How the Carbonation Treatment of Different Types of Recycled Aggregates Affects the Properties of Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement and Admixture

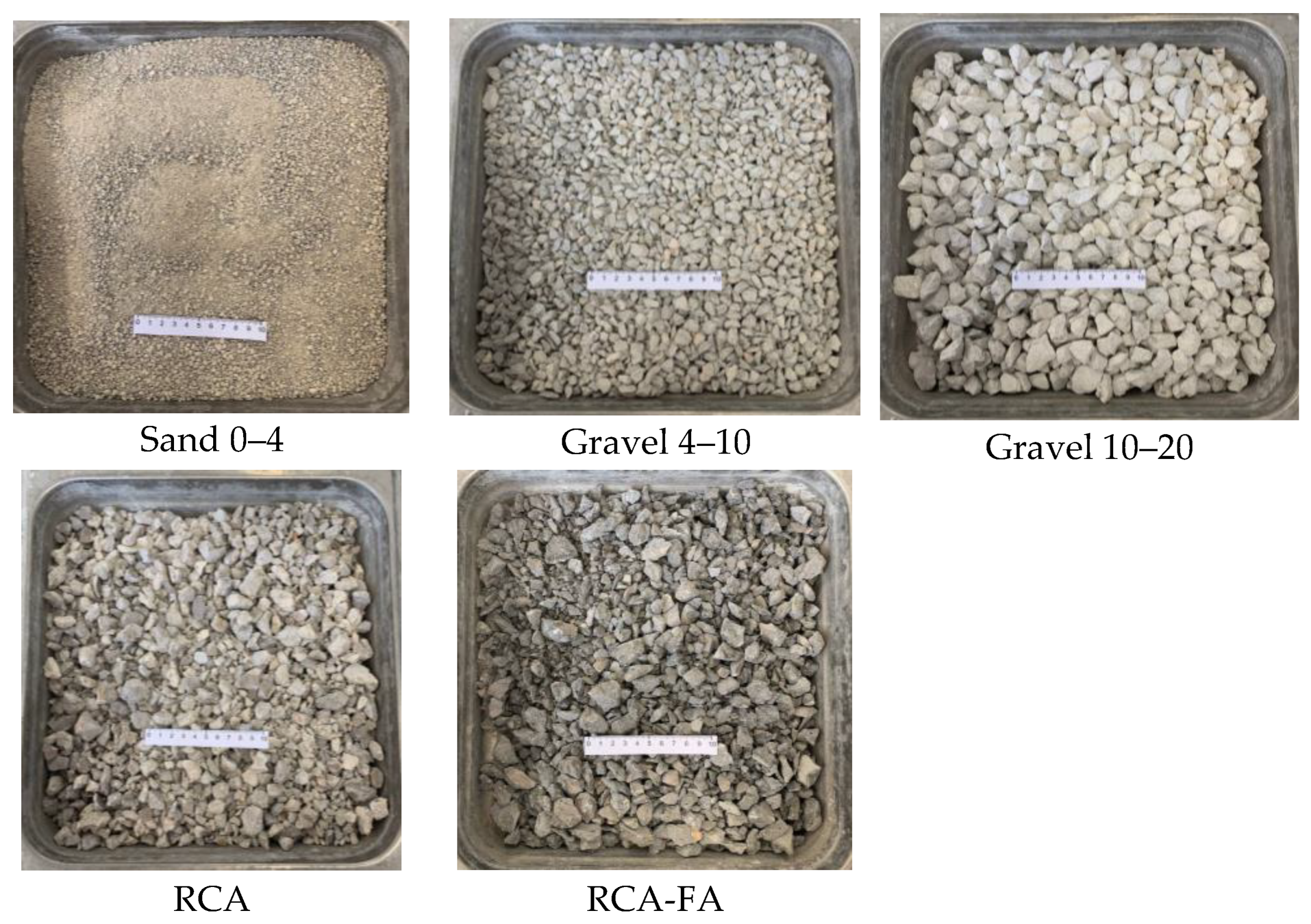

2.1.2. Natural Aggregates

2.1.3. Recycled Aggregates

Carbonated Recycled Aggregates

The Pore Structure of Recycled Aggregates

2.2. Concrete Production

2.3. Test Procedure

2.3.1. Physical Properties

2.3.2. Mechanical Properties

2.3.3. Durability

3. Results

3.1. Physical Properties

3.2. Mechanical Properties

3.3. Durability

3.3.1. Capillary Water Absorption—Sorptivity

3.3.2. Chloride Ion Penetration

3.3.3. Carbonation Resistance

3.3.4. Chloride Ion Penetration vs. Carbonation Resistance

4. Conclusions

- -

- The CO2 treatment increased the density and reduced the absorption capacity of recycled aggregates. However, when the attached mortar of the recycled aggregates was composed with FA (RCA-FA), after carbonation, the pore size distribution was transformed, increasing in the mesopores and macropores. Consequently, the RCA-FA-C (carbonated) aggregate achieved higher permeability than the RCA-FA;

- -

- Therefore, according to the properties of recycled aggregates, the carbonate treatment was effective when the attached mortar of the recycled aggregates was composed of OPC. In contrast, the RCA-FA-C (carbonated) aggregates achieved higher permeability than those of the RCA-FA aggregates;

- -

- According to physical and mechanical properties, the following is true:

- ○

- All the recycled concretes achieved adequate properties as structural concrete. They reached the compressive strength of the CC concrete at 28 days and a lower modulus elasticity than that of the CC concrete;

- ○

- The recycled concrete produced with 50% of the RCA-C and RCA-FA aggregates achieved the most efficient properties of all the recycled concretes:

- ▪

- They only achieved a 7% higher absorption capacity than that of the CC concrete;

- ▪

- The concrete produced with RCA-C achieved the highest strength;

- ▪

- The recycled concrete produced with RCA-C and RCA-FA reached similar or higher splitting tensile strength to that of the CC concrete;

- ▪

