Operational Concept of an Innovative Management Framework for Choosing the Optimal Packaging System for Supply Chains

Abstract

:1. Introduction

2. Materials and Methods

- -

- Keywords: “logistics”, “packaging”, “digitalization”

- -

- Combinations: First search was done without the keyword “digitalization”, to find publications in the field of logistics packaging. Then the search was extended with the keyword “digitalization”. The results are summarized in Figure 4.

- -

- “logistics” AND “packaging”

- -

- “logistics” AND “packaging” AND “digitalization”

3. Summary of the Literature Review

4. Description of the Operational Concept of the Packaging Management System

4.1. Description of Test Cases

- The packaging system does not change in the process under consideration, for example, if the product is removed from the same packaging for a given operation and then returned to the same packaging for quality control.

- The packaging system changes in the process without branching for example, when a different packaging system is required after machining in the case of laser cutting.

- The packaging system is not changed when several processes meet, for example, painting products.

- The packaging system changes when several processes meet, for example, commissioning or assembly.

- The packaging system does not change in the case of branching, for example, delivery of a given product type to several customers.

- The type of unit load device changes in case of branching, for example, after disassembly or sorting.

- Combination of sub-types, for example, a supply chain in which types 4-6-1 are followed by each other.

| Numbers | Type | Numbers | Type |

|---|---|---|---|

| I. |  | IV. |  |

| II. |  | V. |  |

| III. |  | VI. |  |

| VII. |  | ||

4.2. Structure of the Packaging System

- -

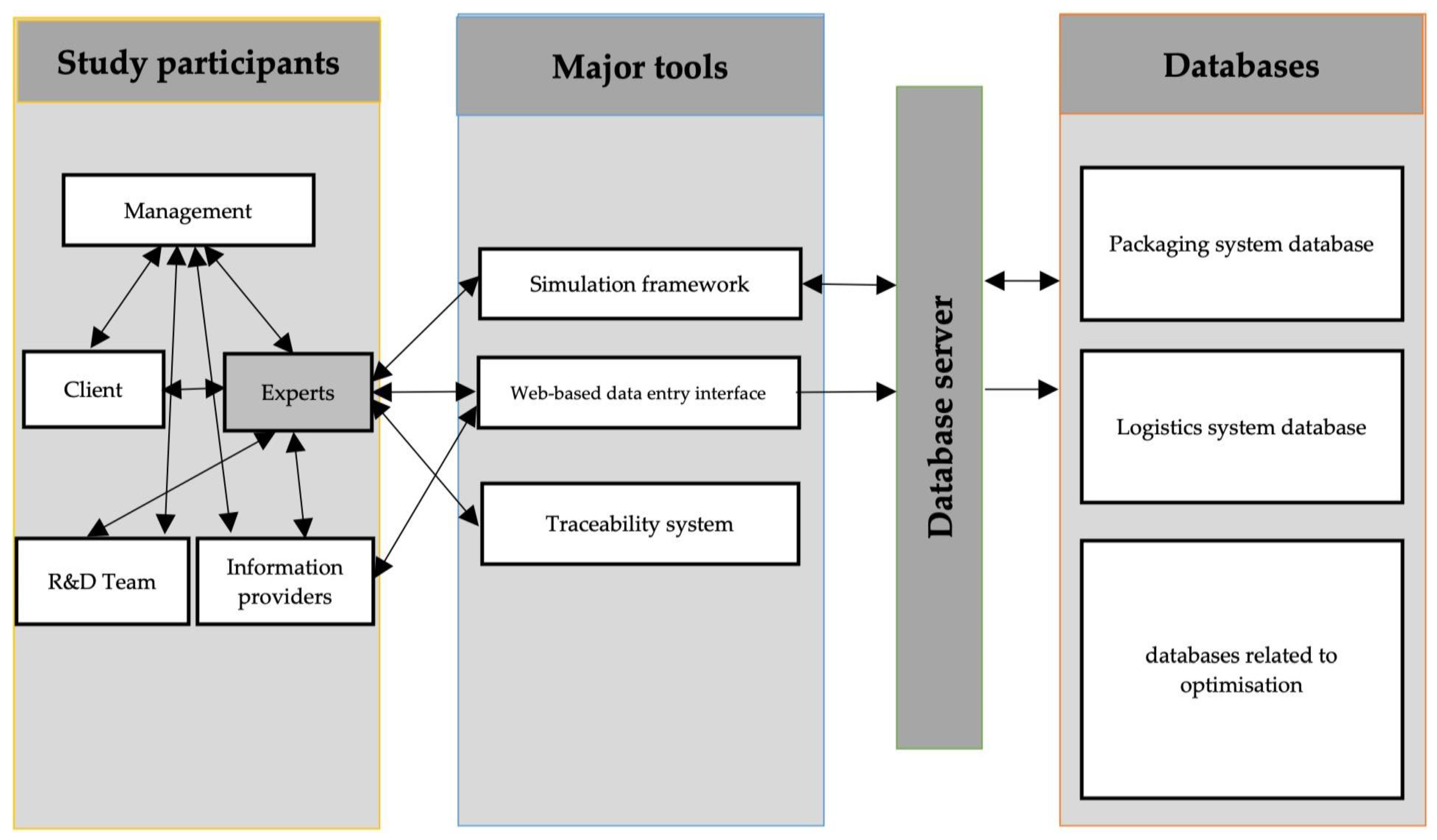

- Management: management sets the development direction. The management sets the strategy. The management is responsible for taking strategic and tactical decisions, negotiating with new companies based on expert advice, and concluding contracts. The development guidelines include defining development ideas for marketing, technology and the services provided.

