A Review on Green Cooling: Exploring the Benefits of Sustainable Energy-Powered District Cooling with Thermal Energy Storage

Abstract

:1. Introduction

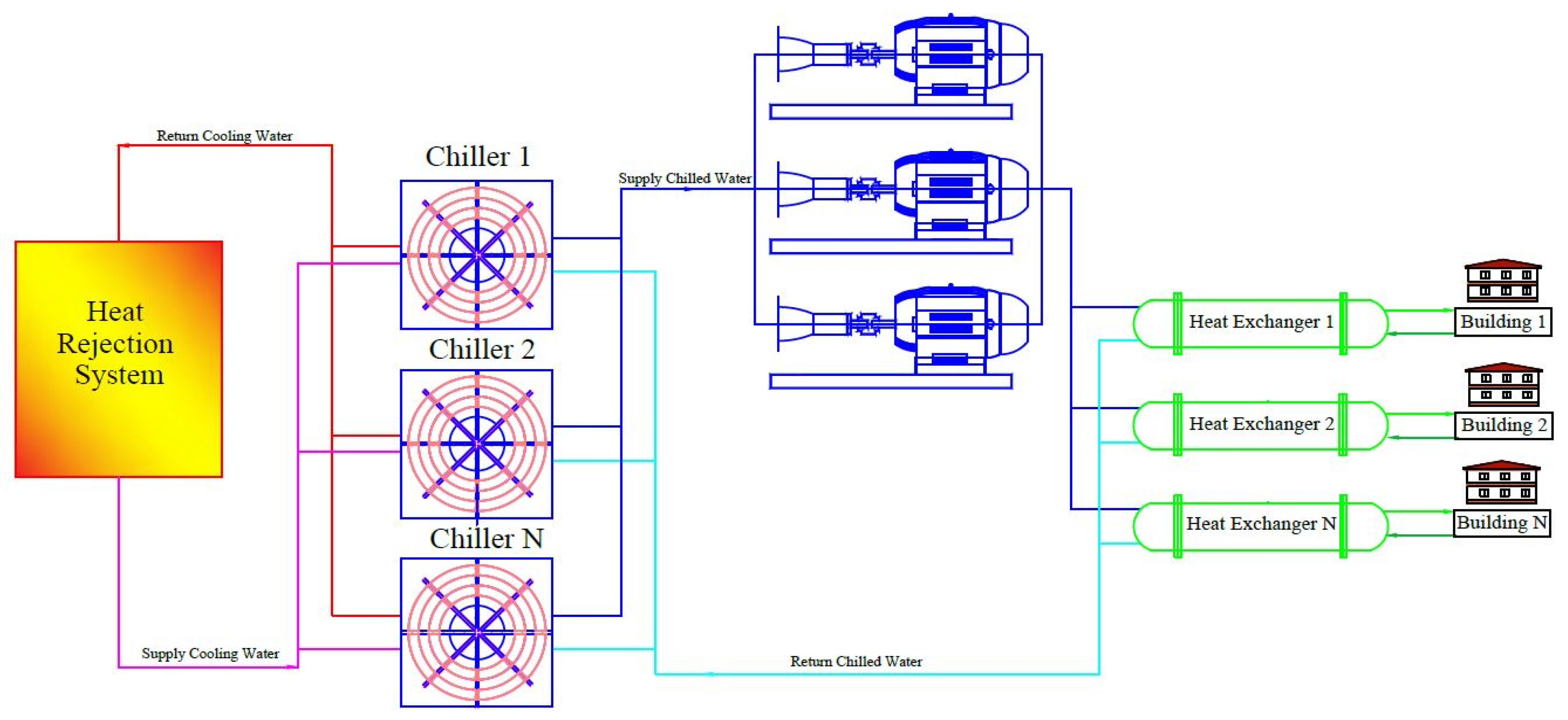

2. District Cooling System (DCS)

Types of District Cooling Systems

3. Renewable Energy Integration into DCS

3.1. The Use of Biomass Energy in DCS

3.2. The Use of Solar Thermal Energy in DCS

3.3. The Use of Geothermal Energy in DCS

3.4. The Use of Solar Photovoltaic Systems in DCS

3.5. The Use of Surface Water in DCS

3.6. The Economic and Environmental Analysis of Renewable Energy-Driven Systems for Cooling

4. Vapor Compression Chiller Integration into Thermal Energy Storage

4.1. Thermal Energy Storage (TES)

4.2. Vapor Compression Chillers (VCCs)

- Enhanced control and monitoring of industrial processes, leading to improved efficiency and reduced waste.

- Reduced dependence on fossil fuels and reduced greenhouse gas emissions.

- Optimization of energy consumption, reducing costs and further benefiting the environment [96].

- Economic and environmental benefits for selected countries as presented in Table 3.