- The recycled concrete produced with RCA-C and RCA-FA suffered a lower decrease of 6% in modulus elasticity compared to the CC concrete.

- -

- All the recycled concrete produced with 50% of RA achieved the durable category defined with a sorptivity value lower than 0.05 mm/min0.5. The concrete made with 50% of the RCA-FA achieved the lowest sorptivity value of 0.032 mm/min0.5, followed by the CC concrete with 0.035 mm/min0.5 and the recycled concrete produced with 50% of the RCA-C with 0.036 mm/min0.5;

- -

- The recycled concrete achieved higher chloride ion penetration than that of the CC concrete. However, the concrete produced with the RCA-FA aggregates achieved the best value with only 4% higher penetration than the CC concrete, followed by the concrete produced with the RCA-C aggregates. In contrast, the concrete produced with the RCA-FA-C aggregates achieved the highest penetration: 38% higher than that of the CC concrete;

- -

- The CC concrete achieved the lowest carbonation rate, followed by the concretes produced with 50% RCA and 50% RCA-FA. The CO2-treated recycled aggregates worsened the carbonation resistance of the recycled concrete, with this worsening condition increasing when the RCA-FA-C aggregates were used;

- -

- It was found that the CC and RAC50 concretes were the only concretes adequate for both XC3 and XC4 environment expositions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Statistics-Eurostat. Energy, Transport and Environment Statistics, 2020th ed.; European Statistics-Eurostat: Luxembourg, 2020. [Google Scholar]

- de Carvalho, J.M.F.; Fontes, W.C.; de Azevedo, C.F.; Brigolini, G.J.; Schmidt, W.; Peixoto, R.A.F. Enhancing the eco-efficiency of concrete using engineered recycled mineral admixtures and recycled aggregates. J. Clean. Prod. 2020, 257, 120530. [Google Scholar] [CrossRef]

- Kaplan, G.; Gulcan, A.; Cagdas, B.; Bayraktar, O.Y. The impact of recycled coarse aggregates obtained from waste concretes on lightweight pervious concrete properties. Environ. Sci. Pollut. Res. 2021, 28, 17369–17394. [Google Scholar] [CrossRef]

- Le, H.B.; Bui, Q.B. Recycled aggregate concretes—A state-of-the-art from the microstructure to the structural performance. Constr. Build. Mater. 2020, 257, 119522. [Google Scholar] [CrossRef]

