Critical Conditions for Wellbore Failure during CO2-ECBM Considering Sorption Stress

Abstract

1. Introduction

2. Model Development

2.1. Stress–strain Constitutive Equation

2.2. Analytical Model of Stress Distribution around the Wellbore

2.2.1. Simplifications and Assumptions

- (1)

- The tectonic stress affects the coal seams and the initial in-situ stress is anisotropic;

- (2)

- A steady reservoir pressure profile changing logarithmically from a constant borehole pressure at the wellbore () to a reservoir pressure at the outer boundary ();

- (3)

- Gas injection can occur after depletion, in which case the reservoir pressure is unequal to the initial value before depletion ();

- (4)

- A zero displacement at the outer boundary rather than each point (common uni-axial strain model) in the reservoir [15];

- (5)

- A plane strain condition near the wellbore and a constant overburden far from the wellbore [14];

- (6)

- At the final steady state, uniform gas composition of the injected gas is achieved.

2.2.2. Mode 1: Stresses Induced by the Initial In-Situ Stress and Borehole Pressure

2.2.3. Mode 2: Stresses Induced by Poroelastic Response and Gas Adsorption

2.2.4. The Total Stresses around the Wellbore with Anisotropic In-Situ Stress

2.3. Failure Criterion

3. Induced Stress during CO2-ECBM and Parametric Analysis

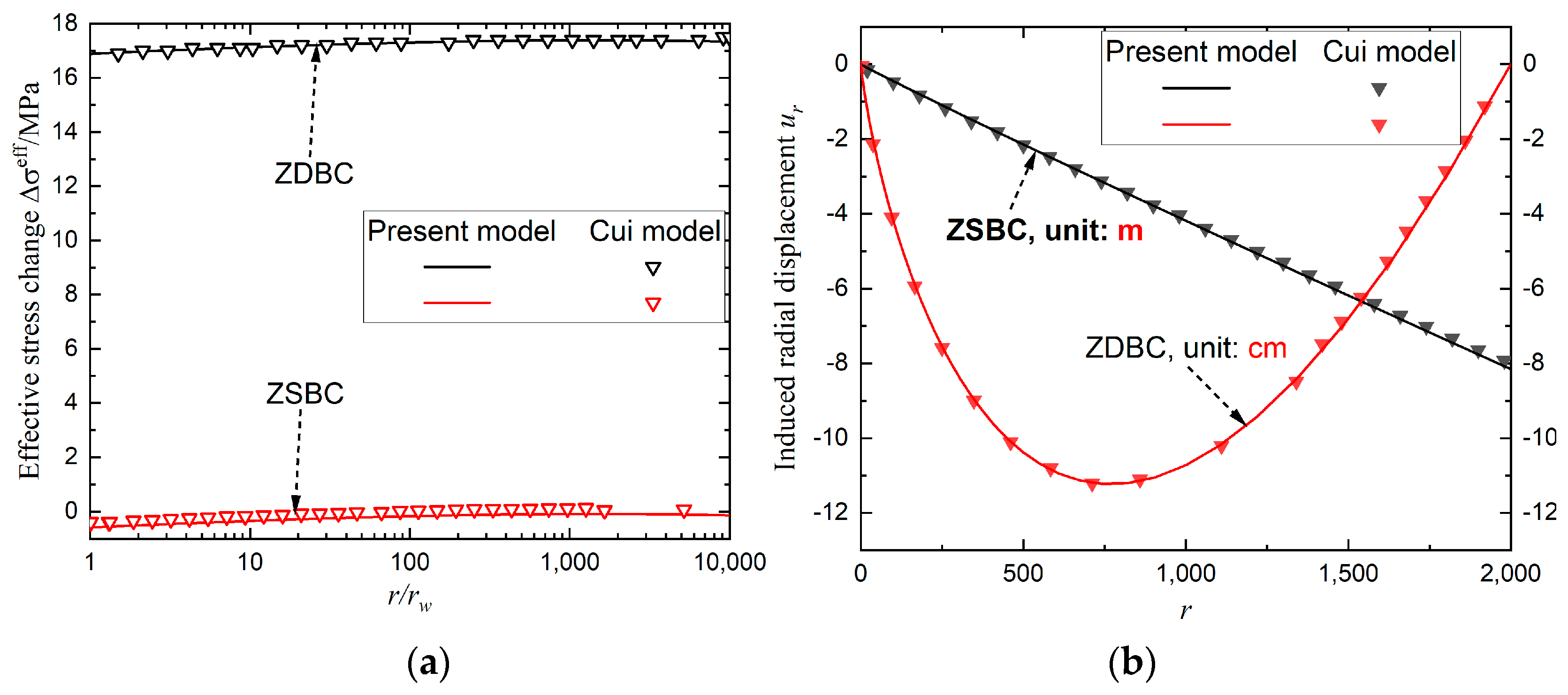

3.1. Model Verification

3.2. The Stress Caused by Poroelastic Response and Gas Adsorption

3.2.1. The Influence of Langmuir-Type Constants ()

3.2.2. The Influence of Young Modulus and Poisson Ratio of Coal

3.2.3. The Influence of Gas Component

4. Wellbore Stability Analysis during Mixture Gas Injection

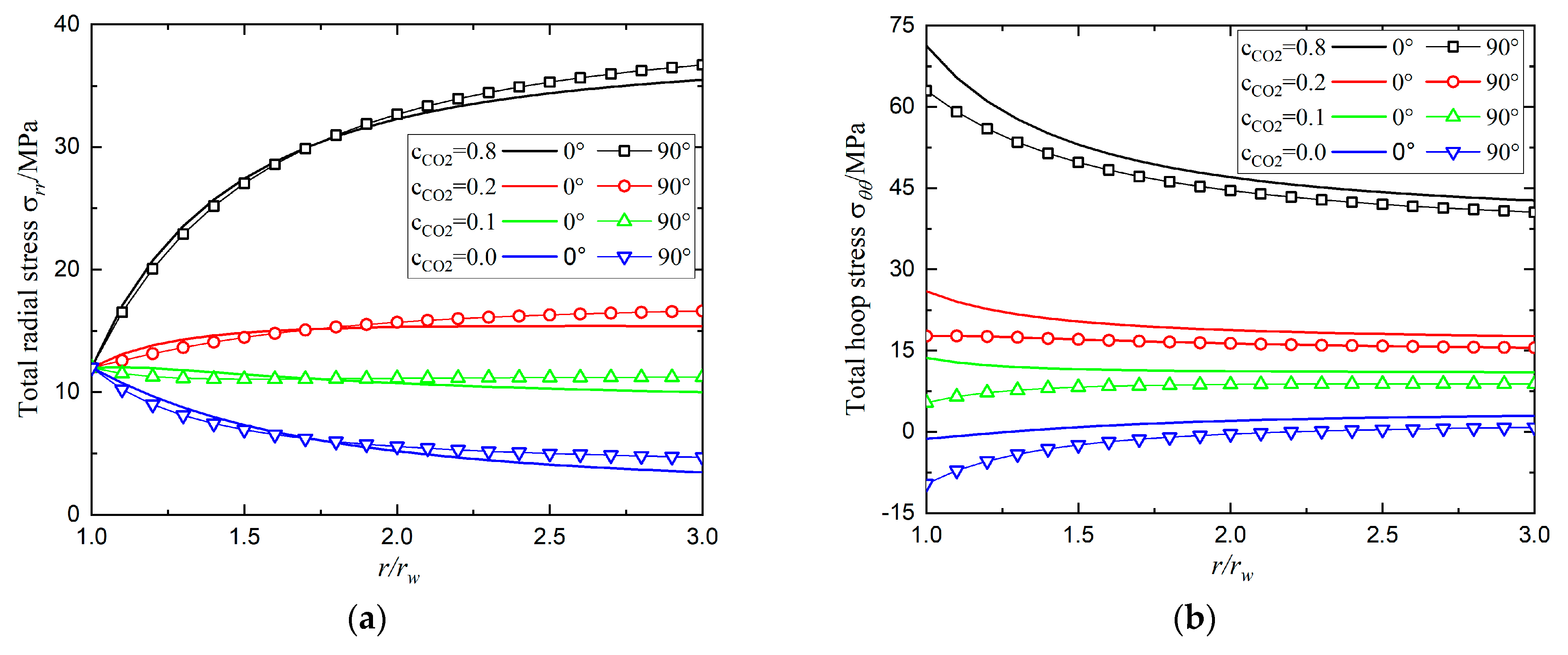

4.1. The Total Stress and Failure Index around the Borehole

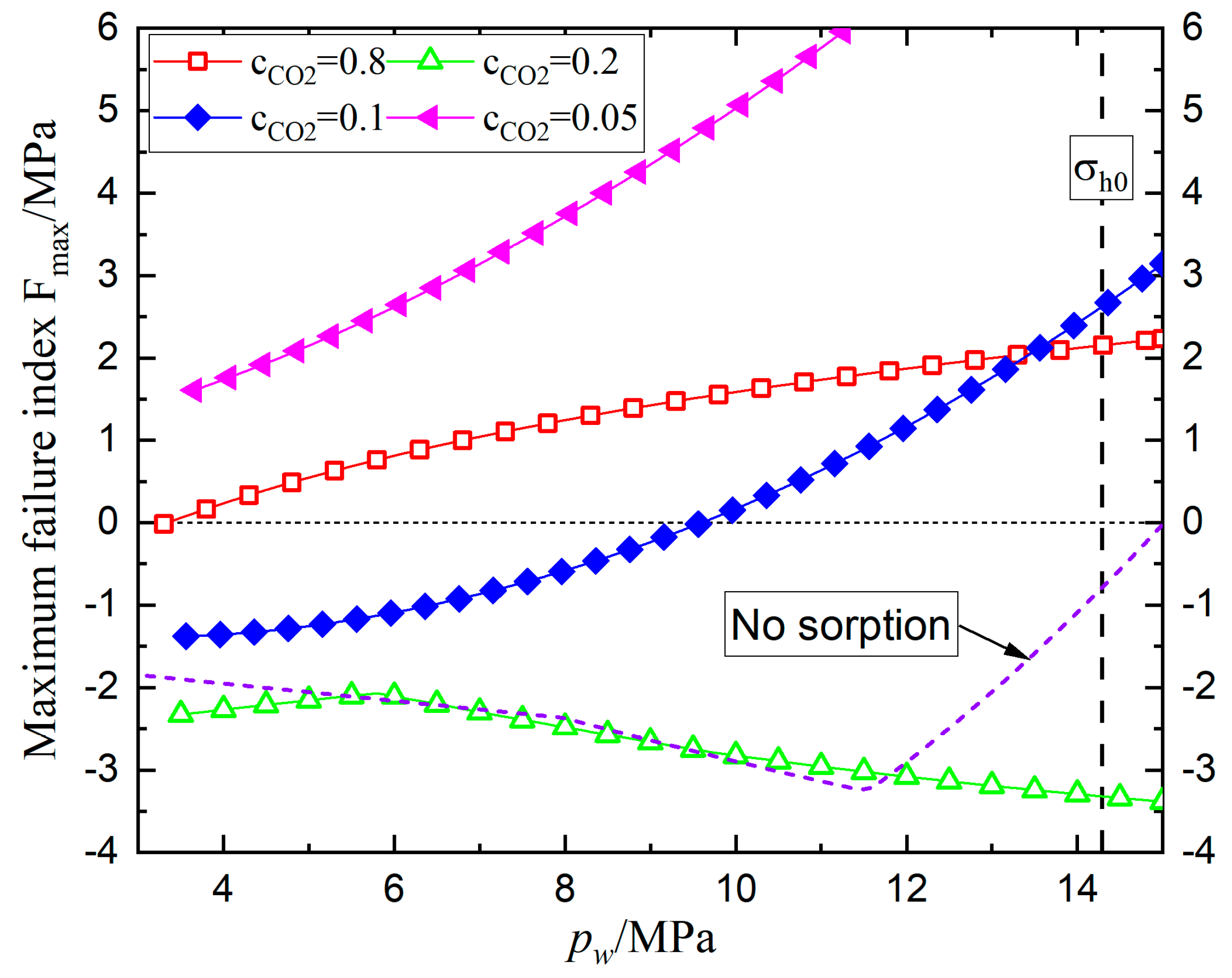

4.2. Critical Borehole Pressure and Gas Component (CBPGC)

5. Conclusions and Suggestions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| i | Gas type |

| Volumetric strain due to adsorption and deformation | |

| Langmuir-type swelling constants | |

| Langmuir-type adsorption constants | |

| Young modulus and Poisson ratio | |

| Kronecker’s delta | |

| Biot coefficient | |

| Initial and depleted reservoir pressure, respectively | |

| Borehole pressure | |

| Directional index in cylindrical coordinates | |

