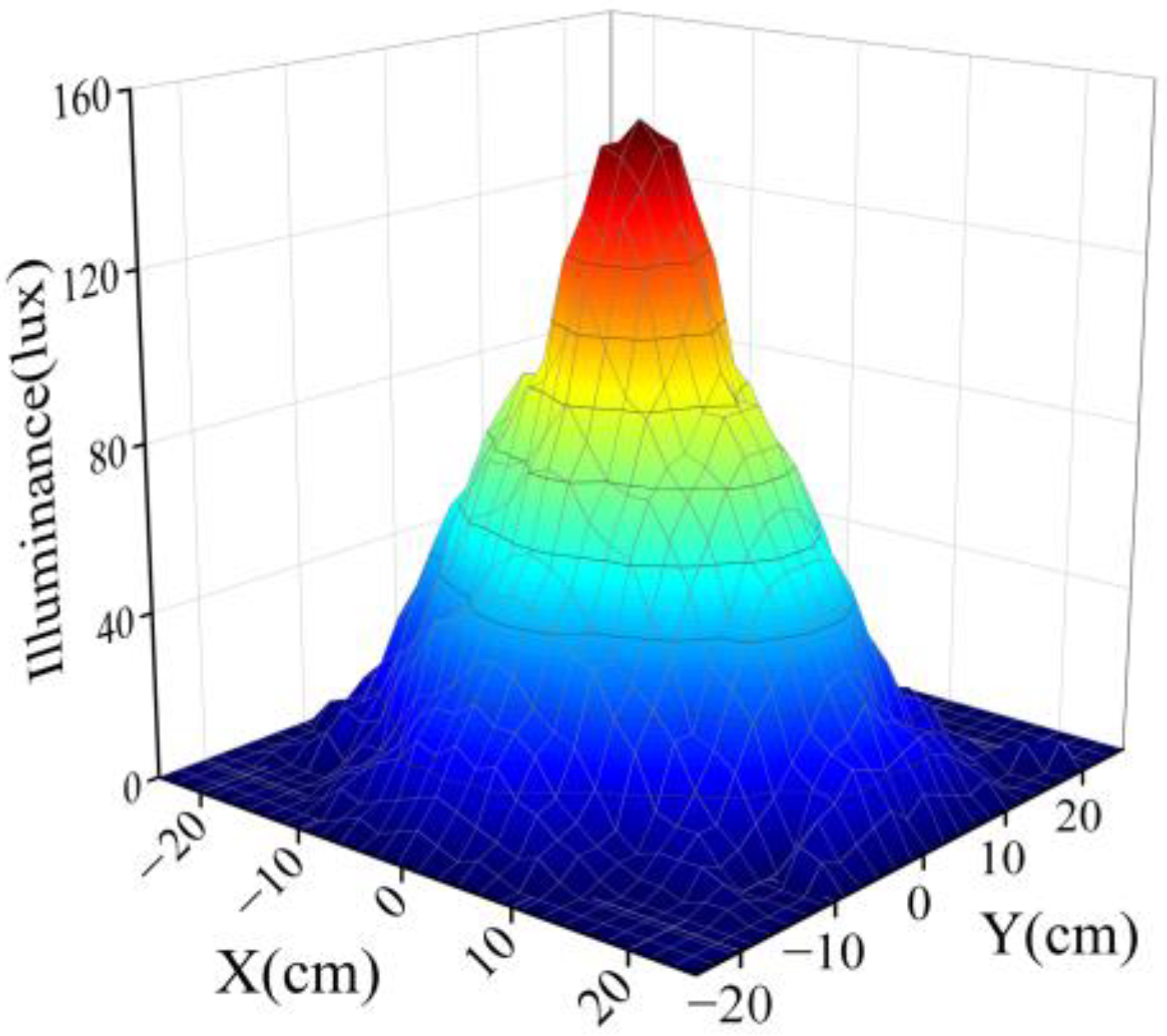

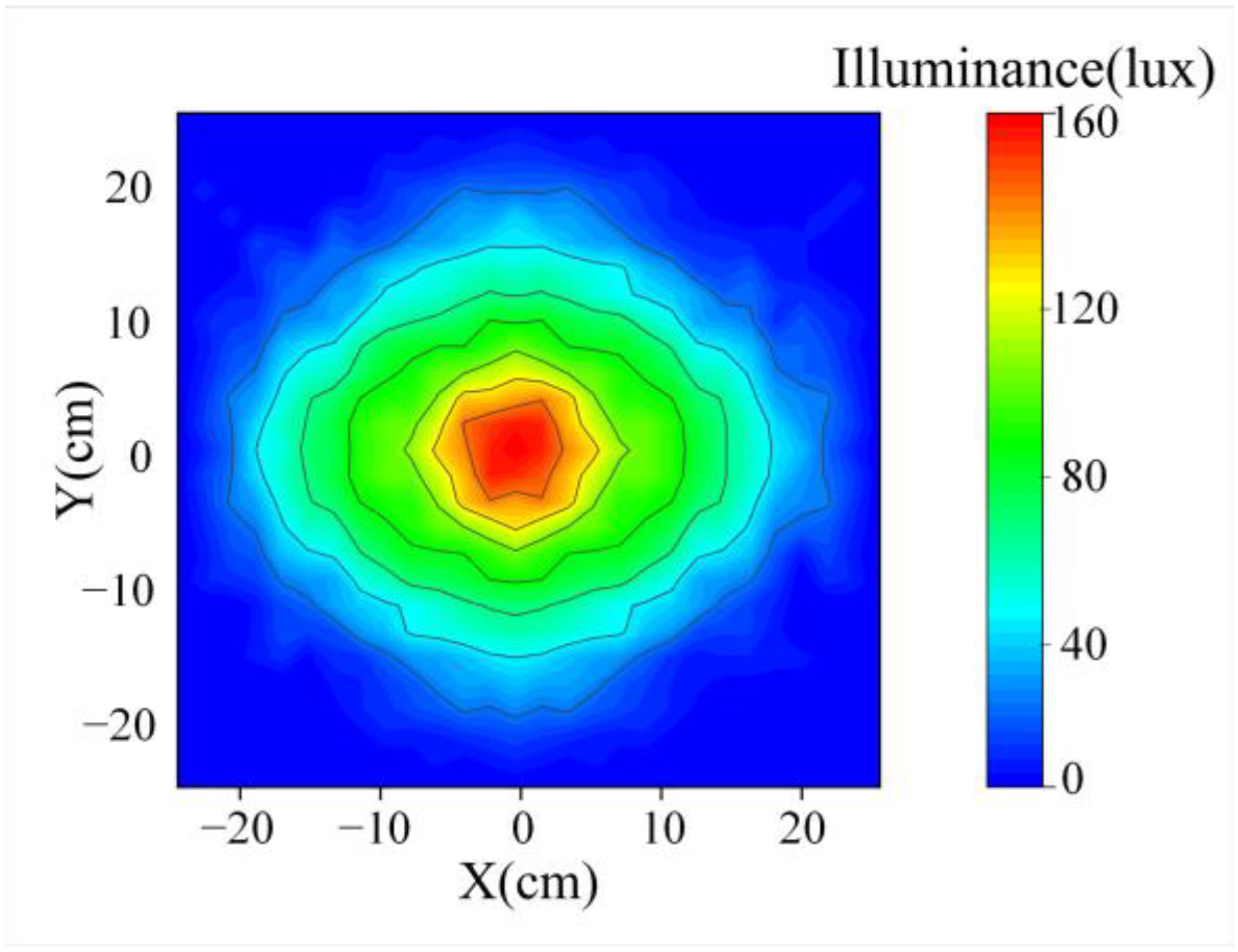

3.3. Light Distribution

3.4. Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hollands, J.; Sesto, E.; Korjenic, A. Thermal Comfort in a Greened Office Building: Investigation and Evaluation through Measurement and Survey. Sustainability 2022, 14, 14450. [Google Scholar] [CrossRef]

- Sun, J.; Li, Z.; Xiao, F.; Xiao, J. Generation of typical meteorological year for integrated climate based daylight modeling and building energy simulation. Renew. Energy 2020, 160, 721–729. [Google Scholar] [CrossRef]

