The Devastation of Waste Plastic on the Environment and Remediation Processes: A Critical Review

Abstract

1. Introduction

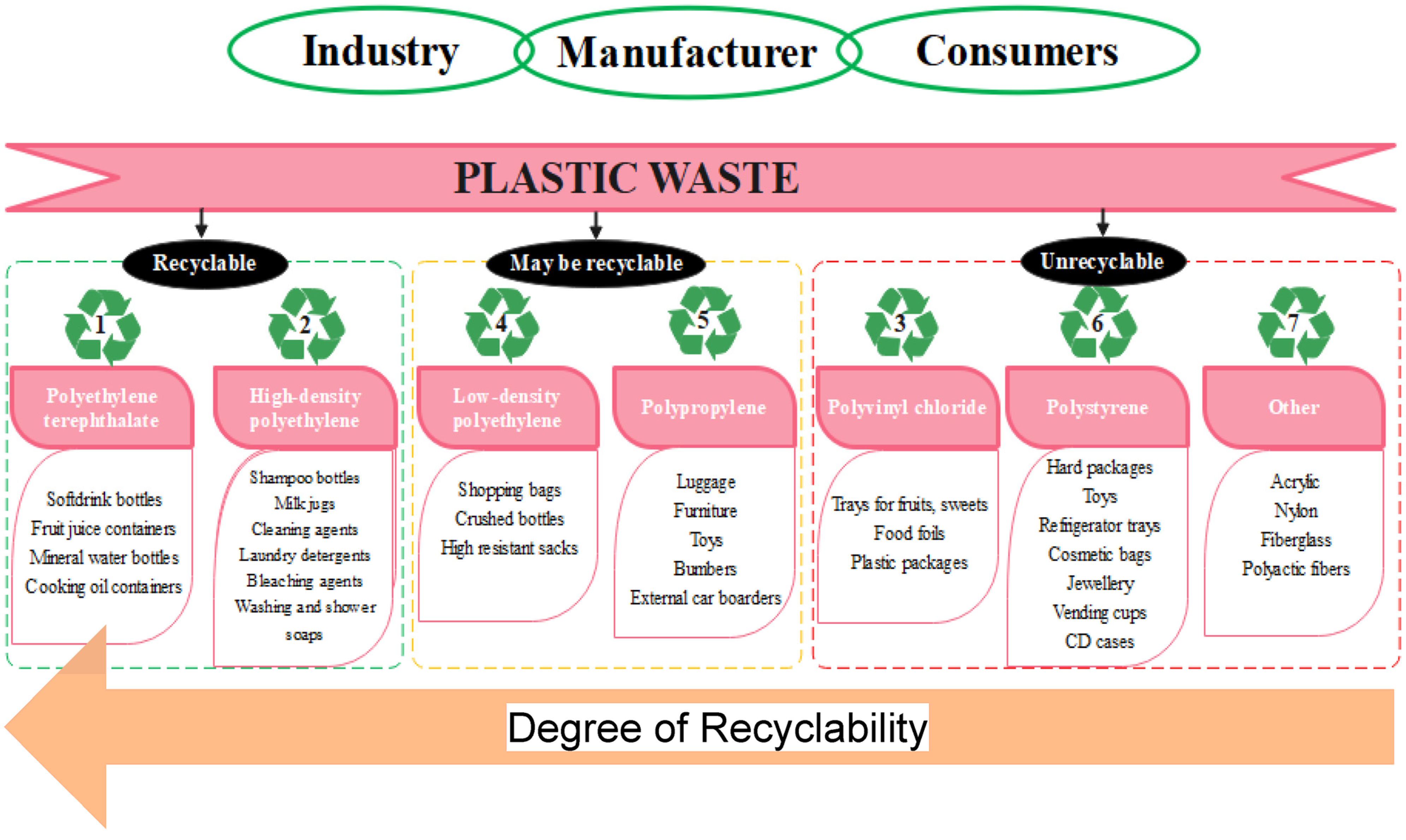

2. Plastics and Their Applications in Daily Lives

3. Environmental Regulation of Plastic Waste

4. Discharge Pathways of Plastic Waste into the Environment

5. Impact of Plastic Waste on Humans, Animals, and the Environment

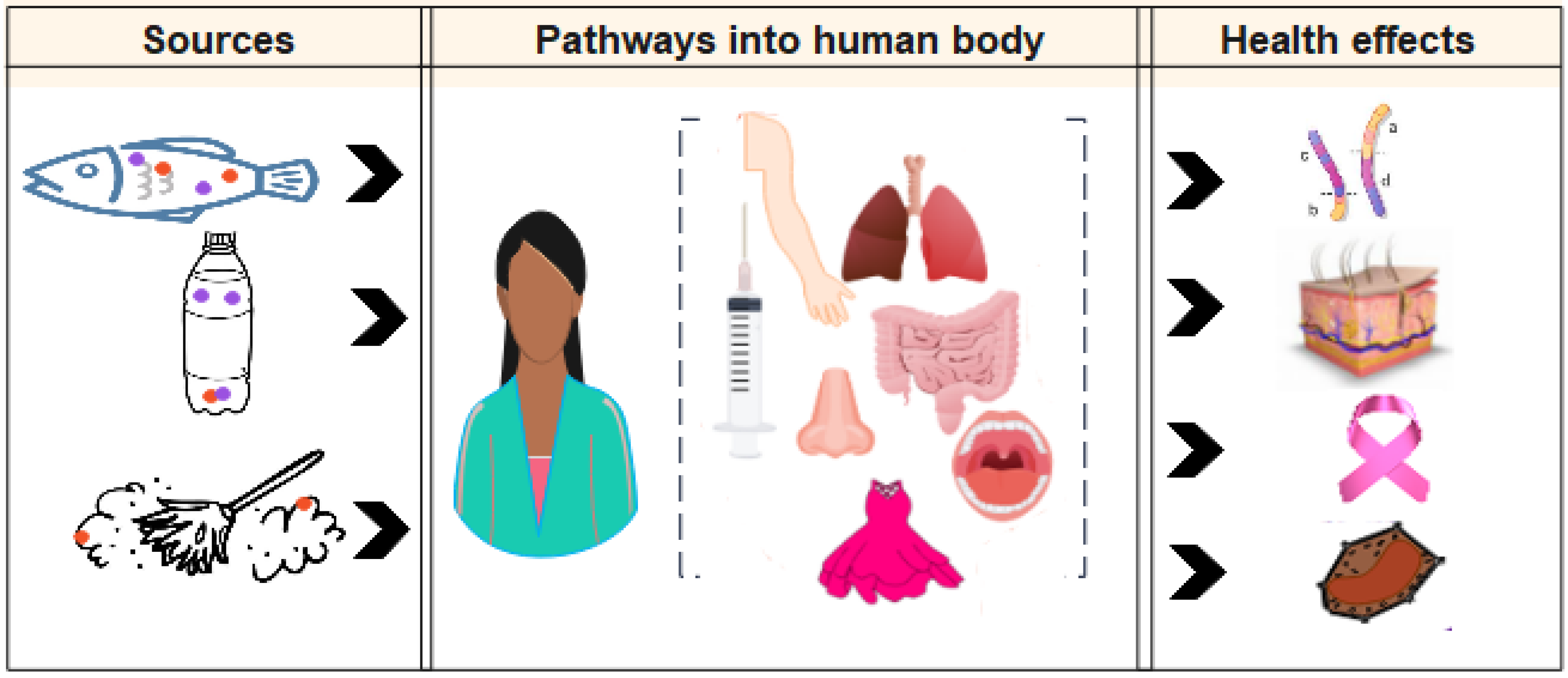

5.1. Human and Animal Health Effects

5.2. Environmental Consequences

6. Regulation Policies of Plastic Waste

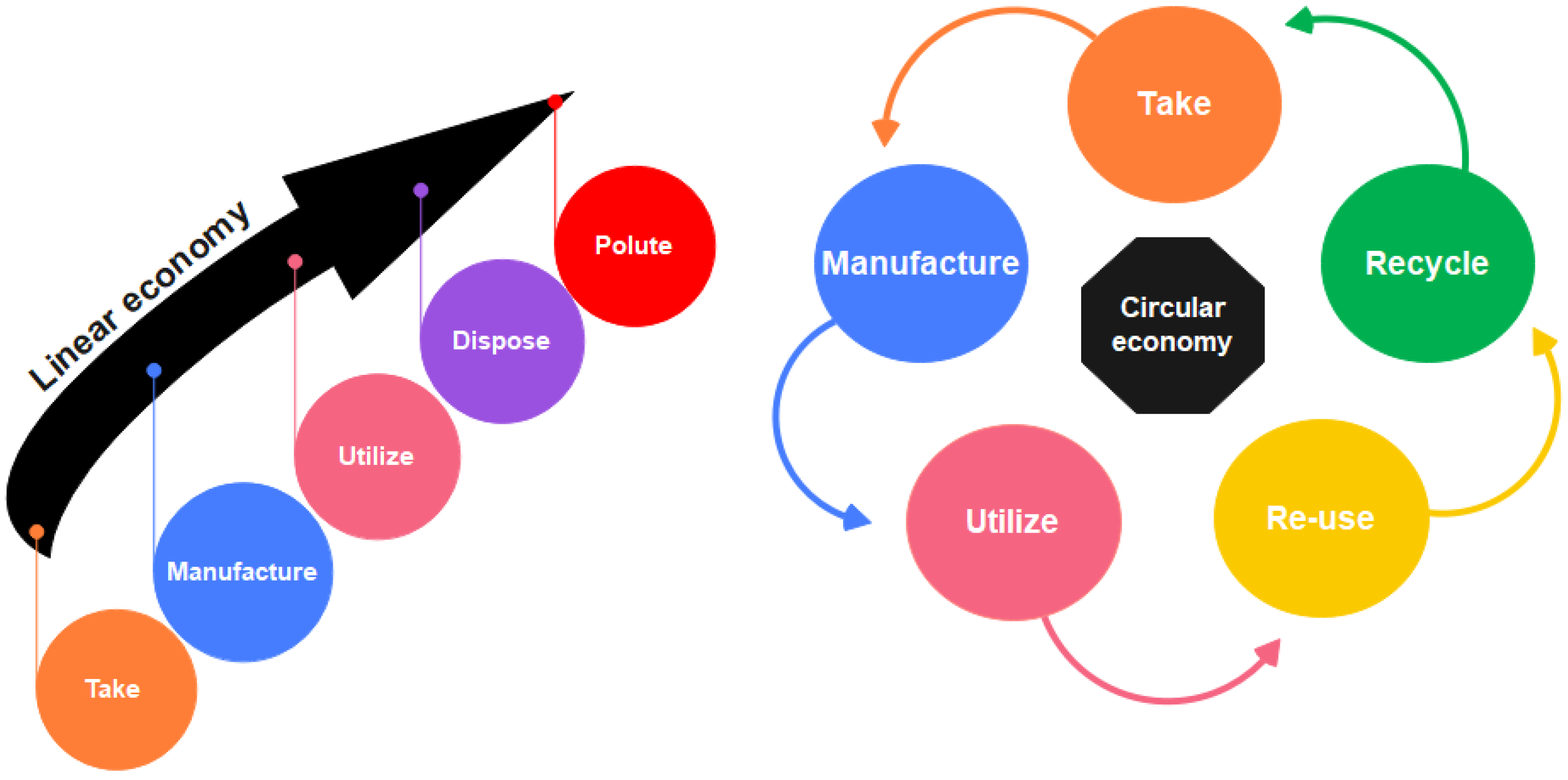

7. Challenges to Plastic Waste Management and Improvements

- (i)

- People—The behavioral patterns of people include the high usage of plastic containers, which may get contaminated and undesirable to be recycled or reused [55]. Lack of awareness of waste separation from the source. These include a lack of education regarding recycling and knowledge of plastic products that are recyclable [55];

- (ii)

- Legislation—A lack of regulations requiring plastic manufacturers to print identification codes for plastic resin on plastic containers is needed for effective recycling [55]. Insufficient financial incentives for recycling plastic waste;

- (iii)