5. Conclusions and Future Research Priorities

- Increase government incentives: Encouraging the development and implementation of renewable energy-powered district cooling systems with thermal energy storage through government incentives such as tax credits, subsidies, and grants can help to overcome the initial investment hurdle and increase the adoption of these systems.

- Improve energy storage technology: Advances in energy storage technology, such as increased capacity, reduced cost, and improved performance, will play a key role in the future development and implementation of renewable energy-powered district cooling systems.

- Encourage public–private partnerships: Encouraging public–private partnerships between government agencies, utility companies, and private sector organizations can help to pool resources and expertise and increase the speed and scale of deployment of these systems.

- Develop new financing models: Developing new financing models, such as energy performance contracting and energy service companies, can provide innovative ways to fund the development and implementation of renewable energy-powered district cooling systems with thermal energy storage.

- Enhance public awareness and education: Raising public awareness and education about the benefits and potential of renewable energy-powered district cooling systems with thermal energy storage can help to build public support and drive demand for these systems.

- Implement smart grid technologies: Integrating smart grid technologies, such as demand response and energy management systems, into renewable energy-powered district cooling systems with thermal energy storage can help to optimize energy consumption, reduce energy waste, and improve system efficiency.

- The focus should be tailored towards exploring synergy among the co-technologies of DCS, renewables, and TES with VCC-integrated systems to effectively overcome many problems associated with the technology.

- Deployment of modern learning tools such as machine learning to forecast the rate of energy efficiency and consumption in the building: This creates an avenue for comparison between the predicted results and the conventional results to detect possible defections.

- A holistic approach to sustainability evaluation should be incorporated in the environmental and economic assessment of the various technologies.

- Strategies for incremental development in terms of the challenges of system efficiency, cost, and sustainability would help these technologies become more viable in the nearest future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rioja-Cabanillas, A.; Valdesueiro, D.; Fernández-Ibáñez, P.; Byrne, J.A. Hydrogen from wastewater by photocatalytic and photoelectrochemical treatment Journal of Physics: Energy OPEN ACCESS Hydrogen from wastewater by photocatalytic and photoelectrochemical treatment. J. Phys. Energy 2021, 3, 012006. [Google Scholar] [CrossRef]

- Inayat, A.; Raza, M. District cooling system via renewable energy sources: A review. Renew. Sustain. Energy Rev. 2020, 107, 360–373. [Google Scholar] [CrossRef]

- Abdallah, L.; El-Shennawy, T. Reducing Carbon Dioxide Emissions from Electricity Sector Using Smart Electric Grid Applications. J. Eng. 2013, 2013, 845051. [Google Scholar] [CrossRef] [Green Version]

- Bauer, C.; Treyer, K.; Heck, T.; Hirschberg, S.; Institut, P.S. Greenhouse Gas Emissions from Energy Systems, Comparison, and Overview; no. October 2014; Elsevier Inc.: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Zhou, X.; Yan, D.; Feng, X.; Deng, G.; Jian, Y.; Jiang, Y. Influence of household air-conditioning use modes on the energy performance of residential district cooling systems. Build. Simul. 2016, 9, 429–441. [Google Scholar] [CrossRef]

- Angrisani, G.; Entchev, E.; Roselli, C.; Sasso, M.; Tariello, F.; Yaici, W. Dynamic simulation of a solar heating and cooling system for an office building located in Southern Italy. Appl. Therm. Eng. 2016, 103, 377–390. [Google Scholar] [CrossRef]

- Liu, H.; Kojima, S. Energy Consumption and Thermal Performance in Different Residential Building Types in Hot-Summer and Cold-Winter Zone. J. Civ. Eng. Arch. 2017, 11, 240–248. [Google Scholar] [CrossRef]

- Kwok, A.G.; Rajkovich, N. Addressing climate change in comfort standards. Build. Environ. 2010, 45, 18–22. [Google Scholar] [CrossRef]

- Eveloy, V.; Ayou, D.S. Challenges, and Future Opportunities, with Emphasis on Cooling-Dominated Regions. Energies 2019, 12, 235. [Google Scholar] [CrossRef] [Green Version]

- Sporleder, M.; Rath, M.; Ragwitz, M. Design optimization of district heating systems: A review. Front. Energy Res. 2022, 10, 1–18. [Google Scholar] [CrossRef]

- Bello, U.; Udofia, L.; Ibitowa, O.A.; Abdullahi, A.M.; Sulaiman, I.; Yahuza, K.M. Renewable Energy Transition: A Panacea to the Ravaging Effects of Climate Change in Nigeria. J. Geosci. Environ. Prot. 2021, 9, 151–167. [Google Scholar] [CrossRef]

- Gang, W.; Wang, S.; Xiao, F.; Gao, D.-C. District cooling systems: Technology integration, system optimization, challenges and opportunities for applications. Renew. Sustain. Energy Rev. 2016, 53, 253–264. [Google Scholar] [CrossRef]

