Indicators as a Foundation of Eco-Labelling of Baked Clay Construction Products in the Republic of Serbia

Abstract

1. Introduction

2. Materials and Methods

2.1. Creating a Set of Indicators That Connect the Manufacture of Baked Clay Construction Products and the Environment

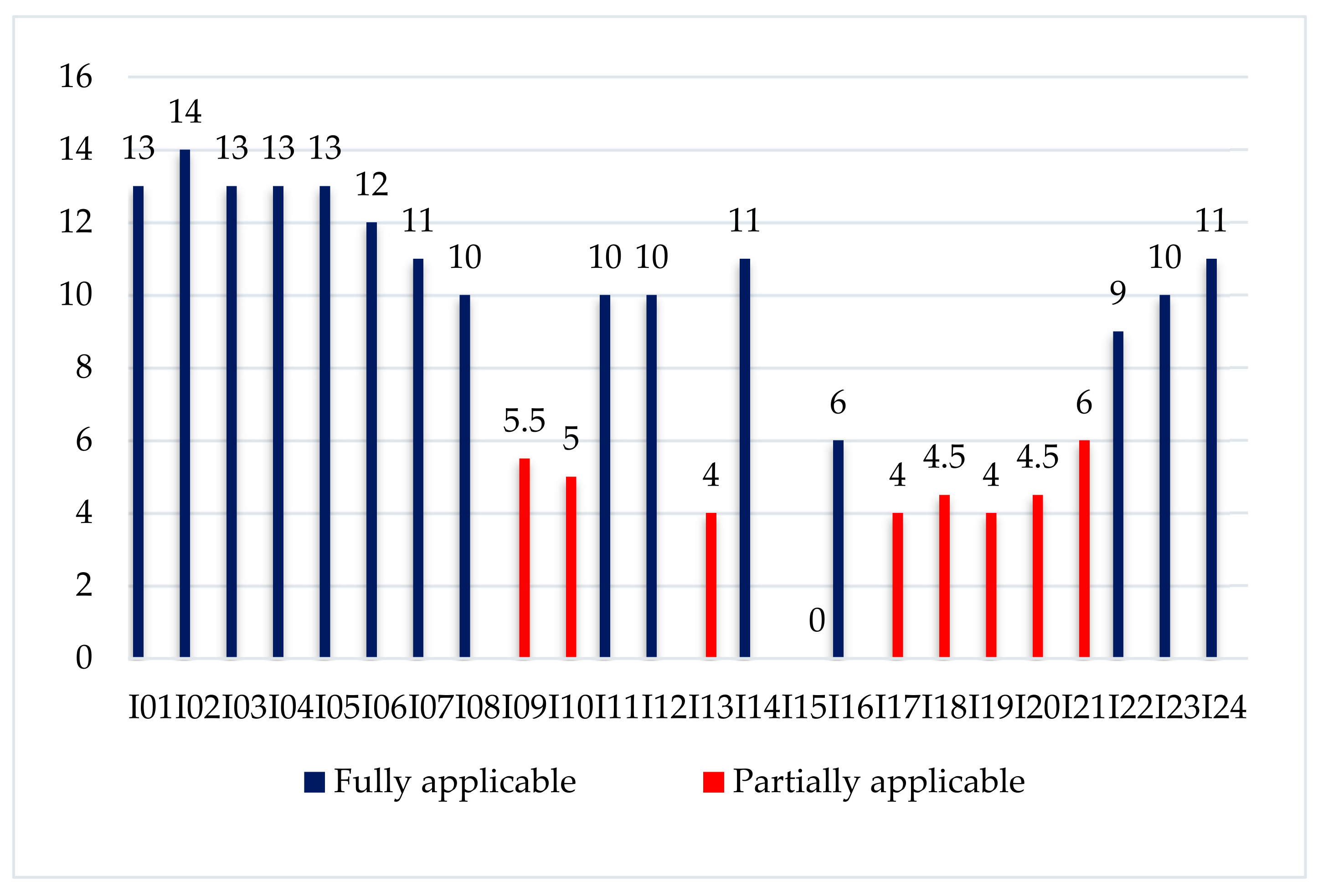

2.2. Indicator Priority