- Infrastructure—Inefficient waste collection management. In many societies, only the local government and waste pickers gather recyclable waste and sell it to waste shops/recyclers [55] gradual growth of private investors and insufficient insight from the financial sector. The final phase of burning plastic in landfills demands significant financial resources [56].

7.1. Remediation Strategies for Plastic Waste

- ✓

- To decrease the use of natural resources in bricks, such as clay. Plastic has been added recently to serve as a binder for brick development.

- ✓

- To reuse and reduce the generation of plastic waste, water degradation, and subsequent pollution.

- ✓

- It might assist in lowering the amount of space needed for dumping, which increases more landscape for farming and other agricultural activities.

- ✓

- It is suitable for regular construction because of its high compression strength.

- ✓

- Environmental pollution is less during the production process.

- ✓

- Offer an exceptional approach to utilizing plastic waste.

- ✓

- The final product recovered is cost-effective.

- ✓

- Products constructed using plastic extend the product lifespan.

7.2. Reusing, Recycling, and Energy Conversion

8. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aizudin, M.; Goei, R.; Ong, A.J.; Tan, Y.Z.; Lua, S.K.; Pottammel, R.P.; Geng, H.; Wu, X.L.; Tok, A.L.Y.; Ang, E.H. Sustainable development of graphitic carbon nanosheets from plastic wastes with efficient photothermal energy conversion for enhanced solar evaporation. J. Mater. Chem. A Mater. 2022, 10, 19612–19617. [Google Scholar] [CrossRef]

- Jnr, A.K.-L.; Galpin, R.; Manjula, S.; Lenkiewicz, Z.; Cheeseman, C. Reuse of Waste Plastics in Developing Countries: Properties of Waste Plastic-Sand Composites. Waste Biomass Valorization 2022, 13, 3821–3834. [Google Scholar] [CrossRef]

- Adeniran, A.A.; Shakantu, W. The Health and Environmental Impact of Plastic Waste Disposal in South African Townships: A Review. Int. J. Environ. Res. Public Health 2022, 19, 779. [Google Scholar] [CrossRef] [PubMed]

- Chae, Y.; An, Y.J. Current research trends on plastic pollution and ecological impacts on the soil ecosystem: A review. Environ. Pollut. 2018, 240, 387–395. [Google Scholar] [CrossRef]

- Amankwa, M.O.; Tetteh, E.K.; Mohale, G.T.; Dagba, G.; Opoku, P. The production of valuable products and fuel from plastic waste in Africa. Discov. Sustain. 2021, 2, 31. [Google Scholar] [CrossRef]

- Shen, M.; Song, B.; Zeng, G.; Zhang, Y.; Huang, W.; Wen, X.; Tang, W. Are biodegradable plastics a promising solution to solve the global plastic pollution? Environ. Pollut. 2020, 263, 114469. [Google Scholar] [CrossRef]

