Monitoring Root and Shoot Characteristics for the Sustainable Growth of Barley Using an IoT-Enabled Hydroponic System and AquaCrop Simulator

Abstract

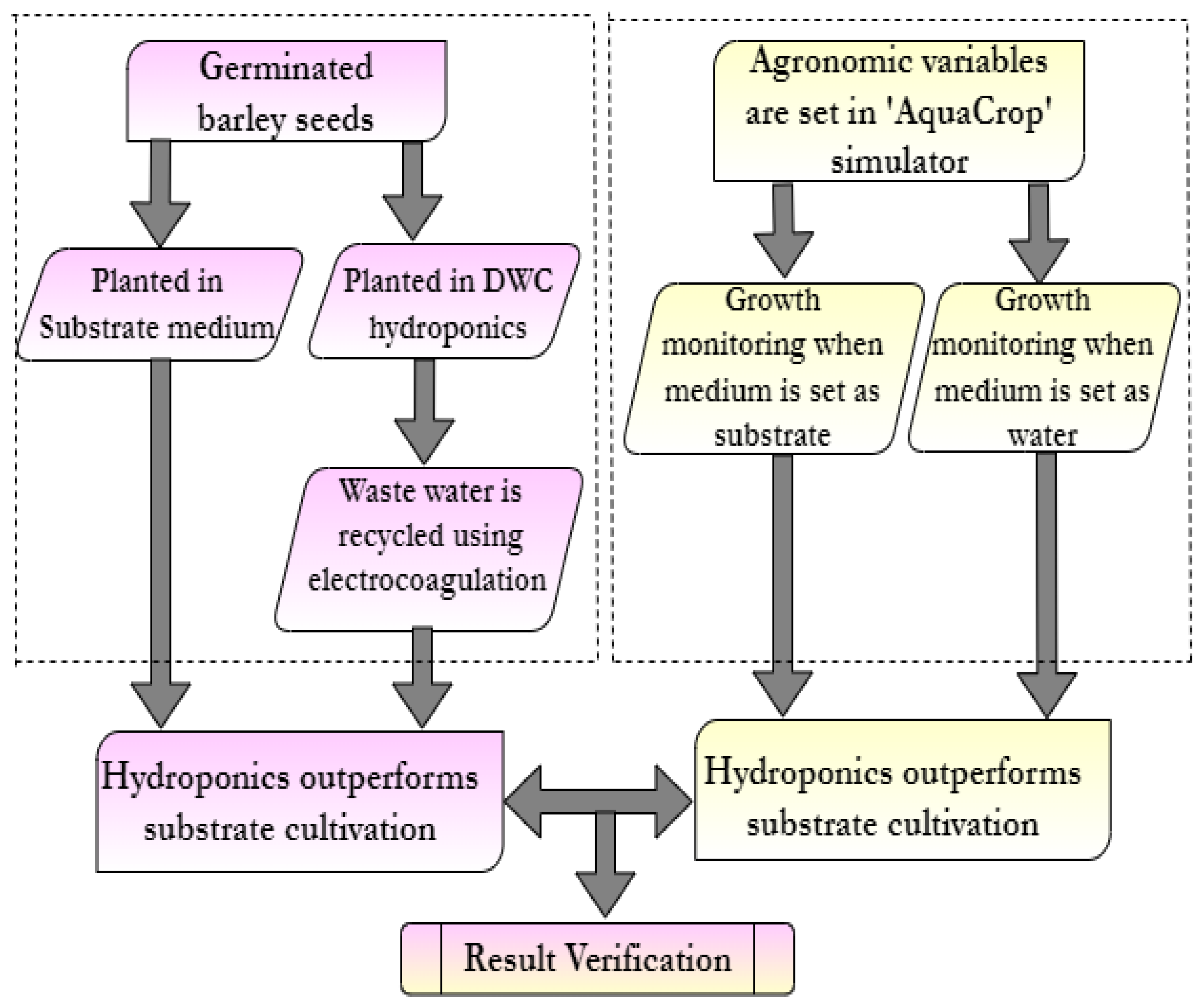

:1. Introduction

- RQ1:

- Which cultivation medium is the most suitable for barley?

- RQ2:

- Compare the shoot and root growth trends of barley in different cultivation mediums.

- RQ3:

- How can water conservation be further enhanced in the hydroponic setup?

