A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic- Environmental and Social Sustainability

Abstract

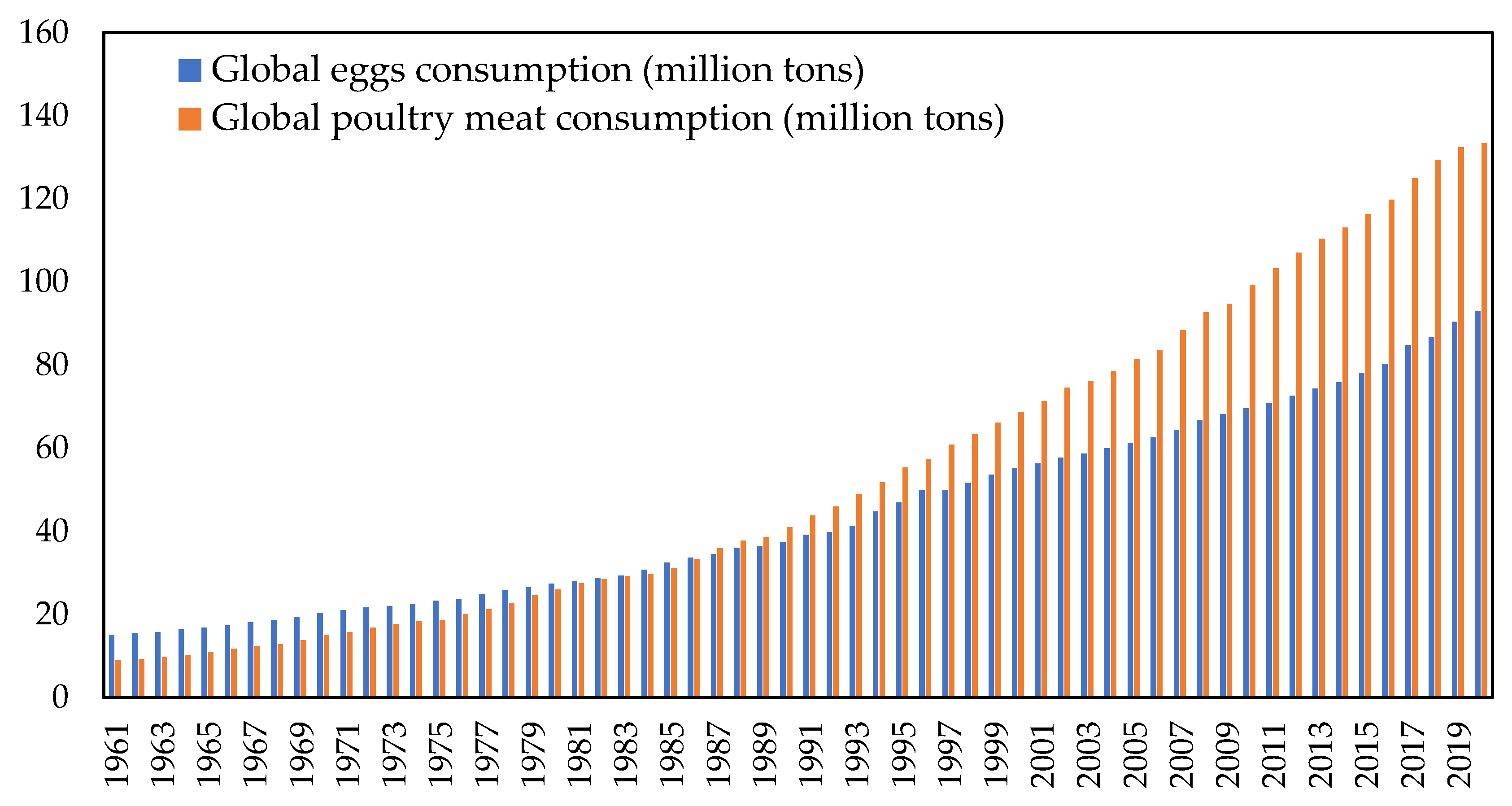

:1. Introduction

2. Waste Generation from the Poultry Industry

2.1. Poultry Litter and Manure Waste

2.2. Feather Waste

2.3. Mortality Waste

2.4. Abattoir Waste

2.5. Poultry Hatchery Waste

3. Modeling and Simulations of Poultry Waste Treatment Processes

4. Technological Progress of Poultry Waste-to-Wealth

4.1. Composting Treatment

4.2. Anaerobic Digestion

4.3. Pyrolysis

4.4. Gasification

4.5. Hydrolysis

4.6. Enzymatic Treatment

4.7. Bioconversion

5. Impacts of Poultry Waste-to-Wealth

5.1. Economic Benefits

5.2. Environmental Benefits

5.3. Social Benefits

6. Conclusions

- Waste generation from the poultry industry is varied and occurs in huge amounts. Presently, waste generated from poultry production includes litter and manure waste, feather waste, mortality waste, and abattoir waste, which can be widely used in various industries and converted into multiple value-added by-products with great potential.

- Modeling and simulations of waste treatment processes serve as convenient tools for exploring the feasibility of converting poultry waste to value-added products. By using simulation software such as Aspen Plus and ECLIPSE, poultry waste treatment processes can be simulated, and the economic and environmental effects can be calculated, evaluated, and compared.

- A variety of technological processes are available for converting poultry waste to wealth. Due to the various categories and the resourceful nutrients and materials contained in poultry waste, different processes can be applied for the production of different value-added by-products. Usually, six main technological options are available for poultry waste valorization: anaerobic digestion, pyrolysis, gasification, hydrolysis, enzymatic treatment, and microbial conversion.

- Great economic, environmental, and social benefits can be derived from the conversion of poultry waste to wealth. From an economic perspective, poultry waste can be utilized for organic fertilizer production, energy recovery, animal feed production, and even for materials used in industrial production, environmental remediation, etc. From the environmental perspective, poultry waste-to-wealth can help reduce emissions of greenhouse gases, prevent environmental pollution, absorb pollutants and heavy metal ions, and repair the ecological environment. In terms of social benefits, these include the reduction of infectious diseases, the improvement of air quality, and the creation of job opportunities.

7. Recommendations for Further Research

- Presently, research on poultry waste-to-wealth is mostly conducted based on theoretical calculations, computer-based modeling, and simulations, which have proven the technical-economic feasibility and the environmental effects. Further studies can be conducted based on poultry waste-to-wealth projects in different regions to compare their differences and verify the proposed systems or models.

- To investigate the performance of the laboratory-scale experiments of different poultry waste-to-wealth processes, a lot of process simulations have been designed and presented. However, the actual operation of poultry waste-to-wealth projects can also be affected by many social-political factors as a lot of stakeholders are involved, such as investors, governments, poultry farmers and slaughterhouses, local residents, consumers of by-products, and even the individuals involved in third-party logistics. Thus, the behavior strategy of different stakeholders and the interactions between them should also be considered and simulated in further studies.