- Hira, A.; Pacini, H.; Attafuah-Wadee, K.; Vivas-Eugui, D.; Saltzberg, M.; Yeoh, T.N. Plastic Waste Mitigation Strategies: A Review of Lessons from Developing Countries. J. Dev. Soc. 2022, 38, 336–359. [Google Scholar] [CrossRef]

- Qin, M.; Chen, C.; Song, B.; Shen, M.; Cao, W.; Yang, H.; Zeng, G.; Gong, J. A review of biodegradable plastics to biodegradable microplastics: Another ecological threat to soil environments? J. Clean. Prod. 2021, 312, 127816. [Google Scholar] [CrossRef]

- Gbadeyan, O.J.; Fagbemi, O.D.; Andrew, J.; Adali, S.; Glen, B.; Sithole, B. Cellulose nanocrystals and snail shell-reinforced polyvinyl alcohol bioplastic films: Additive concentration optimization and mechanical properties assessment. J. Appl. Polym. Sci. 2022, 139, e52839. [Google Scholar] [CrossRef]

- Gbadeyan, O.J.; Linganiso, L.Z.; Deenadayalu, N. Thermomechanical characterization of bioplastic films produced using a combination of polylactic acid and bionano calcium carbonate. Sci. Rep. 2022, 12, 15538. [Google Scholar] [CrossRef]

- Gbadeyan, O.J. Hybrid Nanoshell Reinforced Plant Fiber Biocomposite; University of Kwa-Zulu Natal: Durban, South Africa, 2020. [Google Scholar]

- Li, N.; Liu, H.; Cheng, Z.; Yan, B.; Chen, G.; Wang, S. Conversion of plastic waste into fuels: A critical review. J. Hazard. Mater. 2022, 424, 127460. [Google Scholar] [CrossRef] [PubMed]

- Gnanasekaran, D. Green Biopolymers and Its Nanocomposites in Various Applications: State of the Art. In Green Biopolymers and Their Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–27. [Google Scholar] [CrossRef]

- Prata, J.C.; da Costa, J.P.; Lopes, I.; Duarte, A.C.; Rocha-Santos, T. Environmental exposure to microplastics: An overview on possible human health effects. Sci. Total Environ. 2020, 702, 134455. [Google Scholar] [CrossRef] [PubMed]

- Galafassi, S.; Nizzetto, L.; Volta, P. Plastic sources: A survey across scientific and grey literature for their inventory and relative contribution to microplastics pollution in natural environments, with an emphasis on surface water. Sci. Total Environ. 2019, 693, 133499. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An overview of plasticwaste generation and management in food packaging industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Agyeman, S.; Obeng-Ahenkora, N.K.; Assiamah, S.; Twumasi, G. Exploiting recycled plastic waste as an alternative binder for paving blocks production. Case Stud. Constr. Mater. 2019, 11, e00246. [Google Scholar] [CrossRef]

- Akan, O.D.; Udofia, G.E.; Okeke, E.S.; Mgbechidinma, C.L.; Okoye, C.O.; Zoclanclounon, Y.A.B.; Atakpa, E.O.; Adebanjo, O.O. Plastic waste: Status, degradation and microbial management options for Africa. J. Environ. Manag. 2021, 292, 112758. [Google Scholar] [CrossRef]

- Bui, X.T.; Vo, T.D.H.; Nguyen, P.T.; Nguyen, V.T.; Dao, T.S.; Nguyen, P.D. Microplastics pollution in wastewater: Characteristics, occurrence and removal technologies. Environ. Technol. Innov. 2020, 19, 101013. [Google Scholar] [CrossRef]

- Ayeleru, O.O.; Dlova, S.; Akinribide, O.J.; Ntuli, F.; Kupolati, W.K.; Marina, P.F.; Blencowe, A.; Olubambi, P.A. Challenges of plastic waste generation and management in sub-Saharan Africa: A review. Waste Manag. 2020, 110, 24–42. [Google Scholar] [CrossRef]

- Lithner, D.; Larsson, A.; Dave, G. Environmental and health hazard ranking and assessment of plastic polymers based on chemical composition. Sci. Total Environ. 2011, 409, 3309–3324. [Google Scholar] [CrossRef]

- Muchangos, L.S.D.; Ito, L.; Tokai, A. Plastic waste trade flows in the Southern African Region from 2016 to 2020. In Proceedings of the EcoDesign 2021 International Symposium, Online, 8–12 November 2021; pp. 234–240. [Google Scholar]

- Zheng, Y.; Mao, C.; Zhang, Z.; Liu, R.; Yan, B. Nanotechnology for the remediation of Plastic Wastes. In Sustainable Nanotechnology; Zibiao, L., Zheng, J., Ye, E., Eds.; Royal Society of Chemistry: London, UK, 2022; Volume 57. [Google Scholar]

- Brooks, A.L.; Wang, S.; Jambeck, J.R. The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 2018, 4, 1–7. [Google Scholar] [CrossRef]