- -

- Client: The company using the services of the test system, which concludes a service contract with the management, while the test for the choice of the optimal packaging system is carried out with the assistance of the expert. Publication [54] discusses the procurement of business services becoming increasingly important for companies as they seek competitive advantage. Service contracts are an essential part of the procurement of business services and the complexity of contracts increases with the complexity of services [54].

- -

- Experts: The experts are fully familiar with the functions of the packaging management system, who manage the conduct of the entire inspection. The main tasks include:

- ○

- defining the task to be performed based on the client’s needs,

- ○

- defining the range of data required for the system to operate, and managing their production,

- ○

- uploading data via a web application,

- ○

- conducting a study and negotiating the results with the client.

- -

- R&D team: The team develops the framework along the development guidelines approved by management and maintains the infrastructure necessary for its operation.

- -

- Information providers: Information providers are the actors that provide additional information needed to carry out the study (e.g., important parameters of available packaging systems, distance of actors in supply chains, etc.).

- -

- Simulation framework: A simulation framework is used to model the operation of the supply chain in the case of different packaging system combinations defined at the decision-making points. The simulation test model basically determines the packaging scheme combination containing the most favorable objective function value. Based on the data of the databases uploaded via the web application, the system to be developed will automatically create the system under investigation during the examination initiated by the expert, and then perform the optimization task.

- -

- Web-based data entry interface: An interface accessible via the internet where experts and information providers can enter the data required to perform the study using a predefined data entry structure.

- -

- Tracking system: The availability of a tracking system to capture relevant environmental information to provide the quantitative and qualitative data needed to run the simulation test model. In most cases, these data can be queried by company management systems, but at the same time, if needed, an on-site survey becomes necessary. Monitoring solutions in companies can range from paper-based manual data capture to advanced automated digitalization solutions, which of course have an impact on the quality of the study. The data provided by the traceability system are uploaded via a web-based interface to the databases required to perform the test.

- -

- Databases needed for the system to work are:

- -

- Packaging system database: a database of packaging system that can be used during optimization, which is uploaded by information providers and experts via a web interface.

- -

- Logistics system database: a database containing the data needed to model the process under study, which will be entered by the experts via the web interface, based on the company under study and/or on-site survey.

- -

- Databases related to optimization: a database containing the data (decision variables, conditions, objective functions) needed to select the appropriate packaging system, which is partly captured by the experts and partly by running the simulation study.

4.3. Operational Concept of the Packaging Management System

- Definition of the purpose of the study: the client, with the involvement of the expert, defines the task to be performed, namely the subsystem to be studied, the scope of its processes, products and decision points.

- Contracting: the management and the client, with the support of the expert, fix the task to be performed, the expectations and the method of payment for the service contract.

- Getting to know the system under test: the expert with the assistance of the client, gets to know the logistical processes of the system under test.