2. Materials and Methods

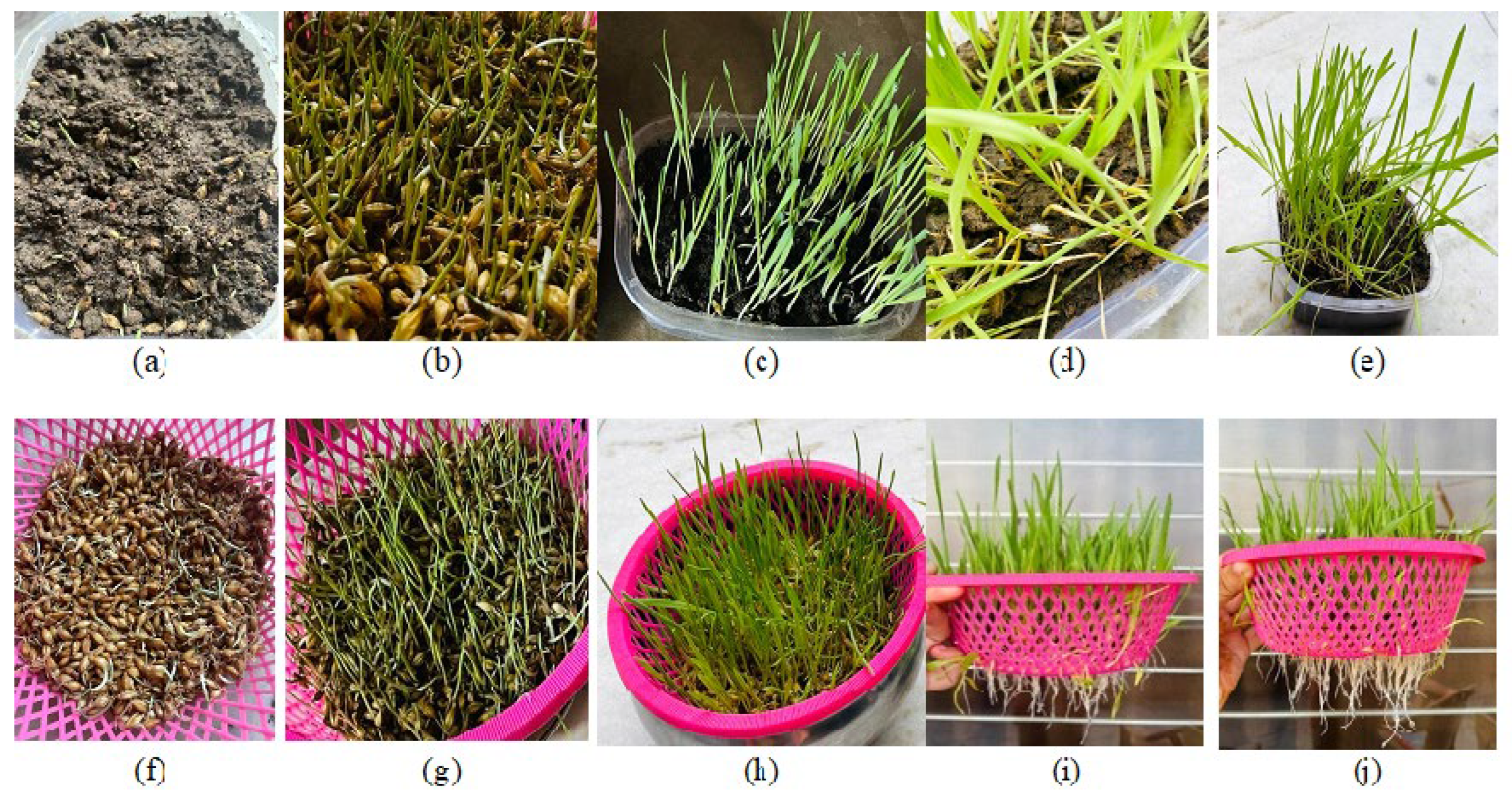

2.1. Cultivation in Substrate Medium

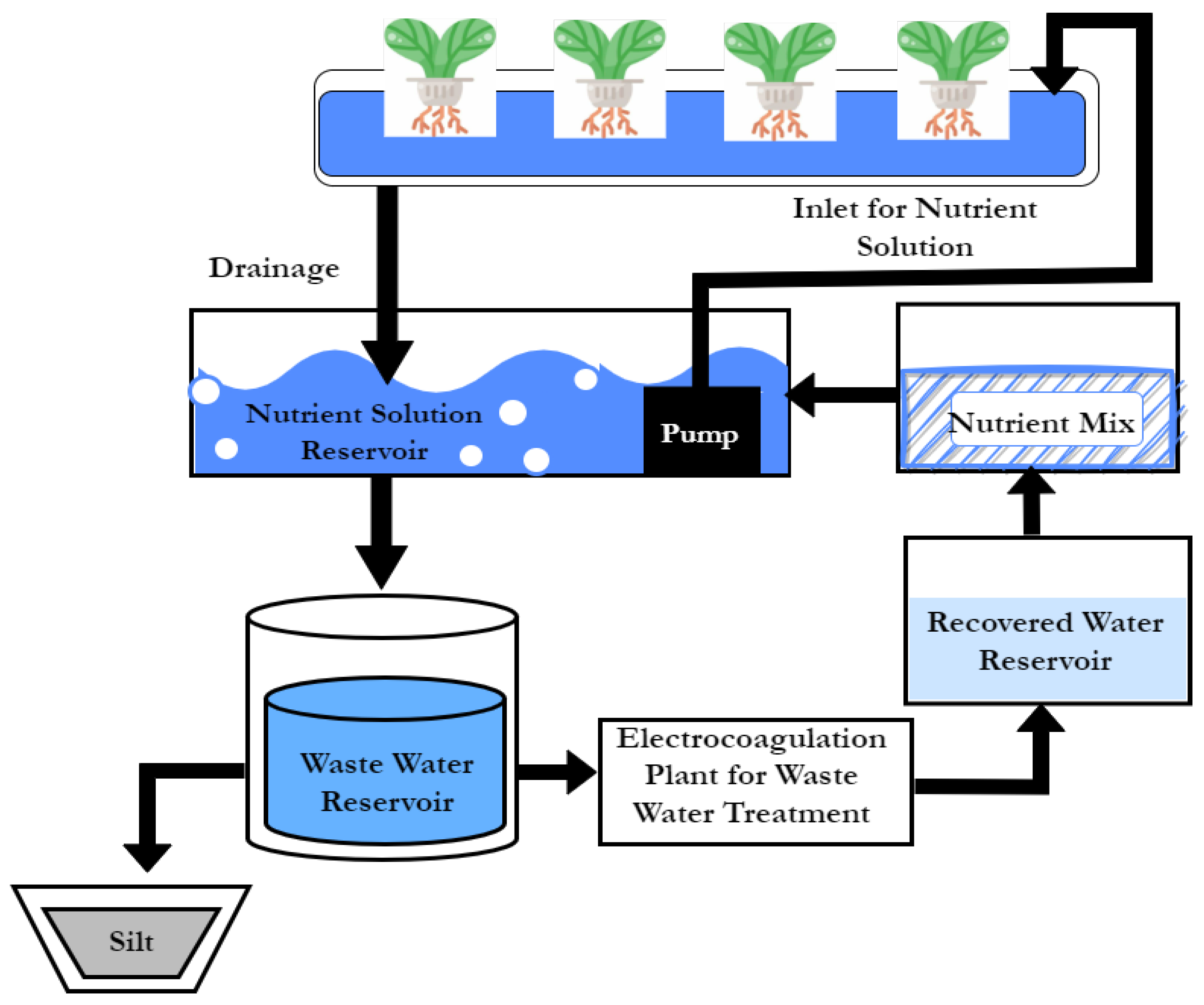

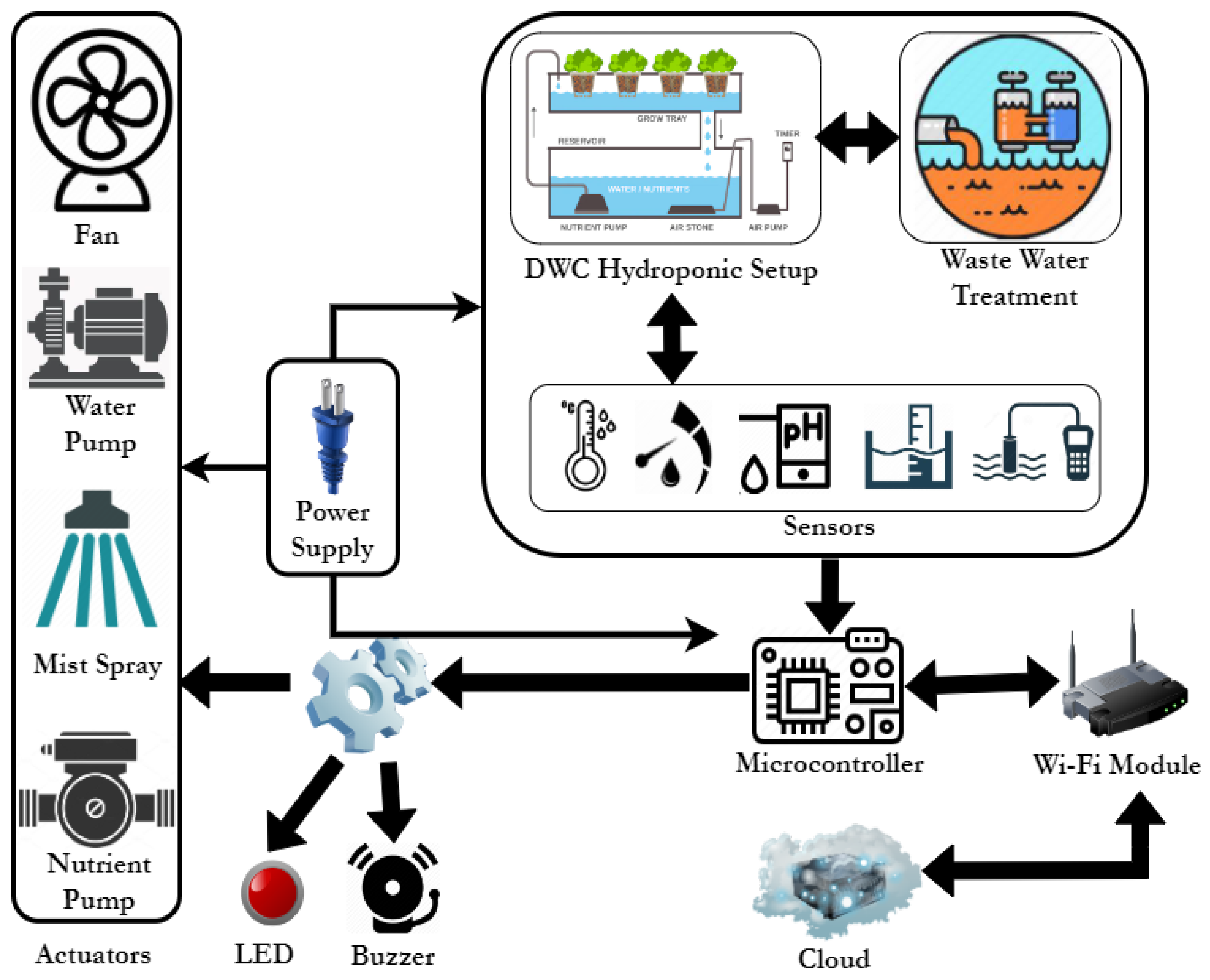

2.2. Cultivation in the DWC Hydroponic Setup

2.3. Growth Comparison in Substrate vs. the DWC Hydroponic Setup

3. Results and Discussions

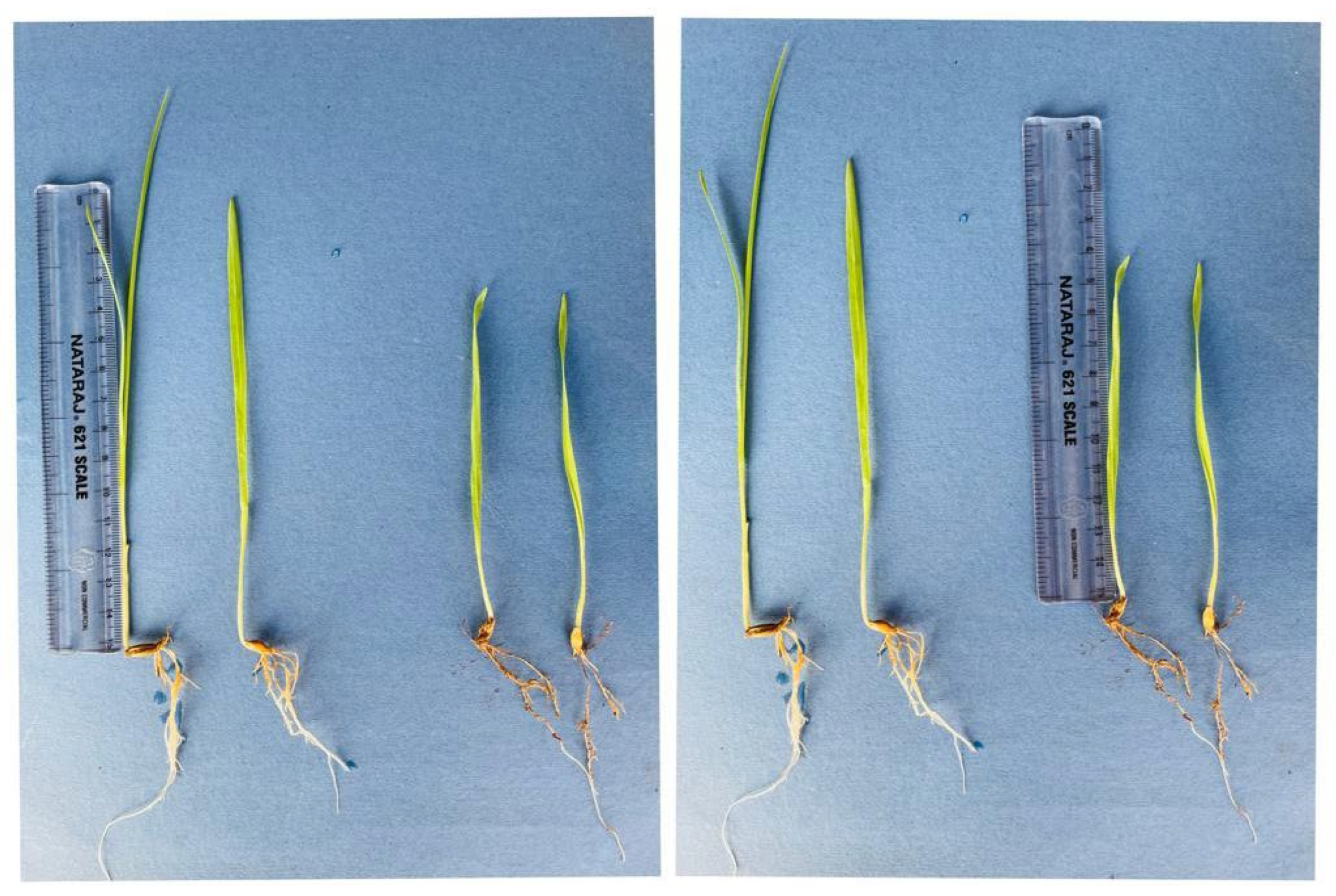

