Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete

Abstract

1. Introduction

2. Materials and Experimental Procedures

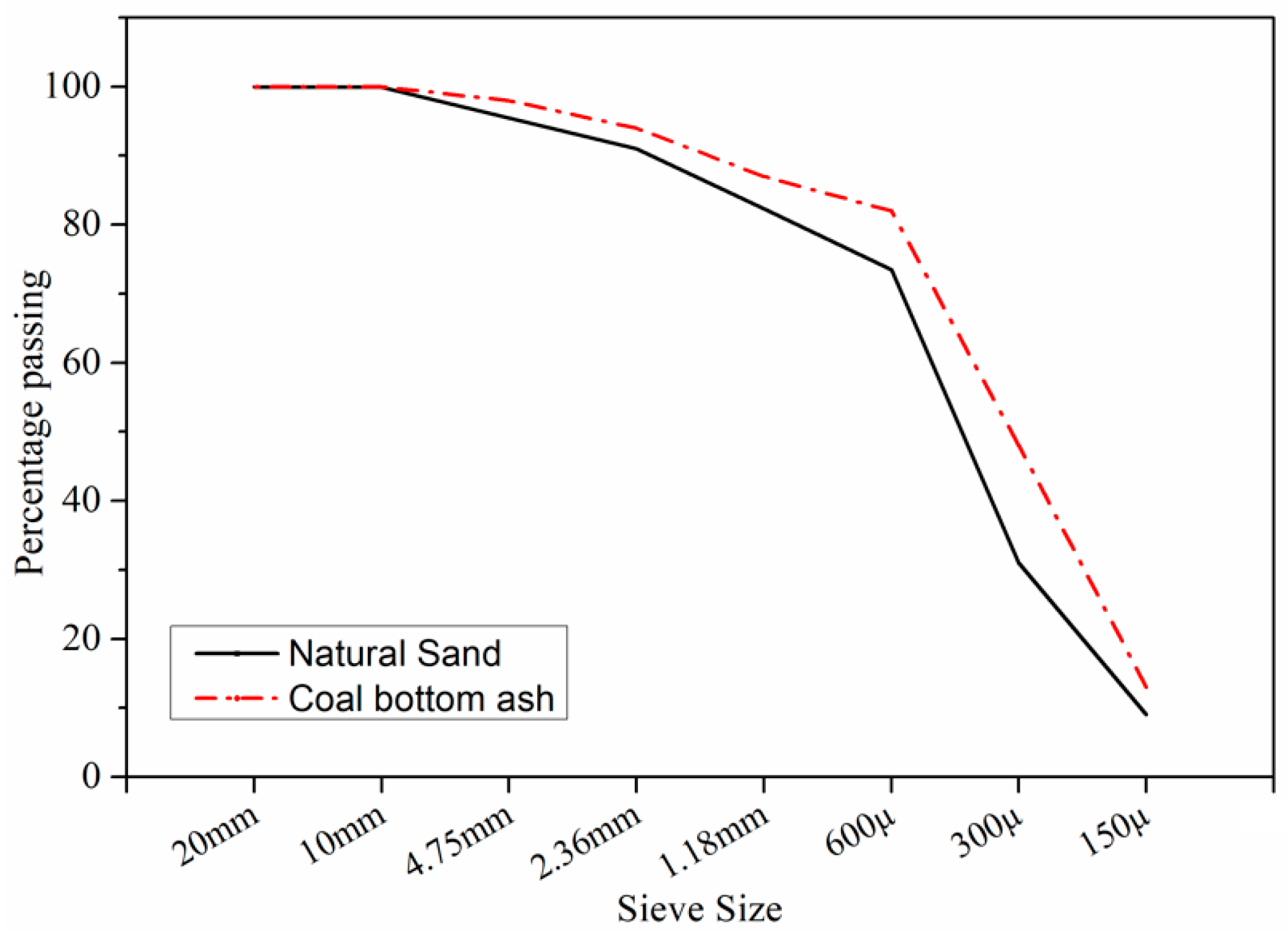

2.1. Coal Bottom Ash

2.1.1. Health and Environmental Concerns of CBA

2.1.2. CBA Treatment

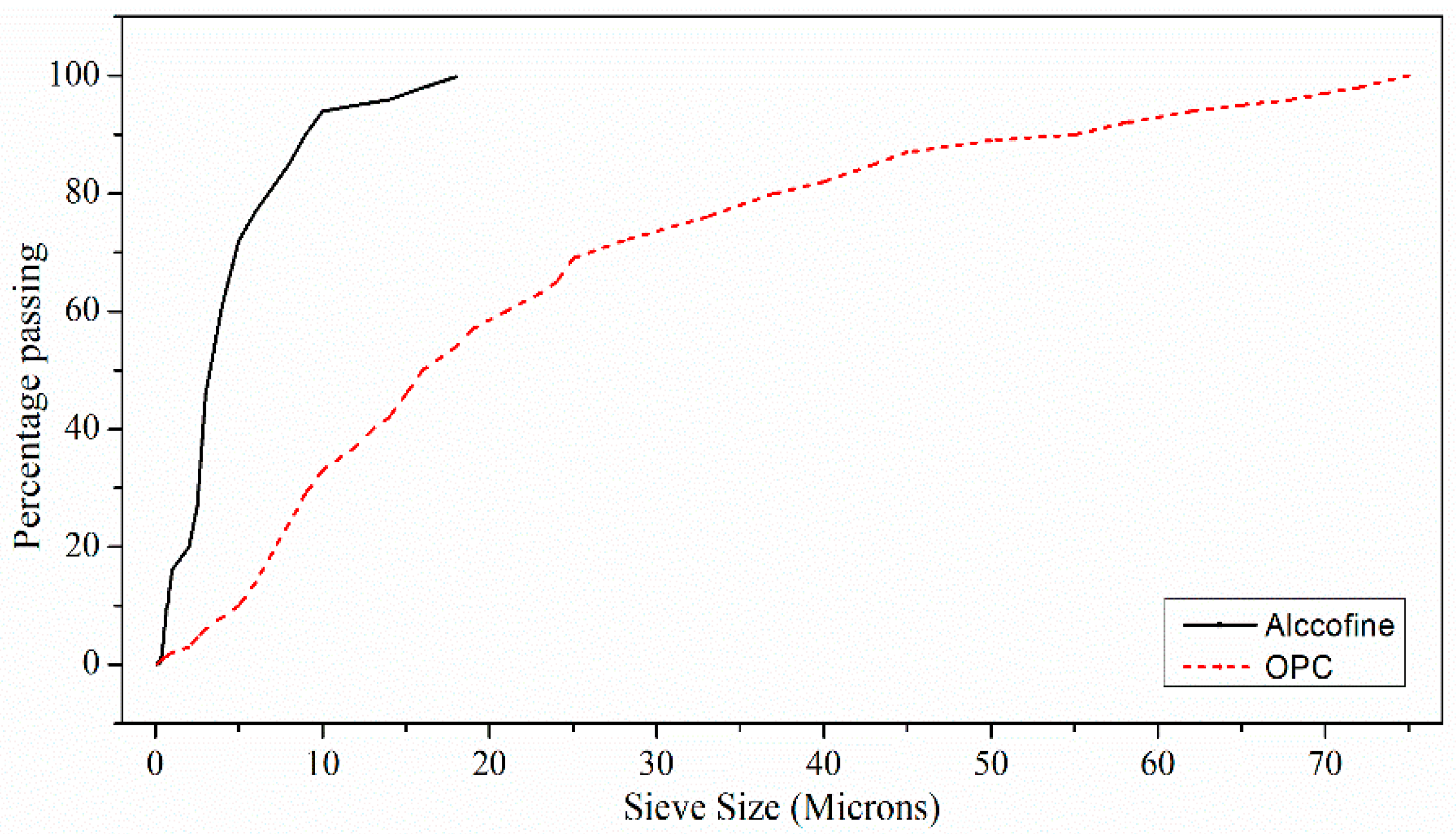

2.2. Alccofine

2.3. Material Classification

2.4. Mix Design

- Achieving maximum replacement of fine aggregates with coal bottom ash between 10% and 50%;

- Dosage of superplasticizer should be limited to 2% to ensure the designed slump value, i.e., 100 mm, after the successful maximum partial replacement of fine aggregates with CBA in combination with Alccofine. To correct this parameter, slump tests were rigorously carried out to analyze the variations in dosage of superplasticizer for CBA concrete mixtures and Alccofine-assisted CBA concrete mixtures. The required dosage of superplasticizer to achieve a slump value of 100 mm is tabulated in Table 4. The detailed research program for Phases I and II can be established in Figure 4.

