Slope Crack Propagation Law and Numerical Simulation of Expansive Soil under Wetting–Drying Cycles

Abstract

:1. Introduction

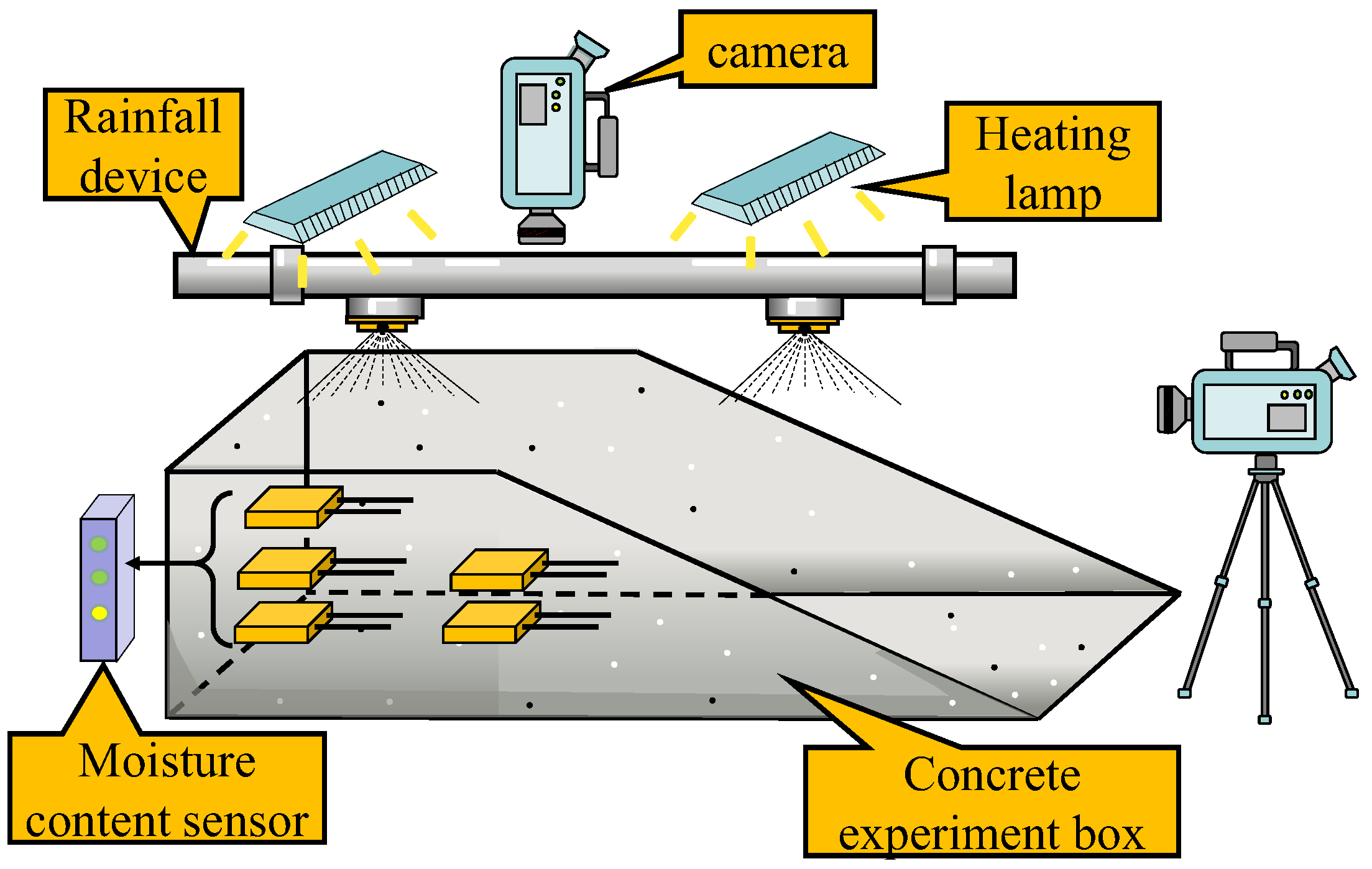

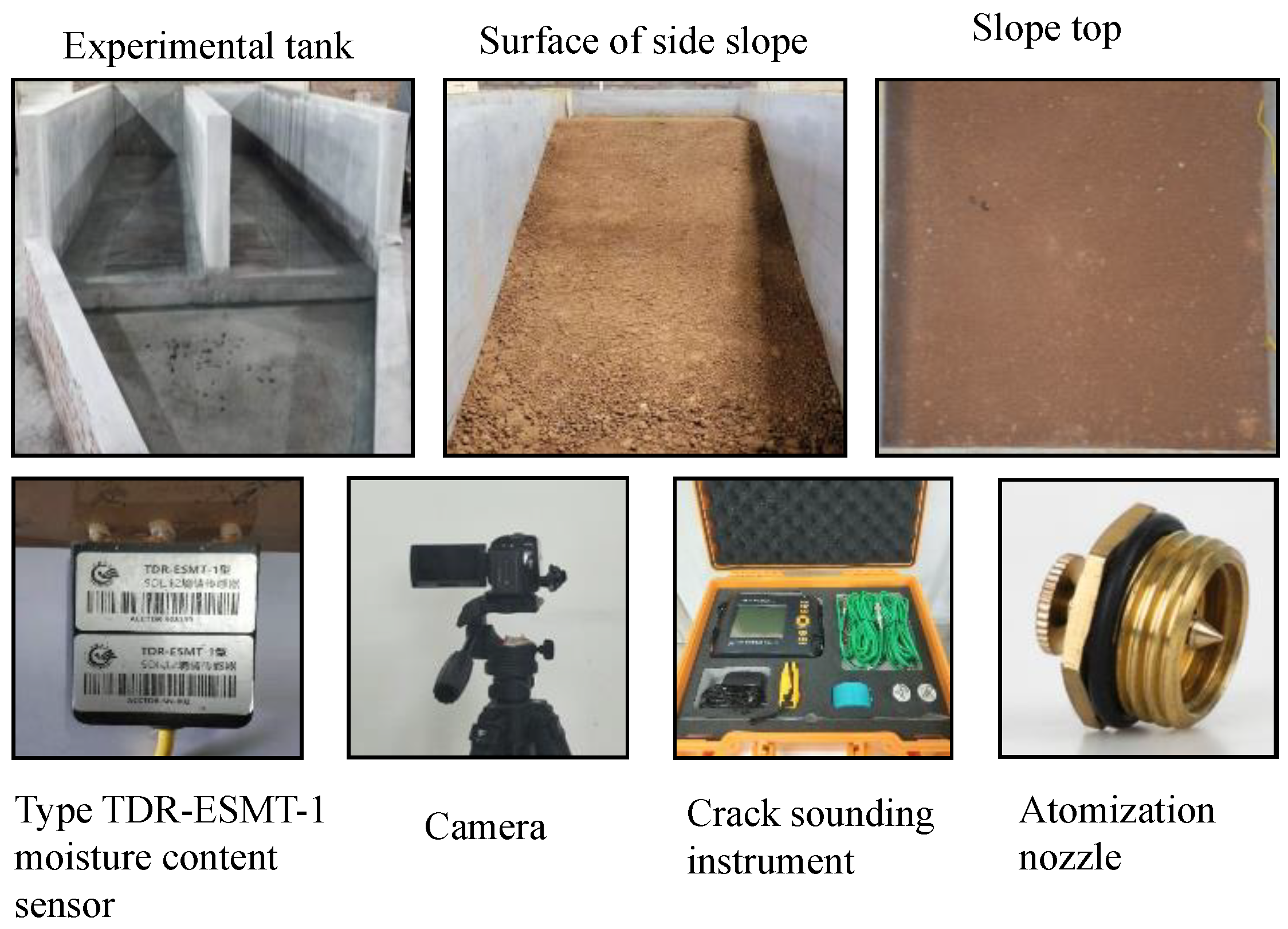