3.1. Growth Comparisons of Barley Shoots and Roots in the Two Trials (Soil and Hydroponics)

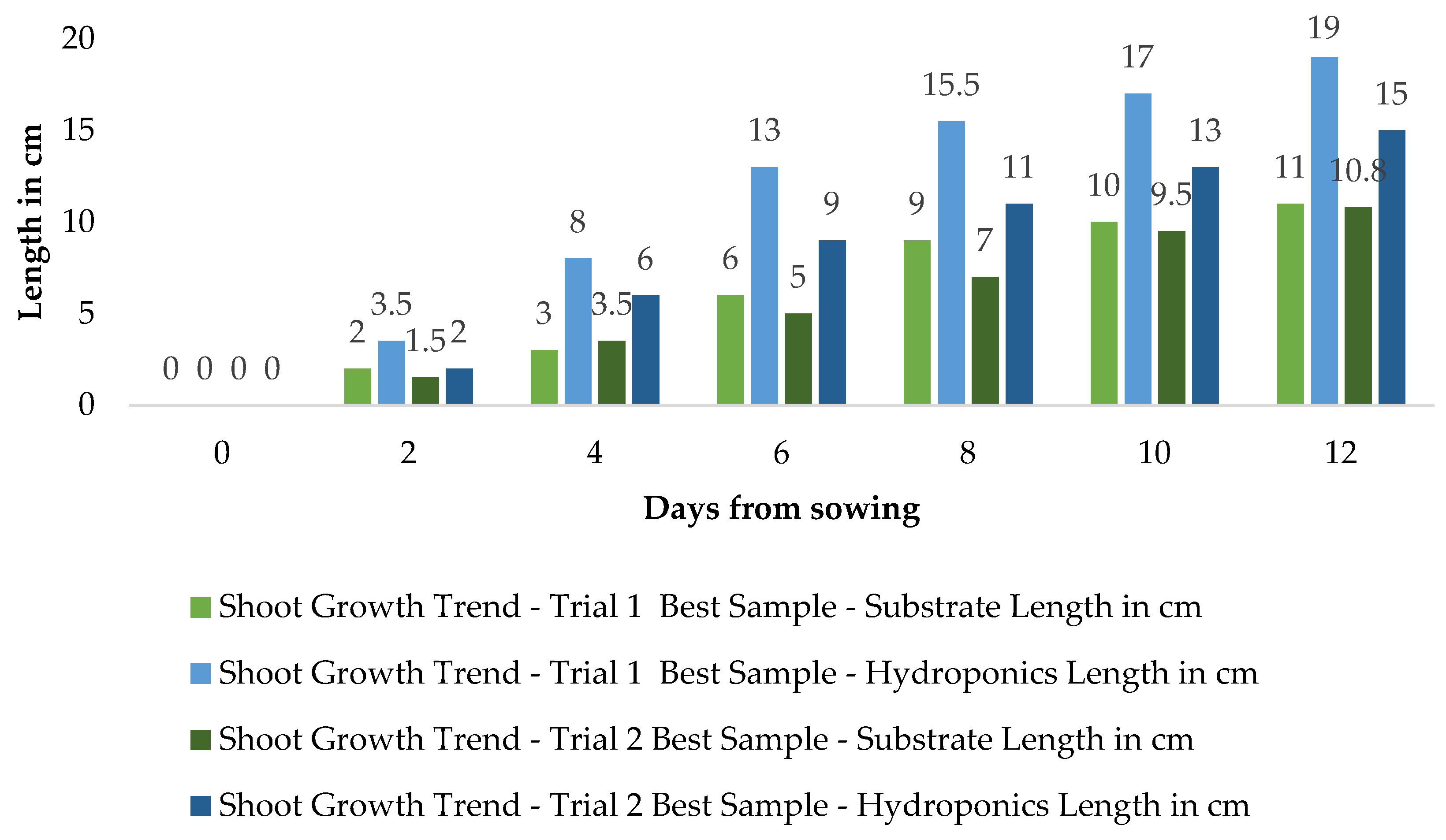

3.2. Growth Comparisons of the Maximum Length of Barley Shoots in the Two Trials (Hydroponics and Soil)

3.3. Growth Comparisons of the Maximum Length of Barley Roots in the Two Trials (Hydroponics and Soil)

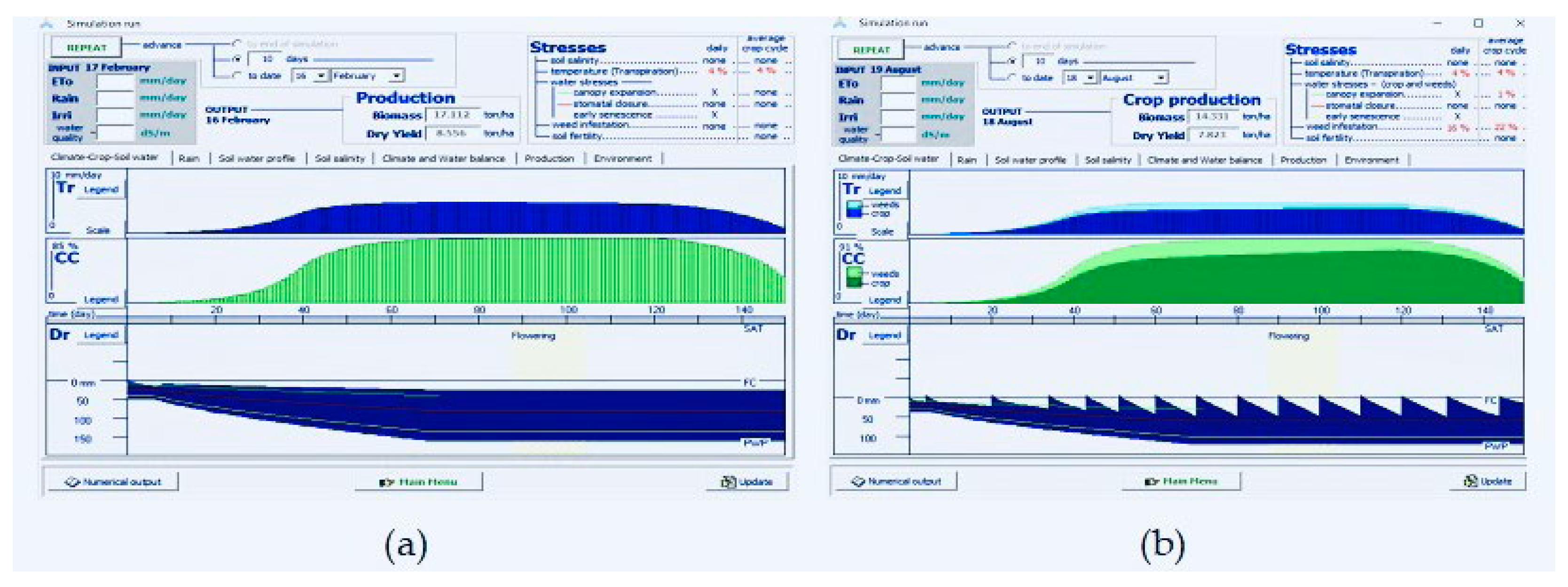

3.4. Growth Comparison Using the Aquacrop Simulator: DWC vs. Soil

4. Conclusions and Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siregar, R.R.A.; Seminar, K.B.; Wahjuni, S.; Santosa, E. Vertical Farming Perspectives in Support of Precision Agriculture Using Artificial Intelligence: A Review. Computers 2022, 11, 135. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Tang, B.; Gu, M. Growth responses and root characteristics of lettuce grown in aeroponics, hydroponics, and substrate culture. Horticulturae 2018, 4, 35. [Google Scholar] [CrossRef] [Green Version]

- Wimmerova, L.; Keken, Z.; Solcova, O.; Bartos, L.; Spacilova, M. A Comparative LCA of Aeroponic, Hydroponic, and Soil Cultivations of Bioactive Substance Producing Plants. Sustainability 2022, 14, 2421. [Google Scholar] [CrossRef]

