Geotechnical Properties and Stabilization Mechanism of Nano-MgO Stabilized Loess

Abstract

1. Introduction

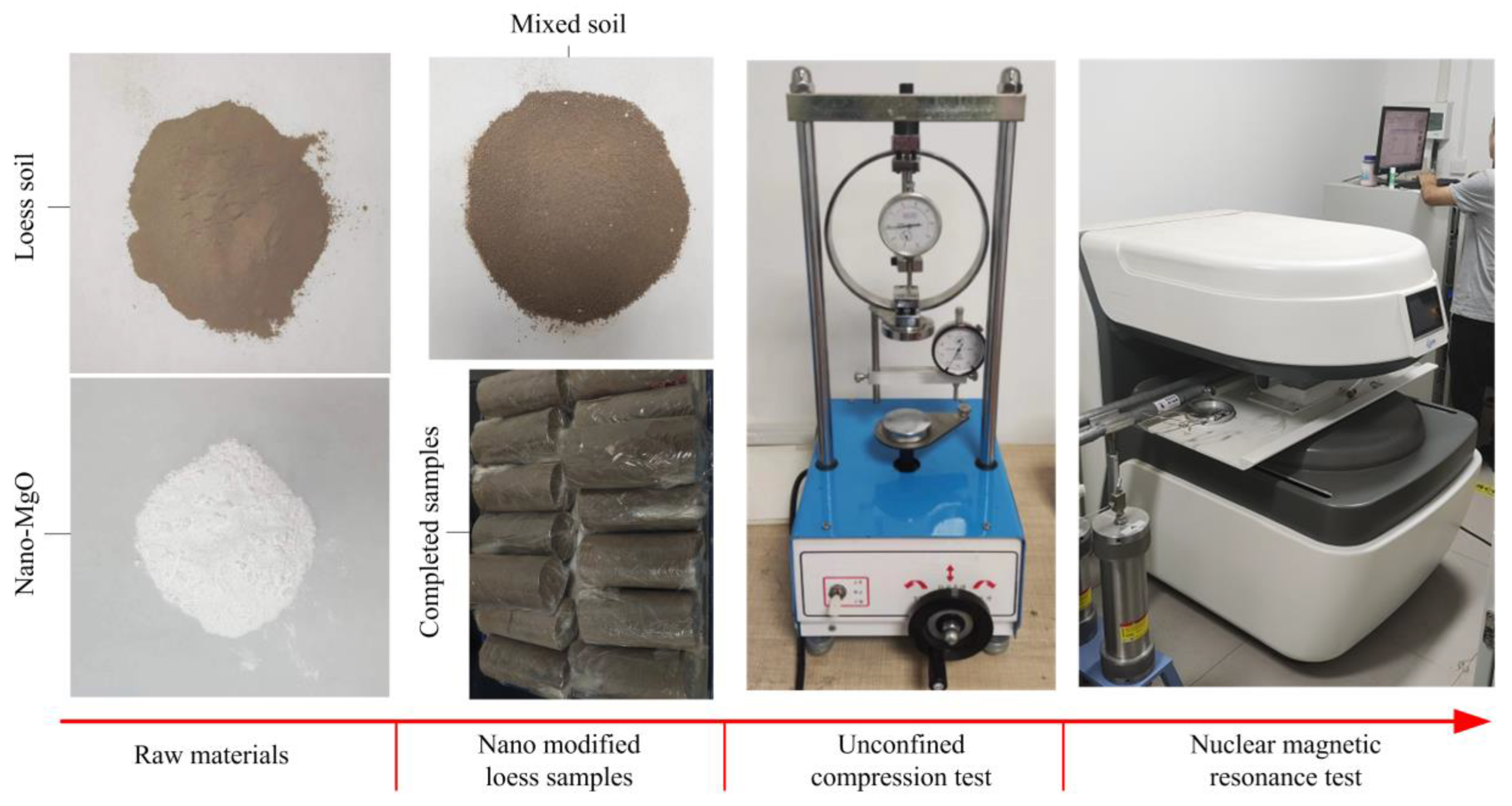

2. Materials and Methods

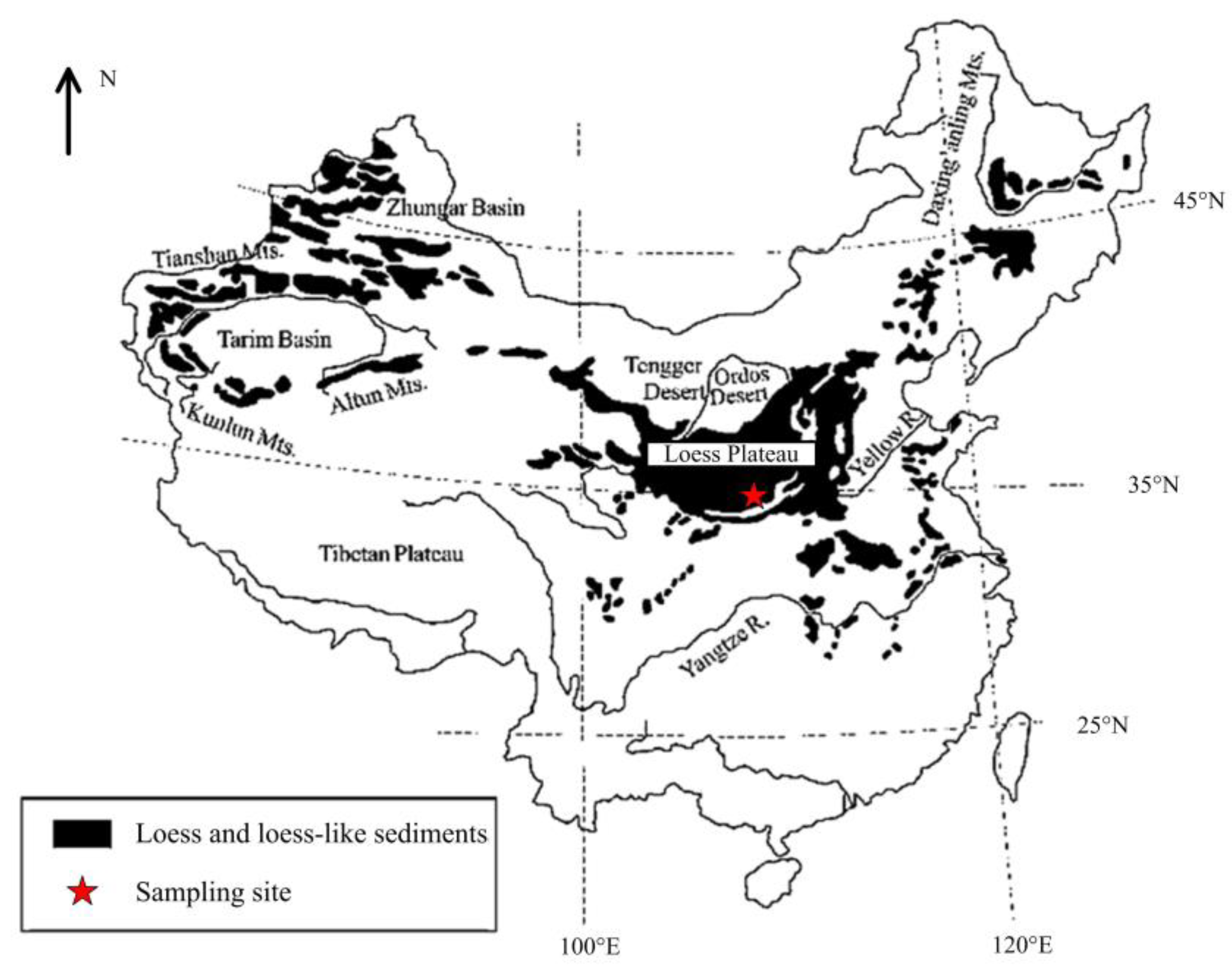

2.1. Raw Materials

2.2. Consistency Limits and Compaction Test

2.3. Unconfined Compression Test

2.4. Nuclear Magnetic Resonance Test

3. Results and Discussion

3.1. Consistency Limits

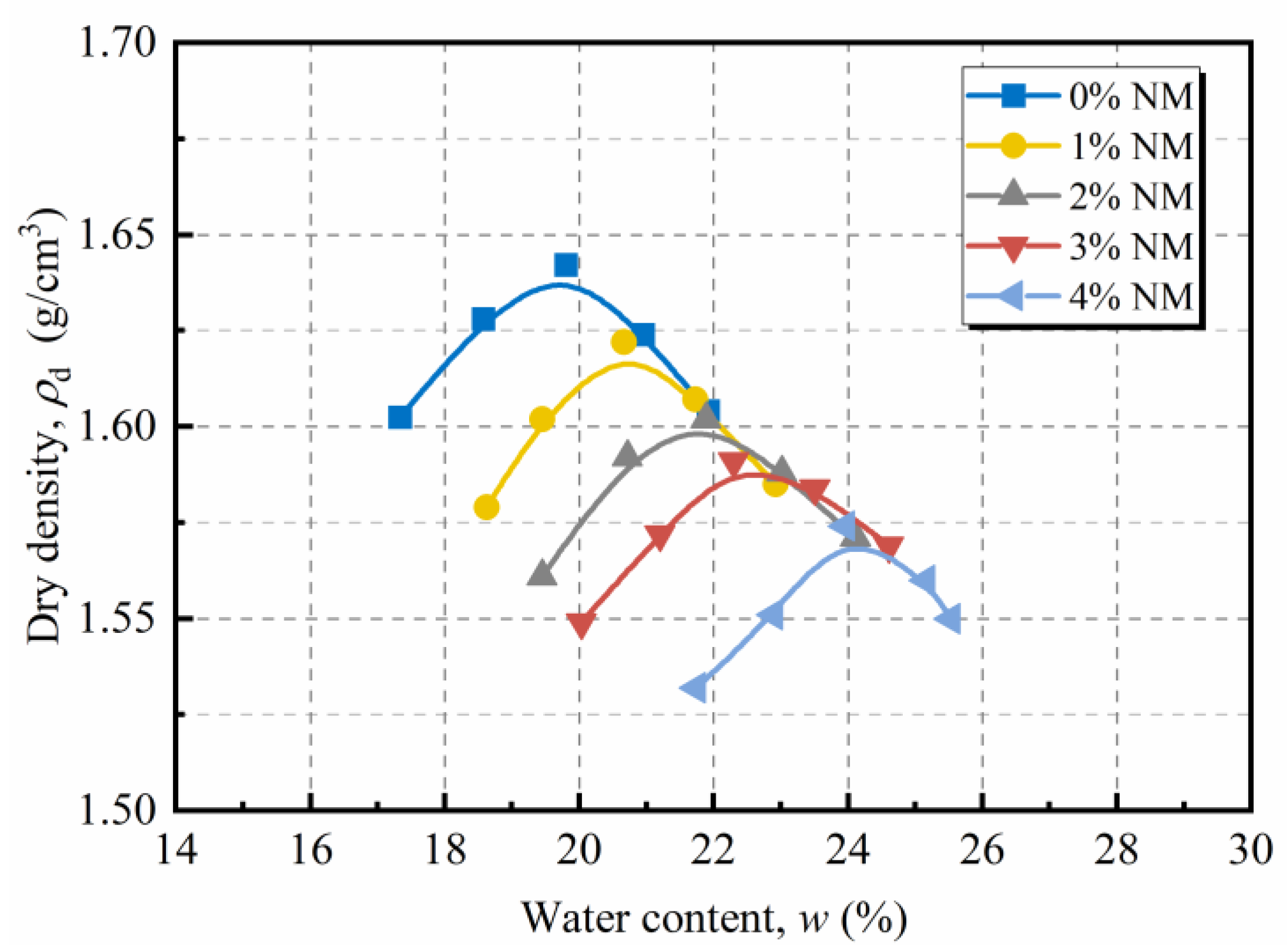

3.2. Compactability

3.3. Mechanical Properties

3.3.1. Stress–Strain Behavior

