Sustainable Design of Self-Consolidating Green Concrete with Partial Replacements for Cement through Neural-Network and Fuzzy Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Proportions

Specimens

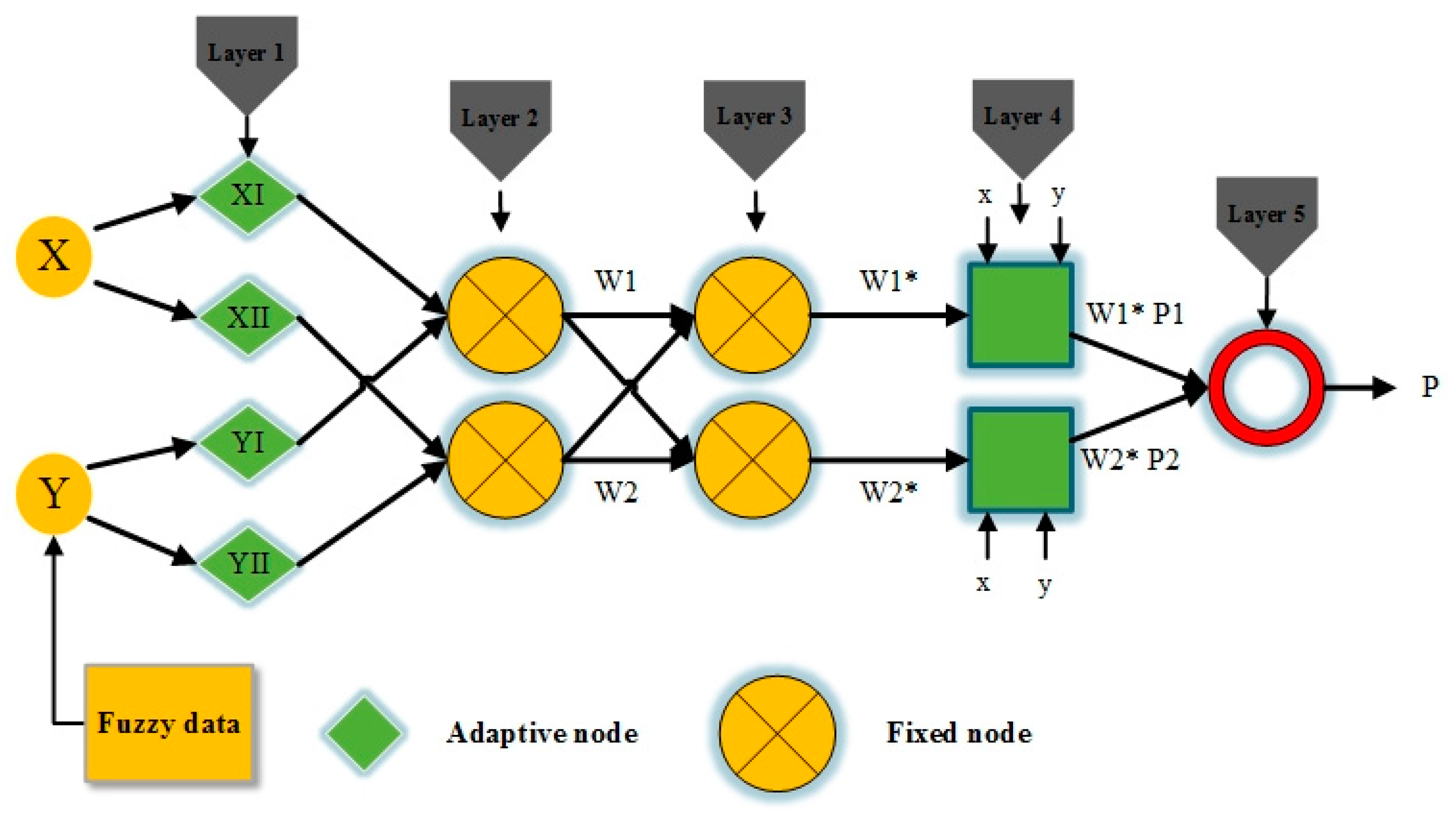

2.3. ANFIS Methodology

2.3.1. Statistical Data

2.3.2. ANFIS Architecture

2.3.3. Parameter Identification

3. Results and Discussions

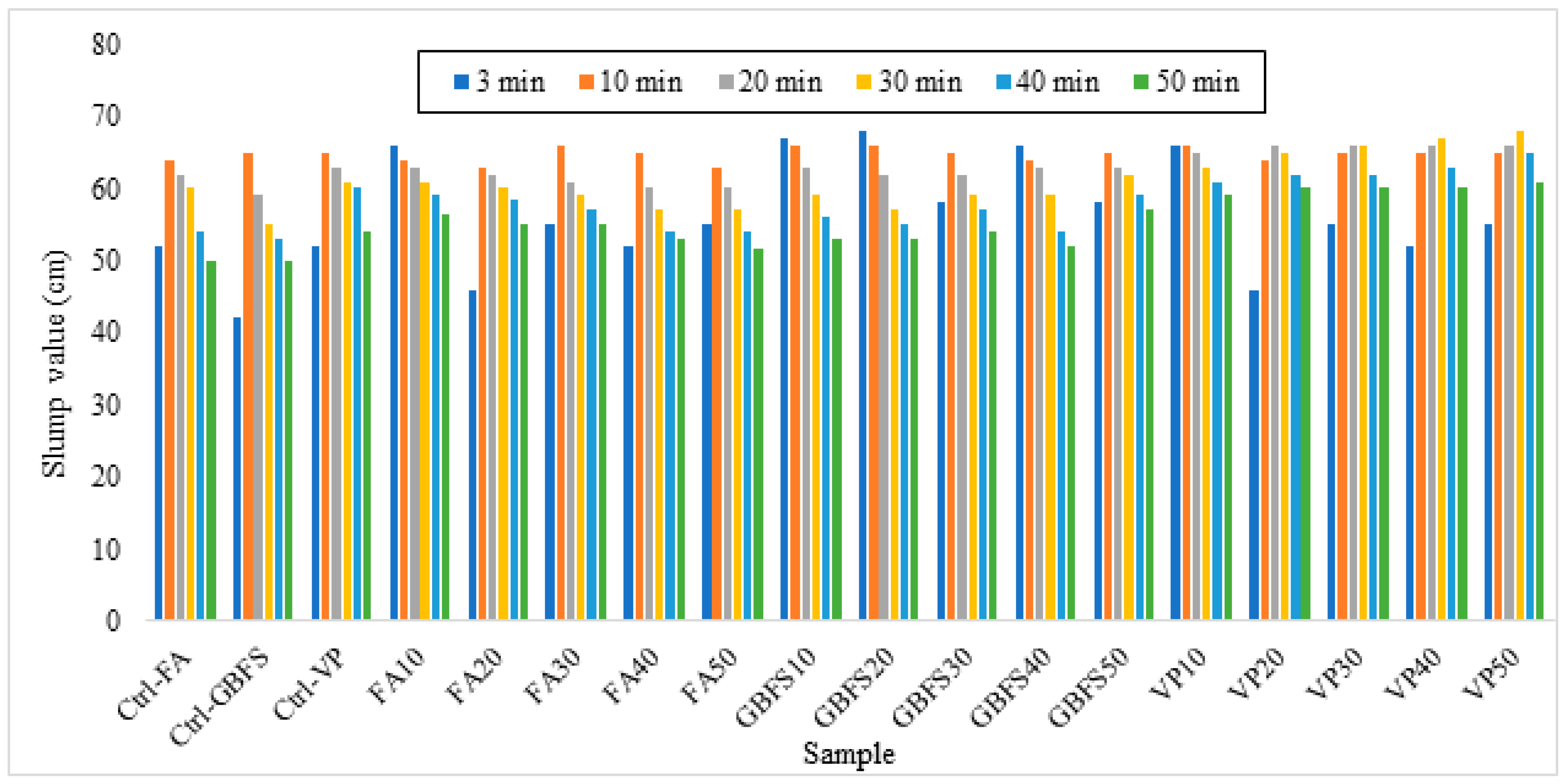

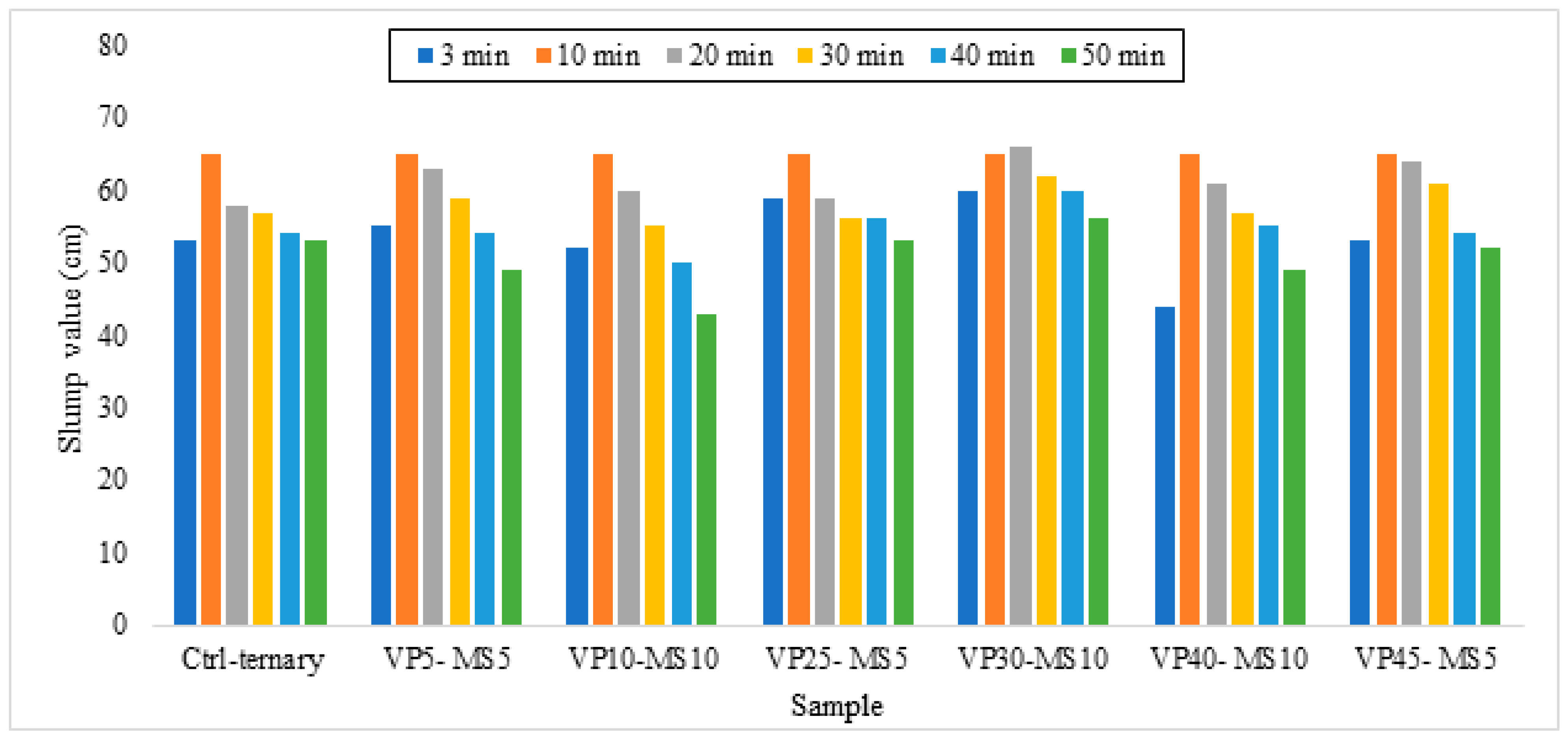

3.1. Fresh Concrete Properties

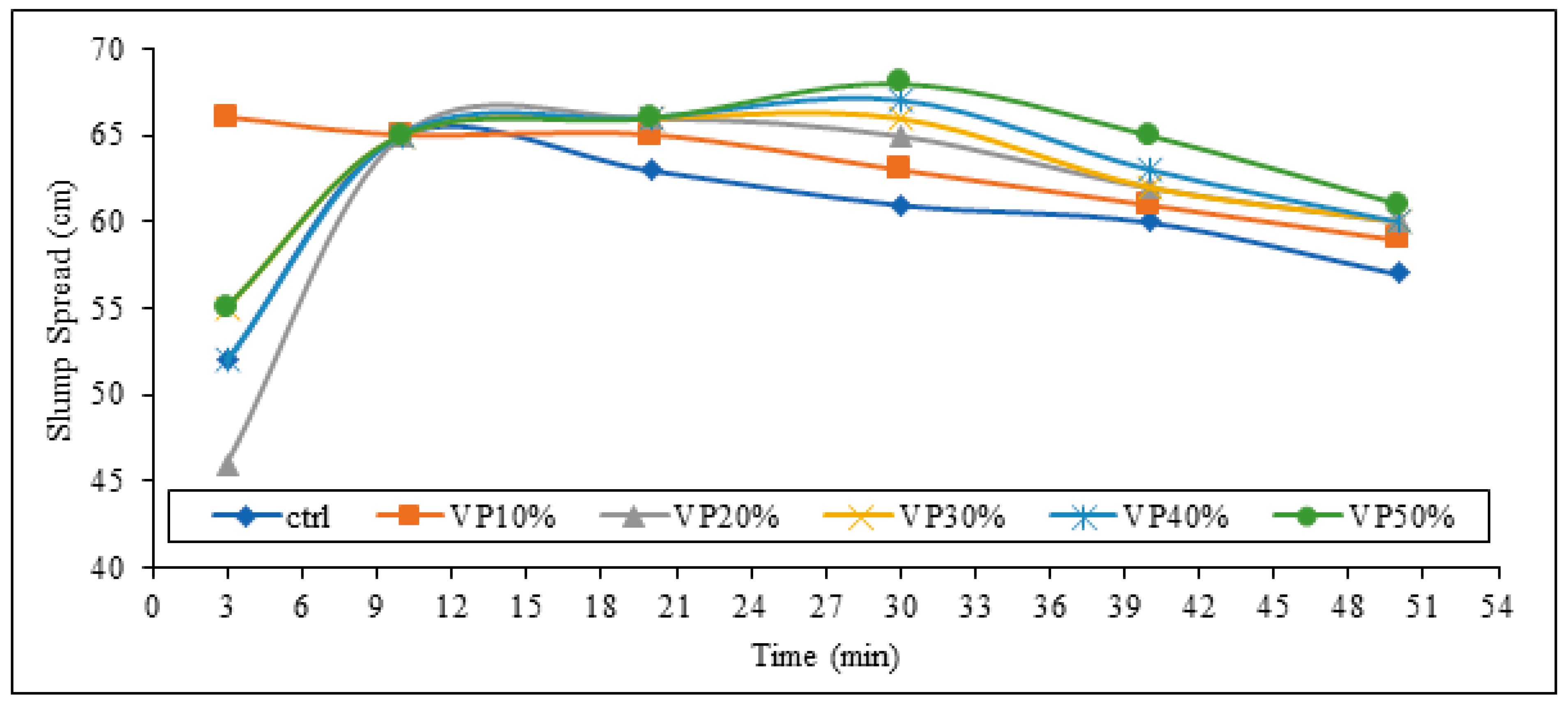

Slump Flow

3.2. Mechanical Properties

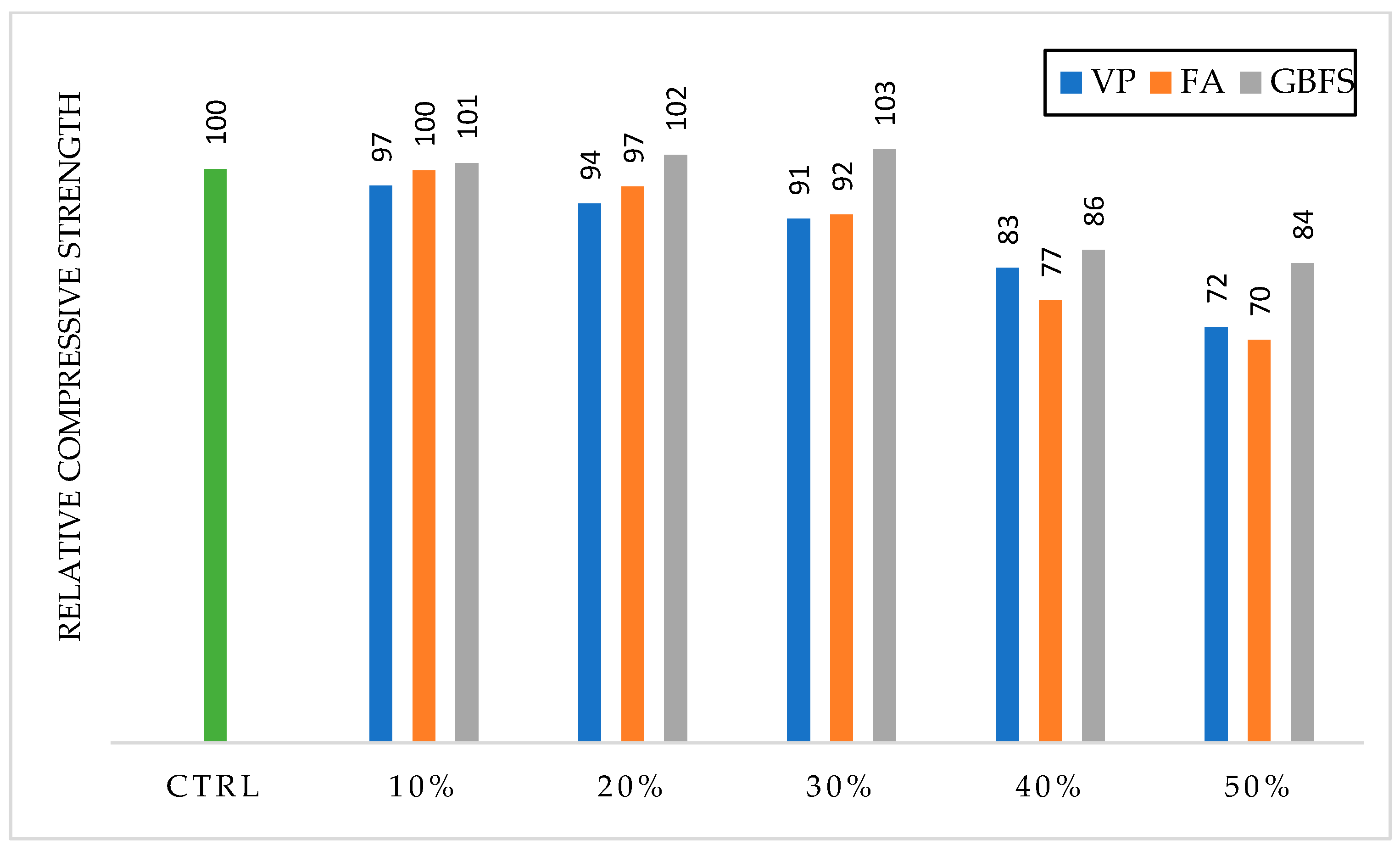

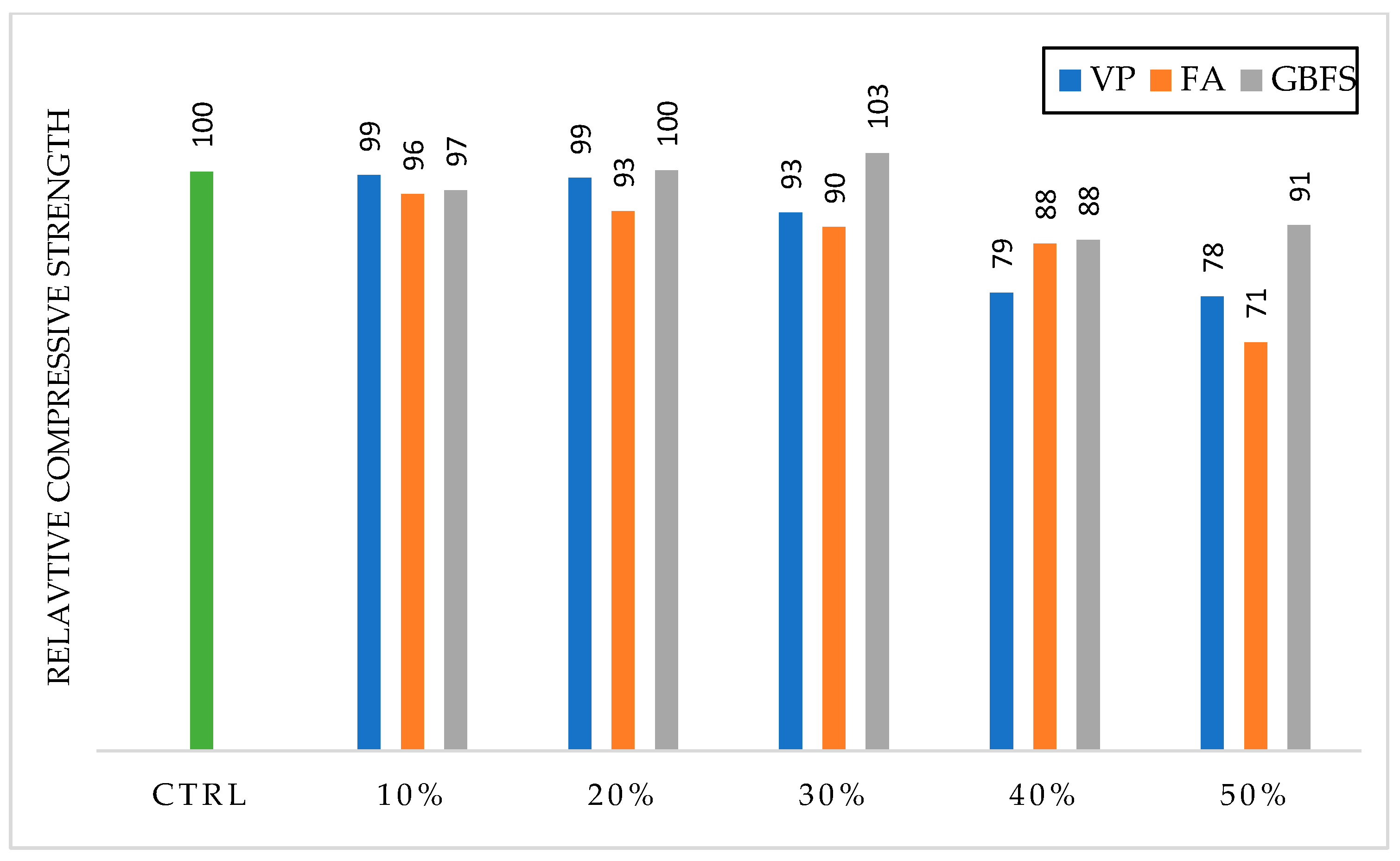

Compressive Strength

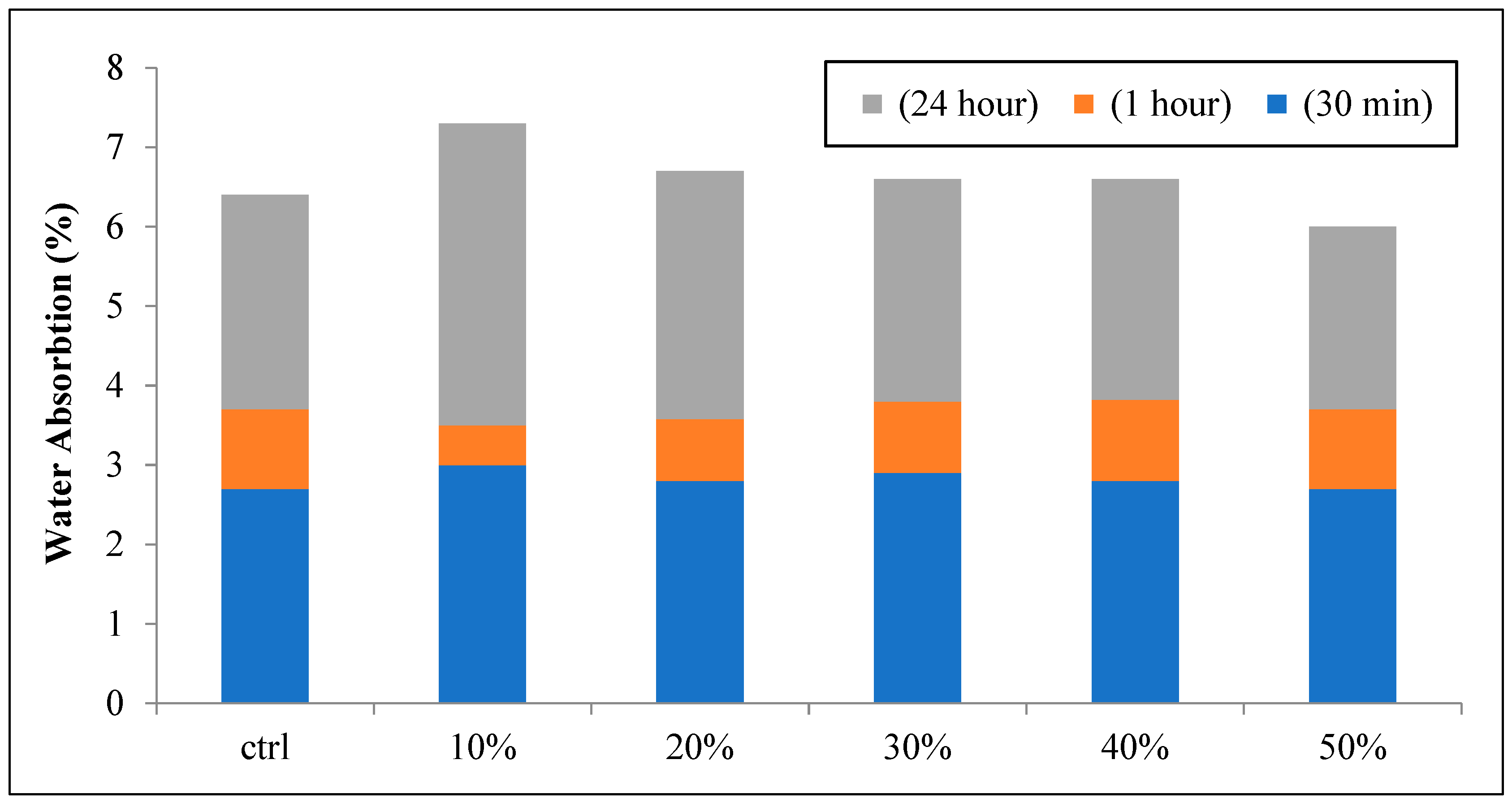

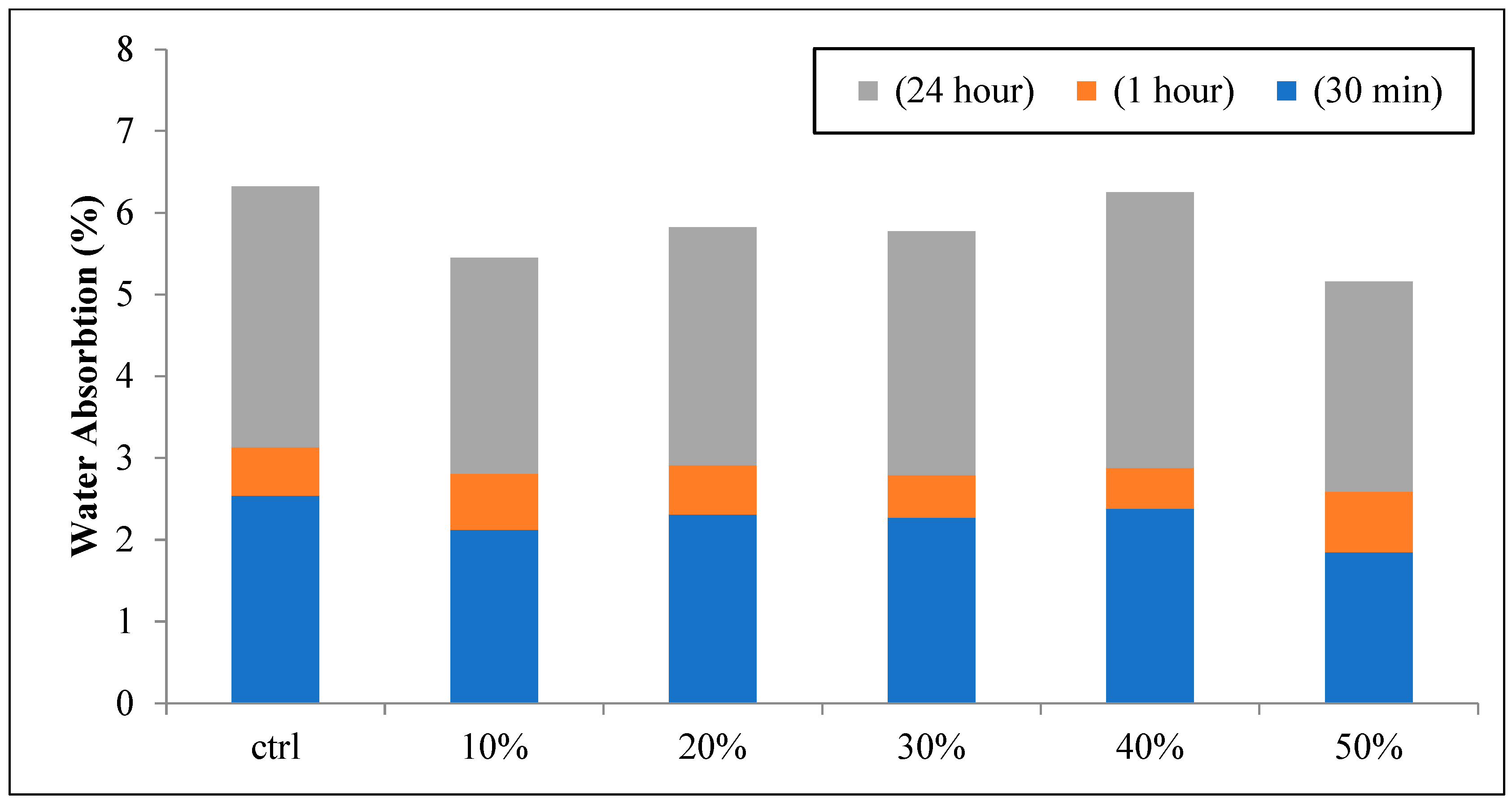

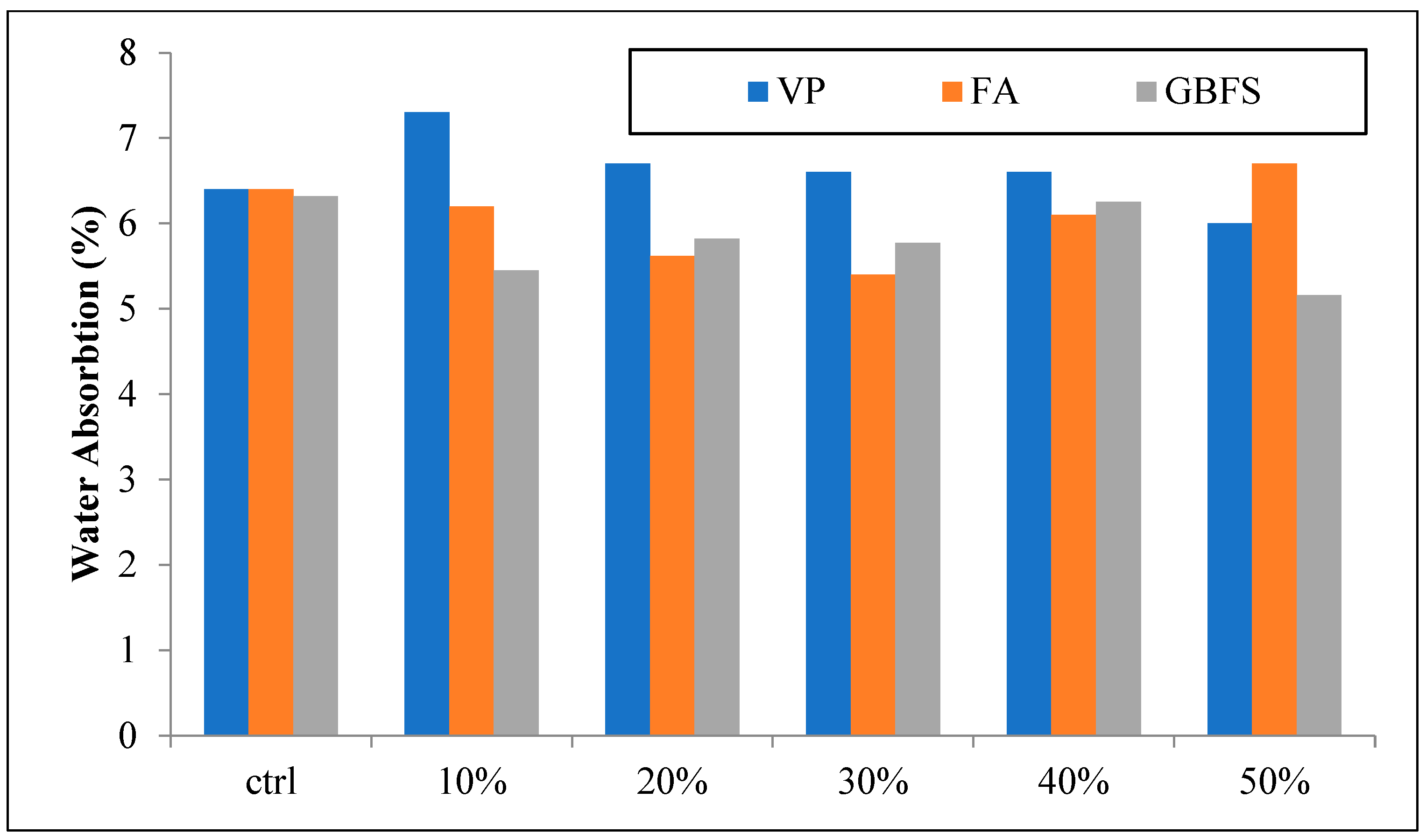

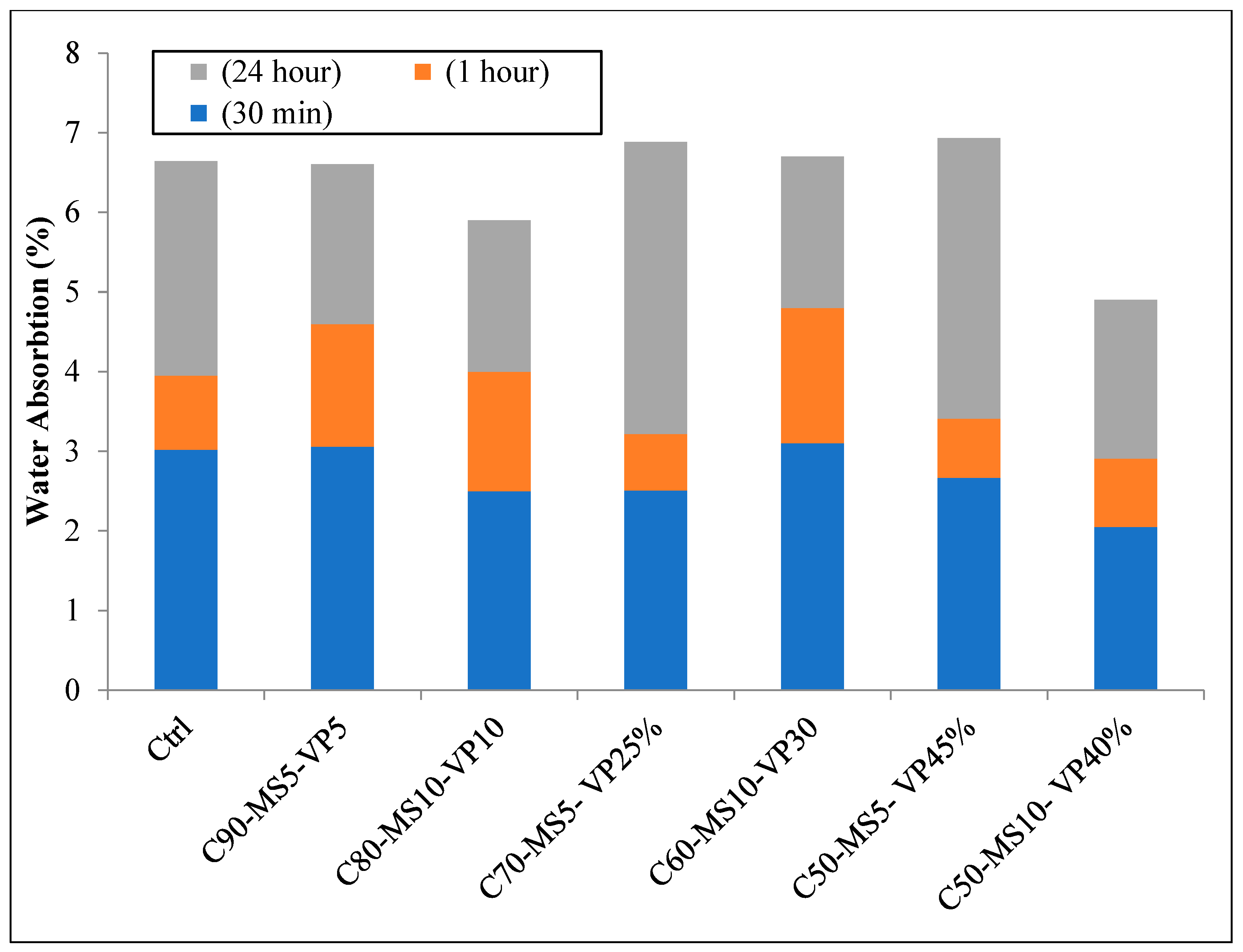

3.3. Water Absorption

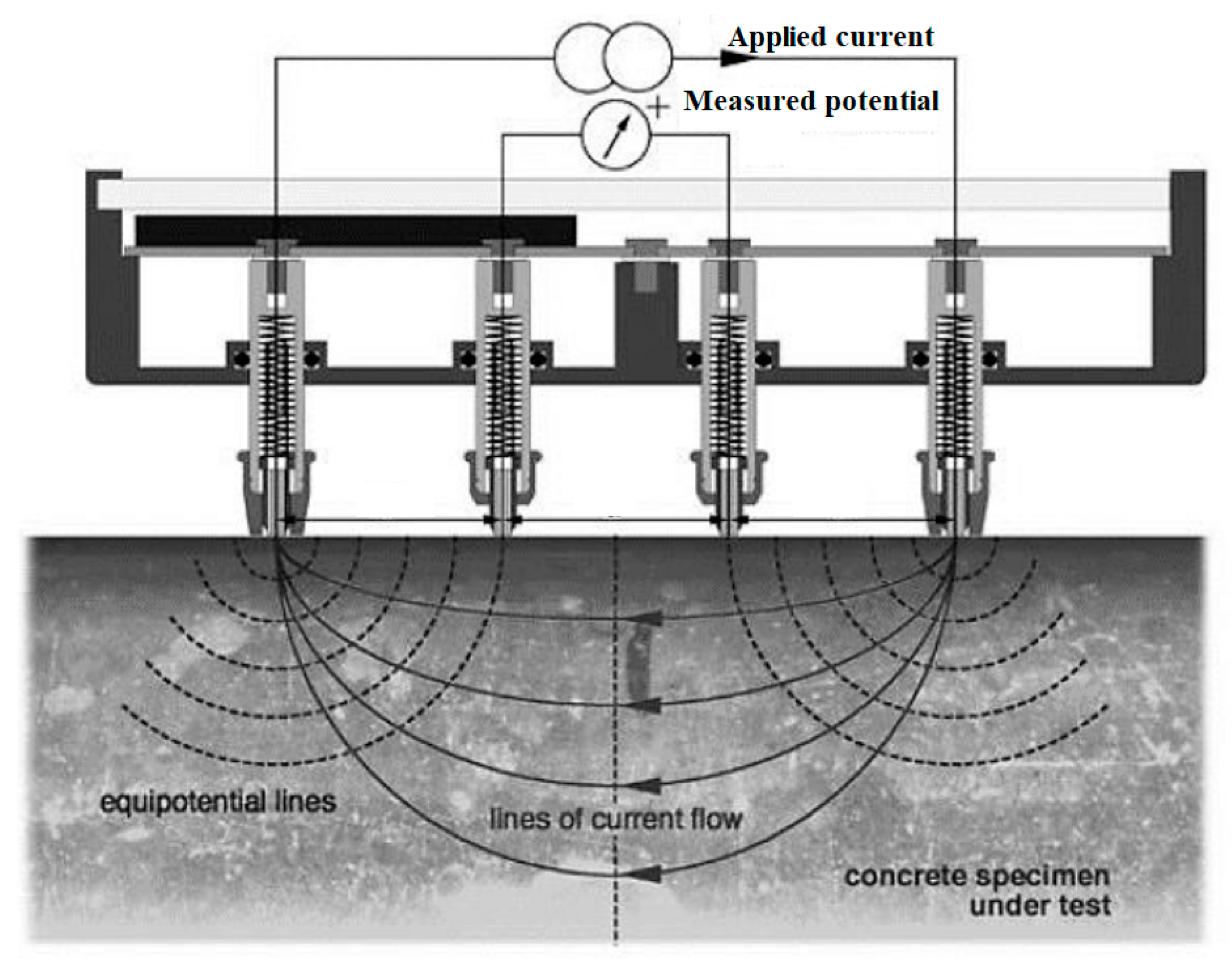