2. Experimental Method

2.1. Experimental Facilities

2.2. Test Method

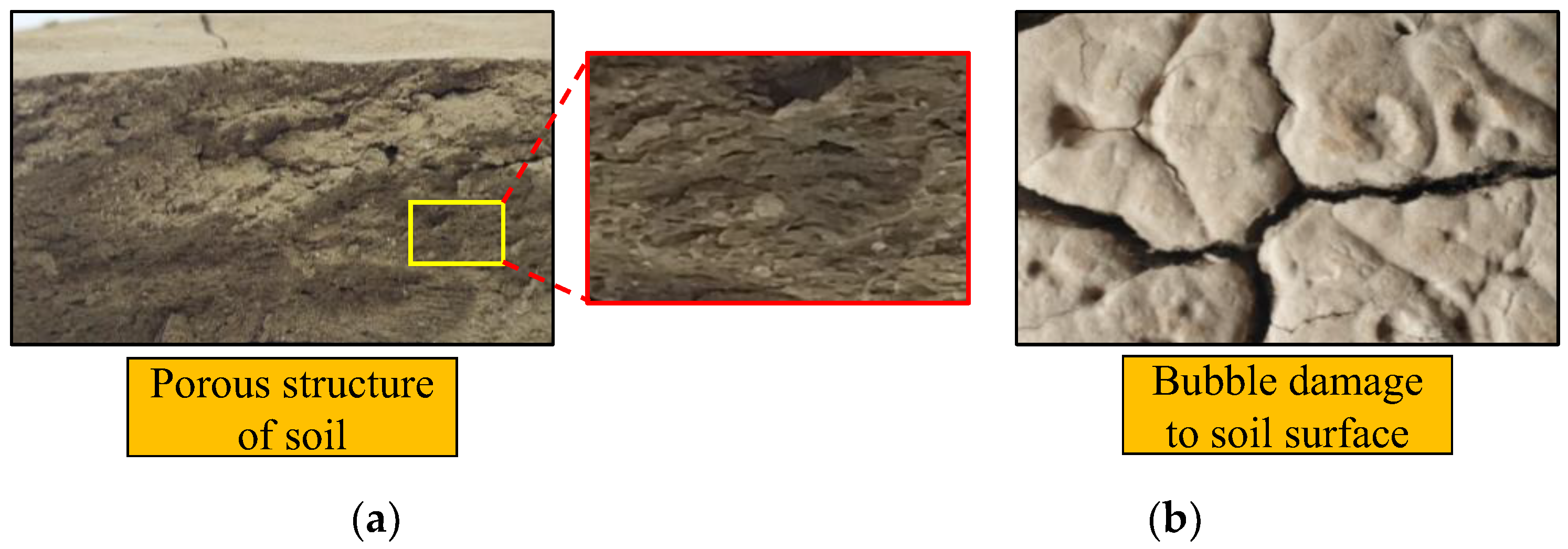

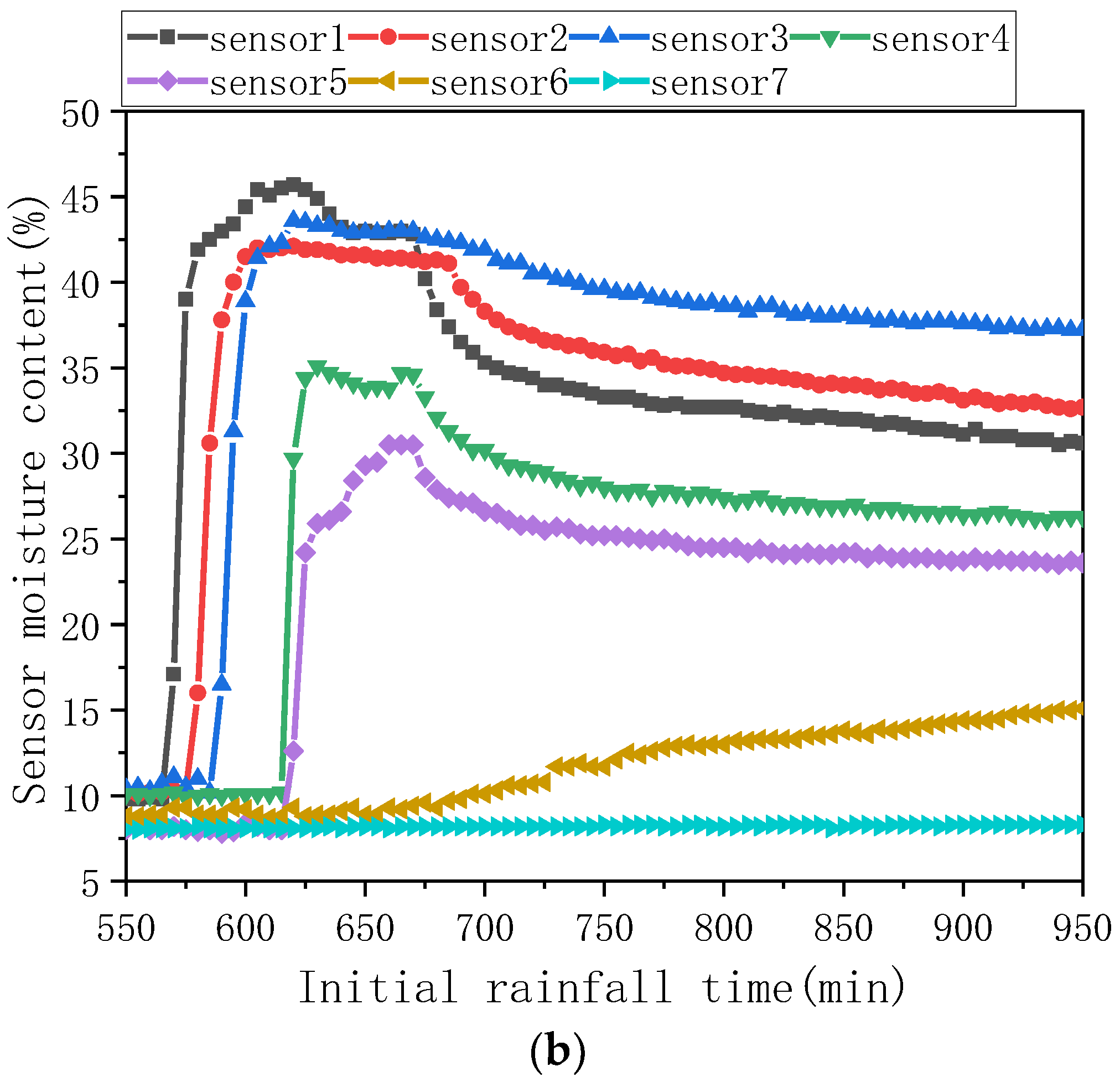

3. Experimental Results and Analysis

3.1. Experimental Results