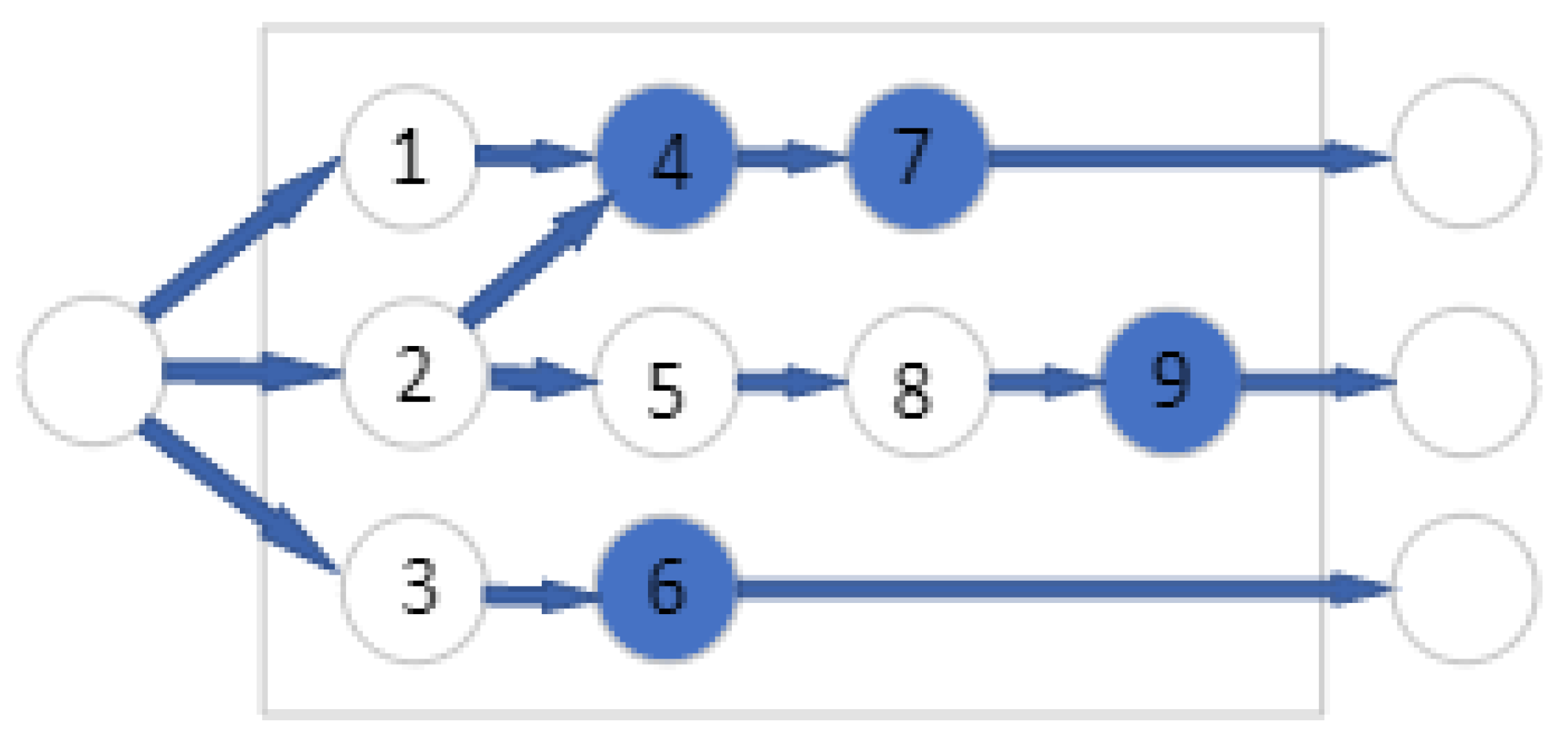

- Preparation of the material flow graph: For the system defined, the fixed objects of the material flow and the links between them shall be identified for each type of product. The objects in the material flow graphs under consideration are given a unique identifier (e.g., a sequence number) and are marked if they are decision points (see Figure 7, color blue). Decision points are defined as objects on which the choice of the optimal packaging system can be tested.

- Recording material flow processes: based on the material flow graphs for the product types, experts record the material flow process of the products via a web-based data entry interface.

- Delimitation of the packaging systems to be tested: based on the data received from the customer and/or information providers, the experts record the data of the packaging systems to be tested (size data, tare weight, load capacity, specific amortization cost per transport relation) via the web data entry interface.

- Determination of the data of packaging systems applicable in material flow nodes: Two types of material flow nodes can be distinguished, those where the packaging scheme does not change for the product types that pass through, and decision points where it is possible to do so. The experts, in consultation with the client, will identify the test options and then, via the web interface, will specify the types of packaging system that can be used for the product types passing through the nodes, as well as their filling volumes, loading times, unit logistics and quality characteristics.

- Enter material flow relations and related data: experts enter, via the web application, the data of possible transport relations for the defined nodes.

- Provide information on technological equipment: In this step, information describing the operation of the technological equipment is provided. If the modelling of the equipment is very specific, the description and modelling of the operation will require future discussion.

- Enter data on material handling activities: in this step, distance and time data for the material handling tasks associated with the nodes representing the material handling activity are entered for the packaging systems for the given product types (transport capacity, average transport time).

- Enter scheduling task: in this step, it is specified when and what quantities of each product type will be launched from each node.

- Discussion of decision criteria: In this step, the logistic indicators that influence the decision are presented, the range of which is defined based on the literature analysis [17]. The value of some indicators can vary depending on the combination of γ packaging system.

- -

- Transit time: The transit time is the time between the objects bounding the delimited system. The transit time may be interpreted by product type associated with the output points of the system under study using Equation (1), and for the whole system using Equation (2).

- -

- i: unique identifier of the unit load of product type p,

- -

- : exit date of the unit load i of product type p from the tested system,

- -

- : for unit range i of product type p, the set of components to be incorporated,

- -

- : data of entry of snap-in j into the system

- -

- Total cost of operation: the cost of operation of the material flow systems depends to a large extent on the choice of the packaging system combination, and the method of determining this for the system under consideration by the following Equation (3).

- -

- : the set of pairs of the transport relation of the system under consideration,

- -

- : set of product types moved in a transport relation k, o,

- -

- : set of unique identifiers of unit loads of product type p in relation k, o,

- -

- : length of the transport relation k, o [km],

- -

- : unit transport cost for unit load i of product type p in transport relation k, o [EUR/UL∙km],

- -

- : specific loading cost for unit load i of product type p at material flow object k [EUR/UL]

- -

- : specific loading cost for unit load i of product type p at material flow object k [EUR/UL]

- -

- : number of storage days for unit load i of product type p at object k [day∙UL]

- -

- : number of storage days for unit load i of product type p at object o [day∙UL]

- -

- : specific storage cost for unit load i of product type p at object s [EUR/day∙UL]

- -

- : unit storage cost for unit load i of product type p at object o [EUR/day∙UL]

- -

- : amortisation cost of the packaging system for unit load i of product type p for transport relation k, o [EUR/UL].

- -

- Average usability within the process under consideration: This factor takes into consideration how many times the packaging system γ under examination is expected to be used in the relation k, o for a given product type p. The values are defined by the information providers, the data structure of which is shown in Equation (4).

- -

- Quality of the packaging system: The choice of the packaging system should be based on its ability to meet expectations. Only packaging systems that meet the essential requirements should be included in the test. This factor will be determined with the help of the company under investigation and external information providers [18]. The following criteria are considered in the evaluation:

- ○

- delivery marks are clear and easy to read on the outer packaging,

- ○

- sufficient choice and number of items,

- ○

- package printing, material, content, size and color are all appropriate,

- ○

- package fully sealed by appropriate methods,

- ○

- carton box drop test,

- ○

- barcodes and labelling are clear, accurate and legible,

- ○

- environmental impact,

- ○

- pallet packaging meets specification.

- 13.