- Silva, S.; Evangelista, L.; de Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Pedro, D.; De Brito, J.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Etxeberria, M. Evaluation of eco-efficient concretes produced with fly ash and uncarbonated recycled aggregates. Materials 2021, 14, 7499. [Google Scholar] [CrossRef]

- Zeng, X. Progress in the research of carbonation resistance of RAC. Constr. Build. Mater. 2020, 230, 116976. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; De Juan, M.S. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2011, 26, 565–573. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and durability properties of concrete based on recycled coarse and fine aggregates produced from demolished concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Adessina, A.; Fraj, A.B.; Barthélémy, J.F.; Chateau, C.; Garnier, D. Experimental and micromechanical investigation on the mechanical and durability properties of recycled aggregates concrete. Cem. Concr. Res. 2019, 126, 105900. [Google Scholar] [CrossRef]

- Leemann, A.; Loser, R. Carbonation resistance of recycled aggregate concrete. Constr. Build. Mater. 2019, 204, 335–341. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Performance of concrete made with aggregates recycled from precasting industry waste: Influence of the crushing process. Mater. Struct. Constr. 2015, 48, 3965–3978. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Cao, Z.; Guo, M.; Zheng, J. Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete. J. Clean. Prod. 2019, 233, 421–428. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.-S.; Xie, Z. Performance Enhancement of Recycled Concrete Aggregates through Carbonation. J. Mater. Civ. Eng. 2015, 27, 04015029. [Google Scholar] [CrossRef]

- Pu, Y.; Li, L.; Wang, Q.; Shi, X.; Fu, L.; Zhang, G.; Luan, C.; Abomohra, A.E.F. Accelerated carbonation treatment of recycled concrete aggregates using flue gas: A comparative study towards performance improvement. J. CO2 Util. 2021, 43, 101362. [Google Scholar] [CrossRef]

- Sereng, M.; Djerbi, A.; Metalssi, O.O.; Dangla, P.; Torrenti, J.M. Improvement of recycled aggregates properties by means of CO2 uptake. Appl. Sci. 2021, 11, 6571. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Wang, R.; Zhao, Y.; Men, C. Effects of carbonation treatment on the crushing characteristics of recycled coarse aggregates. Constr. Build. Mater. 2019, 201, 408–420. [Google Scholar] [CrossRef]

- von Greve-Dierfeld, S.; Lothenbach, B.; Vollpracht, A.; Wu, B.; Huet, B.; Andrade, C.; Medina, C.; Thiel, C.; Gruyaert, E.; Vanoutrive, H.; et al. Understanding the carbonation of concrete with supplementary cementitious materials: A critical review by RILEM TC 281-CCC. Mater. Struct. Constr. 2020, 53, 136. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Ding, Z.; Quy, N.X.; Kim, J.; Hama, Y. Evaluations of frost and scaling resistance of fly ash concrete in terms of changes in water absorption and pore structure under the accelerated carbonation conditions. Constr. Build. Mater. 2022, 345, 128273. [Google Scholar] [CrossRef]

- GB/T50082-2009; Standard for test method of long term performance and durability of ordinary concrete. China Architecture and Building Press: Beijing, China, 2009.

- UNE-EN 1097-6; Tests for mechanical and physical properties of aggregates. Determination of particle density and water absorption—Ensayos para determinas las propiedds mecánicas y físicas de los áridos. (Parte 6: Determinación de la densidad de partículas y la absorción de agua). AENOR: Madrid, Spain, 2014.

- Hyvert, N.; Sellier, A.; Duprat, F.; Rougeau, P.; Francisco, P. Dependency of C-S-H carbonation rate on CO2 pressure to explain transition from accelerated tests to natural carbonation. Cem. Concr. Res. 2010, 40, 1582–1589. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F. Concrete; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1981. [Google Scholar]

- Igarashi, S.I.; Watanabe, A.; Kawamura, M. Evaluation of capillary pore size characteristics in high-strength concrete at early ages. Cem. Concr. Res. 2005, 35, 513–519. [Google Scholar] [CrossRef]

- Jenings, H.M. Design of high strength cement based materials: Part 2 Microstructure. Mater. Sci. Technol. 1988, 4, 285–290. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.; Tang, Y.; Deng, Q.; Wang, D.; Poon, C.S. Fully utilizing carbonated recycled aggregates in concrete: Strength, drying shrinkage and carbon emissions analysis. J. Clean. Prod. 2022, 377, 134520. [Google Scholar] [CrossRef]

