Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Geographical Location and Years of Study

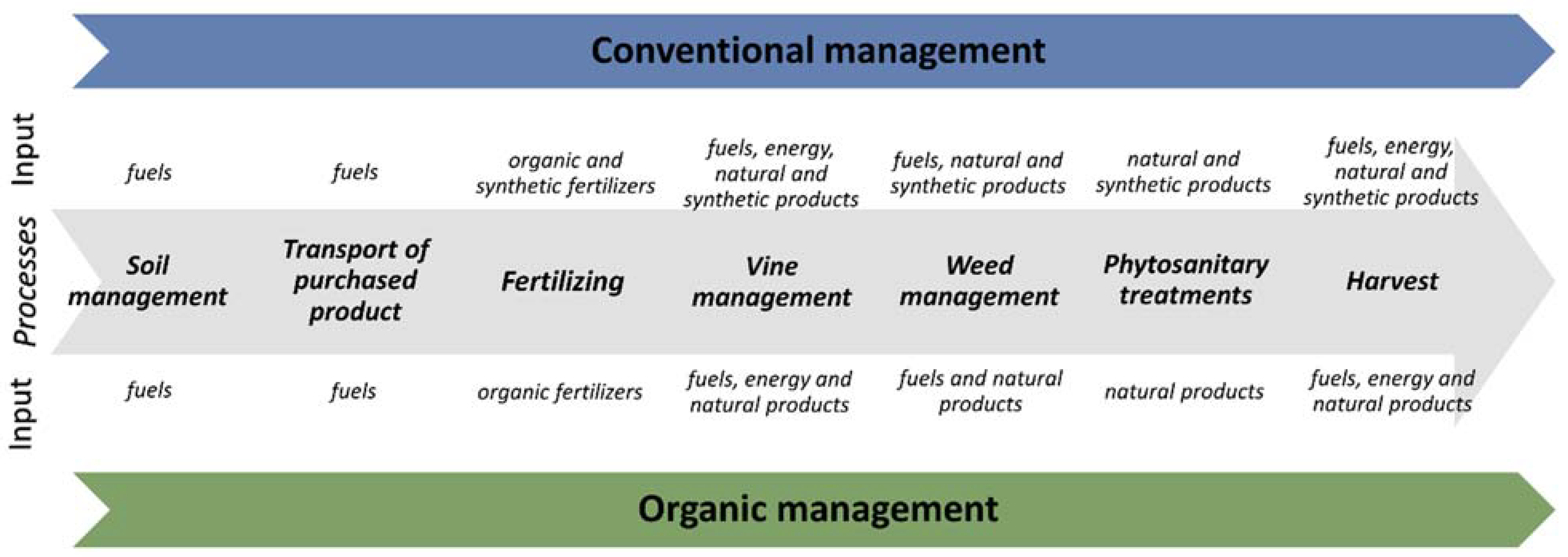

2.2. System Boundaries and Description of Viticultural Practices

2.3. Primary Data Acquisition

2.4. Corporate Carbon-Footprint Method

2.5. Data Analysis

3. Results

3.1. Inventory Data for Vineyard Inputs

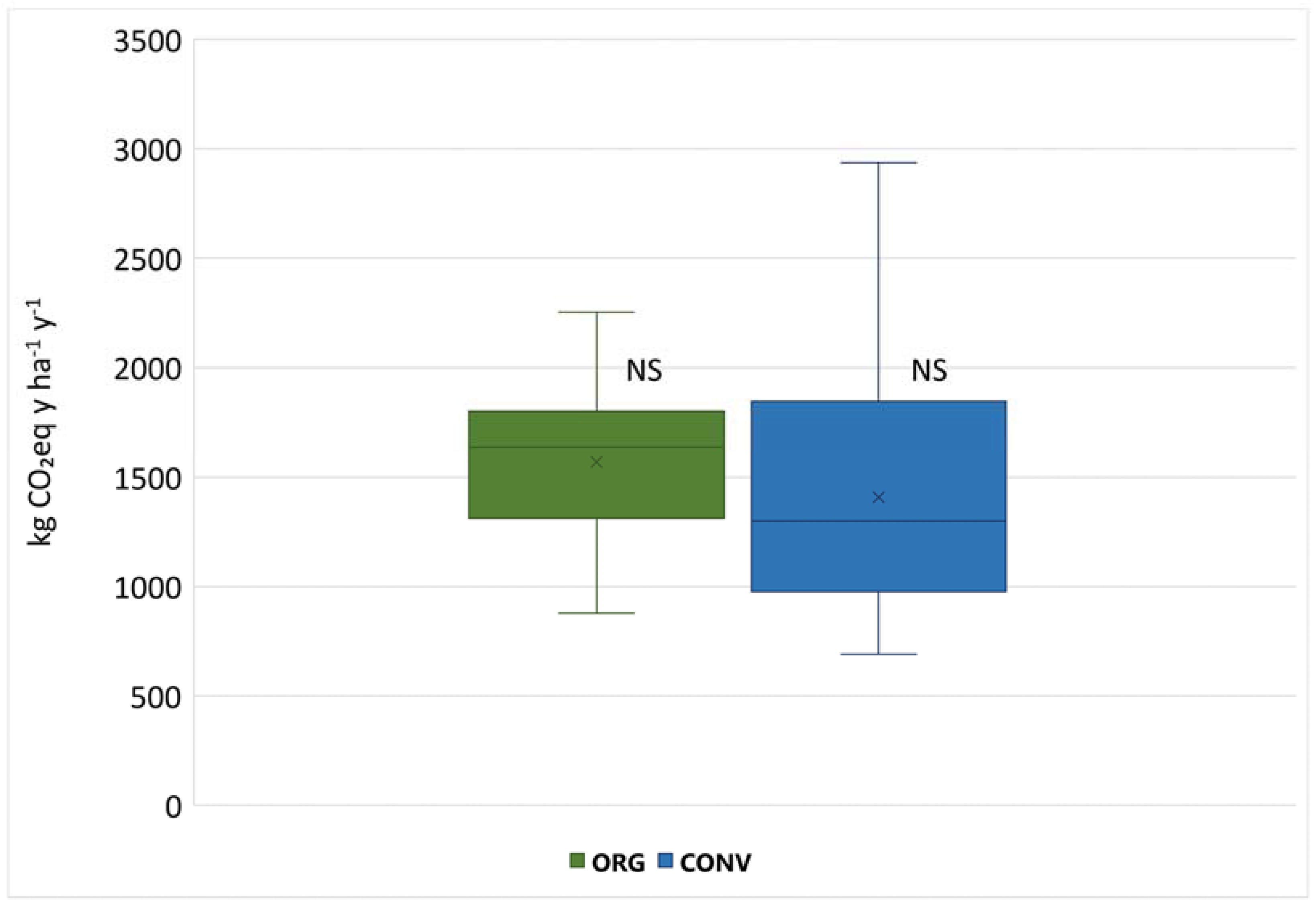

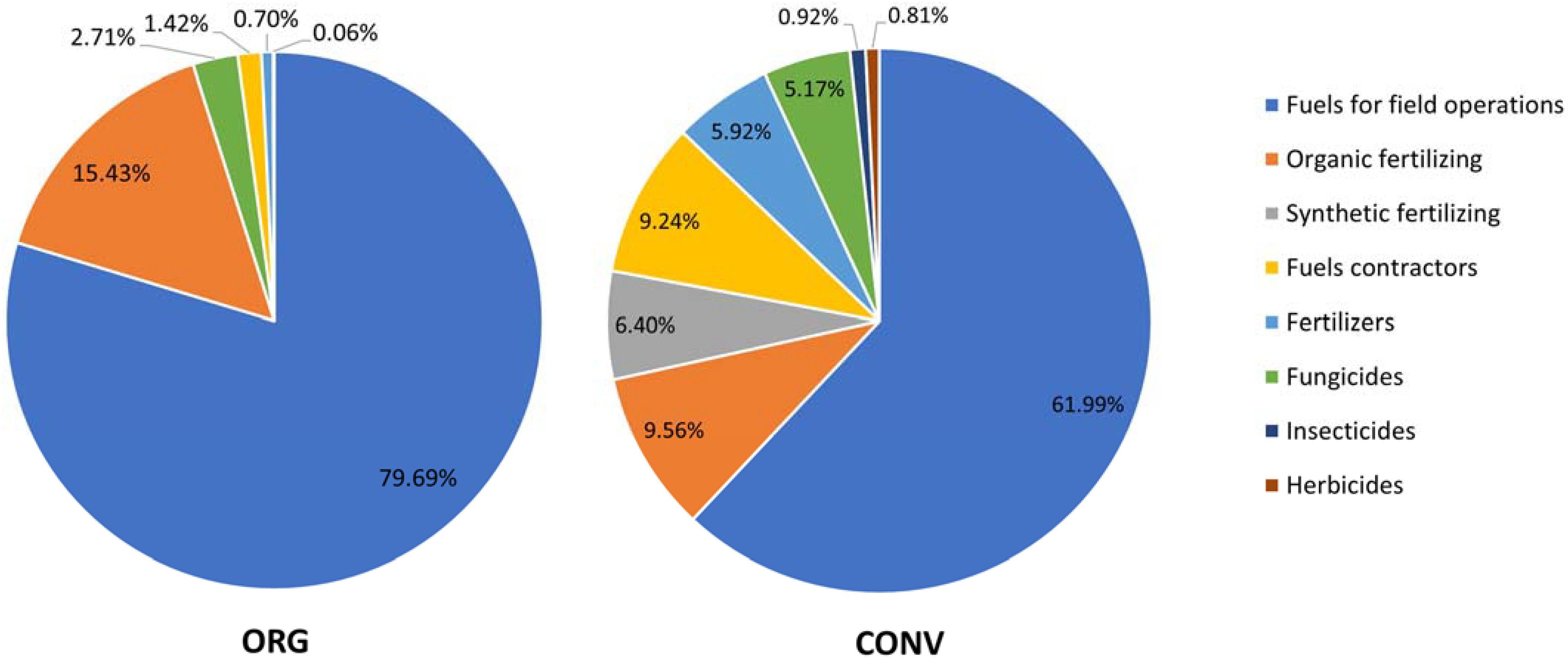

3.2. Overall Organic and Conventional Viticulture Carbon-Footprint Results