2.5. Testing Procedures

3. Results and Discussions

3.1. Phase I Studies

3.1.1. Fresh Concrete Properties

3.1.2. Mechanical Properties of Coal Bottom Ash Concrete Mixtures

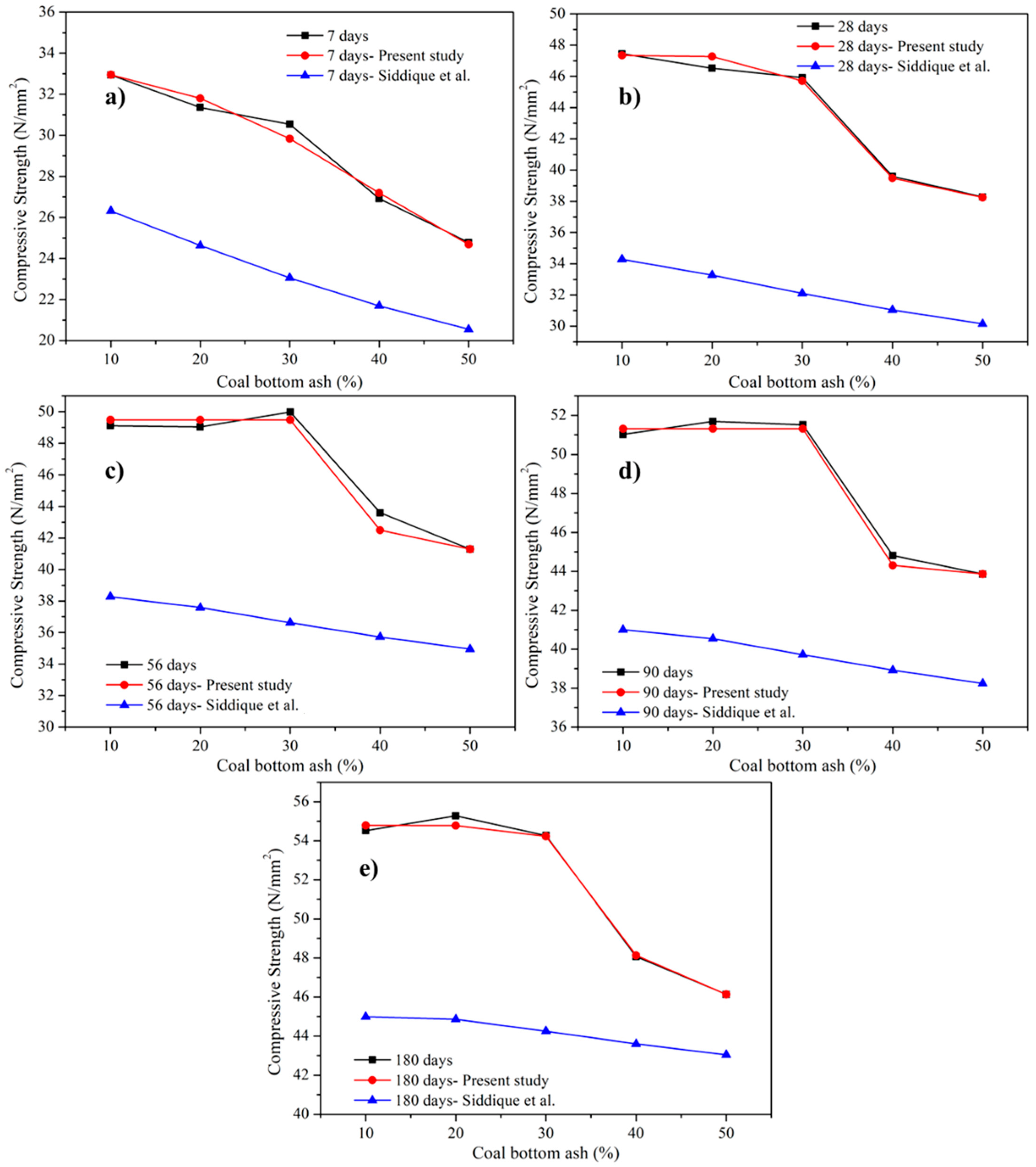

Compressive Strength of Coal Bottom Ash Concrete Mix