- Gang, W.; Wang, S.; Xiao, F. District cooling systems and individual cooling systems: Comparative analysis and impacts of key factors. Sci. Technol. Built Environ. 2017, 23, 241–250. [Google Scholar] [CrossRef]

- Werner, S. International review of district heating and cooling. Energy 2017, 137, 617–631. [Google Scholar] [CrossRef]

- Werner, S. District heating and cooling in Sweden. Energy 2017, 126, 419–429. [Google Scholar] [CrossRef]

- Buoro, D.; Casisi, M.; De Nardi, A.; Pinamonti, P.; Reini, M. Multicriteria optimization of a distributed energy supply system for an industrial area. Energy 2013, 58, 128–137. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Energetic and financial analysis of solar cooling systems with single effect absorption chiller in various climates. Appl. Therm. Eng. 2017, 126, 809–821. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Moschos, K.; Antonopoulos, K.A. Energetic and financial evaluation of solar assisted heat pump space heating systems. Energy Convers. Manag. 2016, 120, 306–319. [Google Scholar] [CrossRef]

- Bello, U.; Shallangwa, G.; Idris, S.; Musa, M.; Aisha, A. Synthesis, spectroscopic characterization and in vitro antibacterial activity studies of Cu(II) complexes derived from 6- hydroxyflavone Schiff bases. Bayero J. Pure Appl. Sci. 2018, 11, 136–141. [Google Scholar] [CrossRef] [Green Version]

- Jebb, S.A.; Cole, T.J.; Doman, D.; Murgatroyd, P.R.; Prentice, A.M. Evaluation of the novel tanita body-fat analyser to measure body composition by comparison with a four-compartment model. Br. J. Nutr. 2000, 83, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Alobaid, M.; Hughes, B.; Calautit, J.K.; O’Connor, D.; Heyes, A. A review of solar driven absorption cooling with photovoltaic thermal systems. Renew. Sustain. Energy Rev. 2017, 76, 728–742. [Google Scholar] [CrossRef] [Green Version]

- Iodice, P.; D’Accadia, M.D.; Abagnale, C.; Cardone, M. Energy, economic and environmental performance appraisal of a trigeneration power plant for a new district: Advantages of using a renewable fuel. Appl. Therm. Eng. 2016, 95, 330–338. [Google Scholar] [CrossRef]

- Palomba, V.; Vasta, S.; Freni, A.; Pan, Q.; Wang, R.; Zhai, X. Increasing the share of renewables through adsorption solar cooling: A validated case study. Renew. Energy 2017, 110, 126–140. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. A detailed working fluid investigation for solar parabolic trough collectors. Appl. Therm. Eng. 2017, 114, 374–386. [Google Scholar] [CrossRef]

- Zhang, W.; Hong, W.; Jin, X. Research on performance and control strategy of multi-cold source district cooling system. Energy 2022, 239, 122057. [Google Scholar] [CrossRef]

- Abushamah, H.A.S.; Skoda, R. Nuclear energy for district cooling systems—Novel approach and its eco-environmental assessment method. Energy 2022, 250, 123824. [Google Scholar] [CrossRef]

- Salameh, T.; Assad, M.E.H.; Tawalbeh, M.; Ghenai, C.; Merabet, A.; Öztop, H.F. Analysis of cooling load on commercial building in UAE climate using building integrated photovoltaic façade system. Sol. Energy 2020, 199, 617–629. [Google Scholar] [CrossRef]

- Howarth, N.; Odnoletkova, N.; Alshehri, T.; Almadani, A. Staying Cool in A Warming Climate: Temperature. Climate 2020, 8, 4. [Google Scholar] [CrossRef] [Green Version]

- Hisham, N.A.; Salim, S.A.Z.S.; Hagishima, A.; Yakub, F.; Saipol, H.F.S. Statistical analysis of air-conditioning and total load diversity in typical residential buildings. Bull. Electr. Eng. Inform. 2021, 10, 1–9. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Are district heating systems and renewable energy sources always an environmental win-win solution? A life cycle assessment case study in Tuscany, Italy. Renew. Sustain. Energy Rev. 2017, 80, 408–420. [Google Scholar] [CrossRef]

- Kalaycıoğlu, E.; Yılmaz, A.Z. A new approach for the application of nearly zero energy concept at district level to reach EPBD recast requirements through a case study in Turkey. Energy Build. 2020, 152, 680–700. [Google Scholar] [CrossRef]

- Lake, A.; Rezaie, B.; Beyerlein, S. Review of district heating and cooling systems for a sustainable future. Renew. Sustain. Energy Rev. 2017, 67, 417–425. [Google Scholar] [CrossRef]

- Sayadi, S.; Akander, J.; Hayati, A.; Cehlin, M. Review on District Cooling and Its Application in Energy Systems; Intech Open: London, UK, 2021. [Google Scholar]

