Abstract

Despite the recent pandemic and sharp increases in fuel costs, portions of the current U.S. transportation infrastructure have reached their capacity, can no longer carry the increasing traffic volumes they are subjected to, nor can they sustain more. Thus, there is a need to enhance the current infrastructure by funding projects that promote more sustainable practices. Alternative intersections and interchanges (AIIs) can help to achieve this by providing significant improvements in traffic volumes while maintaining or improving safety. However, because they involve unique construction approaches that may be unfamiliar to construction professionals, the cost of AII projects are often perceived to be higher than for conventional designs. This research addressed this problem by identifying inhibitors to the construction of AIIs and enhancers that could improve their construction efficiency. To do so, an online survey was distributed and virtual interviews were conducted to gather knowledge from stakeholders (consultants, designers, and contractors) with experience building AII projects. The results were compiled and assessed to better understand the inhibitors that prevent AII projects from being selected and constructed. The results are promising and help DOTs, contractors, and consultants to focus their resources on minimizing inhibitors to improve project performance. The results show that utilities and right of way are the most prevalent inhibitors that prevent AII projects from being selected and constructed.

1. Introduction

The United States had a particularly strong investment in transportation infrastructure (roadways) prior to WWII. This investment influenced the economic growth of the country and positioned the US as an economic leader [1]. However, since WWII, except for the interstate highway system, national infrastructure has not been optimally maintained. To address the effects of the aging and underperforming infrastructure, it is necessary to restore the existing infrastructure to optimal performance levels and to promote sustainable design, construction, and rehabilitation practices for new infrastructure. Doing so is more and more important due to the emergence of practices that promote more transportation networks, smart mobility, connectivity, and resilient systems [2].

Alternative intersections and interchanges (AII) are cost-effective, safe, sustainable, and efficient alternatives to the existing aging intersections and interchanges [3]. AIIs have the potential to improve traffic flow, capacity, and safety, especially in highly congested and spatially constrained areas [3,4]. By increasing capacity and improving traffic flow, there is a reduction in vehicle emissions which is a critical and sustainable step toward reducing negative climate impacts [2,5]. The benefits associated with AIIs often get overlooked due to their unique design, construction, and constructability challenges for the stakeholders (DOTs, consultants, and contractors). Similarly, since most AII designs are relatively new (around 10 years old), they are also unfamiliar to drivers. As a result, projects using AII designs are frequently perceived to require additional time and cost to build compared to conventional designs.

Shumaker et al. [6] first documented this shortcoming by noting that few AIIs see widespread use because they require unique construction approaches that mandate a deep understanding of best practices. However, these best practices are acquired gradually through experience. Without such experience, contractors face challenges when they design and construct new AII projects. This research aims to address these issues by identifying construction inhibitors that could affect AII construction cost, schedule, and safety and construction enhancers that could reduce construction complexity, uncertainty, and cost.

The purpose of this paper is to establish a framework for understanding why many AIIs are not widely and readily adopted for use, especially given their promise to improve both traffic flow and safety and generate more sustainable infrastructure. To do so, an online survey and virtual interviews were conducted with the stakeholders (consultants, designers, and contractors) involved in AII projects to identify the enhancers and inhibitors in the AII design and construction process.

2. Literature Review

To enhance infrastructure sustainability, the building industry has developed sustainable building ratings systems such as LEED, BREEM, Green Globes, and many more [7] for the purpose of integrating design and construction to incorporate sustainability and green construction practices [5]. Such practices have been lacking in the transportation industry. This can be attributed to the fact that achieving sustainability in existing transportation facilities is not an easy task that can be achieved with a rating system or through the use of conventional intersection and interchange (CI) designs [8]. However, sustainability can still be achieved with the promotion of sustainable designs such as AIIs. AIIs can improve operational performance, safety, and environmental performance [5,9].

AIIs have a large number of designs that include diverging diamond interchanges (DDI), quadrant roadways (QR), continuous flow intersections (CFI), reduced conflict intersections (RCI), echelons (EI), roundabouts (RI), and others. Not much information or detail is widely available for contractors on the unique differences between AIIs and CI and interchanges or on how to construct AIIs. This lack of information makes them appear to be complex for construction. There are multiple factors affecting project success that are highly dependent on the project type, size, and complexity [6,10]. For example, AII designs may appear to be more challenging and risky due to the introduction of new products and technologies as well as the combined efforts of multiple contractors.

2.1. Benefits of and Barriers to AIIs

Table 1 identifies some of the most relevant benefits of and barriers to the use of AIIs. CFI and QR are the most cost-effective designs compared to CI (Table 1). The RCI is considered to be one of the safer designs for rural and urban locations and the DDI design is the only one that typically does not require the acquisition of right of way (ROW).

Table 1.

Benefits and Barriers of AIIs.

Just like the benefits of AII, the barriers associated with the construction of each AII design are specific. The acquisition of ROW to construct the AII is a common disadvantage among CFL, RCI, and QR designs. Driver and pedestrian confusion is another barrier affecting CFI, DDI, and EI during construction and initial use. Additional maintenance costs due to special operations or the need for additional structures are barriers that are often associated with CFI, EI, and QR.

In general, most AIIs designs have evoked strong resistance from the public due to their unfamiliar design and routing complexities. Public perception is considered the biggest obstacle preventing the wider implementation of AIIs. Unfortunately, few efforts have been made to address and improve the public perception of AIIs. A recent study by Brown et al. [16] noted that public perception can be relatively negative before the projects are built, but it improves once the design is completed and the public becomes familiar with the design and its use, especially when they see the resulting improvements in traffic flow.

Another problem with AIIs is the contractors’ lack of familiarity with (and negative perception of) their cost and time requirements (compared to CI designs). This perception is often rooted in the AII requirements for unique construction approaches to meet the specific challenges resulting from unique site characteristics [6]. Therefore, when a new design is proposed, and there is limited prior construction experience with it, bid costs are high due to the fact that contractors need to compensate for the risk associated with the new and unique unknowns of AII projects.

A common perception is that some AIIs are more expensive to build than CI designs, therefore these are not feasible for economic reasons [17]. The difference in cost is typically associated with the additional ROW, additional signals and signs, the construction of grade separation, and in some cases, the cost of staging. The complexity of the AII designs does incur high levels of organization and construction; therefore, the cost increases.

Table 2 identifies the construction cost requirements for each of the AIIs of interest. The first column identifies the design, the second column describes the findings related to the construction cost of that respective design, and column three identifies the source. Notice that only information about the cost of CFI, QR, RCI, and DDIs was found in the literature. Notice that from the AIIs of interest presented in this research, the cost associated with EI can be assessed as the cost associated with a grade-separated intersection, which is known for being costly compared to at-grade intersections [18].

Table 2.

AII Construction Cost.

However, despite its cost, extensive research has been conducted on the benefits of AIIs and these benefits include improvements in traffic flow, capacity, and the safety portion of it. Meng and Weng [22] assessed the traffic delay of AIIs by utilizing queuing models and single or multiple sub-work-zone strategies. Sub-work-zone strategies are those that can be adopted to mitigate queue length and travel delay. In this same study, the researchers evaluated multiple approaches to evaluate how traffic affects capacity due to work-zone control measures.

Additionally, AIIs with at-grade designs are characterized by improving capacity at bottleneck intersections, and intersections experiencing a high volume of traffic and high volumes of pedestrians are prone to suffer capacity issues [23]. Therefore, ideal solutions will be to opt for AII designs. For example, one of these designs is the DDI. In their study, Schroeder et al. [21] mentioned that DDI projects are ideal for constraint areas since this design generally fits within the existing interchange ROW and bridge structure.

In another study performed by Brown et al. [24], space constraints, phasing, and safety considerations were evaluated. The findings indicated that detouring traffic away from construction is ideal for safety and operations; however, if maintaining the existing intersection operation with all movements as long as possible at the main intersection is needed, considerations of factors that affect construction timing should be made. Some of these activities that can be monitored to address safety with phasing are construction work related to drainage, utility movements, and other situations that can affect projects. Depending on the specific location, multimodal accommodations for pedestrians, bicycles, and disability accommodations can also be considered.

Table 3 summarizes how safety is enhanced based on the number of conflict points, collision rates/crashes, human factors, signal progression, and sight distance. From the conflict point perspective, if compared to a conventional (CI) signalized intersection, all AII designs have a better performance. A similar trend can be observed in the collision rate reduction, with all AIIs reporting a decrease in fatal/injury collisions. Nonetheless, the results oscillate greatly from study to study and the analysis type being performed. It can also be noted that even though the majority of AII designs improve safety considerations for pedestrians and bicyclists, there is a great deal of confusion from drivers and pedestrians about how to navigate through these designs. Concerning signal progression, AII designs improve signal timing by separating movements. One of the best designs concerning signal to progress is DDIs. Lastly, when considering sight distance, the RCI is of concern. This design has poor sight distance at the crossovers (U-turn), preventing drivers from seeing upcoming traffic and potentially causing crashes.

Table 3.

AII Safety Performance.

2.2. Construction Enhancers

When attempting to achieve a sustainable system, multiple aspects such as design, construction process, delivery methods, and design practices need to be considered [18]. Promising construction concepts such as sustainable practices and emerging technologies that have the potential to promote the sustainable construction of projects are referred to in this paper as construction enhancers. To the authors’ knowledge (and after a thorough literature search), scant research exists addressing the construction enhancement techniques associated with the construction of AII designs. However, some enhancement techniques such as implementing constructability reviews, using modularization and prefabrication, automating tools, incorporating 3D/4D modeling, and producing more detailed staging and sequencing plans are promising. In what follows, we review existing literature on these methods and the potential of each.

2.2.1. Constructability Reviews

Abudayyeh et al. [27] identified that the majority of constructability-related publications in ASCE journals are from the U.S., and they were mainly published from 1991–2002. Since then, constructability studies have eased. This might be due to the fact that construction is one of the largest industries, one of the oldest, and one of the least researched in the United States [27]. This section identified major studies performed by CII, AASHTO, and NCHRP that focused on promoting the buildability, biddability, and most importantly, constructability of a project without affecting schedule or cost.

Constructability was first introduced to construction in the 1970s [28] and is a measure of how constructible a project is. It aims to address how projects meet standards that are well-known to the construction community [29] and how projects meet generally accepted cost and schedule expectations. Without the focus on constructability, a project typically experiences an increased number of change orders, violations of construction schedules, and safety concerns [30].

The Construction Industry Institute (CII) started to perform studies on constructability concepts in the 1980s. The first set of CII constructability publications is related to best practices. These publications include reports on the conceptual planning phase [31], design and procurement phase [31,32], constructability program implementation [33], constructability improvement in project planning, contractual approach [34], constructability barriers [35,36], and implementation tools [33,35,36,37].

