Leveraging Blockchain to Support Collaborative Distributed Manufacturing Scheduling

Abstract

:1. Introduction

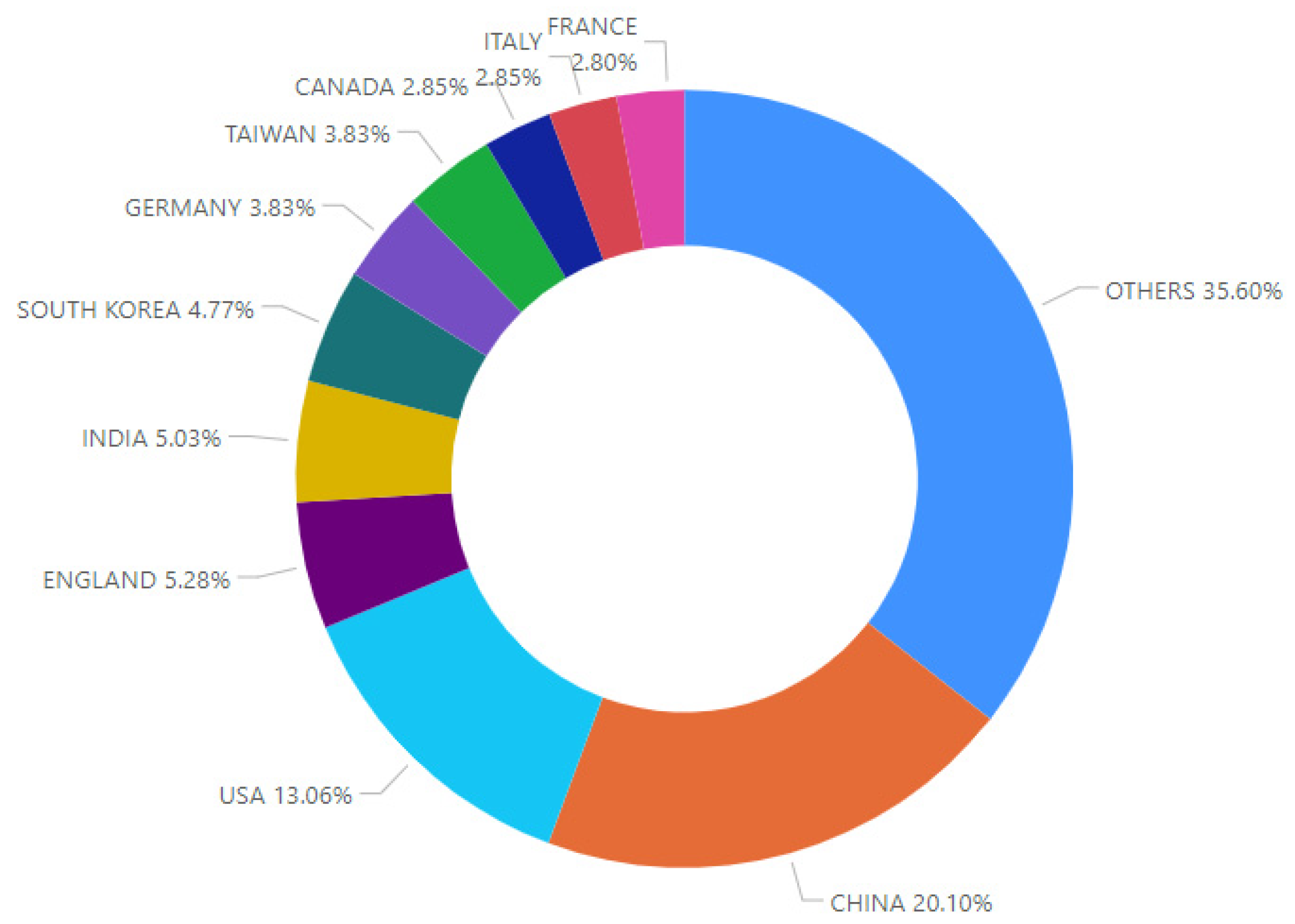

2. Literature Review

2.1. Collaborative Management and Industry 4.0 Technology

2.2. Manufacturing Scheduling Environments and Approaches