- As different processes may bring different economic benefits, the initial investment cost of plant establishment has contributed the largest share to total costs. It is suggested to build one centralized biorefinery or plant with a larger capacity rather than building multiple smaller biorefineries. In addition, poultry wastes can be utilized with other wastes, such as municipal solid waste, sewerage sludge, animal and human excreta, and even agricultural residues, to generate better economic performance.

- Present studies focus on process simulations and laboratory-scale experiments, and there is still a long way before poultry waste-to-wealth can be commercialized and marketized. Therefore, policymakers need to formulate detailed and forward-looking plans to motivate the industrialized development of poultry waste-to-wealth. In addition, more favorable policies and incentives are required to attract the attention and participation of investors, poultry farmers and slaughterhouses, and by-product consumers.

- As one of the sectors of broad agriculture, poultry production has generated numerous solid wastes. From the perspective of circular economy, the waste generated from agriculture should be reused for agricultural production at the very beginning, followed by other sectors. Thus, it is suggested to use poultry waste to produce organic fertilizer or soil amendment with priority.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davies, J. World’s Egg Production Grows 25% in 10 Years. Available online: https://poultry.network/3874-global-egg-consumption-on-the-up/ (accessed on 10 October 2022).

- Agblevor, F.A.; Beis, S.; Kim, S.; Tarrant, R.; Mante, N. Biocrude oils from the fast pyrolysis of poultry litter and hardwood. Waste Manag. 2010, 30, 298–307. [Google Scholar] [CrossRef] [PubMed]

- Dalólio, F.S.; da Silva, J.N.; de Oliveira, A.C.C.; Tinôco, I.d.F.F.; Barbosa, R.C.; de Oliveira Resende, M.; Albino, L.F.T.; Coelho, S.T. Poultry litter as biomass energy: A review and future perspectives. Renew. Sustain. Energy Rev. 2017, 76, 941–949. [Google Scholar] [CrossRef]

- Steinfeld, H.; Gerber, P.; Wassenaar, T.; Castel, V.; Rosales, M.; De Haan, C. Livestock’s Long Shadow: Environmental Issues and Options; Food and Agriculture Organization of the United Nations: Rome, Italy, 2006. [Google Scholar]

- Mustafa, E.A.; Hamad, E.M.; Elhassan, M.M.O.; Salman, A.M.A.; Elsiddig, M.M.E.; Lamyia, M.A. Disposal of dead birds and manure in poultry farms under different production and management systems in Khartoum State, Sudan. World J. Pharm. Pharm. Sci. 2018, 7, 61–70. [Google Scholar]

- Thyagarajan, D.; Barathi, M.; Sakthivadivu, R. Scope of poultry waste utilization. IOSR J. Agric. Vet. Sci. 2013, 6, 29–35. [Google Scholar]

- Brandelli, A.; Sala, L.; Kalil, S.J. Microbial enzymes for bioconversion of poultry waste into added-value products. Food Res. Int. 2015, 73, 3–12. [Google Scholar] [CrossRef] [Green Version]

- Herrero, M.; Henderson, B.; Havlík, P.; Thornton, P.K.; Conant, R.T.; Smith, P.; Wirsenius, S.; Hristov, A.N.; Gerber, P.; Gill, M.; et al. Greenhouse gas mitigation potentials in the livestock sector. 6, 452–461. Nat. Clim. Change 2016, 6, 452–461. [Google Scholar] [CrossRef] [Green Version]

- Huang, R.-J.; Zhang, Y.; Bozzetti, C.; Ho, K.-F.; Cao, J.-J.; Han, Y.; Daellenbach, K.R.; Slowik, J.G.; Platt, S.M.; Canonaco, F.; et al. High secondary aerosol contribution to particulate pollution during haze events in China. Nature 2014, 514, 218–222. [Google Scholar] [CrossRef] [Green Version]

- Karuppannan, S.K.; Dowlath, M.J.H.; Raiyaan, G.I.D.; Rajadesingu, S.; Arunachalam, K.D. Application of poultry industrywaste in producing value-addedproducts—A review. In Concepts of Advanced Zero Waste Tools: Present and Emerging Waste Management Practices; Hussain, C.M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 91–121. [Google Scholar]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of concrete with recycled aggregates: A circular economy mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Petrillo, A.; Colangelo, F.; Farina, I.; Travaglioni, M.; Salzano, C.; Cioffi, R. Multi-criteria analysis for Life Cycle Assessment and Life Cycle Costing of lightweight artificial aggregates from industrial waste by double-step cold bonding palletization. J. Clean. Prod. 2022, 351, 131395. [Google Scholar] [CrossRef]

- Our World in Data. Global Meat Consumption, World, 1961 to 2050. Available online: https://ourworldindata.org/grapher/global-meat-projections-to-2050 (accessed on 13 February 2023).

- Our World in Data. Meat Production by Livestock Type, World, 1961 to 2020. Available online: https://ourworldindata.org/grapher/global-meat-production-by-livestock-type (accessed on 13 February 2023).

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Ma, Q.; Paudel, K.P.; Bhandari, D.; Theegala, C.; Cisneros, M. Implications of poultry litter usage for electricity production. Waste Manag. 2019, 95, 493–503. [Google Scholar] [CrossRef]

- Edwards, D.R.; Daniel, T.C. Environmental impacts of on-farm poultry waste disposal—A review. Bioresour. Technol. 1992, 41, 9–33. [Google Scholar] [CrossRef]

- Bolan, N.S.; Szogi, A.A.; Chuasavathi, T.; Seshadri, B.; Rothrock, M.J., Jr.; Panneerselvam, P. Uses and management of poultry litter. Worlds Poult. Sci. J. 2010, 66, 673–698. [Google Scholar] [CrossRef] [Green Version]

- Żołnowski, A.C.; Bakuła, T.; Rolka, E.; Klasa, A. Effect of Mineral–Microbial Deodorizing Preparation on the Value of Poultry Manure as Soil Amendment. Int. J. Environ. Res. Public Health 2022, 19, 16639. [Google Scholar] [CrossRef] [PubMed]

- BlumI, L.E.B.; do AmaranteII, C.V.T.; GüttlerII, G.; de MacedoII, A.F.; KotheII, D.M.; SimmlerII, A.O.; do PradoII, G.; Guimarães, L.S. Produção de moranga e pepino em solo com incorporação de cama aviária e casca de pinus. Hortic. Bras. 2003, 21, 627–631. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Zhang, P.; Zhang, W.; Tian, Y.; Zheng, Y.; Wang, L. Quantitative appraisal and potential analysis for primary biomass resources for energy utilization in China. Renew. Sustain. Energy Rev. 2010, 14, 3050–3058. [Google Scholar]

