Synthesis and Electrochemical Properties of Co3O4@Reduced Graphene Oxides Derived from MOF as Anodes for Lithium-Ion Battery Applications

Abstract

:1. Introduction

2. Materials and Methods

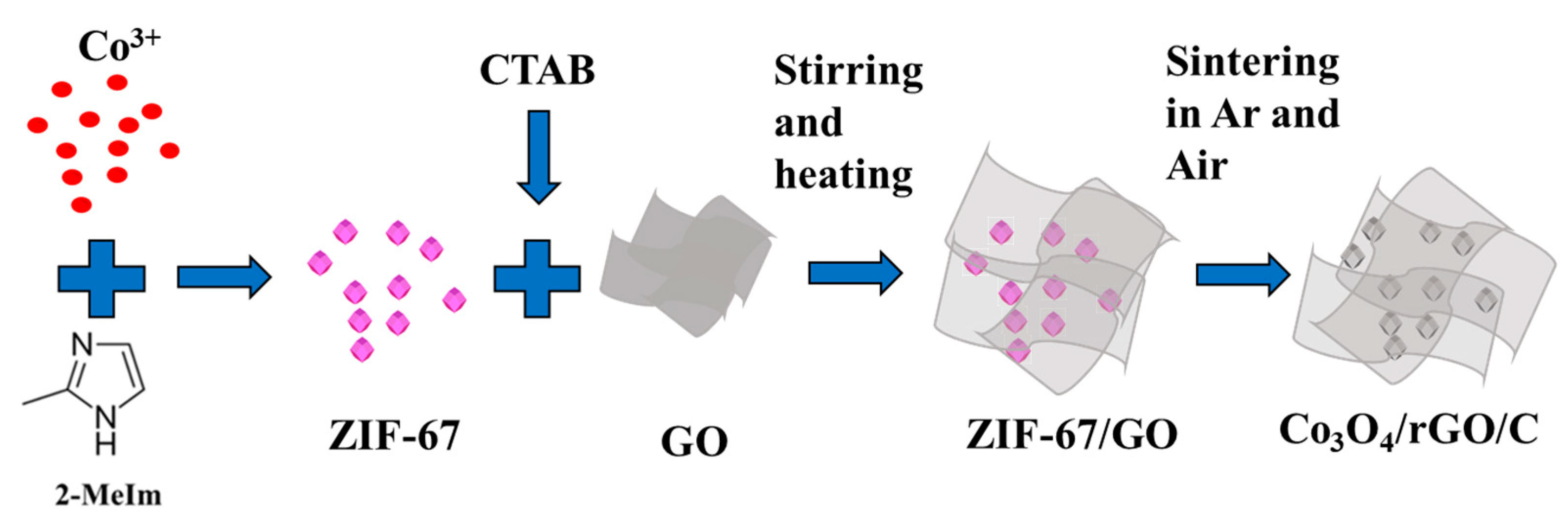

2.1. Synthesis of ZIF-67 and ZIF-67/GO

2.2. Synthesis of ZIF-67/GO

2.3. Synthesis of Co3O4/C and Co3O4/rGO/C Composite

2.4. Characterizations

2.5. Electrochemical Measurements

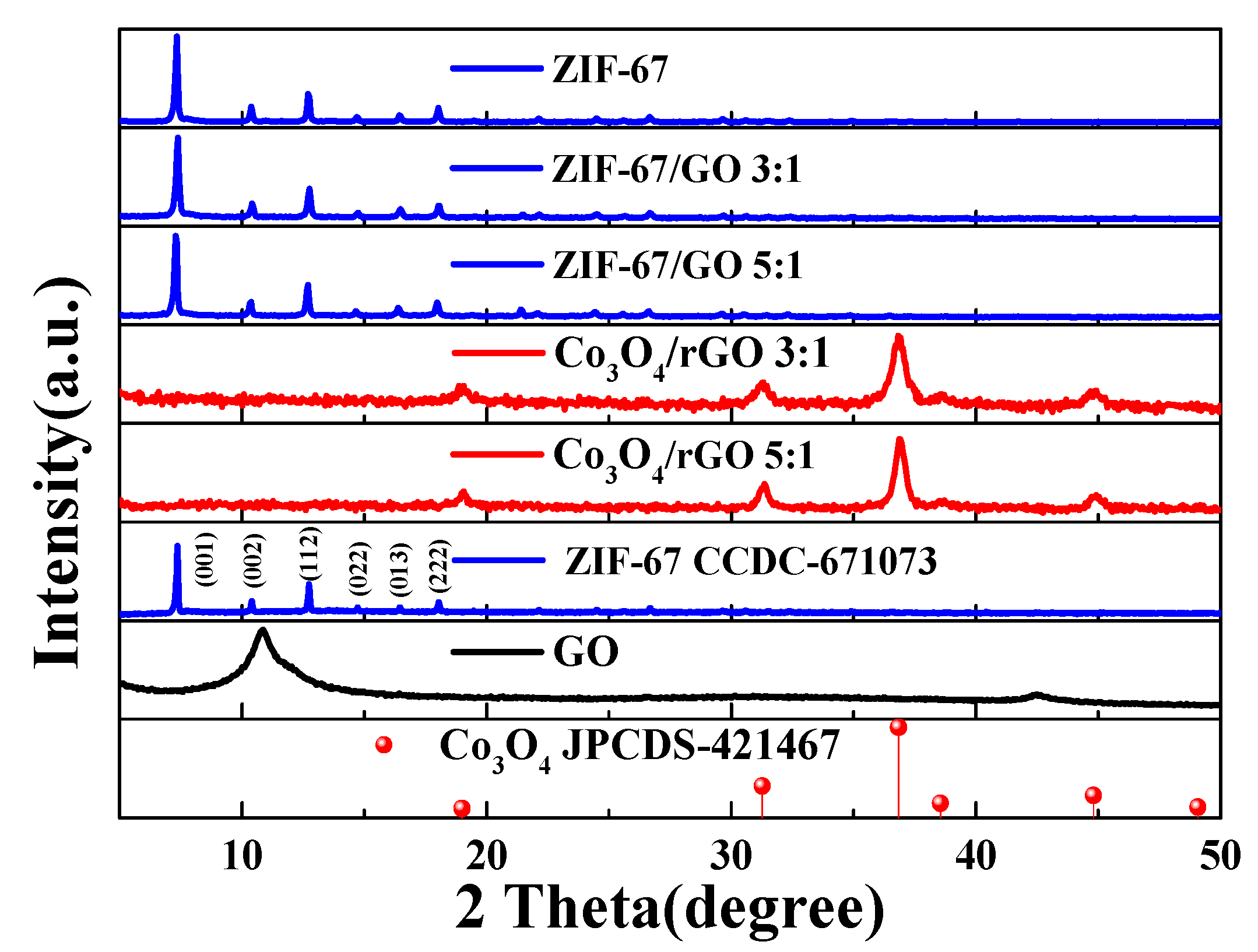

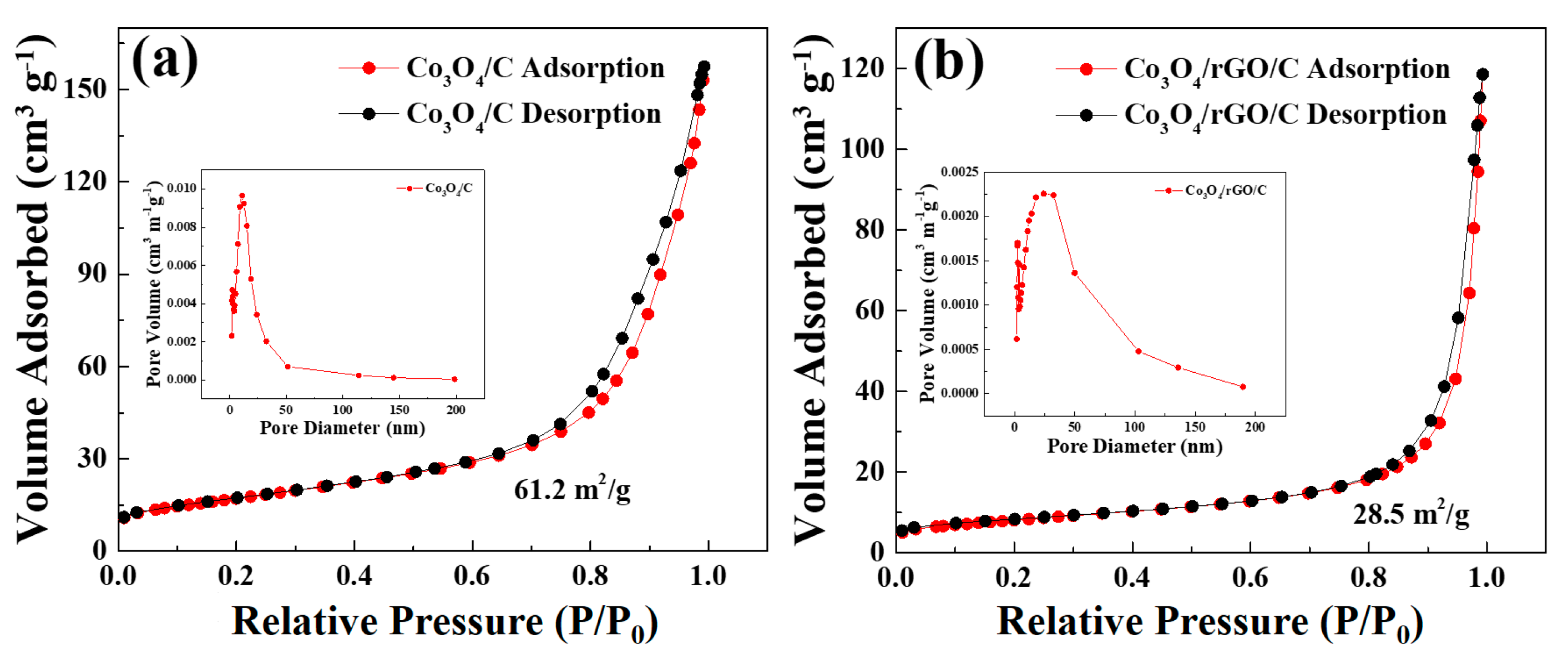

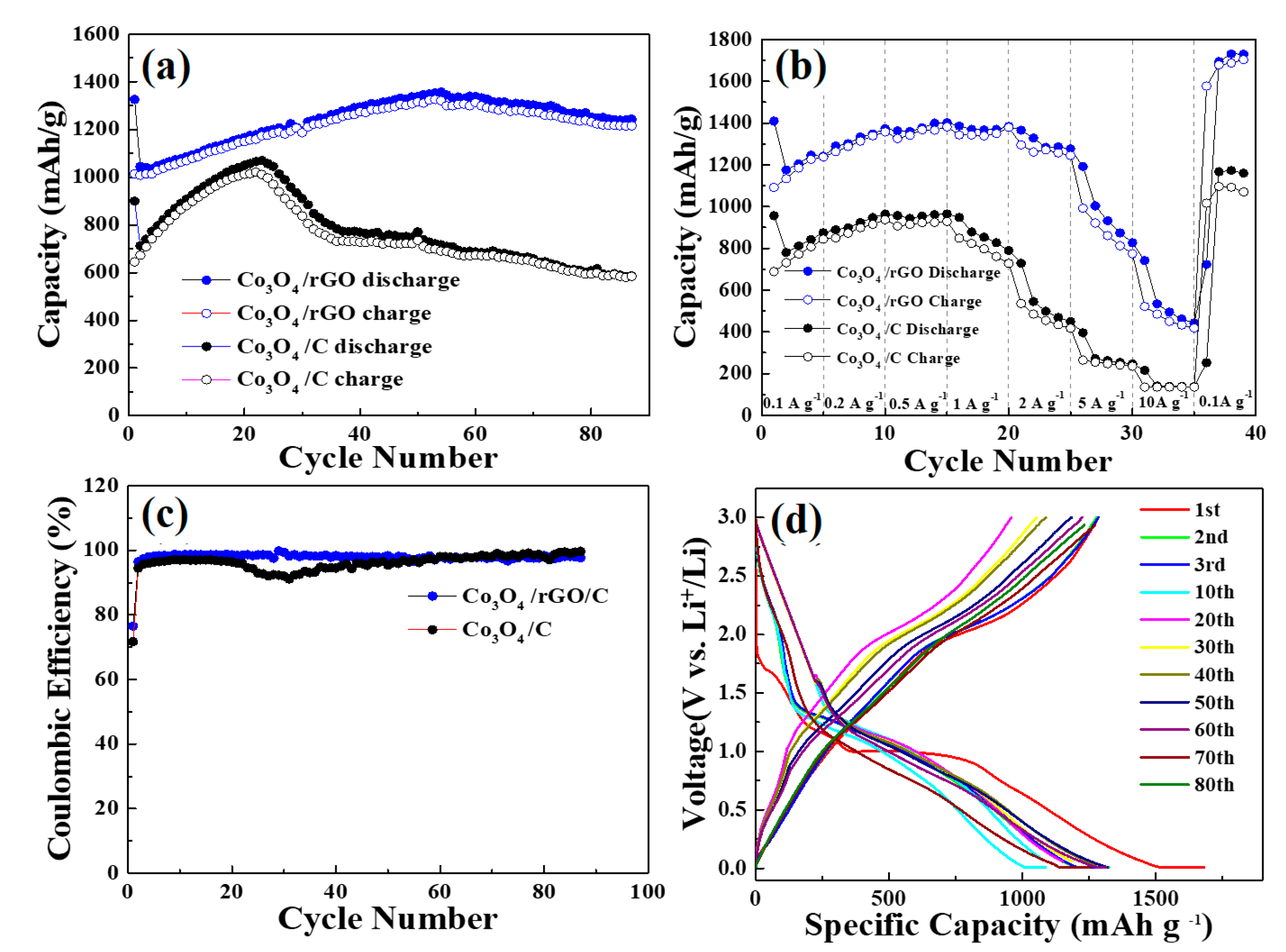

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Yue, H.; Shi, Z.; Wang, Q.; Gao, Z.; Dong, H.; Qiao, Y.; Yin, Y.; Yang, S. MOF-Derived Cobalt-Doped ZnO@C Composites as a High- Performance Anode Material for Lithium-Ion Batteries. Appl. Mater. Interfaces 2014, 16, 17067–17074. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Qi, P.; Feng, X.; Li, S.; Fu, X.; Li, H.; Chen, Y.; Zhou, J.; Li, X.; Wang, B. In Situ Growth of MOFs on the Surface of Si Nanoparticles for Highly Efficient Lithium Storage: Si@MOF Nanocomposites as Anode Materials for Lithium-Ion Batteries. Appl. Mater. Interfaces 2015, 55, 2178–2182. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Chu, R.; Chen, Y.; Jiang, H.; Zeng, Y.; Chen, X.; Zhang, Y.; Huang, N.M.; Guo, H. MOF-derived Transition Metal Oxide Encapsulated in Carbon Layer as Stable Lithium Ion Battery Anodes. J. Alloys Compd. 2019, 797, 83–91. [Google Scholar] [CrossRef]

- Wang, K.; Pei, S.; He, Z.; Huang, L.A.; Zhu, S.; Guo, J.; Shao, H.; Wang, J. Synthesis of a Novel Porous Silicon Microsphere@carbon Core-shell Composite Via in Situ MOF Coating for Lithium-ion Battery Anodes. Chem. Eng. J. 2019, 356, 272–281. [Google Scholar] [CrossRef]

- Suna, X.; Gaoa, G.; Yanb, D.; Fenga, C. Synthesis and Electrochemical Properties of Fe3O4@MOF Core-shell Microspheres as An Anode for Lithium Ion Battery Application. Appl. Surf. Sci. 2017, 405, 52–59. [Google Scholar] [CrossRef]

- Dai, J.; Li, J.; Zhang, Q.; Liao, M.; Duan, T.; Yao, W. Co3S4@C@MoS2 Microstructures Fabricated from MOF Template as Advanced Lithium-ion Battery Anode. Mater. Lett. 2019, 236, 483–486. [Google Scholar] [CrossRef]

- Wu, R.; Qian, X.; Rui, X.; Liu, H.; Yadian, B.; Zhou, K.; Wei, J.; Yan, Q.; Feng, X.Q.; Long, Y.; et al. Zeolitic Imidazolate Framework 67-Derived High Symmetric Porous Co3O4 Hollow Dodecahedra with Highly Enhanced Lithium Storage Capability. Small 2014, 10, 1932–1938. [Google Scholar] [CrossRef]

- Qu, Q.; Gao, T.; Zheng, H.; Li, X.; Liu, H.; Shen, M.; Shao, J.; Zheng, H. Graphene Oxides-guided Growth of Ultrafine Co3O4 Nanocrystallites from MOFs as High-performance Anode of Li-ion Batteries. Carbon 2015, 92, 119–125. [Google Scholar] [CrossRef]

- An, Y.; Fei, H.; Zeng, G.; Ci, L.; Xi, B.; Xiong, S.; Feng, J. Commercial Expanded Graphite as A Low–cost, Long-cycling Life Anode for Potassium–ion Batteries with Conventional Carbonate Electrolyte. J. Power Sources 2018, 378, 66–72. [Google Scholar] [CrossRef]

- Yuana, J.; Liu, Q.; Li, S.; Lu, Y.; Jin, S.; Li, K.; Chena, H.; Zhang, H. Metal Organic Framework (MOF)-derived Carbonaceous Co3O4/Co Microframes Anchored on RGO with Enhanced Electromagnetic Wave Absorption Nerformances. Synth. Met. 2017, 228, 32–40. [Google Scholar] [CrossRef]

- Wang, Y.; Di, X.; Wu, X.; Li, X. MOF-derived Nanoporous Carbon/Co/Co3O4/CNTs/RGO Composite with Hierarchical Structure as A High-efficiency Electromagnetic Wave Absorber. J. Alloys Compd. 2020, 846, 156215. [Google Scholar] [CrossRef]