2.3. Distributed Manufacturing Scheduling

2.4. Blockchain in Distributed Manufacturing Scheduling

3. Proposed Blockchain-Based Collaborative Distributed Manufacturing Scheduling Approach

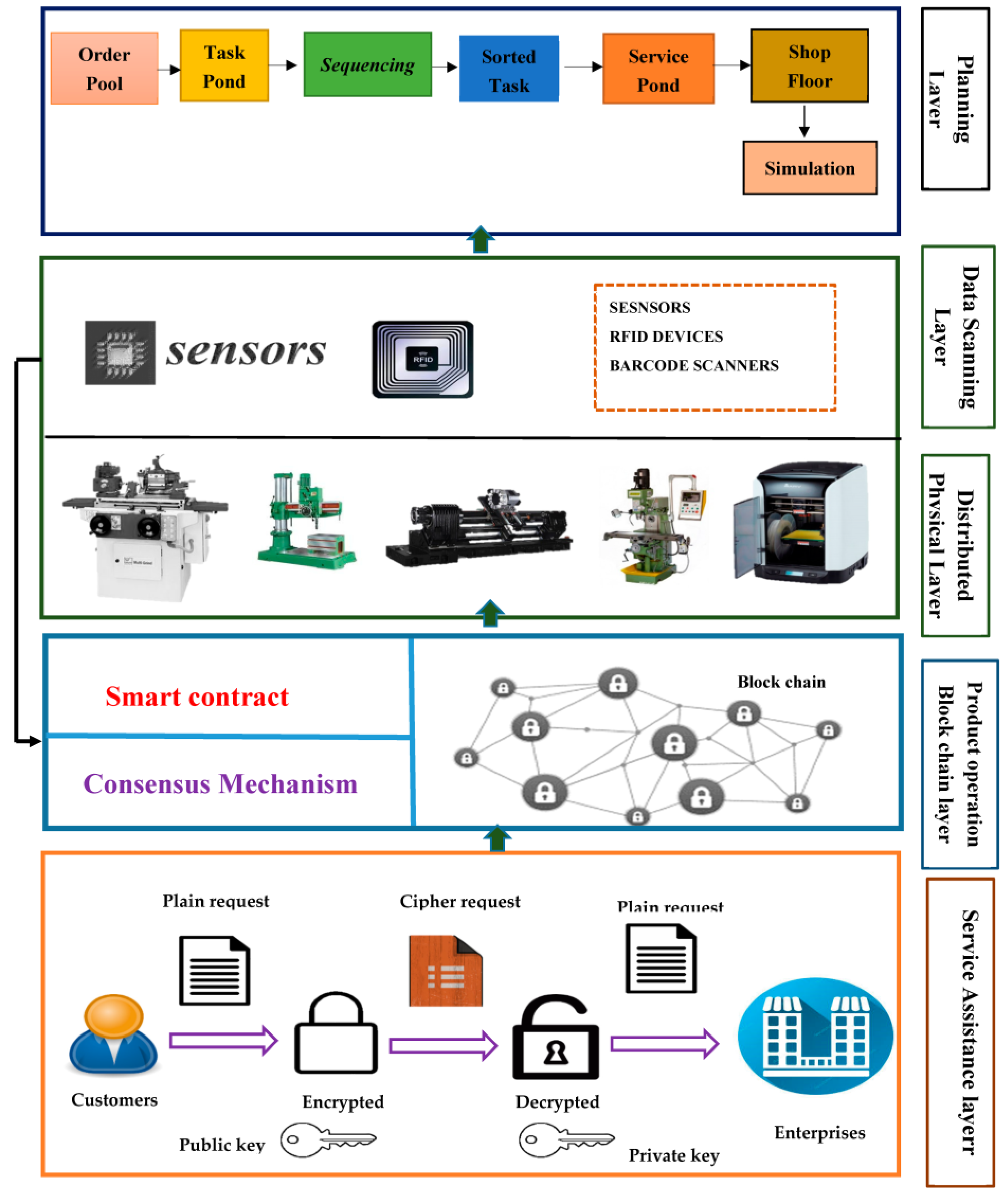

3.1. Proposed Methodology Based on Blockchain Technology