In addition to those, the CII published nine additional reports on constructability implementations. These publications include practical guidance and practices on constructability implementation [38], barriers in constructability [39,40], construction cost influences [41,42], lessons learned, constructability program maturity, and implementation tool#1 [40], along with other journal publications from these studies [43,44].

All of these extensive CII studies concluded that the successful implementation of constructability requires a complete understanding of construction procedures. Most of the time, organizations feel they are implementing constructability, but in reality, their efforts are implemented late in the process and fail to achieve significant benefits [42]. In addition, CII studies indicate that the only way to ensure the success of a constructability program is by performing measurements of the process and tailoring the program to specific project types.

Following the CII studies, in 1997 the National Cooperative Highway Research Program (NCHRP) [45] published a report on constructability processes for projects related to transportation facilities. The NCHRP study attempts to quantify the benefits associated with the constructability review process for transportation projects. This report is tailored to the constructability review practices at DOTs and how to implement constructability review programs. This study first provides an overview of CR programs, and implementation guidelines, and describes in detail each constructability function and its steps, actions, and tools. In addition, it identifies issues affecting CR programs, presents the outcomes, and suggests future tools to measure constructability.

In 2000, the American Association of State Highway and Transportation Officials (AASHTO) published a constructability review of best practices guide [46]. The work presented in this guide emphasized the importance of implementing a CR program due to its numerous benefits. Some of the benefits identified included: the enhancement of early planning, minimization of scope changes, reduction of design-related change orders, improvement of contractor productivity, development of construction friendly specifications, enhancement of quality, reduction of delays, meeting of schedules, improvement in the public image of the industry, promotion of public/work zone safety, reduction of conflicts, disputes, and claims, and a decrease in construction and maintenance costs. This report does not provide any information on how DOTs can measure cost–benefits or the time when CRs should be implemented. Despite the efforts to address CR practices at DOTs, this AASHTO report does not present information related to the constructability practices for an AII project. The relevant information from this report includes the identification of best practices and the identification of benefits.

To ensure that a project is constructible, or simply to enhance constructability, a constructability review (CR) is often performed. The primary goal of a CR is to assemble industry experts from multiple disciplines (construction, structures, geotechnology, utilities, etc.), to identify potential design and construction issues that would negatively impact project cost, duration, and safety [31] and to suggest corrections early in the design process that would enhance the attainment of a more sustainable construction. However, to enhance the benefits and the impact of a CR, it is necessary to know when to implement it. Othman [47] emphasized that CRs enhance transportation projects if implemented across all phases of a project (conceptual planning, design and procurement, and field operations). The actual impact is observed only when a CR is performed at the appropriate time in the project’s life cycle. DOTs have recognized the importance of CRs and have developed checklists and other tools to determine the appropriate time to perform them [48].

2.2.2. Modularization and Prefabrication

In construction, modularization and prefabrication (M&P) refer to construction methods used to build, construct, and assemble some parts of the process off-site and under controlled conditions [49]. M&P has been used in multiple building components for decades (some examples include modular bridges, houses, offices, etc.). However, in transportation projects, M&P has seen limited use because most transportation infrastructure is horizontal construction and M&P units cannot be fully implemented in this form of construction. M&P has only be implemented, thus far, for construction components such as prefabricated walls, precast concrete systems, and bridge modules [50].

2.2.3. Automation

Labor issues ultimately impact the overall performance of a project. From early 2020 to the present, the construction industry has suffered from a shortage of skilled labor which has resulted in low productivity [51]. Therefore, it is important to consider using automation in AII projects. Automation for transportation infrastructure consists of performing a task that can rely on automating processes utilizing tools such as building information modeling (BIM), or geographic information systems (GIS) for linear construction work activities such as road construction, paving, drilling, trench excavation, and pipe laying [52,53].

The capabilities of construction automation tools (e.g., robots) are improving considerably and at an accelerated pace [51]. However, despite their benefits, it is important to acknowledge that this constructability enhancer needs further development. Some activities such as excavating operations and trenching require precise control and current automation technologies may not be up to the required accuracy levels under the often difficult conditions of the construction environment [54]. However, due to the rapid evolution of technology, automation has the potential to be more precise and to be a strong enhancer of transportation projects. Once automation technologies achieve maturity, they have the potential to improve productivity over traditional operations [55]. Therefore, construction automation is a promising catalyst for addressing challenges related to the construction of AII projects.

2.2.4. 3D/4D Modeling

The literature shows that 3D modeling has the potential to identify aspects of the engineering design and construction process that need constructability assessment [56]. However, 3D modeling has been mainly applied to building construction projects, and the use of 3D models for transportation infrastructure modeling has been evolving at a very low pace. One reason for the low adoption of 3D modeling is partially due to DOT’s business practices. When a DOT adopts this technology, so too must all of its external design and construction firms. Otherwise, its life-cycle benefits will not be fully realized. However, 3D modeling is difficult to implement by small firms because of all of its characteristics of cost, learning curve, required computing expertise, hardware, training, etc. This makes it more suitable for larger firms with significant financial and personnel resources. However, DOTs have a civic duty to delay the implementation of such technologies to a time when a reasonable segment of the transportation infrastructure design and construction community can participate or until a unique project type emerges that justifies their adoption. AIIs are one such project type.

Utilizing 3D/4D modeling to identify issues prior to construction is vital for the unique nature of highly complex projects such as AIIs designs. Therefore, 3D modeling merits attention since incorporating such modeling into the design process can improve the management of spatially constrained sites, improve traffic flow, maintain safety for workers and the public, and maintain schedule and cost control [57,58].

2.2.5. Staging and Sequencing

Even though performing construction staging is standard practice for every construction project, it is important to emphasize how significant the staging and sequencing of activities are for the success of a project. Analyzing the scheduling and sequencing of a construction project can eliminate potential conflicts that would result in schedule disruption [59]. Prior research [59,60,61,62] has emphasized the importance of planning staged projects. For example, Reeder and Nelson [63] found that focusing on solving staging and constructability concerns prior to construction helps to reduce risks that result in cost and schedule overruns. Similarly, Zhan and El Diraby [62] suggested that paying significant attention to staging and sequencing for the installation of accelerated bridge construction (ABC) can aid in mitigating construction risks during design. Special attention needs to be given to staging considerations for projects that involve innovative practices. These would especially include AIIs. The findings indicated that properly staged and sequenced projects are enhanced and the overall benefits result in a more buildable, cost-effective, and maintainable project.

2.3. Construction Inhibitors

The success of an AII project is dependent on factors that have the potential to negatively affect its construction. These factors are referred to in this paper as construction inhibitors. Table 4 identifies a number of construction inhibitors that are typically associated with transportation infrastructure projects. Each inhibitor is associated with the literature source where they were found. The majority of the literature identified fabrication and assembly, foundations and soil conditions, safety, and construction/installation specifications as constructability inhibitors in their projects.

Table 4.

Construction Inhibitors.

2.4. Gaps in Literature

The information provided in this literature section presents robust information about the state of practice. The gaps found in this review include the following:

- There is no information related to AII construction inhibitors or enhancers.

- There are no guidelines for the construction of AII designs.

- There are no lessons learned from best practices for the construction of AIIs.

This paper addresses the inhibitors to AII construction.

3. Materials and Methods

3.1. Sample Size

To understand how engineers perceive AII projects, we developed a study using surveys and interviews asking questions about engineering, design, and construction experience on AII projects, the identification of construction inhibitors and enhancers, and best practices. A group of 221 participants from multiple disciplines with previous experience in the construction, planning, and design of AII projects was compiled. The participants’ backgrounds included roadway engineers, traffic engineers, geotechnical engineers, construction engineers, structural engineers, work-zone traffic-control engineers, and congestion managers. Participants were contacted to complete an online survey or schedule a virtual interview. The response rate was 34.8% (77 participants of the 221 contacted) and the participation was as follows:

- 29 participants (20 NCDOT personnel, 4 contractors, and 5 consultants) were interviewed.

- 28 additional responses were received from the North Carolina (NC) stakeholder survey (12 NCDOT personnel, and 16 contractors).

- 20 responses were received from multiple stakeholders in other DOTs. The participating DOTs include California, Colorado, Connecticut, Georgia (n = 3), Illinois, Indiana, Kansas, Kentucky, Maine, Minnesota, New Hampshire, New York, Rhode Island (n = 2), South Carolina, Tennessee, Utah, and Vermont.

In total, we received 32 responses from NCDOT personnel, 21 from consultants, 4 from contractors, and 20 from other DOTs, which is a sample size greater than the minimum needed (68 participants) to have a confidence level of 95% with a real value within ±10% of the measured/surveyed value.