2.3. Evaluation of Indicators

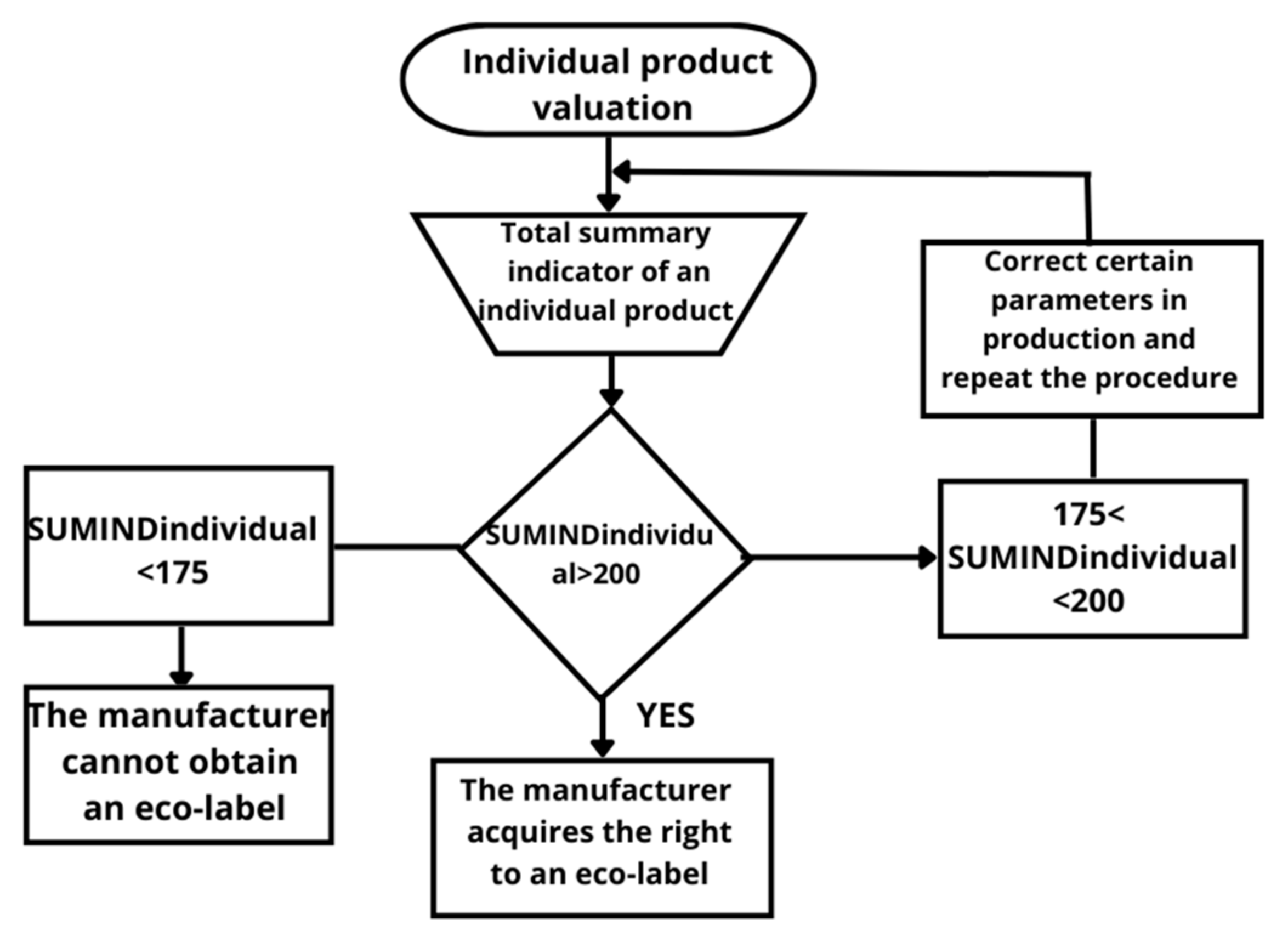

2.4. Criteria for Eco-Labelling

- YES (100%), completely applicable indicator—maximum value of the referent indicator,

- Partially applicable indicator—an estimated value is 50% of the value of the referent indicator and

- NO (0%), the indicator cannot be applied—the indicator value is 0.