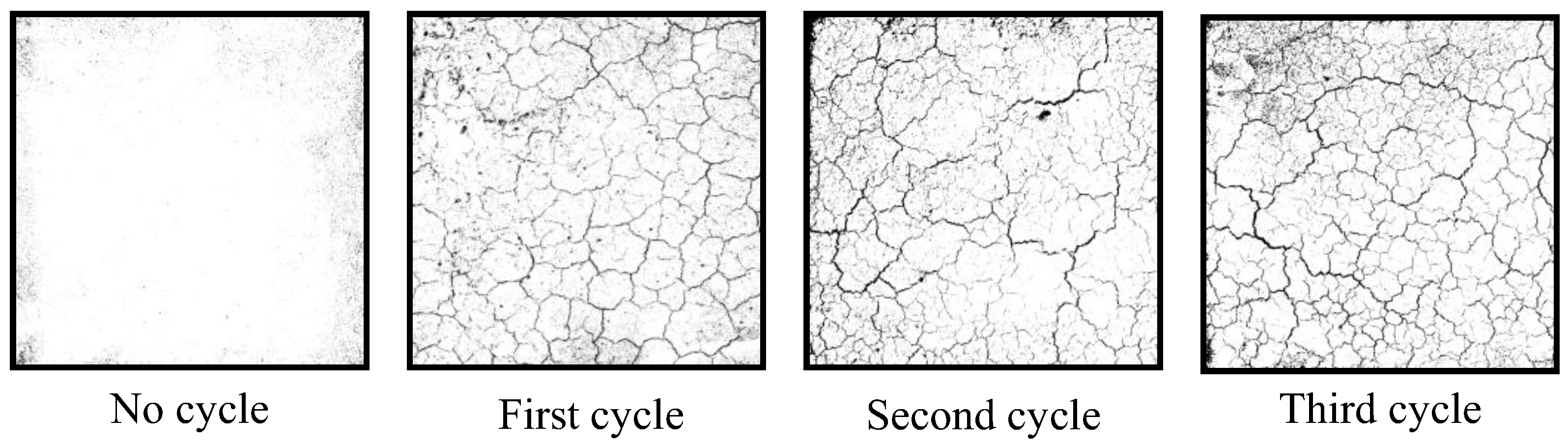

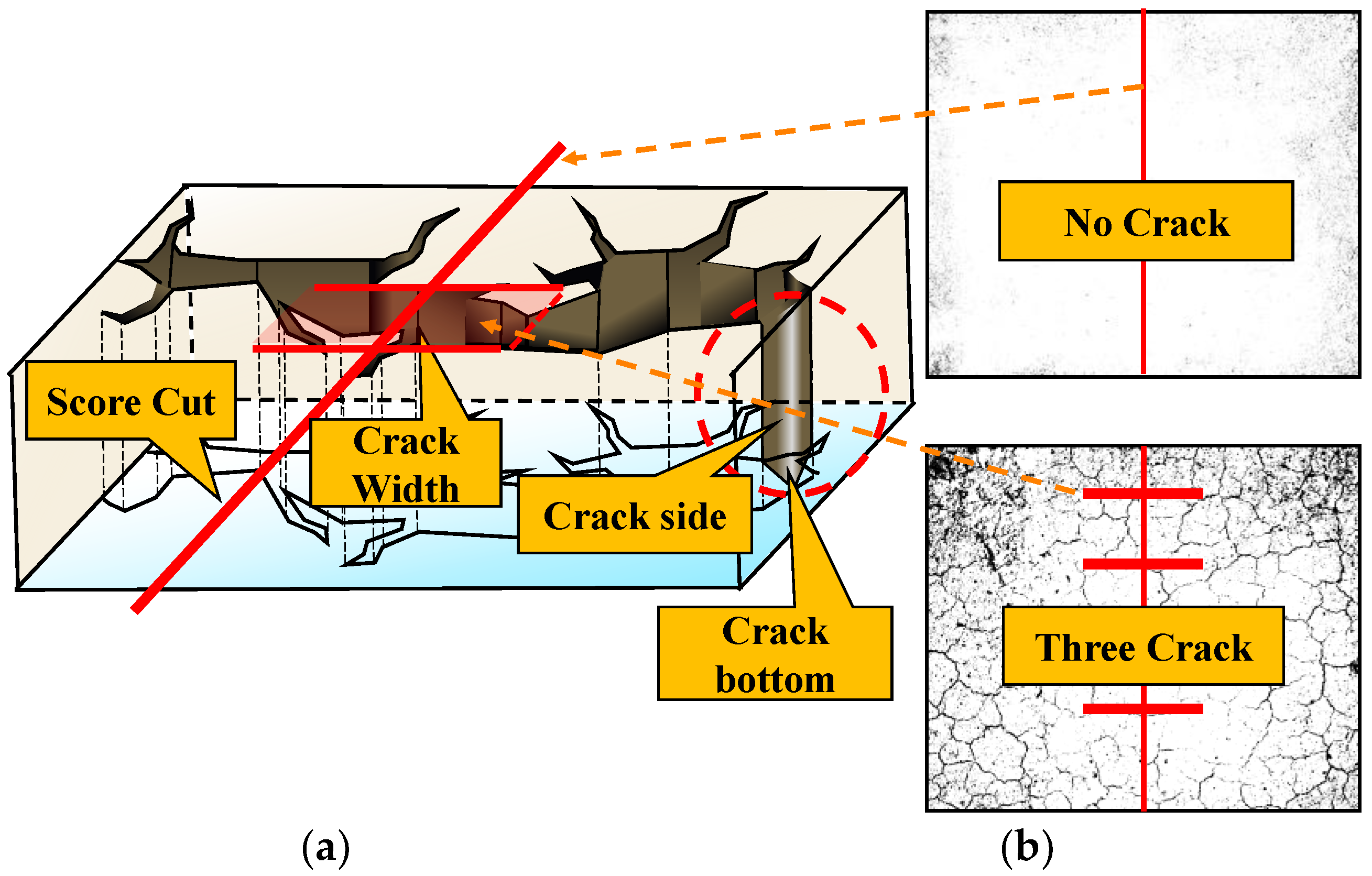

3.2. Binary Image Processing

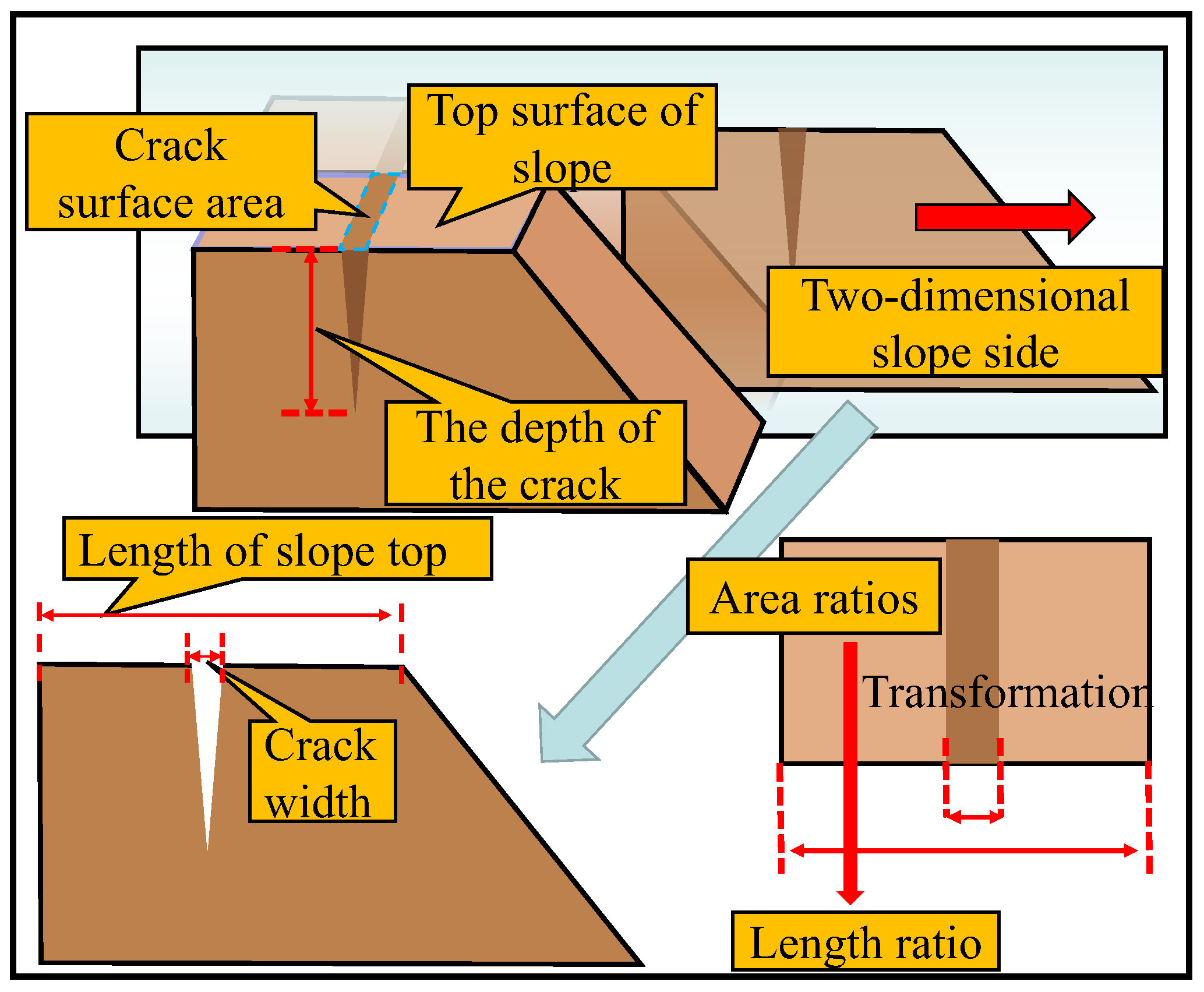

4. Numerical Simulation and Analysis

4.1. Boundary Conditions and Parameters of the Model