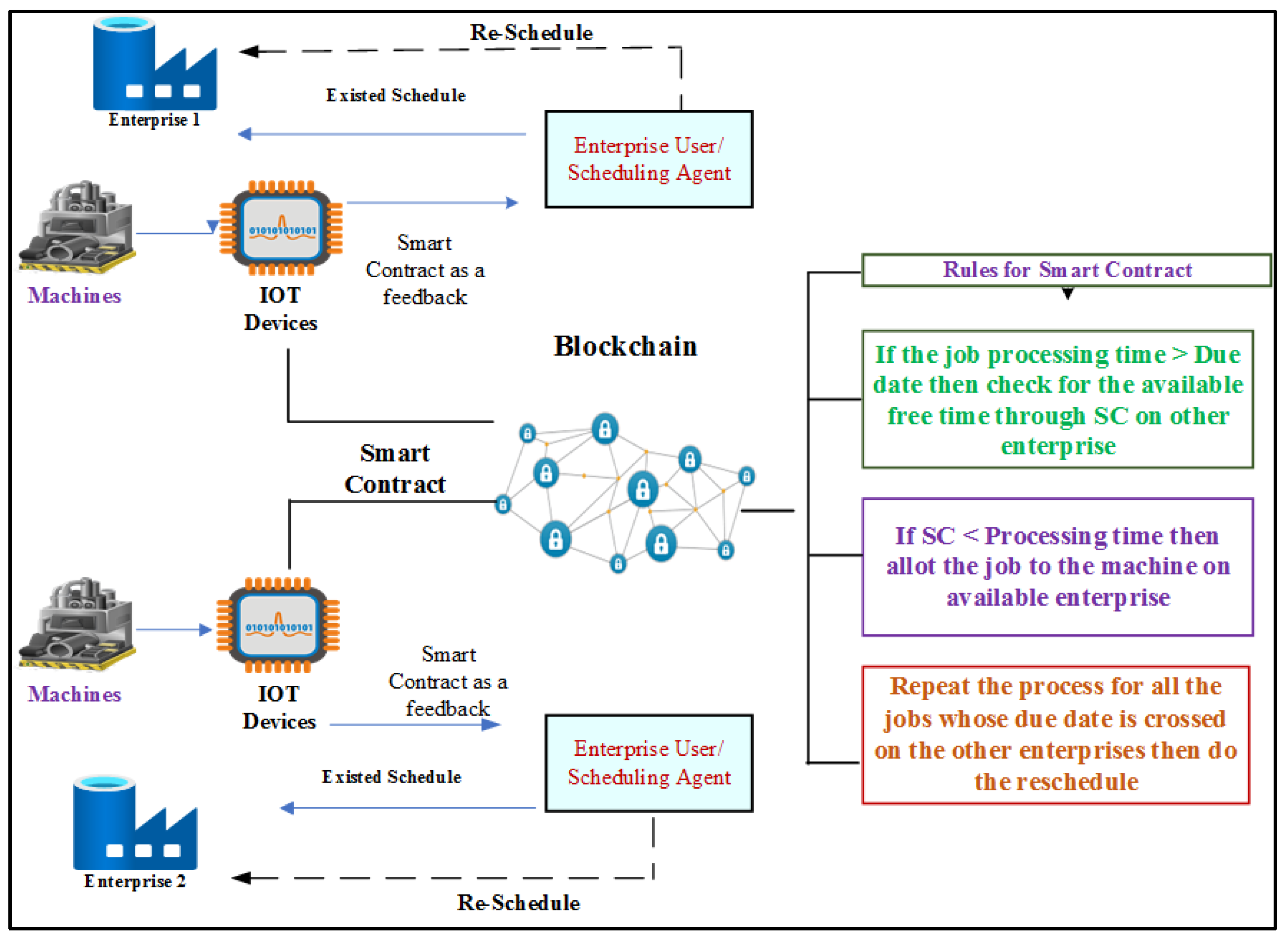

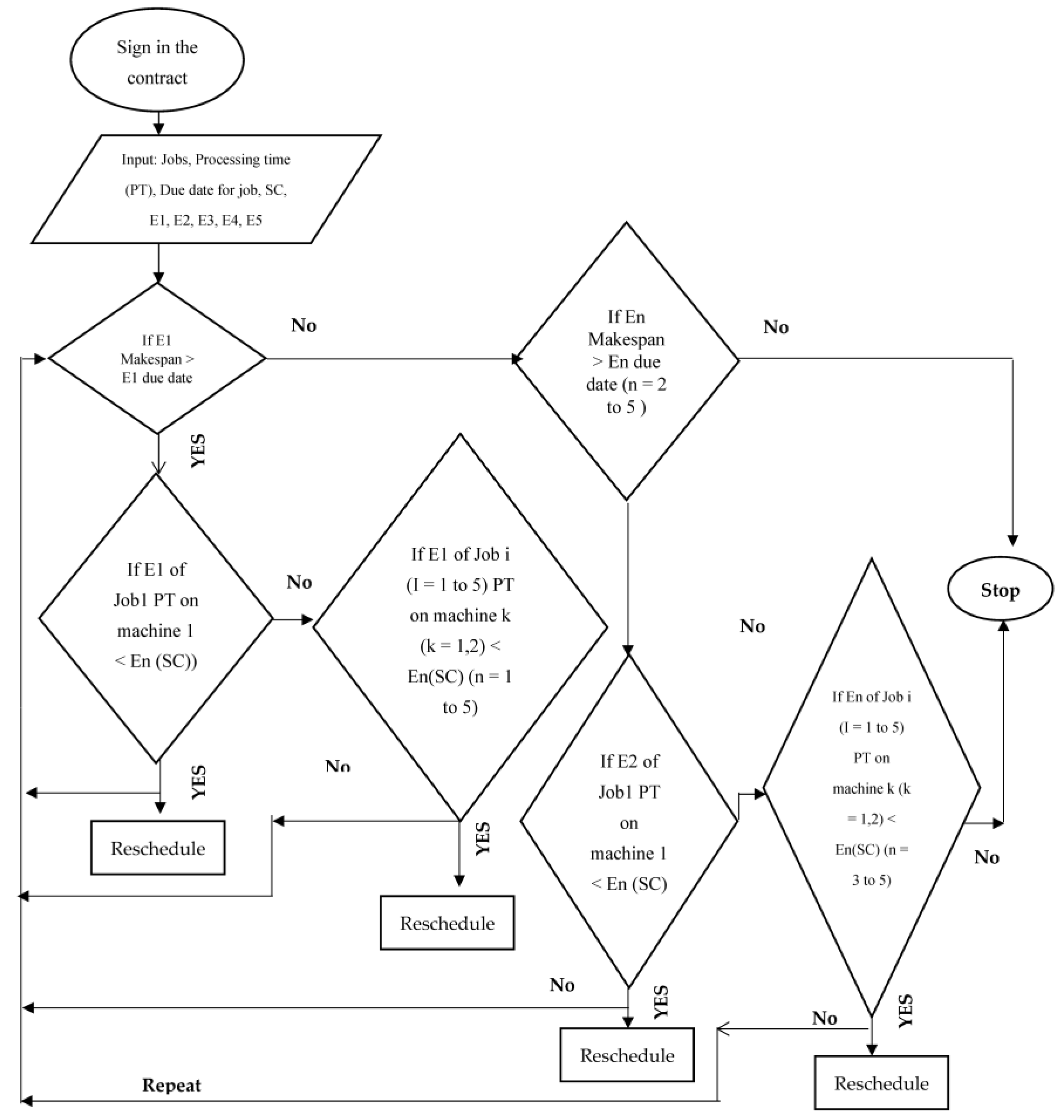

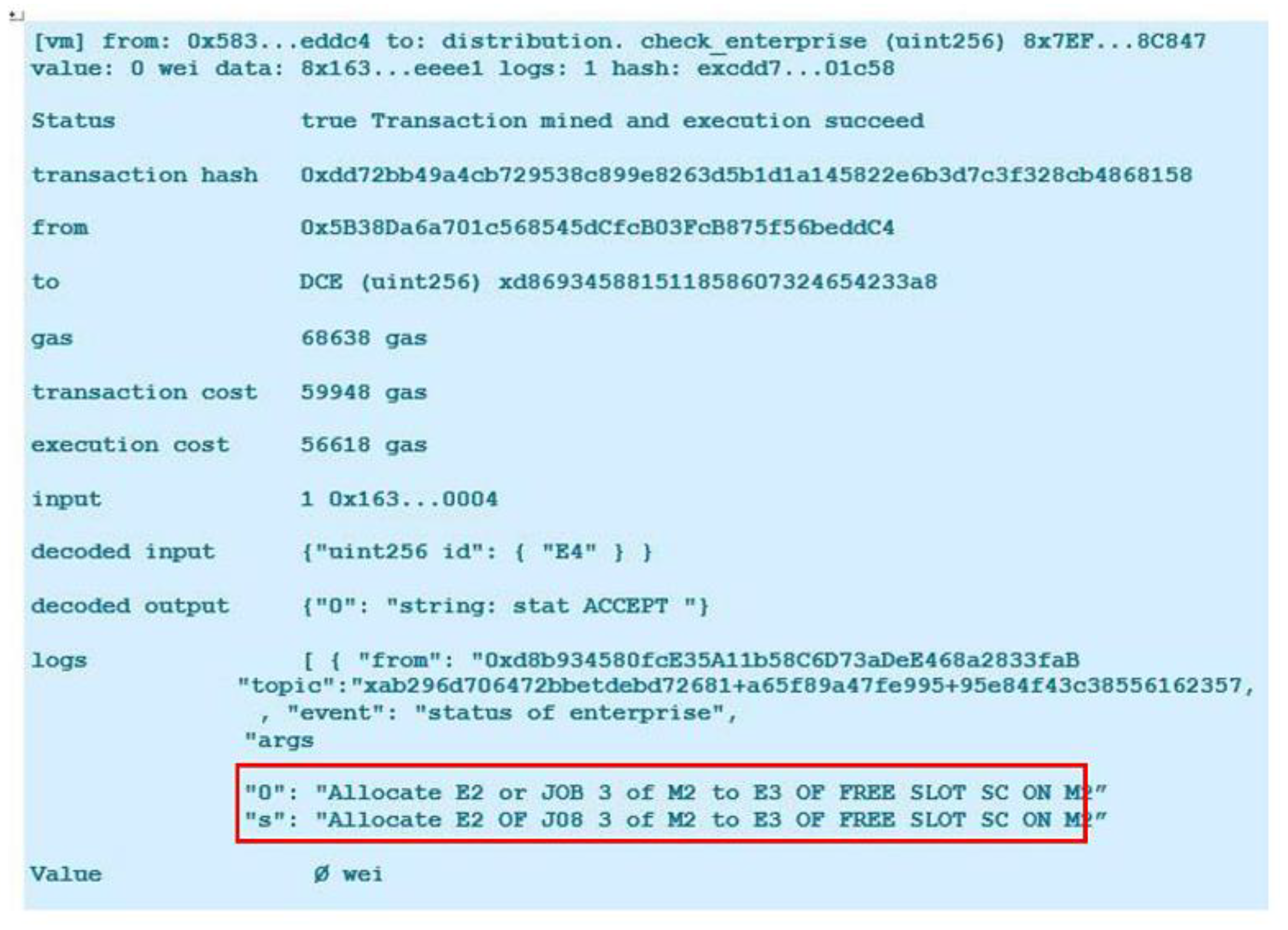

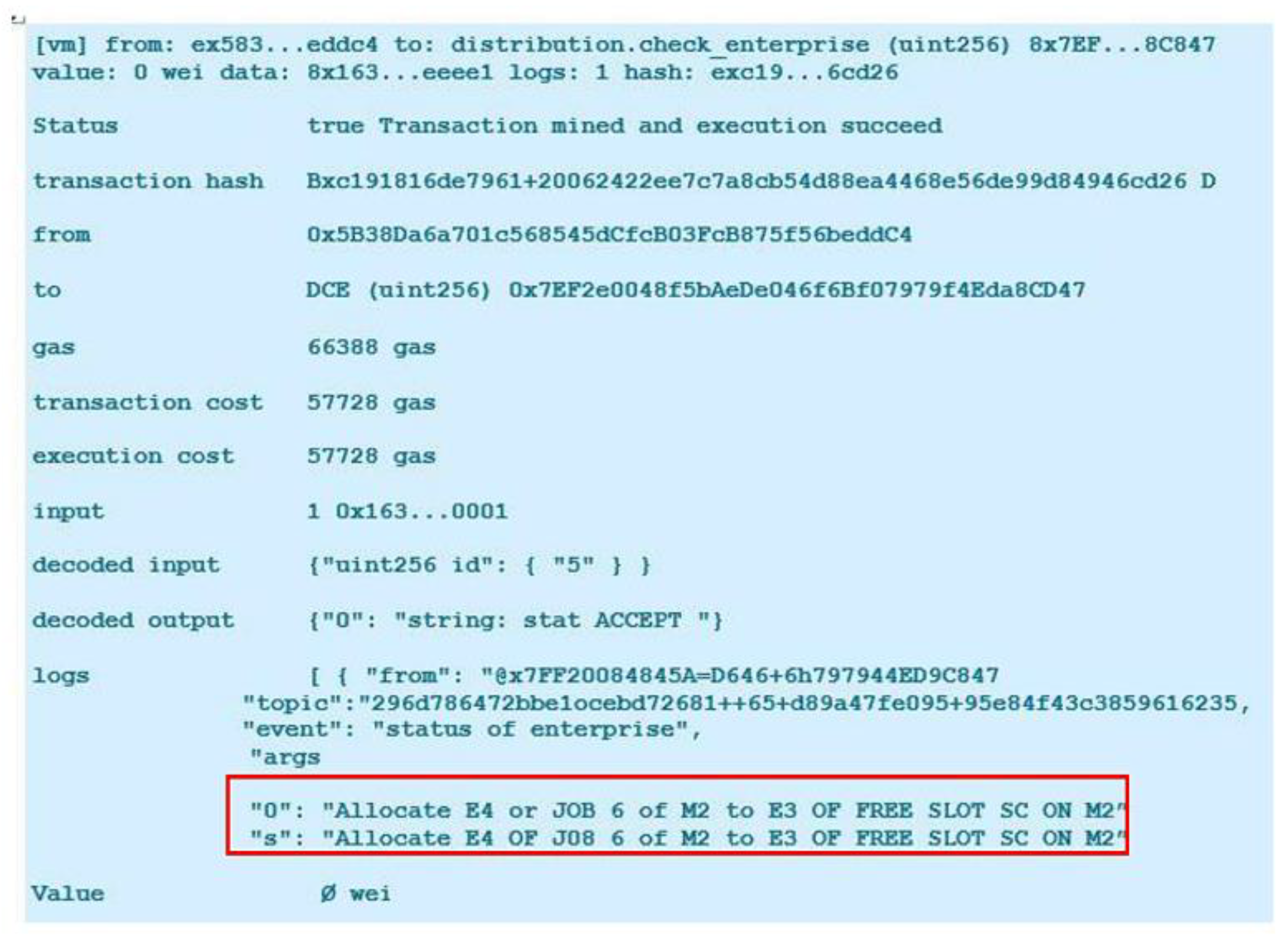

3.2. Smart Contracts

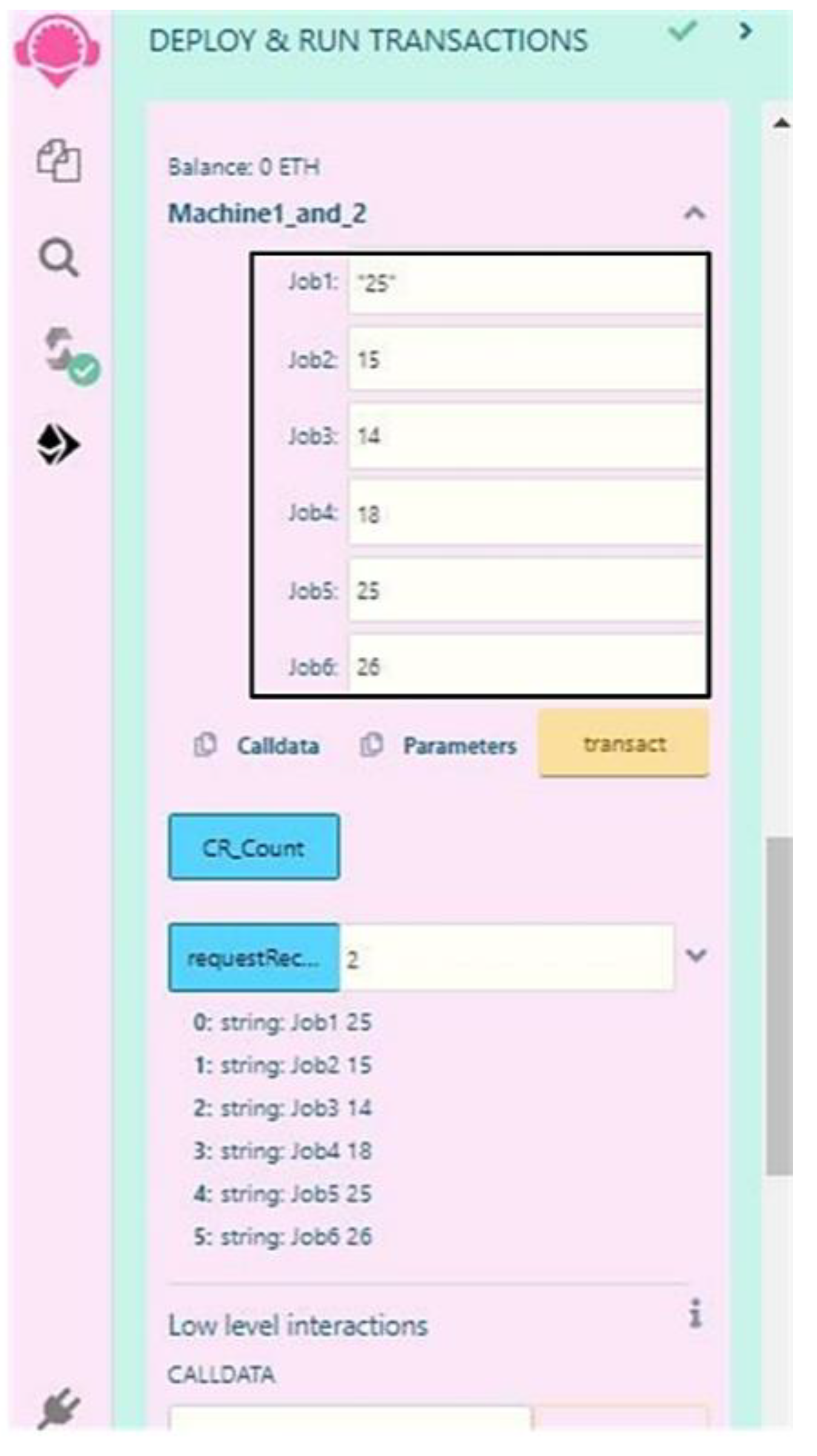

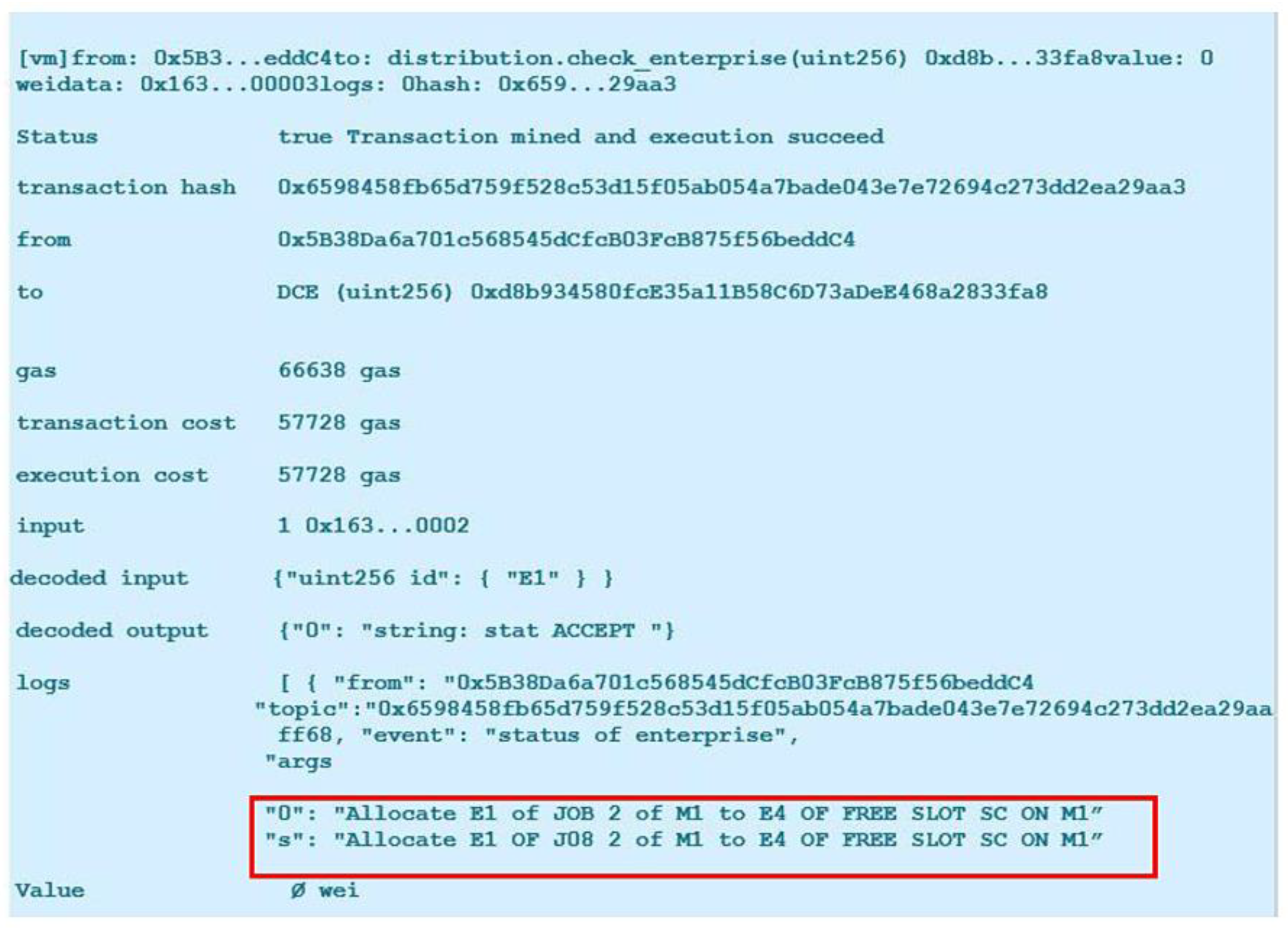

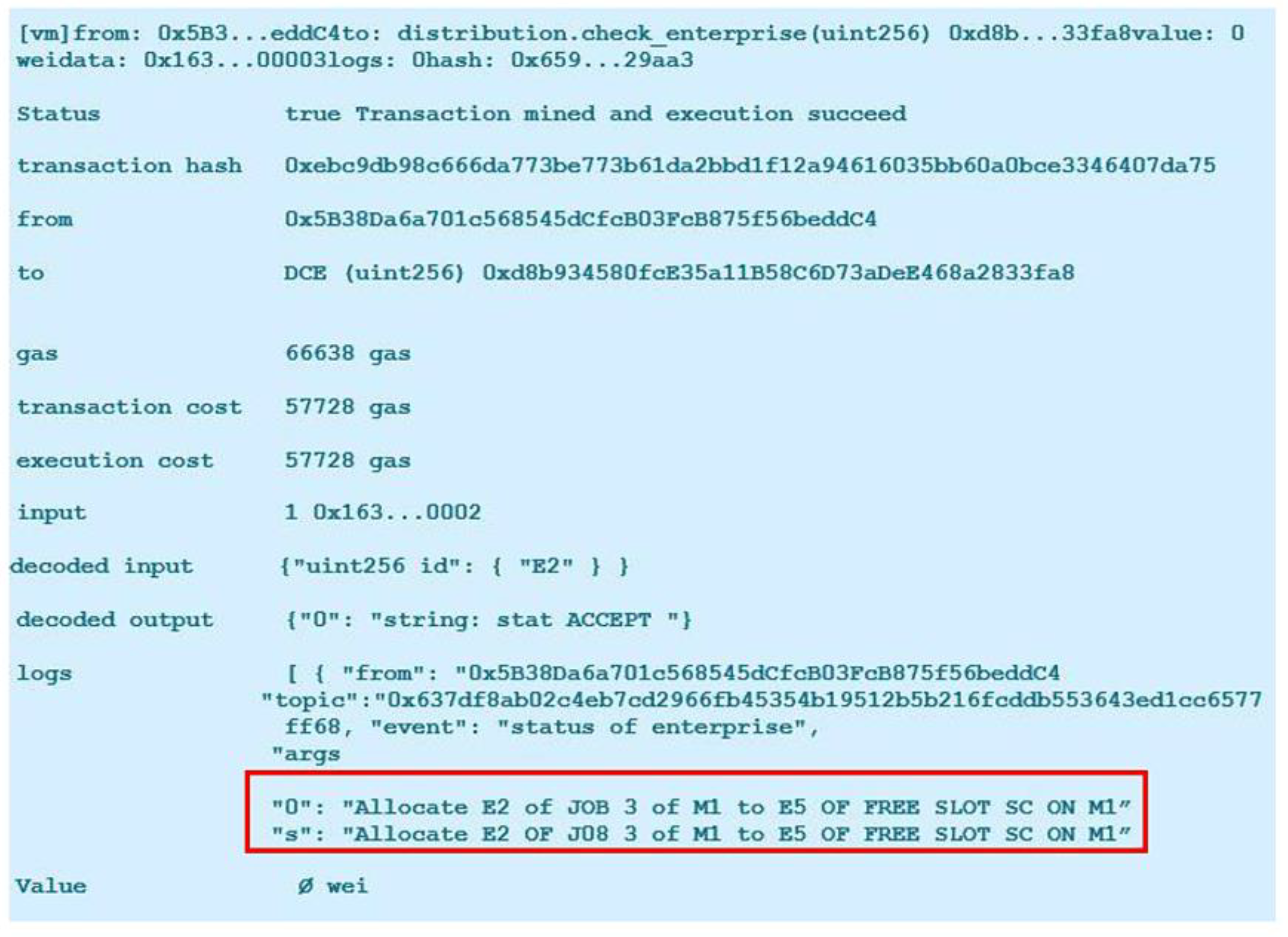