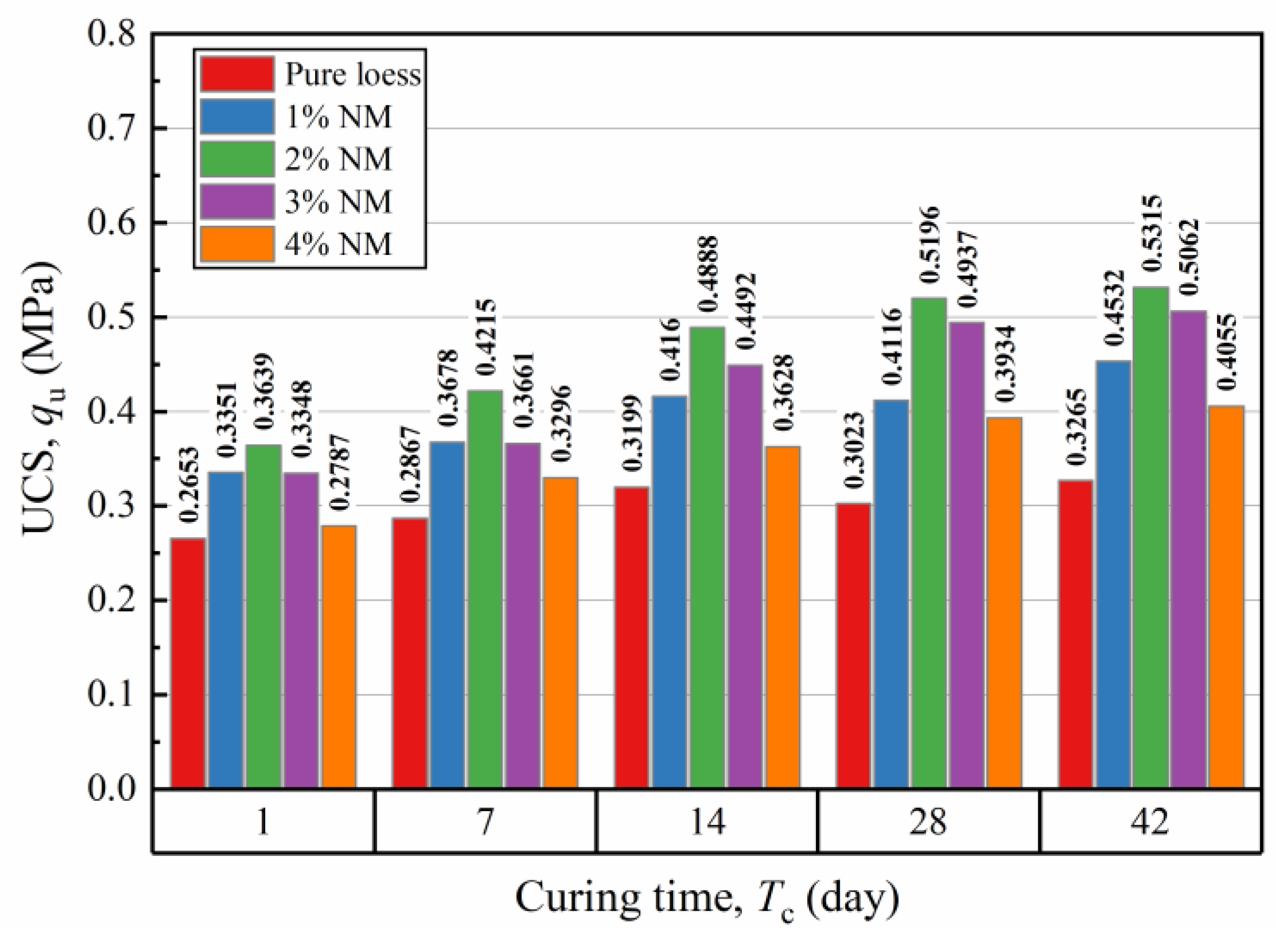

3.3.2. Unconfined Compressive Strength

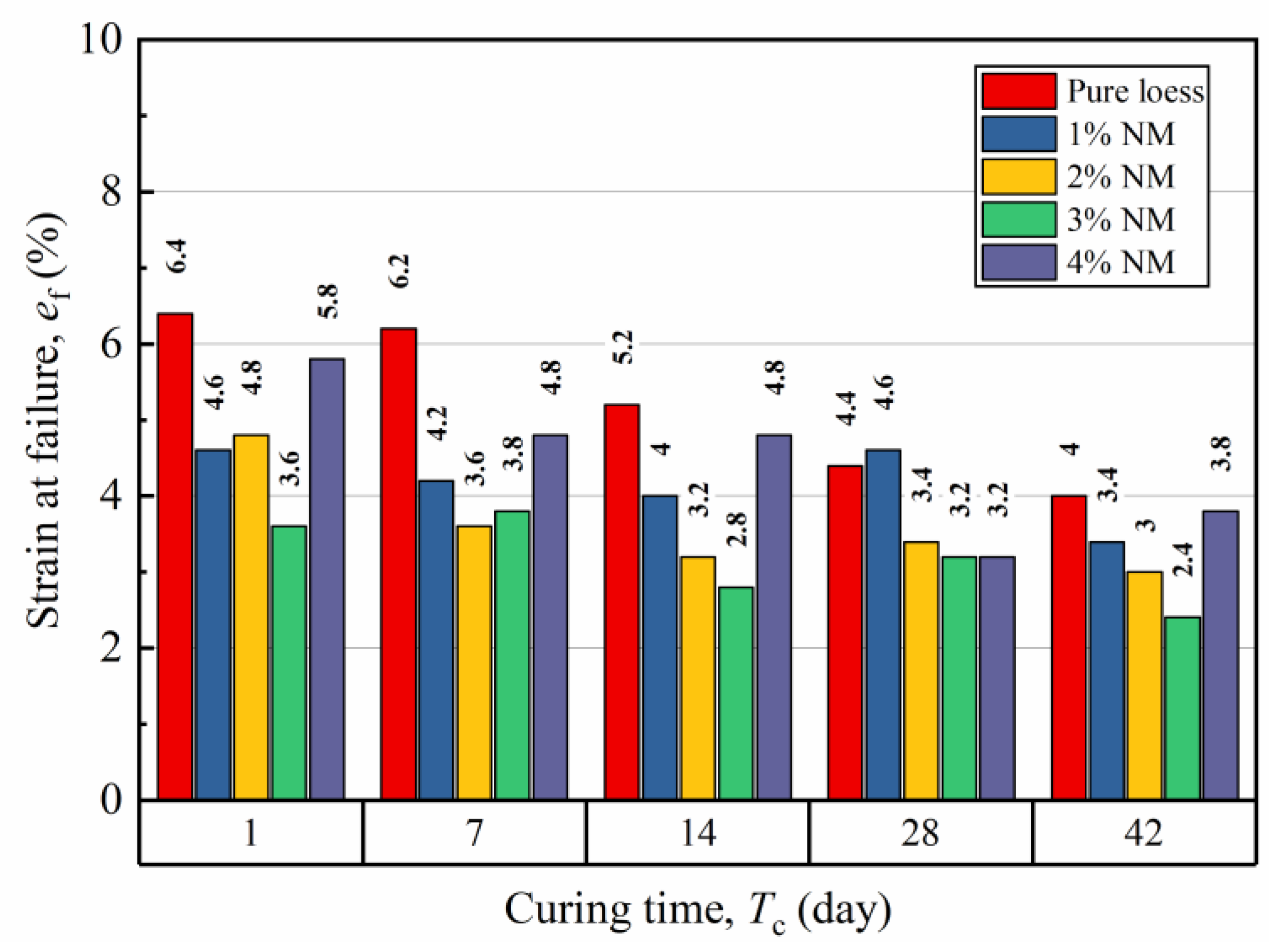

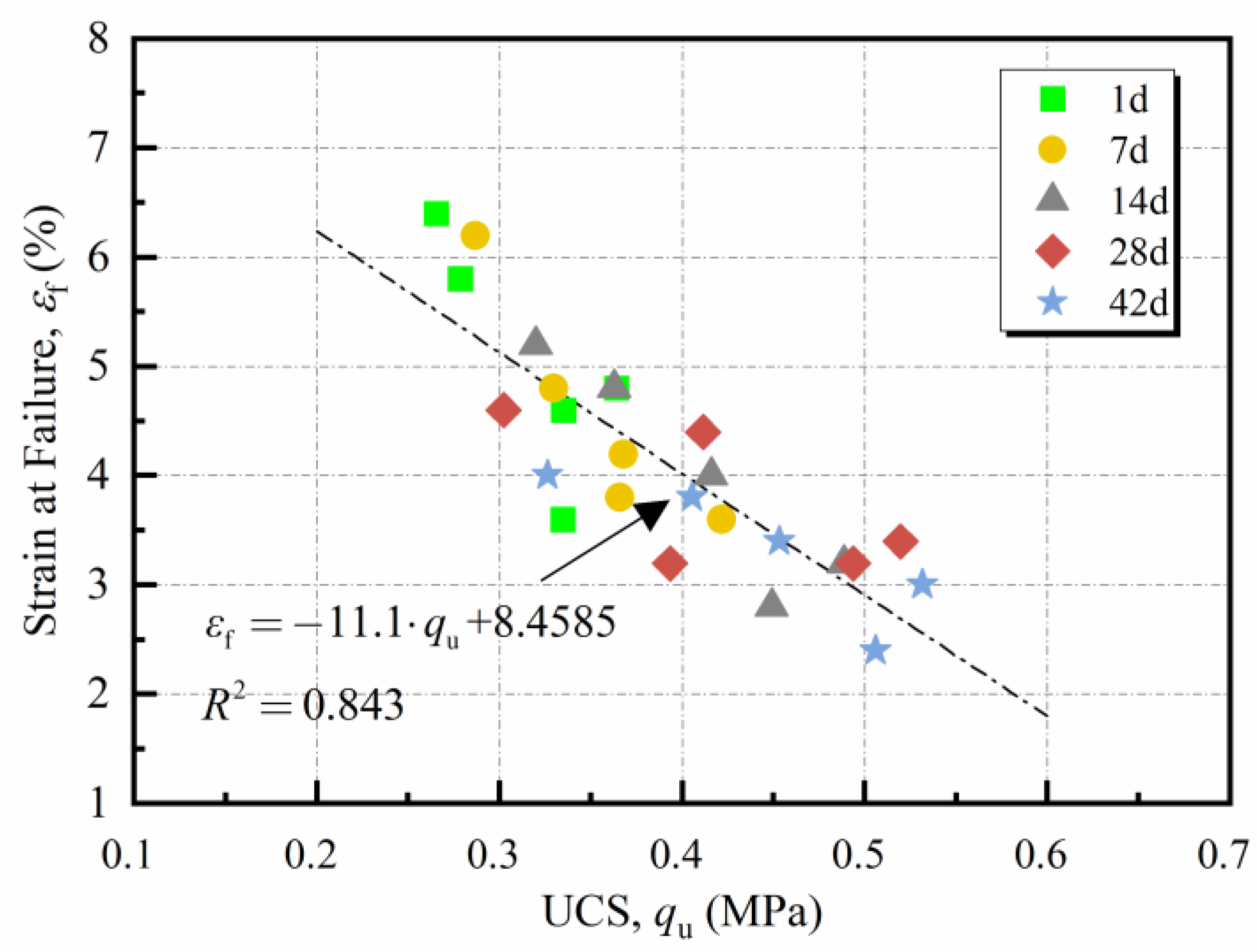

3.3.3. Strain at Failure

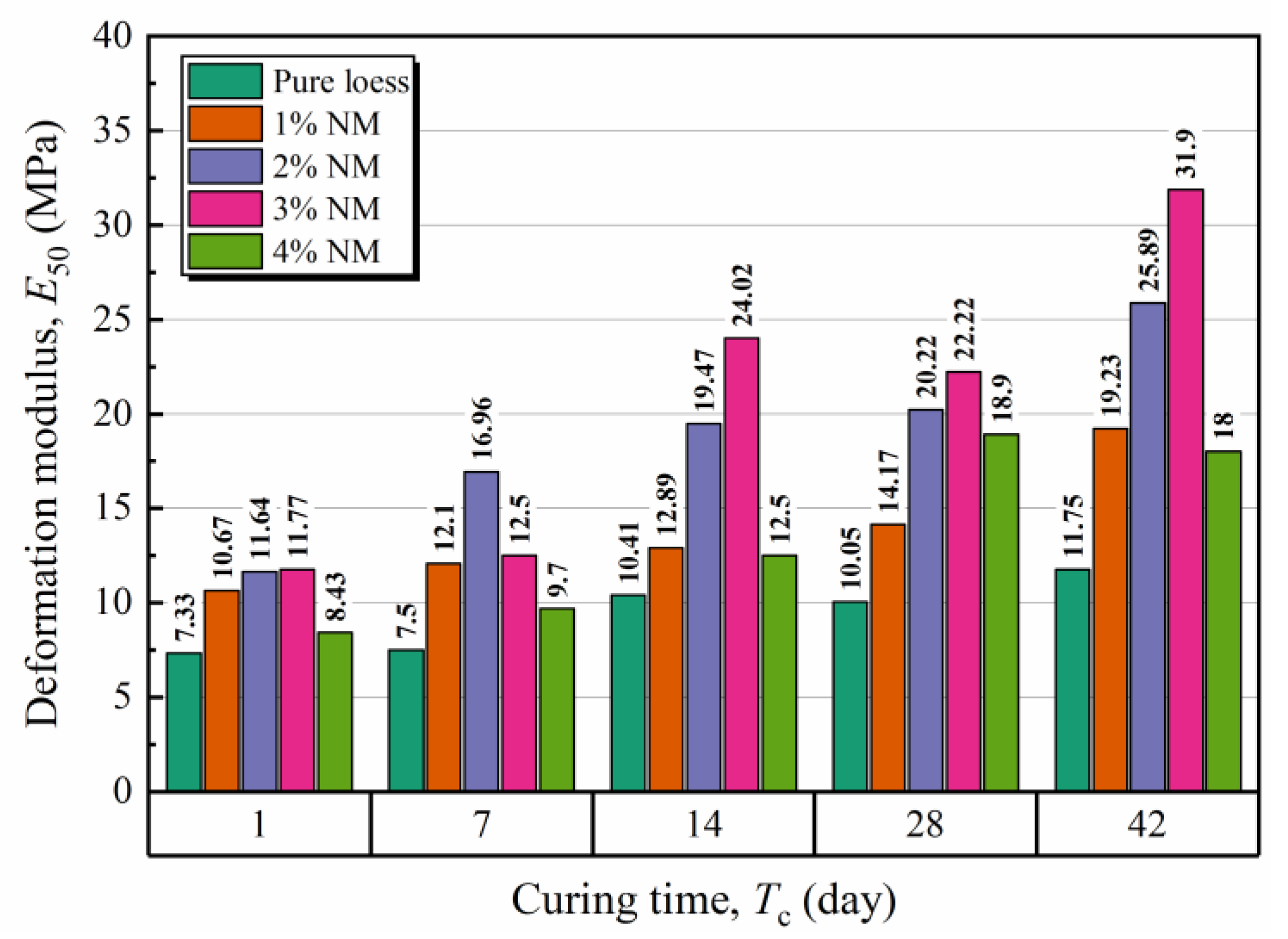

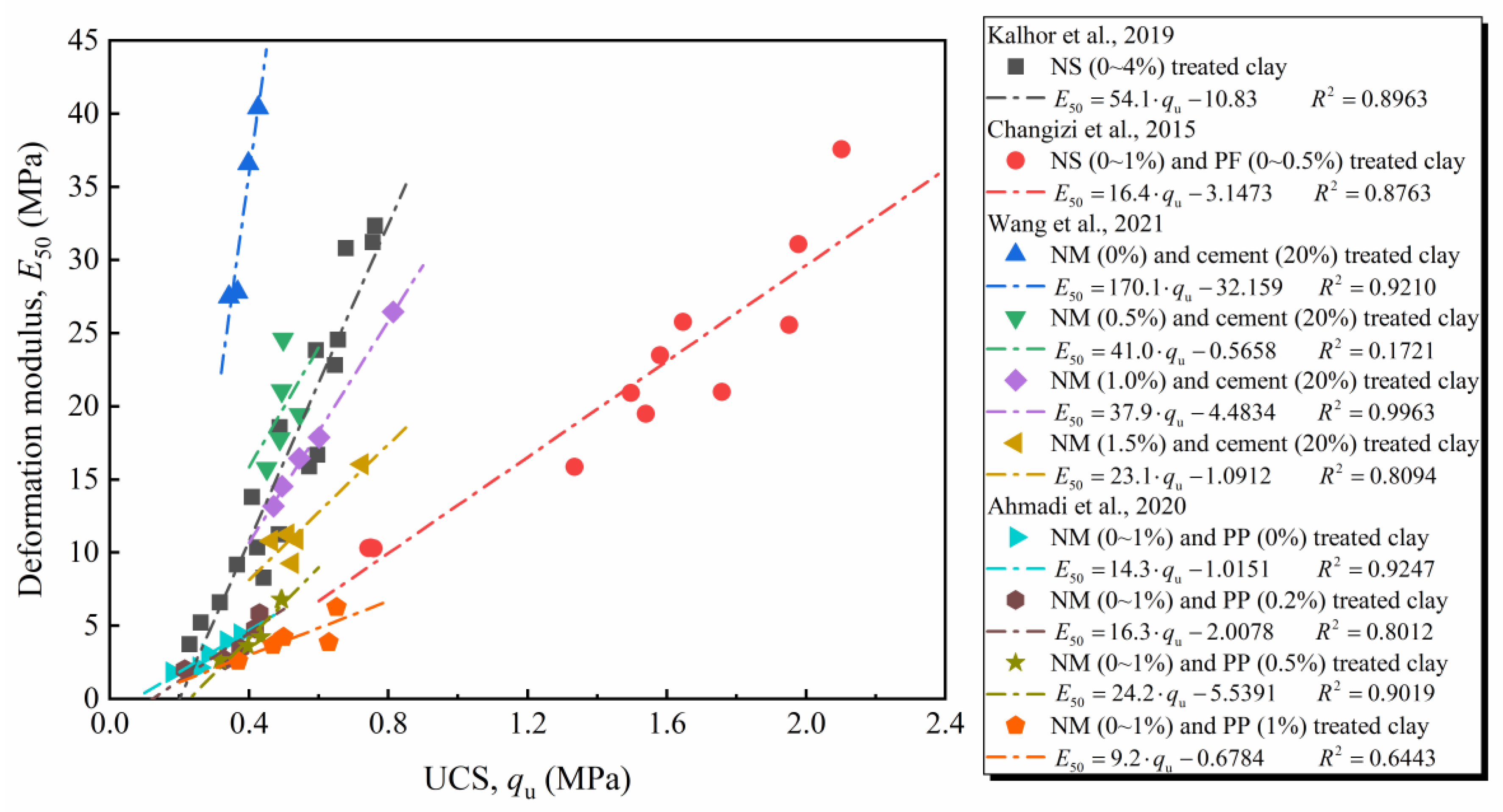

3.3.4. Deformation Modulus

3.4. Stabilization Mechanism

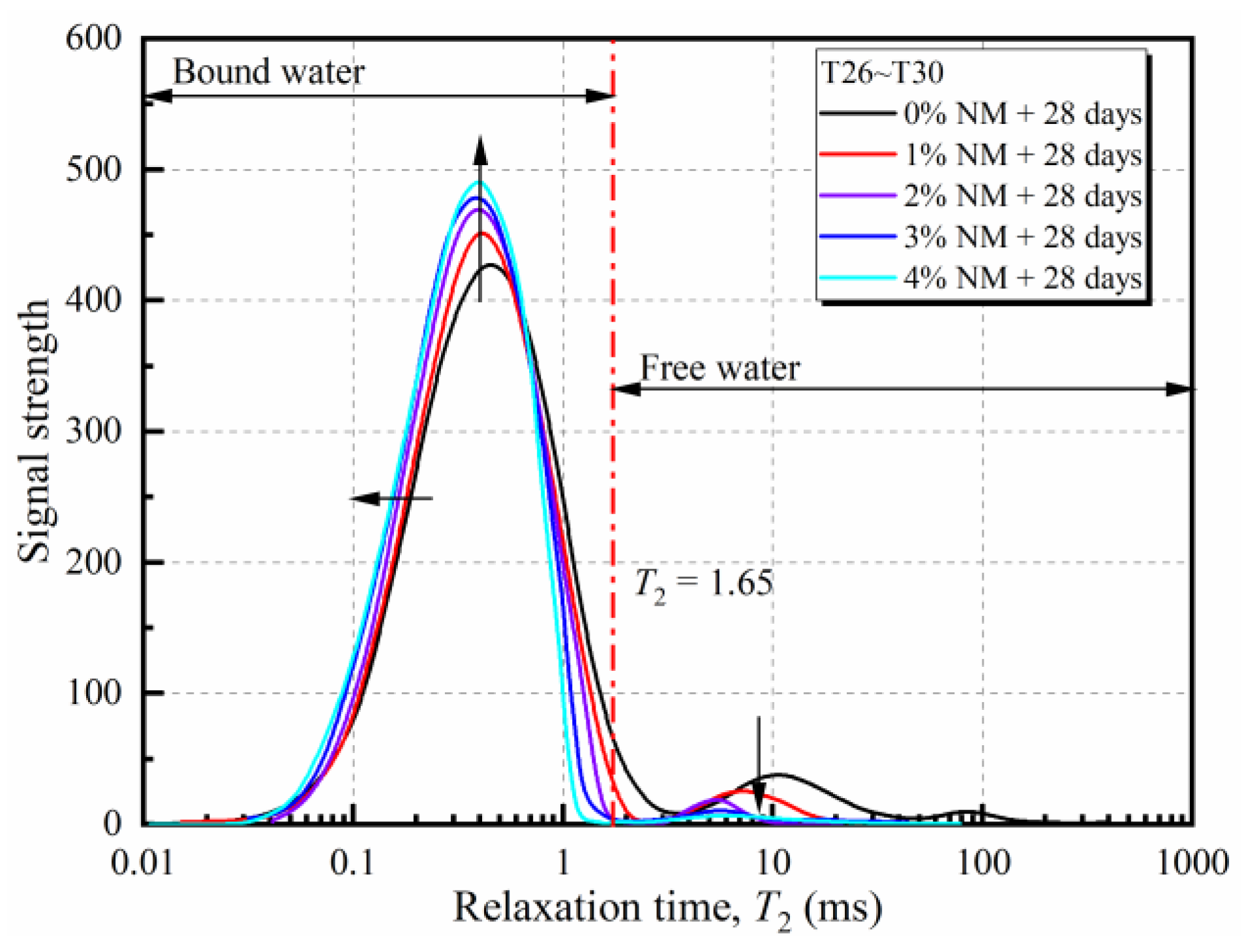

3.4.1. Effect of Nano-MgO

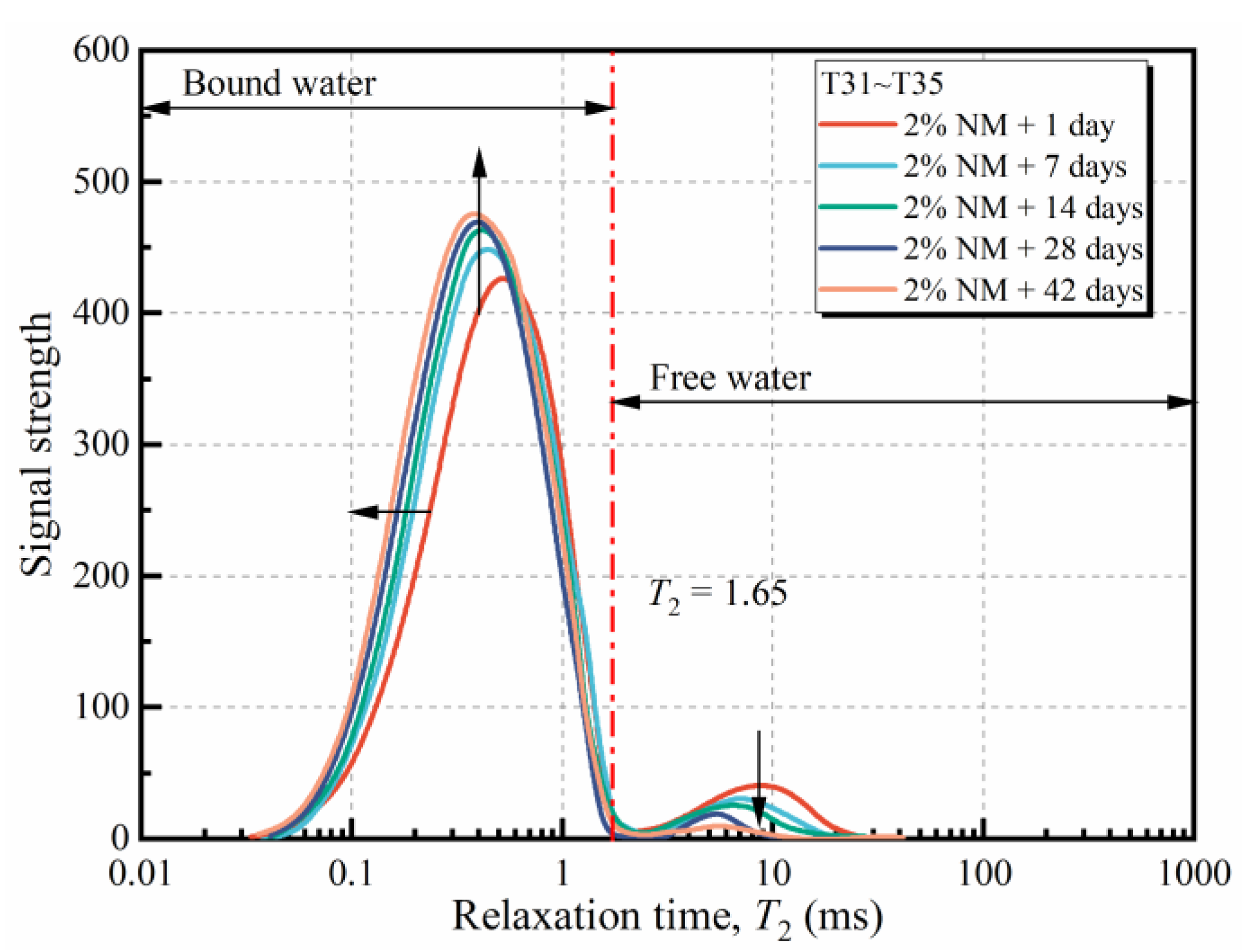

3.4.2. Effects of Curing Time

4. Conclusions