- Agreeing test criteria: the previous step showed how to define test criteria for a packaging system combination (one predefined packaging system per decision point). These criteria may have a different value for each γ packaging system combination, so it may be necessary to formulate criteria to exclude packaging system combinations that are not acceptable to the client. The formulation of the criteria is carried out jointly by the expert and the sponsor, while the data recording is carried out by the expert. From Equations (6)–(10) define the requirements for the optimal packaging system alternative in terms of lead times, costs, availability and quality. In fact, only the alternative which meets these criteria can be selected.

- 14.

- Test objective function matching: In this step, the method of determining the objective function is presented to the client, and the weights of the objective function components are produced and uploaded to the background database. To produce the objective function of the optimization, the weighted sum of the normalized objective function components must be formed in relation to each γ packaging system combination, and then the combination with the most favorable value is chosen. In the analysis, the goal is to select a packaging system combination that minimizes transit time and cost, as well as maximizing usability and quality. The normalization steps are described in Equations (11)–(18).

- -

- Normalization of transit time:

- -

- Normalizing operating cost:

- -

- Usability within the tested system:

- -

- Quality within the system tested:

- 15.

- Create a simulation model: based on the data recorded by the experts, the simulation model is automatically created, which runs based on the data uploaded on the web application.

- 16.

- Testing and validation of the simulation model: After the simulation model has been created, the model is tested by the experts to eliminate any data errors, program errors and conceptual errors. For an existing system, the validation of the simulation model is carried out by comparing the model with reality, while for a future system, it is carried out by checking the data and processes.

- 17.

- Running a simulation model, analysis of the results: As a result of running the tested and validated simulation model, the value of the objective function is generated for each packaging system combination, so that the most favorable variant can be selected. The number of variants tested depends to a large extent on the number of product types, packaging systems and decision points tested.

- 18.

- Checking the adequacy of the results: In this phase, the correctness of the results obtained is checked, and if it is feasible for the company, the test is completed and the next step is to proceed towards implementation. Otherwise, further tests are carried out by modifying the test model.

4.4. Case Study on the Choice of the Optimal Packaging System

- -

- Data was entered directly into the data tables without using a web-based data entry interface.

- -

- The model was created manually, using recorded data. The test model was implemented in the Plant Simulation Framework, version 2021. The simulation framework operates in a discrete, event-driven paradigm, which contributes significantly to user-friendly model creation and shorter runtimes.

- To define the purpose of the examination: to select the optimal type of unit load forming devices at three locations in an automatically operating forging plant with a defined material flow based on a predefined objective function and a set of conditions.

- Contracting: in a real system, the management and the customer, with the support of the expert, would define the task to be performed, the expectations and the method of payment for the service in a service contract.

- Getting to know the system under test: This step would involve getting to know the operational processes of the system under test. In summary, the process starts with an automatic forging machine that produces different types of parts according to a defined production plan and schedule. The coinage parts are placed in an automated way in a unit load device. The unit load is then transferred via conveyor lines to a heat treatment oven to carry out the necessary structural modifications. After the heat treatment, the products are transported via conveyor lines to one of the two granulator units. After the granulation process, the products are also automatically transported to a selected unit loader, from where they are delivered to an external warehouse. In understanding the system, it is important to define the range of material flow and process characteristics to be considered.

- Material flow graphs: In this step, the process operations and material handling equipment of the system under study are selected and uniquely identified as material flow nodes and the connection between them is made using directed edges. For the easier understanding of the model, the circular objects marked in blue are the place where it is possible to choose the way of unit load training, and for the circular objects some material handling/technological operation is performed. For Figure 8, the marking of nodes and edges is incomplete, i.e., not all of them are marked, but the example is a good illustration of the method developed.

- 5.

- Recording material flow process (see Table 3): In this step, the experts record the material flow processes, i.e., the order in which each product goes through which material handling and processing equipment, via a web application, according to the concept developed. For the simplicity of the present case study, this method of data recording is not used, i.e., the connections are created manually.

- 6.

- Delimitation of the packaging systems to be tested: The concept is that experts will record the data of the packaging systems to be tested on the web-based data entry interface, based on the data received from the sponsor and/or information providers. In the present case study, 3 types of unit loaders for loading products coming out of the coinage machine and 2 types of unit loaders for loading products coming out of the granulator. The aim is to select 1 type of unit loader after the coinage and 1 type of unit loader after the granulation process.

- 7.

- Determination of the data of packaging systems applicable in material flow nodes: The concept is that the experts, in consultation with the client, will jointly define the testing options and then, via the web interface, specify the types of packaging system that can be used for the product types passing through the decision nodes, as well as their main data. In this case study, four types of characteristics have been selected, whose data can be as follows (see Figure 9):

- -

- Loading volume (see Figure 9a): shows how much of a given product can be loaded into a given unit loader [pieces per unit loader].

- -

- Loading time (see Figure 9b): shows how long it takes to load one product of a given product type into a given unit loader [s/pcs].

- -

- Specific logistics cost (see Figure 9c): shows the logistics cost of placing one unit load of a given product type in a given unit loader [EUR/pcs].

- -

- Quality feature (see Figure 9d): shows the degree to which the placement of a given product type in a given unit load device meets the company’s quality expectations (1—worst, 10—best).

- 8.

- Enter material flow relations and related data: The concept is to have experts define possible transport relations via the web application. The value of the Table 4 is 1 if there is a material flow relation between the material flow objects they have selected, otherwise it is not filled in.

- 9.

- Enter technological equipment data: In this step, information describing the operation of the technological equipment is provided. In this case study, this means entering the data for two pieces of technological equipment, namely the coinage machine and the grain milling machines (Table 5).

- 10.

- Enter the data of the material handling activity: In this step, the data of the nodes representing the material handling tasks are entered. The data for this case study are given in Table 6.