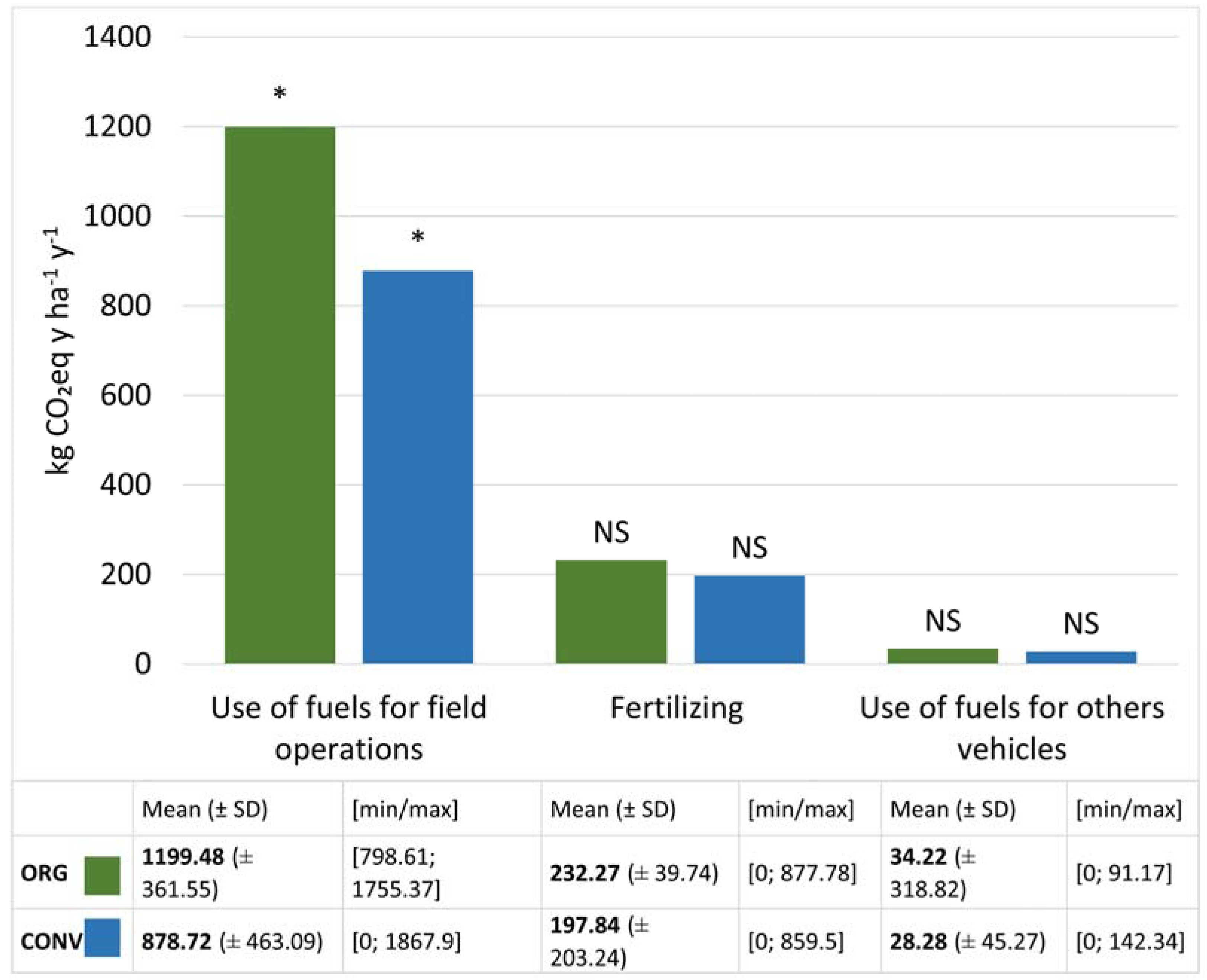

3.3. Direct Emissions in Organic and Conventional Management

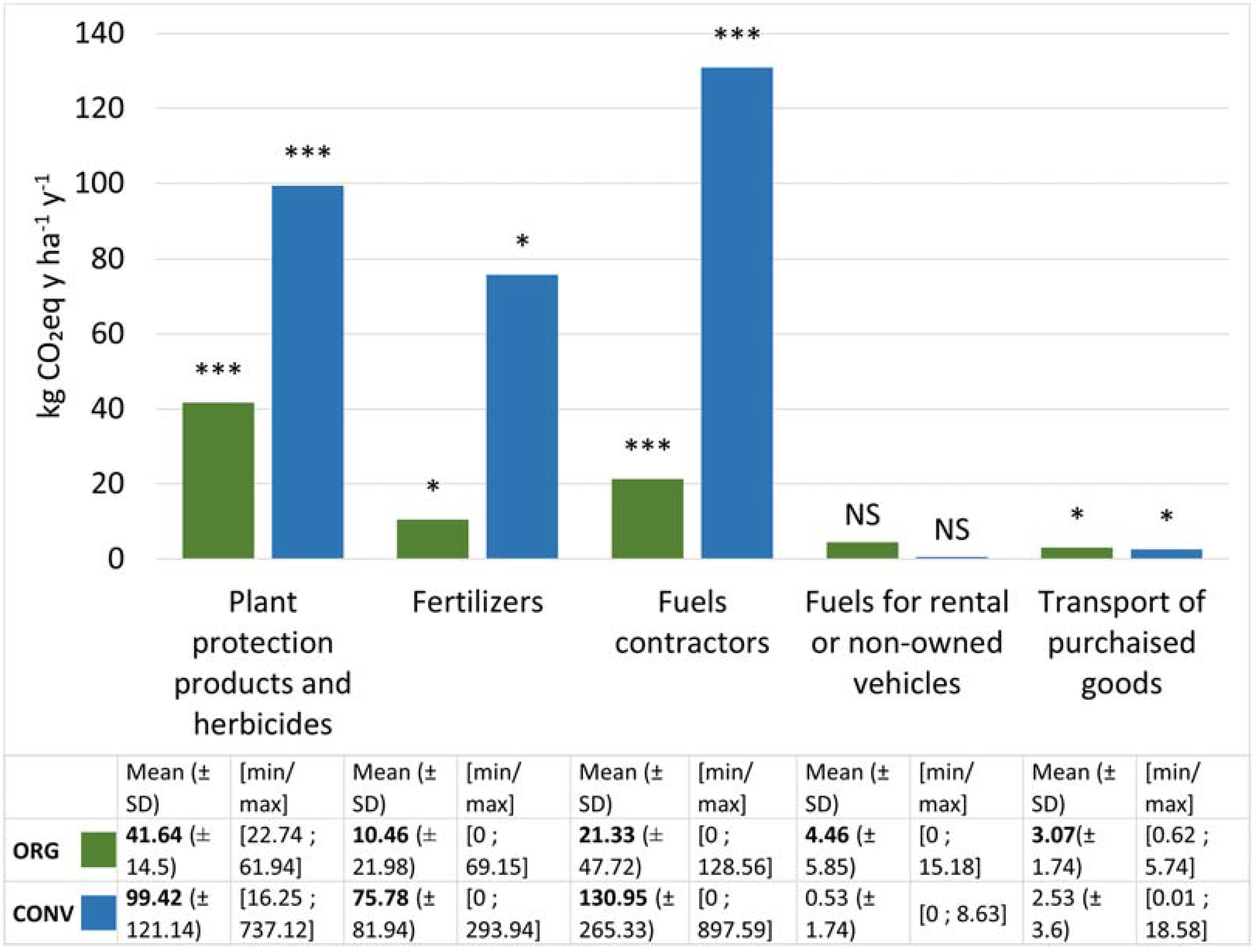

3.4. Indirect Emissions in Organic and Conventional Management

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pörtner, H.O.; Roberts, D.C.; Adams, H.; Adler, C.; Aldunce, P.; Ali, E.; Begum, R.A.; Betts, R.; Kerr, R.B.; Biesbroek, R.; et al. Climate Change 2022: Impacts, Adaptation and