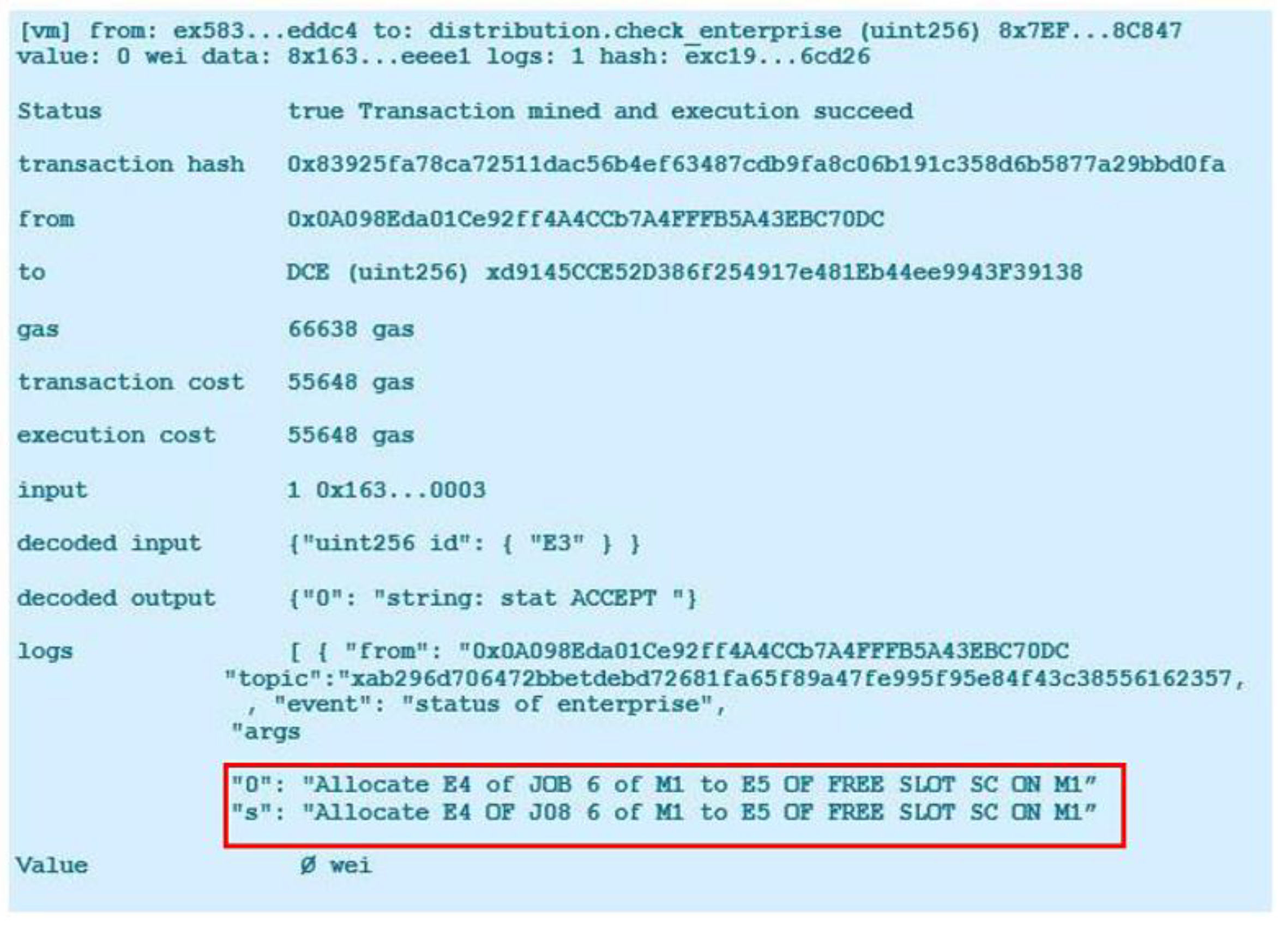

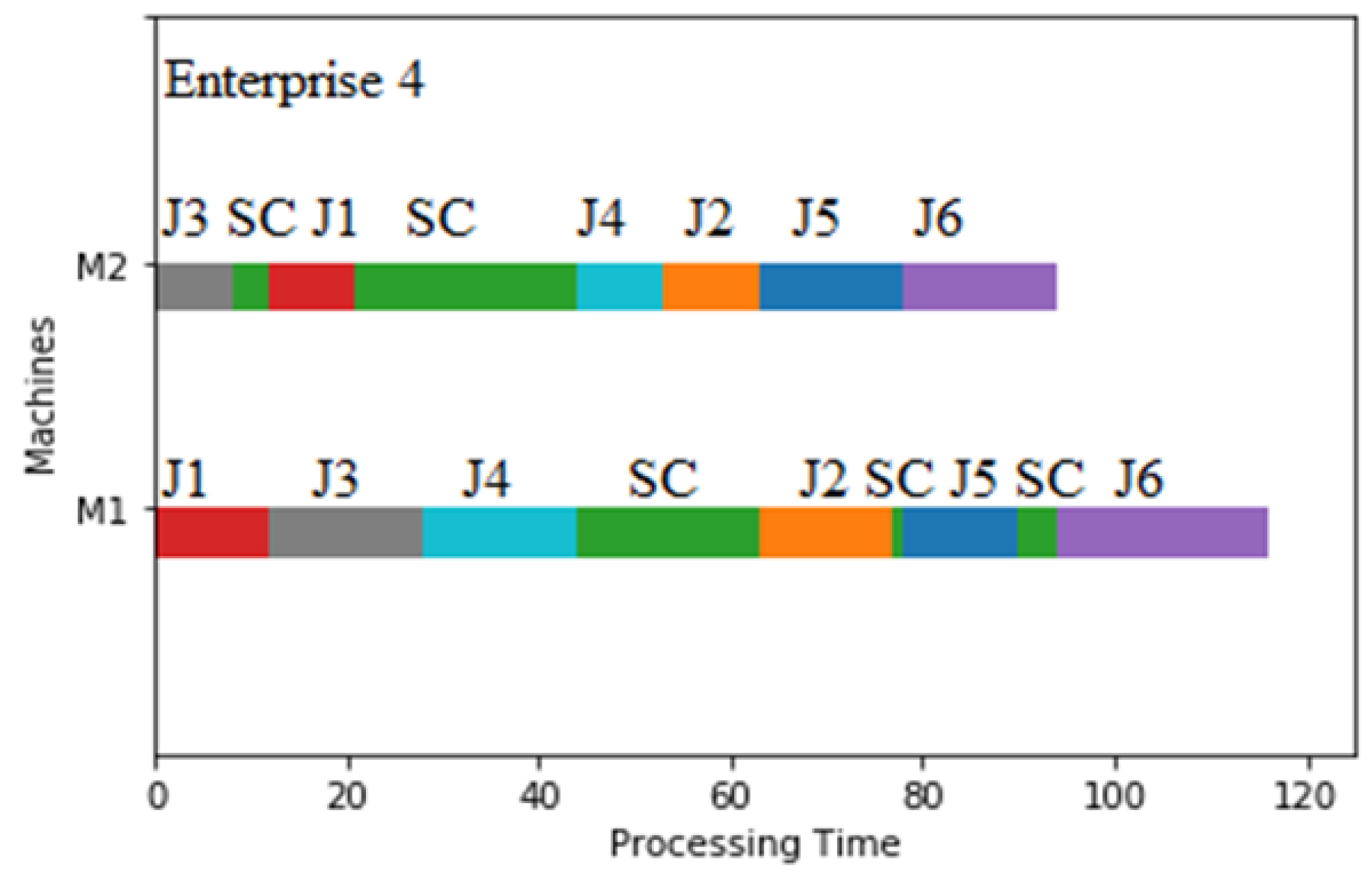

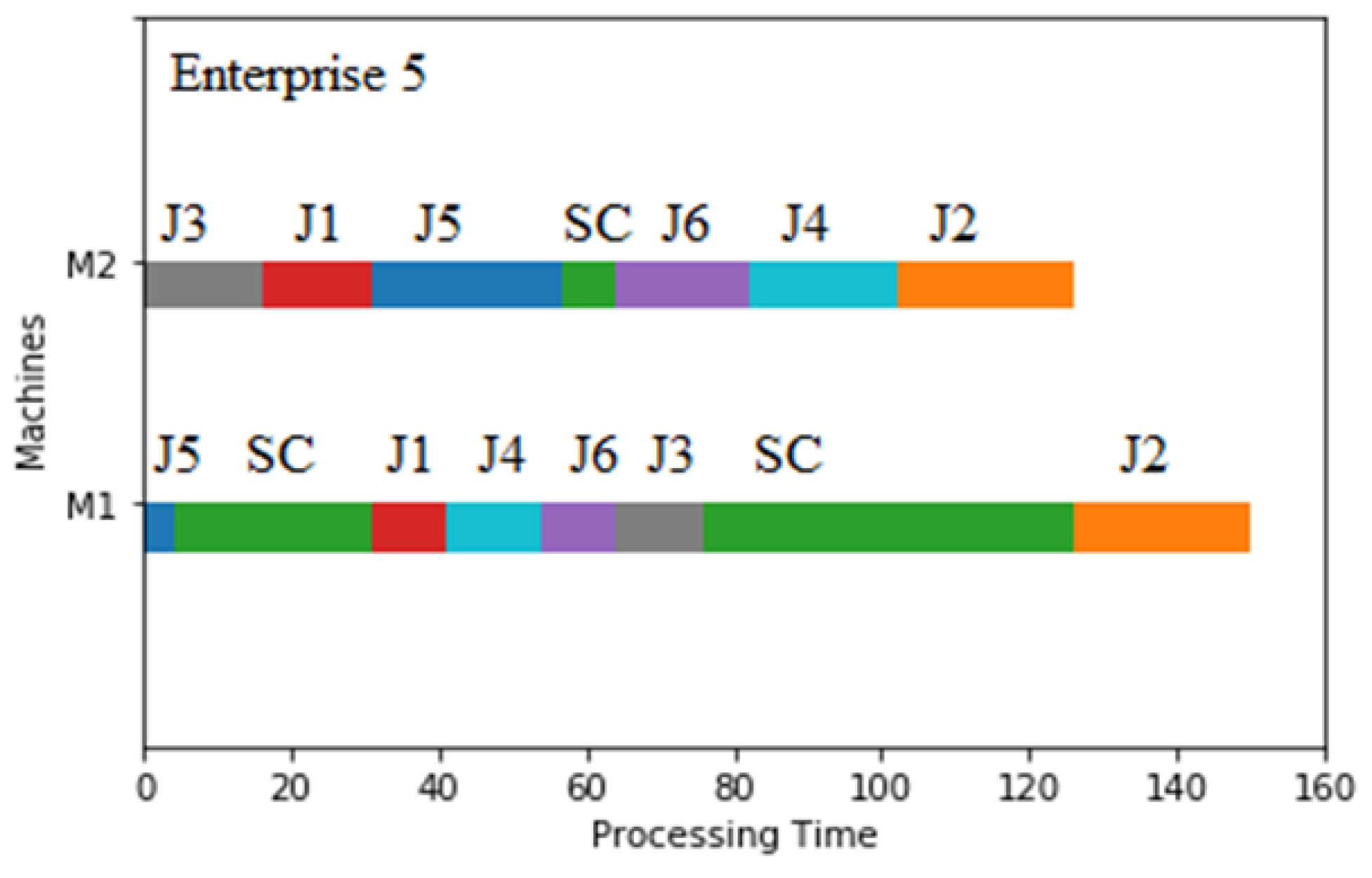

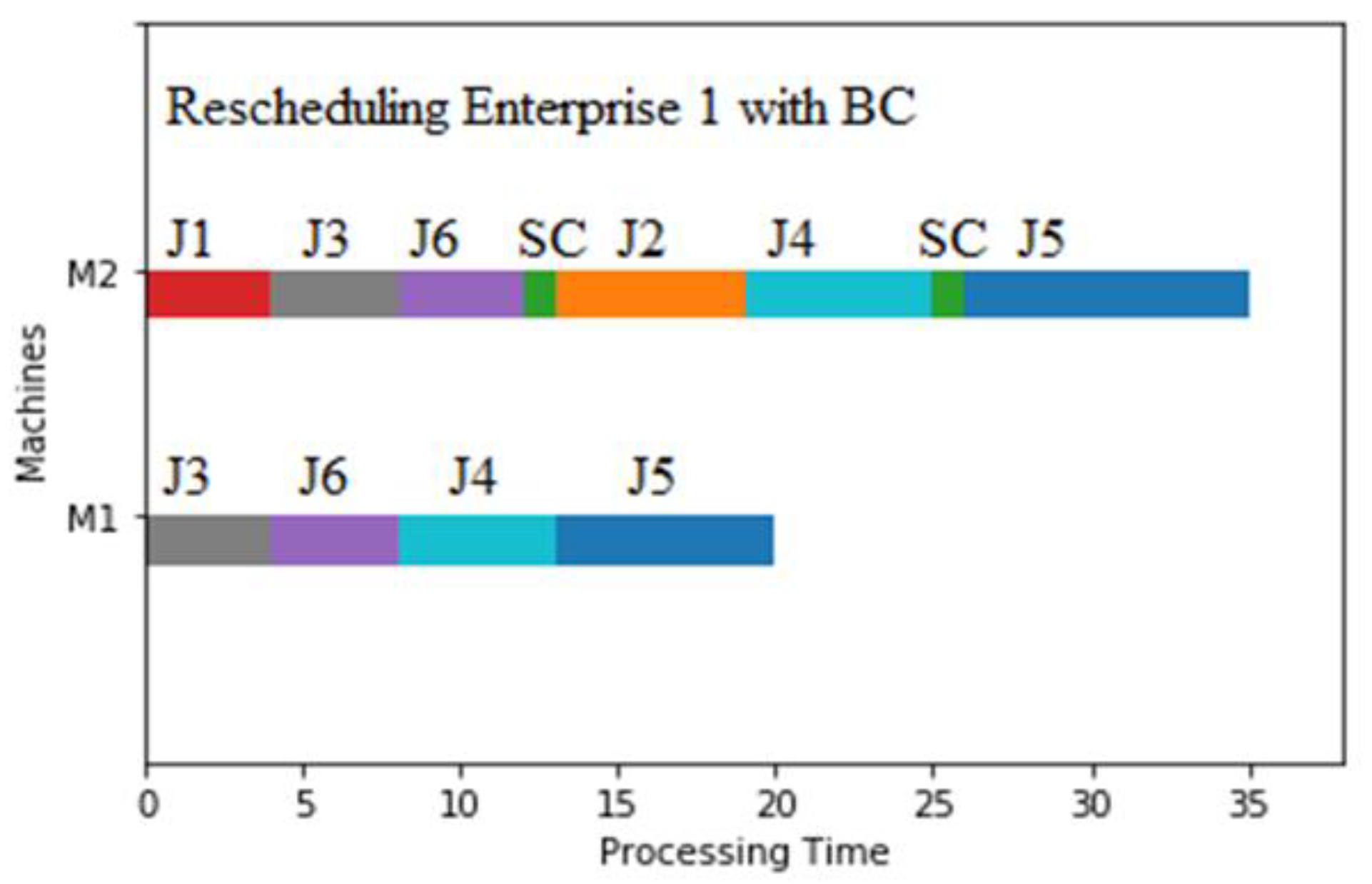

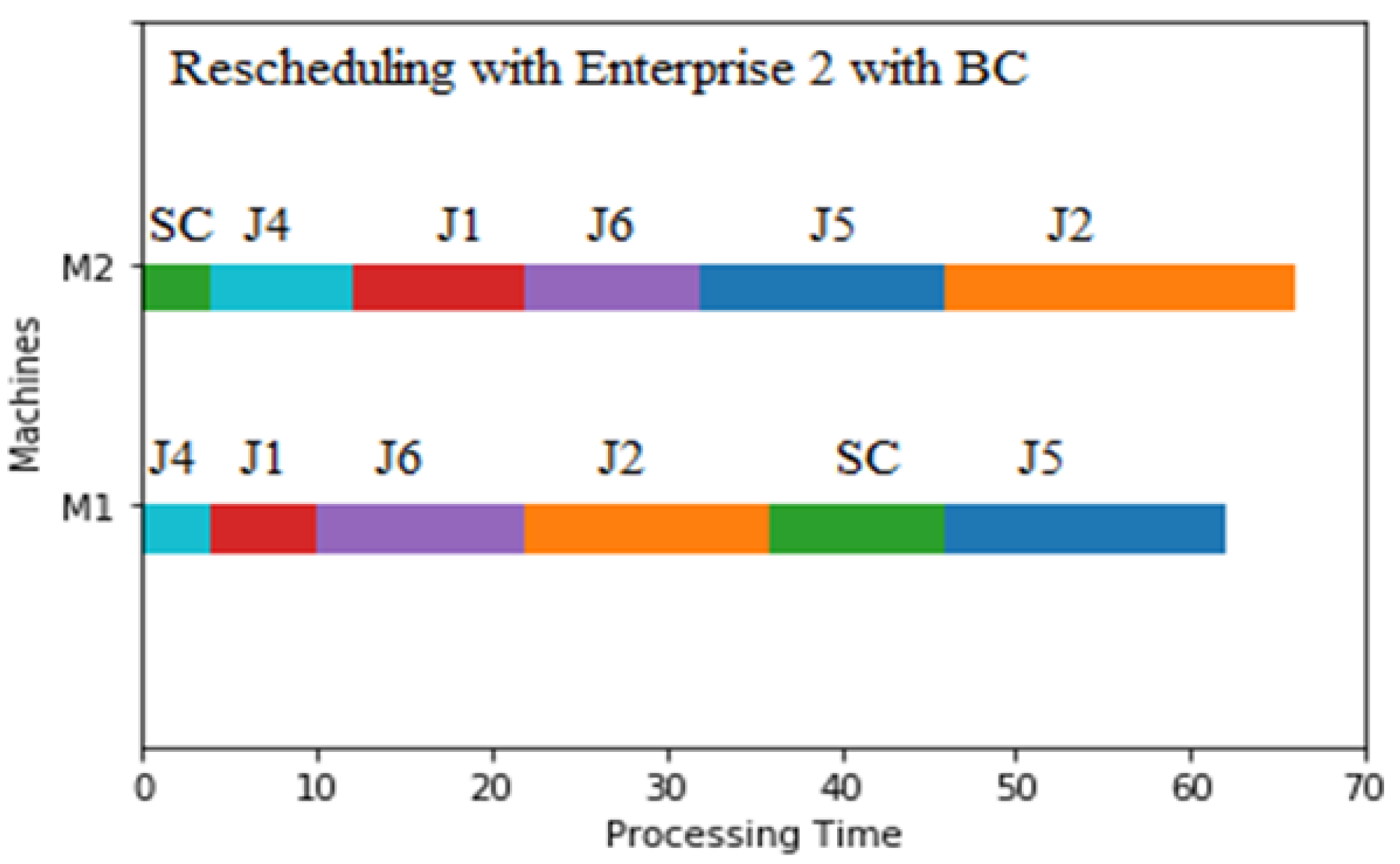

4. Illustrative Example

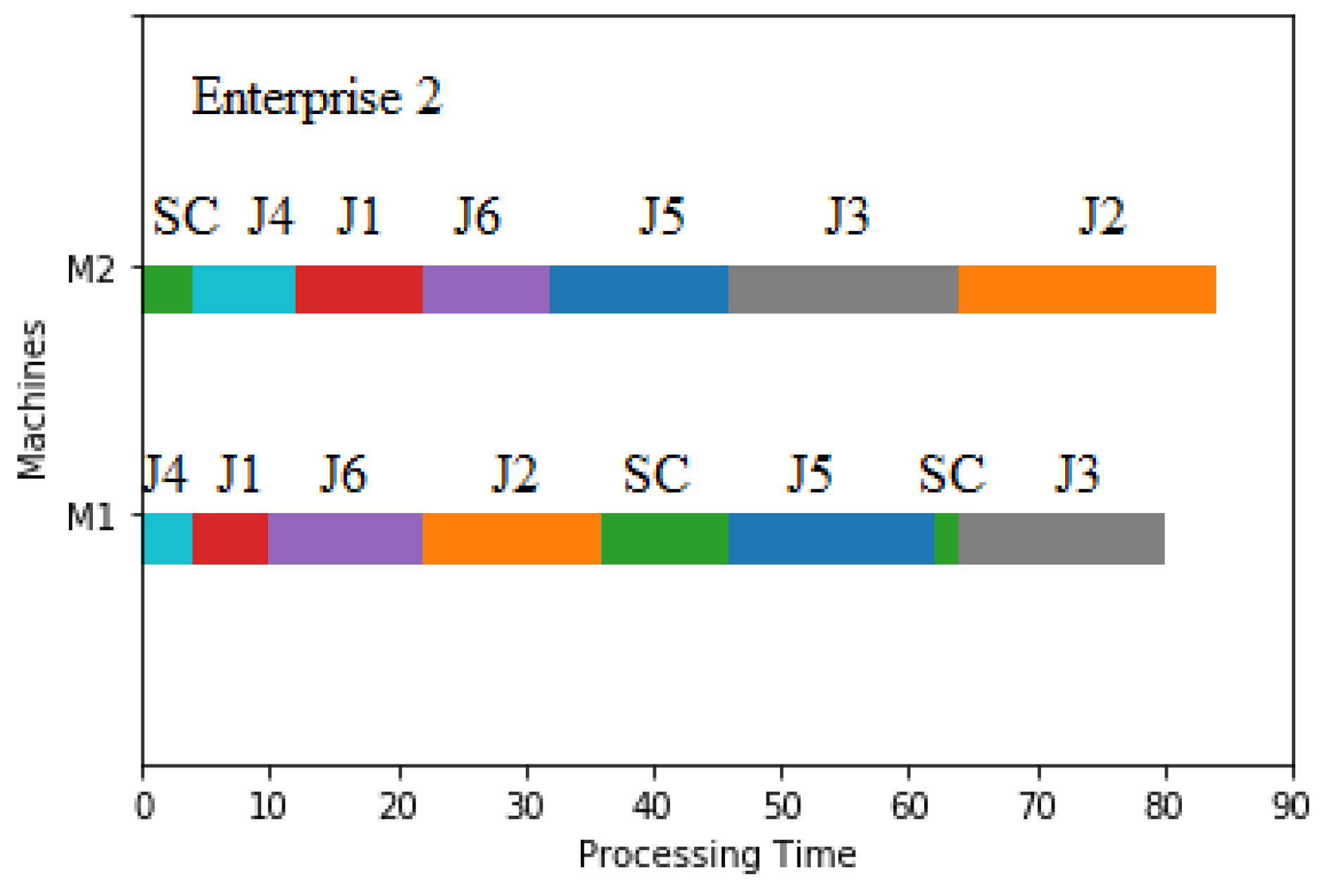

