Evaluation of Aloe barbadensis Miller and Musa x paradisiaca as Internal Curing Agents in Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spectra Analysis of Admixtures

2.3. Mix Design

| Assumed target mean compressive strength | =38.25 MPa |

| Maximum size of aggregates | =20 mm |

| Water–cement ratio | =0.45 |

2.3.1. Fresh Concrete Properties

2.3.2. Hardened Concrete Properties

2.4. Microstructure Studies

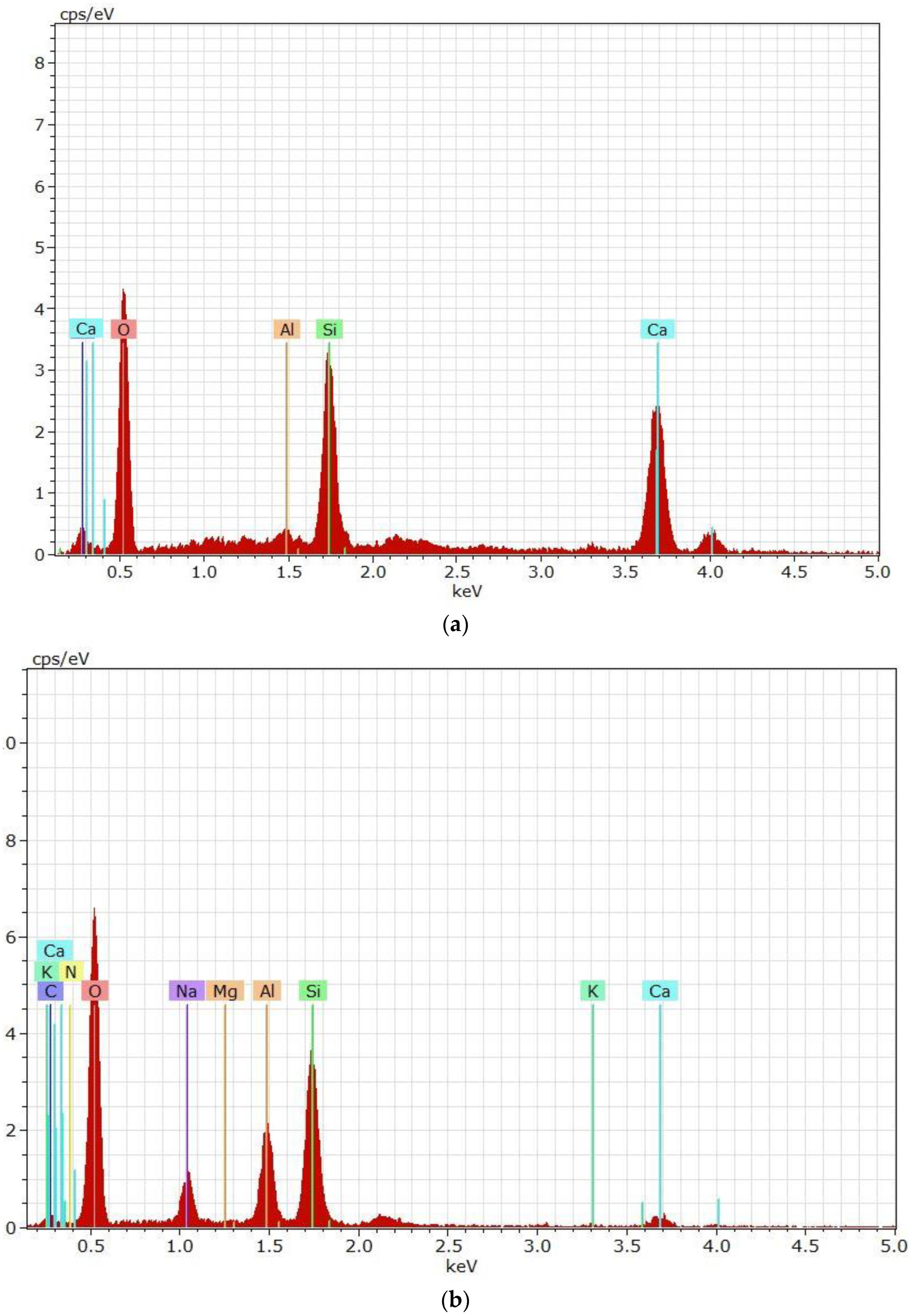

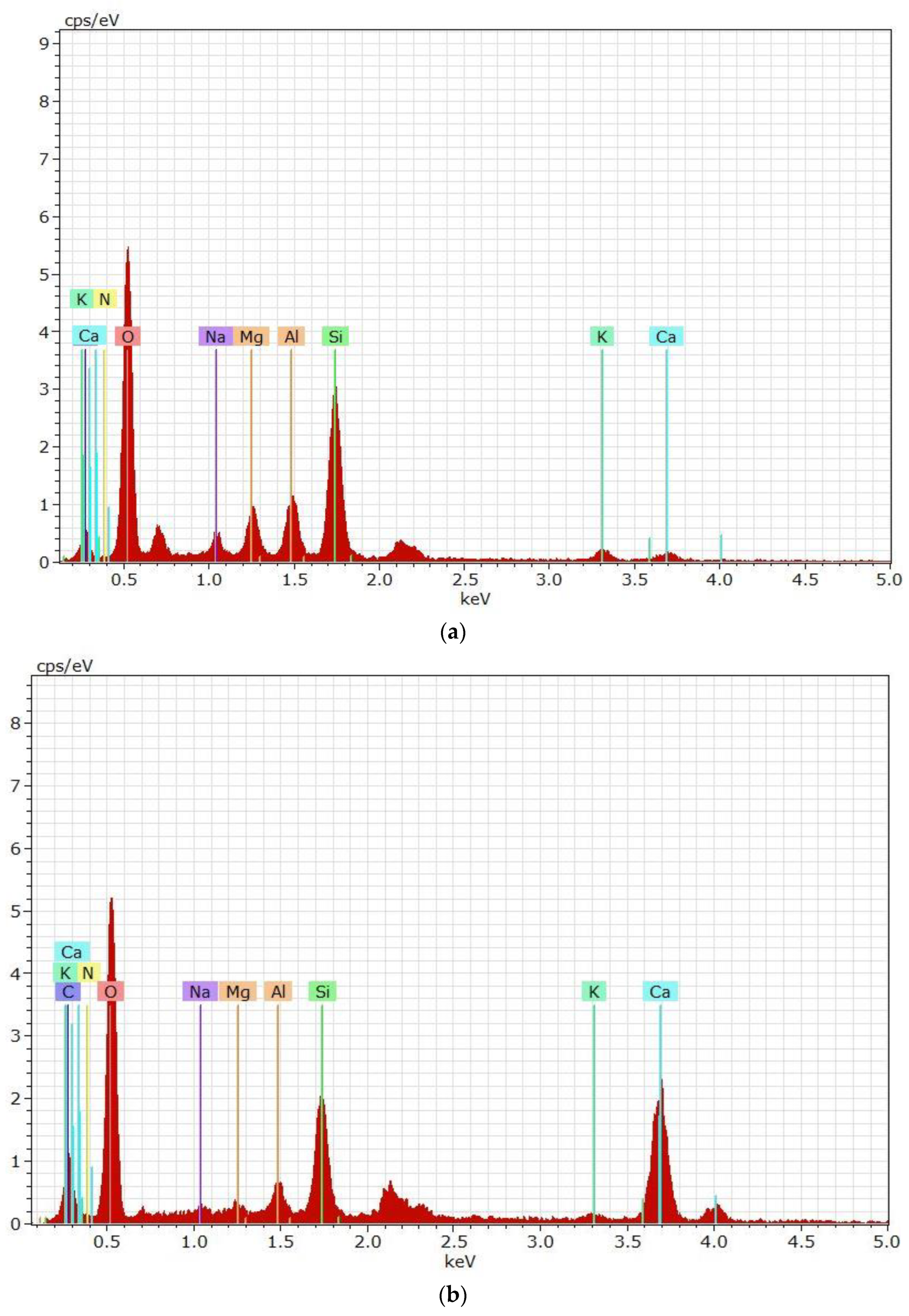

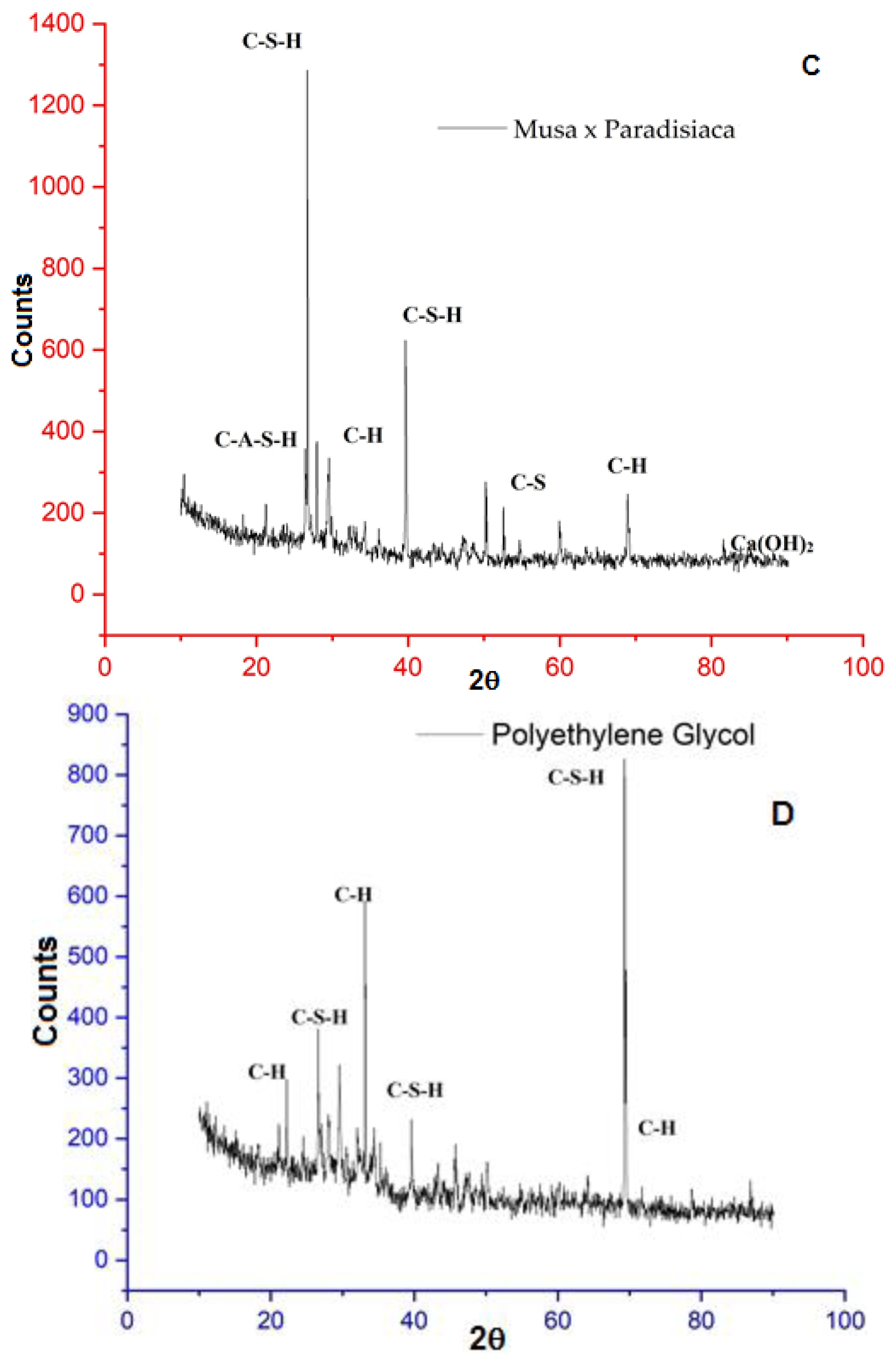

2.4.1. SEM/EDX

2.4.2. Thermogravimetric Analysis (TGA)

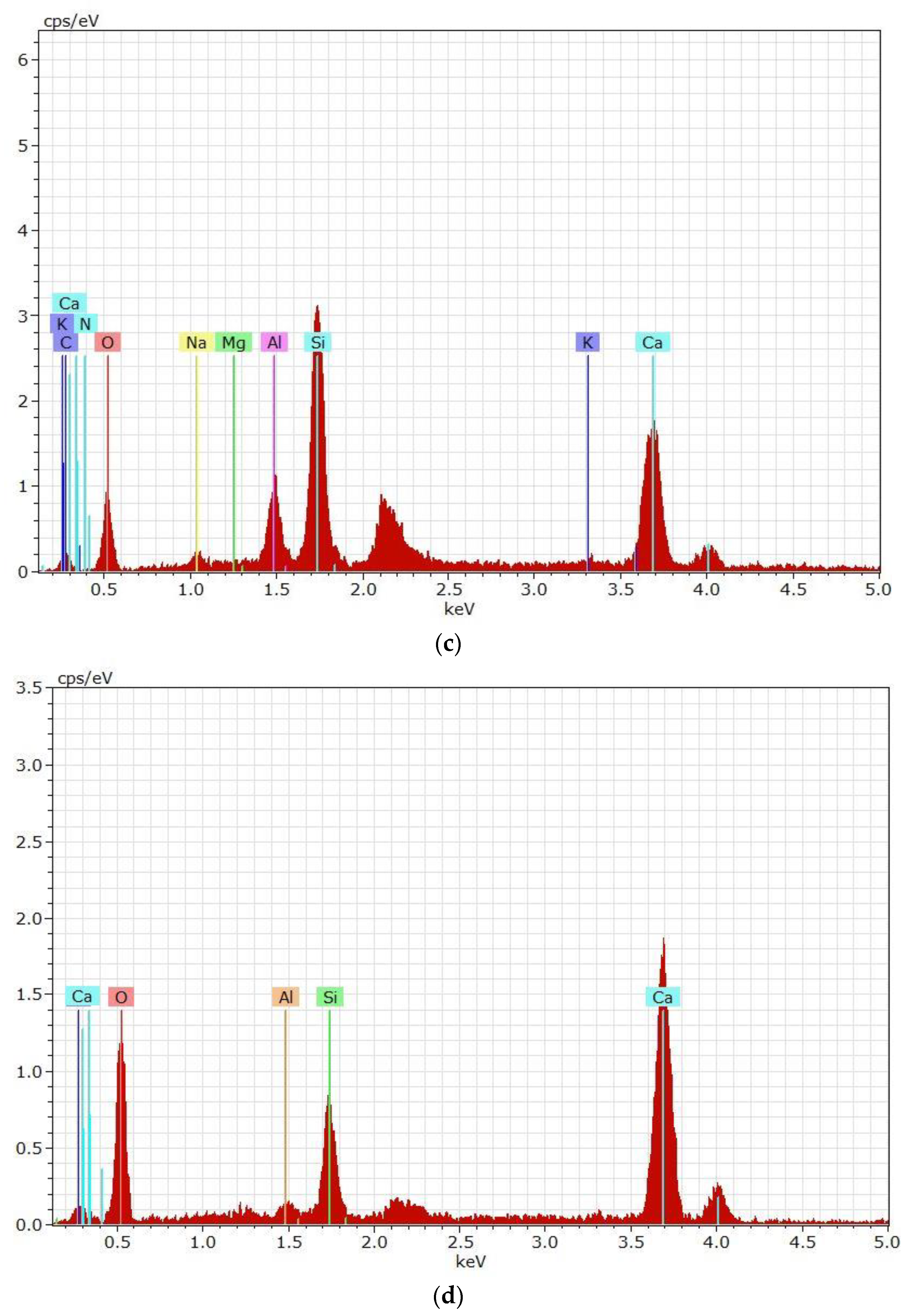

2.4.3. X-ray Powder Diffraction (XRD)

