Research into the Mechanism and Application of Liquid CO2 Phase-Transition Fracturing in a Coal Seam to Enhance Permeability

Abstract

:1. Introduction

1.1. Effect of the Stress Wave on the Coal Mass

1.2. High-Pressure-Gas-Gathering Cutting by the Phase Change of Liquid Carbon Dioxide

1.3. Coal Seams Fractured by the Liquid Carbon Dioxide Phase-Change Expansion Force

2. Methods

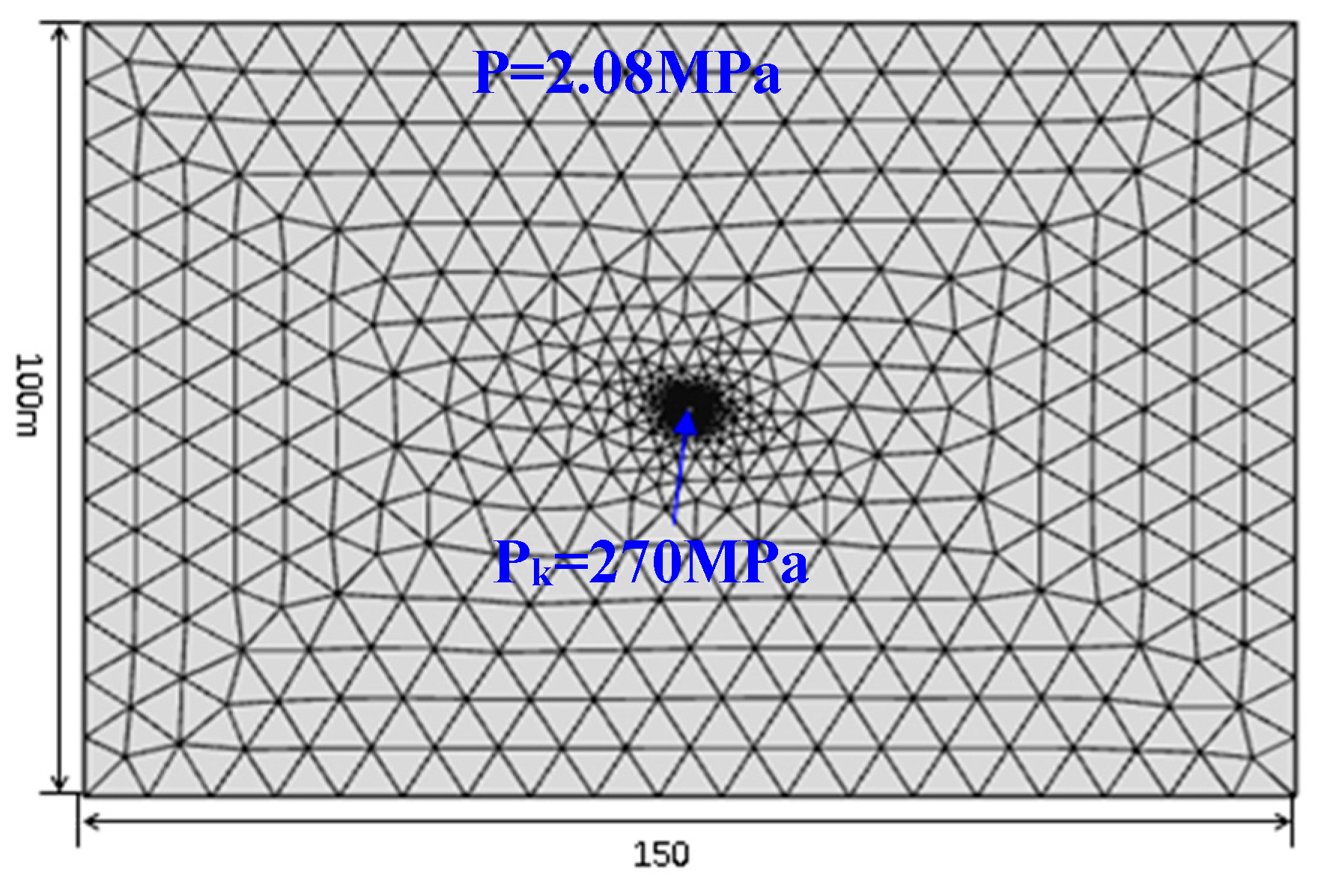

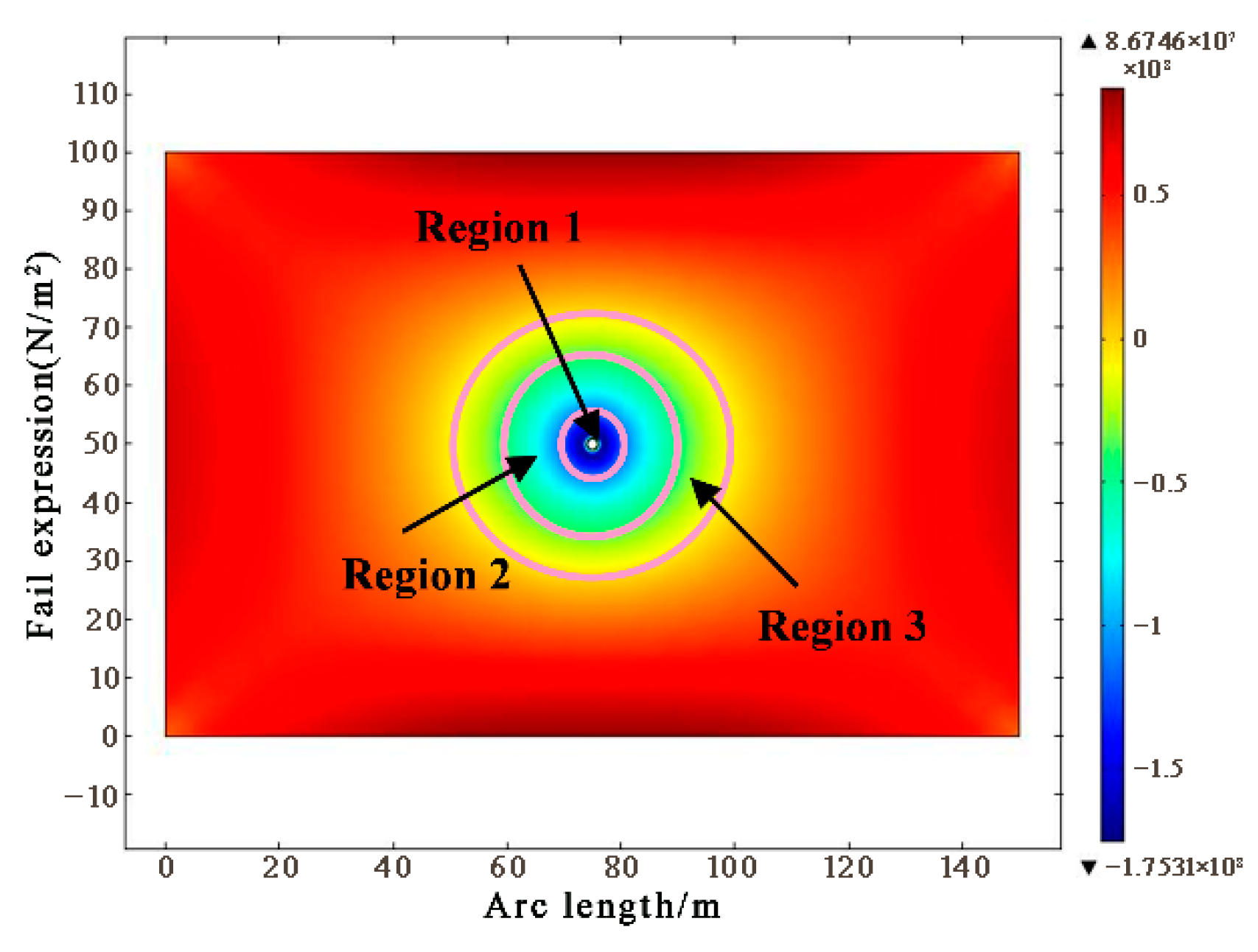

2.1. Numerical Model

2.2. Theoretical Calculation

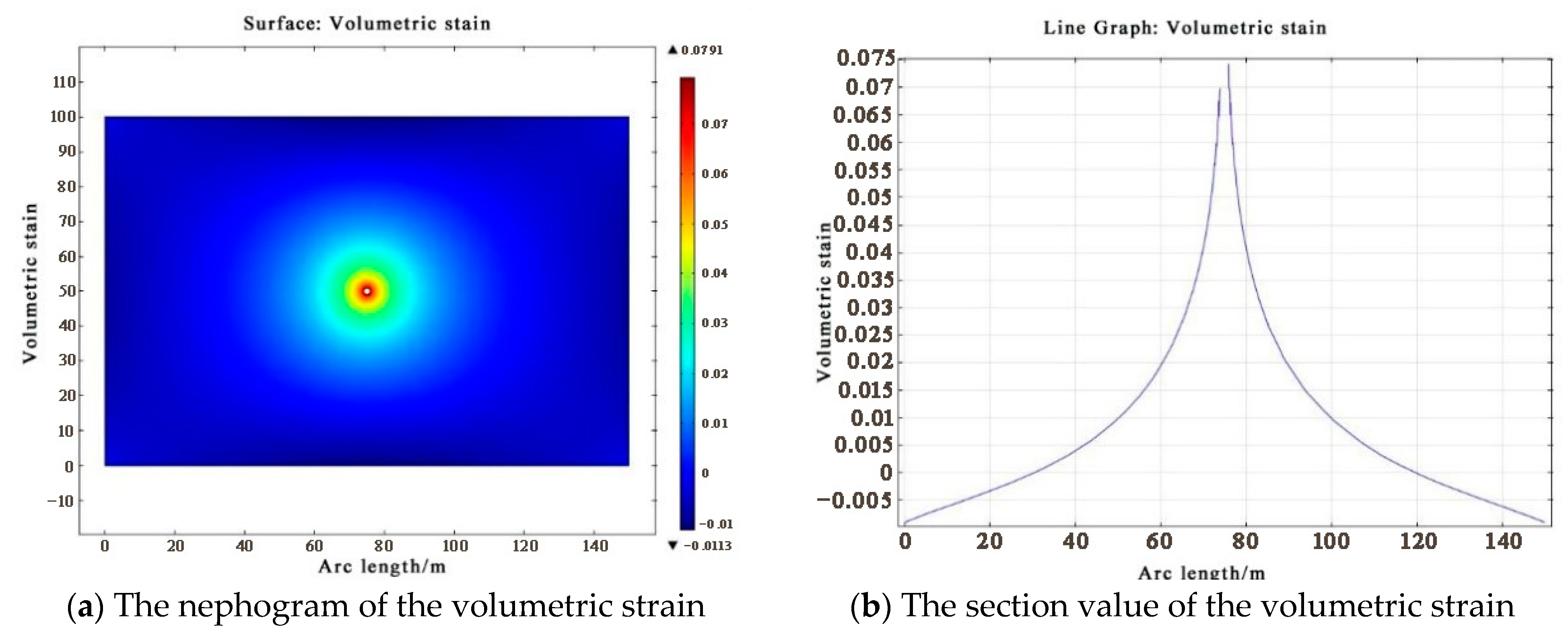

3. Results and Discussion

3.1. Features of the Volumetric Strain

3.2. Engineering Background

3.3. Test Scheme

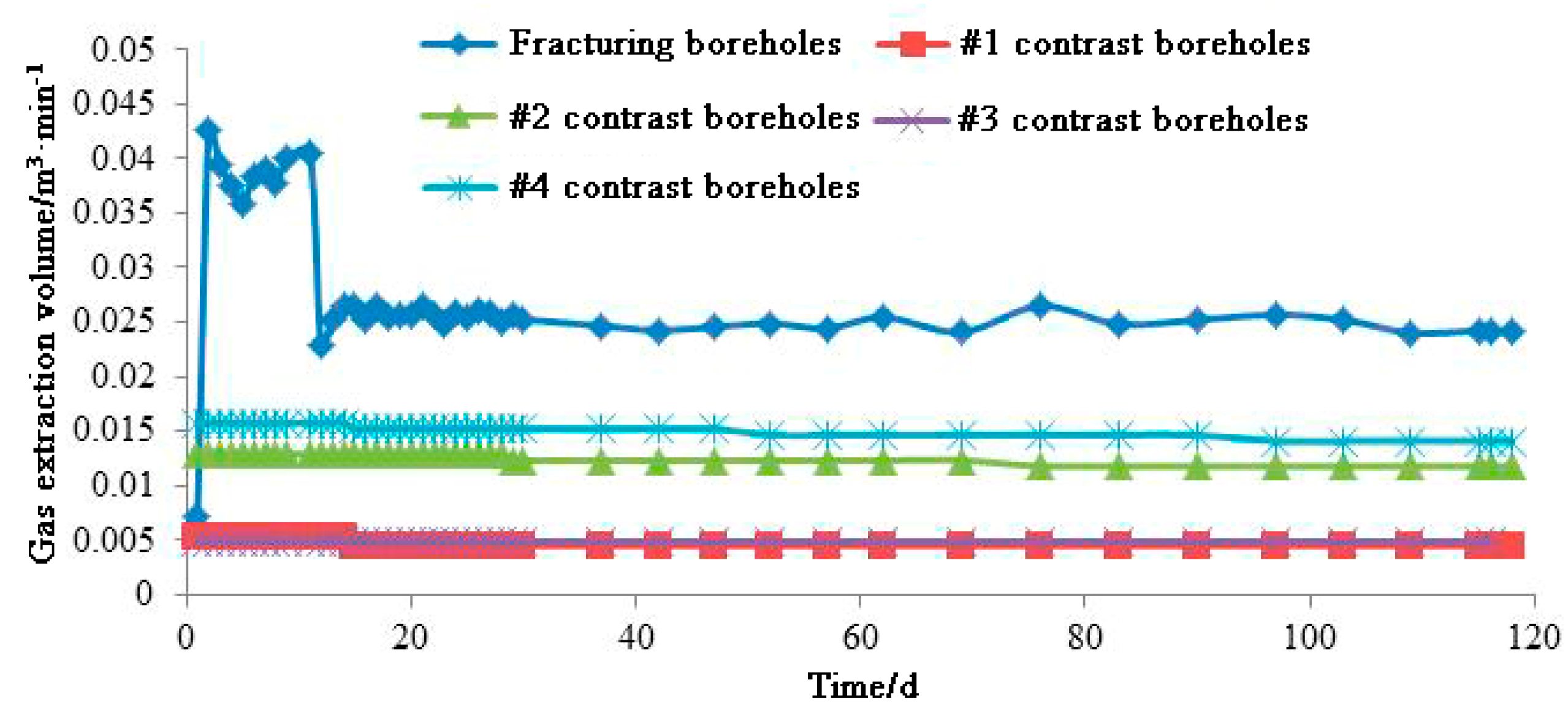

3.4. The Effect of the Fracturing

3.5. Analysis of the Test Results

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kang, X.B.; Luo, S.; Li, Q.S.; Xu, M.; Li, Q. Developing a risk assessment system for gas tunnel disasters in China. J. Mt. Sci. 2017, 14, 1751–1762. [Google Scholar] [CrossRef]

- Wang, K.; Du, F. Coal-gas compound dynamic disasters in China: A review. Process Saf. Env. 2020, 133, 1–17. [Google Scholar] [CrossRef]

- Chen, X.J.; Li, L.Y.; Wang, L.; Qi, L. The current situation and prevention and control countermeasures for typical dynamic disasters in kilometer-deep mines in China. Safety Sci. 2019, 155, 229–236. [Google Scholar] [CrossRef]

- Hu, G.Z.; Sun, C.; Sun, M.F.; Qin, W.; Linghu, J. The case for enhanced coalbed methane using hydraulic fracturing in the geostructural belt. Energy Explor. Exploit. 2018, 36, 1629–1644. [Google Scholar] [CrossRef]