Vulnerability; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- Röös, E.; Sundberg, C.; Tidåker, P.; Strid, I.; Hansson, P.-A. Can Carbon Footprint Serve as an Indicator of the Environmental Impact of Meat Production? Ecol. Indic. 2013, 24, 573–581. [Google Scholar] [CrossRef]

- Pattara, C.; Raggi, A.; Cichelli, A. Life Cycle Assessment and Carbon Footprint in the Wine Supply-Chain. Environ. Manag. 2012, 49, 1247–1258. [Google Scholar] [CrossRef] [PubMed]

- Borsato, E.; Zucchinelli, M.; D’Ammaro, D.; Giubilato, E.; Zabeo, A.; Criscione, P.; Pizzol, L.; Cohen, Y.; Tarolli, P.; Lamastra, L.; et al. Use of Multiple Indicators to Compare Sustainability Performance of Organic vs Conventional Vineyard Management. Sci. Total Environ. 2020, 711, 135081. [Google Scholar] [CrossRef]

- Navarro, A.; Puig, R.; Fullana-i-Palmer, P. Product vs Corporate Carbon Footprint: Some Methodological Issues. A Case Study and Review on the Wine Sector. Sci. Total Environ. 2017, 581–582, 722–733. [Google Scholar] [CrossRef] [PubMed]