- Pampuri, L.; Cereghetti, N.; Strepparava, D.; Caputo, P. Analysis of the electricity consumptions: A first step to develop a district cooling system. Sustain. Cities Soc. 2016, 23, 23–36. [Google Scholar] [CrossRef]

- Udomsri, S.; Bales, C.; Martin, A.R.; Martin, V. Decentralized cooling in district heating network: System simulation and parametric study. Appl. Energy 2012, 92, 175–184. [Google Scholar] [CrossRef]

- Franchini, G.; Brumana, G.; Perdichizzi, A. Performance prediction of a solar district cooling system in Riyadh, Saudi Arabi— A case study. Energy Convers. Manag. 2018, 166, 372–384. [Google Scholar] [CrossRef]

- Jangsten, M.; Filipsson, P.; Lindholm, T.; Dalenbäck, J.-O. High Temperature District Cooling: Challenges and Possibilities Based on an Existing District Cooling System and its Connected Buildings. Energy 2020, 199, 117407. [Google Scholar] [CrossRef]

- Faircloth, C.C.; Wagner, K.H.; Woodward, K.E.; Rakkwamsuk, P.; Gheewala, S.H. The environmental and economic impacts of photovoltaic waste management in Thailand. Resour. Conserv. Recycl. 2018, 143, 260–272. [Google Scholar] [CrossRef]

- Cozzini, M.; Antoni, M.D.; Buffa, S.; Fedrizzi, R.; Denmark, B. District Heating and Cooling Networks Based on Decentralized Heat Pumps: Energy Efficiency and Reversibility at Affordable Costs. Top. Artic. HPT Mag. 2018, 36, 25–29. [Google Scholar]

- Kadam, S.T.; Kyriakides, A.-S.; Khan, M.S.; Shehabi, M.; Papadopoulos, A.I.; Hassan, I.; Rahman, M.A.; Seferlis, P. Thermo-economic and environmental assessment of hybrid vapor compression-absorption refrigeration systems for district cooling. Energy 2022, 243, 122991. [Google Scholar] [CrossRef]

- Ferwati, M.S.; Ahmad, A.M.; Takalkar, G.D.; Bicer, Y. Energy and exergy analysis of parallel flow double effect H2O-[mmim][DMP] absorption refrigeration system for solar powered district cooling. Case Stud. Therm. Eng. 2021, 28, 101382. [Google Scholar] [CrossRef]

- Vakiloroaya, V.; Samali, B.; Pishghadam, K. Investigation of energy-efficient strategy for direct expansion air-cooled air conditioning systems. Appl. Therm. Eng. 2014, 66, 84–93. [Google Scholar] [CrossRef]

- Amran, N.A.; Bello, U.; Ruslan, M.S.H. The role of antioxidants in improving biodiesel’s oxidative stability, poor cold flow properties, and the effects of the duo on engine performance: A review. Heliyon 2022, 8, e09846. [Google Scholar] [CrossRef] [PubMed]

- Khir, R.; Haouari, M. Optimization models for a single-plant District Cooling System. Eur. J. Oper. Res. 2015, 247, 648–658. [Google Scholar] [CrossRef]

- Shahbaz, M.; Yusup, S.; Inayat, A.; Patrick, D.O.; Ammar, M. The influence of catalysts in biomass steam gasification and catalytic potential of coal bottom ash in biomass steam gasification: A review. Renew. Sustain. Energy Rev. 2016, 73, 468–476. [Google Scholar] [CrossRef]

- Bello, U.; Agu, C.U.; Ajiya, D.A.; Mahmoud, A.A.; Udopia, L.; Lawal, N.M.; Abubakar, A.A.; Muhammad, M. Biodiesel in a Quest for Sustainable Renewable Energy: A Review on Its Potentials and Production Strategies. J. Chem. Rev. 2022, 4, 272–287. [Google Scholar] [CrossRef]

- Kirubakaran, V.; Sivaramakrishnan, V.; Nalini, R.; Sekar, T.; Premalatha, M.; Subramanian, P. A review on gasification of biomass. Renew. Sustain. Energy Rev. 2009, 13, 179–186. [Google Scholar] [CrossRef]

- Shen, Y.; Yoshikawa, K. Recent progresses in catalytic tar elimination during biomass gasification or pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 21, 371–392. [Google Scholar] [CrossRef]

- Sharma, A.K. Modeling and simulation of a downdraft biomass gasifier 1. Model development and validation. Energy Convers. Manag. 2011, 52, 1386–1396. [Google Scholar] [CrossRef]

- Cardoen, D.; Joshi, P.; Diels, L.; Sarma, P.M.; Pant, D. Agriculture biomass in India: Part 1. Estimation and characterization. Resour. Conserv. Recycl. 2015, 102, 39–48. [Google Scholar] [CrossRef]