- Xie, K.; Qin, X.; Wang, Y.; Tao, H.; Wu, Q.; Yang, L.; Hu, Z. Carbon Nanocages as Supercapacitor Electrode Materials. Adv. Mater. 2012, 24, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Samuel, E.; Park, C.; Kim, T.; Joshi, B.; Aldalbahi, A.; Alanzi, H.S.; Swihart, M.T.; Yoon, W.Y.; Yoon, S.S. Dodecahedral ZnO/C Framework on Reduced Graphene Oxide Sheets for High-performance Li-ion Battery Anodes. J. Alloys Compd. 2020, 834, 155208. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Zhao, W.; Zou, M.; Chen, Y.; Yang, L.; Xu, L.; Wu, H.; Cao, A. MOF-Derived ZnO Nanoparticles Covered by N-doped Carbon Layers and Hybridized on Carbon Nanotubes for Lithium-Ion Battery Anodes. ACS Appl. Mater. Interfaces 2017, 43, 37813–37822. [Google Scholar] [CrossRef] [PubMed]

- Fan, W.; Wang, X.; Xu, B.; Wang, Y.; Liu, D.; Zhang, M.; Shang, Y.; Dai, F.; Zhang, L.; Sun, D. Amino-functionalized MOFs with High Physicochemical Stability for Efficient Gas Storage/separation, Dye Adsorption and Catalytic Performance. ACS Appl. Mater. Interfaces 2018, 6, 24486–24495. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, D. Mesoporous Carbon Originated from Non-permanent Porous MOFs for Gas Storage and CO2/CH4 Separation. Sci. Rep. 2014, 4, 5711. [Google Scholar] [CrossRef] [Green Version]

- Pan, Y.; Li, Z.; Zhang, Z.; Tong, X.S.; Li, H.; Jia, C.Z.; Liu, B.; Sun, C.Y.; Yang, L.Y.; Chen, G.J.; et al. Adsorptive Removal of Phenol from Aqueous Solution with Zeolitic Imidazolate Framework-67. J. Environ. Manag. 2016, 169, 167–173. [Google Scholar] [CrossRef]

- Xue, W.; Yang, G.; Bi, S.; Zhang, J.; Hou, Z.L. Construction of Caterpillar-like Hierarchically Structured Co/MnO/CNTs Derived from MnO2/ZIF-8@ZIF-67 for Electromagnetic Wave Absorption. Carbon 2021, 173, 521–527. [Google Scholar] [CrossRef]

- Jin, Y.; Zhao, C.; Sun, Z.; Lin, Y.; Chen, L.; Wang, D.; Shen, C. Controllable Synthesis of Isoreticular Pillared-layer MOFs: Gas Adsorption, Iodine Sorption and Sensing Small Molecules. J. Mater. Chem. A 2014, 36, 14827–14834. [Google Scholar]

- Jabbari, V.; Veleta, J.M.; Chaleshtori, M.Z.; Torresdey, J.G.; Villagrán, D. Green Synthesis of Magnetic MOF@GO and MOF@CNT Hybrid Nanocomposites with High Adsorption Capacity towards Organic Pollutants. Chem. Eng. J. 2016, 304, 774–783. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zhao, Y.; Gong, Q.; Li, Z.; Li, J. MOFs for CO2 Capture and Separation from Flue Gas Mixtures: The Effect of Multifunctional Sites on their Adsorption Capacity and Selectivity. Chem. Commun. 2013, 49, 653–661. [Google Scholar] [CrossRef] [PubMed]

- Canivet, J.; Fateev, A.; Guo, Y.; Coasnecd, B.; Farrusseng, D. Water Adsorption in MOFs: Fundamentals and Applications. Chem. Soc. Rev. 2014, 43, 5594–5617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, K.; Xie, A.; Sun, M.; Jiang, W.; Wu, F.; Dong, W. Electromagnetic Dissipation on the Surface of Metal Organic Framework (MOF)/reduced graphene oxide (RGO) Hybrids. Mater. Chem. Phys. 2017, 199, 340–347. [Google Scholar] [CrossRef]

- Hou, S.L.; Dong, J.; Jiang, X.L.; Jiao, Z.H.; Zhao, B. Noble-Metal-Free Metal–Organic Framework (MOF) Catalyst for the Highly Efficient Conversion of CO2 with Propargylic Alcohols. Angew. Chem. 2019, 43, 577–581. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Y.; Ma, D.; Li, L.; Li, G.; Li, G.; Shi, Z.; Feng, S. A Strategy toward Constructing a Bifunctionalized MOF Catalyst: Post-synthetic Modification of MOFs on Organic Ligands and Coordinatively Unsaturated Metal Sites. Appl. Mater. Interfaces 2012, 49, 220–223. [Google Scholar] [CrossRef]