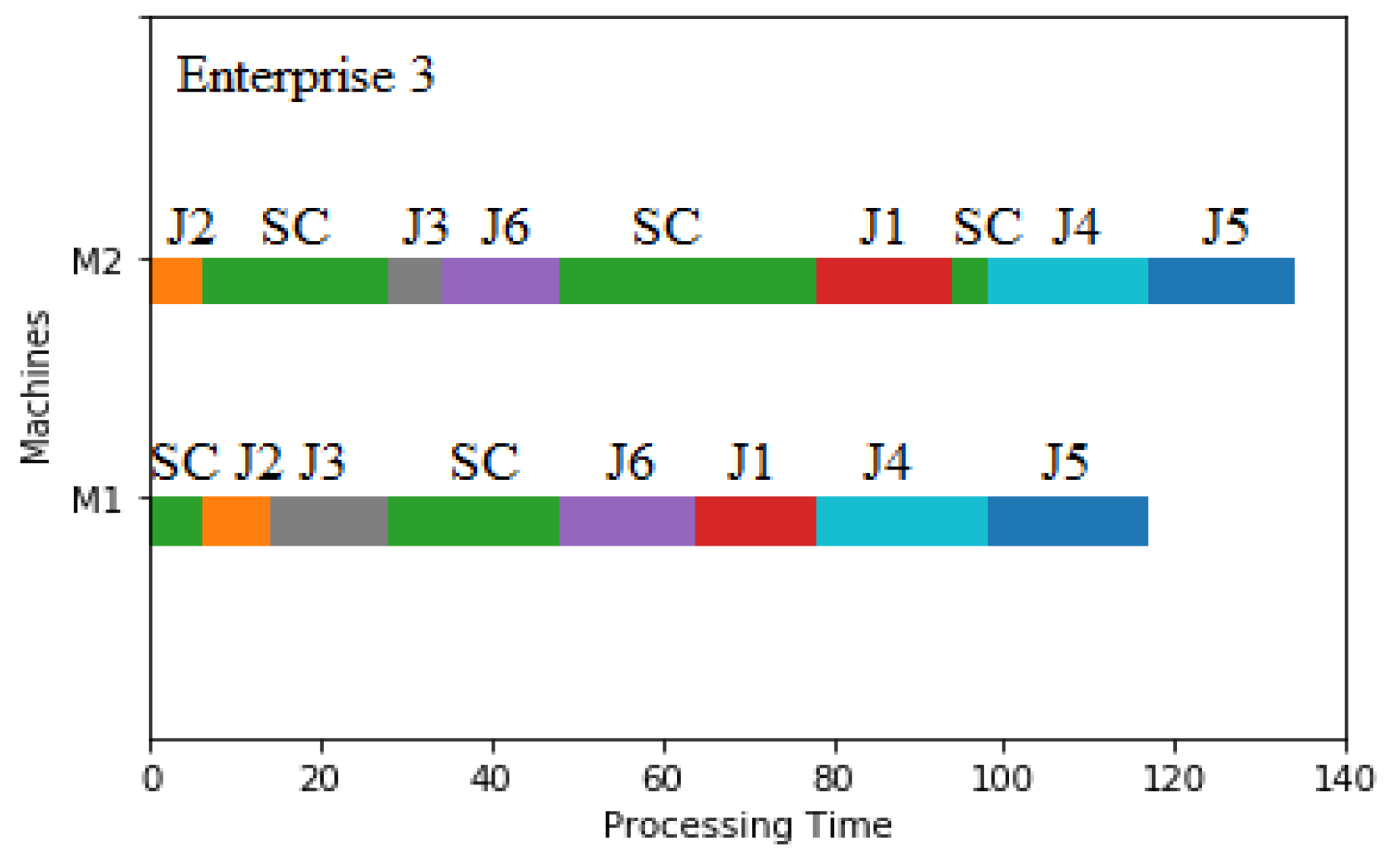

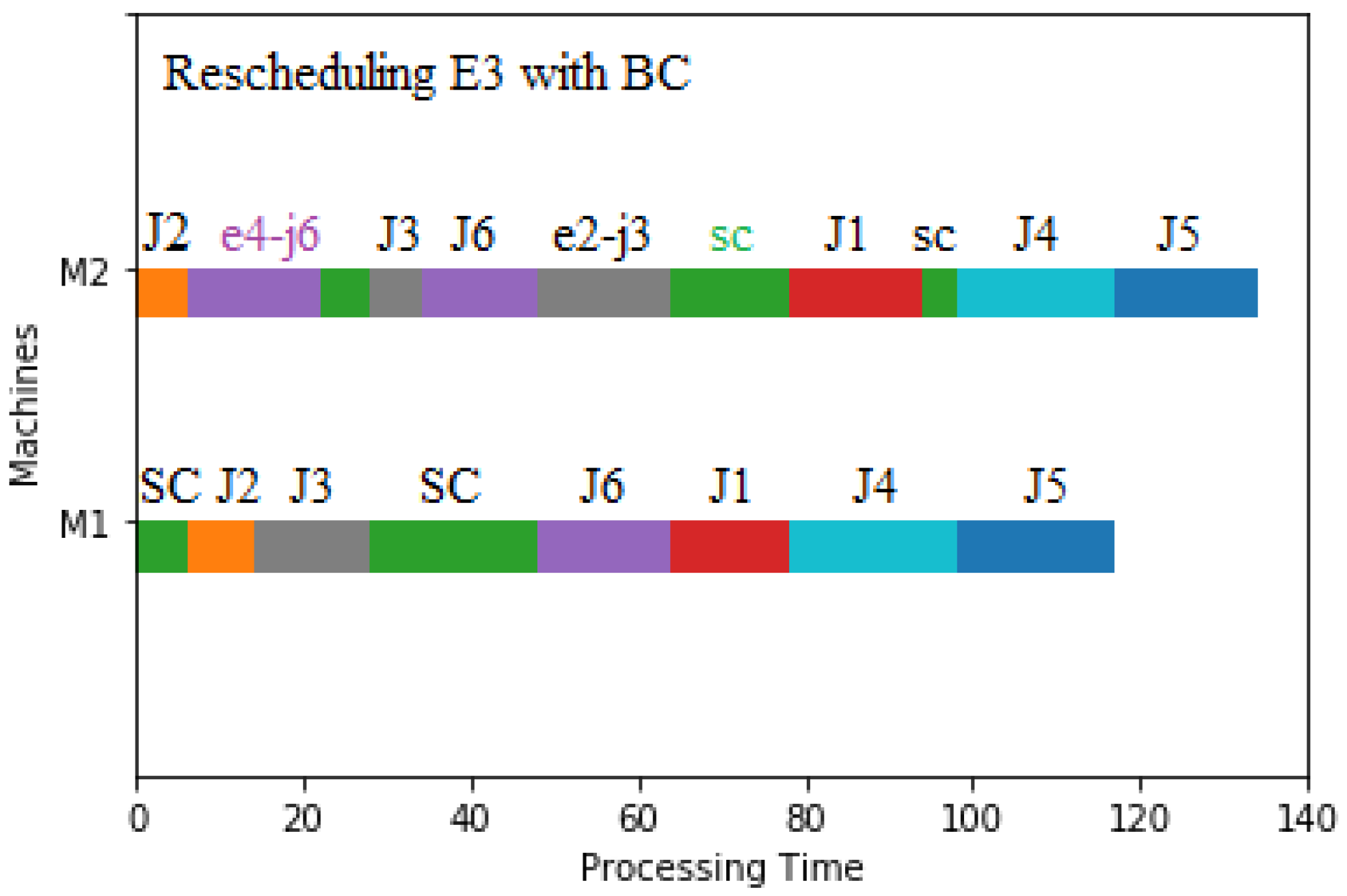

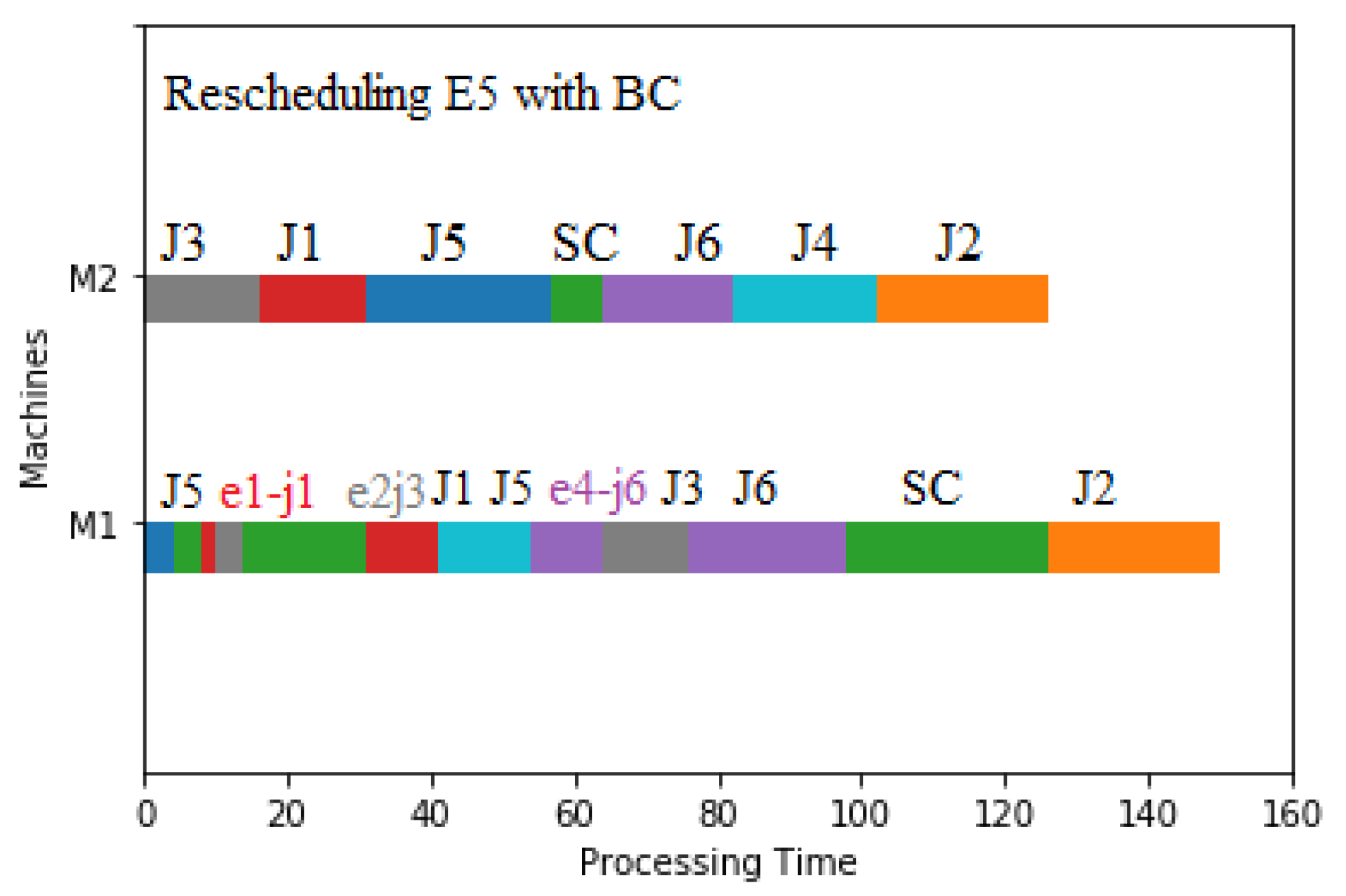

5. Results and Discussion

6. Discussion and Results

7. Managerial and Academic Implications

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Putnik, G.D.; Putnik, Z.; Shah, V.; Varela, L.; Ferreira, L.; Castro, H.; Catia, A.; Pinheiro, P. Collaborative Engineering definition: Distinguishing it from Concurrent Engineering through the complexity and semiotics lenses. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1174, 012027. [Google Scholar] [CrossRef]