- Jambeck, J.; Hardesty, B.D.; Brooks, A.L.; Friend, T.; Teleki, K.; Fabres, J.; Beaudoin, Y.; Bamba, A.; Francis, J.; Ribbink, A.J.; et al. Challenges and emerging solutions to the land-based plastic waste issue in Africa. Mar. Policy 2018, 96, 256–263. [Google Scholar] [CrossRef]

- Ikechukwu, A.F.; Shabangu, C. Strength and durability performance of masonry bricks produced with crushed glass and melted PET plastics. Case Stud. Constr. Mater. 2021, 14, 1–15. [Google Scholar] [CrossRef]

- Rahman, A.; Sarkar, A.; Yadav, O.P.; Achari, G.; Slobodnik, J. Potential human health risks due to environmental exposure to nano- and microplastics and knowledge gaps: A scoping review. Sci. Total Environ. 2021, 757, 143872. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Yang, C.; Du, C.; Liu, H. Microplastics in waters and soils: Occurrence, analytical methods and ecotoxicological effects. Ecotoxicol. Environ. Saf. 2020, 202, 110910. [Google Scholar] [CrossRef] [PubMed]

- Hale, R.C.; Seeley, M.E.; La Guardia, M.J.; Mai, L.; Zeng, E.Y. A Global Perspective on Microplastics. J. Geophys. Res. Ocean. 2020, 125, e2018JC014719. [Google Scholar] [CrossRef]

- Gallowaya, T.S.; Lewisa, C.N. Marine microplastics spell big problems for future generations. Proc. Natl. Acad. Sci. USA 2016, 113, 2331–2333. [Google Scholar] [CrossRef]

- Wang, W.; Gao, H.; Jin, S.; Li, R.; Na, G. The ecotoxicological effects of microplastics on aquatic food web, from primary producer to human: A review. Ecotoxicol. Environ. Saf. 2019, 173, 110–117. [Google Scholar] [CrossRef]

- Mercogliano, R.; Avio, C.G.; Regoli, F.; Anastasio, A.; Colavita, G.; Santonicola, S. Occurrence of microplastics in commercial seafood under the perspective of the human food chain. A review. J. Agric. Food Chem. 2020, 68, 5296–5301. [Google Scholar] [CrossRef]

- Zhou, J.; Cao, Y.; Liu, X.; Jiang, H.; Li, W. Bladder entrance of microplastic likely induces toxic effects in carnivorous macrophyte Utricularia aurea Lour. Environ. Sci. Pollut. Res. 2020, 27, 32124–32131. [Google Scholar] [CrossRef]

- Lamb, J.B.; Willis, B.L.; Fiorenza, E.A.; Couch, C.S.; Howard, R.; Rader, D.N.; True, J.D.; Kelly, L.A.; Ahmad, A.; Jompa, J.; et al. Plastic waste associated with disease on coral reefs. Coral Reefs 2018, 359, 1–3. [Google Scholar] [CrossRef]

- Rasool, F.N.; Saavedra, M.A.; Pamba, S.; Perold, V.; Mmochi, A.J.; Maalim, M.; Simonsen, L.; Buur, L.; Pedersen, R.H.; Syberg, K.; et al. Isolation and characterization of human pathogenic multidrug resistant bacteria associated with plastic litter collected in Zanzibar. J. Hazard. Mater. 2021, 405, 124591. [Google Scholar] [CrossRef] [PubMed]

- Pathan, S.I.; Arfaioli, P.; Bardelli, T.; Ceccherini, M.T.; Nannipieri, P.; Pietramellara, G. Soil pollution from micro-and nanoplastic debris: A hidden and unknown biohazard. Sustainability 2020, 12, 7255. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, X.; Wang, J.; Tan, L. Toxic effects of microplastic on marine microalgae Skeletonema costatum: Interactions between microplastic and algae. Environ. Pollut. 2017, 220, 1282–1288. [Google Scholar] [CrossRef] [PubMed]

- Fournier, E.; Etienne-Mesmin, L.; Grootaert, C.; Jelsbak, L.; Syberg, K.; Blanquet-Diot, S.; Mercier-Bonin, M. Microplastics in the human digestive environment: A focus on the potential and challenges facing in vitro gut model development. J. Hazard. Mater. 2021, 415, 125632. [Google Scholar] [CrossRef] [PubMed]

- Akdis, C.A. Does the epithelial barrier hypothesis explain the increase in allergy, autoimmunity and other chronic conditions? Nat. Rev. Immunol. 2021, 21, 739–751. [Google Scholar] [CrossRef] [PubMed]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Royer, S.J.; Ferrón, S.; Wilson, S.T.; Karl, D.M. Production of methane and ethylene from plastic in the environment. PLoS ONE 2018, 13, e0200574. [Google Scholar] [CrossRef] [PubMed]

- Eneh, A.E.O. Application of Recycled Plastics and its composites in the built environment. Int. J. Manag. Inf. 2015, 3, 9–16. [Google Scholar]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Nor, N.H.M.; Kooi, M.; Diepens, N.J.; Koelmans, A.A. Lifetime Accumulation of Microplastic in Children and Adults. Environ. Sci. Technol. 2021, 55, 5084–5096. [Google Scholar] [CrossRef]