3. Results and Discussions

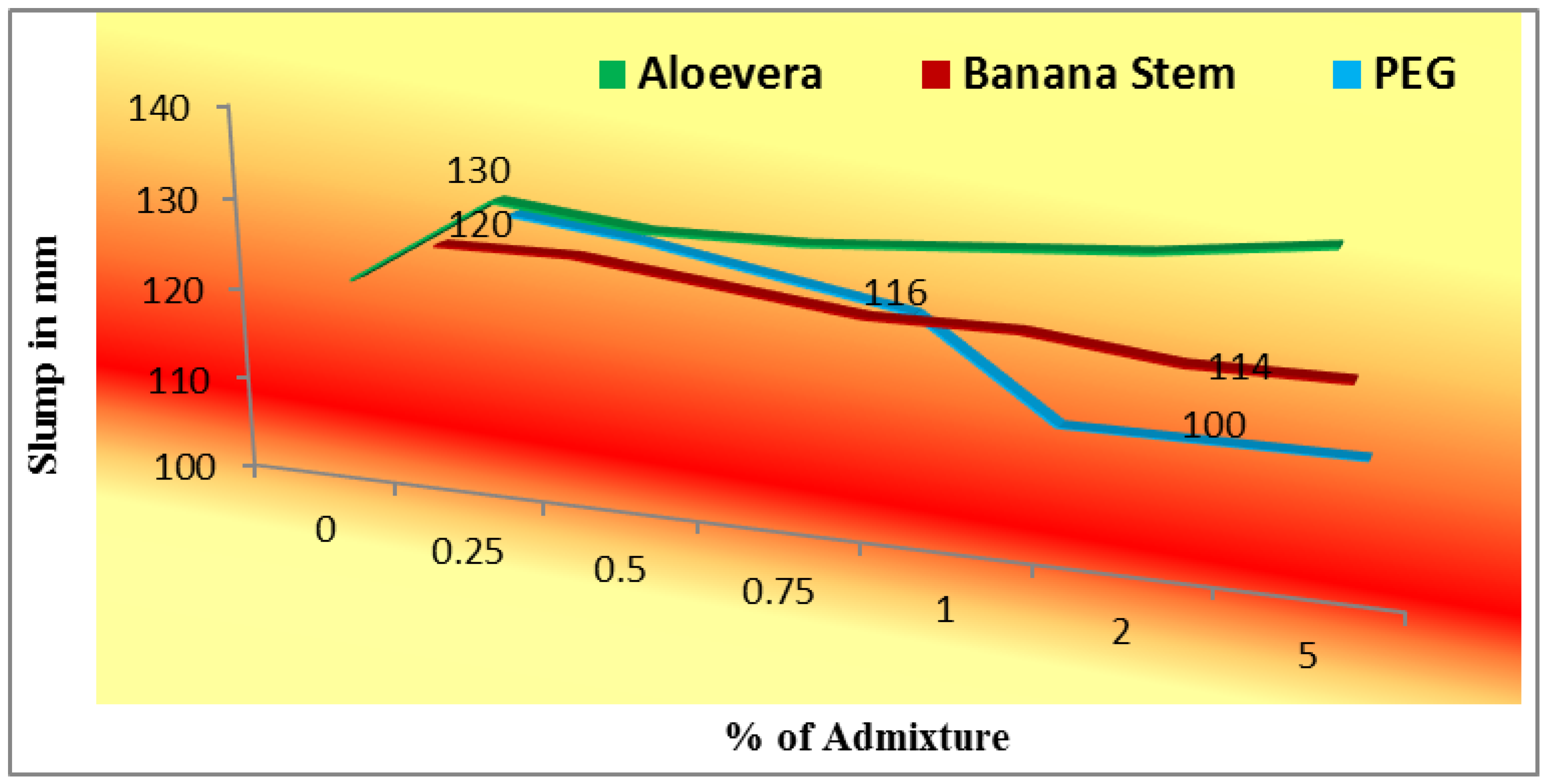

3.1. Fresh Concrete Properties

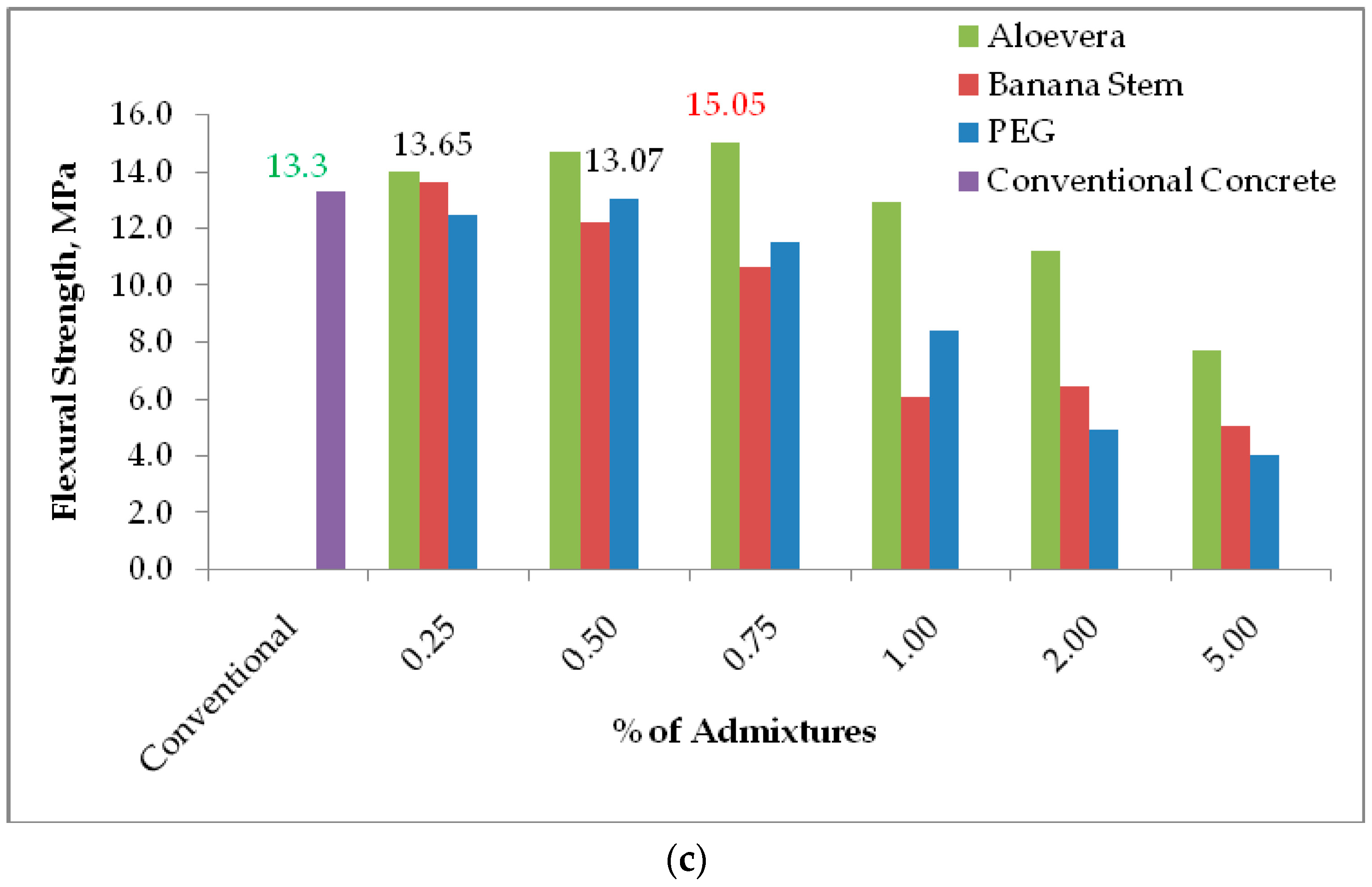

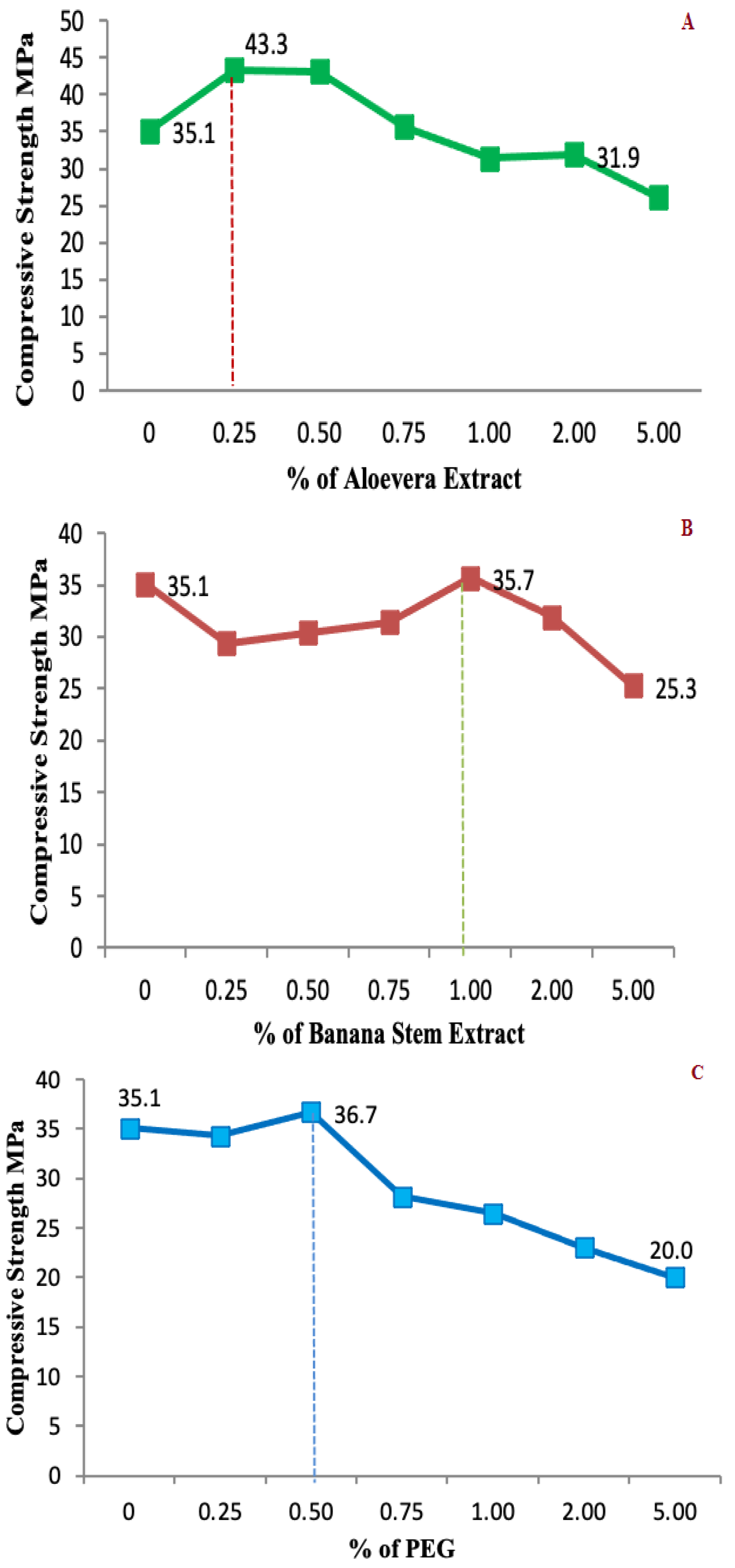

3.2. Strength Properties of Concrete

3.3. Optimum Dosage of Admixtures

3.4. Microstructure Studies

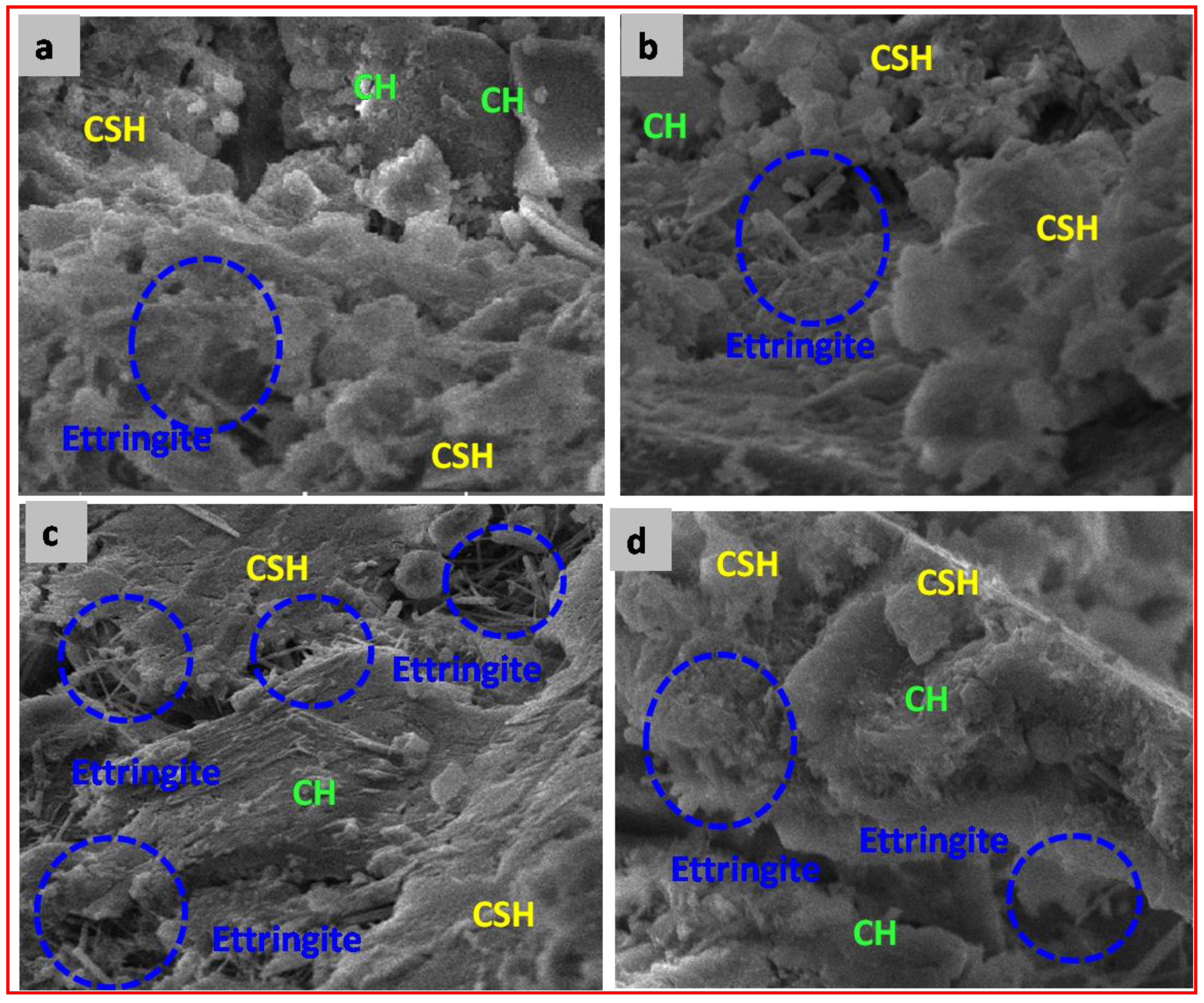

3.4.1. SEM/EDX

3.4.2. XRD

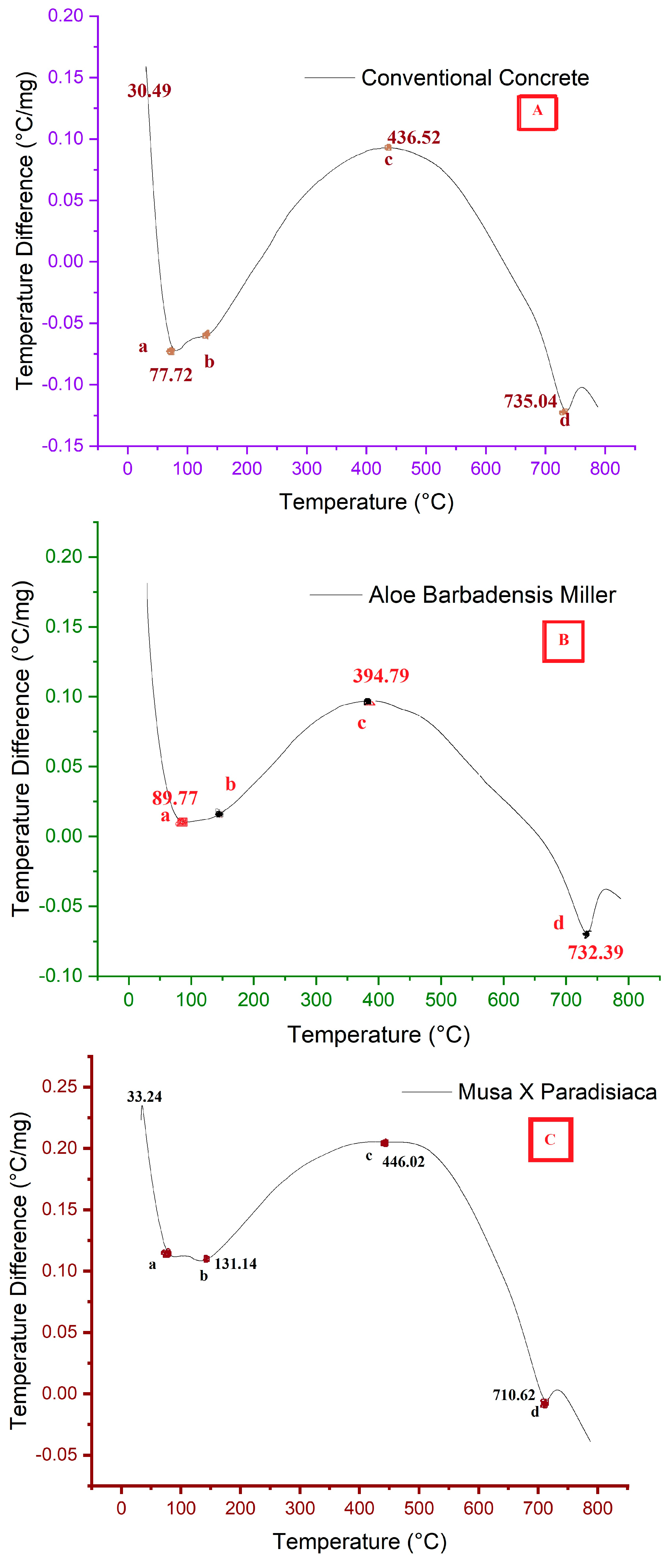

3.4.3. Thermogravimetric Analysis/Differential Thermal Analysis

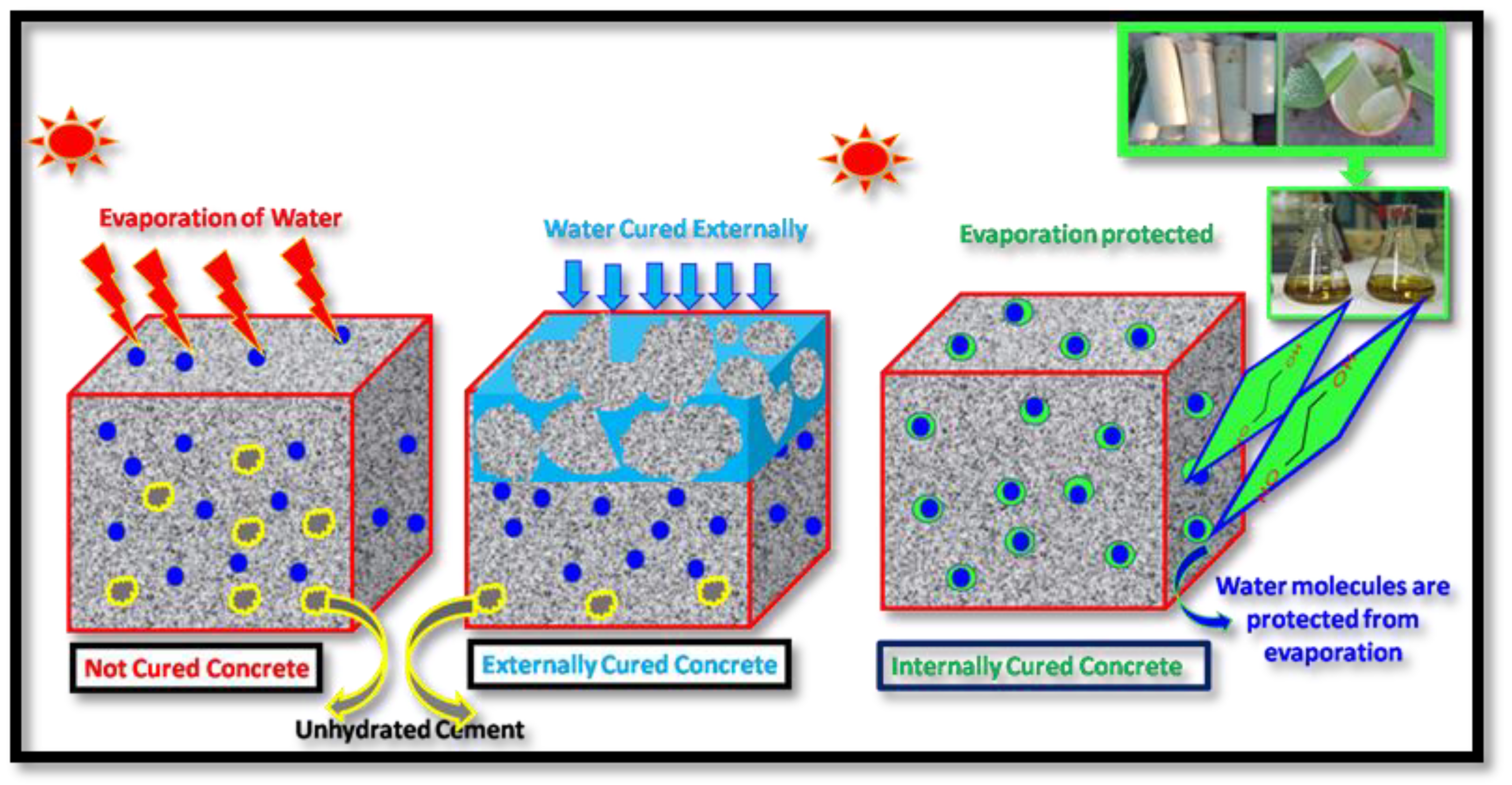

3.5. Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UV-Visible | Ultra Violet visible |

| FT-IR | Fourier-Transform Infrared Spectroscopy |