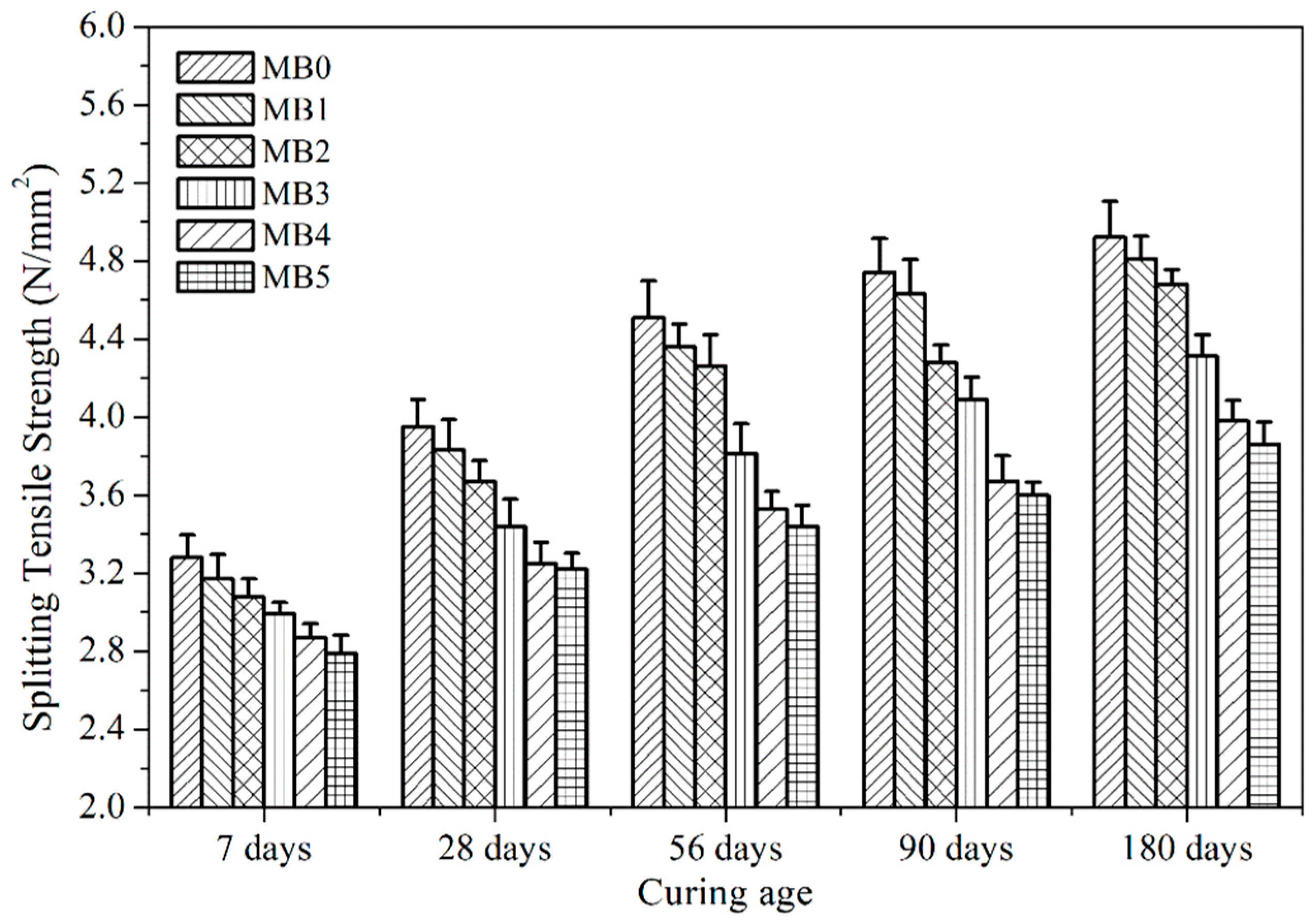

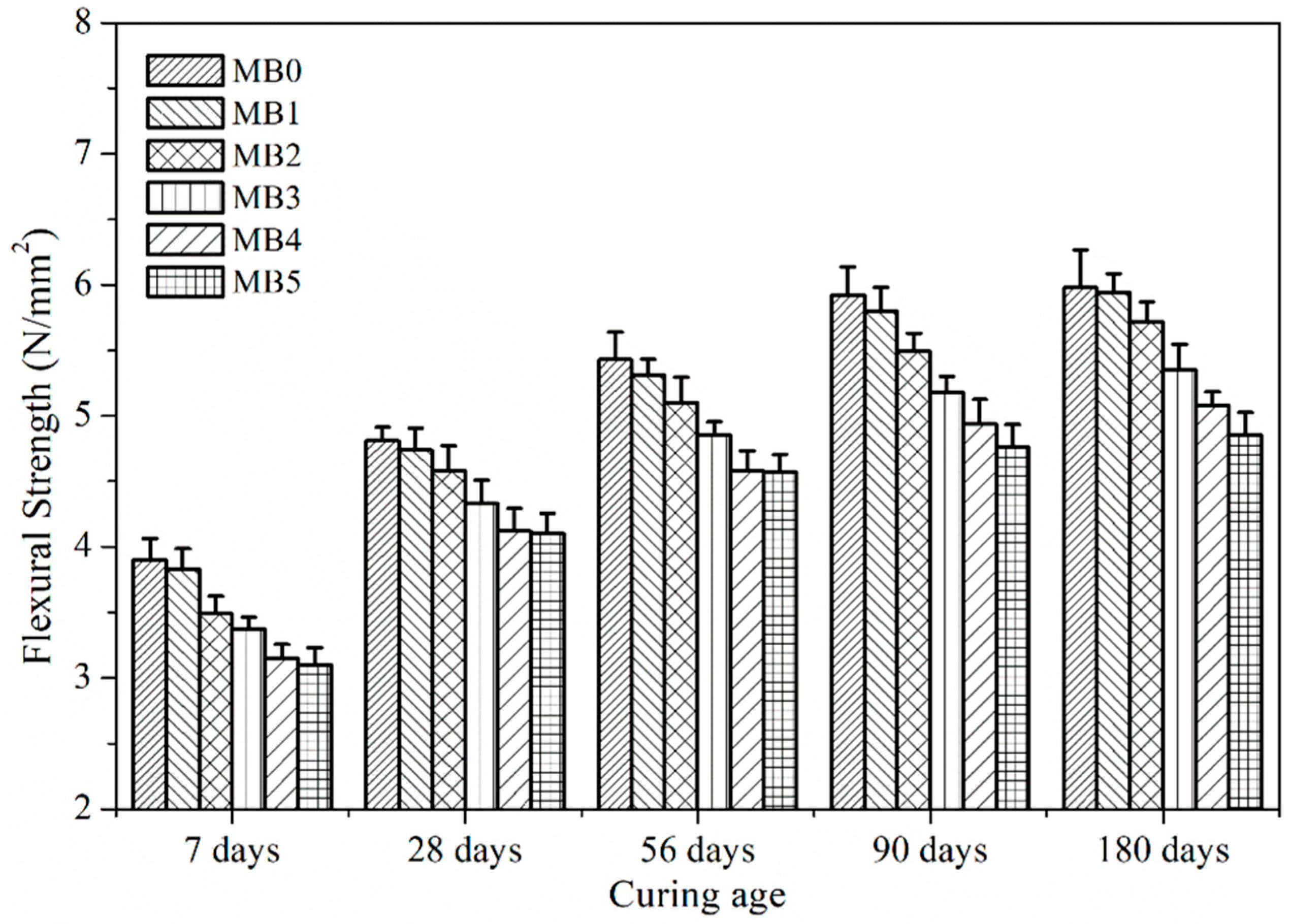

Splitting Tensile and Flexural Strength