- Liang, C.; Ma, H.; Pan, Y.; Ma, Z.; Duan, Z.; He, Z. Chloride permeability and the caused steel corrosion in the concrete with carbonated recycled aggregate. Constr. Build. Mater. 2019, 218, 506–518. [Google Scholar] [CrossRef]

- del de Hormigón, C. Código estructural. Spanish Structural Code; Boletón Oficial del Estado: Madrid, Spain, 2015; pp. 61561–61567. [Google Scholar]

- Neville, A. Properties of Concrete, 5th ed.; Longman: London, UK, 2011. [Google Scholar]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vazquez, E.; Mari, A. Microstructure analysis of hardened recycledaggregate concrete. Mag. Concr. Res. 2006, 58, 683–690. [Google Scholar] [CrossRef]

- UNE-EN 12350-2; Testing hardened concrete. Making and curing specimens for strength tests. Ensayos de hormigón endurecido. Parte 2. Fabricación y curado de probetas para ensayos de resistencia. AENOR: Madrid, Spain, 2020.

- UNE-EN 12350-6; Testing fresh concrete. Density. Ensayos de hormigón fresco. Parte 6. Densidad. AENOR: Madrid, Spain, 2014.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM: West Conshohocken, PA, USA, 2021.

- UNE-EN 12350-3; Testing hardened concrete. Compressive strength of test specimens. Ensayos de hormigón endurecido. Parte 3: Determinación de la resistencia a compresión de probetas. AENOR: Madrid, Spain, 2020.

- UNE-EN 12350-13; Testing hardened concrete. Determination of secant modulus of elasticity in compressionEnsayos de hormigón endurecido. Parte 13: Determinación del módulo secante de elasticidad en compresión. AENOR: Madrid, Spain, 2022.

- UNE-EN 12350-6; Testing hardened concrete. Tensile splitting strength of test specimens. Ensayos de hormigón endurecido. Parte 6: Resistencia a tracción indirecta de probetas. AENOR: Madrid, Spain, 2010.

- ISO 15148:2002(E); Hygrothermal performance of building materials and products—Determination of water absorption coefficient by partial immersion. ISO: Geneva, Switzerland, 2002.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM: West Conshohocken, PA, USA, 2019.

- Ghanem, H.; Trad, A.; Dandachy, M.; ElKordi, A. Effect of Wet-Mat Curing Time on Chloride Permeability of Concrete Bridge Decks. In Advances and Challenges in Structural Engineering: Proceedings of the 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Egypt 2018–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE); Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 194–208. [Google Scholar]

- UNE-EN 12390-12; Testing hardened concrete. Determination of the carbonation resistance of concrete. Accelerated carbonation method. Ensayos de hormigón endurecido. Parte 12: Determinación de la resistencia a la carbonatación del hormigón. Método de carbonatación acelerada. AENOR: Madrid, Spain, 2020.

- UNE-EN 14630; Products and systems for the protection and repair of concrete structures—Test methods—Determination of carbonation depth in hardened concrete by the phenolphthalein method; Productos y sistemas para la protección y reparación de estructuras de hormigón. Métodos de ensayo. Determinación de la profundidad de carbonatación en un hormigón endurecido por el método de la fenolftaleína. AENOR: Madrid, Spain, 2007.

- Kou, S.C.; Zhan, B.J.; Poon, C.S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 2014, 45, 22–28. [Google Scholar] [CrossRef]

- Alexander, M.G.; Ballim, Y.; Stanish, K. A framework for use of durability indexes in performance-based design and specifications for reinforced concrete structures. Mater. Struct. Constr. 2008, 41, 921–936. [Google Scholar] [CrossRef]

- Menéndez, G.; Bonavetti, V.L.; Irassar, E.F. Ternary blend cements concrete. Part II: Transport mechanism. Mater. Construcción 2007, 57, 31–43. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Effect of fly ash and silica fume on compressive and fracture behaviors of concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Dinakar, P.; Reddy, M.K.; Sharma, M. Behaviour of self compacting concrete using Portland pozzolana cement with different levels of fly ash. Mater. Des. 2013, 46, 609–616. [Google Scholar] [CrossRef]