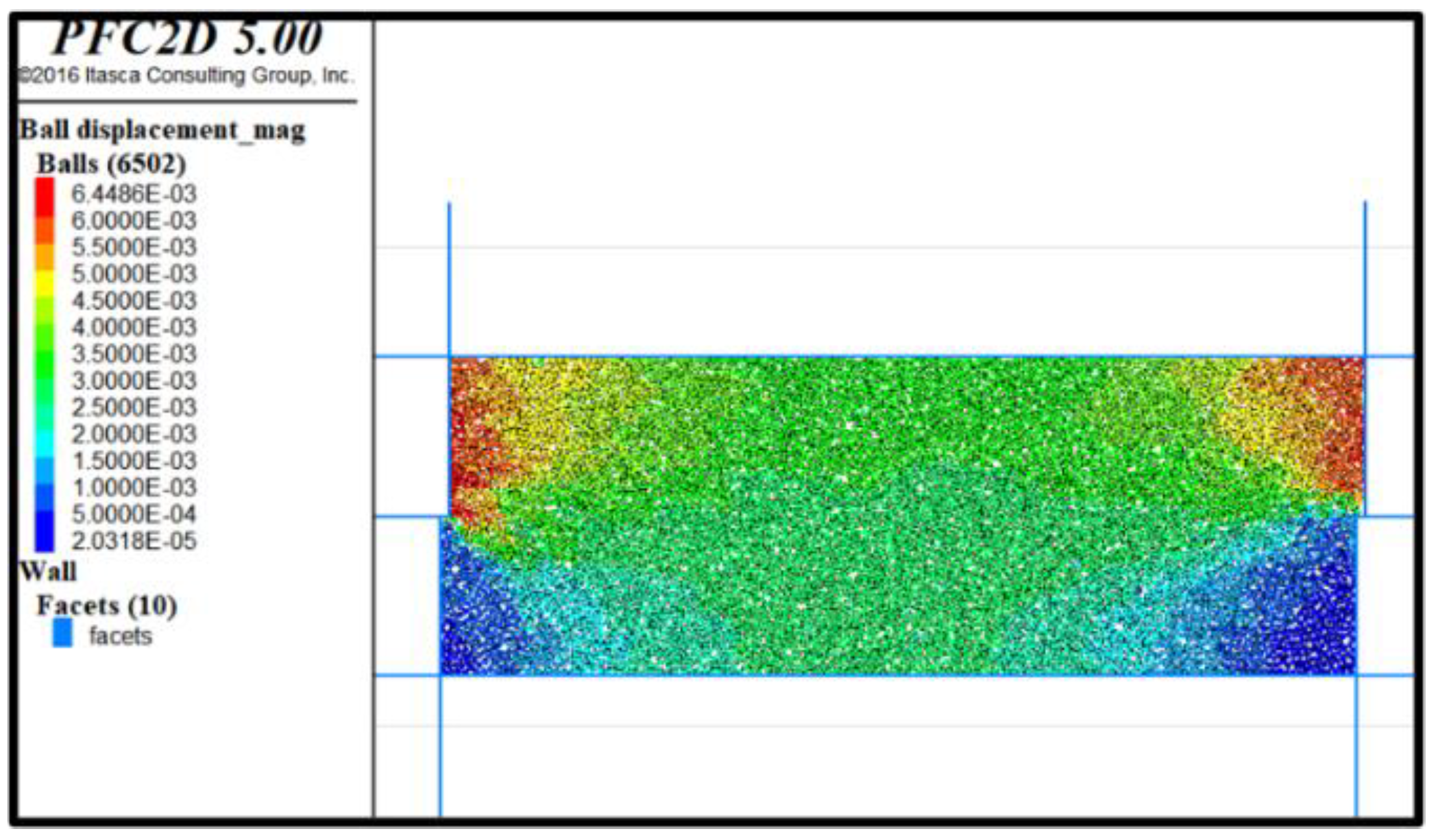

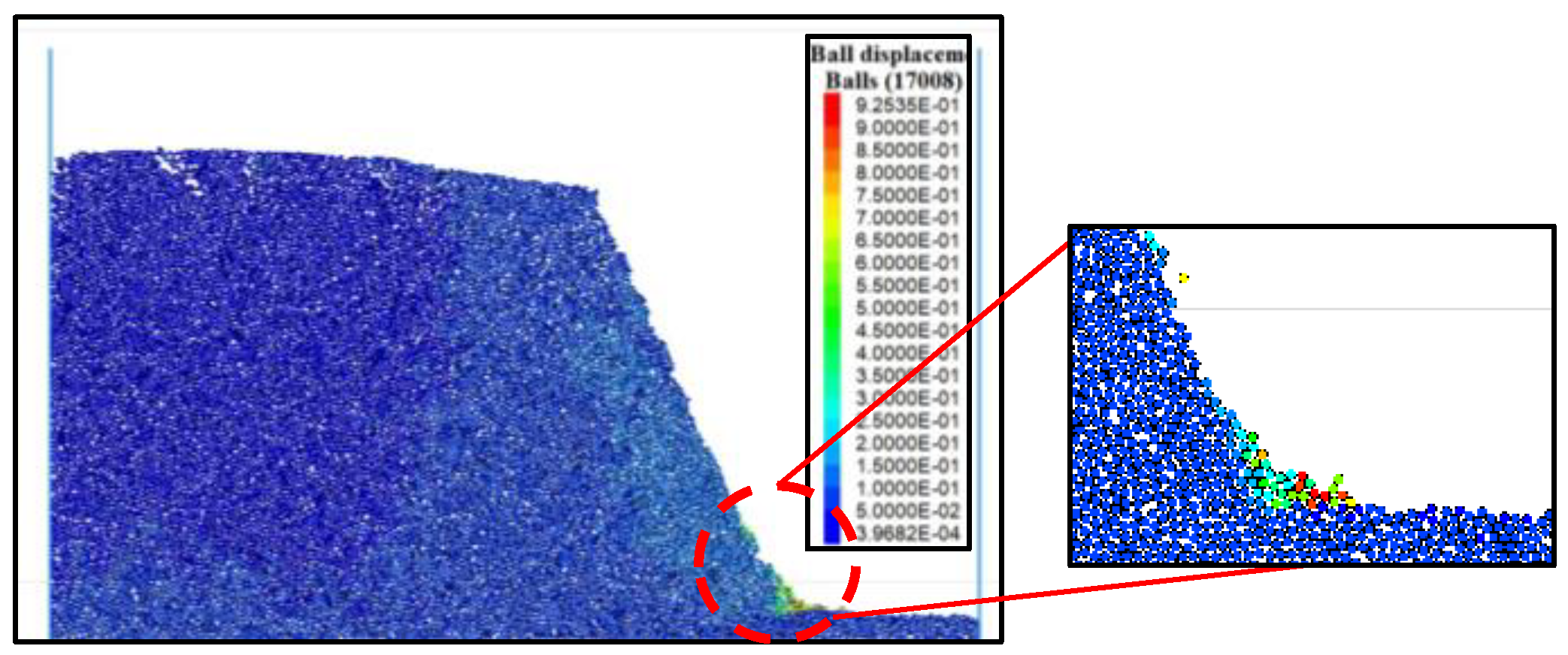

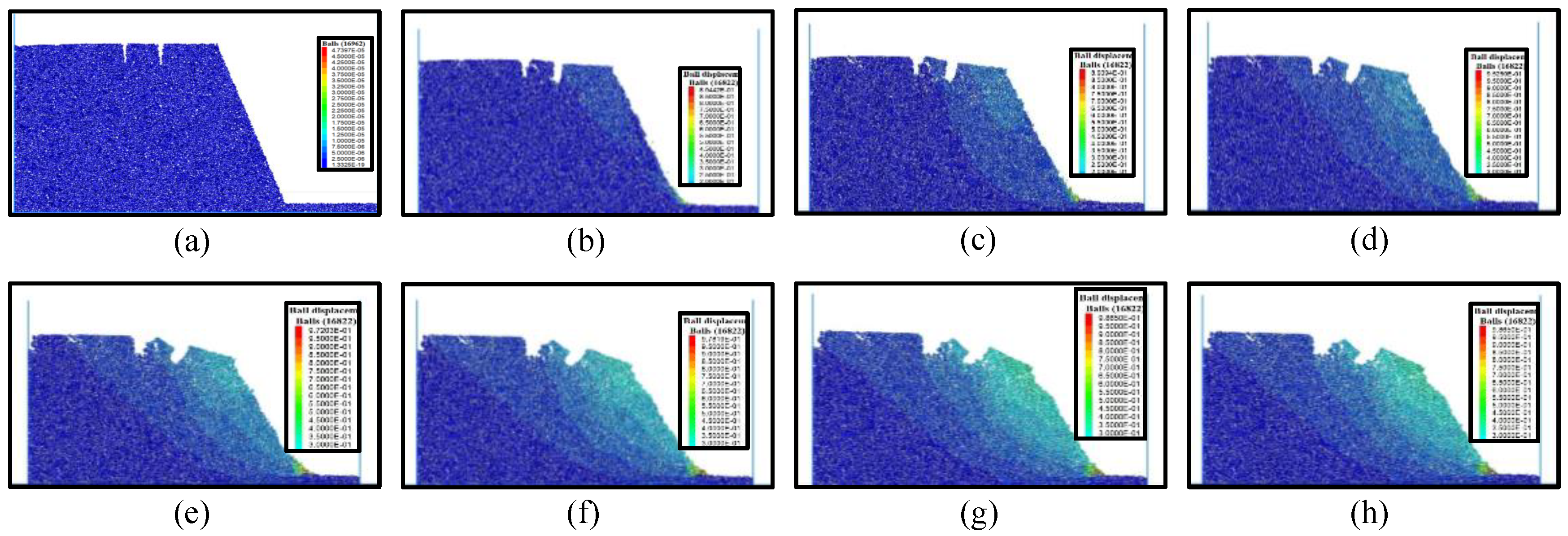

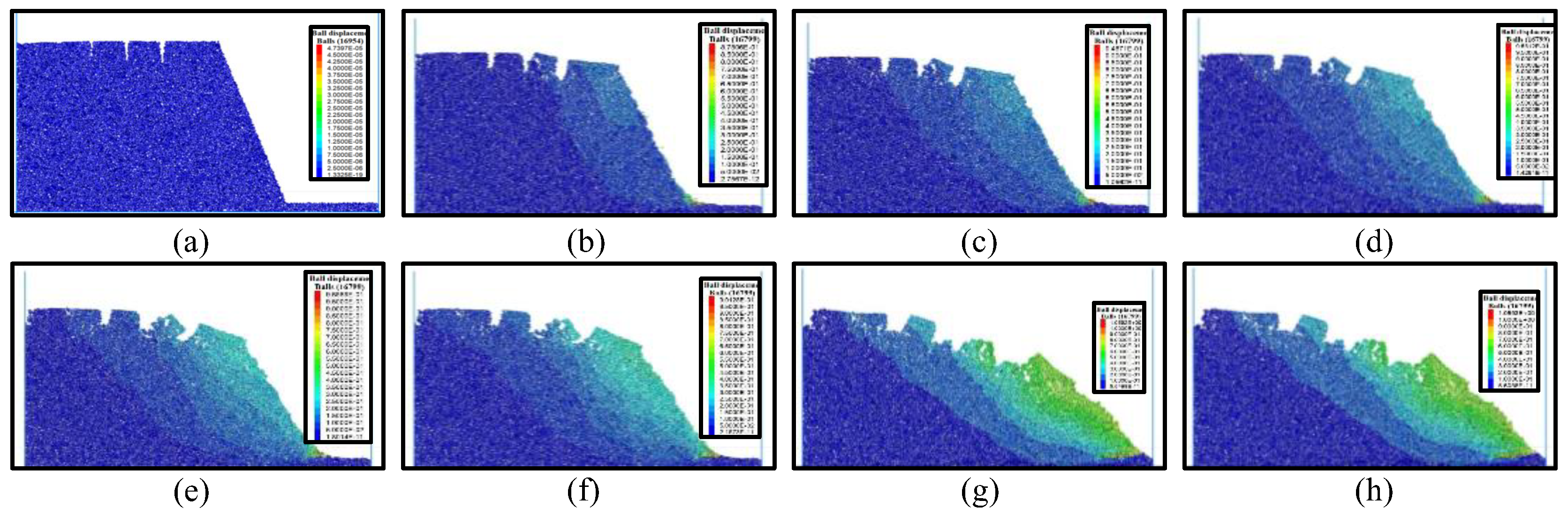

4.2. Numerical Simulation Results

5. Conclusions

- With an increasing number of wetting–drying cycles, the infiltration rate of rainwater into the lower layers of the soil was found to be much higher compared to soil without multiple cycles.