- Rezaei, M.; Sameti, M.; Nasiri, F. An enviro-economic optimization of a hybrid energy system from biomass and geothermal resources for low-enthalpy areas. Energy Clim. Chang. 2021, 2, 100040. [Google Scholar] [CrossRef]

- Espootin, S.; Sameti, M.; Zaker, S. Biodiesel from fish waste oil: Synthesis via supercritical methanol and thermodynamic optimization. Clean Energy 2021, 5, 187–195. [Google Scholar] [CrossRef]

- Ahmadi, P.; Dincer, I.; Rosen, M.A. Development and assessment of an integrated biomass-based multi-generation energy system. Energy 2013, 56, 155–166. [Google Scholar] [CrossRef]

- Moharamian, A.; Soltani, S.; Rosen, M.A.; Mahmoudi, S.; Morosuk, T. A comparative thermoeconomic evaluation of three biomass and biomass-natural gas fired combined cycles using organic Rankine cycles. J. Clean. Prod. 2017, 161, 524–544. [Google Scholar] [CrossRef]

- Buragohain, B.; Mahanta, P.; Moholkar, V.S. Biomass gasification for decentralized power generation: The Indian perspective. Renew. Sustain. Energy Rev. 2010, 14, 73–92. [Google Scholar] [CrossRef]

- Bello, U.; Amran, N.A.; Samsuri, S.; Ruslan, M.S.H. Kinetics, thermodynamic studies, and parametric effects of supercritical CO2 extraction of banana peel wastes. Sustain. Chem. Pharm. 2022, 31, 100912. [Google Scholar] [CrossRef]

- Lin, C.-L.; Weng, W.-C. Effects of different operating parameters on the syngas composition in a two-stage gasification process. Renew. Energy 2017, 109, 135–143. [Google Scholar] [CrossRef]

- Martinez, J.D.; Mahkamov, K.; Andrade, R.V.; Silva Lora, E.E. Syngas production in downdraft biomass gasifiers and its application using internal combustion engines. Renew. Energy 2012, 38, 1–9. [Google Scholar] [CrossRef]

- Rezaei, M.; Sameti, M.; Nasiri, F. Biomass-fuelled combined heat and power: Integration in district heating and thermal-energy storage. Clean Energy 2021, 5, 44–56. [Google Scholar] [CrossRef]

- Udomsri, S.; Martin, A.R.; Martin, V. Thermally driven cooling coupled with municipal solid waste-fired power plant: Application of combined heat, cooling and power in tropical urban areas. Appl. Energy 2011, 88, 1532–1542. [Google Scholar] [CrossRef]

- Rentizelas, A.; Tatsiopoulos, I.P.; Tolis, A. An optimization model for multi-biomass tri-generation energy supply. Biomass Bioenerg. 2009, 33, 223–233. [Google Scholar] [CrossRef] [Green Version]

- Ghafoor, A.; Munir, A. Worldwide overview of solar thermal cooling technologies. Renew. Sustain. Energy Rev. 2015, 43, 763–774. [Google Scholar] [CrossRef]

- Byrne, P.; Fournaison, L.; Delahaye, A.; Oumeziane, Y.A.; Serres, L.; Loulergue, P.; Szymczyk, A.; Mugnier, D.; Malaval, J.-L.; Bourdais, R.; et al. A review on the coupling of cooling, desalination and solar photovoltaic systems. Renew. Sustain. Energy Rev. 2015, 47, 703–717. [Google Scholar] [CrossRef]

- Kalkan, N.; Young, E.; Celiktas, A. Solar thermal air conditioning technology reducing the footprint of solar thermal air conditioning. Renew. Sustain. Energy Rev. 2012, 16, 6352–6383. [Google Scholar] [CrossRef]

- Rad, F.M.; Fung, A.S. Solar community heating and cooling system with borehole thermal energy storage—Review of systems. Renew. Sustain. Energy Rev. 2016, 60, 1550–1561. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. Review of solar refrigeration and cooling systems. Energy Build. 2013, 67, 286–297. [Google Scholar] [CrossRef]

- Lovegrove, K.; Dennis, M. Solar thermal energy systems in Australia. Int. J. Environ. Stud. 2014, 63, 791–802. [Google Scholar] [CrossRef]

- Raja, V.B.; Shanmugam, V. A review and new approach to minimize the cost of solar assisted absorption cooling system. Renew. Sustain. Energy Rev. 2012, 16, 6725–6731. [Google Scholar] [CrossRef]

- Guelpa, E.; Verda, V. Thermal energy storage in district heating and cooling systems: A review. Appl. Energy 2019, 252, 113474. [Google Scholar] [CrossRef]

- Pintaldi, S.; Perfumo, C.; Sethuvenkatraman, S.; White, S.; Rosengarten, G. A review of thermal energy storage technologies and control approaches for solar cooling. Renew. Sustain. Energy Rev. 2015, 41, 975–995. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A. Solar heating and cooling systems by CPVT and ET solar collectors: A novel transient simulation model. Appl. Energy 2013, 103, 588–606. [Google Scholar] [CrossRef]