- Adding NM to loess soil led to increases in the plastic limit (from 20.5% to 28.7%), liquid limit (from 34.2% to 37.8%), and optimum water content (from 19.8% to 23.9%), but declines in the plasticity index (from 13.7% to 9.1%) and maximum dry density (from 1.64 g/cm3 to 1.57 g/cm3).

- NM and curing were two crucial factors influencing the mechanical properties of NM-treated loess. The improvement in UCS with curing was evident in the early 28 days and became insignificant thereafter. As NM content increased, the UCS followed a “rise-fall” path (from about 0.3023 to 0.5196 to 0.3934 MPa for 28d curing), indicating an optimum NM dosage at 2%. So, 2% NM-treated loess with 28 days of curing is accordingly suggested, and about 72% UCS gain is to be expected in this condition.

- The strain at failure decreased at first and then increased with the addition of NM. However, the deformation modulus presented an opposite trend. Both of them exhibited a linear relationship with UCS. Empirical models for them were established and validated by literature data.

- The stabilizing mechanism of NM-treated loess was explored from the aspect of water-state change. The enhancement of mechanical properties primarily was due to the water-absorbing and cementing effects of NM. The former caused water transformation from free-water to bound-water inside the soil and enhanced the interparticle cohesion as potently as the cementing effect did.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xue, Z.F.; Cheng, W.C.; Wang, L.; Song, G. Improvement of the shearing behavior of loess using recycled straw fiber reinforcement. KSCE J. Civ. Eng. 2021, 25, 3319–3335. [Google Scholar] [CrossRef]

- Li, Y.; Shi, W.; Aydin, A.; Beroya-Eitner, M.A.; Gao, G. Loess genesis and worldwide distribution. Earth-Sci. Rev. 2020, 201, 102947. [Google Scholar] [CrossRef]

- Wang, S.L.; Lv, Q.F.; Baaj, H.; Li, X.Y.; Zhao, Y.X. Volume change behavior and microstructure of stabilized loess under cyclic freeze-thaw conditions. Can. J. Civ. Eng. 2016, 43, 865–874. [Google Scholar] [CrossRef]

- Jia, L.; Guo, J.; Zhou, Z.; Fu, Y.; Yao, K. Experimental investigation on strength development of lime stabilized loess. RSC Adv. 2019, 9, 19680–19689. [Google Scholar] [CrossRef]