- Bandinelli, R.; Acuti, D.; Fani, V.; Bindi, B.; Aiello, G. Environmental Practices in the Wine Industry: An Overview of the Italian Market. Br. Food J. 2020, 122, 1625–1646. [Google Scholar] [CrossRef]

- Gierling, F.; Blanke, M. Lower Carbon Footprint from Grapevine Cultivation on Steep Slopes Compared with Flat Terrain? A Case Study. Acta Hortic. 2021, 1327, 703–706. [Google Scholar] [CrossRef]

- Menegat, S.; Ledo, A.; Tirado, R. Greenhouse Gas Emissions from Global Production and Use of Nitrogen Synthetic Fertilisers in Agriculture. Sci. Rep. 2022, 12, 14490. [Google Scholar] [CrossRef] [PubMed]

- Cech, R.; Leisch, F.; Zaller, J.G. Pesticide Use and Associated Greenhouse Gas Emissions in Sugar Beet, Apples, and Viticulture in Austria from 2000 to 2019. Agriculture 2022, 12, 879. [Google Scholar] [CrossRef]

- Chiriacò, M.V.; Belli, C.; Chiti, T.; Trotta, C.; Sabbatini, S. The Potential Carbon Neutrality of Sustainable Viticulture Showed through a Comprehensive Assessment of the Greenhouse Gas (GHG) Budget of Wine Production. J. Clean. Prod. 2019, 225, 435–450. [Google Scholar] [CrossRef]

- Tsalidis, G.A.; Kryona, Z.-P.; Tsirliganis, N. Selecting South European Wine Based on Carbon Footprint. Resour. Environ. Sustain. 2022, 9, 100066. [Google Scholar] [CrossRef]

- Volanti, M.; Cubillas Martínez, C.; Cespi, D.; Lopez-Baeza, E.; Vassura, I.; Passarini, F. Environmental Sustainability Assessment of Organic Vineyard Practices from a Life Cycle Perspective. Int. J. Environ. Sci. Technol. 2022, 19, 4645–4658. [Google Scholar] [CrossRef]

- Letamendi, J.; Sevigne-Itoiz, E.; Mwabonje, O. Environmental Impact Analysis of a Chilean Organic Wine through a Life Cycle Assessment. J. Clean. Prod. 2022, 371, 133368. [Google Scholar] [CrossRef]

- Ahrens, F.; Land, J.; Krumdieck, S. Decarbonization of Nitrogen Fertilizer: A Transition Engineering Desk Study for Agriculture in Germany. Sustainability 2022, 14, 8564. [Google Scholar] [CrossRef]

- Baiano, A. An Overview on Sustainability in the Wine Production Chain. Beverages 2021, 7, 15. [Google Scholar] [CrossRef]

- FAO. Adaptation to Climate Change in Agriculture, Forestry and Fisheries: Perspective, Framework and Priorities; FAO: Rome, Italy, 2007. [Google Scholar]

- Litskas, V.; Mandoulaki, A.; Vogiatzakis, I.N.; Tzortzakis, N.; Stavrinides, M. Sustainable Viticulture: First Determination of the Environmental Footprint of Grapes. Sustainability 2020, 12, 8812. [Google Scholar] [CrossRef]

- Venkat, K. Comparison of Twelve Organic and Conventional Farming Systems: A Life Cycle Greenhouse Gas Emissions Perspective. J. Sustain. Agric. 2012, 36, 620–649. [Google Scholar] [CrossRef]

- Korsaeth, A. Relations between Nitrogen Leaching and Food Productivity in Organic and Conventional Cropping Systems in a Long-Term Field Study. Agric. Ecosyst. Environ. 2008, 127, 177–188. [Google Scholar] [CrossRef]

- EC Commission Implementing Regulation (EU) 2021/1165 of 15 July 2021 Authorising Certain Products and Substances for Use in Organic Production and Establishing Their Lists (Text with EEA Relevance); Official Journal of the European Union: Brussels, Belgium, 2021; Volume 253.

- EP, EC Regulation (EU) 2018/848 of the European Parliament and of the Council of 30 May 2018 on Organic Production and Labelling of Organic Products and Repealing Council Regulation (EC) No 834/2007. 2018. Available online: http://data.europa.eu/eli/reg/2018/848/oj (accessed on 24 June 2022).

- ISO 14064; Greenhouse Gases—Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. International Organization for Standardization: Geneva, Switzerland, 2018.

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Comparative Life Cycle Assessment in the Wine Sector: Biodynamic vs. Conventional Viticulture Activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- D’Ammaro, D.; Capri, E.; Valentino, F.; Grillo, S.; Fiorini, E.; Lamastra, L. Benchmarking of Carbon Footprint Data from the Italian Wine Sector: A Comprehensive and Extended Analysis. Sci. Total Environ. 2021, 779, 146416. [Google Scholar] [CrossRef]

- ANPA. I Rifiuti del Comparto Agroalimentare. Studio di Settore; Technical Report 11/2001; National Agency for the Protection of the Environment (ANPA): Roma, Italy, 2001. Available online: https://www.isprambiente.gov.it/contentfiles/00003800/3854-rapporti-01-11.pdf/ (accessed on 24 June 2022).