- If the value of SUMINDindividual is more than 80% of the value of SUMIND, i.e., is more than 200 points, the manufacturer acquires the right to eco-label their products.

- If the value of SUMINDindividual is within the range of 70% to 80% of the value of SUMIND, i.e., if 175 < SUMINDindividual < 200 points, the manufacturer has a possibility to acquire the right to eco-label their products provided they make certain corrections to the production process.

- If the value of SUMINDindividual is lower than 70% of the value of SUMIND, i.e., is less than 175 points, the manufacturer cannot acquire the right to eco-label their products.

3. Results

- the leading manufacturer from Northern Serbia meets the criteria for an eco-label because SUMINDindividual = 203.5 which is higher than the referent 200 points,

- the leading manufacturer from Western Serbia has SUMINDindividual = 183 (it falls within the range 175 < SUMINDindividual < 200 points) and can meet the requirements for an eco-label provided it makes certain corrections, and that

- the leading manufacturer from Southern Pomoravlje has SUMINDindividual = 136, which is less than the lowest referent value, i.e., less than 175 points, so it does not meet the requirements for an eco-label without significant corrections.

4. Discussion

5. Conclusions

- the manufacturer meets the requirement for obtaining an eco-label,

- the manufacturer can gain the right to an eco-label provided they introduce certain corrections to their production process, and

- the manufacturer does not meet the requirements for an eco-label.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lozano-Miralles, J.A.; Hermoso-Orzáez, M.J.; Martínez-García, C.; Rojas-Sola, J.I. Comparative Study on the Environmental Impact of Traditional Clay Bricks Mixed with Organic Waste Using Life Cycle Analysis. Sustainability 2018, 10, 2917. [Google Scholar] [CrossRef]

- Omer, M.A.; Noguchi, T. A conceptual framework for understanding the contribution of building materials in the achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 2020, 52, 101869. [Google Scholar] [CrossRef]

- López-Aguilar, H.A.; Huerta-Reynoso, E.A.; Gómez, J.A.; Duarte-Moller, J.A.; Pérez-Hernández, A. Life cycle assessment of a traditional brick manufacture improvement. Rev. Int. Contam. Ambient. 2019, 35, 195–206. [Google Scholar] [CrossRef]

- Almusaed, A.; Almssad, A.; Homod, R.Z.; Yitmen, I. Environmental Profile on Building Material Passports for Hot Climates. Sustainability 2020, 12, 3720. [Google Scholar] [CrossRef]

- Hong, Z.; Wang, H.; Gong, Y. Green product design considering functional-product reference. Int. J. Prod. Econ. 2019, 210, 155–168. [Google Scholar] [CrossRef]

- Vasiljević, D.; Petrović, D. Izveštaj o Sprovedenoj Ex Ante Analizi Efekata za Oblast Cirkularne Ekonomije. Publisher: Republic of Serbia, Ministry of European Integration 2021. Available online: https://www.ekologija.gov.rs/sites/default/files/2021-01/exante-analiza_efekata-za-oblast-cirkularne-ekonomije.pdf (accessed on 6 February 2023).

- Adi, T.J.W.; Wibowo, P. Application of circular economy in the Indonesia construction industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 849, 012049. [Google Scholar]

- Riskos, K.; Dekoulou, P.; Mylonas, N.; Tsourvakas, G. Ecolabels and the Attitude–Behavior Relationship towards Green Product Purchase: A Multiple Mediation Model. Sustainability 2021, 13, 6867. [Google Scholar] [CrossRef]

- Amani, N.; Hosseini, S. Effective factors on ECO labeling building-construction, materials and components. Adv. Mater. Res. 2011, 374–377, 1254–1257. [Google Scholar] [CrossRef]

- Du Plessis, C. Agenda 21 for Sustainable Construction in Developing Countries: First Discussion Document. CIB CSIRBoutek. 2002. Available online: https://www.academia.edu/19056415/Agenda_21_for_Sustainable_Construction_in_Developing_Countries (accessed on 6 February 2023).