- Putnik, G.D.; Putnik, Z.; Shah, V.; Varela, L.; Ferreira, L.; Castro, H.; Catia, A.; Pinheiro, P. Collaborative Engineering: A Review of Organisational Forms for Implementation and Operation. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1174, 012028. [Google Scholar] [CrossRef]

- Lou, P.; Ong, S.K.; Nee, A. Agent-based distributed scheduling for virtual job shops. Int. J. Prod. Res. 2010, 48, 3889–3910. [Google Scholar] [CrossRef]

- Vieira, G.; Varela, M.L.R.; Putnik, G.D. Technologies integration for distributed manufacturing scheduling in a virtual enterprise. In Proceedings of the International Conference on Virtual and Networked Organizations, Emergent Technologies, and Tools, Ofir, Portugal, 6–8 July 2011; Springer: Berlin/Heidelberg, Germany, 2012; pp. 337–347. [Google Scholar]

- Eijnatten, F.M.; Putnik, G.D. Chaos, Complexity, Learning, and the Learning Organization: Towards a Chaordic Enterprise; The Learning Organization; Emerald Group Publishing: Bingley, UK, 2004. [Google Scholar]

- Putnik, G.D.; Ferreira, L. Industry 4.0: Models, tools and cyber-physical systems for manufacturing. FME Trans. 2019, 47, 659–662. [Google Scholar] [CrossRef]

- Guo, Z.; Ngai, E.; Yang, C.; Liang, X. An RFID-based intelligent decision support system architecture for production monitoring and scheduling in a distributed manufacturing environment. Int. J. Prod. Econ. 2015, 159, 16–28. [Google Scholar] [CrossRef]

- Varela, M.L.R.; Putnik, G.D.; Cruz-Cunha, M.M. Web-based Technologies Integration for Distributed Manufacturing Scheduling in a Virtual Enterprise. Int. J. Web Portals 2012, 4, 19–34. [Google Scholar] [CrossRef]

- Varela, M.L.R.; Ribeiro, R.A. Distributed Manufacturing Scheduling Based on a Dynamic Multi-criteria Decision Model. In Recent Developments and New Directions in Soft Computing. Studies in Fuzziness and Soft Computing; Zadeh, L., Abbasov, A., Yager, R., Shahbazova, S., Reformat, M., Eds.; Springer: Cham, Switzerland, 2014; Volume 317. [Google Scholar] [CrossRef]

- Jackson, J.R. An extension of Johnson’s results on job lot scheduling. Nav. Res. Logist. Q. 1956, 3, 201–203. [Google Scholar] [CrossRef]

- Varela, L.R.; Alves, C.F.V.; Santos, A.S.; Vieira, G.G.; Lopes, N.; Putnik, G.D. Analysis of a Collaborative Scheduling Model Applied in a Job Shop Manufacturing Environment. Machines 2022, 10, 1138. [Google Scholar] [CrossRef]

- Alves, F.; Varela, M.L.R.; Rocha, A.M.A.; Pereira, A.I.; Leitão, P. A human centered hybrid MAS and meta-heuristics based system for simultaneously supporting scheduling and plant layout adjustment. FME Trans. 2019, 47, 699–710. [Google Scholar] [CrossRef] [Green Version]

- Wilczyński, A.; Kołodziej, J. Modelling and simulation of security-aware task scheduling in cloud computing based on Blockchain technology. Simul. Model. Pract. Theory 2020, 99, 102038. [Google Scholar] [CrossRef]

- Thakur, A.; Chaudhary, N.; Tilokani, P.; Manupati, V.; Costa, E.; Varela, L.; Machado, J. A cyber-physical system based collaborative distributed manufacturing system architecture for intelligent manufacturing. In Proceedings of the Regional HELIX’17-International Conference on Innovation, Entrepreneurship and Technology Transfer, Covilha, Portugal, 21–23 June 2017. [Google Scholar]

- Kays, E.; Karim, A.; Varela, L.; Putnik, G.; Ávila, P. Ranked sequence positional weight heuristic for simultaneous balancing and scheduling jobs in a distributed manufacturing environment. Procedia CIRP 2018, 67, 3–7. [Google Scholar] [CrossRef]

- Ramakurthi, V.; Manupati, V.; Machado, J.; Varela, L. A Hybrid Multi-Objective Evolutionary Algorithm-Based Semantic Foundation for Sustainable Distributed Manufacturing Systems. Appl. Sci. 2021, 11, 6314. [Google Scholar] [CrossRef]

- Ramakurthi, V.; Manupati, V.; Varela, M.L.R.; Putnik, G. A Novel Integrated Framework Approach for TEBC Technologies in Distributed Manufacturing Systems: A Systematic Review and Opportunities. In Innovations in Mechanical Engineering (ICIE 2021), Lecture Notes in Mechanical Engineering; Machado, J., Soares, F., Trojanowska, J., Ottaviano, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; Volume 1. [Google Scholar] [CrossRef]

- Ramakurthi, V.; Manupati, V.; Machado, J.; Varela, L.; Babu, S. An innovative approach for resource sharing and scheduling in a sustainable distributed manufacturing system. Adv. Eng. Inform. 2022, 52, 101620. [Google Scholar] [CrossRef]

- Varela, L.; Putnik, G.; Romero, F. The concept of collaborative engineering: A systematic literature review. Prod. Manuf. Res. 2022, 10, 784–839. [Google Scholar] [CrossRef]

- Kapitonov, A.; Lonshakov, S.; Krupenkin, A.; Berman, I. Blockchain-based protocol of autonomous business activity for multi-agent systems consisting of UAVs. In Proceedings of the Workshop on Research, Education and Development of Unmanned Aerial Systems (RED-UAS), Linkoping, Sweden, 3–5 October 2017; pp. 84–89. [Google Scholar] [CrossRef]

- Sikorski, J.J.; Haughton, J.; Kraft, M. Blockchain technology in the chemical industry: Machine-to-machine electricity market. Appl. Energy 2017, 195, 234–246. [Google Scholar] [CrossRef]

- Skowroński, R. The open blockchain-aided multi-agent symbiotic cyber–physical systems. Futur. Gener. Comput. Syst. 2019, 94, 430–443. [Google Scholar] [CrossRef]

- Yang, X.; Wang, G.; He, H.; Lu, J.; Zhang, Y. Automated Demand Response Framework in ELNs: Decentralized Scheduling and Smart Contract. IEEE Trans. Syst. Man Cybern. Syst. 2019, 50, 58–72. [Google Scholar] [CrossRef]

- Assaqty, M.I.S.; Gao, Y.; Hu, X.; Ning, Z.; Leung, V.C.M.; Wen, Q.; Chen, Y. Private-Blockchain-Based Industrial IoT for Material and Product Tracking in Smart Manufacturing. IEEE Netw. 2020, 34, 91–97. [Google Scholar] [CrossRef]

- Pinedo, M.; Chao, X. Operations Scheduling with Applications in Manufacturing and Services; McGraw Hill: New York, NY, USA, 1999. [Google Scholar]

- Baker, K.R.; Trietsch, D. Safe scheduling: Setting due dates in single-machine problems. Eur. J. Oper. Res. 2009, 196, 69–77. [Google Scholar] [CrossRef]

- Pinedo, M.L. Scheduling Theory, Algorithms and Systems, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Zijm, W.; Kals, H. The Integration of Process Planning and Shop Floor Scheduling in Small Batch Part Manufacturing. Ann. CIRP 1995, 44, 429–432. [Google Scholar] [CrossRef]

- Shen, W. Distributed manufacturing scheduling using intelligent agents. IEEE Intell. Syst. 2002, 17, 88–94. [Google Scholar] [CrossRef]

- Aytug, H.; Lawley, M.A.; McKay, K.; Mohan, S.; Uzsoy, R. Executing production schedules in the face of uncertainties: A review and some future directions. Eur. J. Oper. Res. 2005, 161, 86–110. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Hao, Q. Agent-based distributed manufacturing process planning and scheduling: A state-of-the-art survey. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2006, 36, 563–577. [Google Scholar] [CrossRef]

- Arrais-Castro, A.; Varela, M.L.R.; Putnik, G.D.; Ribeiro, R.A.; Machado, J.; Ferreira, L. Collaborative framework for virtual organisation synthesis based on a dynamic multi-criteria decision model. Int. J. Comput. Integr. Manuf. 2018, 31, 857–868. [Google Scholar] [CrossRef]

- Goren, S.; Sabuncuoglu, I. Robustness and stability measures for scheduling: Single-machine environment. IIE Trans. 2008, 40, 66–83. [Google Scholar] [CrossRef]

- Ouelhadj, D.; Petrovic, S. A survey of dynamic scheduling in manufacturing systems. J. Sched. 2009, 12, 417–431. [Google Scholar] [CrossRef]

- Chiu, C.; Yih, Y. A learning-based methodology for dynamic scheduling in distributed manufacturing systems. Int. J. Prod. Res. 1995, 33, 3217–3232. [Google Scholar] [CrossRef]

- Zhou, R.; Chen, G.; Yang, Z.H.; Zhang, J.B. Distributed manufacturing scheduling using a novel cooperative system. In Proceedings of the 2008 IEEE International Conference on Service Operations and Logistics, and Informatics, Beijing, China, 12–15 October 2018; IEEE: New York, NY, USA, 2008; Volume 1, pp. 256–260. [Google Scholar]

- Saeidlou, S.; Saadat, M.; Sharifi, E.A.; Jules, G.D. Agent-based distributed manufacturing scheduling: An ontological approach. Cogent Eng. 2019, 6, 1565630. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, X.; Tang, S.; Królczyk, G.; Li, Z. Solving Scheduling Problem in a Distributed Manufacturing System Using a Discrete Fruit Fly Optimization Algorithm. Energies 2019, 12, 3260. [Google Scholar] [CrossRef]

- Wang, C.; Ghenniwa, H.; Shen, W. Real time distributed shop floor scheduling using an agent-based service-oriented architecture. Int. J. Prod. Res. 2008, 46, 2433–2452. [Google Scholar] [CrossRef]

- Manupati, V.K.; Krishnan, M.G.; Varela, M.L.R.; Machado, J. Telefacturing based distributed manufacturing envi-ronment for optimal manufacturing service by enhancing the interoperability in the hubs. J. Eng. 2017, 2017, 9305989. [Google Scholar] [CrossRef]

- Özgüven, C.; Özbakır, L.; Yavuz, Y. Mathematical models for job-shop scheduling problems with routing and process plan flexibility. Appl. Math. Model. 2010, 34, 1539–1548. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, H.; Huang, M. Integrated scheduling for a distributed manufacturing system: A stochastic multi-objective model. Enterp. Inf. Syst. 2019, 13, 557–573. [Google Scholar] [CrossRef]

- Mao, X.; Li, J.; Guo, H.; Wu, X. Research on Collaborative Planning and Symmetric Scheduling for Parallel Shipbuilding Projects in the Open Distributed Manufacturing Environment. Symmetry 2020, 12, 161. [Google Scholar] [CrossRef]

- Cheng, Y.; Bi, L.; Tao, F.; Ji, P. Hypernetwork-based manufacturing service scheduling for distributed and collaborative manufacturing operations towards smart manufacturing. J. Intell. Manuf. 2020, 31, 1707–1720. [Google Scholar] [CrossRef]

- Han, X.; Han, Y.Y.; Zhang, B.; Qin, H.X.; Li, J.Q.; Liu, Y.P.; Gong, D.W. An effective iterative greedy algorithm for distributed blocking flowshop scheduling problem with balanced energy costs criterion. Appl. Soft Comput. 2022, 129, 109502. [Google Scholar] [CrossRef]