- Valenti, L.; Ghiglieno, I.; Sambo, F.; Pitacco, A.; Tezza, L.; Vendrame, N.; Virgili, G.; Minardi, I.; Giovenali, E.; LoBello, J. LIFE15 ENV/IT/000392−LIFE VITISOM Project, Viticulture Innovation Technology and GHG Emission Monitoring. BIO Web Conf. 2019, 13, 02008. [Google Scholar] [CrossRef]

- Corbo, C.; Lamastra, L.; Capri, E. From Environmental to Sustainability Programs: A Review of Sustainability Initiatives in the Italian Wine Sector. Sustainability 2014, 6, 2133–2159. [Google Scholar] [CrossRef] [Green Version]

- DEFRA-Department for Environment, Food Rural Affairs Greenhouse Gas Reporting: Conversion Factors 2021. Available online: Https://Www.Gov.Uk/Government/Publications/Greenhouse-Gas-Reporting-Conversion-Factors-2021 (accessed on 24 June 2022).

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; JRC Publications Repository: Brussels, Belgium, 2019. [Google Scholar]

- IPCC. Chapter 11: N2O Emissions from Managed Soils, and CO2 Emissions from Lime and Urea Application 2006. In IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- IPCC. N2O Emissions from Managed Soils, and CO2 Emissions from Lime and Urea Application 2019. In IPCC 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- ADEME. Documentation Base Carbone 18.1.0 2020; French Environment and Energy Management Agency: Paris, France, 2020. Available online: https://www.data.gouv.fr/fr/datasets/base-carbone-complete-de-lademe-en-francais-v17-0/ (accessed on 22 June 2022).

- Frischknecht, R.; Rebitzer, G. The Ecoinvent Database System: A Comprehensive Web-Based LCA Database. J. Clean. Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Rugani, B.; Vázquez-Rowe, I.; Benedetto, G.; Benetto, E. A Comprehensive Review of Carbon Footprint Analysis as an Extended Environmental Indicator in the Wine Sector. J. Clean. Prod. 2013, 54, 61–77. [Google Scholar] [CrossRef]

- Ponstein, H.J.; Meyer-Aurich, A.; Prochnow, A. Greenhouse Gas Emissions and Mitigation Options for German Wine Production. J. Clean. Prod. 2019, 212, 800–809. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T.; Feijoo, G. Environmental Analysis of Ribeiro Wine from a Timeline Perspective: Harvest Year Matters When Reporting Environmental Impacts. J. Environ. Manag. 2012, 98, 73–83. [Google Scholar] [CrossRef]

- Luo, L.; van der Voet, E.; Huppes, G.; Udo de Haes, H.A. Allocation Issues in LCA Methodology: A Case Study of Corn Stover-Based Fuel Ethanol. Int. J. Life Cycle Assess 2009, 14, 529–539. [Google Scholar] [CrossRef]

- Bhatia, P.; Cummis, C.; Draucker, L.; Rich, D.; Lahd, H.; Brown, A. Greenhouse Gas Protocol. Product Life Cycle Accounting and Reporting Standard; GHG Protocol for Products. Product Life Cycle Accounting and Reporting Standard; World Resources Institute: Washington, DC, USA, 2011. [Google Scholar]

- Navarro, A.; Puig, R.; Kılıç, E.; Penavayre, S.; Fullana-i-Palmer, P. Eco-Innovation and Benchmarking of Carbon Footprint Data for Vineyards and Wineries in Spain and France. J. Clean. Prod. 2017, 142, 1661–1671. [Google Scholar] [CrossRef]

- Chiriacò, M.V.; Grossi, G.; Castaldi, S.; Valentini, R. The Contribution to Climate Change of the Organic versus Conventional Wheat Farming: A Case Study on the Carbon Footprint of Wholemeal Bread Production in Italy. J. Clean. Prod. 2017, 153, 309–319. [Google Scholar] [CrossRef]

- Renzulli, P.A.; Bacenetti, J.; Benedetto, G.; Fusi, A.; Ioppolo, G.; Niero, M.; Proto, M.; Salomone, R.; Sica, D.; Supino, S. Life Cycle Assessment in the Cereal and Derived Products Sector. In Life Cycle Assessment in the Agri-Food Sector: Case Studies, Methodological Issues and Best Practices; Notarnicola, B., Salomone, R., Petti, L., Renzulli, P.A., Roma, R., Cerutti, A.K., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 185–249. ISBN 978-3-319-11940-3. [Google Scholar]