- Sinkiewicz, I.; Śliwińska, A.; Staroszczyk, H.; Kołodziejska, I. Alternative methods of preparation of soluble keratin from chicken feathers. Waste Biomass Valorization 2016, 8, 1043–1048. [Google Scholar] [CrossRef]

- Gurav, R.G.; Mirajkar, D.B.; Savardekar, A.V.; Pisal, S.M. Microbial degradation of poultry feather biomass by Klebsiella sp. BTSUK isolated from poultry waste disposal site. Res. J. Life Sci. Bioinform. Pharm. Chem. Sci. 2016, 1, 279. [Google Scholar]

- Zhao, W.; Yang, R.; Zhang, Y.; Wu, L. Sustainable and practical utilization of feather keratin by an innovative physicochemical pretreatment: High density steam flash-explosion. Green Chem. 2012, 14, 3352–3360. [Google Scholar] [CrossRef]

- Bhari, R.; Kaur, M.; Singh, R.S.; Pandey, A.; Larroche, C. Bioconversion of chicken feathers by Bacillus aerius NSMk2: A potential approach in poultry waste management. Bioresour. Technol. Rep. 2018, 3, 224–230. [Google Scholar] [CrossRef]

- Agrahari, S.; Wadhwa, N. Degradation of chicken feather a poultry waste product by keratinolytic bacteria isolated from dumping site at Ghazipur poultry processing plant. Int. J. Poult. Sci. 2010, 9, 482–489. [Google Scholar] [CrossRef] [Green Version]

- Mazotto, A.M.; Coelho, R.R.R.; Cedrola, S.M.L.; de Lima, M.F.; Couri, S.; de Souza, E.P.; Vermelho, A.B. Keratinase production by three Bacillus sp. using feather meal and whole feather as substrate in a submerged fermentation. Enzym. Res. 2011, 11, 723–780. [Google Scholar]

- Delgado, C.L.; Narrod, C.A.; Tiongco, M.M. Policy, Technical, and Environmental Determinants and Implications of the Scaling-Up of Livestock Production in Four Fast-Growing Developing Countries: A Synthesis; Food and Agriculture Organization: Rome, Italy, 2003. [Google Scholar]

- Akanni, K.A.; Benson, O.B. Poultry wastes management strategies and environmental implications on human health in Ogun States of Nigeira. Adv. Econ. Bus. 2014, 2, 164–171. [Google Scholar]

- Akdeniz, N. A systematic review of biochar use in animal waste composting. Waste Manag. 2019, 88, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Gündüz, S.; Aslanova, F.; Abdullah, K.S.H. Poultry waste management techniques in urban agriculture and its implications: A case study of Tripoli, Libya. Ekoloji 2019, 28, 4077–4084. [Google Scholar]

- Yemane, N.; Tamir, B.; Mengistu, A. Poultry waste management practices under small scale intensive urban poultry production in Addis Ababa, Ethiopia. Acad. J. Agric. Res. 2016, 4, 212–217. [Google Scholar]

- Modak, M.; Chowdhury, E.H.; Rahman, M.S.; Sattar, M.N. Waste management practices and profitability analysis of poultry farming in Mymensingh district: A socioeconomic study. J. Bangladesh Agric. Univ. 2019, 17, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Paraso, M.G.V.; Espaldon, M.V.O.; Alcantara, A.J.; Sevilla, C.C.; Alaira, S.A.; Sobremisana, M.J.; Ravalo, R.O.; Macan, K.R.D.; Valdez, C.A. A Survey of waste management practices of selected swine and poultry farms in Laguna, Philippines. J. Environ. Sci. Manag. 2010, 13, 44–52. [Google Scholar]

- Sowmiya, V.; Bhanu, R.V.; Ajay kumar, V.J.; Rajalakshmi, M.; Sivachandiran, R. Poultry farming and food security in Puducherry: Study on problems and prospects. Pharma Innov. J. 2020, 9, 291–294. [Google Scholar]

- Moreki, J.C.; Chiripasi, S.C. Poultry waste management in Botswana: A Review. Online J. Anim. Feed Res. 2011, 1, 285–292. [Google Scholar]

- Balogun, O.L.; Ayo-Bello, T.A.; Afodu, O.J.; Akinwole, O.T.; Ndubuisi-Ogbonna, L.C. Determinants of waste management techniques among the poultry farmers in Ikenne Local Government Area of Ogun State, Nigeria. Int. J. Livest. Res. 2017, 7, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Oluremi, A.; Jemimah, Q. Management of waste by-products in medium-scale commercial poultry facilities in Peri-Urban Ibadan, Nigeria. Russ. J. Agric. Socio-Econ. Sci. 2016, 5, 103–107. [Google Scholar] [CrossRef]

- Geidam, Y.A.; Gambo, H.I.; Adamu, S.B.; Grema, H.A.; Dapchi, A.M.; Sanda, K.A. An assessment of the biosecurity measures in poultry farms in Borno and Yobe States. Sahel J. Vet. Sci. 2011, 10, 83–86. [Google Scholar]

- Ferreira, A.; Kunh, S.S.; Cremonez, P.A.; Dieter, J.; Teleken, J.G.; Sampaio, S.C.; Kunh, P.D. Brazilian poultry activity waste: Destinations and energetic potential. Renew. Sustain. Energy Rev. 2018, 81, 3081–3089. [Google Scholar] [CrossRef]

- Muduli, S.; Champati, A.; Popalghat, H.K.; Patel, P.; Sneha, K.R. Poultry waste management: An approach for sustainable development. Int. J. Adv. Sci. Res. 2019, 4, 8–14. [Google Scholar]

- Alam, M.U.; Rahman, M.; Masud, A.A.; Islam, M.A.; Asaduzzaman, M.; Sarker, S.; Rousham, E.; Unicomb, L. Human exposure to antimicrobial resistance from poultry production: Assessing hygiene and waste-disposal practices in Bangladesh. Int. J. Hyg. Environ. Health 2019, 222, 1068–1076. [Google Scholar] [CrossRef]

- Nicholson, F.A.; Groves, S.J.; Chambers, B.J. Pathogen survival during livestock manure storage and following land application. Bioresour. Technol. 2005, 96, 135–143. [Google Scholar] [CrossRef]

- Salminen, E.; Rintala, J. Anaerobic digestion of organic solid poultry slaughterhouse waste—A review. Bioresour. Technol. 2002, 83, 13–26. [Google Scholar] [CrossRef]