| Radius of wellbore and outer boundary | |

| Initial maximum, minimum horizontal, and vertical stress, respectively | |

| Normal and shear stress components due to in-situ stress and borehole pressure | |

| Radial and hoop stress due to poroelastic response and gas adsorption, respectively | |

| Total stress components, respectively | |

| Total stress components at the wellbore | |

| Incremental reservoir pressure and volumetric strain, respectively | |

| Integration constants | |

| Integration constants related to poroelastic response and sorption effect, respectively | |

| Wellbore failure index | |

| Rock cohesion and friction angle | |

| Maximum, median, and minimum stress, respectively | |

| Octahedral shear stress | |

| Mogi–Coulomb coefficients | |

| Gas component of CO2 and N2, respectively | |

| CBPGC | Critical borehole pressure and gas component of CO2 |

| ZDBC | Zero displacement condition at outer boundary |

| ZSBC | Constant stress condition at outer boundary |

References

- De-Silva, P.N.K.; Ranjith, P.G.; Choi, S.K. A study of methodologies for CO2 storage capacity estimation of coal. Fuel 2012, 91, 1–15. [Google Scholar] [CrossRef]

- Masoudian, M.S.; Airey, D.W.; El-Zein, A. A chemo-poro-mechanical model for sequestration of carbon dioxide in coalbeds. Geotechnique 2013, 63, 235–243. [Google Scholar] [CrossRef]

- Fang, Z.; Li, X.C. A preliminary evaluation of carbon dioxide storage capacity in unmineable coalbeds in China. Acta Geotech. 2014, 9, 109–114. [Google Scholar] [CrossRef]

- Zoback, M.D.; Gorelick, S.M. To prevent earthquake triggering, pressure changes due to CO2 injection need to be limited. Proc. Natl. Acad. Sci. USA 2015, 112, E4510. [Google Scholar] [CrossRef] [PubMed]

- Palmer, I.D.; Moschovidis, Z.A.; Cameron, J.R. Coal failure and consequences for coalbed methane wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Shi, J.Q.; Durucan, S. Drawdown induced changes in permeability of coalbeds: A new interpretation of the reservoir response to primary recovery. Transp. Porous Media 2004, 56, 1–16. [Google Scholar] [CrossRef]

- Shi, J.Q.; Durucan, S. Variation in horizontal stress with pore pressure depletion in coal under uniaxial strain conditions: An update on the modelling of laboratory data. Int. J. Coal Geol. 2018, 187, 94–97. [Google Scholar] [CrossRef]