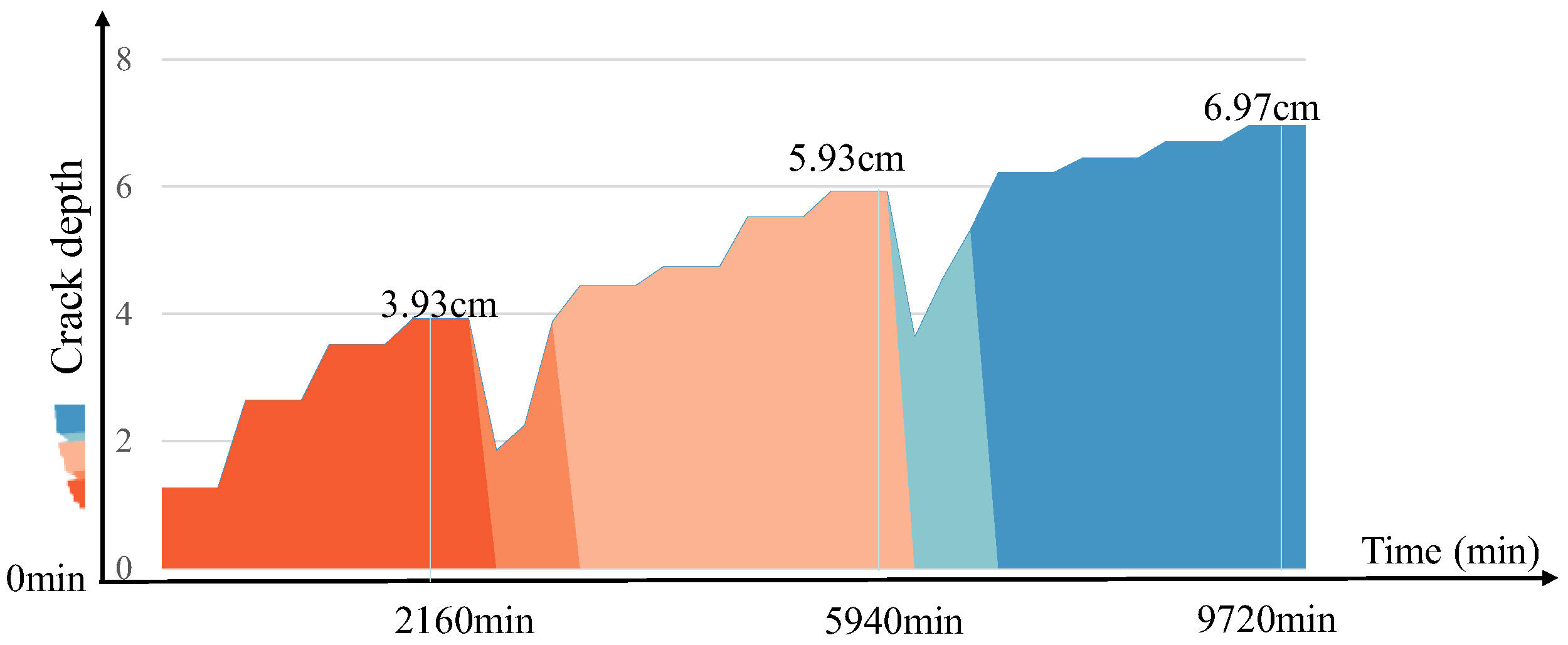

- A self-made binary image processing system was used to quantify the crack area of the soil, and a crack depth detector was used to measure the crack depth of the slope. It was found that the crack area and depth increased with the number of wetting–drying cycles, but the growth trend decreased.

- Using the PFC numerical calculation software and taking the quantitative results as simulation parameters, it was observed that the number of cracks and their location significantly influenced slope failure. An increase in the number of wetting–drying cycles led to a greater number of cracks, resulting in significant changes to the slope, an obvious slip, slope instability, and a backward movement of the slip surface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Number of Drying–Wetting Cycles | Crack Area (m2) | Crack Rate% | Soil Area Ratio% | Water Content% |

|---|---|---|---|---|

| 1 | 0.0848 | 10.6 | 89.4 | 31.8 |

| 2 | 0.1128 | 14.1 | 85.9 | 32.1 |

| 3 | 0.1264 | 15.8 | 84.2 | 32 |

| Depth of Crack (cm) | Period |

|---|---|

| 1.26 | Drying time |

| 2.65 | |

| 3.52 | |

| 3.93 | |

| 1.86 | Rain heals and cracks again |

| 2.25 | |

| 3.88 | |

| 4.45 | Drying time |

| 4.75 | |

| 5.53 | |

| 5.93 | |

| 3.64 | Rain heals and cracks again |

| 4.56 | |

| 5.33 | |

| 6.23 | Drying time |

| 6.450 | |

| 6.710 | |

| 6.970 |

References

- Zienkiewicz, O.C.; Humpheson, C.; Lewis, R.W. Associated and Non-Associated Visco-Plasticity and Plasticity in Soil Mechanics. Geotechnique 1975, 25, 671–689. [Google Scholar] [CrossRef]

- Konrad, J.M.; Ayad, R. An Idealized Framework for the Analysis of Cohesive Soils Undergoing Desiccation: Reply (1). Can. Geotech. J. 1998, 35, 1115. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Rahardjo, H. Soil Mechanics for Unsaturated Soils; John Wiley & Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Tang, C.S.; Cheng, Q.; Leng, T.; Shi, B.; Zeng, H.; Inyang, H. Effects of wetting-drying cycles and desiccation cracks on mechanical behavior of an unsaturated soil. CATENA 2020, 194, 104–116. [Google Scholar] [CrossRef]

- Zhang, J.; Guang, Z. Study of the Fissures, Volume Change and Permeability of Expansive Soil under Wetting and Drying Cycles. Master’s Dissertation, South China University of Technology, Guangzhou, China, 2010. (In Chinese). [Google Scholar]

- Luo, Z.; Wang, S.; Zhang, J.; Yang, Z. Experimental study on thickness effect of crack development in expansive soil. Chin. J. Geotech. Eng. 2020, 42, 1922–1930. [Google Scholar]

- Wang, W.; Kong, L.; Zang, M.; Zhang, C. Experimental Research on Crack Extension and Indoor Rainfall Infiltration of Nanyang Expansive Soil. J. Southwest Pet. Univ. 2015, 37, 174–184. (In Chinese) [Google Scholar]

- Wang, X.; Yao, Z.; Dang, F.; Dong, Z. Meso-structure evolution of cracked expansive soils. Trans. Chin. Soc. Agric. Eng. 2016, 32, 92–100. [Google Scholar]

- Yang, R.; Xiao, P.; Qi, S. Analysis of Slope Stability in Unsaturated Expansive Soil: A Case Study. Front. Earth Sci. 2019, 7, 292. [Google Scholar] [CrossRef]

- Huang, R.; Lizhou, W.U. Stability Analysis of Unsaturated Expansive Soil Slope. Earth Sci. Front. 2007, 14, 129–133. [Google Scholar] [CrossRef]

- Ma, J.; Chen, S.; Yu, F. Experimental study on the evolution of cracks in cracked soil. Rock Soil Mech. 2007, 141, 2203–2208. [Google Scholar]

- Ma, J. Preferential Flow and Stability Analysis Method for Fissure Clay Slopes. Master’s Thesis, Wuhan Institute of Geotechnics, Chinese Academy of Sciences, Wuhan, China, 2007. [Google Scholar]