- Mariri, M.; Moayed, R.Z.; Kordnaeij, A. Stress-strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J. Mater. Civ. Eng. 2019, 31, 04019291. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, Z.; Jing, Y. Characteristics of strength and pore distribution of lime-fly ash loess under freeze-thaw cycles and dry-wet cycles. Arab. J. Geosci. 2017, 10, 544. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Freeze-thaw performance of cement and fly ash stabilized loess. Transp. Geotech. 2019, 21, 100279. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Kannan, G.; Sujatha, E.R. A review on the choice of nano-silica as soil stabilizer. Silicon 2022, 14, 6477–6492. [Google Scholar] [CrossRef]

- Arulrajah, A.; Mohammadinia, A.; Phummiphan, I.; Horpibulsuk, S.; Samingthong, W. Stabilization of recycled demolition aggregates by geopolymers comprising calcium carbide residue, fly ash and slag precursors. Constr. Build. Mater. 2016, 114, 864–873. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Ismael, I.A.; Yavuz, A. Use of zinc coated steel CNC milling waste for road pavement subgrade. Transp. Geotech. 2020, 23, 100342. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Tae, G.H.; Park, J.B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Hanus, M.J.; Harris, A.T. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 2013, 58, 1056–1102. [Google Scholar] [CrossRef]

- Krishnan, J.; Shukla, S. The behavior of soil stabilized with nanoparticles: An extensive review of the present status and its applications. Arab. J. Geosci. 2019, 12, 436. [Google Scholar] [CrossRef]

- Zhang, G. Soil nanoparticles and their influence on engineering properties of soils. In Proceedings of the Geo-Denver 2007, Denver, CO, USA, 18–21 February 2007; pp. 1–13. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L. Experimental studies on nanomaterials for soil improvement: A review. Environ. Earth Sci. 2016, 75, 497. [Google Scholar] [CrossRef]

- Ghasabkolaei, N.; Janalizadeh Choobbasti, A.; Roshan, N.; Ghasemi, S.E. Geotechnical properties of the soils modified with nanomaterials: A comprehensive review. Arch. Civ. Mech. Eng. 2017, 17, 639–650. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Improving the geotechnical properties of soft clay with nano-silica particles. Proc. Inst. Civ. Eng.-Ground Improv. 2017, 170, 62–71. [Google Scholar] [CrossRef]

- Sarli, J.M.; Hadadi, F.; Bagheri, R.A. Stabilizing geotechnical properties of loess soil by mixing recycled polyester fiber and nano-SiO2. Geotech. Geol. Eng. 2020, 38, 1151–1163. [Google Scholar] [CrossRef]

- Mohammadi, M.; Niazian, M. Investigation of nano-clay effect on geotechnical properties of Rasht clay. Int. J. Adv. Sci. Tech. Res. 2013, 3, 37–46. Available online: http://refhub.elsevier.com/S0950-0618(17)31918-9/h0405 (accessed on 17 February 2023).

- Taha, M.R.; Taha, O.M.E. Influence of nano-material on the expansive and shrinkage soil behavior. J. Nanopart. Res. 2012, 14, 1190. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, H.; Li, J.; Tao, F.; Li, C.; Qian, B.; Jiang, P. Influence of carbonization process on the mechanical properties of nano-MgO modified cement soil. Sustainability 2021, 13, 3558. [Google Scholar] [CrossRef]

- Yao, K.; Wang, W.; Li, N.; Zhang, C.; Wang, L. Investigation on strength and microstructure characteristics of nano-MgO admixed with cemented soft soil. Constr. Build. Mater. 2019, 206, 160–168. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Samakoosh, M.A.; Kutanaei, S.S. Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr. Build. Mater. 2019, 211, 1094–1104. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rajabi, A.M.; Khodaparast, M. Experimental and numerical evaluation of the effect of nano calcium carbonate on geotechnical properties of clayey sand soil. KSCE J. Civ. Eng. 2022, 26, 35–46. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Comp. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Wang, D.X.; Wang, H.W.; Wang, X.Q. Compressibility and strength behavior of marine soils solidified with MgO-A green and low carbon binder. Mar. Georesour. Geotechnol. 2017, 35, 878–886. [Google Scholar] [CrossRef]

- Gu, K.; Jin, F.; Al-Tabbaa, A.; Shi, B.; Liu, C.; Gao, L. Incorporation of reactive magnesia and quicklime in sustainable binders for soil stabilization. Eng. Geol. 2015, 195, 53–62. [Google Scholar] [CrossRef]

- Gao, L.; Ren, K.; Ren, Z.; Yu, X. Study on the shear property of nano-MgO-modified soil. Mar. Georesour. Geotechnol. 2018, 36, 465–470. [Google Scholar] [CrossRef]

- Majeed, Z.H.; Taha, M.R. Effect of nanomaterial treatment on geotechnical properties of a Penang soft soil. J. Asian Sci. Res. 2012, 2, 587–592. [Google Scholar]

- Kalhor, A.; Ghazavi, M.; Roustaei, M.; Mirhosseini, S.M. Influence of nano-SiO2 on geotechnical properties of fine soils subjected to freeze-thaw cycles. Cold Reg. Sci. Technol. 2019, 161, 129–136. [Google Scholar] [CrossRef]

- Sharo, A.A.; Alawneh, A.S. Enhancement of the strength and swelling characteristics of expansive clayey soil using nano-clay material. In Proceedings of the Geo-Chicago 2016, Chicago, IL, USA, 14–18 August 2016; pp. 451–457. [Google Scholar] [CrossRef]

- Chen, S.; Hou, X.; Luo, T.; Yu, Y.; Jin, L. Effects of MgO nanoparticles on dynamic shear modulus of loess subjected to freeze-thaw cycles. J. Mater. Res. Technol. 2022, 18, 5019–5031. [Google Scholar] [CrossRef]

- Gao, L.; Ren, Z.; Yu, X. Experimental study of nanometer magnesium oxide-modified clay. Soil Mech. Found. Eng. 2015, 52, 218–224. [Google Scholar] [CrossRef]

- Majeed, Z.H.; Taha, M.R. A review of stabilization of soils by using nanomaterials. Aust. J. Basic. Appl. Sci. 2013, 7, 576–581. [Google Scholar]

- Govindasamy, P.; Taha, M.R.; Alsharef, J.; Ramalingam, K. Influence of nanolime and curing period on unconfined compressive strength of soil. Appl. Environ. Soil Sci. 2017, 2017, 8307493. [Google Scholar] [CrossRef]

- Ahmadi, H.; Janati, S.; Jamshidi Chenari, R. Strength parameters of stabilized clay using polypropylene fibers and nano-MgO: An experimental study. Geotech. Geol. Eng. 2020, 38, 2845–2858. [Google Scholar] [CrossRef]

- Cao, G. Nanostructures and Nanomaterials-Synthesis, Properties and Applications; Imperial College Press: London, UK, 2004. [Google Scholar]

- ASTM D422-63; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2007.

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM: West Conshohocken, PA, USA, 2010.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2012.