- Amiri, A.; Ottelin, J.; Sorvari, J.; Junnila, S. Economic and Technical Considerations in Pursuing Green Building Certification: A Case Study from Iran. Sustainability 2020, 12, 719. [Google Scholar] [CrossRef]

- Blengini, G.A.; Shields, D.J. Green labels and Sustainability Reporting. Manag. Environ. Qual. Int. J. 2010, 21, 477–493. [Google Scholar] [CrossRef]

- Meex, E.; Hollberg, A.; Knapen, E.; Hildebrand, L.; Verbeeck, G. Requirements for applying LCA-based environmental impact assessment tools in the early stages of building design. Build. Environ. 2018, 133, 228–236. [Google Scholar] [CrossRef]

- Gazulla Santos, C. Using life cycle assessment (LCA) methodology to develop eco-labels for construction and building materials. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Sawston, UK, 2014; pp. 84–97. [Google Scholar] [CrossRef]

- Papadaki, D.; Nikolaou, D.A.; Assimakopoulos, M.N. Circular Environmental Impact of Recycled Building Materials and Residential Renewable Energy. Sustainability 2022, 14, 4039. [Google Scholar] [CrossRef]

- Ding, G.K.C. Lifecycle Assessment of Building Materials—A Cradle-to-Gate Approach. Encycl. Renew. Sustain. Mater. 2020, 4, 476–488. [Google Scholar] [CrossRef]

- CerameUnie. TBE PCR for Clay Construction Products—Guidance Document for Developing an EPD. Published by Tiles & Bricks Europe. 2014. Available online: https://www.cerameunie.eu/media/1589/14-10-10-tbe-pcr-guidance-document.pdf (accessed on 15 December 2022).

- Zaborova, D.; Musorina, T. Environmental and Energy-Efficiency Considerations for Selecting Building Envelopes. Sustainability 2022, 14, 5914. [Google Scholar] [CrossRef]

- Zhang, J.; Srinivasan, R.; Peng, C. Ecological assessment of clay brick manufacturing in China using emergy analysis. Buildings 2020, 10, 190. [Google Scholar] [CrossRef]

- Pravilnik o Bližim Uslovima, Kriterijumima i Postupku za Dobijanje Prava na Korišćenje Ekološkog Znaka, Elemenata, Izgledu i načinu Upotrebe Ekološkog Znaka za Proizvode i Usluge (“Sl, Glasnik RS” 49/2016). Available online: https://www.paragraf.rs/propisi.html (accessed on 15 January 2023).

- European Environment Agency. Environmental Indicators. EEA Glossary. Available online: https://www.eea.europa.eu/help/glossary/eea-glossary (accessed on 28 January 2023).

- Stein, A.; Riley, J.; Halberg, N. Issues of scale for environmental indicators. Agric. Ecosyst. Environ. 2001, 87, 215–232. [Google Scholar] [CrossRef]

- Persson, J.G. Eco-indicators in product development. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 627–635. [Google Scholar] [CrossRef]

- Labianca, C.; De Gisi, S.; Todaro, F.; Notarnicola, M. DPSIR Model Applied to the Remediation of Contaminated Sites. A Case Study: Mar Piccolo of Taranto. Appl. Sci. 2020, 10, 5080. [Google Scholar] [CrossRef]

- Swarnakar, V.; Singh, A.R.; Antony, J.; Jayaraman, R.; Tiwari, A.K.; Rathi, R.; Cudney, E. Prioritizing Indicators for Sustainability Assessment in Manufacturing Process: An Integrated Approach. Sustainability 2022, 14, 3264. [Google Scholar] [CrossRef]

- The Clay Brick Association of Southern Africa. 2017 Annual Sustainability Report. Available online: https://www.claybrick.org.za/cba-2017-sustainability-report (accessed on 15 December 2022).