- Nogalska, A.; Załuszniewska, A. The Effect of Meat and Bone Meal (MBM) on Crop Yields, Nitrogen Content and Uptake, and Soil Mineral Nitrogen Balance. Agronomy 2021, 11, 2307. [Google Scholar] [CrossRef]

- Nogalska, A.; Krzebietke, S.J.; Zalewska, M.; Nogalski, Z. The effect of meat and bone meal (MBM) on the nitrogen and phos-phorus content and pH of soil. Agric. Food Sci. 2017, 26, 181–187. [Google Scholar] [CrossRef]

- Osibanjo, O.; Adie, G.U. Impact of effluent from Bodija abattoir on the physicochemical parameters of Oshunkaye stream in Ibadan City, Nigeria. Afr. J. Biotechnol. 2007, 6, 1806–1811. [Google Scholar] [CrossRef] [Green Version]

- Kannadhasan, M.S.; Lawrence, C.; Kumar, V.R.S. Study on disposal of broiler slaughter waste implying eco-friendly waste management. Int. J. Environ. Sci. Technol. 2016, 6, 1918–1924. [Google Scholar]

- Bellaver, C.; Zanotto, D.L. Parâmetros de Qualidade em Gorduras e Subprodutos Protéicos de Origem Animal. In Proceedings of the Conferência APINCO, Santos, Brazil, 4–7 May 2004. [Google Scholar]

- Glatz, P.; Miao, Z.; Rodda, B. Handling and treatment of poultry hatchery waste: A review. Sustainability 2011, 3, 216–237. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; You, F. Superstructure optimization of thermal conversion based poultry litter valorization process. J. Clean. Prod. 2019, 228, 1111–1121. [Google Scholar] [CrossRef]

- Huang, Y.; Anderson, M.; McIlveen-Wright, D.; Lyons, G.; McRoberts, W.; Wang, Y.; Roskilly, A.; Hewitt, N. Biochar and renewable energy generation from poultry litter waste: A technical and economic analysis based on computational simulations. Appl. Energy 2015, 160, 656–663. [Google Scholar] [CrossRef]

- Topal, H.; Taner, T.; Altinsoy, Y.; Amirabedin, E. Application of trigeneration with direct co-combustion of poultry waste and coal: A case study in the poultry industry from Turkey. Therm. Sci. 2018, 22 Pt B, 3073–3082. [Google Scholar] [CrossRef] [Green Version]

- Ayub, Y.; Tao, S.; Ren, J.; Lee, C.K.; He, C.; Manzardo, A. Poultry litter valorization by application of hydrothermal gasification: Process simulation, Economic, Energic, and Environmental analysis. Int. J. Energy Res. 2022, 46, 23095–23109. [Google Scholar] [CrossRef]

- Isemin, R.; Marias, F.; Muratova, N.; Kuzmin, S.; Klimov, D.; Mikhalev, A.; Milovanov, O.; Brulé, M.; Tabet, F. Wet Torrefaction of Poultry Litter in a Pilot Unit: A Numerical Assessment of the Process Parameters. Processes 2021, 9, 1835. [Google Scholar] [CrossRef]

- Lima, I.M.; McAloon, A.; Boateng, A.A. Activated carbon from broiler litter: Process description and cost of production. Biomass Bioenergy 2008, 32, 568–572. [Google Scholar] [CrossRef]

- Ayub, Y.; Ren, J.; Shi, T.; Shen, W.; He, C. Poultry litter valorization: Development and optimization of an electro-chemical and thermal tri-generation process using an extreme gradient boosting algorithm. Energy 2023, 263, 125839. [Google Scholar] [CrossRef]

- Ma, K.; Shi, T.; Hu, Y.; Yang, S.; Shen, W.; He, C.; Liu, Y.; Liu, Z.; Ren, J. Poultry litter utilization for waste-to-wealth: Valorization process simulation and comparative analysis based on thermodynamic and techno-economic assessment. Energy Convers. Manag. 2022, 269, 116135. [Google Scholar] [CrossRef]

- Bora, R.R.; Tao, Y.; Lehmann, J.; Tester, J.W.; Richardson, R.E.; You, F. Techno-economic feasibility and spatial analysis of thermochemical conversion pathways for regional poultry waste valorization. ACS Sustain. Chem. Eng. 2020, 8, 5763–5775. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Ighalo, J.O.; Onifade, D.V.; Adeoye, S.A. Modeling the valorization of poultry litter via thermochemical processing. Biofuels Bioprod. Biorefin. 2020, 14, 242–248. [Google Scholar] [CrossRef]

- De Priall, O.; Brandoni, C.; Gogulancea, V.; Jaffar, M.; Hewitt, N.J.; Zhang, K.; Huang, Y. Gasification of Biowaste Based on Validated Computational Simulations: A Circular Economy Model to Handle Poultry Litter Waste. Waste Biomass Valorization 2022, 13, 3899–3911. [Google Scholar] [CrossRef]

- Fang, H.; Shi, Y.; Li, D.; Song, L.; Li, Y.-Y.; Liu, R.; Yuan, D.; Niu, Q. Synergistic co-digestion of waste commercial yeast and chicken manure: Kinetic simulation, DOM variation and microbial community assessment. Renew. Energy 2020, 162, 2272–2284. [Google Scholar] [CrossRef]

- Sillero, L.; Sganzerla, W.G.; Carneiro, T.F.; Solera, R.; Perez, M. Techno-economic analysis of single-stage and temperature-phase anaerobic co-digestion of sewage sludge, wine vinasse, and poultry manure. J. Environ. Manag. 2023, 325, 116419. [Google Scholar] [CrossRef]

- Gelegenis, J.; Georgakakis, D.; Angelidaki, I.; Christopoulou, N.; Goumenaki, M. Optimization of biogas production from olive-oil mill wastewater, by codigesting with diluted poultry-manure. Appl. Energy 2007, 84, 646–663. [Google Scholar] [CrossRef]

- Tańczuk, M.; Junga, R.; Werle, S.; Chabiński, M. Experimental analysis of the fixed bed gasification process of the mixtures of the chicken manure with biomass. Renew. Energy 2019, 136, 1055–1063. [Google Scholar] [CrossRef]

- Petric, I.; Šestan, A.; Šestan, I. Influence of initial moisture content on the composting of poultry manure with wheat straw. Biosyst. Eng. 2009, 104, 125–134. [Google Scholar] [CrossRef]

- Ramzan, N.; Ashraf, A.; Naveed, S.; Malik, A. Simulation of hybrid biomass gasification using Aspen plus: A comparative performance analysis for food, municipal solid and poultry waste. Biomass Bioenergy 2011, 35, 3962–3969. [Google Scholar] [CrossRef]