- Li, G.; Wang, F.; Ma, W.; Fortier, R.; Mu, Y.; Mao, Y.; Hou, X. Variations in strength and deformation of compacted loess exposed to wetting-drying and freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 151, 159–167. [Google Scholar] [CrossRef]

- ASTM D1557-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2013.

- Alhajji, E. Study of water states in different hydrated and consolidated clay using nuclear magnetic resonance. Spectrosc. Lett. 2013, 46, 235–241. [Google Scholar] [CrossRef]

- Buchmann, C.; Schaumann, G.E. Effect of water entrapment by a hydrogel on the microstructural stability of artificial soils with various clay content. Plant Soil 2017, 414, 181–198. [Google Scholar] [CrossRef]

- Basha, E.M.A.; Hashim, R.; Muntohar, A.S. Effect of the cementrice husk ash on the plasticity and compaction of soil. Electron. J. Geotech. Eng. 2003, 8, 1–8. [Google Scholar]

- Kulanthaivel, P.; Selvakumar, S.; Soundara, B.; Kayalvizhi, V.S.; Bhuvaneshwari, S. Combined effect of nano-silica and randomly distributed fibers on the strength behavior of clay soil. Nanotechnol. Environ. Eng. 2022, 7, 23–34. [Google Scholar] [CrossRef]

- Eswaramoorthi, P.; Kumar, V.S.; Prabhu, P.S.; Prabu, T.; Lavanya, S. Influence of nanosized silica and lime particles on the behaviour of soil. Int. J. Civ. Eng. Technol. 2017, 8, 353–360. [Google Scholar]

- Ahmadi, H.; Shafiee, O. Experimental comparative study on the performance of nano-SiO2 and microsilica in stabilization of clay. Eur. Phys. J. Plus 2019, 134, 459. [Google Scholar] [CrossRef]

- Ren, Y.; Yang, S.; Andersen, K.H.; Yang, Q.; Wang, Y. Thixotropy of soft clay: A review. Eng. Geol. 2021, 287, 106097. [Google Scholar] [CrossRef]

- Kannan, G.; O’Kelly, B.C.; Sujatha, E.R. Geotechnical investigation of low-plasticity organic soil treated with nano-calcium carbonate. J. Rock Mech. Geotech. 2022, in press. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Strength properties of soft clay treated with mixture of nano-SiO2 and recycled polyester fiber. J. Rock Mech. Geotech. 2015, 7, 367–378. [Google Scholar] [CrossRef]

- Cai, G.; Liu, S. Compaction and mechanical characteristics and stabilization mechanism of carbonated reactive MgO-stabilized silt. KSCE J. Civ. Eng. 2017, 21, 2641–2654. [Google Scholar] [CrossRef]

- Du, Y.J.; Wei, M.L.; Jin, F.; Liu, Z.B. Stress-strain relation and strength characteristics of cement treated zinc-contaminated clay. Eng. Geol. 2013, 167, 20–26. [Google Scholar] [CrossRef]

- Liu, Y.S.; Cai, G.H.; Du, Y.; Zhu, H.; Wang, P. Engineering properties of carbonated reactive magnesia-stabilized silt under different activity index. Procedia Eng. 2017, 189, 158–165. [Google Scholar] [CrossRef]

- He, P.; Xu, Q.; Liu, J.L.; Pu, C.H.; Chen, D.; Zhao, K.Y. An experimental study of the influence of loess salinity on combined water film thickness based on NMR and nitrogen adsorption technique. Hydrogeol. Eng. Geol. 2020, 47, 142–149. (In Chinese) [Google Scholar] [CrossRef]

- Chen, Q.S.; Yan, G.; Zhuang, X.S.; Pain, A. Dynamic characteristics and microstructural study of nano calcium carbonate modified cemented soil under different salt water solutions. Transp. Geotech. 2022, 32, 100700. [Google Scholar] [CrossRef]

- He, P.; Xu, Q.; Liu, J.L.; Pu, C.H.; Chen, D. Experimental study on the effect of combined water content on shear strength of remolded loess based on NMR. Mt. Res. 2020, 38, 571–580. (In Chinese) [Google Scholar] [CrossRef]

| Properties | Index | Value | |

|---|---|---|---|

| Physical index | Specific gravity | (-) | 2.64 |

| Plastic limit | (%) | 20.5 | |

| Liquid limit | (%) | 34.2 | |

| Plastic index | (-) | 13.7 | |

| Grain size distribution | 2~0.075 mm | (%) | 12 |

| 0.075~0.002 mm | (%) | 71 | |

| <0.002 mm | (%) | 17 | |

| Mineral components | Quartz | (%) | 42 |

| Feldspar | (%) | 32 | |

| Muscovite | (%) | 17 | |

| Montmorillonite | (%) | 5 | |

| Illite | (%) | 4 |

| Chemical Composition | Physical Properties | ||

|---|---|---|---|

| Formula | Concentration | Property | Value |

| MgO | 99.9 | Mean particle size | 40 nm |

| CaO | 0.004 | Melting point | 2850 °C |

| Fe2O3 | 0.002 | Boiling point | 3600 °C |

| TiO2 | 0.003 | Bulk density | 0.74 g/cm3 |

| Other | 0.001 | Specific surface area | 40 m2/g |

| Test Item | Symbol | (-) | w (-) | (g/cm3) | (day) |

|---|---|---|---|---|---|

| SCT | - | 0%, 1%, 2%, 3%, 4% | - | - | - |

| CLT | - | 0%, 1%, 2%, 3%, 4% | - | - | - |

| UCT | T01~T05 | 0%, 1%, 2%, 3%, 4% | wopt | 1 | |

| T06~T10 | 7 | ||||

| T11~T15 | 14 | ||||

| T16~T20 | 28 | ||||

| T21~T25 | 42 | ||||

| NMR | T26~T30 | 0%, 1%, 2%, 3%, 4% | 18.4% | 1.61 | 28 |

| T31~T35 | 2% | 1, 7, 14, 28, 42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Ni, P.; Sun, Z.; Yuan, K. Geotechnical Properties and Stabilization Mechanism of Nano-MgO Stabilized Loess. Sustainability 2023, 15, 4344. https://doi.org/10.3390/su15054344

Chen S, Ni P, Sun Z, Yuan K. Geotechnical Properties and Stabilization Mechanism of Nano-MgO Stabilized Loess. Sustainability. 2023; 15(5):4344. https://doi.org/10.3390/su15054344

Chicago/Turabian StyleChen, Shufeng, Pengfei Ni, Zhao Sun, and Kekuo Yuan. 2023. "Geotechnical Properties and Stabilization Mechanism of Nano-MgO Stabilized Loess" Sustainability 15, no. 5: 4344. https://doi.org/10.3390/su15054344

APA StyleChen, S., Ni, P., Sun, Z., & Yuan, K. (2023). Geotechnical Properties and Stabilization Mechanism of Nano-MgO Stabilized Loess. Sustainability, 15(5), 4344. https://doi.org/10.3390/su15054344