- 11.

- Specify scheduling task: The tasks to be performed by the forging machine and their sequency are listed in Table 7. The table shows which product types, and in which sequence they will be started by the coinage machine.

- 12.

- Decision criteria matching: For the case study, there are 3 types of pallets to choose from after the forging machine and 2 types of pallets after the granulator. This means a total of 6 packaging system variants for the selection of unit load devices (1 after forging machines and 1 after granulators). To select the appropriate packaging system variant, it is necessary to define the decision criteria (Table 8). Three types of decision criteria were selected, namely:

- -

- Lead time: total lead time per product [sec] for a given packaging system variant.

- -

- Logistics cost: average cost per product [EUR/pcs], determined from the sum of the specific logistics costs assigned for a given packaging system.

- -

- Quality: average quality per product, determined from the sum of the quality attributes assigned to the loading operations for a given packaging system.

- 13.

- Agreement on the test criteria: no restrictive criteria were formulated for the case study in relation to the decision criteria.

- 14.

- Test objective function matching: The weight factors are lead time: 0.5 TTT, 0.2 TTT, logistics cost: 0.3. The objective function is defined as the weighted sum of the normalized objective function components, where the packaging system variant with the lowest value indicates the type of unit load devices to be used.

- 15.

- Simulation model creation: Based on the data recorded in the previous steps, the simulation model was created manually (Figure 8). In the context of the model, different colors were used to indicate the empty pallets (blue color), the unit loads (green color), and the conveyor systems used to move the unit loads during the heat treatment (red color). The technological equipment is indicated by a separate label.

- 16.

- Testing and validation of the simulation model: after the simulation model was created, the model was tested, during which data errors and program errors were corrected and the planned concept was verified.

- 17.

| Version | Pallet1 | Pallet2 | Pallet3 | FPallet1 | FPallet2 | Lead Time | Quality | Cost |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 9785 | 11 | 0.8 | |||

| 2 | 1 | 1 | 11,587 | 15 | 1.1 | |||

| 3 | 1 | 1 | 10,520 | 14 | 0.6 | |||

| 4 | 1 | 1 | 12,268 | 18 | 0.9 | |||

| 5 | 1 | 1 | 11,060 | 15 | 1.2 | |||

| 6 | 1 | 1 | 12,811 | 19 | 1.5 |

| Version | Pallet1 | Pallet2 | Pallet3 | FPallet1 | FPallet2 | Lead Time | Quality | Cost |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 0.76 | 0.52 | 0.53 | |||

| 2 | 1 | 1 | 0.90 | 0.21 | 0.73 | |||

| 3 | 1 | 1 | 0.82 | 0.26 | 0.40 | |||

| 4 | 1 | 1 | 0.96 | 0.05 | 0.60 | |||

| 5 | 1 | 1 | 0.86 | 0.21 | 0.80 | |||

| 6 | 1 | 1 | 1.00 | 0.00 | 1.00 |

| Version | Pallet1 | Pallet2 | Pallet3 | FPallet1 | FPallet2 | Lead Time | Weight (LT) | Quality | Weight (Q) | Cost | Weight (C) | Result |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 0.76 | 0.50 | 0.42 | 0.20 | 0.53 | 0.30 | 0.63 | |||

| 2 | 1 | 1 | 0.90 | 0.50 | 0.21 | 0.20 | 0.73 | 0.30 | 0.71 | |||

| 3 | 1 | 1 | 0.82 | 0.50 | 0.26 | 0.20 | 0.40 | 0.30 | 0.58 | |||

| 4 | 1 | 1 | 0.96 | 0.50 | 0.05 | 0.20 | 0.60 | 0.30 | 0.67 | |||

| 5 | 1 | 1 | 0.86 | 0.50 | 0.21 | 0.20 | 0.80 | 0.30 | 0.71 | |||

| 6 | 1 | 1 | 1.00 | 0.50 | 0.00 | 0.20 | 1.00 | 0.30 | 0.80 |

- 18.

- Checking the adequacy of the results: based on the objective function values, it can be concluded that for the presented case study, the optimal packaging system alternative is packaging system 3 (See Table 11), i.e., the unit load device Pallet2 after the forging machine and FPallet1 after the granulating machine.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kavas, L. A Logisztika És AZ Ellátási Lánc Javitott Lektoralt KL-Hadmernok.Hu. 2010. Available online: http://hadmernok.hu/2010_3_reger2.pdf (accessed on 1 February 2023).

- Pålsson, H.; Finnsgård, C.; Wänström, C. Selection of Packaging Systems in Supply Chains from a Sustainability Perspective: The Case of Volvo. Packag. Technol. Sci. 2012, 26, 289–310. [Google Scholar] [CrossRef]

- Adamashvili, N.; Fiore, M.; Contò, F.; La Sala, P. Ecosystem for Successful Agriculture. Collaborative Approach as a Driver for Agricultural Development. Eur. Countrys. 2020, 12, 242–256. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A Model for Understanding the Mediating Association of Transparency between Emerging Technologies and Humanitarian Logistics Sustainability. Sustainability 2022, 14, 6917. [Google Scholar] [CrossRef]

- Li, G.Z.; Li, W.F.; Xiang, Y.; Ding, Y. The Digital Designing and Optimization Researching of Beverage Packaging Face to the Modern Logistics. Appl. Mech. Mater. 2012, 200, 604–607. [Google Scholar] [CrossRef]

- Adamashvili, N.; State, R.; Tricase, C.; Fiore, M. Blockchain-Based Wine Supply Chain for the Industry Advancement. Sustainability 2021, 13, 13070. [Google Scholar] [CrossRef]

- Palsson, H. The Impact of Packaging on Supply Chain Performance. Available online: https://www.packagingstrategies.com/articles/90769-the-impact-of-packaging-on-supply-chain-performance (accessed on 18 January 2023).