3.1.3. Selection of Bottom Ash Concrete Mix

3.2. Phase II Experimental Investigations

3.2.1. Fresh Properties of Alccofine-Assisted Coal Bottom Ash Concrete Mixtures

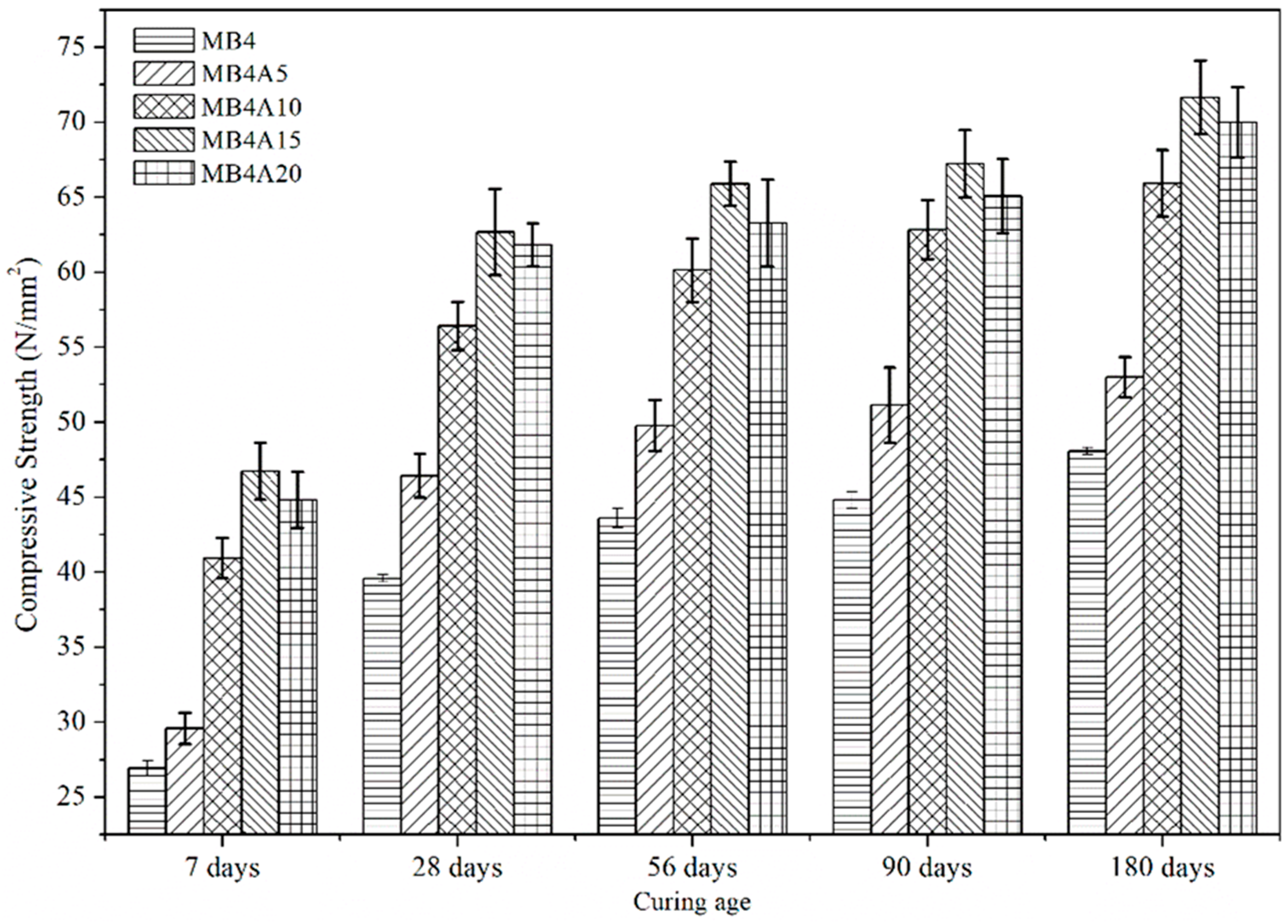

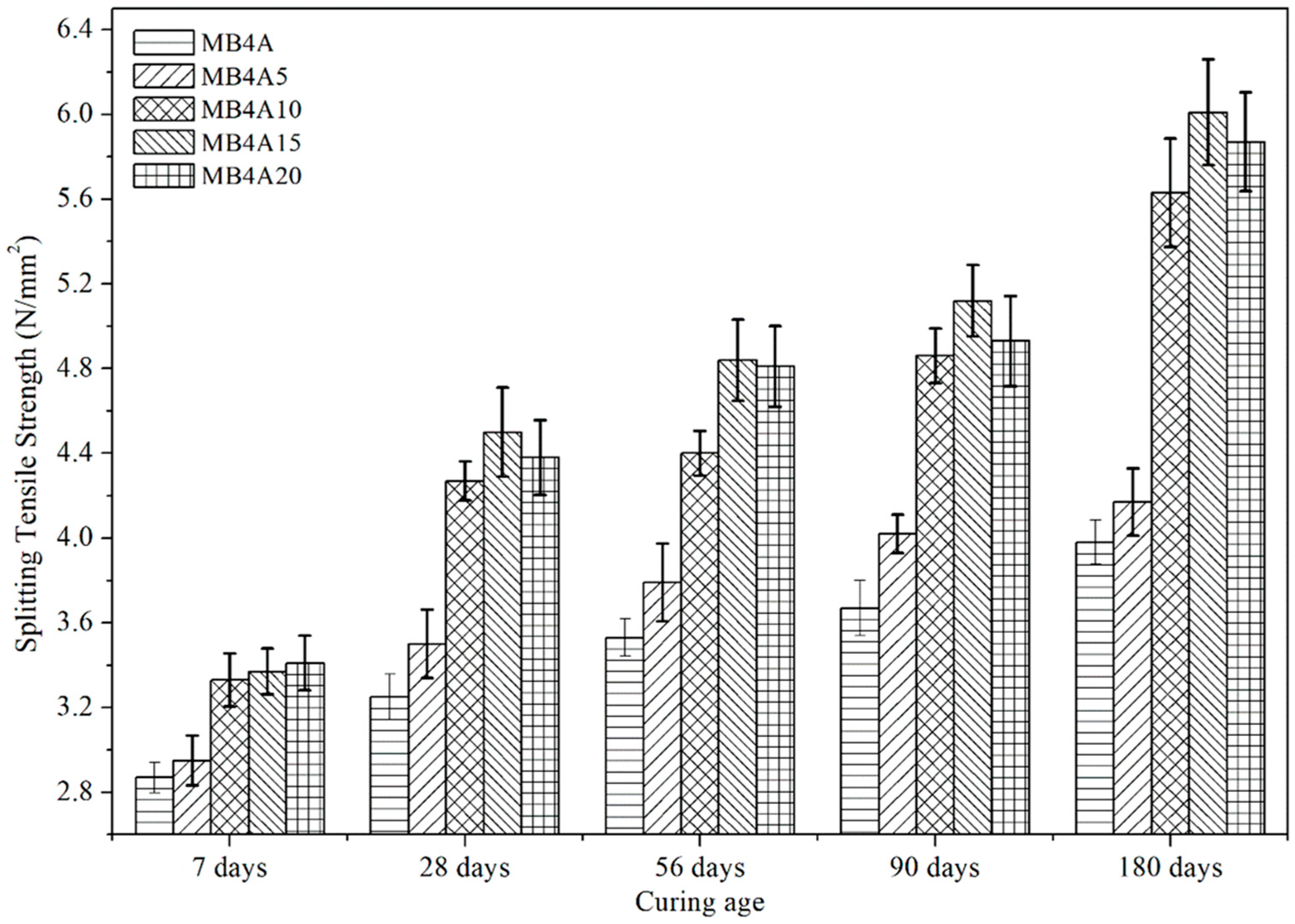