- Park, K.S.; Jin, S.A.; Lee, K.H.; Lee, J.; Song, I.; Lee, B.S.; Kim, S.; Sohn, J.; Pak, C.; Kim, G.; et al. Characterization of Zeolitic Imidazolate Framework–derived Polyhedral Carbonaceous Material and its Application to Electrocatalyst for Oxygen Reduction Reaction. Electrochmical Sci. 2016, 11, 9295–9306. [Google Scholar] [CrossRef]

- García, P.G.; Müller, M.; Corma, A. MOF Catalysis in Perspective to their Homogeneous Counterparts and Conventional Solid Catalysts. Chem. Sci. 2014, 5, 2979–3007. [Google Scholar] [CrossRef]

- Zhao, S.S.; Yang, J.; Liu, Y.Y.; Ma, J.F. Fluorescent Aromatic Tag-Functionalized MOFs for Highly Selective Sensing of Metal Ions and Small Organic Molecules. Inorg. Chem. 2016, 123, 2261–2273. [Google Scholar] [CrossRef]

- Dolgopolova, E.A.; Rice, A.M.; Martin, C.R.; Shustova, N. Photochemistry and Photophysics of MOFs: Steps towards MOF-based Sensing Enhancements. Chem. Soc. Rev. 2018, 47, 4710–4728. [Google Scholar] [CrossRef]

- Hosseinian, A.; Amjad, A.; Khanmiri, R.H.; Kalhor, E.G.; Babazadeh, M.; Vessally, E. Nanocomposite of ZIF-67 Metal–organic Framework with Reduced Graphene Oxide Nanosheets for High-performance Supercapacitor Applications. Mater. Electron. 2017, 28, 18040–18048. [Google Scholar] [CrossRef]

- Zhang, W.; Tan, Y.; Gao, Y.; Wu, J.; Hu, J.; Stein, A.; Tang, B. Nanocomposites of Zeolitic Imidazolate Frameworks on Graphene Oxide for Pseudocapacitor Applications. J. Appl. Electrochem. 2016, 46, 441–450. [Google Scholar] [CrossRef]

- Jiang, Y.; Zou, G.; Hong, W.; Zhang, Y.; Zhang, Y.; Shuai, H.; Xu, W.; Hou, H.; Ji, X. N-Rich Carbon-coated Co3S4 Ultrafine Nanocrystals Derived from ZIF-67 as an Advanced Anode for Sodium-ion Batteries. Nanoscale 2018, 10, 18786–18794. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Huang, X.; Sun, C.; Chen, X.; Hu, J.; Stein, A.; Tang, B. Thin-film Electrode Based on Zeolitic Imidazolate Frameworks (ZIF-8 and ZIF-67) with Ultrastable Performance as a Lithium-ion Battery Anode. J. Mater. Sci. 2017, 52, 3979–3991. [Google Scholar] [CrossRef]

- Avouris, P.; Xia, F. Graphene Applications in Electronics and Photonics. MRS Bull. 2012, 37, 1225–1234. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, W.; Zhang, Y.; Bakenov, Z.; Zhao, Y. Hierarchical Rambutan-Like CNTs-Assembled N-Co-C@rGO Composite as Sulfur Immobilizer for High-Performance Lithium-Sulfur Batteries. ChemElectroChem 2019, 6, 4565–4570. [Google Scholar] [CrossRef]

- Cao, Y.; Lu, Y.; Ang, E.H.; Geng, H.; Cao, X.; Zheng, J.; Gu, J.H. MOFs Derived Uniform Ni Nanoparticles Encapsulated in Carbon Nanotubes Grafted on rGO Ganosheet as Bifunctional Materials for Lithium-ion Batteries and Hydrogen Evolution Reaction. Nanoscale 2019, 11, 15112–15119. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.L.; Liu, F.H.; Wang, H.N.; Qin, C.; Sun, C.Y.; Su, Z.M.; Liu, F.C. Facile Synthesis of Fe-MOF/RGO and its Application as a High-performance Anode in Lithium-ion Batteries. RSC Adv. 2016, 36, 30763–30768. [Google Scholar]