- Primary, Secondary and Tertiary Packaging: What’s the Difference. Available online: https://www.emballagecartier.com/en/article/primary-secondary-and-tertiary-packaging-whats-the-difference/ (accessed on 18 January 2023).

- Demartini, E.; Gaviglio, A. Impact of information and Food Technology Neophobia in consumers’ acceptanfe of shelf-life extension in packaged fresh fish fillets. Sustain. Prod. Consum. 2019, 17, 116–125. [Google Scholar] [CrossRef]

- Collison, M.; Collison, T.; Myroniuk, I.; Boyko, N.; Pellegrini, G. Transformation Trends in Food Logistics for Short Food Supply Chains—What is New? Stud. Agric. Econ. 2019, 121, 102–110. [Google Scholar] [CrossRef]

- Adamashvili, N.; Shervashidze, S.; Salvatore, F.P. Does the Development of the Country Drive the Consumer Behavior? A Two-Country Study. Int. J. Bus. Res. Manag. 2021, 12, 34–49. [Google Scholar]

- British Food Journal, British Food Journal|Emerald Insight. Available online: https://www.emerald.com/insight/publication/issn/0007-070X (accessed on 1 February 2023).

- Faccilongo, N.; Pellegrini, G.; La Sala, P.L. Economia Circolare e scarti nelle filiere Agroalimentari: Prima Indagine Esplorativa sullo stato dell’arte. L’industria 2017, 2, 221–240. [Google Scholar] [CrossRef]

- Rana, R.L.; Adamashvili, N.; Tricase, C. The Impact of Blockchain Technology Adoption on Tourism Industry: A Systematic Literature Review. Sustainability 2022, 14, 7383. [Google Scholar] [CrossRef]

- Christofi, M.; Vrontis, D.; Thrassou, A.; Shams, S.R. Triggering technological innovation through cross-border mergers and acquisitions: A micro-foundational perspective. Technol. Forecast. Soc. Change 2019, 146, 148–166. [Google Scholar] [CrossRef]

- Ginieis, M.; Sánchez-Rebull, M.-V.; Campa-Planas, F. The academic journal literature on air transport: Analysis using systematic literature review methodology. J. Air Transp. Manag. 2012, 19, 31–35. [Google Scholar] [CrossRef]

- Kamarási, V.; Mogyorósy, G. Szisztematikus irodalmi áttekintések módszertana és jelentősége. Segítség Diagn. Terápiás Döntésekhez. Orv. Hetil. 2015, 156, 1523–1531. [Google Scholar] [CrossRef] [PubMed]

- Vinitha, K.; Prabhu, R.A.; Bhaskar, R.; Hariharan, R. Review on industrial mathematics and materials at Industry 1.0 to Industry 4.0. Mater. Today Proc. 2020, 33, 3956–3960. [Google Scholar] [CrossRef]

- Olsmats, C.; Dominic, C. Packaging scorecard—A packaging performance evaluation method. Packag. Technol. Sci. 2003, 16, 9–14. [Google Scholar] [CrossRef]

- Kabadurmus, O.; Kayikci, Y.; Demir, S.; Koc, B. A data-driven decision support system with smart packaging in grocery store supply chains during outbreaks. Socio-Econ. Plan. Sci. 2023, 85, 101417. [Google Scholar] [CrossRef]

- Hellström, D.; Saghir, M. Packaging and logistics interactions in retail supply chains. Packag. Technol. Sci. 2006, 20, 197–216. [Google Scholar] [CrossRef]

- Meherishi, L.; Narayana, S.A.; Ranjani, K. Sustainable packaging for supply chain management in the circular economy: A review. J. Clean. Prod. 2019, 237, 117582. [Google Scholar] [CrossRef]

- Molina-Besch, K.; Palsson, H. Packaging for Eco-Efficient Supply chains: Why logistics should get involved in the packaging development process. In Sustainable Logistics; Emerald Group Publishing Limited: Bingley, UK, 2014. [Google Scholar]

- García-Arca, J.; Prado, J.C. Packaging design model from a supply chain approach. Supply Chain. Manag. 2008, 13, 375–380. [Google Scholar] [CrossRef]

- Twede, D.; Clarke, R. Supply Chain Issues in Reusable Packaging. J. Mark. Channels 2004, 12, 7–26. [Google Scholar] [CrossRef]

- Palchevskyi, B.; Krestyanpol, L. The Use of the “Digital Twin” Concept for Proactive Diagnosis of Technological Packaging Systems. In Communications in Computer and Information Science; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 432–444. [Google Scholar] [CrossRef]

- Sadeghi, K.; Kim, J.; Seo, J. Packaging 4.0: The threshold of an intelligent approach. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2615–2638. [Google Scholar] [CrossRef] [PubMed]

- Sgarbossa, F.; Peron, M.; Fragapane, G. Cloud material handling systems: Conceptual model and cloud-based scheduling of handling activities. Int. Ser. Oper. Res. Manag. Sci. 2020, 289, 87–101. [Google Scholar] [CrossRef]

- Koszorek, M.; Huk, K. Return packaging in the shipment process of ready products on the example of Volkswagen Motor Polska sp. Z O.O. Acta Logist. 2021, 8, 259–267. [Google Scholar] [CrossRef]