- Liu, S.; Harpalani, S. Evaluation of in situ stress changes with gas depletion of coalbed methane reservoirs. J. Geophys. Res. Solid Earth 2014, 119, 6263–6276. [Google Scholar] [CrossRef]

- Liu, T.; Liu, S.; Lin, B.; Fu, X.; Zhu, C.; Yang, W.; Zhao, Y. Stress response during in-situ gas depletion and its impact on permeability and stability of CBM reservoir. Fuel 2020, 266, 117083. [Google Scholar] [CrossRef]

- Hou, X.; Liu, S.; Li, G.; Zhu, Y.; Liu, A. Quantifying and modeling of in situ stress evolutions of coal reservoirs for helium, methane, nitrogen and CO2 depletions. Rock Mech. Rock Eng. 2021, 54, 3701–3719. [Google Scholar] [CrossRef]

- Lu, M.; Connell, L. Coal failure during primary and enhanced coalbed methane production-theory and approximate analyses. Int. J. Coal Geol. 2016, 154, 275–285. [Google Scholar] [CrossRef]

- Lu, M.; Connell, L. Coal seam failure during primary/enhanced gas production: How failure develops in fields. Int. J. Coal Geol. 2019, 221, 103432. [Google Scholar] [CrossRef]

- Espinoza, D.N.; Pereira, J.M.; Vandamme, M.; Dangla, P.; Vidal-Gilbert, S. Desorption-induced shear failure of coal bed seams during gas depletion. Int. J. Coal Geol. 2015, 137, 142–151. [Google Scholar] [CrossRef]

- Huang, F.S.; Kang, Y.L.; Liu, H.; You, L.J.; Li, X.C. Critical conditions for coal wellbore failure during primary coalbed methane recovery: A case study from the San Juan Basin. Rock Mech. Rock Eng. 2019, 52, 4083–4099. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, R.M.; Chikatamarla, L. Adsorption-induced coal swelling and stress: Implications for methane production and acid gas sequestration into coal seams. J. Geophys. Res. Solid Earth 2007, 112, B10202. [Google Scholar] [CrossRef]

- Reisabadi, M.Z.; Haghighi, M.; Salmachi, A.; Sayyafzadeh, M.; Khaksar, A. Analytical modelling of coal failure in coal seam gas reservoirs in different stress regimes. Int. J. Rock Mech. Min. Sci. 2020, 128, 104259. [Google Scholar] [CrossRef]

- Masoudian, M.S.; El-Zein, A.; Airey, D.W. Modelling stress and strain in coal seams during CO2 injection incorporating the rock–fluid interactions. Comput. Geotech. 2016, 76, 51–60. [Google Scholar] [CrossRef]

- Hu, C.; Wang, F.; Ai, C. A model of cement-formation interface failure length in supercritical CO2-ECBM and storage injection well considering the coal swelling effect under high pressure. J. Pet. Explor. Prod. Technol. 2019, 9, 2757–2767. [Google Scholar] [CrossRef]

- Li, Z.; Elsworth, D. Controls of CO2-N2 gas flood ratios on enhanced shale gas recovery and ultimate CO2 sequestration. J. Pet. Sci. Eng. 2019, 179, 1037–1045. [Google Scholar] [CrossRef]

- Wen, H.; Hao, J.; Ma, L.; Zheng, X.H. Experimental Study on Replacing Coal Seam CH4 with CO2 Gas. ACS Omega 2022, 7, 1395–1403. [Google Scholar] [CrossRef]

- Gong, H.R.; Wang, K.; Wang, G.D.; Yang, X.; Du, F. Underground coal seam gas displacement by injecting nitrogen: Field test and effect prediction. Fuel 2020, 306, 121646. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Yang, W.; Zhai, C.; Liu, T. Coal permeability evolution and gas migration under non-equilibrium state. Transp. Porous Medium 2017, 118, 393–416. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.S.; Elsworth, D. Evolution of coal permeability: Contribution of heterogenous swelling processes. Int. J. Coal Geol. 2011, 88, 152–162. [Google Scholar] [CrossRef]