- Oktay, Z.; Aslan, A. Geothermal district heating in Turkey: The Gonen case study. Geothermics 2007, 36, 167–182. [Google Scholar] [CrossRef]

- Ozgener, L.; Hepbasli, A.; Dincer, I. Energy and exergy analysis of the Gonen geothermal district heating system, Turkey. Geothermics 2005, 34, 632–645. [Google Scholar] [CrossRef]

- Mallor, F.; León, T.; De Boeck, L.; Van Gulck, S.; Meulders, M.; Van der Meerssche, B. A method for detecting malfunctions in PV solar panels based on electricity production monitoring. Sol. Energy 2017, 153, 51–63. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Malek, A.B.M.A.; Islam, M.M.; Pandey, A.K.; Rahim, N.A. Global advancement of cooling technologies for PV systems: A review. Sol. Energy 2016, 137, 25–45. [Google Scholar] [CrossRef]

- Syafiq, A.; Pandey, A.; Adzman, N.; Rahim, N.A. Advances in approaches and methods for self-cleaning of solar photovoltaic panels. Sol. Energy 2018, 162, 597–619. [Google Scholar] [CrossRef]

- Matulaitis, V.; Straukaitė, G.; Azzopardi, B.; Martinez-Cesena, E.A. Multi-criteria decision making for PV deployment on a multinational level. Sol. Energy Mater. Sol. Cells 2016, 156, 122–127. [Google Scholar] [CrossRef]

- Barroso, J.S.; Barth, N.; Correia, J.; Ahzi, S.; Khaleel, M. A computational analysis of coupled thermal and electrical behavior of PV panels. Sol. Energy Mater. Sol. Cells 2016, 148, 73–86. [Google Scholar] [CrossRef]

- Roy, T.; Mahmud, A. Active power control of three-phase grid-connected solar PV systems using a robust nonlinear adaptive backstepping approach. Sol. Energy 2017, 153, 64–76. [Google Scholar] [CrossRef]

- Bermudez, V. An overview on electrodeposited Cu(In,Ga)(Se,S)2 thin films for photovoltaic devices. Sol. Energy 2018, 175, 2–8. [Google Scholar] [CrossRef]

- Solar photovoltaic panels as next generation waste: A review. Biointerface Res. Appl. Chem. 2019, 9, 4539–4546. [CrossRef]

- Good, C.; Andresen, I.; Hestnes, A.G. Solar energy for net zero energy buildings—A comparison between solar thermal, PV and photovoltaic–thermal (PV/T) systems. Sol. Energy 2020, 122, 986–996. [Google Scholar] [CrossRef] [Green Version]

- Marugán-Cruz, C.; Sánchez-Delgado, S.; Rodríguez-Sánchez, M.R.; Venegas, M.; Santana, D. District cooling network connected to a solar power tower. Appl. Therm. Eng. 2015, 79, 174–183. [Google Scholar] [CrossRef]

- Kuhn, T.E. State of the art of advanced solar control devices for buildings. Sol. Energy 2017, 154, 112–133. [Google Scholar] [CrossRef]

- Wang, X.; Dennis, M. Influencing factors on the energy saving performance of battery storage and phase change cold storage in a PV cooling system. Energy Build. 2015, 107, 84–92. [Google Scholar] [CrossRef]

- Zhen, L.; Lin, D.; Shu, H.; Jiang, S.; Zhu, Y. District cooling and heating with seawater as heat source and sink in Dalian, China. Renew. Energy 2007, 32, 2603–2616. [Google Scholar] [CrossRef]

- Abedrabboh, O.; Koç, M.; Biçer, Y. Modelling and analysis of a renewable energy-driven climate-controlled sustainable greenhouse for hot and arid climates. Energy Convers. Manag. 2022, 273, 116412. [Google Scholar] [CrossRef]

- Manesh, M.H.K.; Onishi, V.C. Energy, Exergy, and Thermo-Economic Analysis of Renewable Energy-Driven Polygeneration Systems for Sustainable Desalination. Processes 2021, 9, 210. [Google Scholar] [CrossRef]

- Mahon, C.; Gartland, D. Life Cycle Assessment of Irish District Heating Systems: A Comparison of Waste Heat Pump, Biomass- Based and Conventional Gas Boiler. Res. Sq. 2022, 40, 503–513. [Google Scholar] [CrossRef]

- Sarralde, J.J.; Quinn, D.J.; Wiesmann, D.; Steemers, K. Solar energy and urban morphology: Scenarios for increasing the renewable energy potential of neighbourhoods in London. Renew. Energy 2015, 73, 10–17. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, Z.; Musharavati, F.; Ahmadi, P.; Rahimi, S.; Khanmohammadi, S. Advanced exergy investigation of a combined cooling and power system with low-temperature geothermal heat as a prime mover for district cooling applications. Sustain. Energy Technol. Assess. 2022, 51, 101868. [Google Scholar] [CrossRef]