- Varó, I.; Osorio, K.; Estensoro, I.; Naya-Catala, F.; Sitja-Bobadilla, A.; Navarro, J.C.; Pérez-Sánchez, J.; Torreblanca, A.; Piazzon, M.C. Effect of virgin low density polyethylene microplastic ingestion on intestinal histopathology and microbiota of gilthead sea bream. Aquaculture 2021, 545, 737245. [Google Scholar] [CrossRef]

- Alpizar, F.; Carlsson, F.; Lanza, G.; Carney, B.; Daniels, R.C.; Jaime, M.; Ho, T.; Nie, Z.; Salazar, C.; Tibesigwa, B.; et al. A framework for selecting and designing policies to reduce marine plastic pollution in developing countries. Environ. Sci. Policy 2020, 109, 25–35. [Google Scholar] [CrossRef]

- Dauvergne, P. Why is the global governance of plastic failing the oceans? Glob. Environ. Change 2018, 51, 22–31. [Google Scholar] [CrossRef]

- Gilli, M.; Mancinelli, S.; Nicolli, F. Household Waste Management: Some Insights from Behavioural Economics; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- He, H. Effects of environmental policy on consumption: Lessons from the Chinese plastic bag regulation. Environ. Dev. Econ. 2012, 17, 407–431. [Google Scholar] [CrossRef]

- Schnurr, R.E.; Alboiu, V.; Chaudhary, M.; Corbett, R.A.; Quanz, M.E.; Sankar, K.; Srain, H.S.; Thavarajah, V.; Xanthos, D.; Walker, T.R. Reducing marine pollution from single-use plastics (SUPs): A review. Mar. Pollut. Bull. 2018, 137, 157–171. [Google Scholar] [CrossRef]

- Cook, E.; Velis, C. Plastic waste exports and recycling: Myths, misunderstandings and inconvenient truths. In Waste Management and Research; SAGE Publications Ltd.: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Nielsen, T.D.; Holmberg, K.; Stripple, J. Need a bag? A review of public policies on plastic carrier bags—Where, how and to what effect? Waste Manag. 2019, 87, 428–440. [Google Scholar] [CrossRef]

- Pawelczyk, E.; Wysocka, I.; Gębicki, J. Nickel catalysts modified with TiC derived from organic precursor for resource recovery via dry reforming of waste plastics. In Proceedings of the 9th IUPAC International Conference on Green Chemistry, Athens, Greece, 5–9 September 2022. [Google Scholar]

- Hinton, Z.R.; Talley, M.R.; Kots, P.A.; Le, A.V.; Zhang, T.; Mackay, M.E.; Kunjapur, A.M.; Bai, P.; Vlachos, D.G.; Watson, M.P.; et al. Innovations Toward the Valorization of Plastics Waste. Annu. Rev. Mater. Res. 2022, 52, 249–280. [Google Scholar] [CrossRef]

- Wichai-utcha, N.; Chavalparit, O. 3Rs Policy and plastic waste management in Thailand. J. Mater. Cycles Waste Manag. 2019, 21, 10–22. [Google Scholar] [CrossRef]

- Bureecam, C.; Chaisomphob, T.; Sungsomboon, P.Y. Material flows analysis of plastic in Thailand. Therm. Sci. 2018, 22, 2379–2388. [Google Scholar] [CrossRef]

- Da Silva, L.F.; Resnitzkyd, M.H.C.; Gonzalez, E.D.R.S.; de Melo Conti, D.; da Costa, P.R. Management of Plastic Waste and a Circular Economy at the End of the Supply Chain: A Systematic Literature Review. Energies 2022, 15, 976. [Google Scholar] [CrossRef]

- Verbruggen, S.W.; Van Hal, M.; Bosserez, T.; Rongé, J.; Hauchecorne, B.; Martens, J.A.; Lenaerts, S. Harvesting Hydrogen Gas from Air Pollutants with an Unbiased Gas Phase Photoelectrochemical Cell. ChemSusChem 2017, 10, 1413–1418. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X. The thermochemical conversion of biomass into biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy: Construction, Biomedical, and Other Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–368. [Google Scholar] [CrossRef]

- Stroud, T.; Smith, T.J.; Le Saché, E.; Santos, J.L.; Centeno, M.A.; Arellano-Garcia, H.; Odriozola, J.A.; Reina, T.R. Chemical CO2 recycling via dry and bi reforming of methane using Ni-Sn/Al2O3 and Ni-Sn/CeO2-Al2O3 catalysts. Appl. Catal. B 2018, 224, 125–135. [Google Scholar] [CrossRef]

- Lundquist, N.A.; Tikoalu, A.D.; Worthington, M.J.; Shapter, R.; Tonkin, S.J.; Stojcevski, F.; Mann, M.; Gibson, C.T.; Gascooke, J.R.; Karton, A.; et al. Reactive Compression Molding Post-Inverse Vulcanization: A Method to Assemble, Recycle, and Repurpose Sulfur Polymers and Composites. Chem. Eur. J. 2020, 26, 10035–10044. [Google Scholar] [CrossRef]