- Bradley, W.B. Failure of inclined boreholes. J. Energy Resour. Technol. 1979, 101, 232–239. [Google Scholar] [CrossRef]

- Fjær, E.; Holt, R.M.; Horsrud, P.; Raaen, A.M.; Risnes, R. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Li, Y.; Wang, J.; Wang, Z.; Pan, Z. Variation in Permeability during CO2–CH4 Displacement in Coal Seams. Part 2: Modeling and Simulation. ACS Omega 2020, 5, 18432–18440. [Google Scholar] [CrossRef] [PubMed]

- Al-Shaaibi, S.K.; Al-Ajmi, A.M.; Al-Wahaibi, Y. Three dimensional modeling for predicting sand production. J. Pet. Sci. Eng. 2013, 109, 348–363. [Google Scholar] [CrossRef]

- Detournay, E.; Cheng, H.D. Poroelastic response of a borehole in a non-hydrostatic stress field. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 25, 171–182. [Google Scholar] [CrossRef]

- Al-Ajmi, A.M.; Zimmerman, R.W. Relation between the Mogi and the Coulomb failure criteria. Int. J. Rock Mech. Min. Sci. 2005, 42, 431–439. [Google Scholar] [CrossRef]

- Yin, S. Numerical analysis of thermal fracturing in subsurface cold water injection by finite element methods. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 15. [Google Scholar] [CrossRef]

| Parameters | Variables | Values |

|---|---|---|

| Poromechanical parameters | Young modulus E (MPa) | 4.35 |

| Poisson ratio | 0.3 | |

| Cohesion C(MPa) | 6.44 | |

| Friction angle | 45 | |

| Biot coefficient | 1 | |

| Adsorption parameters | Langmuir-type constants | N2: 0.0074; CH4: 0.0106; CO2: 0.0389 |

| Langmuir-type constants (MPa) | N2: 24.71; CH4: 6.02; CO2: 4.31 | |

| In-situ stress state | Vertical stress , MPa | 20.68 |

| Maximum horizontal stress (MPa) | 16.55 | |

| Minimum horizontal stress (MPa) | 14.48 | |

| Initial reservoir pressure (MPa) | 9.5148 | |

| Injection parameters | Reservoir pressure before injection (MPa) | 3 |

| Borehole pressure (MPa) | >3 | |

| Pure CO2 injection | 1 | |

| Mixture gas injection | 0.8, 0.2, 0.1, 0.05 | |

| Mixture gas injection | 0.2, 0.8, 0.9, 0.95 | |

| Wellbore radius (m) | 0.1 | |

| Studied cylindrical domain radius (m) | 2000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Li, W.; Wang, Z.; Yang, S.; Tan, P. Critical Conditions for Wellbore Failure during CO2-ECBM Considering Sorption Stress. Sustainability 2023, 15, 3696. https://doi.org/10.3390/su15043696

Xiao H, Li W, Wang Z, Yang S, Tan P. Critical Conditions for Wellbore Failure during CO2-ECBM Considering Sorption Stress. Sustainability. 2023; 15(4):3696. https://doi.org/10.3390/su15043696

Chicago/Turabian StyleXiao, Hecheng, Wenda Li, Zaiyong Wang, Shuai Yang, and Peng Tan. 2023. "Critical Conditions for Wellbore Failure during CO2-ECBM Considering Sorption Stress" Sustainability 15, no. 4: 3696. https://doi.org/10.3390/su15043696

APA StyleXiao, H., Li, W., Wang, Z., Yang, S., & Tan, P. (2023). Critical Conditions for Wellbore Failure during CO2-ECBM Considering Sorption Stress. Sustainability, 15(4), 3696. https://doi.org/10.3390/su15043696