- Chaurasia, R.; Gairola, S.; Pal, Y. Technical, economic feasibility and sensitivity analysis of solar photovoltaic/battery energy storage off-grid integrated renewable energy system. Energy Storage 2021, 4, e283. [Google Scholar] [CrossRef]

- Ryland, M.; He, W. Domestic thermal energy storage applications: What parameters should they focus on? J. Energy Storage 2022, 60, 106685. [Google Scholar] [CrossRef]

- Momeni, M.; Fartaj, A. Numerical thermal performance analysis of a PCM-to-air and liquid heat exchanger implementing latent heat thermal energy storage. J. Energy Storage 2023, 58, 106363. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, H.; Ren, J.; Nevzat, A.; Xu, Q.; Nie, B.; Li, C.; Ding, Y. Carbide slag recycling to fabricate shape-stable phase change composites for thermal energy storage. J. Energy Storage 2023, 60, 106694. [Google Scholar] [CrossRef]

- Abd Majid, M.A.; Muhammad, M.; Hampo, C.C.; Akmar, A.B. Analysis of a Thermal Energy Storage Tank in a Large District Cooling System: A Case Study. Processes 2020, 8, 1158. [Google Scholar] [CrossRef]

- Pans, M.; Claudio, G.; Eames, P. Modelling of 4th generation district heating systems integrated with different thermal energy storage technologies—Methodology. Energy Convers. Manag. 2023, 276, 116545. [Google Scholar] [CrossRef]

- Yılmaz, M.; Erdoğan, A.K.; Özdemir, M. Experimental study on improving the performance of vapor compression cycle by using loop-type heat pipe. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 2023, 09544089221148328. [Google Scholar] [CrossRef]

- Al-Sayyab, A.K.S.; Mota-Babiloni, A.; Navarro-Esbrí, J. Performance evaluation of modified compound organic Rankine-vapour compression cycle with two cooling levels, heating, and power generation. Appl. Energy 2023, 334, 120651. [Google Scholar] [CrossRef]

- Zheng, N.; Zhang, H.; Duan, L.; Wang, Q.; Bischi, A.; Desideri, U. Techno-economic analysis of a novel solar-driven PEMEC-SOFC-based multi-generation system coupled parabolic trough photovoltaic thermal collector and thermal energy storage. Appl. Energy 2022, 331, 120400. [Google Scholar] [CrossRef]

- Lu, S.; Su, N.; Li, Y.; Liu, Y.; Wang, R. Suitability evaluation of cold sources in green buildings based on a field study. J. Build. Eng. 2020, 32, 101795. [Google Scholar] [CrossRef]

- Kadier, A.; Simayi, Y.; Logrono, W.; Kalil, M.S. The significance of key operational variables to the enhancement of hydrogen production in a single-chamber microbial electrolysis cell (MEC). Iran. J. Hydrog. Fuel Cell 2015, 2, 85–97. [Google Scholar] [CrossRef]

- Gang, W.; Augenbroe, G.; Wang, S.; Fan, C.; Xiao, F. An uncertainty-based design optimization method for district cooling systems. Energy 2016, 102, 516–527. [Google Scholar] [CrossRef]

- Ondeck, A.D.; Edgar, T.F.; Baldea, M. Optimal operation of a residential district-level combined photovoltaic/natural gas power and cooling system. Appl. Energy 2015, 156, 593–606. [Google Scholar] [CrossRef]

- Erdem, H.H.; Akkaya, A.V.; Dagdas, A.; Sevilgen, S.H.; Cetin, B.; Sahin, B.; Teke, I.; Gungor, C.; Atas, S.; Basak, M.Z. Renovating thermal power plant to trigeneration system for district heating/cooling: Evaluation of performance variation. Appl. Therm. Eng. 2015, 86, 35–42. [Google Scholar] [CrossRef]

- Ravelli, S.; Franchini, G.; Perdichizzi, A. Comparison of different CSP technologies for combined power and cooling production. Renew. Energy 2018, 121, 712–721. [Google Scholar] [CrossRef]

- Gao, J.; Kang, J.; Zhang, C.; Gang, W. Energy performance and operation characteristics of distributed energy systems with district cooling systems in subtropical areas under different control strategies. Energy 2018, 153, 849–860. [Google Scholar] [CrossRef]

- Karlsson, V.; Nilsson, L. Co-production of pyrolysis oil and district cooling in biomass-based CHP plants: Utilizing sequential vapour condensation heat as driving force in an absorption cooling machine. Appl. Therm. Eng. 2015, 79, 9–16. [Google Scholar] [CrossRef]