- Wandosell, G.; Parra-Meroño, M.; Alcayde, A.; Baños, R. Green Packaging from Consumer and Business Perspectives. Sustainability 2021, 13, 1356. [Google Scholar] [CrossRef]

- Richnák, P.; Gubová, K. Green and Reverse Logistics in Conditions of Sustainable Development in Enterprises in Slovakia. Sustainability 2021, 13, 581. [Google Scholar] [CrossRef]

- Richter, B.; Hanf, J. Cooperatives in the Wine Industry: Sustainable Management Practices and Digitalisation. Sustainability 2021, 13, 5543. [Google Scholar] [CrossRef]

- Gupta, H.; Yadav, A.K.; Kusi-Sarpong, S.; Khan, S.A.; Sharma, S.C. Strategies to overcome barriers to innovative digitalisation technologies for supply chain logistics resilience during pandemic. Technol. Soc. 2022, 69, 101970. [Google Scholar] [CrossRef]

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and intelligent robotics in value chain of circular economy oriented waste management—A review. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef]

- Parrag, V.; Szegedyné, F.; Sebők, A. Application of digital solutions to improve the operation of short food supply chains. Int. J. Food Stud. 2022, 11, SI151–SI160. [Google Scholar] [CrossRef]

- Fernandez, C.M.; Alves, J.; Gaspar, P.D.; Lima, T.M. Fostering Awareness on Environmentally Sustainable Technological Solutions for the Post-Harvest Food Supply Chain. Processes 2021, 9, 1611. [Google Scholar] [CrossRef]

- Fahim, P.; Rezaei, J.; Jayaraman, R.; Poulin, M.; Montreuil, B.; Tavasszy, L. The Physical Internet and Maritime Ports: Ready for the Future? IEEE Eng. Manag. Rev. 2021, 49, 136–149. [Google Scholar] [CrossRef]

- Polster, S.; Lassnig, H.; Rainer, K.; Rathammer, K.; Kundratitz, V.; Peer, A.; Göllner, J.; Silvestru, D.; Domig, K.; Burtscher, J.; et al. Securing food production & Logistics in crisis situations: The NUTRISAFE project approach on challenges and perspectives of supply chain security. In Proceedings of the IDIMT 2021—Pandemics: Impacts, Strategies and Responses, 29th Interdisciplinary Information Management Talks, Kutná Hora, Czech Republic, 1–3 September 2021. [Google Scholar]

- Barge, P.; Biglia, A.; Comba, L.; Ricauda Aimonino, D.; Tortia, C.; Gay, P. Radio frequency identification for Meat Sup-ply-chain digitalization. Sensors 2020, 20, 4957. [Google Scholar] [CrossRef] [PubMed]

- Tsitsiashvili, G.S. Non-stationary Poisson model of continuously functioning queuing system. J. Phys. Conf. Ser. 2020, 98–103. [Google Scholar] [CrossRef]

- Kretschmer, V.; Schmidt, M.; Schwede, C.; Schafer, S.; Müller, G. Playfully to training success: Evaluation study of a pc-based serious game for packaging logistics at DB Schenker. Logist. J. 2018. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Dedahanov, A.T.; Abdurazzakov, O.S.; Rakhmonov, D.A. The Impact of Technologies of Traceability and Transparency in Supply Chains. Sustainability 2022, 14, 16336. [Google Scholar] [CrossRef]

- Adamashvili, N.; Chiara, F.; Fiore, M. Food Loss and Waste, a global responsibility?! Econ. Agro-Aliment. 2020, 825–846. [Google Scholar] [CrossRef]

- Curran, M.A. Environmental Life-Cycle Assessment; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Saghir, M.; Jönson, G. Packaging handling evaluation methods in the grocery retail industry. Packag. Technol. Sci. 2001, 14, 21–29. [Google Scholar] [CrossRef]

- Facanha, C.; Horvath, A. Environmental assessment of logistics outsourcing. J. Manag. Eng. 2005, 21, 27–37. [Google Scholar] [CrossRef]

- Rocha, T.B.; Penteado, C.S.G. Life cycle assessment of a small WEEE reverse logistics system: Case study in the Campinas Area, Brazil. J. Clean. Prod. 2021, 314, 128092. [Google Scholar] [CrossRef]

- Johnson, G.; Johnson, M. Valuation methods for increased efficiency in the supply chain. In Proceedings of the International Conference on Computer Integrated Manufacturing, Singapore, 28–30 March 2000. [Google Scholar]

- Brynzér, H.; Johansson, M.I.; Medbo, L. A methodology for evaluation of order picking systems as a base for system design and managerial decisions. Int. J. Oper. Prod. Manag. 1994, 14, 126–139. [Google Scholar] [CrossRef]

- Zhang, L.; Jiandong, L.; Guorong, C.; Hongtao, M. Research on Packaging Evaluation System of Fast Moving Consumer Goods Based on Analytical Hierarchy Process Method. In Advanced Graphic Communications and Media Technologies; Zhao, P., Ed.; Springer Singapore: Singapore, 2017; pp. 711–718. [Google Scholar]

- Shannon, P. The value-added ratio. Qual. Prog. 1997, 30, 94–97. [Google Scholar]

- Tamas, P.; Drávucz, D. Simulation Modelling in Logistics; Hungarian Book: Miskolc, Hungary, 2020. [Google Scholar]

- Tamás, P. Theoretical Foundation and Development of a Test Method for the Organization of the Storage Activity of Finished Products. Hungarian Dissertation, University of Miskolc, Miskolc, Hungary, 2012. [Google Scholar]

- Zou, W. Managing the Complexity of Service Contracting in Buyer-Supplier Collaboration. 2022. Available online: https://aaltodoc.aalto.fi/handle/123456789/113134 (accessed on 1 February 2023).