- Lu, W.; He, C. Numerical simulation of the fracture propagation of linear collaborative directional hydraulic fracturing controlled by pre-slotted guide and fracturing boreholes. Eng. Fract. Mech. 2020, 235, 107128. [Google Scholar] [CrossRef]

- Yang, W.; Lu, C.; Si, G.; Lin, B.; Jiao, X. Coal and gas outburst control using uniform hydraulic fracturing by destress blasting and water-driven gas release. J. Nat. Gas Sci. Eng. 2020, 79, 103360. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Z.; Wang, Z. A Mechanical Model of Gas Drainage Borehole Clogging under Confining Pressure and Its Application. Energies 2018, 11, 2817. [Google Scholar] [CrossRef]

- Sun, X.; Cheng, Z.; Chen, L.; Li, Z.; Wang, H.; Yin, S. Deflection Laws of Gas Drainage Boreholes in Interbedded Soft and Hard Seams: A Case Study at Xinzheng Coal Mine, China. Adv. Civ. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Hu, C.; Li, Q.; Wang, Y.; Li, Y.; Wang, Y.; Chang, K. Influence Mechanism of Mine Pressure on Coal Seam Gas Emission During Mining. Geotech. Geol. Eng. 2022, 40, 3067–3074. [Google Scholar] [CrossRef]

- Zhang, Y.A.; Deng, J.R.; Deng, H.W.; Ke, B. Peridynamics simulation of rock fracturing under liquid carbon dioxide blasting. Int. J. Damage Mech. 2019, 28, 1038–1052. [Google Scholar] [CrossRef]

- Xia, J.Q.; Dou, B.; Tian, H.; Zheng, J.; Cui, G.; Kashif, M. Research on initiation of carbon dioxide fracturing pipe using the liquid carbon dioxide phase-transition blasting technology. Energies 2021, 14, 521. [Google Scholar] [CrossRef]

- Chen, H.-D.; Wang, Z.-F.; Qi, L.-L.; An, F.-H. Effect of liquid carbon dioxide phase change fracturing technology on gas drainage. Arab. J. Geosci. 2017, 10, 314. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, J.; Ke, B.; Deng, H.; Li, J. Experimental Study on Explosion Pressure and Rock Breaking Characteristics under Liquid Carbon Dioxide Blasting. Adv. Civ. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Ishida, T.; Aoyagi, K.; Niwa, T.; Chen, Y.; Murata, S.; Chen, Q.; Nakayama, Y. Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2. Geophys. Res. Lett. 2012, 39. [Google Scholar] [CrossRef]

- Niezgoda, T.; Miedzinska, D.; Malek, E. Study on carbon dioxide thermodynamic behavior for the purpose of shale rock fracturing. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 605–612. [Google Scholar] [CrossRef]

- Cui, X.J.; Ke, B.; Yu, S.T.; Li, P.; Zhao, M. Energy characteristics of seismic waves on Cardox Blasting Tube. Geofluids 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Pan, Z.J.; Connell, L.D. A theoretical model for gas adsorption-induced coal swelling. Int. J. Coal Geol. 2007, 69, 243–252. [Google Scholar] [CrossRef]

- Gorgulu, K.; Arpaz, E.; Uysal, O.; Durutürk, Y.S.; Yüksek, A.G.; Koçaslan, A.; Dilmaç, M.K. Investigation of the effects of blasting design parameters and rock properties on blast-induced ground vibrations. Arab. J. Geosci. 2015, 8, 4269–4278. [Google Scholar] [CrossRef]

- Lekontsev, Y.M.; Sazhin, P.V. Directional hydraulic fracturing in difficult caving roof control and coal degassing. J. Min. Sci. 2014, 50, 914–917. [Google Scholar] [CrossRef]

- Lisienko, V.G.; Lapteva, A.V.; Chesnokov, Y.N.; Zagainov, S. Comparative Analysis of the Influence of Fuel Injection on the Energy Intensity and Carbon Footprint of the Blast-Furnace Process. Metallurgist 2017, 61, 183–187. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, G.M.; Li, Y.M. Key technologies and engineering practices for soft-rock protective seam mining. Int. J. Min. Sci. Technol. 2020, 30, 889–899. [Google Scholar] [CrossRef]