- Aklilu, E.G.; Waday, Y.A. Optimizing the process parameters to maximize biogas yield from anaerobic co-digestion of alkali-treated corn stover and poultry manure using artificial neural network and response surface methodology. Biomass Convers. Biorefin. 2021, 1–14. [Google Scholar] [CrossRef]

- Petric, I.; Helić, A.; Avdić, E.A. Evolution of process parameters and determination of kinetics for co-composting of organic fraction of municipal solid waste with poultry manure. Bioresour. Technol. 2012, 117, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Purnomo, C.W.; Indarti, S.; Wulandari, C.; Hinode, H.; Nakasaki, K. Slow release fertiliser production from poultry manure. Chem. Eng. Trans. 2017, 56, 1531–1536. [Google Scholar]

- Amenorfenyo, D.K.; Huang, X.; Li, C.; Li, F.; Zeng, Q.; Zhang, N.; Xie, L.; Wang, P. A review of microalgae and other treatment methods of distillery wastewater. Water Environ. J. 2020, 34, 988–1002. [Google Scholar] [CrossRef]

- Meiramkulova, K.; Devrishov, D.; Zhumagulov, M.; Arystanova, S.; Karagoishin, Z.; Marzanova, S.; Kydyrbekova, A.; Mkilima, T.; Li, J. Performance of an integrated membrane process with electrochemical pre-treatment on poultry slaughterhouse wastewater purification. Membranes 2020, 10, 256. [Google Scholar] [CrossRef] [PubMed]

- Zahan, Z.; Othman, M.Z. Effect of pre-treatment on sequential anaerobic co-digestion of chicken litter with agricultural and food wastes under semi-solid conditions and comparison with wet anaerobic digestion. Bioresour. Technol. 2019, 281, 286–295. [Google Scholar] [CrossRef]

- Kanani, F.; Heidari, M.D.; Gilroyed, B.H.; Pelletier, N. Waste valorization technology options for the egg and broiler industries: A review and recommendations. J. Clean. Prod. 2020, 262, 121129. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, M.; Han, B.; Impraim, R.; Butterly, C.; Hu, H.; He, J.; Chen, D. Enhanced nitrogen retention by lignite during poultry litter composting. J. Clean. Prod. 2020, 277, 122422. [Google Scholar] [CrossRef]

- Asses, N.; Farhat, W.; Hamdi, M.; Bouallagui, H. Large scale composting of poultry slaughterhouse processing waste: Microbial removal and agricultural biofertilizer application. Process Saf. Environ. Prot. 2019, 124, 128–136. [Google Scholar] [CrossRef]

- Lu, Q.; Xiao, Y. From manure to high-value fertilizer: The employment of microalgae as a nutrient carrier for sustainable agriculture. Algal Res. 2022, 67, 102855. [Google Scholar] [CrossRef]

- Wheatley, A.; Fisher, M.; Grobicki, A. Applications of anaerobic digestion for the treatment of industrial wastewaters in Europe. Water Environ. J. 1997, 11, 39–46. [Google Scholar] [CrossRef]

- Miteva, K. Production of sustainable energy from solid waste by pyrolysis: A review. Recycl. Sustain. Dev. 2019, 12, 69–77. [Google Scholar] [CrossRef]

- Jin, C.-L.; Wu, Z.-M.; Wang, S.-W.; Cai, Z.-Q.; Chen, T.; Farahani, M.R.; Li, D.-X. Economic assessment of biomass gasification and pyrolysis: A review. Energy Sources Part B Econ. Plan. Policy 2017, 12, 1030–1035. [Google Scholar] [CrossRef]

- Singh, R.; Tyagi, V.; Allen, T.; Ibrahim, M.H.; Kothari, R. An overview for exploring the possibilities of energy generation from municipal solid waste (MSW) in Indian scenario. Renew. Sustain. Energy Rev. 2011, 15, 4797–4808. [Google Scholar] [CrossRef]

- Hafid, H.S.; Shah, U.K.M.; Baharuddin, A.S.; Ariff, A.B. Feasibility of using kitchen waste as future substrate for bioethanol production: A review. Renew. Sustain. Energy Rev. 2017, 74, 671–686. [Google Scholar] [CrossRef]

- Liguori, R.; Faraco, V. Biological processes for advancing lignocellulosic waste biorefinery by advocating circular economy. Bioresour. Technol. 2016, 215, 13–20. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Zhang, W.; Wang, S.; Fan, Y.; Xie, J.; Liao, W.; Gao, Z. Mitigating gas emissions from poultry litter composting with waste vinegar residue. Sci. Total Environ. 2022, 842, 156957. [Google Scholar] [CrossRef]

- Demelash, N.; Bayu, W.; Tesfaye, S.; Ziadat, F.; Sommer, R. Current and residual effects of compost and inorganic fertilizer on wheat and soil chemical properties. Nutr. Cycl. Agroecosyst. 2014, 100, 357–367. [Google Scholar] [CrossRef]

- Evangelisti, S.; Lettieri, P.; Borello, D.; Clift, R. Life cycle assessment of energy from waste via anaerobic digestion: A UK case study. Waste Manag. 2014, 34, 226–237. [Google Scholar] [CrossRef]

- Zanina, I.; Kostromina, E.; Stuzhenko, N.; Chertov, Y. Processing of poultry farm waste by microbial conversion. E3S Web Conf. 2020, 175, 04004. [Google Scholar] [CrossRef]

- Fuertez, J.; Boakye, R.; McLennan, J.; Adams, D.J.; Sparks, T.D.; Gottschalk, A. Developing methanogenic microbial consortia from diverse coal sources and environments. J. Nat. Gas Sci. Eng. 2017, 46, 637–650. [Google Scholar] [CrossRef]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Coimbra-Araújo, C.H.; Mariane, L.; Júnior, C.B.; Frigo, E.P.; Frigo, M.S.; Araújo, I.R.C.; Alves, H.J. Brazilian case study for biogas energy: Production of electric power, heat and automotive energy in condominiums of agroenergy. Renew. Sustain. Energy Rev. 2014, 40, 826–839. [Google Scholar] [CrossRef]

- Andriani, D.; Wresta, A.; Saepudin, A.; Prawara, B. A review of recycling of human excreta to energy through biogas generation: Indonesia case. Energy Procedia 2015, 68, 219–225. [Google Scholar] [CrossRef] [Green Version]

- Bayrakdar, A.; Molaey, R.; Sürmeli, R.Ö.; Sahinkaya, E.; Çalli, B. Biogas production from chicken manure: Co-digestion with spent poppy straw. Int. Biodeterior. Biodegrad. 2017, 119, 205–210. [Google Scholar] [CrossRef]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew. Sustain. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Joshi, T.N.; Nepali, D.B.; Sah, R.; Bhattarai, T.; Midmore, D.J. A comparison of composting and vermicomposting for the disposal of poultry waste. Anim. Prod. Sci. 2020, 60, 986–992. [Google Scholar] [CrossRef]