- Seinfeld, J.H.; Pandis, S.N. Atmospheric Chemistry and Physics—From Air Pollution to Climate Change; John Wiley and Sons Inc.: Hoboken, NJ, USA, 1998. [Google Scholar]

- Zuskin, E.; Mustajbegovic, J.; Schachter, E.N.; Kern, J.; Doko-Jelinic, J.; Godnic-Cvar, J. Respiratory findings in workers employed in the brick-manufacturing industry. J. Occup. Environ. Med. 1998, 40, 814–820. [Google Scholar] [CrossRef]

- Maynard, R.L.; Waller, R. Carbon monoxide. In Air Pollution and Health; Academic Press: Cambridge, MA, USA, 1999; pp. 749–796. [Google Scholar] [CrossRef]

- Koskela, R.S.; Mutanen, P.; Sorsa, J.A.; Klockars, M. Respiratory disease and cardiovascular morbidity. Occup. Environ. Med. 2005, 62, 650–655. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.K.; Dudani, I. Environmental health effects of brick kilns in Kathmandu valley. Kathmandu Univ. Med. J. 2008, 6, 3–11. Available online: http://www.kumj.com.np/issue/21/3-11.pdf (accessed on 6 February 2023).

- Facade Bricks. Available online: https://www.zorka-opeka.rs/proizvodi/fasadna-opeka-proizvodi (accessed on 13 March 2023).

- Standard Blocks. Available online: https://mladost.co.rs/sr/products/giter-5/ (accessed on 13 March 2023).

- Porotherm Brick (Energy+). Available online: https://www.wienerberger.rs/proizvodi/zid/Porotherm-opeka.html?2079_f_propertyfilter_2036839649=EPL (accessed on 13 March 2023).

- Stevanović Čarapina, H. Zagađenje Vazduha i Urbano Stanovništvo–Metodološki Pristup Uspostavljanju Uzročno-Posledičnih veza. Doctoral Dissertation, Faculty of Environmental Protection, University of Educons, Sremska Kamenica, Serbia, 2011. [Google Scholar]

- Radojević, Z.; Arsenović, M.; Vasić, M. Ocena kvaliteta opekarskih sirovina sa juga Srbije. Izgradnja 2008, 62, 157–161. Available online: https://rims.institutims.rs/handle/123456789/72 (accessed on 31 January 2023).

- Arsenović, M.V.; Pezo, L.L.; Radojević, Z.M.; Stanković, S.M. Opekarske gline iz Srbije—Primena u proizvodnji grube keramike. Hem. Ind. 2013, 67, 811–822. [Google Scholar] [CrossRef]

- Arsenović, M.; Pezo, L.; Mančić, L.; Radojević, Z. Thermal and mineralogical characterization of loess heavy clays for potential use in brick industry. Thermochim. Acta 2014, 580, 38–45. [Google Scholar] [CrossRef]

- Radosavljević, S.; Stojanović, J.; Radosavljević-Mihajlović, A.; Vuković, N.; Matijašević, S.; Stojanović, M.; Kašić, V. Ceramic clays from the western part of the Tamnava Tertiary Basin, Serbia: Deposits and clay types. Geološki Anal. Balk. Poluostrva 2014, 75, 75–83. [Google Scholar] [CrossRef]

- Filipović-Petrović, L.; Stanojević, D.; Antonijević-Nikolić, M.; Mijić, L. Mineraloška, fizičko-hemijska i keramička svojstva gline Brezaci. Zaštita Mater. 2018, 59, 39–44. [Google Scholar] [CrossRef]

| Label | Indicator Name | Indicator Interpretation | Category DPSIR |

|---|---|---|---|

| I01 | Technological characteristics of the production process based on baked clay | Significant for forming a relationship between the production and the environment because it can be used to identify the consumption of raw materials and energy sources. | D |

| I02 | Technical characteristics of construction product—brick, block | Serves to estimate: object energy efficiency, sound isolation, compliance with EU guidelines and European product standards (CE). | D |

| I03 | Clay consumption | Useful for assessing the remaining amount of the non-renewable natural resource—brick clay—and for long-term production capacity planning. | P |

| I04 | Fresh water consumption | A measure of optimal exploitation of water in the production process. It can also indicate the problems related to water consumption. | P |

| I05 | Energy consumption | Indicates the consumption of energy in the production process and the assessment of non-renewable energy sources consumption. | P |

| I06 | Emissions of pollutants into the air | Used for tracking emissions released from the production line into air (checking whether the emissions fall within the range of emission limit values—ELV) | P |

| I07 | Emissions of pollutants into water | Refers to measuring and examining the quality of wastewater (checking the range of emission limit values—ELV, impact on recipient, data collection for register keeping) | P |

| I08 | Noise emissions | Refers to noise measurement in a closed space—an industrial facility, in accordance with corresponding legal regulations. | P |