| GC-MS | Gas Chromatography-Mass Spectrometry |

| SEM | Scanning Electron Microscope |

| EDX | Energy Dispersive X-ray |

| XRD | X-ray Diffraction |

| TGA | Thermogravimetric Analysis |

| DTA | Differential Thermal Analysis |

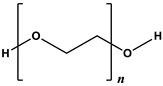

| PEG | Polyethylene Glycol |

| TNPCB | Tamilnadu Pollution Control Board |

| FA | Fine Aggregate |

| CA | Coarse Aggregate |

| RCC | Ordinary Reinforced Cement Concrete |

| CH | Calcium Hydroxide |

| CS | Calcium Silicate |

| CSH | Calcium Silicate Hydroxide |

| RH | Relative Humidity |

References

- History of Concrete. Available online: https://www.worldscientific.com/ (accessed on 26 November 2022).

- Herzog, A. The Concrete Conundrum, 2008, PP 62–66. Available online: https://www.rsc.org/images/Construction_tcm18-114530.pdf (accessed on 6 February 2023).

- Nurdeen, M.; Kabir, S. A Comparative Study on the Effect of Cement Source on Engineering Properties of Concrete. In Proceedings of the 5th National Civil Engineering Conference AWAM, Kalalumbur, Malaysia, 27–29 October 2016; Volume 9, pp. 27–29. [Google Scholar]

- Yilmaz, M.; Bakis, A. Sustainability in Construction Sector. Procedia-Soc. Behav. Sci. 2015, 195, 2253–2262. [Google Scholar] [CrossRef] [Green Version]

- Raheem, A.A.; Soyingb, A.A.; Emenika, A. Effects of Curing Methods on Density and Compressive Strength of Concrete. Int. J. Appl. Sci. Technol. 2013, 3, 55–64. [Google Scholar]