- Liedl, B.E.; Bombardiere, J.; Chaffield, J.M. Fertilizer potential of liquid and solid effluent from thermophilic anaerobic digestion of poultry waste. Water Sci. Technol. 2006, 53, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Karaeva, J.V.; Kamalov, R.F.; Kadiyrov, A.I. Production of biogas from poultry waste using the biomass of plants from Amaranthaceae family. IOP Conf. Ser. Earth Environ. Sci. 2019, 288, 012096. [Google Scholar] [CrossRef] [Green Version]

- Awasthi, M.K.; Pandey, A.K.; Bundela, P.S.; Wong, J.W.C.; Li, R.; Zhang, Z. Co-composting of gelatin industry sludge combined with organic fraction of municipal solid waste and poultry waste employing zeolite mixed with enriched nitrifying bacterial consortium. Bioresour. Technol. 2016, 213, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Mushtaq, M.; Iqbal, M.K.; Khalid, A.; Khan, R.A. Humification of poultry waste and rice husk using additives and its application. Int. J. Recycl. Org. Waste Agric. 2018, 8, 15–22. [Google Scholar] [CrossRef] [Green Version]

- Demirbas, A.; Arin, G. An overview of biomass pyrolysis. Energy Sources 2002, 24, 471–482. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Mihăescu, L.; Pîşă, I.; Berbece, V.; Negreanu, G.P. Research Regarding the Pyrolysis of Poultry Waste As an Alternative for Its Use in Energy Production. In Proceedings of the 57th Annual Scientific Conference of University of Ruse and Union of Scientists, Ruse, Bulgaria, 25–26 October 2018. [Google Scholar]

- Zhou, S.; Han, L.; Huang, G.; Yang, Z.; Peng, J. Pyrolysis characteristics and gaseous product release properties of different livestock and poultry manures: Comparative study regarding influence of inherent alkali metals. J. Anal. Appl. Pyrolysis 2018, 134, 343–350. [Google Scholar] [CrossRef]

- Isemin, R.L.; Mikhalev, A.V.; Milovanov, O.Y.; Stepantsova, L.V.; Solopov, V.A. Development of the Technology of Poultry Litter Treatment into Organic Fertilizer through Its Decontamination by the Low-Temperature Pyrolysis Method. Int. J. Chem. Eng. Appl. 2017, 8, 184–188. [Google Scholar] [CrossRef] [Green Version]

- Rasheed, T.; Anwar, M.T.; Ahmad, N.; Sher, F.; Khan, S.U.-D.; Ahmad, A.; Khan, R.; Wazeer, I. Valorisation and emerging perspective of biomass based waste-to-energy technologies and their socio-environmental impact: A review. J. Environ. Manag. 2021, 287, 112257. [Google Scholar] [CrossRef]

- Hameed, Z.; Aslam, M.; Khan, Z.; Maqsood, K.; Atabani, A.; Ghauri, M.; Khurram, M.S.; Rehan, M.; Nizami, A.-S. Gasification of municipal solid waste blends with biomass for energy production and resources recovery: Current status, hybrid technologies and innovative prospects. Renew. Sustain. Energy Rev. 2021, 136, 110375. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Coccia, V.; Cotana, F.; Gelosia, M.; Nicolini, A.; Petrozzi, A. Energy from poultry waste: An Aspen Plus-based approach to the thermo-chemical processes. Waste Manag. 2018, 73, 496–503. [Google Scholar] [CrossRef]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Y.; Guo, Q.; Zhang, R.; Wang, C.; Yan, B.; Lin, F.; Chen, G. Evaluation on energetic and economic benefits of the coupling anaerobic digestion and gasification from agricultural wastes. Renew. Energy 2021, 176, 494–503. [Google Scholar] [CrossRef]

- Chen, H.; Li, J.; Li, T.; Xu, G.; Jin, X.; Wang, M.; Liu, T. Performance assessment of a novel medical-waste-to-energy design based on plasma gasification and integrated with a municipal solid waste incineration plant. Energy 2022, 245, 123156. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Tao, S. Environmental and human health challenges of industrial livestock and poultry farming in China and their mitigation. Environ. Int. 2017, 107, 111–130. [Google Scholar] [CrossRef] [PubMed]

- Zang, G.; Zhang, J.; Jia, J.; Weger, N.; Ratner, A. Clean Poultry Energy System Design Based on Biomass Gasification Technology: Thermodynamic and Economic Analysis. Energies 2019, 12, 4235. [Google Scholar] [CrossRef] [Green Version]

- Singh, D.K.; Tirkey, J. Process modelling and thermodynamic performance optimization of biomass air gasification fuelled with waste poultry litter pellet by integrating Aspen plus with RSM. Biomass Bioenergy 2022, 158, 106370. [Google Scholar] [CrossRef]

- Pandey, D.S.; Yazhenskikh, E.; Müller, M.; Ziegner, M.; Trubetskaya, A.; Leahy, J.J.; Kwapinska, M. Transformation of inorganic matter in poultry litter during fluidised bed gasification. Fuel Process. Technol. 2021, 221, 106918. [Google Scholar] [CrossRef]

- Arias, J.Z.; Reuter, T.; Sabir, A.; Gilroyed, B.H. Ambient alkaline hydrolysis and anaerobic digestion as a mortality management strategy for whole poultry carcasses. Waste Manag. 2018, 81, 71–77. [Google Scholar] [CrossRef]

- Altınelataman, C.; Koroleva, O.; Fedorova, T.; Torkova, A.; Lisitskaya, K.; Tsentalovich, M.; Kononikhin, A.; Popov, I.; Vasina, D.; Kovalyov, L. An in vitro and in silico study on the antioxidant and cell culture-based study on the chemoprotective activities of fish muscle protein hydrolysates obtained from European seabass and gilthead seabream. Food Chem. 2019, 271, 724–732. [Google Scholar] [CrossRef] [PubMed]

- Volik, V.; Ismailova, D.; Lukashenko, V.; Saleeva, I.; Morozov, V. Biologically active feed additive development based on keratin and collagen-containing raw materials from poultry waste. Int. Trans. J. Eng. Manag. Appl. Sci. Technol. 2020, 10, 11A05P. [Google Scholar]

- Cheong, C.W.; Lee, Y.S.; Ahmad, S.A.; Ooi, P.T.; Phang, L.Y. Chicken feather valorization by thermal alkaline pretreatment followed by enzymatic hydrolysis for protein-rich hydrolysate production. Waste Manag. 2018, 79, 658–666. [Google Scholar] [CrossRef]