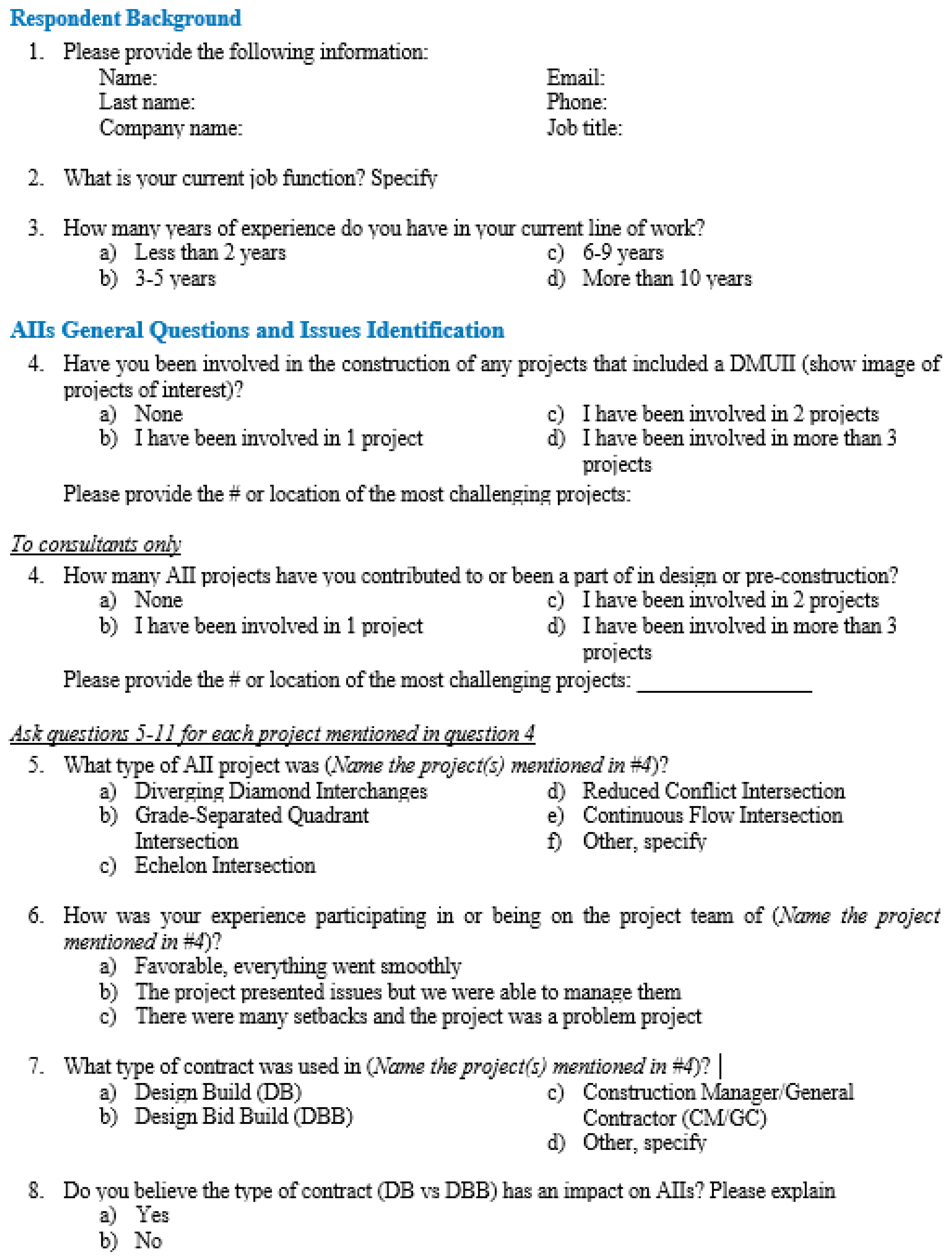

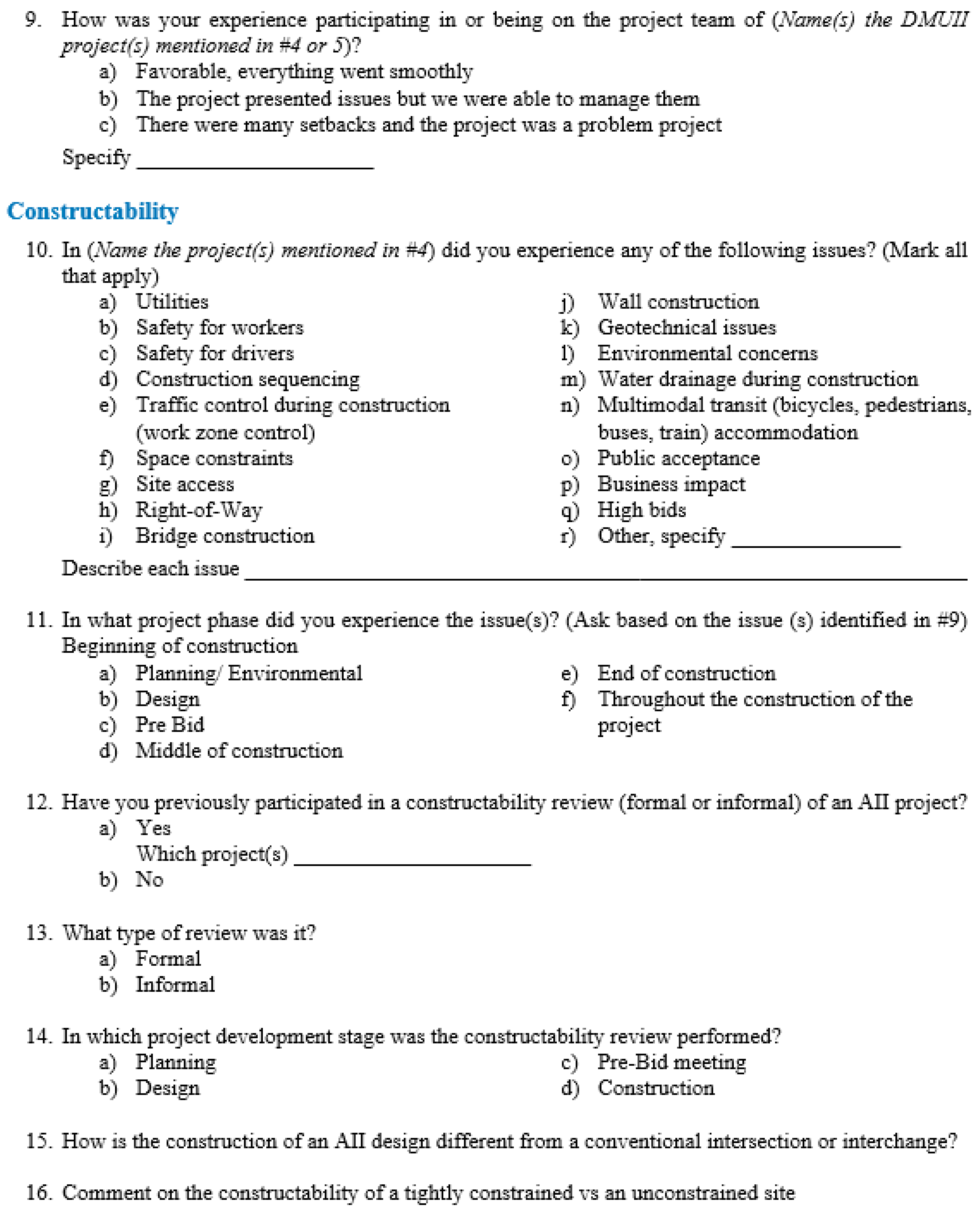

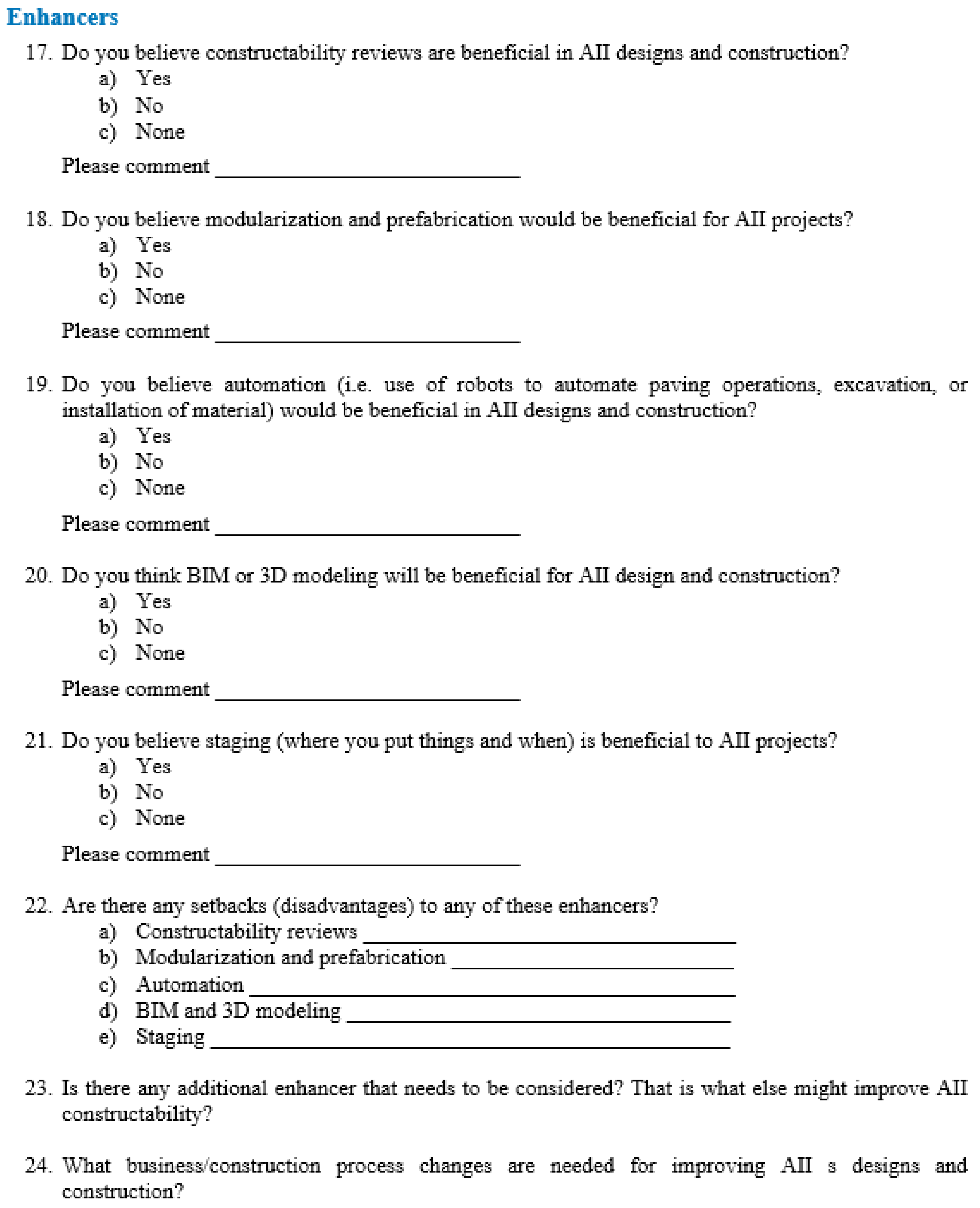

3.2. Questionnaire

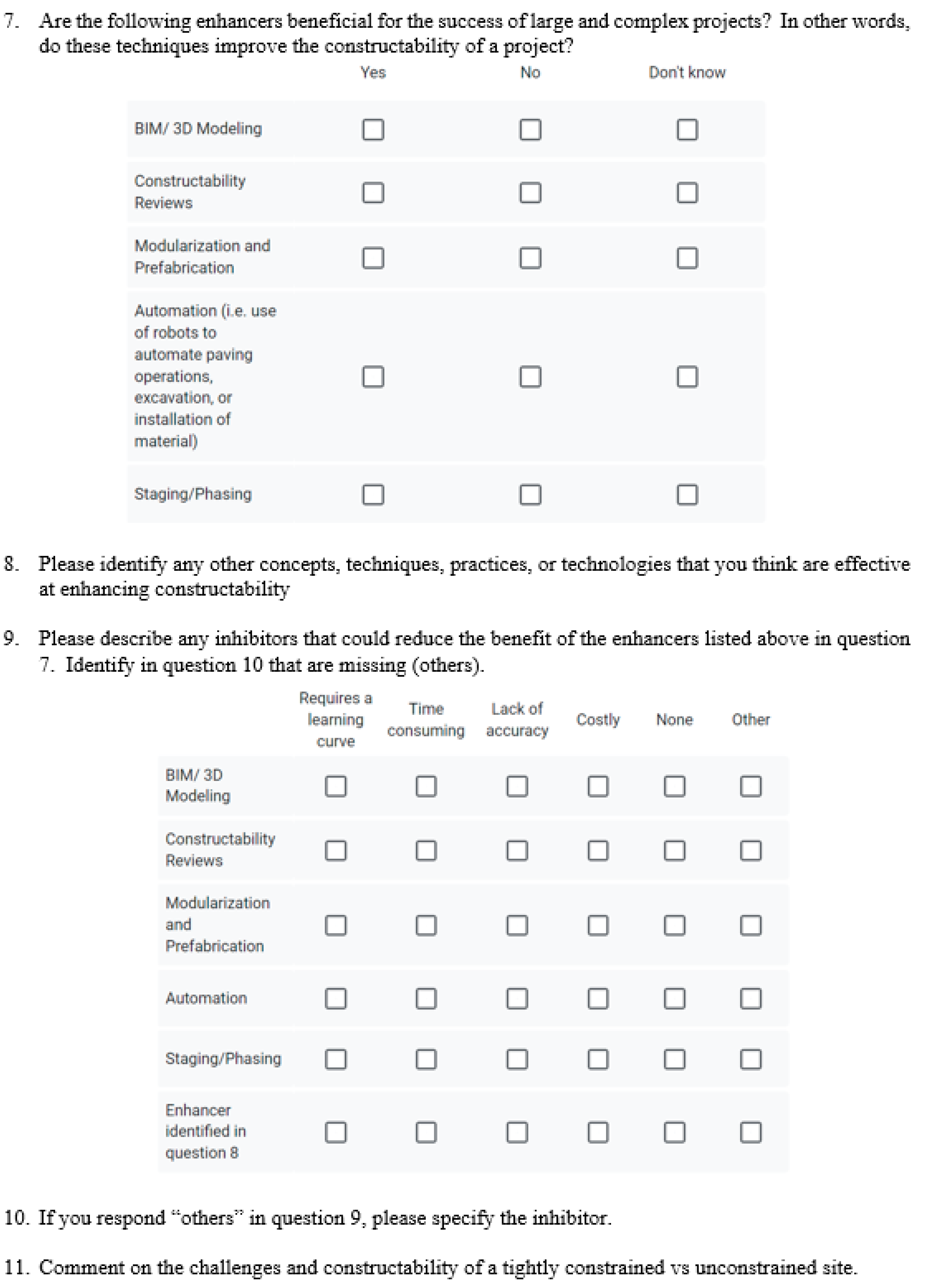

Two sets of questionnaires were developed to capture participants’ responses. The first questionnaire included a total of 24 questions that were used to guide the conversation during the interviews (see a sample questionnaire in Appendix A). This questionnaire was used as a guide to direct the flow of the conversational data collection effort, but deviations in the questioning during the interviews allowed the research team to have greater latitude and to identify unanticipated responses. This was one of the advantages of the interview process.

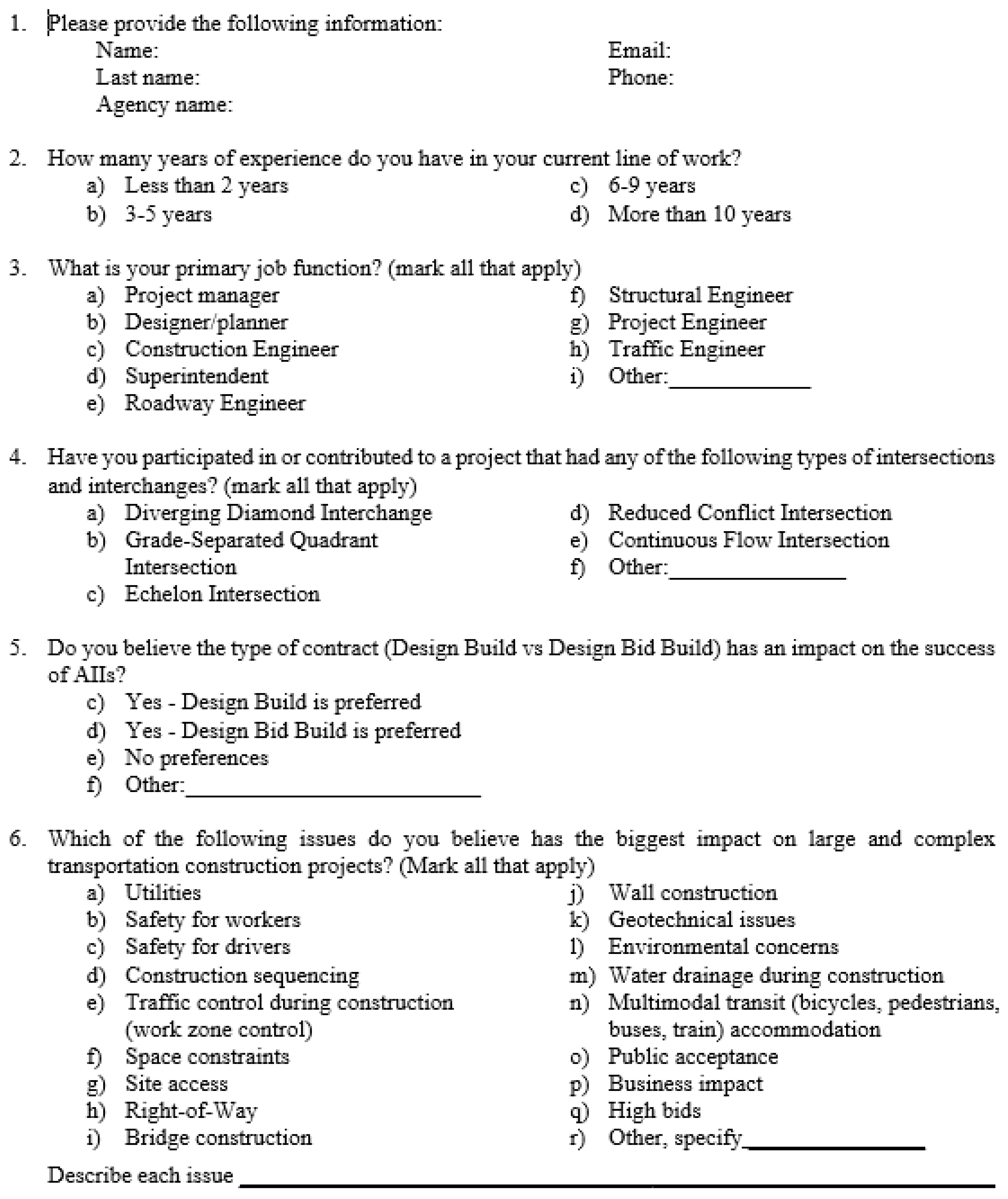

The questionnaire, developed for the online survey, only contained 11 questions (see questionnaire in Appendix B). The questions asked in the survey were similar to those developed for the interview. However, the research team opted to shorten the online survey to capture the most relevant information from participants in a time-efficient manner for the participants.

4. Survey Results

The surveys focused on details related to the identification of construction inhibitors, the identification of unique construction practices for AIIs, and the identification of sustainable practices that have the potential to enhance projects. The interview and survey participants were asked to identify their level of experience with AII projects.

The results from this inquiry are displayed in Table 5. Out of the 77 participants, 61 of them were familiar with the construction or design process of a DDI project. With 39 responses, RCI is the second most common design that participants have contributed to or participated in, followed by QR (n = 34), CFI (n = 26), and EI (n = 2). Other AII designs were also identified and classified as “Others” because these designs were out of the scope of this study. The “Other” category includes roundabouts, single-point urban interchanges, and turbines.

Table 5.

Participants’ Familiarity with AII Design.

The general findings from the interviews and surveys are presented below. In addition to general findings, the discussion session of this report presents lessons learned and documents best practices identified by interview and survey participants.