- Nassif, H.; Suksawang, N. Effects of Curing Methods on Durability of High-Performance Concrete. Transp. Res. Rec. J. Transp. Res. Board 2002, 1798, 31–38. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; van Breugel, K.; Copuroglu, O. Hydration and Microstructure of Ultra-High Performance Concrete Incorporating Rice Husk Ash. Cem. Concr. Res. 2011, 41, 1104–1111. [Google Scholar] [CrossRef]

- Pawar, Y.; Kate, S. Curing of Concrete: A Review. Int. Res. J. Eng. Technol. 2020, 07, 1820–1824. [Google Scholar]

- Usman, N.; Isa, M.N. Curing Methods and Their Effects on The Strength of Concrete. Int. J. Eng. Res. Appl. 2015, 05, 107–110. [Google Scholar]

- Nduka, D.; Ameh, J.; Joshua, O.; Ojelabi, R. Awareness and Benefits of Self-curing Concrete in Construction Projects: Builders and Civil Engineers Perceptions. Buildings 2018, 8, 109. [Google Scholar] [CrossRef] [Green Version]

- Subramani, R.; Rajan, D. Experimental Study on Impact on Fineness of Sand and M-Sand in M20 Grade of Concrete. Mater. Today Proc. 2020, 21, 36–40. [Google Scholar] [CrossRef]

- A Handbook of Sand Mining Framework, Ministry of Mines, Government of India. 2018. Available online: www.mines.gov.in/writereaddata/UploadFile/sandminingframework260318.pdf (accessed on 15 November 2022).