- Munaaim, M.A.C.; Al-Obaidi, K.M.; Ismail, M.R.; Rahman, A.M. Empirical Evaluation of the Effect of Heat Gain from Fiber Optic Daylighting System on Tropical Building Interiors. Sustainability 2014, 6, 9231–9243. [Google Scholar] [CrossRef]

- Wong, L.I. A review of daylighting design and implementation in buildings. Renew. Sustain. Energy Rev. 2017, 74, 959–968. [Google Scholar] [CrossRef]

- Vu, N.H.; Pham, T.T.; Shin, S. Modified optical fiber daylighting system with sunlight transportation in free space. Opt. Express 2016, 24, A1528–A1545. [Google Scholar] [CrossRef]

- Yin, P.; Lv, J.; Wang, X.; Huang, R. A spectral splitting planar solar concentrator with a linear compound parabolic lightguide for optical fiber daylighting. Renew. Energy 2021, 179, 778–787. [Google Scholar] [CrossRef]

- Ravn, M.; Mach, G.; Hansen, E.K.; Triantafyllidis, G. Simulating Physiological Potentials of Daylight Variables in Lighting Design. Sustainability 2022, 14, 881. [Google Scholar] [CrossRef]

- Whang, A.J.W.; Yang, T.H.; Deng, Z.H.; Chen, Y.Y.; Tseng, W.C.; Chou, C.H. A Review of Daylighting System: For Prototype Systems Performance and Development. Energies 2019, 12, 2863. [Google Scholar] [CrossRef]

- Schlegel, G.O.; Burkholder, F.W.; Klein, S.A.; Beckman, W.A.; Wood, B.D.; Muhs, J.D. Analysis of a full spectrum hybrid lighting system. Sol. Energy 2004, 76, 359–368. [Google Scholar] [CrossRef]

- Sabbagh, M.; Mandourah, S.; Hareri, R. Light Shelves Optimization for Daylight Improvement in Typical Public Classrooms in Saudi Arabia. Sustainability 2022, 14, 13297. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, W. A Study on Parametric Design Method for Optimization of Daylight in Commercial Building’s Atrium in Cold Regions. Sustainability 2022, 14, 7667. [Google Scholar] [CrossRef]

- Casquero-Modrego, N. Optical fiber light scattering outdoor tests for interior daylighting. Energy Build. 2019, 198, 138–148. [Google Scholar] [CrossRef]

- Gomes, M.G.; Santos, A.J.; Calhau, M. Experimental study on the impact of double tilted Venetian blinds on indoor daylight conditions. Build. Environ. 2022, 225, 109675. [Google Scholar] [CrossRef]

- Song, J.; Yang, Y.; Zhu, Y.; Jin, Z. A high precision tracking system based on a hybrid strategy designed for concentrated sunlight transmission via fibers. Renew. Energy 2013, 57, 12–19. [Google Scholar] [CrossRef]

- Mayhoub, M.S.; Elqattan, A.A.; Algendy, A.S. Experimental investigation of dust accumulation effect on the performance of tubular daylight guidance systems. Renew. Energy 2021, 169, 726–737. [Google Scholar] [CrossRef]

- Mayhoub, M.S.; Rabboh, E.H. Daylighting in shopping malls: Customer’s perception, preference, and satisfaction. Energy Build. 2022, 255, 111691. [Google Scholar] [CrossRef]

- Song, J.; Wu, Z.; Wang, J.; Zhang, K.; Wang, K.; Liu, K.; Duan, L.; Hou, H. Application of highly concentrated sunlight transmission and daylighting indoor via plastic optical fibers with comprehensive cooling approaches. Renew. Energy 2021, 180, 1391–1404. [Google Scholar] [CrossRef]

- Kandilli, C.; Ulgen, K. Review and modelling the systems of transmission concentrated solar energy via optical fibres. Renew. Sustain. Energy Rev. 2009, 13, 67–84. [Google Scholar] [CrossRef]

- Sreelakshmi, K.; Ramamurthy, K. Review on fibre-optic-based daylight enhancement systems in buildings. Renew. Sustain. Energy Rev. 2022, 163, 112514. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Zhang, J.; Jin, P. Design and analysis of an active daylight harvesting system for building. Renew. Energy 2019, 139, 670–678. [Google Scholar] [CrossRef]