- Yao, Z.; Chen, Z. Experimental study on meso-structure change of remolded expansive soil during drying and wetting. J. Undergr. Space Eng. 2009, 5, 429–434. [Google Scholar]

- Chen, Z.; Fang, X.; Zhu, Y.; Qin, B.; Wei, X.; Yao, Z. Study on mesostructure and Evolution of expansive soil and loess. Rock Soil Mech. 2009, 30, 1–11. [Google Scholar]

- Cao, L.; Wang, Z.; Zhang, Z. Experimental study on crack evolution characteristics of expansive soil under rainfall and evaporation conditions. Chin. J. Rock Mech. Eng. 2016, 35, 413–421. [Google Scholar]

- Luo, Y.; Zhang, J.; Zhou, Z.; Qie, H.; Mi, M.; Shen, J. Study on evolution of critical water content of soil cracking under rainfle-evaporation condition. Rock Soil Mech. 2020, 41, 2592–2600. [Google Scholar]

- Xie, C.; Shen, Q.; Wu, Z.; Zhao, Y.; Mei, G. Stability Analysis for the Expansive Soil Slope Considering the Influence of Cracks Based on the Upper Bound Method. IOP Conf. Ser. Earth Environ. Sci. 2018, 189, 2014–2033. [Google Scholar] [CrossRef]

- Liu, H.; Yin, Z. Experimental study on the influence of cracks on shear strength of expansive soil. Rock Soil Mech. 2010, 31, 727–731. [Google Scholar]

- Chen, X.; Jing, X.; Chen, Y. Tailings Dam-break: The Influence of Slurry with Different Concentrations on Downstream. Front. Earth Sci. 2021, 9, 1176. [Google Scholar] [CrossRef]

- Julina, M.; Thyagaraj, T. Determination of Volumetric Shrinkage of an Expansive Soil Using Digital Camera Images. Int. J. Geotech. Eng. 2018, 15, 624–632. [Google Scholar] [CrossRef]

- Fityus, S.; Wells, T.; Huang, W. Water Content Measurement in Expansive Soils Using the Neutron Probe. Geotech. Test. J. 2011, 34, 255–264. [Google Scholar]

- Inci, G. Numerical Modeling of Desiccation Cracking in Compacted Soils. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India, 1–6 October 2008. [Google Scholar]

- Sima, J.; Jiang, M.; Zhou, C. Numerical Simulation of Desiccation Cracking in a Thin Clay Layer Using 3D Discrete Element Modelling. Comput. Geotech. 2014, 56, 168–180. [Google Scholar] [CrossRef]

- Le, T.C.; Liu, C.; Tang, C.S. Numerical Simulation of Desiccation Cracking in Clayey Soil Using a Multifield Coupling Discrete-Element Model. J. Geotech. Geoenviron. Eng. 2022, 148, 04021183. [Google Scholar] [CrossRef]

- Wang, P.; Fu, Q. Influence of Rainfall Infiltration on Stability of Fissured Clay Slope. Highw. Eng. 2013, 38, 165–170+192. [Google Scholar]

- Yuan, J.; Lin, Y.; Ding, P.; Han, C. Influence of Fissure Induced Anisotropy on Rainfall Infiltration of Slope. Chin. J. Geotech. Eng. 25, 143–149. 2016, 38, 76–82. [Google Scholar]

- Wei, J.; Cao, X.; Yuan, J. Yang, C. Effect of Rainfall/Evaporation on Stability of Expansive Soil Slope. Eng. Investig. 2010, 38, 8–13. [Google Scholar]

- Bai, Y.; Wei, B.; Zheng, W. Stability Analysis of Expansive Soil Slope Considering Crack and Expansive Force. Transp. Sci. Technol. Econ. 2020, 22, 49–56. [Google Scholar]

- Chen, X.; Jing, X.; Cai, H. Hydraulic Erosion Rate of Reinforced Tailings: Laboratory Investigation and Prediction Model. Adv. Mater. Sci. Eng. 2021, 2, 1–13. [Google Scholar] [CrossRef]

- Xiao, F.; Jing, X.; Zhou, Y.; Zhao, S. Study on Influence of Reinforcement Density on Overtopping Failure of Tailings Dam. J. Saf. Sci. Technol. 2016, 12, 68–74. [Google Scholar]

- Liu, K.H.; Cai, H.; Jing, X.F. Study on Hydraulic Incipient Motion Model of Reinforced Tailings. Water 2021, 13, 2033. [Google Scholar] [CrossRef]

- Sun, K.; Tang, C.; Liu, C.; Li, H.; Wang, P.; Leng, T. Research Method of Soil Cracking. Rock Soil Mech. 2017, 38 (Supp. 1), 11–26. [Google Scholar]

- Zhao, G.L.; Shi, J.W.; Zhen, B.Y. Quantitative Analysis of Fracture Evolution of Expansive Soils Under Wetting-Drying Cycles. Rock Soil Mech. 2020, 41, 11. [Google Scholar]

- Zhao, G.L.; Shi, J.W.; Ji, W.Z. Thickness Effect on Crack Evolution of Expansive Soil. Chin. J. Geotech. Eng. 2020, 42, 1922–1930. [Google Scholar]

- Xiao, F.; Jing, Y.U.L.C.; Dacid, J.W.; Marcelo, L.S.; Hengwei, Z. Overtopping Failure of a Reinforced Tailings Dam: Laboratory Investigation and Forecasting Model of Dam Failure. Water 2019, 11, 315–331. [Google Scholar]

- Yin, Z.; Yuan, J.; Wei, J.; Cao, X.; Liu, H.; Xu, S. Influence of Cracks on Stability of Expansive Soil Slope. Chin. J. Geotech. Eng. 2012, 34, 2155–2161. [Google Scholar]

- Liu, Y. Study on the Relationship between Water Content and Mechanical Characteristics of Expansive Soil; Southwest Jiaotong University: Chengdu, China, 2013. [Google Scholar]

- Tang, C.-s.; Shi, B.; Liu, C. Experimental characterization of shrinkage and desiccation cracking in thin clay layer. Appl. Clay Sci. 2011, 52, 69–77. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, J.; Wang, C. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Gao, W.; Yang, H.; Hu, R. Soil–rock mixture slope stability analysis by microtremor survey and discrete element method. Bull. Eng. Geol. Environ. 2022, 81, 121. [Google Scholar] [CrossRef]

- Lv, Y.; Li, H.; Zhu, X. Discrete element method simulation of random Voronoi grain-based models. Clust. Comput. 2017, 20, 335–345. [Google Scholar] [CrossRef]

- Jin, L.; Zeng, Y. Refined simulation for macro-and meso-mechanical properties and failure mechanism of soil-rock mixture by 3d dem. Chin. J. Rock Mech. Eng. 2018, 37, 1540–1550. [Google Scholar]

- Xu, G.; Zhong, K.; Fan, J. Stability analysis of cohesive soil embankment slope based on discrete element method. Cent. South Univ. 2020, 27, 1981–1991. [Google Scholar] [CrossRef]

- Lin, H.Z. Experimental and Numerical Analysis of Soil Slope Instability Induced by Rainfall; Tsinghua University: Beijing, China, 2007. [Google Scholar]