- Manupati, V.K.; Chang, P.C.; Tiwari, M.K. Intelligent search techniques for network-based manufacturing systems: Multi-objective formulation and solutions. Int. J. Comput. Integr. 2016, 29, 850–869. [Google Scholar] [CrossRef]

- Cambou, B.F.; Jain, S. Key Recovery for Content Protection Using Ternary PUFs Designed with Pre-Formed ReRAM. Appl. Sci. 2022, 12, 1785. [Google Scholar] [CrossRef]

- Westerkamp, M.; Victor, F.; Küpper, A. Tracing manufacturing processes using blockchain-based token compositions. Digit. Commun. Netw. 2020, 6, 167–176. [Google Scholar] [CrossRef]

- Xu, J.; Tian, Y.; Ma, T.; Al-Nabhan, N. Intelligent manufacturing security model based on improved blockchain. Math. Biosci. Eng. 2020, 17, 5633–5650. [Google Scholar] [CrossRef]

- Vangala, A.; Das, A.K.; Kumar, N.; Alazab, M. Smart secure sensing for IoT-based agriculture: Blockchain perspective. IEEE Sens. J. 2020, 21, 17591–17607. [Google Scholar] [CrossRef]

- Kumar, A.; Abhishek, K.; Nerurkar, P.; Ghalib, M.R.; Shankar, A.; Cheng, X. Secure smart contracts for cloud-based manufacturing using Ethereum blockchain. Trans. Emerg. Telecommun. Technol. 2022, 33, e4129. [Google Scholar] [CrossRef]

- Wan, J.; Li, J.; Imran, M.; Li, D.; Amin, F.E. A Blockchain-Based Solution for Enhancing Security and Privacy in Smart Factory. IEEE Trans. Ind. Inform. 2019, 15, 3652–3660. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.-C. Integration of Blockchain, IoT and Machine Learning for Multistage Quality Control and Enhancing Security in Smart Manufacturing. Sensors 2021, 21, 1467. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Hu, M.; Liu, M.; Wang, J. BPIIoT: A Light-Weighted Blockchain-Based Platform for Industrial IoT. IEEE Access 2019, 7, 58381–58393. [Google Scholar] [CrossRef]

- Yu, C.; Jiang, X.; Yu, S.; Yang, C. Blockchain-based shared manufacturing in support of cyber physical systems: Concept, framework, and operation. Robot. Comput. Manuf. 2020, 64, 101931. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.-C. Improving Transactional Data System Based on an Edge Computing–Blockchain–Machine Learning Integrated Framework. Processes 2021, 9, 92. [Google Scholar] [CrossRef]

- Leng, J.; Yan, D.; Liu, Q.; Xu, K.; Zhao, J.L.; Shi, R.; Wei, L.; Zhang, D.; Chen, X. ManuChain: Combining Permissioned Blockchain with a Holistic Optimization Model as Bi-Level Intelligence for Smart Manufacturing. IEEE Trans. Syst. Man Cybern. Syst. 2019, 50, 182–192. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Peron, M.; Fragapane, G. Cloud Material Handling Systems: Conceptual Model and Cloud-Based Scheduling of Handling Activities. In Scheduling in Industry 4.0 and Cloud Manufacturing; Springer: Cham, Switzerland, 2020; pp. 87–101. [Google Scholar] [CrossRef]

- Peron, M.; Fragapane, G.; Sgarbossa, F.; Kay, M. Digital Facility Layout Planning. Sustainability 2020, 12, 3349. [Google Scholar] [CrossRef]

- Szabo, N. Formalizing and Securing Relationships on Public Networks. First Monday 1997, 2. [Google Scholar] [CrossRef]

- Fairfield, J.A. Smart contracts, Bitcoin bots, and consumer protection. Wash. Lee L. Rev. Online 2014, 71, 35. [Google Scholar]

- Reddy, M.S.; Ratnam, C.; Agrawal, R.; Varela, M.; Sharma, I.; Manupati, V. Investigation of reconfiguration effect on makespan with social network method for flexible job shop scheduling problem. Comput. Ind. Eng. 2017, 110, 231–241. [Google Scholar] [CrossRef]

- Vafaei, N.; Ribeiro, R.A.; Camarinha-Matos, L.M.; Valera, L.R. Normalization techniques for collaborative networks. Kybernetes 2019, 49, 1285–1304. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S.S. Ten Lessons for Managers While Implementing Industry 4.0. IEEE Eng. Manag. Rev. 2019, 47, 45–52. [Google Scholar] [CrossRef]

- Qin, H.-X.; Han, Y.-Y.; Liu, Y.-P.; Li, J.-Q.; Pan, Q.-K.; Han, X. A collaborative iterative greedy algorithm for the scheduling of distributed heterogeneous hybrid flow shop with blocking constraints. Expert Syst. Appl. 2022, 201, 117256. [Google Scholar] [CrossRef]

- Torabi Yeganeh, F.; Zegordi, S.H. A Multi-Objective Optimization Approach to Project Scheduling with Resiliency Criteria under Uncertain Activity Duration. Ann. Oper. Res. 2020, 285, 161–196. [Google Scholar] [CrossRef]

- Yang, D.-L.; Kuo, W.-H. Minimizing Makespan in A Two-Machine Flowshop Problem with Processing Time Linearly Dependent on Job Waiting Time. Sustainability 2019, 11, 6885. [Google Scholar] [CrossRef] [Green Version]

| Source Title | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Computers & Industrial Engineering | 1 | 3 | 5 | 2 | 2 | 1 | 3 | 2 | 3 | 8 | 3 | 3 | 5 | 8 | 12 | 5 | 66 |

| IEEE ACCESS | 1 | 3 | 12 | 10 | 5 | 31 | |||||||||||

| International Journal of Advanced Manufacturing Technology | 3 | 1 | 2 | 2 | 6 | 5 | 7 | 5 | 3 | 4 | 3 | 4 | 1 | 1 | 7 | 54 | |

| International Journal of Computer Integrated Manufacturing | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 1 | 4 | 2 | 6 | 3 | 2 | 1 | 33 | ||

| International Journal of Production Economics | 3 | 1 | 1 | 3 | 2 | 2 | 3 | 2 | 2 | 1 | 4 | 3 | 27 | ||||

| International Journal of Production Research | 1 | 7 | 11 | 1 | 9 | 14 | 7 | 6 | 3 | 5 | 6 | 5 | 7 | 11 | 5 | 10 | 108 |

| Journal of Intelligent Manufacturing | 1 | 2 | 1 | 1 | 2 | 2 | 4 | 2 | 1 | 2 | 2 | 20 | |||||

| Journal of Manufacturing Systems | 1 | 3 | 3 | 2 | 3 | 4 | 8 | 8 | 32 | ||||||||

| Robotics And Computer-Integrated Manufacturing | 1 | 1 | 2 | 4 | 1 | 2 | 1 | 3 | 4 | 4 | 24 | ||||||

| Sustainability | 2 | 2 | 1 | 5 | 7 | 10 | 27 | ||||||||||

| Total | 11 | 16 | 25 | 12 | 17 | 24 | 20 | 20 | 23 | 23 | 19 | 29 | 26 | 48 | 54 | 54 | 422 |

| E1 | E2 | E3 | E4 | E5 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Job | Op | Mac | PT | DD | Job | Op | Mac | PT | DD | Job | Op | Mac | PT | DD | J | o | M | PT | D | J | O | M | T | D |

| 1 | i | P | 2 | 1 | i | P | 6 | 1 | i | P | 18 | 1 | i | P | 12 | 1 | i | Q | 15 | |||||

| ii | Q | 4 | 10 | ii | Q | 10 | ii | Q | 16 | ii | Q | 9 | ii | P | 10 | |||||||||

| 2 | i | P | 5 | 2 | i | P | 14 | 2 | i | Q | 6 | 15 | 2 | i | Q | 10 | 22 | 2 | i | Q | 24 | 102 | ||

| ii | Q | 6 | 14 | ii | Q | 20 | ii | P | 8 | ii | P | 14 | ii | P | 7 | |||||||||

| 3 | i | P | 4 | 3 | i | Q | 18 | 3 | i | P | 14 | 3 | i | P | 16 | 3 | i | P | 16 | |||||

| ii | Q | 4 | 12 | ii | P | 16 | 75 | ii | Q | 6 | ii | Q | 8 | ii | Q | 12 | ||||||||

| 4 | i | Q | 5 | 4 | i | P | 4 | 4 | i | P | 20 | 4 | i | P | 16 | 52 | 4 | i | P | 13 | 93 | |||

| ii | P | 6 | ii | Q | 8 | ii | Q | 20 | ii | Q | 9 | ii | Q | 20 | ||||||||||

| 5 | i | P | 7 | 5 | i | Q | 14 | 5 | i | P | 19 | 5 | i | Q | 15 | 5 | i | P | 4 | |||||

| ii | Q | 9 | 16 | ii | P | 16 | ii | Q | 17 | 20 | ii | P | 12 | ii | Q | 26 | ||||||||

| 6 | i | Q | 12 | 6 | i | P | 12 | 6 | i | Q | 14 | 6 | i | Q | 18 | 6 | i | P | 14 | |||||

| ii | P | 4 | ii | Q | 10 | ii | P | 14 | ii | P | 22 | ii | Q | 18 | ||||||||||

| Test Scenario (Small-Sized Problems) | Jobs × Machines | CPLEX Solver in GAMS | BCDMS Model | ||

|---|---|---|---|---|---|

| Makespan | Machine Utilization | Makespan | Machine Utilization | ||

| Test Scenario 1 | 2 × 2 | 33 | 0.6 | 31 | 0.63 |

| Test Scenario 3 | 2 × 2 | 39 | 0.54 | 36 | 0.61 |

| Test Scenario 3 | 3 × 2 | 36 | 0.51 | 33 | 0.56 |

| Test Scenario 4 | 3 × 2 | 45 | 0.53 | 43 | 0.56 |

| Test Scenario 5 | 3 × 2 | 49 | 0.59 | 41 | 0.67 |

| Test Scenario 6 | 3 × 2 | 44 | 0.53 | 39 | 0.64 |

| Test Scenario 7 | 3 × 3 | 49 | 0.54 | 43 | 0.63 |

| Test Scenario 8 | 3 × 4 | 54 | 0.56 | 46 | 0.59 |

| Test Scenario 9 | 3 × 5 | 51 | 0.58 | 39 | 0.63 |

| Test Scenario 10 | 4 × 5 | 53 | 0.51 | 43 | 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramakurthi, V.B.; Manupati, V.K.; Varela, L.; Putnik, G. Leveraging Blockchain to Support Collaborative Distributed Manufacturing Scheduling. Sustainability 2023, 15, 3283. https://doi.org/10.3390/su15043283

Ramakurthi VB, Manupati VK, Varela L, Putnik G. Leveraging Blockchain to Support Collaborative Distributed Manufacturing Scheduling. Sustainability. 2023; 15(4):3283. https://doi.org/10.3390/su15043283

Chicago/Turabian StyleRamakurthi, Veera Babu, Vijaya Kumar Manupati, Leonilde Varela, and Goran Putnik. 2023. "Leveraging Blockchain to Support Collaborative Distributed Manufacturing Scheduling" Sustainability 15, no. 4: 3283. https://doi.org/10.3390/su15043283

APA StyleRamakurthi, V. B., Manupati, V. K., Varela, L., & Putnik, G. (2023). Leveraging Blockchain to Support Collaborative Distributed Manufacturing Scheduling. Sustainability, 15(4), 3283. https://doi.org/10.3390/su15043283