- Yurdakul, S. Determination of co-combustion properties and thermal kinetics of poultry litter/coal blends using thermogravimetry. Renew. Energy 2016, 89, 215–223. [Google Scholar] [CrossRef]

- Ojha, S.; Gaikwad, S.T.; Suthar, T.; Gavane, A. Microbial Bioconversion of Poultry Waste: Value added Products. Indian J. Pure Appl. Biosci. 2020, 8, 165–173. [Google Scholar] [CrossRef]

- Mutucumarana, R.; Samarasinghe, K.; Ranjith, G.; Wijeratne, A.; Wickramanayake, D. Poultry offal meal as a substitute to dietary soybean meal for Japanese quails (Coturnix coturnix japonica): Assessing the maximum inclusion level and the effect of supplemental enzymes. Trop. Agric. Res. 2010, 21, 293–307. [Google Scholar] [CrossRef] [Green Version]

- Adewumi, A.A.; Adewumi, I.K.; Olaleye, V.F. Livestock waste-menace: Fish wealth-solution. Afr. J. Environ. Sci. Technol. 2011, 5, 149–154. [Google Scholar]

- Paul, T.; Das, A.; Mandal, A.; Halder, S.K.; DasMohapatra, P.K.; Pati, B.R.; Mondal, K.C. Valorization of chicken feather waste for concomitant production of keratinase, oligopeptides and essential amino acids under submerged fermentation by Paenibacillus woosongensis TKB2. Waste Biomass Valorization 2014, 5, 575–584. [Google Scholar] [CrossRef]

- Agwa, O.K.; Abu, G.O. Utilization of poultry waste for the cultivation of Chlorella sp. for biomass and lipid production. Int. J. Curr. Microbiol. Appl. Sci. 2014, 3, 1036–1047. [Google Scholar]

- Yuvaraj, A.; Thangaraj, R.; Maheswaran, R. Decomposition of poultry litter through vermicomposting using earthworm Drawida sulcata and its effect on plant growth. Int. J. Environ. Sci. Technol. 2019, 16, 7241–7254. [Google Scholar] [CrossRef]

- Luperdi, A.P.; Flores-Calla, S.S.; Barriga, X.J.; Rivera, V.; Salazar, I.; Manrique, P.L.; Reátegui, J.E. Bioprocessing of organic wastes from poultry and bovine slaughterhouses as food substrate for Hermetia illucens larval development. Glob. J. Environ. Sci. Manag. 2023, 9, 31–42. [Google Scholar]

- Singh, S.; Sinha, R.K. Vermicomposting of organic wastes by earthworms: Making wealth from waste by converting ‘garbage into gold’for farmers. In Advanced Organic Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 93–120. [Google Scholar]

- Siddiqui, S.A.; Ristow, B.; Rahayu, T.; Putra, N.S.; Widya Yuwono, N.; Nisa, K.; Mategeko, B.; Smetana, S.; Saki, M.; Nawaz, A.; et al. Black soldier fly larvae (BSFL) and their affinity for organic waste processing. Waste Manag. 2022, 140, 1–13. [Google Scholar] [CrossRef]

- Jeong, J.-H.; Lee, O.-M.; Jeon, Y.-D.; Kim, J.-D.; Lee, N.-R.; Lee, C.-Y.; Son, H.-J. Production of keratinolytic enzyme by a newly isolated feather-degrading Stenotrophomonas maltophilia that produces plant growth-promoting activity. Process Biochem. 2010, 45, 1738–1745. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Wang, Y.; Hu, Y.; Christie, P.; Zhang, J.; Li, X. Maize yield and soil fertility with combined use of compost and inorganic fertilizers on a calcareous soil on the North China Plain. Soil Tillage Res. 2016, 155, 85–94. [Google Scholar] [CrossRef]

- Committee for Agriculture and Rural Development. Poultry Litter Utilisation and Disposal: Alternative Technologies to Fluidised Bed Combustion. Available online: http://www.niassembly.gov.uk/assembly-business/official-report/committee-minutes-of-evidence/session-2011-2012/may-2012/poultry-litter-utilisation-and-disposal--alternative-technologies-to-fluidised-bed-combustion-/ (accessed on 18 February 2023).

- Ichida, J.M.; Krizova, L.; LeFevre, C.A.; Keener, H.M.; Elwell, D.L.; Burtt, E.H., Jr. Bacterial inoculum enhances keratin degradation and biofilm formation in poultry compost. J. Microbiol. Methods 2001, 47, 199–208. [Google Scholar] [CrossRef]

- Lakshmi, V.V.; Devi, D.A.; Rani, K.P.J. Wealth from Poultry Waste. In Waste Management as Economic Industry Towards Circular Economy; Ghosh, S.K., Ed.; Springer Nature Singapore Pte Ltd.: Singapore, 2020. [Google Scholar]

- Arshad, M.; Bano, I.; Khan, N.; Shahzad, M.I.; Younus, M.; Abbas, M.; Iqbal, M. Electricity generation from biogas of poultry waste: An assessment of potential and feasibility in Pakistan. Renew. Sustain. Energy Rev. 2018, 81, 1241–1246. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, W. Sustainability of crop–based biodiesel for transportation in China: Barrier analysis and life cycle ecological footprint calculations. Technol. Forecast. Soc. Change 2021, 164, 120526. [Google Scholar] [CrossRef]

- Gohil, A.; Budholiya, S.; Mohan, C.G.; Prakash, R. Utilization of Poultry Waste as a Source of Biogas Production. In Proceedings of the International Conference on Advances in Materials Research (ICAMR), Sathyamangalam, India, 6–7 December 2019; pp. 783–787. [Google Scholar]

- Wyatt, V.T.; Hess, M.A.; Dunn, R.O.; Foglia, T.A.; Haas, M.J.; Marmer, W.N. Fuel properties and nitrogen oxide emission levels of biodiesel produced from animal fats. J. Am. Oil Chem. Soc. 2005, 82, 585–591. [Google Scholar] [CrossRef]

- Mozhiarasi, V.; Natarajan, T.S. Slaughterhouse and poultry wastes: Management practices, feedstocks for renewable energy production, and recovery of value added products. Biomass Convers. Biorefin. 2022, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Abraham, J. Production of Bio-Diesel from Poultry Farm Waste. Ph.D. Thesis, Tamil Nadu Veterinary and Animal Sciences University, Chennai, India, 2014. [Google Scholar]

- Prabakaran, R.; Valavan, S.E. Wealth from poultry waste: An overview. Worlds Poult. Sci. J. 2021, 77, 389–401. [Google Scholar] [CrossRef]