- Renaud- Gentié, C.; Dieu, V.; Thiollet-Scholtus, M.; Merot, A. Addressing Organic Viticulture Environmental Burdens by Better Understanding Interannual Impact Variations. Int. J. Life Cycle Assess. 2020, 25, 1307–1322. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; Hodge, I.D.; Riordan, P.; Macdonald, D.W. Does Organic Farming Reduce Environmental Impacts?--A Meta-Analysis of European Research. J. Environ. Manag. 2012, 112, 309–320. [Google Scholar] [CrossRef]

- Reganold, J.; Wachter, J. Organic Agriculture in the Twenty-First Century. Nat. Plants 2016, 2, 15221. [Google Scholar] [CrossRef] [PubMed]

- Gierling, F.; Blanke, M. Carbon Reduction Strategies for Regionally Produced and Consumed Wine: From Farm to Fork. J. Environ. Manag. 2021, 278, 111453. [Google Scholar] [CrossRef] [PubMed]

- Rouault, A.; Beauchet, S.; Renaud-Gentie, C.; Jourjon, F. Life Cycle Assessment of Viticultural Technical Management Routes (TMRs): Comparison between an Organic and an Integrated Management Route. OENO One 2016, 50, 84. [Google Scholar] [CrossRef] [Green Version]

- Probst, B.; Schüler, C.; Joergensen, R.G. Vineyard Soils under Organic and Conventional Management—Microbial Biomass and Activity Indices and Their Relation to Soil Chemical Properties. Biol. Fertil. Soils 2008, 44, 443–450. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, P.; Soto-Gómez, D.; López-Periago, J.E.; Paradelo, M. Modeling Raindrop Strike Performance on Copper Wash-off from Vine Leaves. J. Environ. Manag. 2015, 150, 472–478. [Google Scholar] [CrossRef] [PubMed]

- Fregoni, M. Viticoltura di Qualità; Tecniche Nuove: Milano, Italy, 1999; ISBN 978-88-7220-103-9. [Google Scholar]

- Brunori, E.; Farina, R.; Biasi, R. Sustainable Viticulture: The Carbon-Sink Function of the Vineyard Agro-Ecosystem. Agric. Ecosyst. Environ. 2016, 223, 10–21. [Google Scholar] [CrossRef]

- Patinha, C.; Durães, N.; Dias, A.C.; Pato, P.; Fonseca, R.; Janeiro, A.; Barriga, F.; Reis, A.P.; Duarte, A.; Ferreira da Silva, E.; et al. Long-Term Application of the Organic and Inorganic Pesticides in Vineyards: Environmental Record of Past Use. Appl. Geochem. 2018, 88, 226–238. [Google Scholar] [CrossRef]

- Briar, S.S.; Grewal, P.S.; Somasekhar, N.; Stinner, D.; Miller, S.A. Soil Nematode Community, Organic Matter, Microbial Biomass and Nitrogen Dynamics in Field Plots Transitioning from Conventional to Organic Management. Appl. Soil Ecol. 2007, 37, 256–266. [Google Scholar] [CrossRef]

- Nye, C. Agriculture’s ‘Other’ Contingent Labour Source. Agricultural Contractors and Relationships of Interdependence at the Farmer-Contractor Interface. J. Rural. Stud. 2020, 78, 223–233. [Google Scholar] [CrossRef]

- Abad, J.; de Mendoza, I.H.; Marín, D.; Orcaray, L.; Santesteban, L.G. Cover Crops in Viticulture. A Systematic Review (1): Implications on Soil Characteristics and Biodiversity in Vineyard. OENO One 2021, 55, 295–312. [Google Scholar] [CrossRef]

- Mian, G.; Comuzzo, P.; Iacumin, L.; Zanzotti, R.; Celotti, E. Study to Optimize the Effectiveness of Copper Treatments for a Low Impact Viticulture. Internte J. Vitic. Enol. 2021. [Google Scholar] [CrossRef]

| Administrative Region | Management | Years of Data Collection | Number of Case Studies | Vineyard Surface Area (ha) | |

|---|---|---|---|---|---|

| Mean | [min; max] | ||||

| Friuli-Venezia Giulia | CONV | 2012, 2013, 2015, 2017 | 4 | 69.31 | [38.85; 83.65] |

| Lombardy | ORG | 2009, 2010, 2011, 2014, 2015, 2016, 2017 | 9 | 49.24 | [3.41; 84.65] |

| CONV | 2009, 2010, 2011, 2012, 2013, 2014, 2016 | 34 | 57.37 | [9.22; 180.63] | |

| Piedmont | CONV | 2010 | 1 | 93.01 | [93.01; 93.01] |

| Veneto | ORG | 2012, 2013 | 2 | 17.19 | [17.18; 17.19] |

| Overall | 50 | 55.96 | [3.41; 180.63] | ||

| Categories According to ISO 14064 | Subcategories According to ISO 14064 | Entries | Emission Factor Sources |

|---|---|---|---|

| Direct GHG emissions. | Direct emissions from mobile combustion. | Fuels for field operations. Fuels for other vehicles. | DEFRA-Department for Environment, Food Rural Affairs, 2021 [28]. |