- Behnoudfar, P.; Asadi, M.B.; Gholilou, A.; Zendehboudi, S. A new model to conduct hydraulic fracture design in coalbed methane reservoirs by incorporating stress variations. J. Pet. Sci. Eng. 2019, 174, 1208–1222. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.L.; Owusu, A.B. A modified Ester-branched thickener for rheology and wettability during CO2 fracturing for improved fracturing property. Environ. Sci. Pollut. Res. 2019, 26, 20787–20797. [Google Scholar] [CrossRef] [PubMed]

- Liao, Z.W.; Liu, X.F.; Song, D.Z.; He, X.; Nie, B.; Yang, T.; Wang, L. Micro-structural damage to coal induced by liquid CO2 phase change fracturing. Nat. Resour. Res. 2020, 30, 1613–1627. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Zhang, J.; Meng, S.; Duan, Y. Fracturing with carbon dioxide: Application status and development trend. Pet. Explor. Dev. 2014, 41, 513–519. [Google Scholar] [CrossRef]

- Rogala, A.; Ksiezniak, K.; Krzysiek, J.; Hupka, J. Carbon dioxide sequestration during shale gas recovery. Physicochem. Probl. Miner. Process. 2014, 50, 681–692. [Google Scholar]

- Yang, Z.Z.; Yi, L.P.; Li, X.G.; Li, Y.; Jia, M. Phase control of downhole fluid during supercritical carbon dioxide fracturing. Greenh. Gases Sci. Technol. 2018, 8, 1079–1089. [Google Scholar] [CrossRef]

- Hu, C.; Yang, X.; Huang, R.; Ma, X. Presplitting Blasting the Roof Strata to Control Large Deformation in the Deep Mine Roadway. Adv. Civ. Eng. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Fan, C.; Li, S.; Luo, M.; Yang, Z.; Lan, T. Numerical simulation of hydraulic fracturing in coal seam for enhancing underground gas drainage. Energy Explor. Exploit. 2019, 37, 166–193. [Google Scholar] [CrossRef]

- Reisabadi, M.Z.; Sayyafzadeh, M.; Haghighi, M. Stress and permeability modelling in depleted coal seams during CO2 storage. Fuel 2022, 325, 124958. [Google Scholar] [CrossRef]

- Qu, Q.; Shi, J.; Wilkins, A. A Numerical Evaluation of Coal Seam Permeability Derived from Borehole Gas Flow Rate. Energies 2022, 15, 3828. [Google Scholar] [CrossRef]

- Yang, X.; Hu, C.; Liang, J.; Zhou, Y.; Ni, G.; Huang, R. A Case Study on the Control of Large Deformations in a Roadway Located in the Du’erping Coal Mine in China. Adv. Mater. Sci. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Jovanovic, A.P.; Stankov, M.N.; Loffhagen, D.; Becker, M.M. Automated fluid model generation and numerical analysis of dielectric barrier discharges using Comsol. IEEE Trans. Plasma Sci. 2021, 49, 3710–3718. [Google Scholar] [CrossRef]

- Hu, C.; Liu, W.; Wang, Y. Study on the Influence of the Location of Dirt Band on Top Coal Caving Property in Extra-Thick Coal Seam. Geotech. Geol. Eng. 2020, 38, 6221–6230. [Google Scholar] [CrossRef]