- McGauran, T.; Dunne, N.; Smyth, B.M.; Cunningham, E. Feasibility of the use of poultry waste as polymer additives and implications for energy, cost and carbon. J. Clean. Prod. 2021, 291, 125948. [Google Scholar] [CrossRef]

- Lewis, M.J.; Francis, D.S.; Blyth, D.; Moyano, F.J.; Smullen, R.P.; Turchini, G.M.; Booth, M.A. A comparison of in-vivo and in-vitro methods for assessing the digestibility of poultry by-product meals using barramundi (Lates calcarifer); impacts of cooking temperature and raw material freshness. Aquaculture 2019, 498, 187–200. [Google Scholar] [CrossRef]

- Seidavi, A.R.; Zaker-Esteghamati, H.; Scanes, C.G. Present and potential impacts of waste from poultry production on the environment. Worlds Poult. Sci. J. 2019, 75, 29–42. [Google Scholar] [CrossRef]

- Abraham, J.; Kumar, R.S.; Xavier, F.; Mathew, D. Biodiesel production from broiler chicken waste. Int. J. Agric. Biosyst. Eng. 2015, 9, 1190–1193. [Google Scholar]

- Lazzari, L.K.; Perondi, D.; Zattera, A.J.; Campomanes Santana, R.M.J.P. CO 2 adsorption by cryogels produced from poultry litter wastes. Polímeros 2022, 32, e2022004. [Google Scholar] [CrossRef]

- Kazemi-Bonchenari, M.; Alizadeh, A.; Javadi, L.; Zohrevand, M.; Odongo, N.E.; Salem, A.Z.M. Use of poultry pre-cooked slaughterhouse waste as ruminant feed to prevent environmental pollution. J. Clean. Prod. 2017, 145, 151–156. [Google Scholar] [CrossRef] [Green Version]

- Joardar, J.; Rahman, M. Poultry feather waste management and effects on plant growth. Int. J. Recycl. Org. Waste Agric. 2018, 7, 183–188. [Google Scholar] [CrossRef] [Green Version]

- Chiramba, R.; Charis, G.; Fungura, N.; Danha, G.; Mamvura, T. Production of activated carbon from poultry feathers for waste water treatment. Water Sci. Technol. 2019, 80, 1407–1412. [Google Scholar] [CrossRef] [PubMed]

- Zhan, M.; Wool, R.P. Mechanical properties of chicken feather fibers. Polym. Compos. 2011, 32, 937–944. [Google Scholar] [CrossRef]

- Balaji, S.; Kumar, R.; Sripriya, R.; Rao, U.; Mandal, A.; Kakkar, P.; Reddy, P.N.; Sehgal, P.K. Characterization of keratin–collagen 3D scaffold for biomedical applications. Polym. Adv. Technol. 2012, 23, 500–507. [Google Scholar] [CrossRef]

- Mataragas, M.; Skandamis, P.; Drosinos, E. Risk profiles of pork and poultry meat and risk ratings of various pathogen/product combinations. Int. J. Food Microbiol. 2008, 126, 1–12. [Google Scholar] [CrossRef]

- Cabral, J.P. Water microbiology. Bacterial pathogens and water. Int. J. Environ. Res. Public Health 2010, 7, 3657–3703. [Google Scholar] [CrossRef]

- Raman, N.; Narayanan, D.S. Impact of solid waste effect on ground water and soil quality nearer to Pallavaram solid waste landfill site in Chennai. Rasayan J. Chem. 2008, 1, 828–836. [Google Scholar]

- Irfan, M.; Mehmood, S.; Mahmud, A.; Anjum, A. An Assessment of Chemical and Microbiological Properties of Different Types of Poultry Waste Compost Prepared by Bin and Windrow Composting System. Braz. J. Poult. Sci. 2020, 22, 001–010. [Google Scholar] [CrossRef]

- Dróżdż, D.; Wystalska, K.; Malińska, K.; Grosser, A.; Grobelak, A.; Kacprzak, M. Management of poultry manure in Poland–Current state and future perspectives. J. Environ. Manag. 2020, 264, 110327. [Google Scholar] [CrossRef]

| Processes | Advantages | Disadvantages |

|---|---|---|

| Composting treatment | Cost-effective [75], sanitation, mass and bulk reduction, and decrease of carbon to nitrogen ratio [76] | Significant nitrogen loss through ammonia volatilization [75]. Risks caused by heavy metals, pathogens, and ammonia toxicity [77] |

| Anaerobic digestion | Lower running costs, low energy consumption, low sludge production, no aerosols, useful by-products, lower nutrient requirements, and rapid re-start [78] | Expensive investment costs, retention periods usually more than 1 day, heating requirements, corrosive and malodorous by-products, potential risks of pathogens spreading, long start-up and recovery periods, and additional alkalinity requirements [78] |

| Pyrolysis | Higher commercial value, higher level in the reduction of initial waste, low demands for land, and easy control of process [79] | Necessity of waste pre-treatment and wastewater treatment, product disposal with further treatment, demand for high quantities of waste, and need for specialized personnel [79] |

| Gasification | Economic benefits, easy availability, low emissions [80], and wide application of products [81] | High investment cost [80], requirement on energy input [81], and technical problems caused by high viscosity of pyrolysis oil [80,81] |

| Hydrolysis | Carried out under optimal conditions, minimized interaction between steps, and can be applied to wide range of microorganisms [82] | High cost and contamination due to long period process [82] |

| Enzymatic treatment | Eco-friendly, low temperature and pressure, wide temperature and pH ranges, no nutrient supplementation, no sugars consumption, short time duration, high conversion efficiency, low waste generation, and low energy demand [83] | High enzyme costs, moderate enzymatic performances, enzyme recycling, enzyme immobilization, and enzyme activity improvement [83] |

| Microbial conversion | Low cost, eco-friendly, low temperature and pressure, no water and chemical agent requirement, no growth inhibitor formation, low waste generation, and low energy demand [83] | Long time duration, feedstock loss, and low conversion efficiency [83] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Ren, J.; Bai, W. A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic- Environmental and Social Sustainability. Sustainability 2023, 15, 5620. https://doi.org/10.3390/su15075620

Zhang L, Ren J, Bai W. A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic- Environmental and Social Sustainability. Sustainability. 2023; 15(7):5620. https://doi.org/10.3390/su15075620

Chicago/Turabian StyleZhang, Long, Jingzheng Ren, and Wuliyasu Bai. 2023. "A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic- Environmental and Social Sustainability" Sustainability 15, no. 7: 5620. https://doi.org/10.3390/su15075620

APA StyleZhang, L., Ren, J., & Bai, W. (2023). A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic- Environmental and Social Sustainability. Sustainability, 15(7), 5620. https://doi.org/10.3390/su15075620