- Albreem, M.A.; El-Saleh, A.A.; Isa, M.; Salah, W.; Jusoh, M.; Azizan, M.M.; Ali, A. Green internet of things (IoT): An overview. In Proceedings of the IEEE 4th International Conference on Smart Instrumentation, Measurement, and Application (ICSIMA), Putrajaya, Malaysia, 28 November 2017; IEEE: Piscataway Township, NJ, USA; pp. 1–6. [Google Scholar]

- Gadre, M.; Gadre, C. Green Internet of Things (IoT): Go Green with IoT. In Proceedings of the Iciot-2016, Zhangjiajie, China, 14 November 2016; Volume 4, pp. 1–6. [Google Scholar]

- Ranawade, P.S.; Tidke, S.D.; Kate, A.K. Comparative cultivation and biochemical analysis of spinacia oleraceae grown in aquaponics, hydroponics and field conditions. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 1007–1013. [Google Scholar]

- Lucero, L.; Lucero, D.; Ormeno-Mejia, E.; Collaguazo, G. Automated aeroponics vegetable growing system. Case study Lettuce. In Proceedings of the 2020 IEEE ANDESCON, Quito, Pichincha, Ecuador, 13 October 2020; IEEE: Piscataway Township, NJ, USA; pp. 1–6. [Google Scholar]

- Mohamed, T.M.K.; Gao, J.; Tunio, M. Development and experiment of the intelligent control system for rhizosphere temperature of aeroponic lettuce via the Internet of Things. Int. J. Agric. Biol. Eng. 2022, 15, 225–233. [Google Scholar]

- Aishwarya, K.S.; Harish, M.; Prathibhashree, S.; Panimozhi, K. Survey on automated aquaponics based gardening approaches. In Proceedings of the 2018 Second International Conference on Inventive Communication and Computational Technologies (ICICCT), Coimbatore, India, 20 April 2018; IEEE: Piscataway Township, NJ, USA; pp. 1377–1381. [Google Scholar]

- Gayam, K.K.; Jain, A.; Gehlot, A.; Singh, R.; Akram, S.V.; Singh, A.; Noya, I.D. Imperative Role of Automation and Wireless Technologies in Aquaponics Farming. Wirel. Commun. Mob. Comput. 2022, 2022, 8290255. [Google Scholar] [CrossRef]

- Aishwarya, K.S.; Harish, M.; Prathibhashree, S.; Panimozhi, K. Survey on IoT based automated aquaponics gardening approaches. In Proceedings of the 2018 Second International Conference on Inventive Communication and Computational Technologies (ICICCT), Coimbatore, India, 21 April 2018; IEEE: Piscataway Township, NJ, USA; pp. 1495–1500. [Google Scholar]

- Chaudhry, A.R.; Mishra, V.P. A comparative analysis of vertical agriculture systems in residential apartments. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), HCT-Dubai, UAE, 26 March 2019; IEEE: Piscataway Township, NJ, USA; pp. 1–5. [Google Scholar]

- Halgamuge, M.N.; Bojovschi, A.; Fisher, P.M.; Le, T.C.; Adeloju, S.; Murphy, S. Internet of Things and autonomous control for vertical cultivation walls towards smart food growing: A review. Urban For. Urban Green 2021, 61, 127094. [Google Scholar] [CrossRef]

- Farooq, M.S.; Riaz, S.; Helou, M.A.; Khan, F.S.; Abid, A.; Alvi, A. Internet of Things in Greenhouse Agriculture: A Survey on Enabling Technologies, Applications, and Protocols. IEEE Access 2022, 10, 53374–53397. [Google Scholar] [CrossRef]

- Hadinata, A. Internet of Things-based Hydroponic: Literature Review. J. Phys. Conf. Ser. 2021, 2111, 012014. [Google Scholar] [CrossRef]

- Gour, M.S.; Reddy, V.; Vamsi, M.; Sridhar, N.; Ram, V.T. IoT based Farming Techniques in Indoor Environment: A Brief Survey. In Proceedings of the 2020 5th International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 10 June 2020; IEEE: Piscataway Township, NJ, USA; pp. 790–795. [Google Scholar]

- Mokhtar, A.; El-Ssawy, W.; He, H.; Al-Anasari, N.; Sammen, S.S.; Gyasi-Agyei, Y.; Abuarab, M. Using machine learning models to predict hydroponically grown lettuce yield. Front. Plant Sci. 2022, 13, 197. [Google Scholar] [CrossRef]

- Vidhya, R.; Valarmathi, K. Survey on automatic monitoring of hydroponics farms using IoT. In Proceedings of the 2018 3rd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 15 October 2018; IEEE: Piscataway Township, NJ, USA; pp. 125–128. [Google Scholar]

- Ruengittinun, S.; Phongsamsuan, S.; Sureeratanakorn, P. Applied internet of thing for smart hydroponic farming ecosystem (HFE). In Proceedings of the 2017 10th International Conference on Ubi-media Computing and Workshops (Ubi-Media), Pattaya, Thailand, 1 August 2017; IEEE: Piscataway Township, NJ, USA; pp. 1–4. [Google Scholar]

- Booneua, W.; Chai-Arayalert, S.; Boonnam, N. Automated Hydroponics Notification System Using IOT. Int. J. Interact. Mob. Technol. 2022, 16, 206–220. [Google Scholar] [CrossRef]

- Mya, K.T.; Sein, M.M.; Nyunt, T.T.S.; Chong, Y.W.; Zainal, R.N. Automatic Data-Driven Agriculture System for Hydroponic Farming. In Proceedings of the 2021 3rd Asia Pacific Information Technology Conference, Bangkok, Thailand, 15 January 2021; pp. 6–11. [Google Scholar]