- Yin, D.; Huang, G.; Suna, Q.; Li, Q.; Wang, X.; Yuana, D.; Wang, C.; Wang, L. RGO/Co3O4 Composites Prepared Using GO-MOFs as Precursor for Advanced Lithium-ion Batteries and Supercapacitors Electrodes. Electrochim. Acta 2016, 215, 410–419. [Google Scholar] [CrossRef]

- Gao, C.; Wang, W.; Wang, Z.; Kær, S.K.; Zhang, Y.; Yue, Y. The Disordering-Enhanced Performances of The Al-MOF/graphene Composite Anodes for Lithium Ion Batteries. Nano. Energy 2019, 65, 104032. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Y.; Liu, W.; Song, Y.; Wang, L. Hollow Co-Co3O4@CNTs derived from ZIF-67 for Lithium Ion Batteries. J. Alloys Compd. 2017, 784, 439–446. [Google Scholar] [CrossRef]

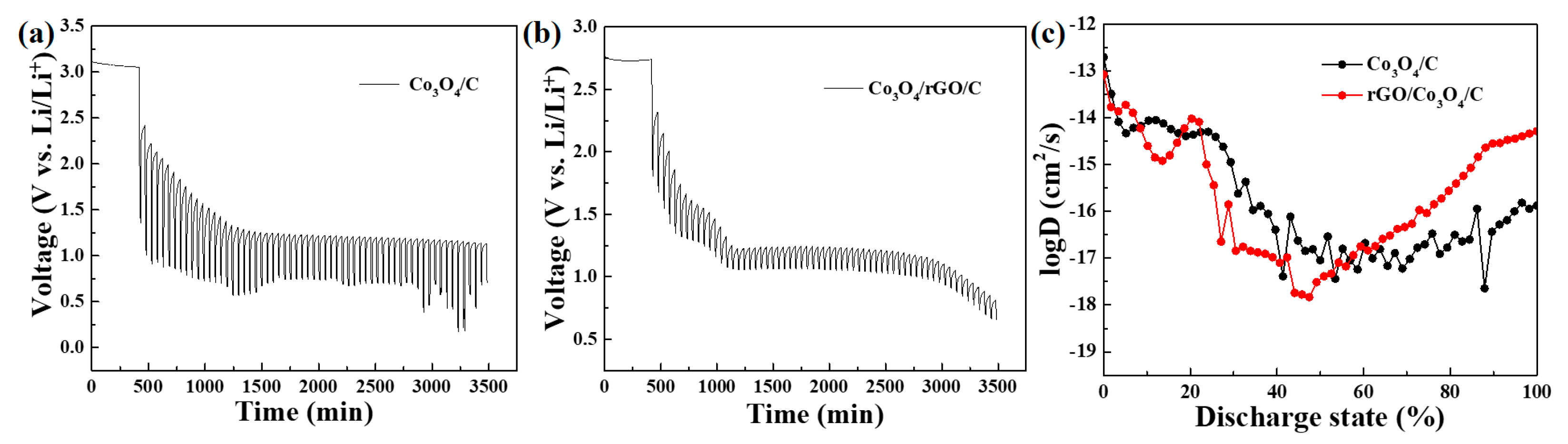

- Zhu, Y.; Wang, C. Galvanostatic Intermittent Titration Technique for Phase-Transformation Electrodes. J. Phys. Chem. C 2010, 114, 2830–2841. [Google Scholar] [CrossRef]

- Wang, J.; Yao, J.; Li, W.; Zhu, W.; Yang, J.; Zhao, J.; Gao, L. Lithium molybdate composited with carbon nanofibers as a high-capacity and stable anode material for lithium-ion batteries. Energy Mater. 2022, 2, 200026. [Google Scholar] [CrossRef]

- Chang, H.; Wu, Y.-R.; Han, X.; Yi, T.-F. Recent developments in advanced anode materials for lithium-ion batteries. Energy Mater. 2021, 1, 100003. [Google Scholar] [CrossRef]

- Xia, S.; Zhou, Q.; Peng, B.; Zhang, X.; Liu, L.; Guo, F.; Fu, L.; Wang, T.; Liu, Y.; Wu, Y. Co3O4@MWCNT modified separators for Li–S batteries with improved cycling performance. Mater. Today Energy 2021, 30, 101163. [Google Scholar] [CrossRef]