- Parrott, L. A Review of Carbonation in Reinforced Concrete; BCA, British Cement Association Crowthorne: Berkshire, UK, 1987. [Google Scholar]

- Van Den Heede, P.; De Belie, N. A service life based global warming potential for high-volume fly ash concrete exposed to carbonation. Constr. Build. Mater. 2014, 55, 183–193. [Google Scholar] [CrossRef]

| SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 | Na2O | K2O | LOI | Blaine (cm2/g) | Density (g/cm3) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CEM II A-L | 18.27 | 3.29 | 4.09 | 61.82 | 1.35 | 2.9 | 0.10 | 0.77 | 5.07 | 3900 | 3.16 |

| FA | 58.4 | 7.3 | 21.6 | 2.3 | 1.9 | 0.2 | 0.9 | 2.1 | 3.1 | 3400 | 2.16 |

| CEM I 52.5R | 19.4 | 3.4 | 4.2 | 63.5 | 1.4 | 3.0 | 0.12 | 0.53 | 3.7 | 4900 | 3.15 |

| Raw Aggregates, NA | Recycled Aggregates, RA | Carbonated RA | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0/4 mm | 4/10 mm | 10/20 mm | RCA | RCA-FA | Process 1 | Process 2 | |||

| RCA-C | RCA-FA-C | RCA-C | RCA-FA-C | ||||||

| ρrd (kg/m3) | 2590 | 2640 | 2650 | 2310 | 2240 | 2360 | 2310 | 2370 | 2310 |

| WA24 (%) | 1.79 | 0.75 | 0.57 | 5.8 | 6.8 | 4.85 | 5.64 | 4.8 | 5.68 |

| Concrete Reference | CEM | Raw Aggregates | RA | Total Water | S (%) | SLUMP (mm) | DENSITY (kg/m3) | ||

|---|---|---|---|---|---|---|---|---|---|

| 0–4 mm | 4–10 mm | 10–20 mm | |||||||

| CC | 350 | 900 | 275.2 | 644.6 | - | 192.5 | 0.5 | 170 | 2420 |

| RAC50 | 350 | 900 | 137.6 | 322.3 | 399.6 | 211.1 | 0.5 | 150 | 2310 |

| RAC50-C | 350 | 900 | 137.6 | 322.3 | 411.8 | 208.9 | 0.5 | 170 | 2340 |

| RAC50-FA | 350 | 900 | 137.6 | 322.3 | 389.2 | 217 | 0.5 | 170 | 2310 |

| RAC50-FA-C | 350 | 900 | 137.6 | 322.3 | 401.3 | 211.8 | 0.6 | 190 | 2360 |

| Concrete Reference | Water Absorption (%) | Dry Density (Kg/m3) | Accessible Voids (%) | Sorptivity (mm/min0.5) |

|---|---|---|---|---|

| CC | 4.86 (0.13) | 2290 (20) | 11.13 (0.23) | 0.035 |

| RAC50 | 5.75 (0.14) | 2240 (10) | 12.85 (0.23) | 0.039 |

| RAC50-C | 5.38 (0.14) | 2240 (10) | 12.06 (0.27) | 0.036 |

| RAC50-FA | 5.2 (0.07) | 2240 (10) | 11.66 (0.13) | 0.032 |

| RAC50-FA-C | 5.62 (0.05) | 2230 (10) | 12.53 (0.09) | 0.048 |

| Test | Time (Days) | CC | RAC50 | RAC50-C | RAC50-FA | RAC50-FA-C |

|---|---|---|---|---|---|---|

| Compressive strength (MPa) | 7 | 44.63 (0.31) | 42.23 (0.19) | 42.76 (0.52) | 42.26 (0.33) | 39.19 (2.76) |

| 28 | 45.92 (0.21) | 44.10 (1.83) | 45.71(1.48) | 45.09 (1.22) | 43.82 (2.22) | |

| 56 | 54.0 (1.52) | 50.29 (0.38) | 50.65(1.30) | 49.90 (1.22) | 49.07 (1.76) | |

| Splitting tensile (MPa) | 28 | 3.19 (0.08) | 2.89 (0.25) | 3.36 (0.16) | 3.14 (0.17) | 3.02 (0.44) |