- Jha, P.K.; Lipton, R.P. Kinetic relations and local energy balance for LEFM from a nonlocal peridynamic model. Int. J. Fract. 2020, 226, 81–95. [Google Scholar] [CrossRef]

| Symbol | Parameter | Value | Unit |

|---|---|---|---|

| ρ1 | Density of coal seam | 1490 | kg/m3 |

| E | Elastic modulus | 2 × 109 | Pa |

| V | Poisson ratio | 0.35 | – |

| K | Permeability | 10−17 | m2 |

| K1 | Porosity | 6.58 | % |

| c | Cohesion | 4 | MPa |

| φ | Internal friction angle | 33 | ° |

| ρ2 | Density of CO2 | 1.977 | kg/m3 |

| μ | Dynamic viscosity of CO2 | 1.48 × 10−5 | Pa·s |

| Z | Compressibility factor of CO2 | 1.02 | – |

| Strata | Lithology | Thickness/m |

|---|---|---|

| Main roof | Medium sandstone, Mudstone | 10 |

| Immediate roof | Siltstone, Sandy mudstone | 8.4 |

| Immediate floor | Siltstone | 5.6 |

| Main floor | Grit stone | 5.3 |

| Location | Type | Gas Drainage Volume | |

|---|---|---|---|

| Maximum Value | Mean Value | ||

| Fracturing zone | Fracturing boreholes | 0.0426 | 0.0276 |

| #1 Contrast zone | #1 contrast boreholes | 0.0052 | 0.0046 |

| #2 contrast boreholes | 0.0129 | 0.0122 | |

| #2 Contrast zone | #3 contrast boreholes | 0.0049 | 0.0049 |

| #4 contrast boreholes | 0.0158 | 0.0148 | |

| Location | Type | Gas Drainage Concentration/% | |

|---|---|---|---|

| Maximum Value | Mean Value | ||

| Fracturing zone | Fracturing boreholes | 71 | 62.3 |

| #1 Contrast zone | #1 contrast boreholes | 11.2 | 9.9 |

| #2 contrast boreholes | 56.4 | 55 | |

| #2 Contrast zone | #3 contrast boreholes | 12.4 | 12 |

| #4 contrast boreholes | 62.6 | 61.6 | |

| Location | Type | Sample Depth | K1 (mL/g·min1/2) | Decreased Degree | |

|---|---|---|---|---|---|

| Value | Maximum Value | ||||

| Fracturing zone | Without extraction | 2 m | 0.05 | 0.17 | 64.7% |

| 4 m | 0.12 | ||||

| 6 m | 0.09 | ||||

| 8 m | 0.17 | ||||

| 10 m | 0.11 | ||||

| With extraction | 2 m | 0.08 | 0.06 | ||

| 4 m | 0.06 | ||||

| 6 m | 0.03 | ||||

| 8 m | 0.02 | ||||

| 10 m | 0.05 | ||||

| Contrast zone | Without extraction | 2 m | 0.03 | 0.21 | 19.1% |

| 4 m | 0.15 | ||||

| 6 m | 0.10 | ||||

| 8 m | 0.21 | ||||

| 10 m | 0.10 | ||||

| With extraction | 2 m | 0.08 | 0.17 | ||

| 4 m | 0.17 | ||||

| 6 m | 0.10 | ||||

| 8 m | 0.04 | ||||

| 10 m | 0.11 | ||||

| Location | The Coal Seam Permeability Coefficient m2/MPa2·d | Multiple | |

|---|---|---|---|

| Before Fracturing | After Fracturing | ||

| #3 panel | 0.052755 | 0.159058 | 3.01 |

| #5 panel | 0.030846 | 0.23915 | 7.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F. Research into the Mechanism and Application of Liquid CO2 Phase-Transition Fracturing in a Coal Seam to Enhance Permeability. Sustainability 2023, 15, 3308. https://doi.org/10.3390/su15043308

Zhang F. Research into the Mechanism and Application of Liquid CO2 Phase-Transition Fracturing in a Coal Seam to Enhance Permeability. Sustainability. 2023; 15(4):3308. https://doi.org/10.3390/su15043308

Chicago/Turabian StyleZhang, Feng. 2023. "Research into the Mechanism and Application of Liquid CO2 Phase-Transition Fracturing in a Coal Seam to Enhance Permeability" Sustainability 15, no. 4: 3308. https://doi.org/10.3390/su15043308

APA StyleZhang, F. (2023). Research into the Mechanism and Application of Liquid CO2 Phase-Transition Fracturing in a Coal Seam to Enhance Permeability. Sustainability, 15(4), 3308. https://doi.org/10.3390/su15043308