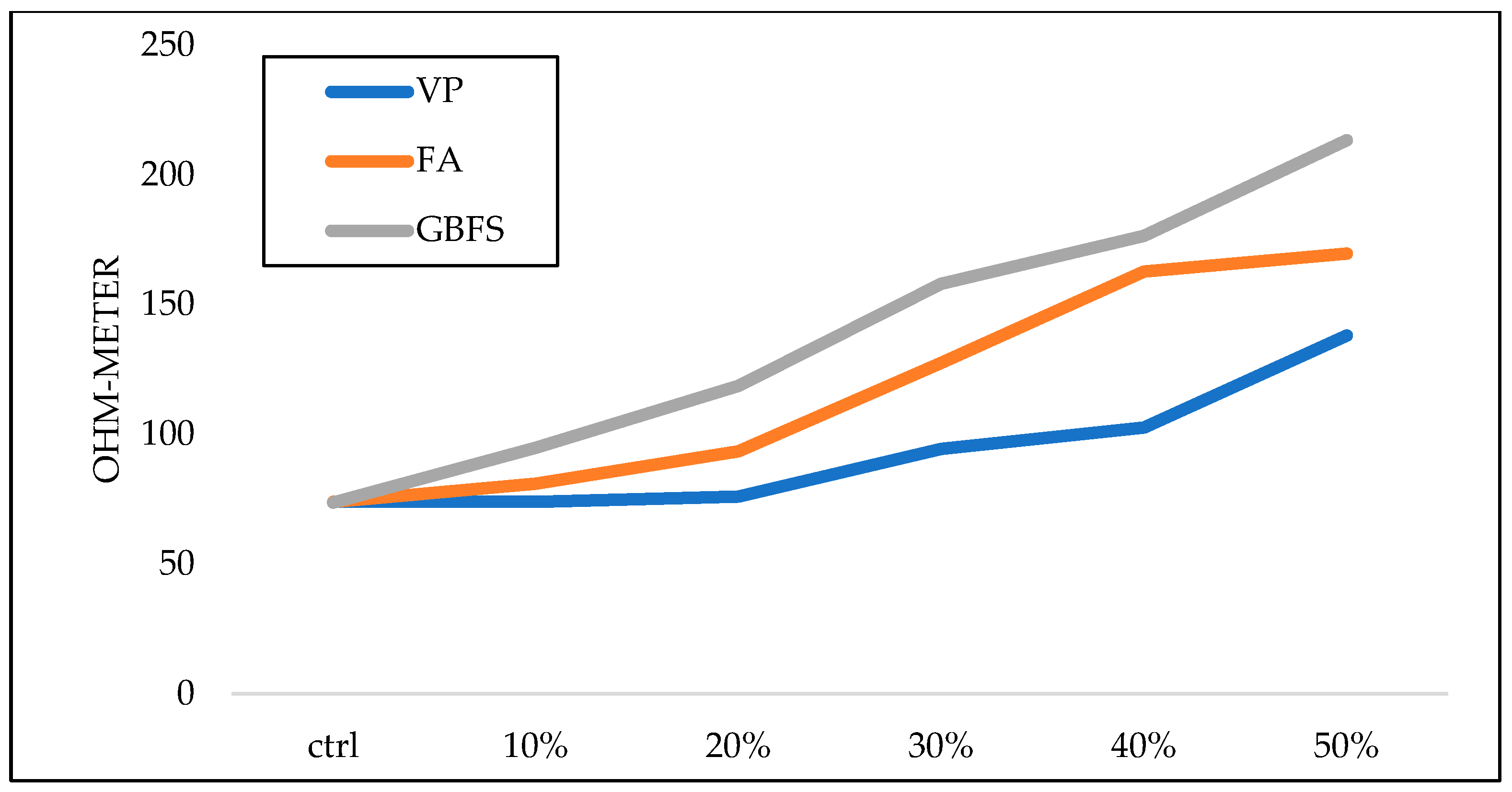

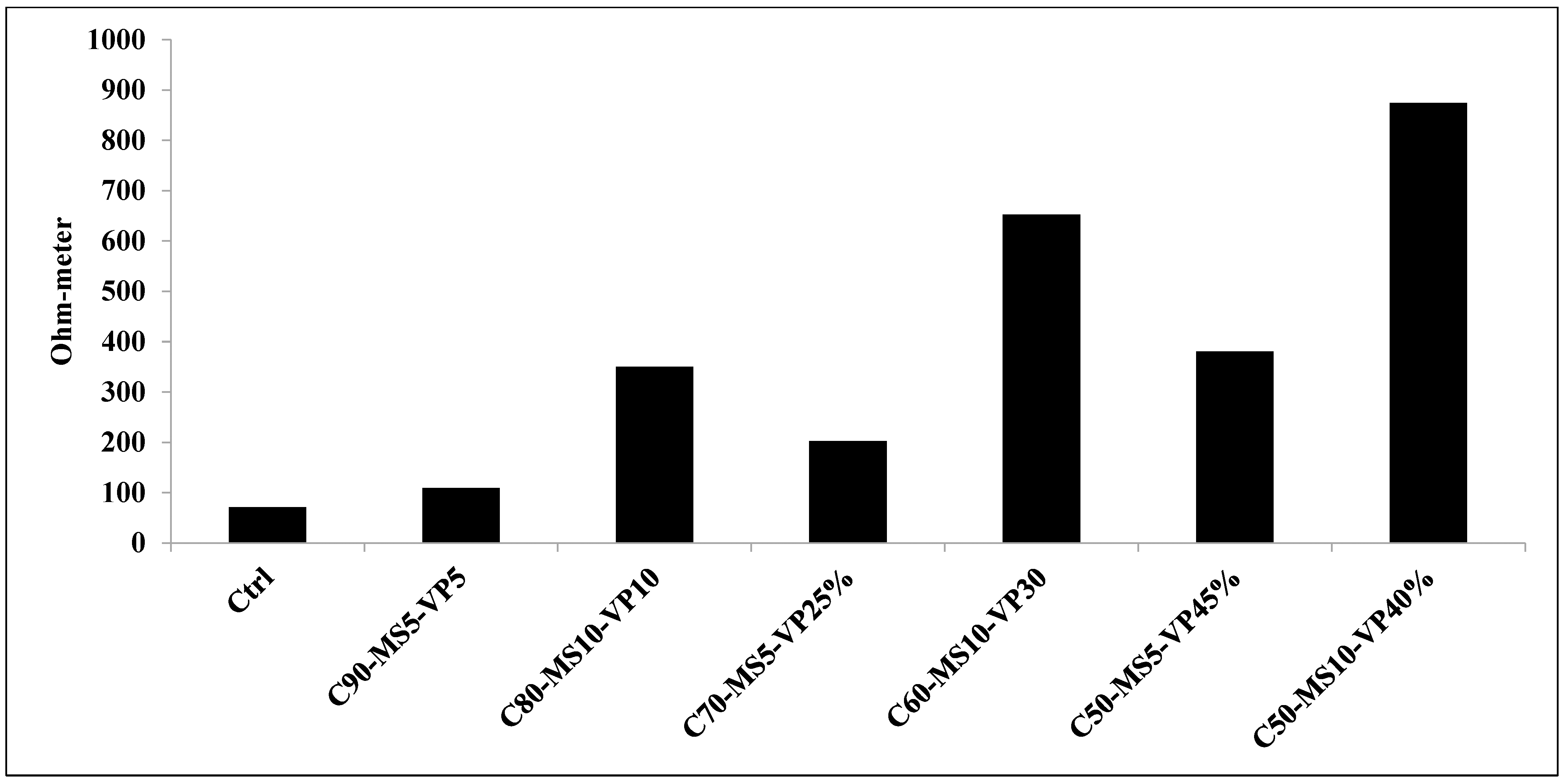

3.4. Electerical Resistance

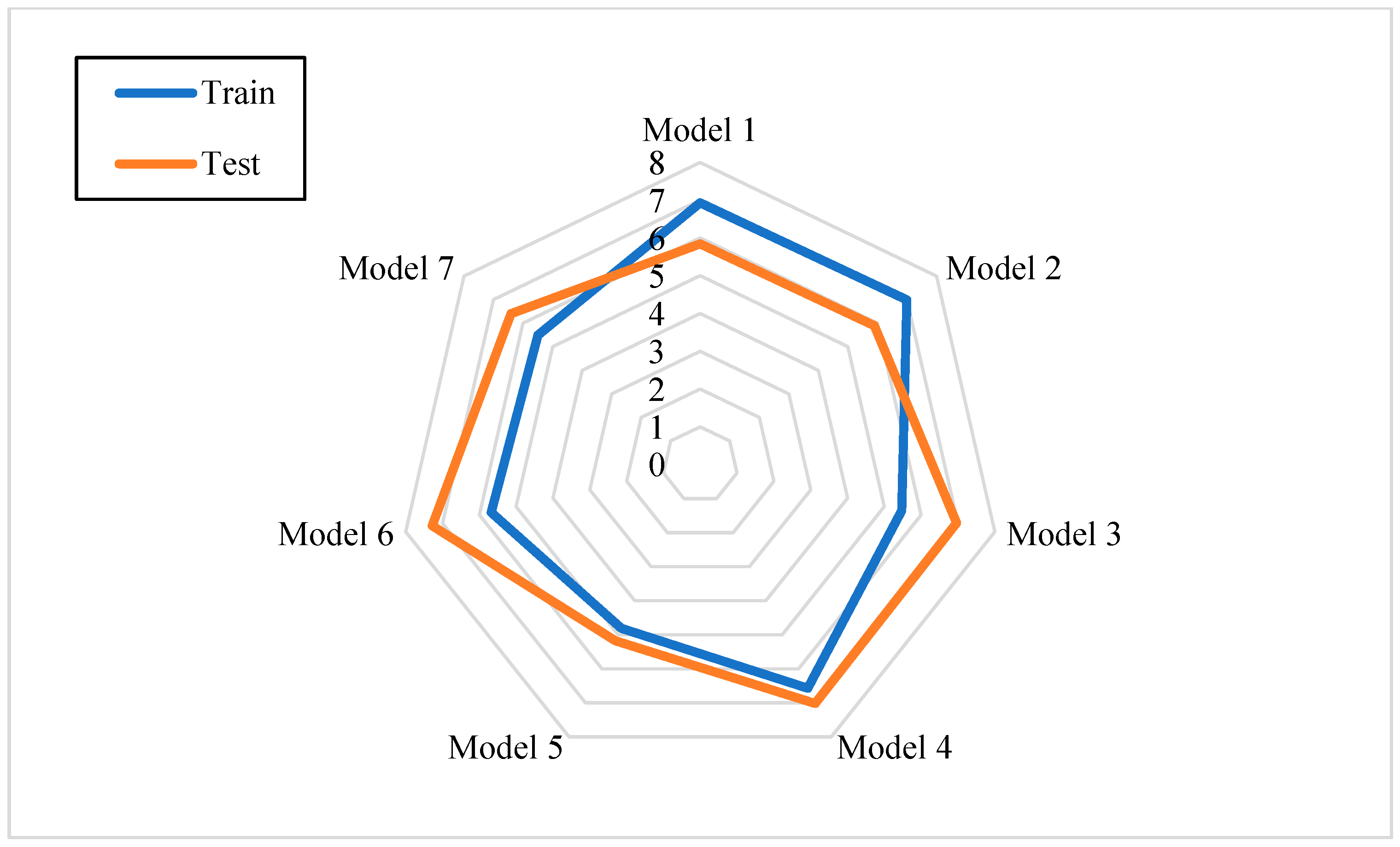

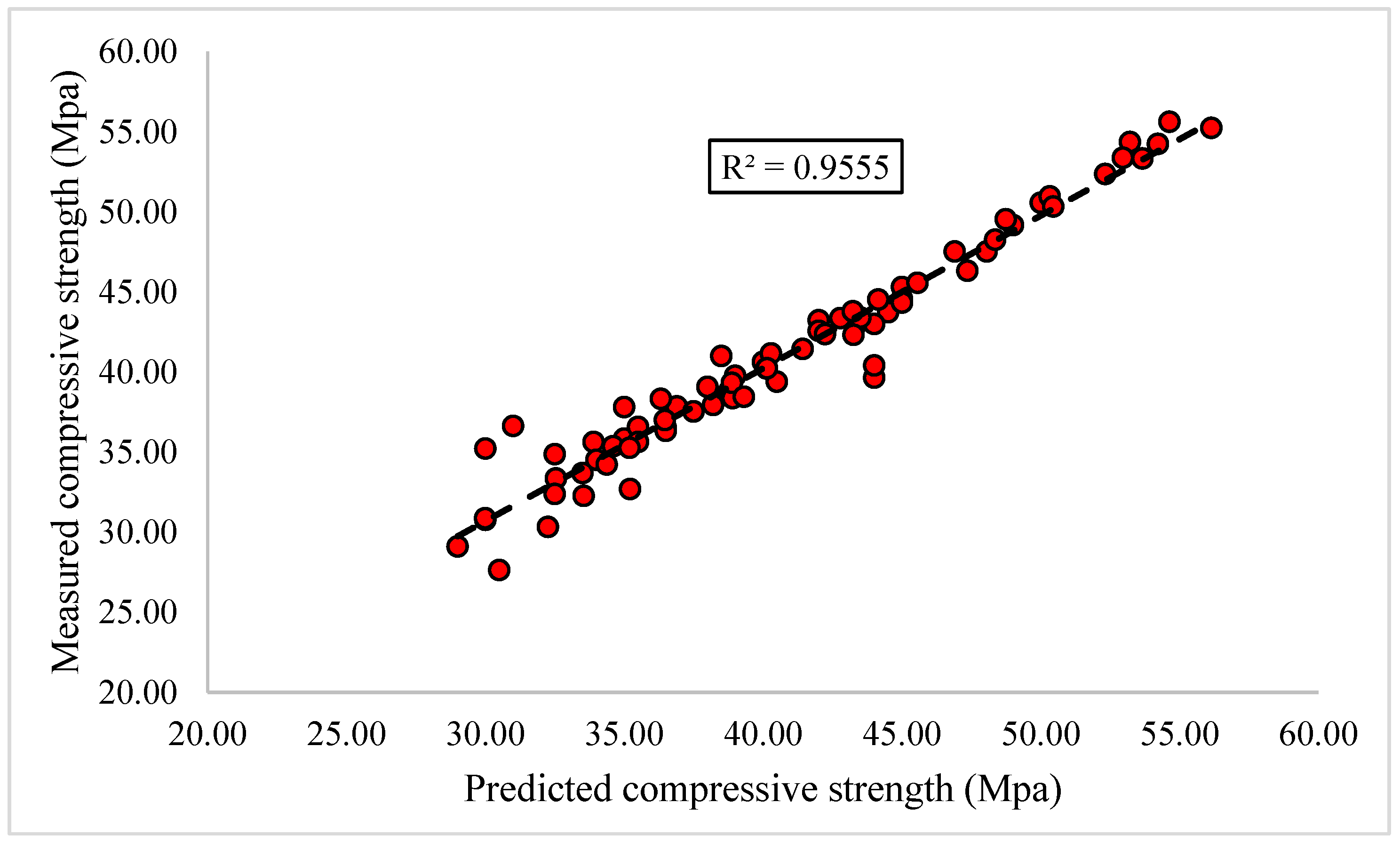

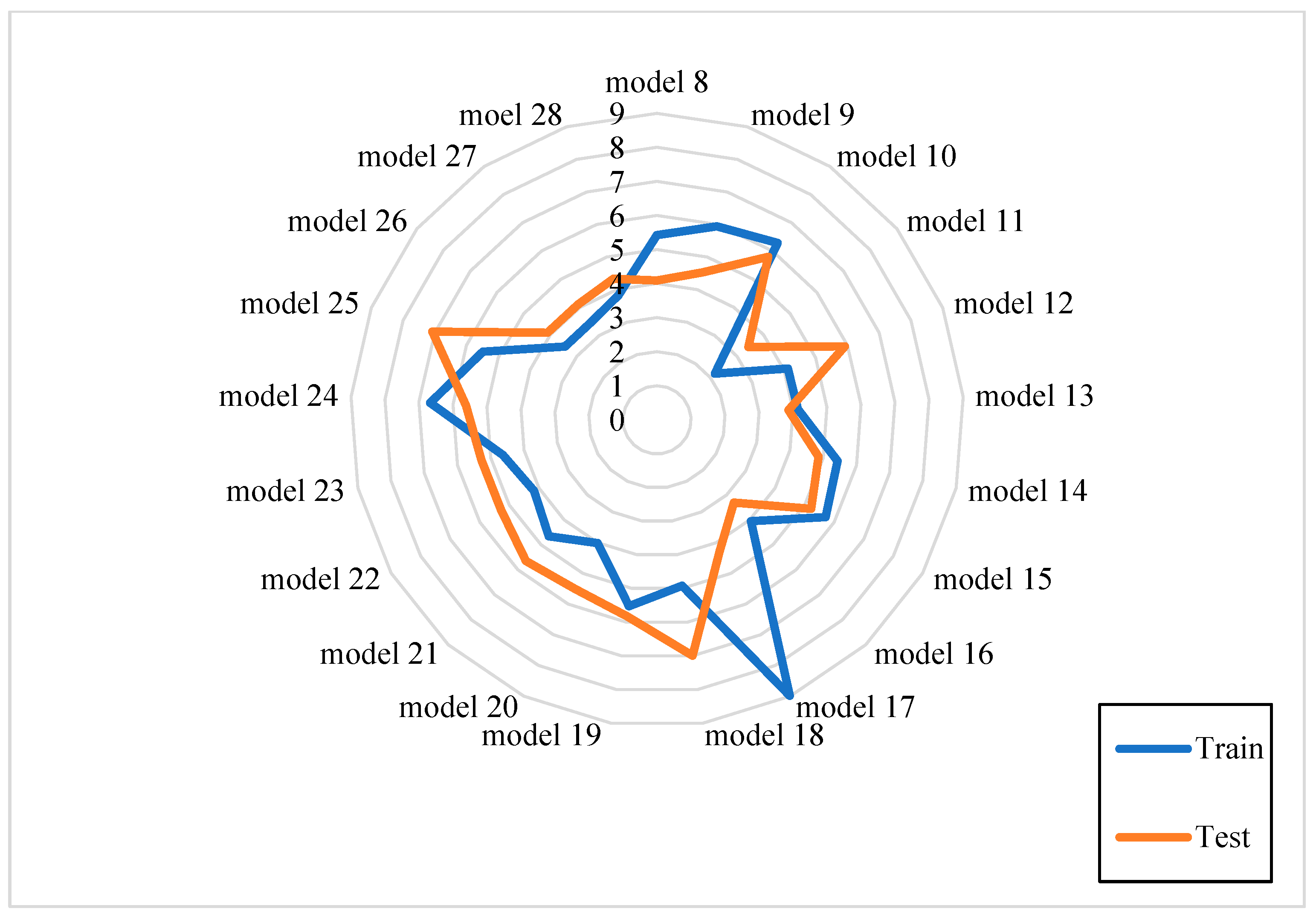

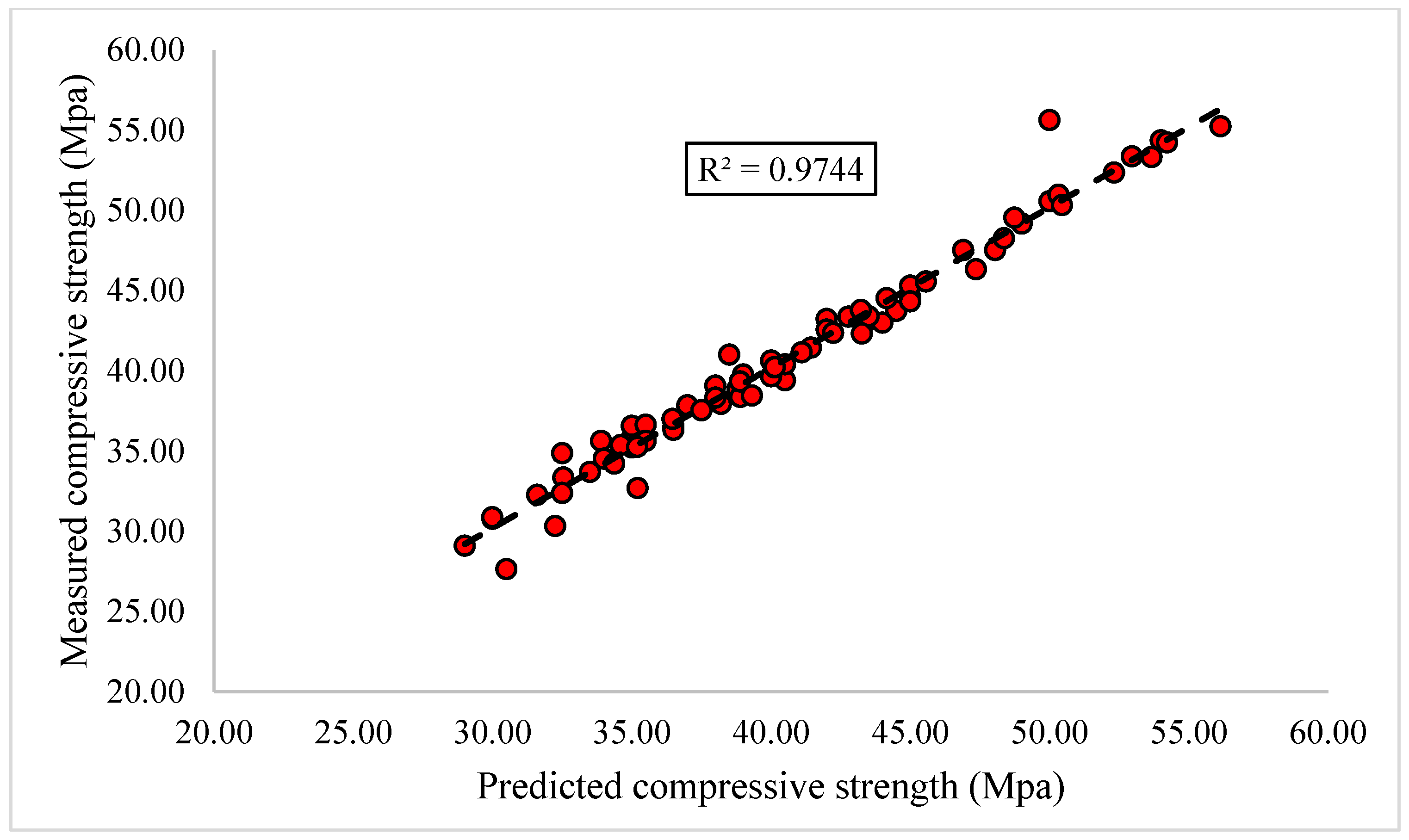

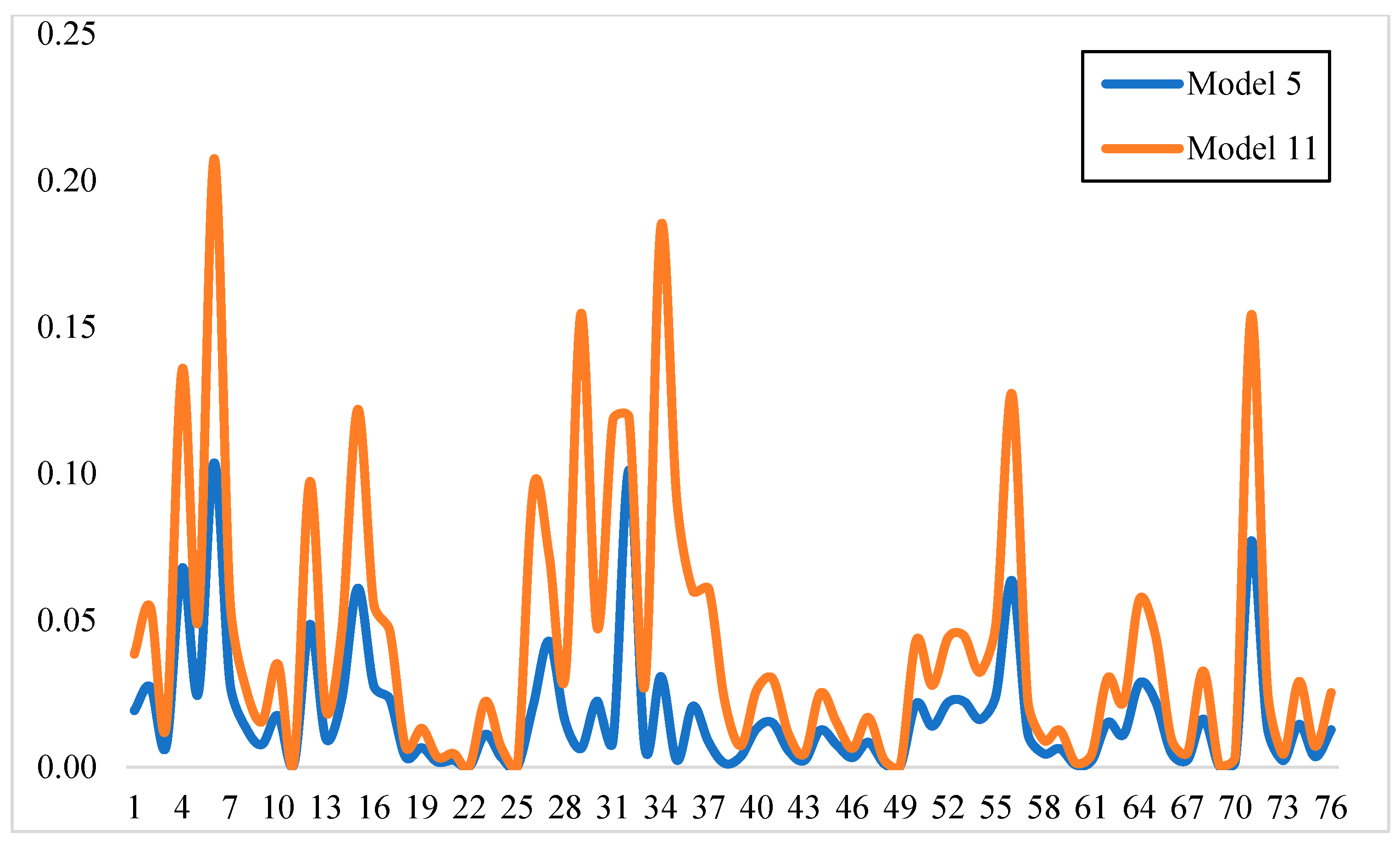

3.5. ANFIS Analysis Results

4. Conclusions

- The volcanic powder has a significant impact on maintaining SCGC slump optimal performance. However, the superplasticizer demand of VP is greater than the other two powders.

- The compressive strength of binary designs in the replacement range of 0–30% indicates that GBFS and VP have similar results to the control specimen, which favour compressive strength compared to fly ash.

- The electrical resistance results of the specimens showed that all three pozzolans had a better performance than the control ones. However, this effect in GBFS and VP were the highest and the lowest values, respectively.