- Kalair, A.R.; Seyedmahmoudian, M.; Stojcevski, A.; Abas, N.; Khan, N. Waste to energy conversion for a sustainable future. Heliyon 2021, 7, e08155. [Google Scholar] [CrossRef] [PubMed]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Singh, J.K.; Singh, H.; Mavi, S.; Singh, V.; Khan, M.I. An overview on recycling plastic wastes in bricks. Mater. Today Proc. 2021, 47, 4067–4073. [Google Scholar] [CrossRef]

- Chow, C.F.; So, W.M.W.; Cheung, T.Y.; Yeung, S.K.D. Plastic waste problem and education for plastic waste management. In Emerging Practices in Scholarship of Learning and Teaching in a Digital Era; Springer: Singapore, 2017; pp. 125–140. [Google Scholar] [CrossRef]

- Kognole, R.S.; Shipkule, K.; Patil, M.; Patil, L.; Survase, U. Utilization of Plastic Waste for Making Plastic Bricks. Int. J. Trend Sci. Res. Dev. 2019, 3, 878–880. Available online: www.ijtsrd.com (accessed on 15 September 2022). [CrossRef]

- Salaou, N.M.L.; Thuo, J.; Kabubo, C.; Gariy, Z.A. Performance of polypropylene fibre reinforced laterite masonry bricks. Civ. Eng. Archit. 2021, 9, 2178–2186. [Google Scholar] [CrossRef]

- Cañado, N.; Lizundia, E.; Akizu-Gardoki, O.; Minguez, R.; Lekube, B.; Arrillaga, A.; Iturrondobeitia, M. 3D printing to enable the reuse of marine plastic waste with reduced environmental impacts. J. Ind. Ecol. 2022, 26, 2092–2107. [Google Scholar] [CrossRef]

- Silva, P.; Prata, J.C.; Duarte, A.C.; Barcelò, D.; Rocha-Santos, T. An urgent call to think globally and act locally on landfill disposable plastics under and after COVID-19 pandemic: Pollution prevention and technological (Bio) remediation solutions. Chem. Eng. J. 2021, 426, 131201. [Google Scholar] [CrossRef]

- Rajmohan, K.V.S.; Ramya, C.; Viswanathan, R.M.; Varjani, S. Plastic pollutants: Effective waste management for pollution control and abatement. Curr. Opin. Environ. Sci. Health 2019, 12, 72–84. [Google Scholar] [CrossRef]

- Mondal, M.K.; Bose, B.P.; Bansal, P. Recycling waste thermoplastic for energy efficient construction materials: An experimental investigation. J. Environ. Manag. 2019, 240, 119–125. [Google Scholar] [CrossRef]

- Herki, B.A.; Khatib, J.M. Valorisation of waste expanded polystyrene in concrete using a novel recycling technique. Eur. J. Environ. Civ. Eng. 2017, 21, 1384–1402. [Google Scholar] [CrossRef]

- Dai, L.; Zhou, N.; Lv, Y.; Cheng, Y.; Wang, Y.; Liu, Y.; Cobb, K.; Chen, P.; Lei, H.; Ruan, R. Pyrolysis technology for plastic waste recycling: A state-of-the-art review. Prog. Energy Combust. Sci. 2022, 93, 101021. [Google Scholar] [CrossRef]

- Davidson, M.G.; Furlong, R.A.; McManus, M.C. Developments in the life cycle assessment of chemical recycling of plastic waste–A review. J. Clean. Prod. 2021, 293, 126163. [Google Scholar] [CrossRef]

- Kunwar, B.; Cheng, H.N.; Chandrashekaran, S.R.; Sharma, B.K. Plastics to fuel: A review. Renew. Sustain. Energy Rev. 2016, 54, 421–428. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Burra, K.G.; Liu, X.; Li, X.; Zhang, M.; Lei, T.; Gupta, A.K. Synergetic Effect on CO2-Assisted Co-Gasification of Biomass and Plastics. J. Energy Resour. Technol. Trans. ASME 2021, 143, 031901. [Google Scholar] [CrossRef]

- Singh, P.; Déparrois, N.; Burra, K.G.; Bhattacharya, S.; Gupta, A.K. Energy recovery from cross-linked polyethylene wastes using pyrolysis and CO2 assisted gasification. Appl. Energy 2019, 254, 113722. [Google Scholar] [CrossRef]

- Gerasimov, G.Y. Comparative Analysis of PCDD/Fs Formation during Pyrolysis and Incineration of Medical Waste. IOP Conf. Ser. Earth Environ. Sci. 2019, 272, 022116. [Google Scholar] [CrossRef]

- Fivga, A.; Dimitriou, I. Pyrolysis of plastic waste for production of heavy fuel substitute: A techno-economic assessment. Energy 2018, 149, 865–874. [Google Scholar] [CrossRef]