- Kribus, A.; Zik, O.; Karni, J. Optical fibers and solar power generation. Sol. Energy 2000, 68, 405–416. [Google Scholar] [CrossRef]

- Vu, N.-H.; Shin, S. Cost-effective optical fiber daylighting system using modified compound parabolic concentrators. Sol. Energy 2016, 136, 145–152. [Google Scholar] [CrossRef]

- Oh, S.J.; Chun, W.; Riffat, S.B.; Jeon, Y.I.; Dutton, S.; Han, H.J. Computational analysis on the enhancement of daylight penetration into dimly lit spaces: Light tube vs. fiber optic dish concentrator. Build. Environ. 2013, 59, 261–274. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Z.; Hu, P.; Cheng, X. Design and optical analysis of the band-focus Fresnel lens solar concentrator. Appl. Therm. Eng. 2016, 102, 695–700. [Google Scholar] [CrossRef]

- Vu, D.T.; Vu, H.; Shin, S.; Tien, T.Q.; Vu, N.H. New mechanism of a daylighting system using optical-fiber-less design for illumination in multi-storey building. Sol. Energy 2021, 225, 412–426. [Google Scholar] [CrossRef]

- Qin, X.; Zhang, X.; Qi, S.; Han, H. Design of Solar Optical Fiber Lighting System for Enhanced Lighting in Highway Tunnel Threshold Zone: A Case Study of Huashuyan Tunnel in China. Int. J. Photoenergy 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Vu, D.T.; Nghiem, V.T.; Tien, T.Q.; Hieu, N.M.; Minh, K.N.; Vu, H.; Shin, S.; Vu, N.H. Optimizing optical fiber daylighting system for indoor agriculture applications. Sol. Energy 2022, 247, 1–12. [Google Scholar] [CrossRef]

- Rouag-Saffidine, D. Adoption of optical fibres or of optical light films in architecture. Renew. Energy 1996, 8, 202–205. [Google Scholar] [CrossRef]

- Song, J.; Luo, G.; Li, L.; Tong, K.; Yang, Y.; Zhao, J. Application of heliostat in interior sunlight illumination for large buildings. Renew. Energy 2018, 121, 19–27. [Google Scholar] [CrossRef]

- Wang, C.; Abdul-Rahman, H.; Rao, S.P. Daylighting can be fluorescent: Development of a fiber solar concentrator and test for its indoor illumination. Energy Build. 2010, 42, 717–727. [Google Scholar] [CrossRef]

- Ullah, I.; Shin, S. Highly concentrated optical fiber-based daylighting systems for multi-floor office buildings. Energy Build. 2014, 72, 246–261. [Google Scholar] [CrossRef]

- Lv, J.; Xu, X.; Yin, P. Design of leak-free sawtooth planar solar concentrator for daylighting system. J. Clean. Prod. 2020, 266, 121895. [Google Scholar] [CrossRef]

- Barbón, A.; Pardellas, A.; Fernández-Rubiera, J.A.; Barbón, N. New daylight fluctuation control in an optical fiber-based daylighting system. Build. Environ. 2019, 153, 35–45. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Yang, Z.; Luo, G.; Tong, K.; Zhao, J.; Song, J. An optical fiber daylighting system with large Fresnel lens. Energy Procedia 2018, 152, 342–347. [Google Scholar] [CrossRef]

- Sedki, L.; Maaroufi, M. Design of parabolic solar daylighting systems based on fiber optic wires: A new heat filtering device. Energy Build. 2017, 152, 434–441. [Google Scholar] [CrossRef]

- Savović, S.; Kovacevic, M.; Bajic, J.; Stupar, D.; Djordjevich, A.; Zivanov, M.; Drljača, B.; Simovic, A.; Oh, K. Temperature Dependence of Mode Coupling in low-NA Plastic Optical Fibers. J. Light. Technol. 2015, 33, 89–94. [Google Scholar] [CrossRef]

- Savović, S.; Djordjevich, A.; Rui, M.; Savović, I. Investigation of performance properties of plastic optical fibers employed as a part of a traffic light system. Quantum Electron. 2021, 51, 1026–1029. [Google Scholar] [CrossRef]