- Results of the first seven ANFIS models in which parameters were investigated separately showed that electrical resistivity has the most significant influence on the compressive strength of SCGC, as the lowest value of RMSE was obtained for the input corresponding to cement replacements.

- Among the powders used in this study, ANFIS models revealed that the combination of VP with micro-silica has the highest effect on the resistance of concrete compared with other powders.

- Results of the second 21 ANFIS models illustrated that the combined use of cement with VP had exerted a far-reaching effect on the compressive strength of the SCGC specimens by resulting in the smallest RMSE among the other coupled parameters.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Mohammadi, M.; Zhan, Y.; Zheng, P.; Rashidi, M.; Mehrabi, P. Utilizing Artificial Intelligence to Predict the Superplasticizer Demand of Self-Consolidating Concrete Incorporating Pumice, Slag, and Fly Ash Powders. Materials 2021, 14, 6792. [Google Scholar] [CrossRef] [PubMed]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.I.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri, M.M.S.; Beskopylny, A.N.; Stel’Makh, S.A.; Shcherban’, E.M. Flexural behavior of reinforced concrete beams using waste marble powder towards application of sustainable concrete. Front. Mater. 2022, 9, 1068791. [Google Scholar] [CrossRef]

- Shariati, M.; Rafie, S.; Zandi, Y.; Fooladvand, R.; Gharehaghaj, B.; Mehrabi, P. Experimental investigation on the effect of cementitious materials on fresh and mechanical properties of self-consolidating concrete. Adv. Concr. Constr. 2019, 8, 225–237. [Google Scholar]