- Perdichizzi, A.; Barigozzi, G.; Franchini, G.; Ravelli, S. Peak shaving strategy through a solar combined cooling and power system in remote hot climate areas. Appl. Energy 2015, 143, 154–163. [Google Scholar] [CrossRef]

| DCS Type | Benefits | Challenges | Reference |

|---|---|---|---|

| Centralized DCS | Improved air quality, high energy efficiency, reduced carbon footprint, and high initial investment. | Long-term maintenance costs and complex infrastructure. | [38] |

| Decentralized DCS | Flexibility to adapt to changing demand, lower initial investment, and lower maintenance costs. | Lower energy efficiency, higher energy consumption and costs, and limited cooling capacity. | [39] |

| Hybrid DCS | Combines the benefits of both centralized and decentralized systems and lowers energy consumption and costs. | Long-term maintenance costs and complex infrastructure. | [40] |

| Absorption chiller-based DCS | High energy efficiency, and reduced energy consumption and costs. | Dependence on waste heat or renewable energy sources and complex technology. | [41] |

| Chilled-water DCS | Reduced energy consumption and costs; reduced carbon footprint and high energy efficiency. | The high initial investment, complex infrastructure, and long-term maintenance costs. | [37] |

| Direct-expansion DCS | High energy efficiency, reduced energy consumption and costs, improved air quality, and minimized carbon footprint. | The high initial investment, complex infrastructure, and highly dependent on refrigerants and cooling fluids. | [42] |

| Renewable Energy Type | Economic | Environmental | Ref. |

|---|---|---|---|

| Biomass energy integration into DCS |

|

| [90,91] |

| Solar thermal energy integration into DCS |

|

| [70,82,92] |

| Geothermal energy integration into DCS |

|

| [93] |

| Solar photovoltaic integration into DCS |

|

| [94] |

| Surface water energy integration into DCS |

|

| [70] |

| Country | Energy Source/ Integration | Environmental Benefit | Economic Benefits | Reference |

|---|---|---|---|---|

| District cooling system | ||||

| Hong Kong | DCS powered by grid | Has no environmental gain | Lowere electricity consumption by the DCS especially for an ice storage system with 60% chiller priority. This in turn reduces the electricity tariff. | [102] |

| ✓ | ✓ | Approximately 80% of the annual operating cost of DCS with ice storage compared to DCS optimized using a conventional method. | [103] | |

| USA | ✓ | ✓ | In 2015, a sum of USD 421,434 was realized in one week (i.e., 1–7 July) as profit from the sales of electricity from the grid to cooling system stations and other heating sales. | [104] |

| Turkey | DCS powered by grid using coal-fired power plants | Lower emissions (not quantified) | No economic benefit was recorded. | [105] |

| Kuwait | DCS powered by grid using Natural gas | There is a 50% annual reduction in CO2 emissions | The relative cost per ton-hour for cooling was reduced by approximately 53%. | [9] |

| District cooling system using renewable energy | ||||

| Saudi Arabia | DCS powered by solar system integration |

|

| [106] |

| ✓ | CO2 emissions are reduced by an average of 500 tons (i.e., 70%) and 1400 tons per year relative to DCS with a centralized electrical compression chiller cooling plant |

| [36] | |

| Singapore | DCS powered by PV electric system integration | CO2 emissions would be reduced by an average of 19.7% from 2020 to 2050 | An estimate of three hudred and thirty million dollars, was earmarked for DC grid investment of the Singapore 2050 energy system, which is projected to save by up to 32.7% energy. | [107] |

| Sweden | DCS powered by biomass | Zero CO2 emissions | Not reported. | [108] |

| Dubai | DCS powered by solar system integration | Not reported | Non-quantified economic savings associated with reduced electricity consumption, reduced peak demand charges and reduced CC investment costs. | [109] |

| District cooling system using vapor compressor cooling/thermal energy storage | ||||

| Malaysia | DCS integrated by TES/VCC | Lowest CO2 emissions, reduced by approximately 40% as recorded by TES | Approximately 40% savings. | [20] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Nini, A.; Ya, H.H.; Al-Mahbashi, N.; Hussin, H. A Review on Green Cooling: Exploring the Benefits of Sustainable Energy-Powered District Cooling with Thermal Energy Storage. Sustainability 2023, 15, 5433. https://doi.org/10.3390/su15065433

Al-Nini A, Ya HH, Al-Mahbashi N, Hussin H. A Review on Green Cooling: Exploring the Benefits of Sustainable Energy-Powered District Cooling with Thermal Energy Storage. Sustainability. 2023; 15(6):5433. https://doi.org/10.3390/su15065433

Chicago/Turabian StyleAl-Nini, Ahmed, Hamdan Haji Ya, Najib Al-Mahbashi, and Hilmi Hussin. 2023. "A Review on Green Cooling: Exploring the Benefits of Sustainable Energy-Powered District Cooling with Thermal Energy Storage" Sustainability 15, no. 6: 5433. https://doi.org/10.3390/su15065433