- Han, H.; Tai Kim, J. Application of high-density daylight for indoor illumination. Energy 2010, 35, 2654–2666. [Google Scholar] [CrossRef]

- Song, J.; Zhu, Y.; Tong, K.; Yang, Y.; Reyes-Belmonte, M.A. A note on the optic characteristics of daylighting system via PMMA fibers. Sol. Energy 2016, 136, 32–34. [Google Scholar] [CrossRef]

- Cariou, J.; Martin, L.; Dugas, J. Concentrated Solar-Energy Transport by Optical Fibers. Am. Ceram. Soc. Bull. 1980, 59, 343. [Google Scholar]

- Mildner, D.F.R.; Chen, H. The neutron transmission through a cylindrical guide tube. J. Appl. Cryst. 1994, 27, 316–325. [Google Scholar] [CrossRef]

- Dawei, L.; Yuri, N.; Luis Fraser, M.; Monteiro, M.L.F.; Manuel, C.-P. 200-W solar energy delivery with optical fiber bundles. Proc. SPIE 2017, 3139, 217–224. [Google Scholar]

- Nakamura, T.; Comaskey, B.; Bell, M. Development of Optical Components for Space-Based Solar Plant Lighting. SAE Tech. Pap. 2000, 1. [Google Scholar] [CrossRef]

- Dugas, J.; Sotom, M.; Martin, L.; Cariou, J.M. Accurate characterization of the transmittivity of largediameter multimode optical fibers. Appl. Opt. 1987, 26, 4198–4208. [Google Scholar] [CrossRef] [PubMed]

- Feuermann, D.; Gordon, J.M.; Huleihil, M. Light leakage in optical fibers: Experimental results, modeling and the consequences for solar concentrators. Sol. Energy 2002, 72, 195–204. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Du, J. The potential of circadian lighting in office buildings using a fibre optics daylighting system in Beijing. Build. Environ. 2020, 182, 107118. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Liu, Z.; Luo, Y.; Lian, J.; Liang, P. Daylighting performance simulation and analysis of translucent concrete building envelopes. Renew. Energy 2020, 154, 754–766. [Google Scholar] [CrossRef]

- He, K.; Chen, Z.; Zhong, S.; Qian, Y.; Liu, H.; Yin, J.; Zhou, B. A solar fiber daylighting system without tracking component. Sol. Energy 2019, 194, 461–470. [Google Scholar] [CrossRef]

- Ullah, I.; Lv, H.; Whang, A.J.-W.; Su, Y. Analysis of a novel design of uniformly illumination for Fresnel lens-based optical fiber daylighting system. Energy Build. 2017, 154, 19–29. [Google Scholar] [CrossRef]

- Goel, C.; Yoo, S. Hybrid daylight harvesting system using static ball lens concentrator and movable optical fiber. Sol. Energy 2021, 216, 121–132. [Google Scholar] [CrossRef]

- Barbón, A.; Sánchez-Rodríguez, J.A.; Bayón, L.; Barbón, N. Development of a fiber daylighting system based on a small scale linear Fresnel reflector: Theoretical elements. Appl. Energy 2018, 212, 733–745. [Google Scholar] [CrossRef]

- Song, J.; Luo, N.; Wang, W. Configuration of daylighting system via fibers and experiments of concentrated sunlight transmission. In Proceedings of the 2013 International Conference on Materials for Renewable Energy and Environment, Nanjing, China, 19–21 August 2013; pp. 128–132. [Google Scholar]

- Ioannides, N.; Chunga, E.B.; Bachmatiuk, A.; Gonzalez-Martinez, I.G.; Trzebicka, B.; Adebimpe, D.B.; Kalymnios, D.; Rümmeli, M.H. Approaches to mitigate polymer-core loss in plastic optical fibers: A review. Mater. Res. Express 2014, 1, 032002. [Google Scholar] [CrossRef]

- Zazoum, B.; Hassan, M.E.; Jendoubi, A. Solar optical fiber daylighting system with an IR filter: Experimental and modeling studies. Energy Rep. 2020, 6, 903–908. [Google Scholar] [CrossRef]