- Ardalan, R.B.; Joshaghani, A.; Hooton, R.D. Workability retention and compressive strength of self-compacting concrete incorporating pumice powder and silica fume. Constr. Build. Mater. 2017, 134, 116–122. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkiliç, Y.O.; Sabri, M.M.S. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Boukendakdji, O.; Kadri, E.-H.; Kenai, S. Effects of granulated blast furnace slag and superplasticizer type on the fresh properties and compressive strength of self-compacting concrete. Cem. Concr. Compos. 2012, 34, 583–590. [Google Scholar] [CrossRef]

- Najaf, E.; Abbasi, H.; Zahrai, S.M. Effect of waste glass powder, microsilica and polypropylene fibers on ductility, flexural and impact strengths of lightweight concrete. Int. J. Struct. Integr. 2022, 13, 511–533. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, P.; Parashar, A.K. Use of waste glass and demolished brick as coarse aggregate in production of sustainable concrete. Mater. Today Proc. 2022, 62, 4030–4035. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Özkılıç, Y.O.; Sabri, M.M.S. Effects of Waste Powder, Fine and Coarse Marble Aggregates on Concrete Compressive Strength. Sustainability 2022, 14, 14388. [Google Scholar] [CrossRef]

- Ren, W.; Xu, J.; Su, H. Dynamic compressive behavior of basalt fiber reinforced concrete after exposure to elevated temperatures. Fire Mater. 2015, 40, 738–755. [Google Scholar] [CrossRef]

- Shen, M.; Zhou, L.; Chen, Z.; Shen, Y.; Huang, B.; Lv, J. Effects of basalt powder and silica fume on ultra-high-strength cementitious matrix: A comparative study. Case Stud. Constr. Mater. 2022, 17, e01397. [Google Scholar] [CrossRef]

- Bouguerra, A.; Amiri, O.; Aït-Mokhtar, A.; Diop, M.B. Water sorptivity and pore structure of wood–cementitious composites. Mag. Concr. Res. 2002, 54, 103–112. [Google Scholar] [CrossRef]