| Direct fugitive emissions arising from the release of GHGs in anthropogenic systems. | Synthetic fertilizing. Organic fertilizing (manure, compost, digestate). | For nitrous oxide emissions from fertilizing: Joint Research Centre (JRC), the European Commission’s science and knowledge service provides scientific evidence throughout the whole policy cycle [29]. For carbon dioxide emissions from urea use: Intergovernmental Panel on climate Change. [30,31] | |

| Indirect GHG emissions from transportation. | Indirect emissions from upstream transport for goods. | Transport of purchased goods. | DEFRA-Department for Environment, Food and Rural Affairs, 2021 [28]. |

| Indirect GHG emissions from products and services used by organization. | Indirect emissions from purchased goods which are associated with product manufacturing activities. | Synthetic fertilizers. Organic fertilizers; Fungicides, Herbicides, Insecticides. | ADEME’s Bilan Carbone database [32]. The ecoinvent database [33]. |

| Indirect emissions from mobile combustion. | Fuels for rental or non-owned vehicles. Fuels for agricultural contractors. | DEFRA-Department of the Environment, Food and Rural Affairs, 2021 [28]. |

| Vineyard Inputs | Organic | Conventional | ||

|---|---|---|---|---|

| Mean (±SD) | [min; max] | Mean (±SD) | [min; max] | |

| Fuels for field work (kg ha−1) | 324.31 (±97.44) | [216.44; 475.32] | 237.1 (±125.12) | [0; 500.81] |

| Fuel for other vehicles (km ha−1) | 169.22 (±197.45) | [0; 459.28] | 139.14 (±221.24) | [0; 693.86] |

| Manure (q ha−1) | 3659.09 (±6115.74) | [0; 16,738.65] | 2098.3 (±3456.63) | [0; 13,731.48] |

| Compost (q ha−1) | 562.33 (±1735.34) | [0; 5781.81] | 78.62 (±361.03) | [0; 2029.78] |

| Nitrous-based fertilizers (kg N ha−1) | - | - | 8.07 (±15.15) | [0; 72.59] |

| Urea-based synthetic fertilizers (kg ha−1) | - | - | 5.99 (±10) | [0; 45.08] |

| Phospho-potassium fertilizers and others (kg a.s. ha−1) | - | - | 20.43 (±23.81) | [0; 167.72] |

| Sulphur-based fungicides (kg a.s. ha−1) | 125.07 (±65.92) | [38.16; 225.39] | 47.63 (±48.94) | [0; 210.06] |

| Copper-based fungicides (kg a.s. ha−1) | 4.66 (±0.86) | [3.68; 5.76] | 3.43 (±2.75) | [0; 10.44] |

| Unspecific fungicides (kg a.s. ha−1) | - | - | 9.84 (±20.05) | [0; 116.31] |

| Herbicides (kg a.s. ha−1) | - | - | 0.73 (±0.88) | [0; 3.38] |

| Insecticides (kg a.s. ha−1) | - | - | 0.46 (±0.46) | [0; 2.05] |

| Natural insecticides (kg a.s. ha−1) | 0.59 (±1.17) | [0; 3.92] | 0.25 (±0.62) | [0; 2.43] |

| Fuels for rental or non-owned vehicles (km ha−1) | 21.32 (±28.38) | [0; 73.99] | 2.37 (±7.72) | [0; 37.02] |

| Fuels for agricultural contractors (kg ha−1) | 238.91 (±534.52) | [0; 1440.00] | 1213.02 (±2596.32) | [0; 9489.15] |

| Management | GHG Emissions Mean (±SD) | GHG Emissions [min/max] |

|---|---|---|

| ORG | 1568.77 (±396.80) | [876.99; 2253.34] |

| CONV | 1408.34 (±535.27) | [690.39; 2937.03] |

| ALL | 1443.63 (±508.76) | [690.39; 2937.03] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghiglieno, I.; Simonetto, A.; Facciano, L.; Tonni, M.; Donna, P.; Valenti, L.; Gilioli, G. Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy. Sustainability 2023, 15, 5252. https://doi.org/10.3390/su15065252

Ghiglieno I, Simonetto A, Facciano L, Tonni M, Donna P, Valenti L, Gilioli G. Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy. Sustainability. 2023; 15(6):5252. https://doi.org/10.3390/su15065252

Chicago/Turabian StyleGhiglieno, Isabella, Anna Simonetto, Luca Facciano, Marco Tonni, Pierluigi Donna, Leonardo Valenti, and Gianni Gilioli. 2023. "Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy" Sustainability 15, no. 6: 5252. https://doi.org/10.3390/su15065252

APA StyleGhiglieno, I., Simonetto, A., Facciano, L., Tonni, M., Donna, P., Valenti, L., & Gilioli, G. (2023). Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy. Sustainability, 15(6), 5252. https://doi.org/10.3390/su15065252