- Lv, Y.; Xia, L.; Li, M.; Wang, L.; Su, Y.; Yan, J. Techno-economic evaluation of an optical fiber based hybrid solar lighting system. Energy Convers. Manag. 2020, 225, 113399. [Google Scholar] [CrossRef]

- Andersen, M. Validation of the performance of a new bidirectional video-goniophotometer. Light. Res. Technol. 2006, 38, 295–313. [Google Scholar] [CrossRef]

- Han, H.J.; Riffat, S.B.; Lim, S.H.; Oh, S.J. Fiber optic solar lighting: Functional competitiveness and potential. Sol. Energy 2013, 94, 86–101. [Google Scholar] [CrossRef]

- Snchez Montero, D.R.; Vzquez, C. Multimode graded-index optical fibers for next-generation broadband access. In Current Developments in Optical Fiber Technology; IntechOpen: Rijeka, Croatia, 2013; Chapter 4, pp. 73–121. [Google Scholar] [CrossRef]

- Montero, D.S.; Vazquez, C. Analysis of the electric field propagation method: Theoretical model applied to perfluorinated graded-index polymer optical fiber links. Opt. Lett. 2011, 36, 4116–4118. [Google Scholar] [CrossRef]

- Pinzon, P.J.; Montero, D.S.; Tapetado, A.; Vazquez, C. Dual-Wavelength Speckle-Based SI-POF Sensor for Cost-Effective Detection of Microvibrations. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 217–222. [Google Scholar] [CrossRef]

- Song, J.; Jin, Z.; Zhu, Y.; Zhou, Z.; Yang, Y. Development of a fiber daylighting system based on the parallel mechanism and direct focus detection. Sol. Energy 2015, 115, 484–493. [Google Scholar] [CrossRef]

- Yang, Z.; Li, L.; Wang, J.; Wang, W.; Song, J. Realization of high flux daylighting via optical fibers using large Fresnel lens. Sol. Energy 2019, 183, 204–211. [Google Scholar] [CrossRef]

| Parameters | Units | Value |

|---|---|---|

| Lens aperture | mm | 52 |

| Focal length | mm | 60 |

| Optical fiber length | m | 5, 10, 20 |

| Range of the aperture of the diaphragm | mm | 3–52 |

| Critical angle of the fiber | degree | 30 |

| Core | - | PMMA |

| Cladding | - | Fluorinated polymer |

| Dichroic filter | - | Infrared interference filter |

| Type of absorbing glass | - | GRB3 |

| Glass thickness | mm | 2 |

| Lens material | - | Glass |

| Model of the spectrometer | - | SPIC-300 |

| Picture |  |  |  |

| Lens aperture | 100 mm | 240 mm | 70 mm |

| Focal length | 110 mm | 360 mm | 150 mm |

| Incident angle | 24° | 18° | 13° |

| Global efficiency | 13% (20 m) | 15% (20 m) | 18% (20 m) |

| Input power | 490 W/m2 | 921 W/m2 | 50 W/m2 |

| Output power | 63 W/m2 | 138 W/m2 | 9 W/m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Zou, L.; Li, Y.; Wang, K.; Wang, H.; Song, J. Measurement and Analysis of Light Leakage in Plastic Optical Fiber Daylighting System. Sustainability 2023, 15, 3155. https://doi.org/10.3390/su15043155

Liu K, Zou L, Li Y, Wang K, Wang H, Song J. Measurement and Analysis of Light Leakage in Plastic Optical Fiber Daylighting System. Sustainability. 2023; 15(4):3155. https://doi.org/10.3390/su15043155

Chicago/Turabian StyleLiu, Kunhao, Lianglin Zou, Yuanlong Li, Kai Wang, Haiyu Wang, and Jifeng Song. 2023. "Measurement and Analysis of Light Leakage in Plastic Optical Fiber Daylighting System" Sustainability 15, no. 4: 3155. https://doi.org/10.3390/su15043155

APA StyleLiu, K., Zou, L., Li, Y., Wang, K., Wang, H., & Song, J. (2023). Measurement and Analysis of Light Leakage in Plastic Optical Fiber Daylighting System. Sustainability, 15(4), 3155. https://doi.org/10.3390/su15043155