- Ali, B.; Hawreen, A.; Ben Kahla, N.; Amir, M.T.; Azab, M.; Raza, A. A critical review on the utilization of coir (coconut fiber) in cementitious materials. Constr. Build. Mater. 2022, 351, 128957. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’Makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’Nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Najm, H.M.; Nanayakkara, O.; Ahmad, M.; Sabri, M.M.S. Mechanical Properties, Crack Width, and Propagation of Waste Ceramic Concrete Subjected to Elevated Temperatures: A Comprehensive Study. Materials 2022, 15, 2371. [Google Scholar] [CrossRef]

- Meena, R.V.; Jain, J.K.; Chouhan, H.S.; Beniwal, A.S. Use of waste ceramics to produce sustainable concrete: A review. Clean. Mater. 2022, 4, 100085. [Google Scholar] [CrossRef]

- Alsaif, A.; Alharbi, Y.R. Strength, durability and shrinkage behaviours of steel fiber reinforced rubberized concrete. Constr. Build. Mater. 2022, 345, 128295. [Google Scholar] [CrossRef]

- Bu, C.; Zhu, D.; Lu, X.; Liu, L.; Sun, Y.; Yu, L.; Xiao, T.; Zhang, W. Modification of Rubberized Concrete: A Review. Buildings 2022, 12, 999. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’Makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Sirba, N.; Paul, S.C.; Miah, J. Mechanical and Durability Assessment of Recycled Waste Plastic (Resin8 & PET) Eco-Aggregate Concrete. Sustainability 2022, 14, 5725. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.I.; Deifalla, A.F.; Ahmad, M.; Sabri, M.M.S. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 692. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Z.; Yu, H.; Ma, H.; Da, B. Mesoscopic Modeling Approach and Application for Steel Fiber Reinforced Concrete under Dynamic Loading: A Review. Engineering 2022, 16, 220–238. [Google Scholar] [CrossRef]

- Akhtar, T.; Ali, B.; Ben Kahla, N.; Kurda, R.; Rizwan, M.; Javed, M.M.; Raza, A. Experimental investigation of eco-friendly high strength fiber-reinforced concrete developed with combined incorporation of tyre-steel fiber and fly ash. Constr. Build. Mater. 2021, 314, 125626. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Khayat, K.; Yahia, A.; Sayed, M. Effect of supplementary cementitious materials on rheological properties, bleeding, and strength of structural grout. ACI Mater. J. 2008, 105, 585. [Google Scholar]

- Hwang, K.; Noguchi, T.; Tomosawa, F. Prediction model of compressive strength development of fly-ash concrete. Cem. Concr. Res. 2004, 34, 2269–2276. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Volcanic ash and pumice as cement additives: Pozzolanic, alkali-silica reaction and autoclave expansion characteristics. Cem. Concr. Res. 2005, 35, 1141–1144. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Performance of volcanic ash and pumice-based blended cements in sulphate and sulphate–chloride environments. Adv. Cem. Res. 2006, 18, 71–82. [Google Scholar] [CrossRef]

- Aydin, A.; Gül, R. Influence of volcanic originated natural materials as additives on the setting time and some mechanical properties of concrete. Constr. Build. Mater. 2007, 21, 1277–1281. [Google Scholar] [CrossRef]

- Deng, E.-F.; Zhang, Z.; Zhang, C.-X.; Tang, Y.; Wang, W.; Du, Z.-J.; Gao, J.-P. Experimental study on flexural behavior of UHPC wet joint in prefabricated multi-girder bridge. Eng. Struct. 2023, 275, 115314. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, W.; Liu, X. Assessment of Diagonal Macrocrack-Induced Debonding Mechanisms in FRP-Strengthened RC Beams. J. Compos. Constr. 2022, 26, 04022056. [Google Scholar] [CrossRef]

- Xu, C. Using genetic algorithms method for the paramount design of reinforced concrete structures. Struct. Eng. Mech. Int. J. 2019, 71, 503–513. [Google Scholar]

- Orouji, M.; Najaf, E. Effect of GFRP rebars and polypropylene fibers on flexural strength in high-performance concrete beams with glass powder and microsilica. Case Stud. Constr. Mater. 2023, 18, e01769. [Google Scholar] [CrossRef]

- Zhang, Z.; Liang, G.; Niu, Q.; Wang, F.; Chen, J.; Zhao, B.; Ke, L. A Wiener degradation process with drift-based approach of determining target reliability index of concrete structures. Qual. Reliab. Eng. Int. 2022, 38, 3710–3725. [Google Scholar] [CrossRef]

- Feng, Y.; Mohammadi, M.; Wang, L.; Rashidi, M.; Mehrabi, P. Application of Artificial Intelligence to Evaluate the Fresh Properties of Self-Consolidating Concrete. Materials 2021, 14, 4885. [Google Scholar] [CrossRef]

- Mehrabi, P.; Honarbari, S.; Rafiei, S.; Jahandari, S.; Bidgoli, M.A. Seismic response prediction of FRC rectangular columns using intelligent fuzzy-based hybrid metaheuristic techniques. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 10105–10123. [Google Scholar] [CrossRef]

- Taheri, E.; Mehrabi, P.; Rafiei, S.; Samali, B. Numerical Evaluation of the Upright Columns with Partial Reinforcement along with the Utilisation of Neural Networks with Combining Feature-Selection Method to Predict the Load and Displacement. Appl. Sci. 2021, 11, 11056. [Google Scholar] [CrossRef]

- Taheri, E.; Firouzianhaji, A.; Usefi, N.; Mehrabi, P.; Ronagh, H.; Samali, B. Investigation of a Method for Strengthening Perforated Cold-Formed Steel Profiles under Compression Loads. Appl. Sci. 2019, 9, 5085. [Google Scholar] [CrossRef] [Green Version]

- Taheri, E.; Firouzianhaji, A.; Mehrabi, P.; Hosseini, B.V.; Samali, B. Experimental and Numerical Investigation of a Method for Strengthening Cold-Formed Steel Profiles in Bending. Appl. Sci. 2020, 10, 3855. [Google Scholar] [CrossRef]

- Huang, H.; Li, M.; Yuan, Y.; Bai, H. Experimental Research on the Seismic Performance of Precast Concrete Frame with Replaceable Artificial Controllable Plastic Hinges. Eng. Struct. 2023, 149, 04022222. [Google Scholar] [CrossRef]

- Fang, B.; Hu, Z.; Shi, T.; Liu, Y.; Wang, X.; Yang, D.; Zhu, K.; Zhao, X.; Zhao, Z. Research progress on the properties and applications of magnesium phosphate cement. Ceram. Int. 2023, 49, 4001–4016. [Google Scholar] [CrossRef]

- Sari, P.A.; Suhatril, M.; Osman, N.; Mu’Azu, M.A.; Katebi, J.; Abavisani, A.; Ghaffari, N.; Chahnasir, E.S.; Wakil, K.; Khorami, M.; et al. Developing a hybrid adoptive neuro-fuzzy inference system in predicting safety of factors of slopes subjected to surface eco-protection techniques. Eng. Comput. 2019, 36, 1347–1354. [Google Scholar] [CrossRef]

- Shariati, M.; Mafipour, M.S.; Mehrabi, P.; Zandi, Y.; Dehghani, D.; Bahadori, A.; Shariati, A.; Trung, N.T.; Salih, M.N.A.; Poi-Ngian, S. Application of Extreme Learning Machine (ELM) and Genetic Programming (GP) to design steel-concrete composite floor systems at elevated temperatures. Steel Compos. Struct. 2019, 33, 319–332. [Google Scholar]

- Shariati, M.; Trung, N.T.; Wakil, K.; Mehrabi, P.; Safa, M.; Khorami, M. Estimation of moment and rotation of steel rack connections using extreme learning machine. Steel Compos. Struct. 2019, 31, 427–435. [Google Scholar]

- Shariati, M.; Mafipour, M.S.; Mehrabi, P.; Bahadori, A.; Zandi, Y.; Salih, M.N.A.; Nguyen, H.; Dou, J.; Song, X.; Poi-Ngian, S. Application of a Hybrid Artificial Neural Network-Particle Swarm Optimization (ANN-PSO) Model in Behavior Prediction of Channel Shear Connectors Embedded in Normal and High-Strength Concrete. Appl. Sci. 2019, 9, 5534. [Google Scholar] [CrossRef] [Green Version]

- Shariati, M.; Tahmasbi, F.; Mehrabi, P.; Bahadori, A.; Toghroli, A. Monotonic behavior of C and L shaped angle shear connectors within steel-concrete composite beams: An experimental investigation. Steel Compos. Struct. 2020, 35, 237–247. [Google Scholar]

- Huang, H.; Li, M.; Yuan, Y.; Bai, H. Theoretical analysis on the lateral drift of precast concrete frame with replaceable artificial controllable plastic hinges. J. Build. Eng. 2022, 62, 105386. [Google Scholar] [CrossRef]

- Hossain, K.M.; Lachemi, M. Development of volcanic ash concrete: Strength, durability, and microstructural investigations. ACI Mater. J. 2006, 103, 11. [Google Scholar]

- Bheel, N.; Keerio, M.A.; Kumar, A.; Shahzaib, J.; Ali, Z.; Ali, M.; Sohu, S. An Investigation on Fresh and Hardened Properties of Concrete Blended with Rice Husk Ash as Cementitious Ingredient and Coal Bottom Ash as Sand Replacement Material. Silicon 2021, 14, 677–688. [Google Scholar] [CrossRef]

- Bheel, N.; Memon, F.A.; Meghwar, S.L. Study of Fresh and Hardened Properties of Concrete Using Cement with Modified Blend of Millet Husk Ash as Secondary Cementitious Material. Silicon 2020, 13, 4641–4652. [Google Scholar] [CrossRef]

- Zhang, C.; Ali, A. The advancement of seismic isolation and energy dissipation mechanisms based on friction. Soil Dyn. Earthq. Eng. 2021, 146, 106746. [Google Scholar] [CrossRef]

- Dong, Z.; Quan, W.; Ma, X.; Li, X.; Zhou, J. Asymptotic homogenization of effective thermal-elastic properties of concrete considering its three-dimensional mesostructure. Comput. Struct. 2023, 279, 106970. [Google Scholar] [CrossRef]

- Cervantes, V.; Roesler, J. Ground Granulated Blast Furnace Slag; Technical Note; Center of Excellence for Airport Technology: Urbana, IL, USA, 2007; pp. 1–4. [Google Scholar]

- Karri, S.K.; Rao, G.R.; Raju, P.M. Strength and durability studies on GGBS concrete. SSRG Int. J. Civ. Eng. 2015, 2, 34–41. [Google Scholar] [CrossRef]

- Raman, J.M.; Krishnan, V. Partial Replacement of Cement with GGBS in Self Compacting Concrete for Sustainable Construction. Int. J. Civ. Eng. 2017, 4, 24–28. [Google Scholar] [CrossRef] [Green Version]

- Hossain, K.M. Blended cement using volcanic ash and pumice. Cem. Concr. Res. 2003, 33, 1601–1605. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoglu, M.; Al-Rawi, S.; Mermerdaş, K. Effect of volcanic pumice powder on the fresh properties of self-compacting concretes with and without silica fume. Mater. Struct. 2013, 47, 1857–1865. [Google Scholar] [CrossRef]

- Li, W.; Luo, Z.; Tao, Z.; Duan, W.H.; Shah, S.P. Mechanical behavior of recycled aggregate concrete-filled steel tube stub columns after exposure to elevated temperatures. Constr. Build. Mater. 2017, 146, 571–581. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chang, J.-N.; Wang, H.-Y.; Wen, F.-L. Effect of Adding Waste Polyethylene and GGBFS on the Engineering Properties of Cement Mortar. Appl. Sci. 2022, 12, 12665. [Google Scholar] [CrossRef]

- Vittalaiah, A.; Ravinder, R.; Kumar, C.V. Study on effect of strength and durability parameters and performance of Self Compacting Concrete replacement with GGBS at different dosages. E3S Web Conf. 2020, 184, 01106. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Miyandehi, B.M.; Naseri, F.; Ozbakkaloglu, T.; Jafari, F.; Mohseni, E. Effect of SnO2, ZrO2, and CaCO3 nanoparticles on water transport and durability properties of self-compacting mortar containing fly ash: Experimental observations and ANFIS predictions. Constr. Build. Mater. 2018, 158, 823–834. [Google Scholar] [CrossRef]