- Pan, R.; Martins, M.F.; Debenest, G. Pyrolysis of waste polyethylene in a semi-batch reactor to produce liquid fuel: Optimization of operating conditions. Energy Convers. Manag. 2021, 237, 114114. [Google Scholar] [CrossRef]

| Class V | Class IV | Class III | Class II | Class I | Not Classified | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Polymer | S | Polymer | S | Polymer | S | Polymer | S | Polymer | S | |

| Polyurethane (PUR) | 13,844 | Polyoxymethylene (POM) | 1500 | Polyphenylene ether (PPE) | 400 | Polyamide 6-Nylon 6 | 50 | Polyvinyl acetate (PVAc) | 1 | Polylactic acid (PLA) |

| Polyacrylonitrile (PAN) | 12,379 | Phenol formaldehyde resins (PF.) | 1500 | Polyacrylic acid (PAA) | 230 | Polystyrene (PS.) | 30 | Polypropylene (PP.) | 1 | Polybutylene terephthalate (PBT) |

| Polyvinyl chloride (PVC) | 10,551 | Unsaturated polyester (UP) | 1414 | Polyoxymethylene (POM) | 103 | Low-density polyethylene (LDPE) | 11 | Polytetrafluorethylene (PTFE) | ||

| Acrylonitrile-butadiene-styrene (ABS) | 6552 | Polycarbonate (PC.) | 1177 | Polyamide 6.6-Nylon 6.6 | 63 | High-density polyethylene (HDPE) | 11 | Polyvinylidene fluoride (PVDF) | ||

| Epoxy resin | 4226 | Unsaturated polyester (UP) | 1117 | Polyamide 6.10-Nylon 6.10 | 47 | Linear-low-density polyethylene(LLDPE) | 10 | Polyamide 11-Nylon 11 | ||

| Styrene-acrylonitrile (SAN) | 2788 | Thermoplastic polyurethanes (TPU) | 1094 | Expanded polystyrene (EPS) | 44 | Polyethylene terephthalate (PET) | 4 | Polyamide 12-Nylon 12 | ||

| High-impact polystyrene (HIPS) | 1628 | Polymethyl methacrylate (PMMA) | 1021 | |||||||

| Polyphenylene sulfide (PPS) | 897 | |||||||||

| Process | Definition | Operational Parameter |

|---|---|---|

| Chemical/feedstock | Plastic waste is broken down chemically into component monomers, oligomers, solid, liquid, and gaseous hydrocarbon mixtures. | Plastic waste could be dissolved using different solvents, e.g., PLA dissolves in acetone |

| Depolymerization | The process of melting waste plastic produces the monomers and oligomers that make up plastic, which can subsequently be used in other polymerization reactions. | Operated at a pressure and temperature above a solvent’s critical point |

| Gasification | Syngas is a gaseous combination rich in hydrogen and carbon monoxide produced when plastic waste is broken down using heat, regulated steam, oxygen, and/or air content. | It is operated mainly under atmospheric pressure, between 850 °C and 1200 °C. |

| Hydrocracking/hydrogenation | This process is achieved by producing liquid, solid, and gaseous hydrocarbons by breaking the carbon-to-carbon bonds and adding hydrogen in an inert, hydrogen-rich environment. | High pressures up to 100 bars, with reaction temperatures between 350 °C and 490 °C. |

| Incineration | Rapid burning of plastic garbage produces heat and power. This heat is trapped and utilized to produce energy indirectly or directly to heat structures. Over stoichiometric, the air is utilized extensively as an oxidizing agent and is occasionally known as waste-to-energy (WTE). | It is operated mainly under atmospheric pressure, between 850 °C and 1200 °C. |

| Mechanical | This process involves melting down used plastic waste and forming plastic pellets using separation processes, such as extrusion, heat, and crushing. | |

| Pyrolysis | The breaking down of hydrocarbon bonds in plastic trash with heat in an oxygen-poor environment yields a variety of solid, liquid, and gaseous hydrocarbon compounds. For an inert atmosphere, use a vacuum or nitrogen and helium | Open outlet pressure slightly beyond atmospheric, at a temperature between 300 °C and 900 °C. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoaele, K.K.; Gbadeyan, O.J.; Chunilall, V.; Sithole, B. The Devastation of Waste Plastic on the Environment and Remediation Processes: A Critical Review. Sustainability 2023, 15, 5233. https://doi.org/10.3390/su15065233

Khoaele KK, Gbadeyan OJ, Chunilall V, Sithole B. The Devastation of Waste Plastic on the Environment and Remediation Processes: A Critical Review. Sustainability. 2023; 15(6):5233. https://doi.org/10.3390/su15065233

Chicago/Turabian StyleKhoaele, Katleho Keneuwe, Oluwatoyin Joseph Gbadeyan, Viren Chunilall, and Bruce Sithole. 2023. "The Devastation of Waste Plastic on the Environment and Remediation Processes: A Critical Review" Sustainability 15, no. 6: 5233. https://doi.org/10.3390/su15065233

APA StyleKhoaele, K. K., Gbadeyan, O. J., Chunilall, V., & Sithole, B. (2023). The Devastation of Waste Plastic on the Environment and Remediation Processes: A Critical Review. Sustainability, 15(6), 5233. https://doi.org/10.3390/su15065233