4.1. Identification of Construction Inhibitors

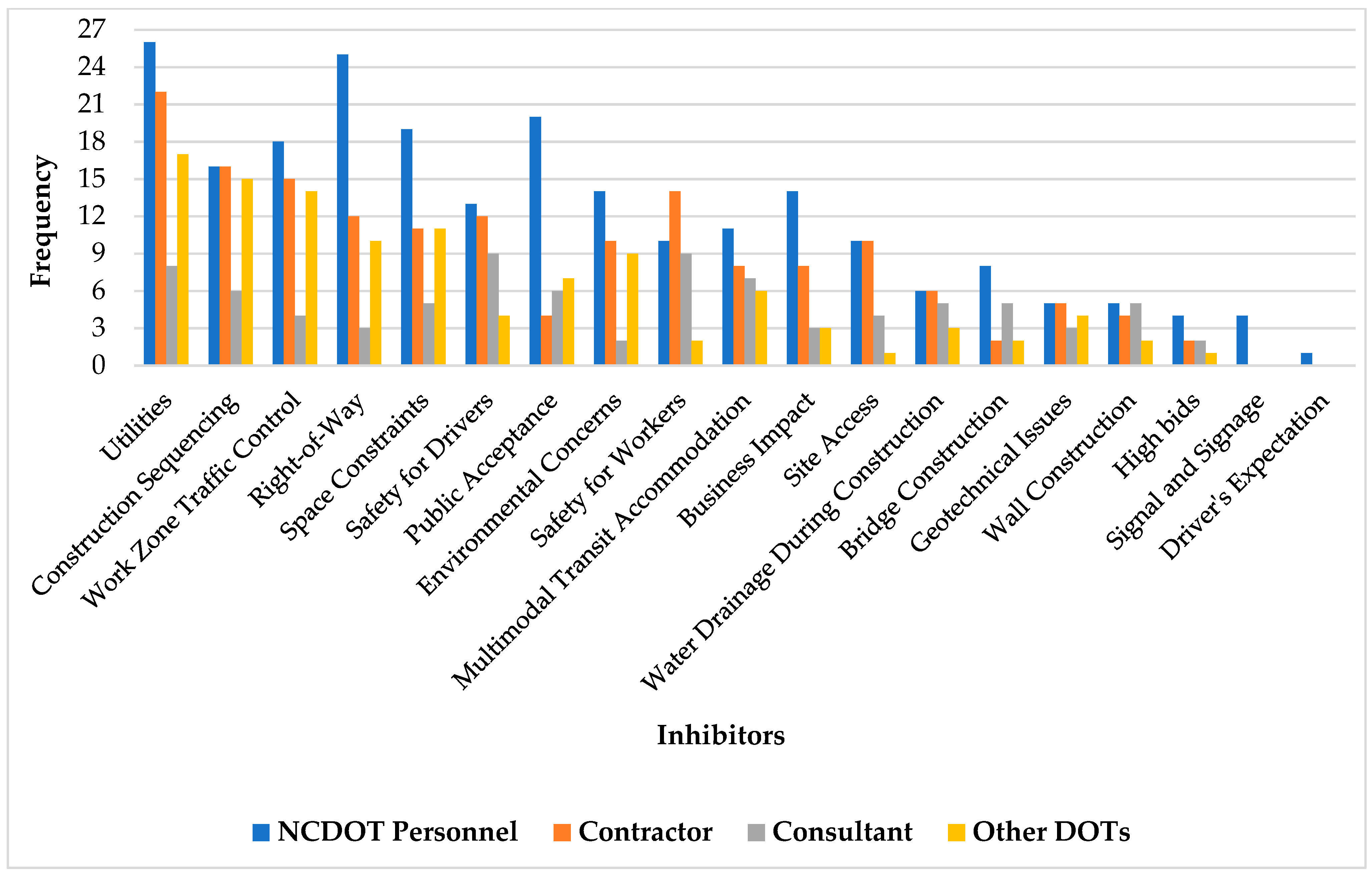

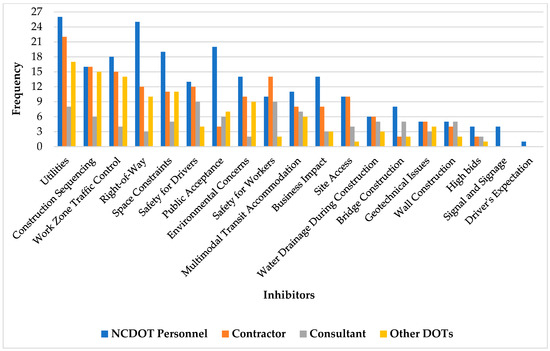

After identifying the participants’ familiarity with AII projects, they were then asked to identify the specific construction inhibitors that they saw as most significantly affecting AII projects. The participants were encouraged to identify multiple inhibitors for a project, if appropriate. In total, the participants identified 19 inhibitors affecting AII projects. The results from their identification of inhibitors and their frequency are displayed in Figure 1.

Figure 1.

Construction Inhibitors Associated with AII Projects.

In Figure 1, it can be observed that the most common inhibitor was utilities (n = 73). The second-largest inhibitor was construction sequencing (n = 53), followed by work-zone traffic control (n = 51), ROW (n = 50), and space constraints (n = 46). Through the interview conversations, it became clear that participants feel these inhibitors are not limited to AII projects, nor are they entirely due to AII project characteristics. Instead, they are more likely to be present based on the unique characteristics of each project site. However, AIIs result in an added complexity to a number of the inhibitors identified in Figure 1. The next section further addresses this point.

4.2. AII Unique Construction Characteristics

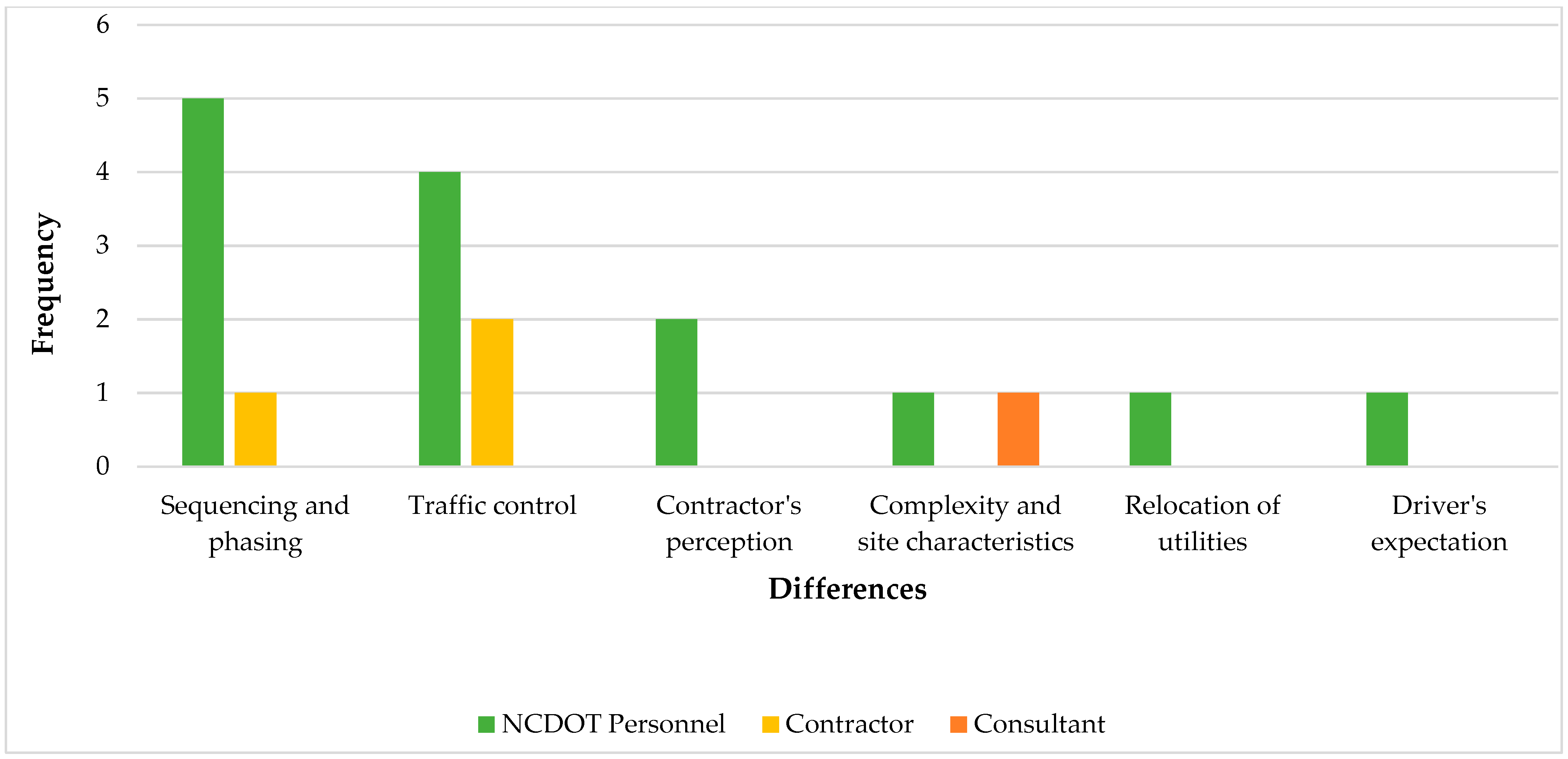

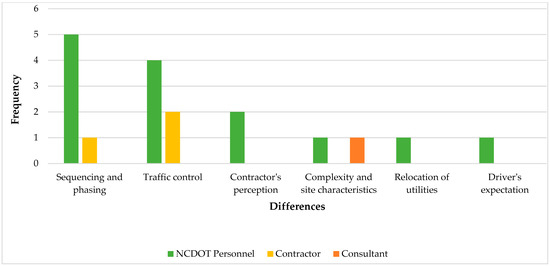

This research sought to identify the differences in the process of constructing a project with an AII vs. one with a conventional design. The interview participants noted six main areas in which AII and conventional projects differ: sequencing and phasing, traffic control, contractor’s perception, complexity and site characteristics, relocation of utilities, and driver’s perception (see Figure 2).

Figure 2.

Difference between the Construction of AII vs. Conventional Designs.

The results obtained indicated that sequencing/phasing and traffic control are two of the most notable differences. This and the remaining results agree with the findings in prior research [59,60,61,62,63]. Since the geometry of AII projects is new and unique, guidelines or manuals are not available to address sequencing or traffic control. Stakeholders experienced difficulties in these areas, mainly because the total phasing and traffic control required for a particular design varies drastically depending on its geometric constraints. Therefore, these two factors were identified as the most predominant differences in this study.

In addition, contractors perceive AII projects to be more challenging than conventional projects. This is in part due to the greater complexity of AIIs, resulting in increased cost. Therefore, the construction of AIIs is considered to be riskier. Additionally, participants indicated that the complexity of AII projects, combined with unusual site characteristics, make construction more challenging. Because AII designs are ideal for addressing capacity problems, they are typically implemented in congested and complex areas.

The relocation of utilities and driver’s expectations were also identified as differences in the process of constructing a project with an AII vs. a conventional design. Participants indicated that in some cases, due to the unique geometry of AIIs, some projects are built within the existing ROW. In such cases, utilities are already located outside of the construction footprint; therefore, utility impact is lower. In other cases, AII designs require a larger ROW, and therefore, utility relocations are more significantly impacted. With respect to driver perception, participants indicated that AII projects have unconventional geometry, and therefore, drivers perceive them to be complicated, unfamiliar, and uncomfortable.