- Cheng-Yi, H.; Feldman, R. Hydration reactions in portland cement-silica fume blends. Cem. Concr. Res. 1985, 15, 585–592. [Google Scholar] [CrossRef] [Green Version]

- Cohen, M. A look at silica fume and its actions in Portland cement concrete. Indian Concr. J. 1990, 64, 429–438. [Google Scholar]

- Mehdizadeh, B.; Jahandari, S.; Vessalas, K.; Miraki, H.; Rasekh, H.; Samali, B. Fresh, Mechanical, and Durability Properties of Self-Compacting Mortar Incorporating Alumina Nanoparticles and Rice Husk Ash. Materials 2021, 14, 6778. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | Density (kg/m3) | Fineness (m2/kg) | Type |

|---|---|---|---|

| Properties | |||

| Cement | 3160 | 290 | Portland (II) |

| Coarse aggregate | 2500 | - | ASTM C33 |

| Fine aggregate | 2700 | 3.6 | ASTM C33 |

| High-range water reducing admixture (HWRA) | 1070 | - | Polycarboxylate Ether |

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | G * | S ** |

|---|---|---|---|---|---|---|---|---|

| Components (%) | ||||||||

| Fly ash | 62.79 | 45.89 | 0.93 | 2.59 | 1.40 | 0.49 | 2200 | 0.26 |

| GBFS | 33.09 | 13.78 | 3.13 | 40.70 | 8.70 | 0.60 | 2850 | 0.445 |

| Micro-silica | 86.19 | 1.43 | 0.19 | 3.07 | 1.32 | 0.34 | 2350 | 30 |

| Volcanic powder | 44.14 | 16.70 | 1.73 | 11.08 | 1.95 | 0.39 | 2830 | 0.32 |

| Cement | 22.41 | 4.69 | 3.69 | 63.26 | 3.63 | 1.74 | 3160 | 0.42 |

| Specimen | Aggregate (kg/m3) | Binder (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| Proportion | Fine | Coarse | Cement | Volcanic Pumice | Micro-Silica | GGBFS | Fly Ash |

| GBFS10 | 1072 | 595 | 450 | - | - | 50 | - |

| GBFS20 | 1069 | 594 | 400 | - | - | 100 | - |

| GBFS30 | 1066 | 592 | 350 | - | - | 150 | - |

| GBFS40 | 1063 | 590 | 300 | - | - | 200 | - |

| GBFS50 | 1069 | 580 | 250 | - | - | 250 | - |

| VP10 | 1072 | 595 | 450 | 50 | - | - | - |

| VP20 | 1069 | 594 | 400 | 100 | - | - | - |

| VP30 | 1066 | 592 | 350 | 150 | - | - | - |

| VP40 | 1063 | 590 | 300 | 200 | - | - | - |

| VP50 | 1060 | 589 | 250 | 250 | - | - | - |

| FA10 | 1063 | 590 | 450 | - | - | - | 50 |

| FA20 | 1052 | 584 | 400 | - | - | - | 100 |

| FA30 | 1040 | 578 | 350 | - | - | - | 150 |

| FA40 | 1029 | 571 | 300 | - | - | - | 200 |

| FA50 | 1017 | 565 | 250 | - | - | - | 250 |

| Specimen | Aggregate (kg/m3) | Binder (kg/m3) | |||

|---|---|---|---|---|---|

| Proportion | Fine | Coarse | Cement | Volcanic Pumice | Micro-Silica |

| VP5-MS5 | 1064 | 576 | 450 | 25 | 25 |

| VP10-MS10 | 1047 | 585 | 400 | 50 | 50 |

| VP25-MS5 | 1039 | 580 | 350 | 125 | 25 |

| VP30-MS10 | 1066 | 592 | 300 | 150 | 50 |

| VP40-MS10 | 1051 | 584 | 250 | 250 | 50 |

| VP45-MS5 | 1057 | 587 | 250 | 225 | 25 |

| Inputs and Output | Parameters Description |

|---|---|

| Input 1 | Volcanic powder (kg/m3) |

| Input 2 | Micro-silica (kg/m3) |

| Input 3 | Fly ash (kg/m3) |

| Input 4 | Furnace slag (kg/m3) |

| Input 5 | Electrical resistivity (ohm-meter) |

| Input 6 | Water absorption (%) |

| Input 7 | Cement (kg/m3) |

| Output | Compressive strength (MPa) |

| Specimen | Slump Value (cm) | |||||

|---|---|---|---|---|---|---|

| 3 min | 10 min | 20 min | 30 min | 40 min | 50 min | |

| Ctrl-FA | 52 | 64 | 62 | 60 | 54 | 50 |

| FA10 | 66 | 64 | 63 | 61 | 59 | 56.5 |

| FA20 | 46 | 63 | 62 | 60 | 58.5 | 55 |

| FA30 | 55 | 66 | 61 | 59 | 57 | 55 |

| FA40 | 52 | 65 | 60 | 57 | 54 | 53 |

| FA50 | 55 | 63 | 60 | 57 | 54 | 51.5 |

| Ctrl-GBFS | 42 | 65 | 59 | 55 | 53 | 50 |

| GBFS10 | 67 | 66 | 63 | 59 | 56 | 53 |

| GBFS20 | 68 | 66 | 62 | 57 | 55 | 53 |

| GBFS30 | 58 | 65 | 62 | 59 | 57 | 54 |

| GBFS40 | 66 | 64 | 63 | 59 | 54 | 52 |

| GBFS50 | 58 | 65 | 63 | 62 | 59 | 57 |

| Ctrl-VP | 52 | 65 | 63 | 61 | 60 | 54 |

| VP10 | 66 | 66 | 65 | 63 | 61 | 59 |

| VP20 | 46 | 64 | 66 | 65 | 62 | 60 |

| VP30 | 55 | 65 | 66 | 66 | 62 | 60 |

| VP40 | 52 | 65 | 66 | 67 | 63 | 60 |

| VP50 | 55 | 65 | 66 | 68 | 65 | 61 |

| Ctrl-ternary | 53 | 65 | 58 | 57 | 54 | 53 |

| VP5-MS5 | 55 | 65 | 63 | 59 | 54 | 49 |

| VP10-MS10 | 52 | 65 | 60 | 55 | 50 | 43 |

| VP25-MS5 | 59 | 65 | 59 | 56 | 56 | 53 |

| VP30-MS10 | 60 | 65 | 66 | 62 | 60 | 56 |

| VP40-MS10 | 44 | 65 | 61 | 57 | 55 | 49 |

| VP45-MS5 | 53 | 65 | 64 | 61 | 54 | 52 |

| Specimen | Compressive Strength (MPa) | ||

|---|---|---|---|

| Value | 7 days | 28 days | 90 days |

| Ctrl-FA | 31.7 | 46.7 | 55.3 |

| FA10% | 29.3 | 46.6 | 53.1 |

| FA20% | 26.2 | 45.3 | 51.5 |

| FA30% | 25.2 | 43.0 | 50.0 |

| FA40% | 23.1 | 36.0 | 48.4 |

| FA50% | 15.5 | 32.8 | 39.0 |

| Ctrl-GBFS | 36.1 | 44.7 | 48.9 |

| GBFS10% | 35.2 | 45.2 | 47.3 |

| GBFS20% | 34.7 | 45.8 | 49.0 |

| GBFS30% | 34.5 | 46.2 | 50.5 |

| GBFS40% | 31.1 | 38.4 | 43.1 |

| GBFS50% | 25.1 | 37.4 | 44.4 |

| Ctrl-VP | 31.7 | 38.3 | 49.3 |

| VP10% | 31.0 | 37.2 | 49.0 |

| VP20% | 29.0 | 36.0 | 48.8 |

| VP30% | 23.8 | 35.0 | 45.8 |

| VP40% | 21.6 | 31.7 | 39.0 |

| VP50% | 16.4 | 27.8 | 38.7 |

| Ctrl-ternary | 41.3 | 46.6 | 48.0 |

| VP5-MS5 | 30.2 | 40.2 | 46.2 |

| VP10-MS10 | 37.3 | 43.8 | 49.1 |

| VP25-MS5 | 39.7 | 43.0 | 54.0 |

| VP30-MS10 | 40.1 | 52.4 | 59.2 |

| VP40-MS10 | 35.2 | 54.0 | 58.3 |

| VP45-MS5 | 32.1 | 40.8 | 51.4 |

| Name | Composition | RMSE | |

|---|---|---|---|

| Train | Test | ||

| Model 1 | Input 1 | 6.9291 | 5.8419 |

| Model 2 | Input 2 | 6.9913 | 5.8988 |

| Model 3 | Input 3 | 5.4751 | 6.959 |

| Model 4 | Input 4 | 6.5671 | 7.0164 |

| Model 5 | Input 5 | 4.8102 | 5.1792 |

| Model 6 | Input 6 | 5.682 | 7.2819 |

| Model 7 | Input 7 | 5.4928 | 6.4055 |

| Name | Composition | RMSE | |

|---|---|---|---|

| Train | Test | ||

| Model 8 | Input 1 & Input 2 | 5.4212 | 4.0932 |

| Model 9 | Input 1 & Input 3 | 5.9475 | 4.5269 |

| Model 10 | Input 1 & Input 4 | 6.2803 | 5.7961 |

| Model 11 | Input 1 & Input 5 | 2.1721 | 3.4315 |

| Model 12 | Input 1 & Input 6 | 4.1214 | 5.9134 |

| Model 13 | Input 1 & Input 7 | 4.1452 | 3.8691 |

| Model 14 | Input 2 & Input 3 | 5.4312 | 4.8613 |

| Model 15 | Input 2 & Input 4 | 5.7102 | 5.2212 |

| Model 16 | Input 2 & Input 5 | 4.0510 | 3.3129 |

| Model 17 | Input 2 & Input 6 | 8.9812 | 4.2554 |

| Model 18 | Input 2 & Input 7 | 4.9213 | 6.99102 |

| Model 19 | Input 3 & Input 4 | 5.5310 | 5.8312 |

| Model 20 | Input 3 & Input 5 | 4.0127 | 5.5146 |

| Model 21 | Input 3 & Input 6 | 4.6613 | 5.6517 |

| Model 22 | Input 3 & Input 7 | 4.1632 | 5.2813 |

| Model 23 | Input 4 & Input 5 | 4.6312 | 5.2813 |

| Model 24 | Input 4 & Input 6 | 6.6747 | 5.6147 |

| Model 25 | Input 4 & Input 7 | 5.4831 | 7.0815 |

| Model 26 | Input 5 & Input 6 | 3.4519 | 4.1035 |

| Model 27 | Input 5 & Input 7 | 3.4518 | 4.1014 |

| Model 28 | Input 6 & Input 7 | 3.8315 | 4.3315 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Zheng, D.; Mehdizadeh, B.; Nasr, E.A.; Khandaker, M.U.; Salman, M.; Mehrabi, P. Sustainable Design of Self-Consolidating Green Concrete with Partial Replacements for Cement through Neural-Network and Fuzzy Technique. Sustainability 2023, 15, 4752. https://doi.org/10.3390/su15064752

Han S, Zheng D, Mehdizadeh B, Nasr EA, Khandaker MU, Salman M, Mehrabi P. Sustainable Design of Self-Consolidating Green Concrete with Partial Replacements for Cement through Neural-Network and Fuzzy Technique. Sustainability. 2023; 15(6):4752. https://doi.org/10.3390/su15064752

Chicago/Turabian StyleHan, Shaoyong, Dongsong Zheng, Bahareh Mehdizadeh, Emad Abouel Nasr, Mayeen Uddin Khandaker, Mohammad Salman, and Peyman Mehrabi. 2023. "Sustainable Design of Self-Consolidating Green Concrete with Partial Replacements for Cement through Neural-Network and Fuzzy Technique" Sustainability 15, no. 6: 4752. https://doi.org/10.3390/su15064752

APA StyleHan, S., Zheng, D., Mehdizadeh, B., Nasr, E. A., Khandaker, M. U., Salman, M., & Mehrabi, P. (2023). Sustainable Design of Self-Consolidating Green Concrete with Partial Replacements for Cement through Neural-Network and Fuzzy Technique. Sustainability, 15(6), 4752. https://doi.org/10.3390/su15064752