| E (GPa) | 28 | 34.1 (0.87) | 30.9 (0.35) | 31.9 (0.33) | 31.9 (0.71) | 30.6 (0.19) |

| Concrete Reference | 28 Days (Coulombs) | 56 Days (Coulombs) | Increase of Resistance |

|---|---|---|---|

| (%) | |||

| CC | 6731 (49.2) | 5180 (821.1) | 23 |

| RAC50 | 8799 (582.2) | 6377 (810.2) | 27 |

| RAC50-C | 7407 (411.0) | 6166 (319.7) | 17 |

| RAC50-FA | 7006 (352.5) | 5412 (300.1) | 23 |

| RAC50-FA-C | 9296 (1088.2) | 7221 (270.2) | 22 |

| Concrete Reference | Carbonation Depth (mm) at Exposure Time | Carbonation Coefficient | |||||

|---|---|---|---|---|---|---|---|

| 0 Days | 14 Days | 28 Days | 56 Days | 91 Days | kacc (mm/day0.5) | KnatTHEO (mm/year0.5) | |

| CC | 0 (0.00) | 3.5 (0.29) | 5.2 (0.77) | 7.0 (0.82) | 8.8 (0.27) | 0.926 | 2.105 |

| RAC50 | 0 (0.00) | 4.4 (0.18) | 5.4 (0.53) | 7.0 (0.00) | 9.5 (0.35) | 0.958 | 2.180 |

| RAC50-C | 0 (0.00) | 5.1 (0.62) | 7.4 (0.44) | 9.9 (0.32) | 12.9 (1.18) | 1.338 | 3.043 |

| RAC50-FA | 0 (0.00) | 4.5 (0.53) | 6.9 (0.29) | 9.9 (0.74) | 11.8 (1.41) | 1.269 | 2.886 |

| RAC50-FA-C | 0 (0.00) | 5.0 (0.06) | 8.7 (1.36) | 10.0 (0.18) | 13.9 (1.97) | 1.432 | 3.257 |

| CC | RAC50 | RAC50-C | RAC50-FA | RAC50-FA-C | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No | CO2 | No | CO2 | No | CO2 | No | CO2 | No | CO2 | |

| Porosity (%) | 11.12 (1.6) | 8.95 (0.98) | 13.18 (1.3) | 11.64 (2.01) | 12.05 (1.1) | 11.84 (1.45) | 9.36 (0.8) | 12.67 (1.6) | 14.93 (2.2) | 12.92 (1.9) |

| Average pore D (nm) | 35.61 (1.1) | 32.74 (0.7) | 46.29 (2.3) | 32.57 (1.5) | 38.48 (1.8) | 34.25 (1.4) | 47.67 (1.9) | 34.45 (1.7) | 61.92 (2.6) | 35.35 (0.7) |

| CC | RAC50 | RAC50-C | RAC50-FA | RAC50-FA-C | XC3 | XC4 | |

|---|---|---|---|---|---|---|---|

| Carbonation Depth (mm) | Min. Cover (mm) | ||||||

| 50 years (knatTHEO) | 14.9 | 15.5 | 21.6 | 20.5 | 23.1 | 20 | 25 |

| 100 years (knatTHEO) | 21.1 | 21.9 | 30.5 | 28.9 | 32.6 | 30 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Etxeberria, M.; Castillo, S. How the Carbonation Treatment of Different Types of Recycled Aggregates Affects the Properties of Concrete. Sustainability 2023, 15, 3169. https://doi.org/10.3390/su15043169

Etxeberria M, Castillo S. How the Carbonation Treatment of Different Types of Recycled Aggregates Affects the Properties of Concrete. Sustainability. 2023; 15(4):3169. https://doi.org/10.3390/su15043169

Chicago/Turabian StyleEtxeberria, Miren, and Silvia Castillo. 2023. "How the Carbonation Treatment of Different Types of Recycled Aggregates Affects the Properties of Concrete" Sustainability 15, no. 4: 3169. https://doi.org/10.3390/su15043169

APA StyleEtxeberria, M., & Castillo, S. (2023). How the Carbonation Treatment of Different Types of Recycled Aggregates Affects the Properties of Concrete. Sustainability, 15(4), 3169. https://doi.org/10.3390/su15043169