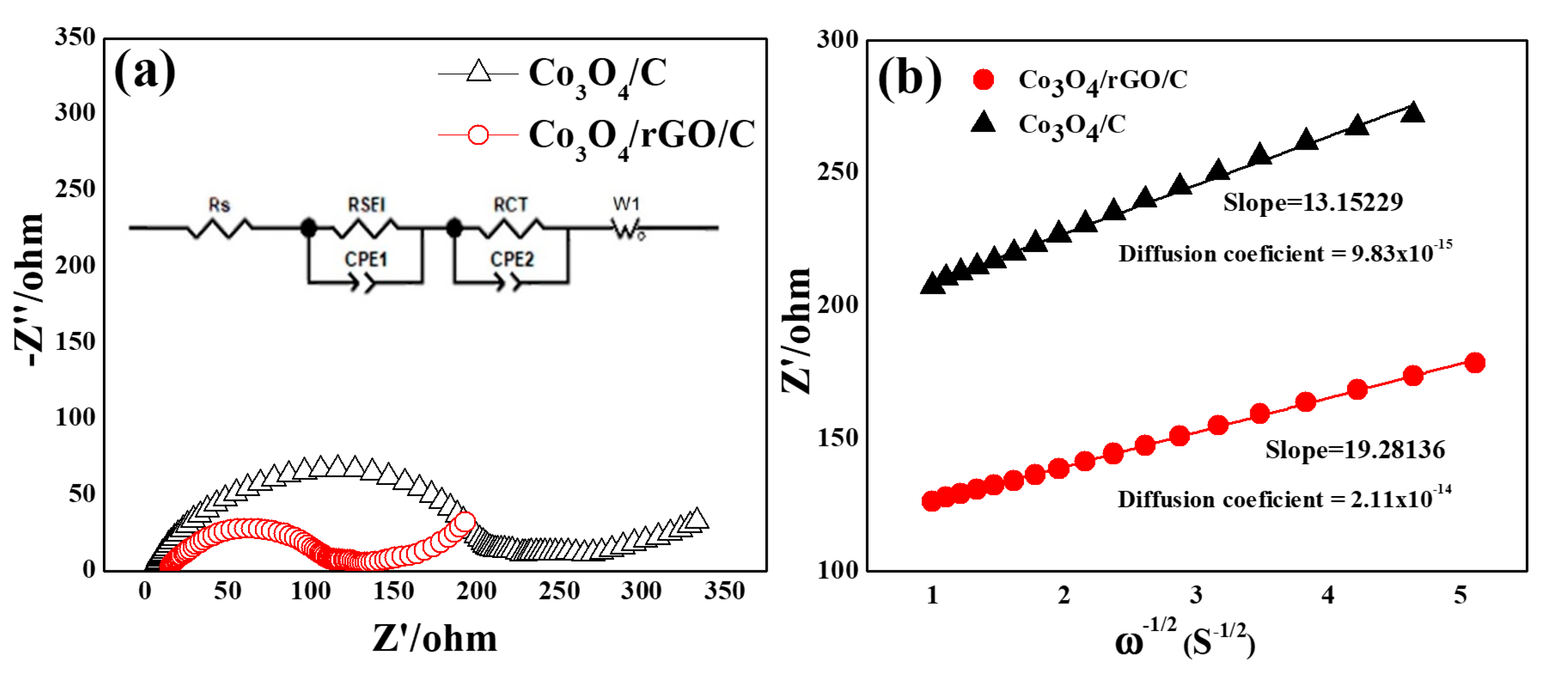

| Components | Co3O4/C | Co3O4/rGO/C |

|---|---|---|

| RSEI (Ω) | 201.1 | 98.9 |

| RCT (Ω) | 21.4 | 12.1 |

| (Ω /s0.5) | 13.15 | 19.28 |

| D (cm2/s) | 9.83 × 10−15 | 2.11 × 10−14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.-X.; Huang, C.-H.; Gandomi, Y.A.; Hsieh, C.-T.; Liu, W.-R. Synthesis and Electrochemical Properties of Co3O4@Reduced Graphene Oxides Derived from MOF as Anodes for Lithium-Ion Battery Applications. Sustainability 2023, 15, 4988. https://doi.org/10.3390/su15064988

Guo Y-X, Huang C-H, Gandomi YA, Hsieh C-T, Liu W-R. Synthesis and Electrochemical Properties of Co3O4@Reduced Graphene Oxides Derived from MOF as Anodes for Lithium-Ion Battery Applications. Sustainability. 2023; 15(6):4988. https://doi.org/10.3390/su15064988

Chicago/Turabian StyleGuo, Yi-Xuan, Chia-Hung Huang, Yasser Ashraf Gandomi, Chien-Te Hsieh, and Wei-Ren Liu. 2023. "Synthesis and Electrochemical Properties of Co3O4@Reduced Graphene Oxides Derived from MOF as Anodes for Lithium-Ion Battery Applications" Sustainability 15, no. 6: 4988. https://doi.org/10.3390/su15064988