4.3. Benefits of AII Enhancers

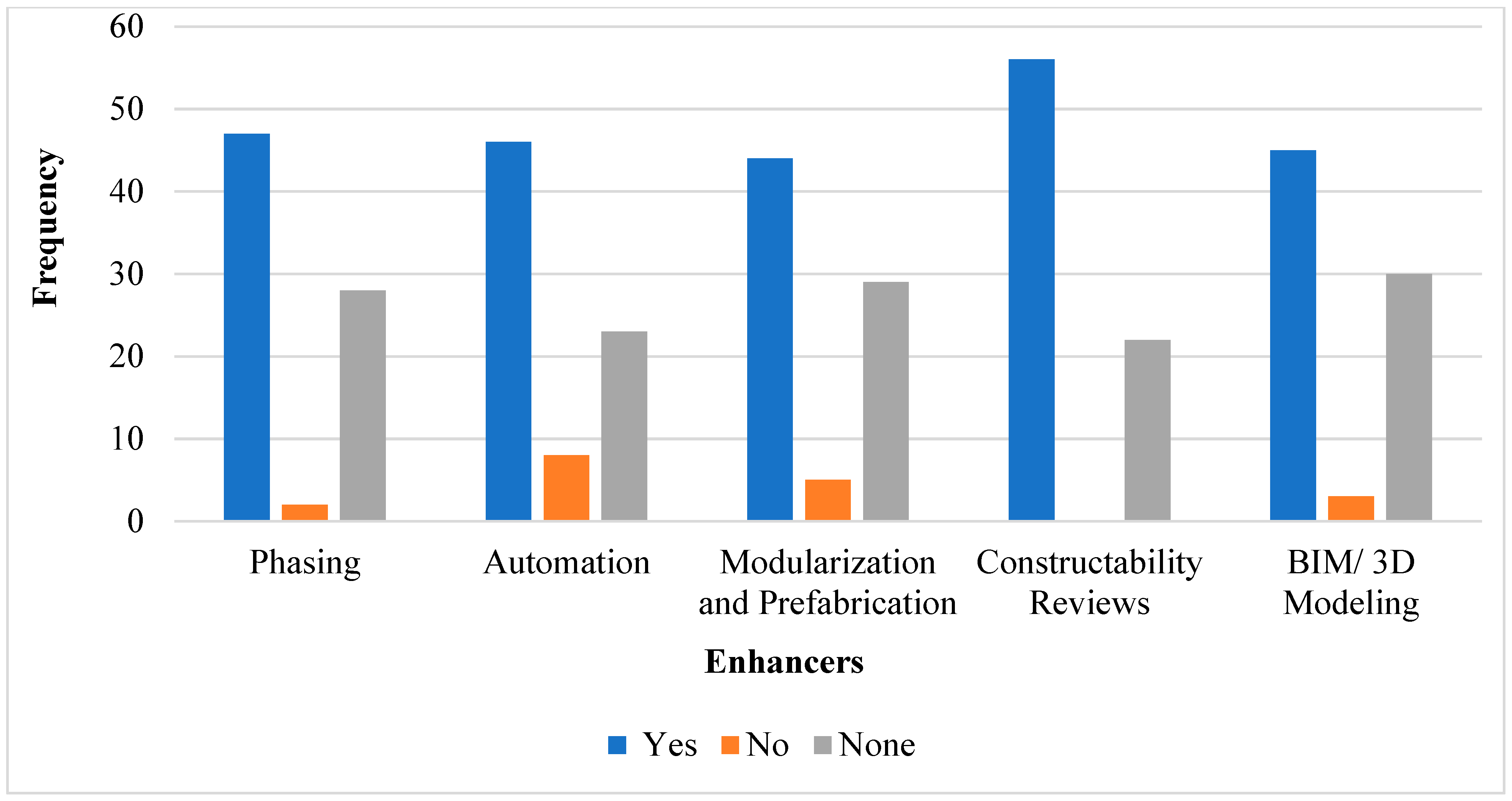

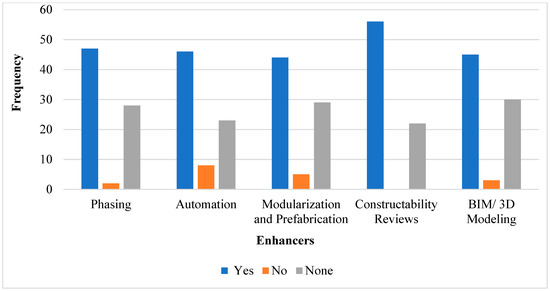

To supplement the effectiveness of the construction enhancers previously found in the literature, the survey and interview participants answered specific questions that identified the benefits and inhibitors of each enhancer. The benefits identified by participants are displayed in Figure 3. Participants agreed that the five enhancers provide benefits.

Figure 3.

Assessment of the Benefits of Construction Enhancers.

Participants indicated that the enhancer to be perceived as the most beneficial is constructability reviews, as shown in Figure 3. Participants indicated that having CRs allows them to improve project efficiency because CRs allow interaction and feedback from multiple experts. Additionally, CRs allow designers to address any issues or concerns while still in the design stage, resulting in a reduction in project delays and cost savings. Phasing is also important (n = 47). Participants indicated that planning and organizing phasing plans for AIIs are essential to maximizing project performance, and more emphasis should be given to doing so, especially for space-constrained locations.

Automation (n = 46) is the third most common enhancer identified by participants. This enhancer allows practitioners to reduce human errors and enhance safety. Most importantly, due to the shortage of skilled labor, the use of automation is a clear advantage. Similarly, BIM/3D modeling was considered to be beneficial (n = 45) because it allows consultants and designers, to better visualize conflicts and helps to identify potential issues during construction, planning, and staging.

Lastly, with a total of 44 responses, modularization and prefabrication are also considered to be an enhancer for AII projects. Participants indicated that modularization and prefabrication shorten on-site construction time and improve safety conditions in the construction process.

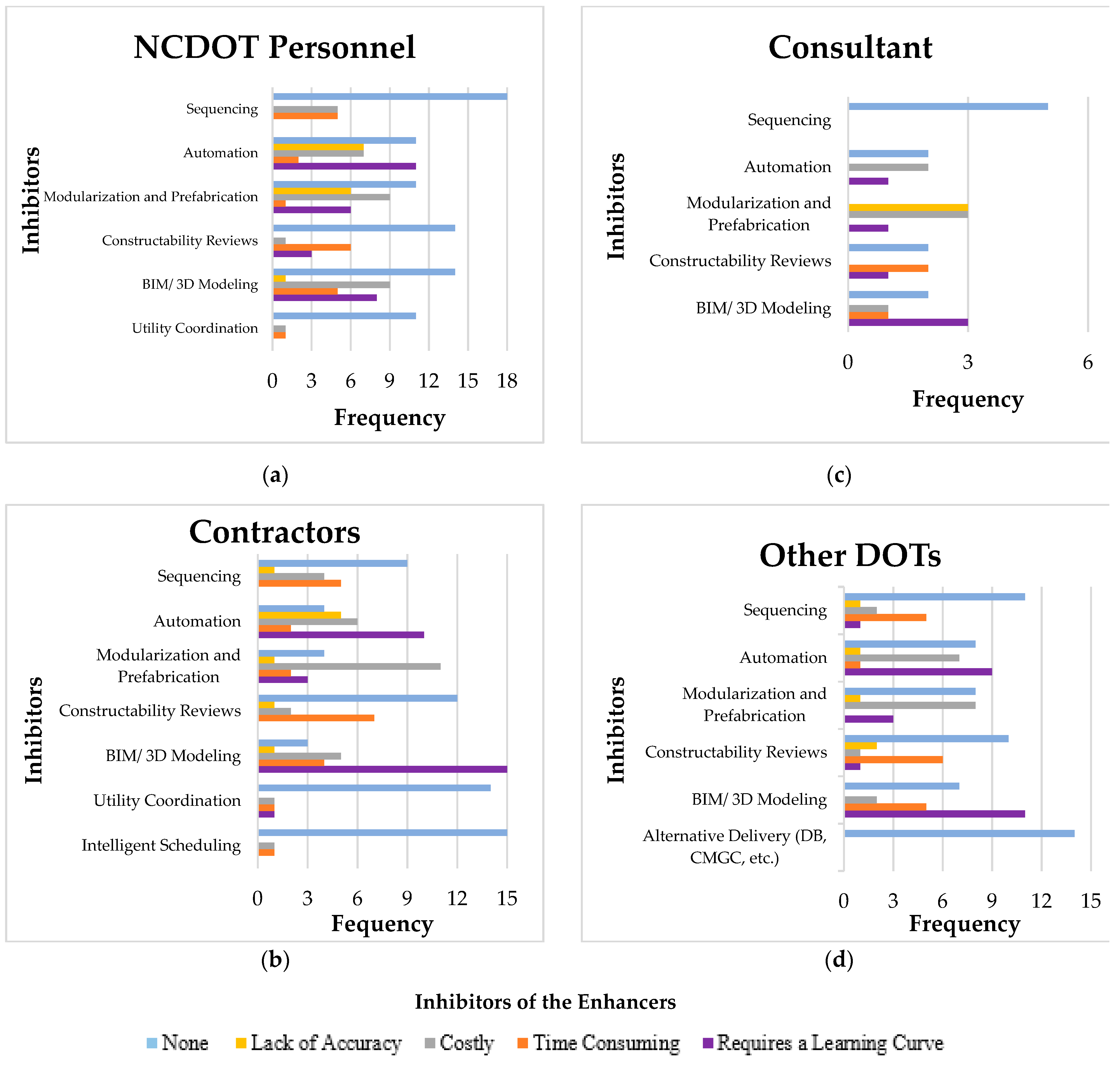

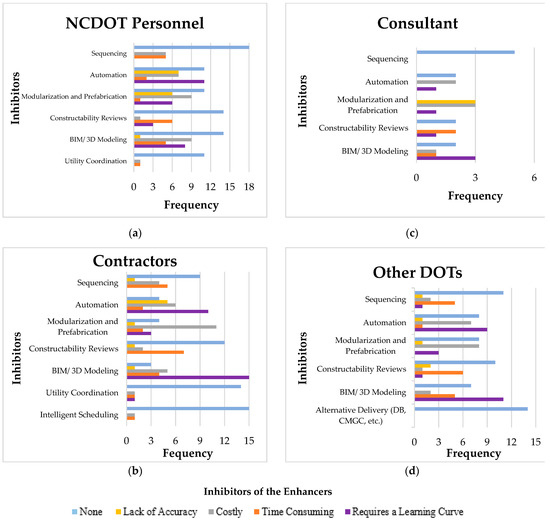

4.4. Drawbacks of AII Enhancers

To further investigate the extent to which enhancers are beneficial, the survey asked participants to identify inhibitors that could overshadow the benefit of the enhancers. How inhibitors are perceived slightly changes between the groups of survey participants as seen in the results displayed in Figure 4 which capture the frequency of the inhibitors to each enhancer that participants have previously identified. In other words, they identify the negative aspects of the construction enhancements. For example, NCDOT participants (a) consider the cost to be the main inhibitor (n = 9) for BIM/3D modeling, followed by the learning curve of the technology (n = 8). However, the results from all other stakeholders (Figure 4b–d) indicate that the learning curve of the technology is the most predominant inhibitor. Similarly, consultants (c) perceive automation to be a costly technology. On the contrary, NCDOT personnel, contractors, and other DOTs acknowledge that automation requires a learning curve.

Figure 4.

Identification of Construction Inhibitors for Constructability Enhancement.

The remaining enhancers (constructability review, modularization and prefabrication, and sequencing) have more consistent results. The participants consider CRs and sequencing to be of value, but time-consuming. With respect to modularization and prefabrication, participants also consider them to be costly. In general, enhancers are well-perceived by participants since the majority of participants recognized few to no significant inhibitors associated with the respective enhancers.

Interview participants were also asked to provide feedback or suggestions on what business or construction process changes were needed to improve AII design and construction. The majority of participants (n = 14) decided not to respond to this question. Four participants felt that no change is needed to improve the construction and design of AIIs. However, utility relocation (n = 3), public perception (n = 3), and traffic control (n = 2) are three activities that were mentioned. Participants consider that a greater focus should be placed on identifying and moving utilities before construction begins and solving issues related to public perception. Since AIIs are relatively new, efforts in managing traffic control (n = 2) are critical because of a lack of user familiarity with them.

One participant directly mentioned that construction inhibitors are more likely to emerge for AII projects during construction due to a lack of knowledge of best construction practices for them. Therefore, educating contractors and consultants about how to efficiently construct AII projects and how to identify inhibitors is a critical next step in promoting their adoption.

5. Discussion

AII projects support sustainability in multiple ways [3]; therefore, documenting solutions that can lead to improving the construction of AII projects is essential. Findings from this interview process are documented in form of lessons learned and best practices. Lessons learned describe the knowledge gained from industry experts about the process of conducting a project [76] and best practices are described as the processes or methods that, when executed effectively, lead to enhanced project performance [77].