- Saraswathi, D.; Manibharathy, P.; Gokulnath, R.; Sureshkumar, E.; Karthikeyan, K. Automation of hydroponics green house farming using IoT. In Proceedings of the 2018 IEEE International Conference on System, Computation, Automation and Networking (ICSCA), Pondicherry, India, 6 July 2018; IEEE: Piscataway Township, NJ, USA; pp. 1–4. [Google Scholar]

- Munandar, A.; Fakhrurroja, H.; Anto, I.F.; Pratama, R.P.; Wibowo, J.W.; Salim, T.I.; Rizqyawan, M.I. Design and development of an IoT-based smart hydroponic system. In Proceedings of the 2018 International Seminar on Research of Information Technology and Intelligent Systems (ISRITI), Yogyakarta, Indonesia, 21 November 2018; IEEE: Piscataway Township, NJ, USA; pp. 582–586. [Google Scholar]

- Pawar, S.; Tembe, S.; Khan, S. Design of an affordable ph module for iot based ph level control in hydroponics applications. In Proceedings of the 2020 International Conference on Convergence to Digital World-Quo Vadis (ICCDW), Mumbai, India, 18 February 2020; IEEE: Piscataway Township, NJ, USA; pp. 1–4. [Google Scholar]

- Rahadiyan, D.; Hartati, S.; Nugroho, A.P. Design of an Intelligent Hydroponics System to Identify Macronutrient Deficiencies in Chili. Int. J. Adv. Comput. Sci. Appl. 2022, 13, 137–145. [Google Scholar] [CrossRef]

- Pawar, S.; Tembe, S.; Acharekar, R.; Khan, S.; Yadav, S. Design of an IoT enabled Automated Hydroponics system using NodeMCU and Blynk. In Proceedings of the 2019 IEEE 5th International Conference for Convergence in Technology (I2CT), Pune, India, 29 March 2019; IEEE: Piscataway Township, NJ, USA; pp. 1–6. [Google Scholar]

- Namee, K.; Kamjumpol, C.; Pimsiri, W. Development of Smart Vegetable Growing Cabinet with IoT, Edge Computing and Cloud Computing. In Proceedings of the 2020 2nd International Conference on Image Processing and Machine Vision, Bangkok, Thailand, 5 August 2020; pp. 47–52. [Google Scholar]

- Ramos, C.; Nóbrega, L.; Baras, K.; Gomes, L. Experimental NFT hydroponics system with lower energy consumption. In Proceedings of the 2019 5th Experiment International Conference, Madeira, Portugal, 12 June 2019; IEEE: Piscataway Township, NJ, USA; pp. 102–106. [Google Scholar]

- Palande, V.; Zaheer, A.; George, K. Fully automated hydroponic system for indoor plant growth. Procedia Comput. Sci. 2018, 129, 482–488. [Google Scholar] [CrossRef]

- Seth, I.; Panda, S.N.; Guleria, K. The Essence of Smart Computing: Internet of Things, Architecture, Protocols, and Challenges. In Proceedings of the 9th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 4 September 2021; IEEE: Piscataway Township, NJ, USA; pp. 1–6. [Google Scholar]

- Shao, C.; Yang, Y.; GSeetharam, T. IoT data visualization for business intelligence in corporate finance. Inf. Process. Manag. 2022, 59, 102736. [Google Scholar] [CrossRef]

- Dutta, M.; Gupta, D. Towards Green IoTs-Enabling Sustainable Environment, Bibliometric Analysis and Beyond. In Proceedings of the 2022 10th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 25 August 2022; IEEE: Piscataway Township, NJ, USA; pp. 1–6. [Google Scholar]

- Juneja, A. Multi-criterion decision making for wireless communication technologies adoption in IoT. Int. J. Syst. Dyn. Appl. 2021, 10, 1–15. [Google Scholar] [CrossRef]

- AlShrouf, A. Hydroponics, aeroponic and aquaponic as compared with conventional farming. Am. Acad. Sci. Res. J. Eng. Technol. Sci. 2017, 27, 247–255. [Google Scholar]

- Seth, I.; Panda, S.N.; Guleria, K. IoT based smart applications and recent research trends. In Proceedings of the 6th International Conference on Signal Processing, Computing and Control (ISPCC), Solan, India, 7 October 2021; IEEE: Piscataway Township, NJ, USA; pp. 407–412. [Google Scholar]

- Upadhyay, H.K.; Muhammad, G.; Nauman, A.; Awad, N.A. Analysis of IoT-Related Ergonomics-Based Healthcare Issues Using Analytic Hierarchy Process Methodology. Sensors 2022, 22, 8232. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Li, S.; Ke, Z.; Zhao, H.; Yang, J.; Zhang, Z. Investigation on environment monitoring system for a combination of hydroponics and aquaculture in greenhouse. Inf. Process. Agric. 2022, 9, 123–134. [Google Scholar] [CrossRef]

- Srivastava, G.; Manoharan, H.; Gadekallu, T.R.; Jhaveri, R.H.; Selvarajan, S.; Kadiyala, R. Connotation of Unconventional Drones for Agricultural Applications with Node Arrangements Using Neural Networks. In Proceedings of the 2022 IEEE 96th Vehicular Technology Conference (VTC2022-Fall), London, UK, 26–29 September 2022; IEEE: Piscataway Township, NJ, USA; pp. 1–6. [Google Scholar]

- Manikandan, S.; Kaliyaperumal, G.; Hakak, S.; Gadekallu, T.R. Curve-Aware Model Predictive Control (C-MPC) Trajectory Tracking for Automated Guided Vehicle (AGV) over On-Road, In-Door, and Agricultural-Land. Sustainability 2022, 14, 12021. [Google Scholar] [CrossRef]