- Wu, S.; Wu, D.; Xiao, F. Rainfall Erosion Predictions for Artificial High-Filled Embankment with Reinforcement. Adv. Mater. Sci. Eng. 2021, 2021, 3648105. [Google Scholar] [CrossRef]

| Sampling Depth | Water Content | Specific Gravity of Soil Particles | Wet Density | Dry Density | Saturation Degree | Void Ratio | Free Swelling Ratio |

|---|---|---|---|---|---|---|---|

| m | W/% | Gs | /(g/cm3) | /(g/cm3) | Sr | e | % |

| 0.5 | 25.3 | 2.77 | 1.73 | 1.38 | 69.6 | 1.006 | 51 |

| Particle Density (kg/m3) | Minimum Particle Size (mm) | Maximum Particle Size (mm) | Stiffness Ratio | Tangential Cohesive Force (KN) | Normal Cohesive Force (kN) | Elastic Modulus | Coefficient of Friction |

|---|---|---|---|---|---|---|---|

| 2000 | 2 | 2.7 | 1 | 2 | 2 | 1 × 108 | 0.7 |

| Depth of Crack 1 (cm) | Depth of Crack 2 (cm) | Depth of Crack 3 (cm) | Depth of Crack 4 (cm) | Depth of Crack 5 (cm) | Depth of Crack 6 (cm) | |

|---|---|---|---|---|---|---|

| Side slope 1 | 6.97 | 0 | 0 | 7.9 | 0 | 0 |

| Side slope 2 | 6.97 | 5.93 | 0 | 7.9 | 7.05 | 0 |

| Side slope 3 | 6.97 | 5.93 | 3.93 | 7.9 | 7.05 | 5.3 |

| Number of Cracks | One Crack | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

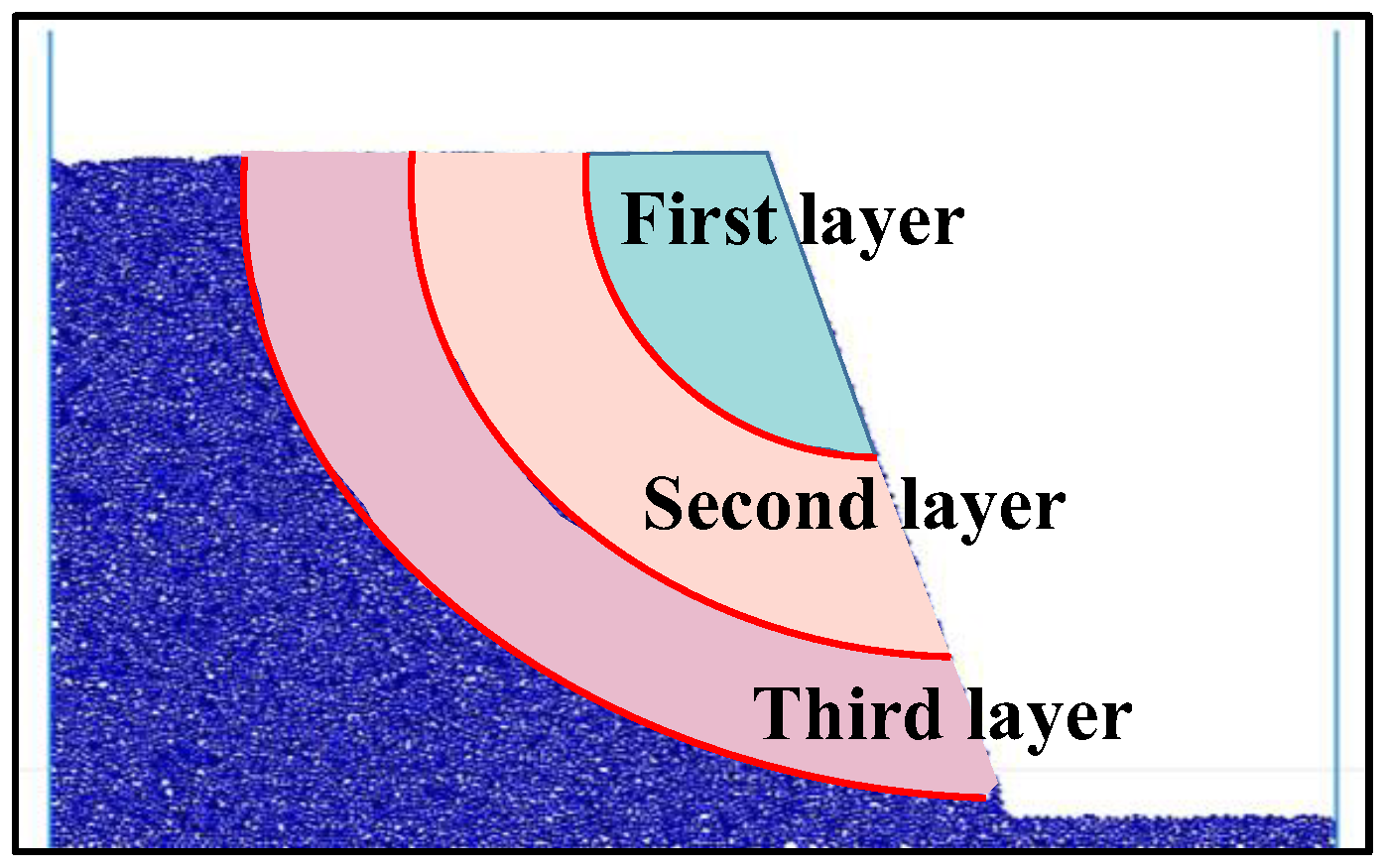

| Layers of Soil | First Layer | Second Layer | Third Layer | ||||||||||||

| Time (s) | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 |

| Displacement (m) | 0.2 | 0.25 | 0.3 | 0.35 | 0.45 | 0 | 0.2 | 0.25 | 0.3 | 0.35 | 0 | 0 | 0.15 | 0.2 | 0.25 |

| (a) | |||||||||||||||

| Number of Cracks | Two Cracks | ||||||||||||||

| Layers of Soil | First Layer | Second Layer | Third Layer | ||||||||||||

| Time (s) | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 |

| Displacement (m) | 0.2 | 0.25 | 0.3 | 0.35 | 0.47 | 0 | 0.2 | 0.25 | 0.3 | 0.35 | 0 | 0 | 0.15 | 0.2 | 0.25 |

| (b) | |||||||||||||||

| Number of Cracks | Three Cracks | ||||||||||||||

| Layers of Soil | First Layer | Second Layer | Third Layer | ||||||||||||

| Time (s) | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 |

| Displacement (m) | 0.2 | 0.35 | 0.6 | 0.65 | 0.7 | 0.15 | 0.3 | 0.4 | 0.45 | 0.5 | 0 | 0.2 | 0.3 | 0.35 | 0.4 |

| (c) | |||||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Jing, X.; Li, X.; Chen, J.; Ma, Q.; Liu, X. Slope Crack Propagation Law and Numerical Simulation of Expansive Soil under Wetting–Drying Cycles. Sustainability 2023, 15, 5655. https://doi.org/10.3390/su15075655

Chen X, Jing X, Li X, Chen J, Ma Q, Liu X. Slope Crack Propagation Law and Numerical Simulation of Expansive Soil under Wetting–Drying Cycles. Sustainability. 2023; 15(7):5655. https://doi.org/10.3390/su15075655

Chicago/Turabian StyleChen, Xuanyi, Xiaofei Jing, Xiaoshuang Li, Junji Chen, Qiang Ma, and Xiaohua Liu. 2023. "Slope Crack Propagation Law and Numerical Simulation of Expansive Soil under Wetting–Drying Cycles" Sustainability 15, no. 7: 5655. https://doi.org/10.3390/su15075655