Based on the survey and interview results, we compiled a set of lessons learned and identified the main construction inhibitors. The two most frequently identified inhibitors on AII projects were utilities and ROW. It was found that the construction input (at CR meetings) during planning and design is important to enhance project performance. The factor most affecting AIIs is the contractor’s perception of the complexity and risks involved in the project, not the design. Lastly, creating consistent documentation to identify issues related to constructability and assessing those issues throughout the project’s life are essential to meet the unique challenges and construction practices of AII projects. In addition, planning was identified as the “key” to a successful project. Therefore, it is important to focus on the early identification and relocation of utilities by performing a utility assessment early in the planning stages of a project. Additionally, it is important to incorporate constructability reviews into the process.

One of the best practices identified by participants includes a recommendation to regularly visit the evolving construction site to check the placement of temporary signs and to assess turning movements and overall performance during construction. It would be ideal if traffic control designers and safety officers perform these inspections. Workshops or “lunch and learns” within each discipline are recommended to share knowledge gained. Similarly, it is recommended that designers and structural personnel periodically visit construction sites to improve their understanding of construction-related activities. Providing field exposure to designers will allow them to better address common construction concerns during design and to more clearly understand the project scope and characteristics.

6. Conclusions

To gain a deeper understanding of how to successfully and sustainably build AIIs, this research utilized interviews and online surveys to collect data from industry experts on the construction inhibitors affecting AII projects and the identification of enhancers that improve project performance. This study was the first to investigate construction inhibitors for AII projects and its results provide an insight into how inhibitors affect AII projects. These inhibitors include utilities, construction sequencing, traffic control, ROW, space constraints, safety for drivers and workers, public acceptance, environmental concerns, multimodal transit accommodations, business impact, site access, water drainage during construction, bridge construction, geotechnical issues, wall construction, high bids, signal and signage, and driver’s expectations. By mitigating the negative effects of these, project performance inhibitors can be mitigated. The primary benefits associated with AIIs are safety improvement, an increase in mobility through higher traffic volumes, higher cost–benefit ratios, and a reduction in traffic signal phases.

The significance of this study includes the identification of lessons learned and best practices that will help DOTs and other transportation agencies to focus their resources on identifying and mitigating inhibitors before they can impact an AII project, in addition to opting for enhancement strategies that will allow them to have AII projects constructed more efficiently. It is also important to emphasize that the results of this research are qualitative. The study was conducted to gain an initial understanding of the inhibitors affecting AII projects. To enhance the significance and reliability of these results, future efforts will focus on the consideration of benchmarking cost and schedule data, claim information, and live monitoring of construction work to identify and quantify the impact of each inhibitor on the performance of AII projects.

Author Contributions

Conceptualization, M.B. and W.R.; methodology, M.B.; validation, M.B.; formal analysis, M.B.; investigation, M.B. and W.R.; data curation, M.B.; writing—original draft preparation, M.B.; writing—review and editing, W.R.; visualization, M.B.; supervision, W.R.; project administration, W.R.; funding acquisition, W.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the North Carolina Department of Transportation, grant number RP 2021-12.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Survey results are available from the authors.

Acknowledgments

The research team thanks the participants (NCDOT personnel, consultants, contractors, and other DOT personnel) for participating in these interviews and surveys. Without their contribution, the identification of best practices and lessons learned would not be possible.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Interview Questionnaire

Appendix B. Survey Questionnaire

References

- Council on Foreign Relations. State of U.S. Infrastructure. Available online: https://www.cfr.org/backgrounder/state-us-infrastructure (accessed on 5 October 2022).

- Raza, A.; Ali, M.; Ullah, U.; Fayaz, M.; Alvi, M.; Kallu, K.; Zafar, A.; Nengroo, S. Evaluation of a Sustainable UrbanTransportation System in Terms of Traffic Congestion-A Case Study in Taxila, Pakistan. Sustainability 2022, 14, 12325. [Google Scholar] [CrossRef]

- Almoshaogeh, M.; Abou-Senna, H.; Radwan, E.; Haider, H. Sustainable Design of Diverging Diamond Interchange: Development of Warrants for Improving Operational Performance. Sustainability 2020, 12, 5840. [Google Scholar] [CrossRef]

- Shaw, J.; Chlewicki, G. Overview of Innovative Intersections. TRB Intersections Joint Subcommittee Webinar. 2016. Available online: https://www.fhwa.dot.gov/Planning/freight_planning/talking_freight/september_2016/talkingfreight9_21_16gc.pdf (accessed on 26 October 2022).

- Sabory, N.; Senjyu, T.; Momand, A.; Waqfi, H.; Saboor, N.; Mobarez, R.; Razeqi, F. LEED Scores of Residential Buildings in Poor Cities: Kabul City Case. Sustainability 2021, 13, 6959. [Google Scholar] [CrossRef]

- Shumaker, M.; Hummer, J.; Huntsinger, L. Barriers to Implementation of Unconventional Intersection Designs: A Survey of Transportation Professionals. Public Work. Manag. Policy 2012, 18, 245–262. [Google Scholar] [CrossRef]

- Iulian, F.G. MATOOL Solution in Evaluating Smart Buildings. Int. J. Electr. Eng. Comput. Sci. 2019, 1, 19–23. [Google Scholar]

- Humble, P.L.; Furtado, G. Innovation in Interchange Design-Golden Hill to West. In Proceedings of the Paper prepared for presentation at 2010, Adjusting to New Realities Conference of the 2010 Annual Conference of the Transportation Association of Canada, Halifax, NS, Canada, 26–29 September 2010. [Google Scholar]

- Organization for Economic Co-operation and Development (OECD); Development Intermodal Freight Transport Advisory Group. Intermodal Freight Transport: Institutional Aspects; OECD Publishing: Paris, France, 2001. [Google Scholar]

- Wisconsin DOT. Overview of Reduced Conflict Intersection Design and Operations. Wisconsin Department of Transportation Webinar, 2013. Available online: https://wisconsindot.gov/dtsdManuals/traffic-ops/programs/training/innovative-intersection-ppt.pdf (accessed on 26 October 2022).

- Furtado, G.; Tencha, G.; Devos, H. Unconventional Arterial Design: Jughandle Intersection Concept for McKnight Boulevard in Calgary. The Transportation Factor, The Transportation Factor Annual Conference and Exhibition of the Transportation Association of Canada. 2003. Available online: https://pdfs.semanticscholar.org/af2a/777190b63db8ff976c356bd41a2b19a4a2ce.pdf (accessed on 26 October 2022).

- Fitzpatrick, K.; Wooldridge, M.; Blaschke, J. Urban Intersection Design Guide: Volume 2-Applications; Technical Report, FHWA/TX-05/0-4365-P2 Vol. 2; Texas Transportation Institute, Texas Department of Transportation Research and Technology Implementation: Austin, TX, USA, 2005.

- Hiddlebrand, T. Unconventional Intersection Designs for Improving Through Traffic Along the Arterial Road. Master’s Thesis, Florida State University, Tallahassee, FL, USA, 2007. Available online: http://purl.flvc.org/fsu/fd/FSU_migr_etd-4052 (accessed on 26 October 2022).

- Hughes, W.; Jagannathan, R.; Sengupta, D.; Hummer, J. Alternative Intersection/Interchanges: Informational Report (AIIR); Technical Report, FHWA-HRT-09-060; Turner–Fairbank Highway Research Center, FHWA, U.S. Department of Transportation: McLean, WV, USA, 2010.

- Virginia Department of Transportation. Innovative Intersections and Interchanges—Echelon. 2021. Available online: https://www.virginiadot.org/info/innovative_intersections_and_interchanges/echelon.asp (accessed on 26 October 2022).

- Brown, H.; Edara, P.; Hartman, G.; Chlewicki, G. Alternative Intersection Design and Selection: A Synthesis of Highway Practice; The National Academies Press: Washington, DC, USA, 2020. [Google Scholar] [CrossRef]

- Olarte, C. Operational and Environmental Comparisons Between Left-Turn Bypass, Diverging Flow and Displaced Left-Turn; Florida Atlantic University: Boca Raton, FL, USA, 2011; Available online: https://fau.digital.flvc.org/islandora/object/fau%3A3656 (accessed on 26 October 2022).

- Shin, E.; Lee, J.; Kim, J.; Kim, J.; Jeong, Y. Two-Level Signalized Intersection. Transp. Res. Rec. J. Transp. Res. Board 2008, 2060, 53–64. [Google Scholar] [CrossRef]

- Steyn, H.; Bugg, Z.; Ray, B.; Daleiden, A.; Penior, J.; Knudsen, J. Displaced Left Turn Intersection Informational Guide; Technical Report, FHWA-SA-14-068; U.S. Department of Transportation Federal Highway Administration Office of Safety: Washington, DC, USA, 2014.

- Hummer, J.; Ray, B.; Daleiden, A.; Jenior, P.; Knudsen, J. Restricted Crossing U-turn Informational Guide; Technical Report, FHWA-SA-14-070; U.S. Department of Transportation Federal Highway Administration Office of Safety: Washington, DC, USA, 2014.

- Schroeder, B.; Cunningham, C.; Ray, B.; Daleiden, A.; Jenior, P.; Knudsen, J. Diverging Diamond Interchange Informational Guide; Technical Report, FHWA-SA-14-067; U.S. Department of Transportation Federal Highway Administration Office of Safety: Washington, DC, USA, 2014.

- Meng, Q.; Weng, J. Optimal Sub Work Zone Length and Project Start Time for Short-Term Daytime Work Zones from the Contractor’s Perspective. Transp. Res. Part C 2013, 29, 72–83. [Google Scholar] [CrossRef]

- He, Q.; Kamineni, R.; Zhang, Z. Traffic signal control with partial grade separation for oversaturated Conditions. Transp. Res. Part C Emerg. Technol. 2016, 71, 267–283. [Google Scholar] [CrossRef]

- Brown, H.; Cope, T.; Khezerzadeh, A.; Sun, C.; Edara, P. Maintenance of Traffic for Innovative Geometric Design Work Zones. Transp. Res. Rec. 2016, 2556, 49–64. [Google Scholar] [CrossRef]

- Hummer, J.; Jagannathan, R. An Update on Superstreet Implementation and Research. In Proceedings of the Eighth National Conference on Access Management Transportation Research Board, Baltimore, MD, USA, 13–16 July 2008. [Google Scholar]

- Federal Highway Administration. Drivers’ Evaluation of the Diverging Diamond Interchange; Technical Brief, FHWA-HRT-07-048; Federal Highway Administration: New York, NY, USA, 2017. Available online: https://www.fhwa.dot.gov/publications/research/safety/07048/ (accessed on 2 February 2023).