| I09 | Air pollution | Used for measuring the quality of air in the area surrounding the production facility and for forecasting the air pollution prevention measures. | S |

| I10 | Water pollution | Used for quality rating of surface water in the recipient into which wastewater from the production facility is released and for forecasting the measures for surface water pollution prevention. | S |

| I11 | Impact on soil | Used for assessing: the surface of the soil which changes its purpose, the surface of degraded soil, disposed waste and spilled oil derivatives in the surface mining. | I |

| I12 | Process waste | Indicates the quantity of process waste and the quantity of waste materials used for secondary purposes. | P |

| I13 | Dust from waste gas purification devices | Used for estimating the quantity of dust resulting from waste gas purification and the quality of the purification. | P |

| I14 | Wastewater quality | Represents a measure of the pressure which the wastewater from the production process puts on the environment. | P |

| I15 | Sludge from water treatment plants | Enables the estimate of the quantity of sludge made during the purification of wastewater in the process and the assessment of economic profitability of its use for other purposes after additional processing. | P |

| I16 | Packaging waste | Used for the estimate of the quantity of packaging waste made during the packaging of finished products and the possibility of its recycling and reuse. | P |

| I17 | Industrial consumption index in the municipality | Indicates the environmental problems in the municipality created by the manufacturing of baked clay construction products, the taking of appropriate monitoring measures and financial investments into gas purification plants, wastewater treatment plants and waste treatment. | D/P |

| I18 | Greenhouse gases emission | Provides information on the trends concerning emissions from main anthropogenic sources of GHG in the industry of baked clay construction products. | P |

| I19 | Basic emergy indicators in clay brick production | Indicates the assessment of the share of renewable/non-renewable resources and the assessment of clay brick production sustainability taking into consideration the environment, services and economic factors. | I |

| I20 | Other emergy indicators in clay brick production | Serves for the assessment of emergy sustainability based on emergy degrees. | I |

| I21 | Potential incidence of disease due to emissions from brick kilns | Measures the incidence of human diseases caused by emissions from brick kilns. | I |

| I22 | Legislation | The need to define a legal framework in the industry of baked clay construction products so as to avoid negative impacts on the environment and to make the products environmentally acceptable. | R |

| I23 | Production of electricity by solar power plants | Indicates the possibility of producing electricity for personal needs by solar power plants and the reduction of carbon footprint on a global level. | R/I |

| I24 | Switch to BAT (best available technology) | Reflects a manufacturer’s willingness to switch to BAT. | R |

| Group | Description | Value |

|---|---|---|

| I | Data availability | |

| Not available | 0 | |

| Partially available | 1 | |

| Available | 2 | |

| II | Data quality | |

| No data on methodology | 0 | |

| There are quality data or methodology for data collection | 1 | |

| There are both data and methodology for data collection | 2 | |

| III | Significance for the production of baked clay construction products | |

| No significance | 1 | |

| Has some significance | 2 | |

| Useful | 3 | |

| Significantly useful | 4 | |

| Extremely useful | 5 | |

| IV | Significance for the environment | |

| No significance | 1 | |

| Has some significance | 2 | |

| Useful | 3 | |

| Significantly useful | 4 | |

| Extremely useful | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knežević, S.; Prokić, D. Indicators as a Foundation of Eco-Labelling of Baked Clay Construction Products in the Republic of Serbia. Sustainability 2023, 15, 5515. https://doi.org/10.3390/su15065515

Knežević S, Prokić D. Indicators as a Foundation of Eco-Labelling of Baked Clay Construction Products in the Republic of Serbia. Sustainability. 2023; 15(6):5515. https://doi.org/10.3390/su15065515

Chicago/Turabian StyleKnežević, Suzana, and Dunja Prokić. 2023. "Indicators as a Foundation of Eco-Labelling of Baked Clay Construction Products in the Republic of Serbia" Sustainability 15, no. 6: 5515. https://doi.org/10.3390/su15065515

APA StyleKnežević, S., & Prokić, D. (2023). Indicators as a Foundation of Eco-Labelling of Baked Clay Construction Products in the Republic of Serbia. Sustainability, 15(6), 5515. https://doi.org/10.3390/su15065515