- Murali Krishnan, S.; Felix Kala, T.; Asha, P.; Elavenil, S. Properties of Concrete using Manufactured Sand as Fine Aggregat. Int. J. ChemTech Res. 2018, 11, 94–100. [Google Scholar]

- Public Works Department, Circular Memorandum No. AEE/T10/57017/2007, Dated 09.05.2008, Office of the Chief Engineer (Building), Chepauk, Chennai-600 005, Tamilnadu. Available online: https://gtmsind.com/Doc/CIRCULARS%20FOR%20CRUSHED%20STONE%20SAND%20OR%20M-SAND.pdf (accessed on 20 November 2022).

- Enforcement & Monitoring Guidelines for Sand Mining, Ministry of Environment, Forest and Climate Change, January 2020. Available online: http://environmentclearance.nic.in/writereaddata/SandMiningManagementGuidelines2020.pdf (accessed on 23 November 2022).

- Ma, X.; Liu, J.; Shi, C. A Review on the use of LWA as an Internal Curing Agent of High-Performance Cement Based Materials. Constr. Build. Mater. 2019, 218, 385–393. [Google Scholar] [CrossRef]

- El-Dieb, A.S. Self-curing Concrete: Water Retention, Hydration and Moisture Transport. Constr. Build. Mater. 2007, 21, 1282–1287. [Google Scholar] [CrossRef]

- Wedatalla, A.M.O.; Jia, Y.; Ahmed, A.A.M. Curing Effects on High Strength Concrete Properties. Hindawi Adv. Civ. Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- Gunasekar, S.; Santhi, H.M. Self-Compacting Self-curing Low-Density Concrete Using Cinder Aggregate and PEG. Int. J. Civ. Eng. Technol. 2019, 10, 1030–1039. [Google Scholar]

- Paul, A.; Lopez, M. Assessing Light Weight Aggregate Efficiency for Maximizing Internal Curing Performance. ACI Mater. J. 2011, 108, 385–393. [Google Scholar]

- Eberhardt, A.B.; Flatt, R.J. Working Mechanisms of Shrinkage-Reducing Admixtures. Sci. Technol. Concr. Admix. 2016, 305–320. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W. A Starch-Based Admixture for Reduction of Hydration Heat in Cement Composites. Constr. Build. Mater. 2018, 173, 317–322. [Google Scholar] [CrossRef]

- Malathy, R.; Chung, I.-M.; Prabakaran, M. Characteristics of fly ash based concrete prepared with bio admixtures as internal curing agents. Constr. Build. Mater. 2020, 262, 120596. [Google Scholar] [CrossRef]

- Sabaoon, A.M.; Deepsingh, N. Experimental Investigation of Self-Curing Concrete by Using Natural and Chemical Admixtures. Indian J. Sci. Technol. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Kim, Y.J.; Wang, J. Interfacial Behavior of Glass Fiber Reinforced Polymer Bars Embedded in Concrete with Internal Curing Agents. ACI Struct. J. 2016, 113, 595–604. [Google Scholar] [CrossRef]

- Farooq, M.; Bhutta, A.; Banthia, N. Strain-Hardening Ambient-Cured Ecofriendly Ductile Geopolymer Composites. ACI Mater. J. 2020, 117, 181–189. [Google Scholar]

- Afroz, S.; Manzur, T.; Hossain, K.M.A. Arrowroot Bio-Admixture for Performance Enhancement of Concrete. J. Build. Eng. 2020, 30, 101313. [Google Scholar] [CrossRef]

- Seghir, N.T.; Mellas, M.; Sadowski, L.; Krolicka, A.; Zak, A. The Effect of Curing Conditions on the Properties of Cement-Based Composites Blended with Waste Marble Dust. J. Miner. Met. Mater. Soc. 2019, 71, 1002–1015. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Fu, S.; Zhan, H.; Zhan, Y.; Lucia, L.A. Analysis of the Chemical Composition and Morphological Structure of Banana Pseudo Stem. BioResources 2010, 05, 576–585. [Google Scholar]

- Elbehiry, A.; Mostafa, M. Performance of Concrete Beams Reinforced Using Banana Fiber Bars. Case Stud. Constr. Mater. 2020, 13, e00361. [Google Scholar] [CrossRef]

- Tiroutchelvame, T.; Pragalyaashree, M.M.; Peter, D. Process Development for the Value Addition of Banana Central Core [Pseudo Stem]. Int. J. Recent Technol. Eng. 2019, 08, 1055–1060. [Google Scholar] [CrossRef]

- Sahu, O.; Damne, B. Effect of Oven Drying Temperature on Banana Powder Quality. Asian J. Innov. Res. Sci. Eng. Technol. 2016, 1, 1–8. [Google Scholar]

- Elbehiry, A.; Mostafa, M. Finite Element Analysis of Beams Reinforced with Banana Fiber Bars. Fibers 2020, 08, 52. [Google Scholar] [CrossRef]

- Hamman, J.H. Composition and Application of Aloe Vera Gel. Molecules 2008, 13, 1599–1616. [Google Scholar] [CrossRef] [Green Version]

- Jawade, N.R.; Chavan, A.R. Ultrasonic Assisted Extraction of Aloin from Aloe Vera Gel. Procedia Eng. 2013, 51, 487–493. [Google Scholar] [CrossRef]

- Lawrrence, R.; Tripathi, P.; Jeyakumar, E. Isolation, Purification and Evaluation of Antibacterial Agents from Aloe Vera. Braz. J. Microbiol. 2009, 40, 906–915. [Google Scholar] [CrossRef] [Green Version]

- Quispe, C.; Villalobos, M.; Borquez, J.; Simirgiotis, M. Chemical Composition and Antioxidant Activity of Aloe Vera from the Pica Oasis [Tarapaca, Chile] By UHPLC-Q/Orbitrap/MS. J. Chem. 2018, 2018, 6123850. [Google Scholar] [CrossRef] [Green Version]