- Abudayyeh, O.; Dibert-DeYoung, A.; Jaselskis, E. Analysis of Trends in Construction Research: 1985–2002. J. Constr. Eng. Manag. 2004, 130, 433–439. [Google Scholar] [CrossRef]

- Construction Industry Institute Australia. Constructability Manual; Construction Industry Institute Australia: Brisbane, Australia, 1996. [Google Scholar]

- AASHTO. Constructability Review Best Practices Guide; Technical Report; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2000. [Google Scholar]

- Ansyorie, M. Concepts of Constructability for Project Construction in Indonesia. In Proceedings of the 2nd International Conference on Green Civil and Environmental Engineering, Langkawi, Kedah, Malaysia, 21 November 2019. [Google Scholar]

- Construction Industry Institute. Constructability: A Primer; Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1986. [Google Scholar]

- O’Connor, J.; Rusch, S.; Schulz, M. Constructability Improvement During Engineering and Procurement. Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1986. [Google Scholar]

- Tatum, C.; Vanegas, J.; Williams, J. Constructability Improvement Using Prefabrication, Preassembly, and Modularization. Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1987. [Google Scholar]

- Tatum, C.; Vanegas, J.; Williams, J. Constructability Improvement During Conceptual Planning. Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1986. [Google Scholar]

- Construction Industry Institute. Constructability Concepts File; Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1987. [Google Scholar]

- Construction Industry Institute. Guidelines for Implementing a Constructability Program; Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1987. [Google Scholar]

- O’Connor, T.; Miller, S. Barriers to Constructability Implementation. J. Perform. Constr. Facil. 1994, 8, 110–129. [Google Scholar] [CrossRef]

- Construction Industry Institute. Constructability Improvement During Field Operations; Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1993. [Google Scholar]

- O’Connor, J.; Norwich, W. Fossil Power Plant Constructability Applications of CII Concepts. J. Energy Eng. 1993, 119, 55–73. [Google Scholar] [CrossRef]

- O’Connor, J. Constructability Implementation Guide; Construction Industry Institute, University of Texas: Austin, TX, USA, 2006. [Google Scholar]

- Russell, J.; Gugel, J.; Radtke, M. Comparative Analysis of Three Constructability Approaches. J. Constr. Eng. Manag. 1992, 120, 180–195. [Google Scholar] [CrossRef]

- Russell, J.; Radtke, M.; Gugel, J. Project-Level Model and Approaches to Implement Constructability; Technical Report; Construction Industry Institute, University of Texas: Austin, TX, USA, 1992. [Google Scholar]

- Radtke, M.; Russell, J. Project-Level Model Process for Implementing Constructability. J. Constr. Eng. Manag. 1993, 119, 813–831. [Google Scholar] [CrossRef]

- Russell, J.; Swiggum, K.; Shapiro, J.; Alaydrus, A. Constructability Related to TQM, Value Engineering, and Cost/Benefits. J. Perform. Constr. Facil. 1994, 8, 31–45. [Google Scholar] [CrossRef]

- Anderson, S.; Fisher, D. NCHRP Report 390: Constructability Review Process for Transportation Facilities. In National Cooperative Highway Research Program; National Academy Press: Washington, DC, USA, 1997. [Google Scholar]

- Madson, K.; Franz, B.; Leicht, R.; Nelson, J. Evaluating the Sustainability of New Construction Projects over Time by Examining the Evolution of the LEED Rating System. Sustainability 2022, 14, 15422. [Google Scholar] [CrossRef]

- Othman, A. Improving Building Performance through Integrating Constructability in the Design Process. Organ. Technol. Manag. Constr. Int. J. 2011, 333–347. [Google Scholar] [CrossRef]

- Smadi, A.; Tran, D. A Proposed Approach for Determining Appropriate Constructability Reviews Level for Highway Construction Projects. In Proceedings of the Construction Research Congress 2020, Tempe, Arizona, 8–10 March 2020. [Google Scholar]

- RealProjectives. The Advantages and Challenges of Modular Construction. 2019. Available online: https://www.realprojectives.com/the-advantages-and-challenges-of-modular-construction/ (accessed on 26 October 2022).

- El-Abidi, K.; Ghazali, F. Motivations and Limitations of Prefabricated Building: An Overview. Appl. Mech. Mater. 2015, 802, 668–675. Available online: https://www.scientific.net/AMM.802.668.pdf (accessed on 26 October 2022). [CrossRef]

- Castro-Lacouture, D.; Bryson, L.; Maynard, C.; Williams, R.; Bosscher, P. Concrete Paving Productivity Improvement Using a Multi-Task Autonomous Robot. In Proceedings of the 24th International Symposium Robotics Construction, Kochi, India, 19–21 September 2007. [Google Scholar]

- Karimi, S.; Iordanova, I. Integration of BIM and GIS for Construction Automation, a Systematic Literature Review (SLR) Combining Bibliometric and Qualitative Analysis. Arch. Comput. Methods Eng. 2021, 28, 4573–4594. [Google Scholar] [CrossRef]

- Haas, C.; Skibniewski, M.; Budny, E. Robotics in Civil Engineering. Comput.-Aided Civ. Infrastruct. Eng. 1995, 10, 371–381. [Google Scholar] [CrossRef]

- Shah, R.; Dean, D.; Castro, S. A Virtual Construction Model of 4D Planning in Road Project. In Proceedings of the 25th Annual ARCOM Conference, Nottingham, UK, 7–9 September 2009. [Google Scholar]

- Park, J.; Cai, H. Framework of Dynamic Daily 4D BIM for Tracking Construction Progress through a Web Environment; ASCE International Workshop on Computing in Civil Engineering: Seattle, WA, USA, 2017. [Google Scholar]

- Chong, H.; Lopez, R.; Wang, J.; Wang, X.; Zhao, Z. Comparative Analysis on the Adoption and Use of BIM in Road Infrastructure Projects. J. Manag. Eng. 2016, 32, 1–13. [Google Scholar] [CrossRef]

- Excelize. Why you Need Construction Sequencing Management? 2021. Available online: https://excelizeblog.wordpress.com/2020/02/20/why-you-need-construction-sequencing-management/ (accessed on 26 October 2022).

- Tynan, J. Constructability Review; Checklist; New York State Department of Transportation Engineering Instruction: New York, NY, USA, 1999; pp. 1–9. Available online: https://www.dot.ny.gov/portal/pls/portal/mexis_app.pa_ei_eb_admin_app.show_pdf?id=1574 (accessed on 26 October 2022).

- Hancher, D.; Thozhal, J.; Goodrum, P. Constructability Issues on KYTC Projects; Technical Report, KTC-03-17/SPR-236-02-1F; Kentucky Transportation Center, University of Kentucky: Lexington, KY, USA, 2003. [Google Scholar]

- Wong, F.; Lam, P.; Chan, E.; Shen, L. A Study of Measures to Improve Constructability. Int. J. Qual. Reliab. Manag. 2006, 24, 586–601. [Google Scholar] [CrossRef]

- U.S. Army Corps of Engineers. Engineering and Construction: Biddability, Constructability, Operability, Environmental and Sustainability (BCOES) Reviews; Technical Report, ER 415-1-11; U.S. Army Corps of Engineers: Washington, DC, USA, 2013.

- Zhan, J.; El Diraby, T.E. Constructability Analysis of the Bridge Superstructure Rotation Construction Method in China. J. Constr. Eng. Manag. 2006, 132, 353–362. [Google Scholar] [CrossRef]

- Reeder, G.; Nelson, G. Implementation Manual 3D Engineered Models for Highway Construction: The Iowa Experience; Technical Report, Project RB33-014; Iowa Department of Transportation, Federal Highway Administration: Ames, Iowa, 2015.

- Brown, D. Constructability Considerations in Selection and Design of Drilled Shaft Foundations for Bridges. Transp. Res. Rec. J. Transp. Res. Board 2010, 2202, 3–9. [Google Scholar] [CrossRef]

- Terzioglu, T.; Jiang, D.; Hueste, B.; Mander, J. Design and Constructability of Spread Slab-Beam Bridges. J. Transp. Eng. 2016, 21, 1–11. [Google Scholar] [CrossRef]

- Arzamendi, M.; Montesi, M.; Owsiany, F. Geotechnical Considerations for Retaining Walls Below Interstate I-5 and SR-52 Interchange, San Diego, CA. In Geo-Congress 2020: Engineering, Monitoring, and Management of Geotechnical Infrastructure; Minneapolis Minnesota, US; American Society of Civil Engineers: Washington, DC, USA, 2020. [Google Scholar] [CrossRef]

- Bradshaw, A.; Baxter, C.; Osborn, P. Lessons Learned from Pile Driving at the Central Artery/Tunnel Project. J. Transp. Eng. 2005, 2016, 143–148. [Google Scholar]

- Cadenazzi, T.; Nolan, S.; Mazzocchi, G.; Stringer, Z.; Nanni, A. Bridge Case Study: What a Contractor Needs to Know on an FRP Reinforcement Project. J. Constr. Eng. Manag. 2020, 24, 1–12. [Google Scholar] [CrossRef]

- Michelle, L.; Hubert, K.; Tighe, S. Conceptual Design of Road and Bridge Substructure in Northern Canada with Considerations for Constructability and Climate Change. In Proceedings of the Annual Conference—Canadian Society for Civil Engineering, Laval, QC, Canada, 12–15 June 2019. [Google Scholar]

- Sanchez, T.; White, D. Stability of Curved Steel I-Girder Bridges During Construction. Transp. Res. Rec. J. Transp. Res. Board 2012, 2268, 122–129. [Google Scholar] [CrossRef]

- Yang, Q.J. Geotechnical Design and Bridge Foundations and Approaches in Hilly Granite Formation. Geotech. Geol. Eng. 2017, 11, 803–809. [Google Scholar]

- Concrete Opening. CSDA Contractor Assists in Planning and Engineering Demolition of Arlington Memorial Bridge. Magazine; Concrete Opening: Montreal, QC, Canada, 2020; pp. 6–9. [Google Scholar]

- Maves, M.; Furrer, M. Ready for Launch. Modern Steel Construction. 2020. Available online: https://lsc-pagepro.mydigitalpublication.com/publication/?m=7946&i=672453&p=26 (accessed on 26 October 2022).

- Aktan, H.; Attanayake, U. Research on Evaluation and Standardization of Accelerated Bridge Construction Techniques; Technical Report, RC-1618A; Michigan Department of Transportation, Western Michigan University: Kalamazoo, MI, USA, 2015. [Google Scholar]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Alternative ABC Connections Utilizing UHPC. In Proceedings of the Transportation Research Board 96th Annual Meeting Transportation Research Board, Washington, DC, USA, 8–12 January 2017. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge, 4th ed.; Project Management Institute: Newton Square, PA, USA, 2009; p. 6. ISBN 9781933890517. [Google Scholar]

- Construction Industry Institute. CII Best Practices. 2022. Available online: https://www.construction-institute.org/resources/knowledgebase/best-practices (accessed on 26 October 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).