- Haditechnikai Eszközök Összehasonlítása KÖZBESZERZÉSI Eljárás Során.” (In Hungarian). Available online: https://hadmernok.hu/archivum/2006/2/2006_2_gyarmati.pdf (accessed on 26 January 2023).

- Kavas, L. The problem of weight numbers during the evaluation of complex systems. Aeronaut. Sci. J. 2007. Available online: https://www.repulestudomany.hu/kulonszamok/2007_cikkek/kavas_laszlo.pdf (accessed on 18 January 2023).

- Pataki, A. “Oktatási Segédlet Folyamatfejlesztés, Minőségszabályozás Című Tárgyhoz” adoc.pub. 2010. Available online: https://adoc.pub/oktatasi-segedlet-folyamatfejlesztes-minsegszabalyozas-cim-t.html (accessed on 21 October 2022).

| Publication Topic | Solution | Literature Reference Identifier in the Thesis |

|---|---|---|

| Sustainable production and overall process efficieny | Research and development, efficient and effective implementation | [3] |

| Food waste, spread of harmful products | Timely acces to information, sustainability | [6] |

| Extending product life with packaging | New packaging | [9] |

| Providing the necessary information to consumers | Labelling, the importance of correct packaging | [10,11,12,13] |

| Packaging system performance | Packaging scorecard | [19] |

| Contactless packaging solution | Decision support system | [20] |

| Tasks to be performed by a packaging system in a retail supply chain | Increasing awareness | [21] |

| Sustainable packaging in the supply chain | A literature review of 20 years of studies | [22] |

| Food and processing industry packaging development, packaging designs | Using integrated approach | [23,24] |

| Reusable packaging and system costs | Description of the case study | [25] |

| Applying the digital twin concept to proactively diagnose the system | Modernisation of production systems | [26] |

| Industry 4.0 applicability in packaging and its gaps | Applying the benefits of Industry 4.0 | [27] |

| Gaps in material handling systems for cloud manufacturing | Introducing a new material handling paradigm | [28] |

| Managing recyclable packaging in the automotive industry | Reusable packaging in preparation for the delivery of the finished product | [29] |

| Using sustainable materials and designs for packaging goods | Green packaging | [30,31] |

| Sustainable management practices | Data content analysis | [32,33,34] |

| Operation of short food supply chains | Innovations with digital elements | [35] |

| Food supply chain | Innovative and environmentally friendly technological solutions | [36] |

| Cargo transport in seaports, sustainability | Digitalization, improvements | [37,40,42] |

| Food safety | Overview of project work | [38] |

| Automatic identification of meat products at labelling level | RFID, UHF, NFC technologies | [39] |

| PC-based serious game evaluation study | Packaging logistics game to train employees | [41] |

| Reducing food waste | The role of correct packaging | [43] |

| Name of Product | Material Flow Object | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | … | |

| Product_1 | 1 | 2 | 3 | 4 | 5 | … |

| Material Flow Object | Material Flow Object | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | … | |

| 1 | 1 | |||||

| 2 | 1 | |||||

| 3 | 1 | |||||

| 4 | 1 | |||||

| … | ||||||

| Node ID | Name of Technological Equipment | Product Type | Operation Time [sec/pcs] | Setup Time [sec/type] | Capacity [pcs] | Width [mm] | Length [mm] | Specific Property |

|---|---|---|---|---|---|---|---|---|

| 10 | Abrasive blast equipment | Product_I | 300 | - | 1500 | 2000 | 2000 | handling products together |

| … |

| Name | Speed [m/s] | Remark |

|---|---|---|

| HK2 | 0.2 | Roller conveyor |

| HK3 | 0.2 | Roller conveyor |

| HK4 | 0.005 | Roller conveyor |

| HK5 | 0.01 | Heat treatment unit |

| MU | Number | Name |

|---|---|---|

| .UserObjects.Product_I | 4000 | Product_I |

| .UserObjects.Product_II | 3000 | Product_II |

| .UserObjects.Product_III | 7000 | Product_III |

| Version | Pallet1 | Pallet2 | Pallet3 | FPallet1 | FPallet2 | Lead Time | Quality | Cost |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | ||||||

| 2 | 1 | 1 | ||||||

| 3 | 1 | 1 | ||||||

| 4 | 1 | 1 | ||||||

| 5 | 1 | 1 | ||||||

| 6 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matyi, H.; Tamás, P. Operational Concept of an Innovative Management Framework for Choosing the Optimal Packaging System for Supply Chains. Sustainability 2023, 15, 3432. https://doi.org/10.3390/su15043432

Matyi H, Tamás P. Operational Concept of an Innovative Management Framework for Choosing the Optimal Packaging System for Supply Chains. Sustainability. 2023; 15(4):3432. https://doi.org/10.3390/su15043432

Chicago/Turabian StyleMatyi, Henriett, and Péter Tamás. 2023. "Operational Concept of an Innovative Management Framework for Choosing the Optimal Packaging System for Supply Chains" Sustainability 15, no. 4: 3432. https://doi.org/10.3390/su15043432

APA StyleMatyi, H., & Tamás, P. (2023). Operational Concept of an Innovative Management Framework for Choosing the Optimal Packaging System for Supply Chains. Sustainability, 15(4), 3432. https://doi.org/10.3390/su15043432