- Pandya, S.; Gadekallu, T.R.; Maddikunta, P.K.R.; Sharma, R. A study of the impacts of air pollution on the agricultural community and yield crops (Indian context). Sustainability 2022, 14, 13098. [Google Scholar] [CrossRef]

- Sharma, S.; Turabieh, H.; Sharma, S. SWOT: A Hybrid Hardware-Based Approach for Robust Fault-Tolerant Framework in a Smart Day Care. Secur. Commun. Networks 2022, 2022, 2939469. [Google Scholar] [CrossRef]

- Hossain, M.S.; Muhammad, G. Cloud-assisted speech and face recognition framework for health monitoring. Mob. Netw. Appl. 2015, 20, 391–399. [Google Scholar] [CrossRef]

- Hossain, M.S.; Rahman, M.A.; Muhammad, G. Cyber–physical cloud-oriented multi-sensory smart home framework for elderly people: An energy efficiency perspective. J. Parallel Distrib. Comput. 2017, 103, 11–21. [Google Scholar] [CrossRef]

- Masud, M.; Gaba, G.S.; Choudhary, K.; Hossain, M.S.; Alhamid, M.F.; Muhammad, G. Lightweight and anonymity-preserving user authentication scheme for IoT-based healthcare. IEEE Internet Things J. 2021, 9, 2649–2656. [Google Scholar] [CrossRef]

- Uppal, M.; Dhiman, G.; Kautish, S. Cloud-based fault prediction using IoT in office automation for improvisation of health of employees. J. Healthc. Eng. 2021, 2021, 8106467. [Google Scholar] [CrossRef]

- Kautish, S.; Viriyasitavat, W.; Yadav, K. A perspective roadmap for IoMT-based early detection and care of the neural disorder, dementia. J. Healthc. Eng. 2021, 2021, 6712424. [Google Scholar]

- Kour, K.; Gupta, D.; Gupta, K.; Dhiman, G.; Juneja, S.; Viriyasitavat, W.; Mohafez, H.; Islam, M.A. Smart-Hydroponic-Based Framework for Saffron Cultivation: A Precision Smart Agriculture Perspective. Sustainability 2022, 14, 1120. [Google Scholar] [CrossRef]

- Kour, K.; Gupta, D.; Gupta, K.; Juneja, S.; Kaur, M.; Alharbi, A.H.; Lee, H.N. Controlling Agronomic Variables of Saffron Crop Using IoT for Sustainable Agriculture. Sustainability 2022, 14, 5607. [Google Scholar] [CrossRef]

- Upadhyay, C.; Upadhyay, H.K.; Juneja, S.; Juneja, A. Plant Disease Detection Using Imaging Sensors, Deep Learning and Machine Learning for Smart Farming. In Healthcare Solutions Using Machine Learning and Informatics; Auerbach Publications: Boca Raton, FL, USA, 2022; pp. 173–185. [Google Scholar]

| Parameters | Values | |

|---|---|---|

| The temperature in the sowing and growing period | 12–15 | |

| The temperature in the maturity and harvest period | 30–32 | |

| Average rainfall | 146.48 mm | |

| Humidity | 64% | |

| pH | 7.8 | |

| Growth cycle | Up to 20 days | |

| Nitrogen (N) | Percentage of each component in the mixture | 7% |

| Phosphorous (P) | 9% | |

| Potassium (K) | 5% | |

| Parameters | Values | |

|---|---|---|

| Temperature (°C) | 15–35 | |

| Average rainfall | 150 mm | |

| Humidity | 68% | |

| pH | 6.9 | |

| Growth cycle | Up to 12 days | |

| Nitrogen (N) | Percentage of each component in the mixture | 7% |

| Phosphorous (P) | 9% | |

| Potassium (K) | 5% | |

| Growing Technique | Best Samples of Two Trials | Root Length in cm |

|---|---|---|

| DWC Hydroponics | Best sample trial 1 | 9.9 |

| Best sample trial 2 | 6.2 | |

| Soil cultivation | Best sample trial 1 | 7.5 |

| Best sample trial 2 | 7.1 |

| Cultivation Medium | Quantitative Parameters | Values in ton/ha |

|---|---|---|

| DWC hydroponics | Biomass | 17.112 |

| Dry yield | 8.556 | |

| Substrate medium | Biomass | 14.331 |

| Dry yield | 7.823 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dutta, M.; Gupta, D.; Javed, Y.; Mohiuddin, K.; Juneja, S.; Khan, Z.I.; Nauman, A. Monitoring Root and Shoot Characteristics for the Sustainable Growth of Barley Using an IoT-Enabled Hydroponic System and AquaCrop Simulator. Sustainability 2023, 15, 4396. https://doi.org/10.3390/su15054396

Dutta M, Gupta D, Javed Y, Mohiuddin K, Juneja S, Khan ZI, Nauman A. Monitoring Root and Shoot Characteristics for the Sustainable Growth of Barley Using an IoT-Enabled Hydroponic System and AquaCrop Simulator. Sustainability. 2023; 15(5):4396. https://doi.org/10.3390/su15054396

Chicago/Turabian StyleDutta, Monica, Deepali Gupta, Yasir Javed, Khalid Mohiuddin, Sapna Juneja, Zafar Iqbal Khan, and Ali Nauman. 2023. "Monitoring Root and Shoot Characteristics for the Sustainable Growth of Barley Using an IoT-Enabled Hydroponic System and AquaCrop Simulator" Sustainability 15, no. 5: 4396. https://doi.org/10.3390/su15054396