- Dahyabhai, P.M.; Pitroda, J. Self-Curing Concrete: New Technique for Concrete Curing–A Literature Review. J. Int. Acad. Res. Multidiscip. 2013, 1, 539–544. [Google Scholar]

- Suryawanshi, N.; Thakare, S. Water-Soluble Super Absorbent Polymer as Self-curing Agents in High-Strength Cement Concrete Mixes. Adv. Comput. Methods Geomech. 2020, 56, 553–563. [Google Scholar] [CrossRef]

- Sudharson, G.; Kalpana, M.; Anburaja, D.; Prathap, M.G. PEG 400 Effect on Properties of Self Curing Concrete. IOP Conf. Series Mater. Sci. Eng. 2021, 1026, 012014. [Google Scholar] [CrossRef]

- Bele, A.A.; Khale, A. Comparison of Constituents in Aloe vera Gel Collected in Different Seasons by Chromatography and Spectroscopy Techniques. World J. Pharm. Res. 2016, 05, 1028–1040. [Google Scholar]

- Niamah, A.K. Determination, Identification of Bio-Active Compounds Extracts from Yellow Banana Peels and Used in Vitro as Antimicrobial. Int. J. Phytomed. 2014, 06, 625–632. [Google Scholar]

- Borges, A.H.; Guedes, O.A.; Volpato, L.E.R.; Filho, G.S.; Borba, A.M.; Zina, O.; Piva, E.; Estrela, C. Physicochemical Properties of MTA and Portland Cement After Addition of Aloe Vera. Iran. Endod. J. 2017, 12, 312–317. [Google Scholar]

- Reddy, N.; Naqash, A. Experimental Study on TGA, XRD and SEM analysis of Concrete with Ultra-fine Slag. Int. J. Eng. 2019, 32, 679–684. [Google Scholar]

- Younis, M.O.; Amin, M.; Tahwia, A.M. Durability and Mechanical Characteristics of Sustainable Self-curing Concrete Utilizing Crushed Ceramic and Brick Wastes. Case Stud. Constr. Mater. 2022, 17, e01251. [Google Scholar] [CrossRef]

- Meng, F.; Wang, G.; Du, X.; Wang, Z.; Xu, S.; Zhang, Y. Extraction and characterization of cellulose nanofibers and nanocrystals from liquefied banana pseudo-stem residue. Compos. Part B Eng. 2018, 160, 341–347. [Google Scholar] [CrossRef]

- Xu, S.; Xiong, C.; Tan, W.; Zhang, Y. Microstructural, Thermal, and Tensile Characterization of Banana Pseudo-stem Fibres Obtained with Mechanical, Chemical, and Enzyme Extraction. BioResources 2015, 10, 3724–3735. [Google Scholar] [CrossRef] [Green Version]

- Khaleel, O.; Al-Mishhadani, S.; Razak, H.A. The Effect of Coarse Aggregate on Fresh and Hardened Properties of Self-Compacting Concrete, The Twelfth East Asia-Pacific Conference on Structural Engineering and Construction. Procedia Eng. 2011, 14, 805–813. [Google Scholar] [CrossRef] [Green Version]

- Danso, H. Influence of Plantain Pseudostem fibres and Lime on the Properties of Cement Mortar. Hindawi Adv. Mater. Sci. Eng. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Malathy, R.; Narayanan, K.; Mayakrishnan, P. Performance of prestressed concrete beams using magnetic water for concrete mixing. J. Adhes. Sci. Technol. 2022, 36, 666–684. [Google Scholar] [CrossRef]

- Ramalingam, M.; Narayanan, K.; Masilamani, A.; Kathirvel, P.; Murali, G.; Vatin, N.I. Influence of Magnetic Water on Concrete Properties with Different Magnetic Field Exposure Times. Materials 2022, 15, 4291. [Google Scholar] [CrossRef]

- Zhou, Z.; Sofi, M.; Lumantarna, E.; Nicolas, R.S.; Mend, G.H.A. Strength Development and Thermogravimetric Investigation of High-Volume Fly Ash Binders. Materials 2019, 12, 3344. [Google Scholar] [CrossRef] [Green Version]

- Ramalingam, M.; Narayanan, K.; Sivamani, J.; Kathirvel, P.; Murali, G.; Vatin, N.I. Experimental Investigation on the Potential Use of Magnetic Water as a Water Reducing Agent in High Strength Concrete. Materials 2022, 15, 5219. [Google Scholar] [CrossRef]

| S. No. | Material Properties | Remarks |

|---|---|---|

| 1. | Specific gravity of cement | 3.10 |

| 2. | Specific gravity of FA and CA | 2.57 and 2.72 |

| 3. | Fineness modulus of FA and CA | 2.70 and 6.4 |

| 4. | Impact value of coarse aggregate | 17% |

| 5. | pH of water | 7.0 |

| 6. | pH of Musa x paradisiaca tree stem | 6.5 |

| 7. | pH of Aloe barbadensis miller | 5.5 |

| 8. | Bulk density of FA and CA | 1450 and 1750 kg/m3 |

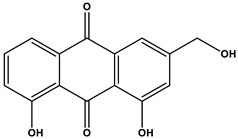

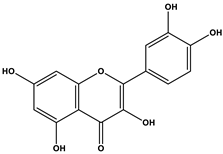

| Name of the Admixture | Functional Group | Role |

|---|---|---|

| Aloe barbadensis Miller |  | The presence of Hydroxyl ether in plants holds water initially and releases whenever needed for hydration of cement in concrete. |

| Musa x paradisiaca |  | |

| Polyethylene Glycol |  | The presence of the polyether group reduces self-desiccation and works through the retention of water molecules around the particle layer of concrete ingredients. Hence, continuous hydration of concrete is enabled. |

| Cement | Fine Aggregate | Coarse Aggregate | Water |

|---|---|---|---|

| 420 kg | 640 kg | 1155 kg | 190 L |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malathy, R.; Selvam, B.; Prabakaran, M. Evaluation of Aloe barbadensis Miller and Musa x paradisiaca as Internal Curing Agents in Concrete. Sustainability 2023, 15, 3591. https://doi.org/10.3390/su15043591

Malathy R, Selvam B, Prabakaran M. Evaluation of Aloe barbadensis Miller and Musa x paradisiaca as Internal Curing Agents in Concrete. Sustainability. 2023; 15(4):3591. https://doi.org/10.3390/su15043591

Chicago/Turabian StyleMalathy, Ramalingam, Balakrishnan Selvam, and Mayakrishnan Prabakaran. 2023. "Evaluation of Aloe barbadensis Miller and Musa x paradisiaca as Internal Curing Agents in Concrete" Sustainability 15, no. 4: 3591. https://doi.org/10.3390/su15043591

APA StyleMalathy, R., Selvam, B., & Prabakaran, M. (2023). Evaluation of Aloe barbadensis Miller and Musa x paradisiaca as Internal Curing Agents in Concrete. Sustainability, 15(4), 3591. https://doi.org/10.3390/su15043591