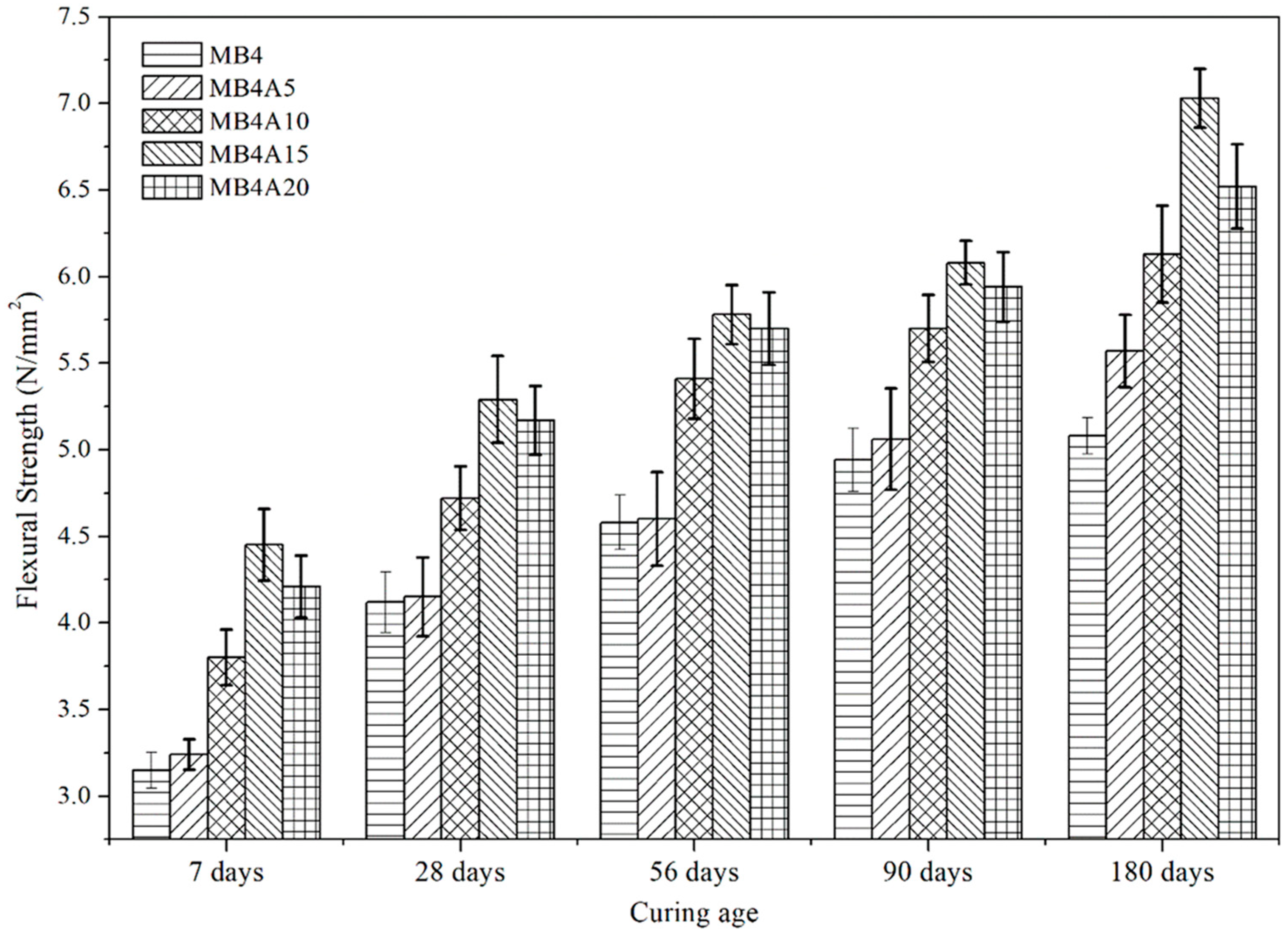

3.2.2. Mechanical Properties of Alccofine-Assisted Coal Bottom Ash Concrete Mixtures

3.2.3. Pulse Velocity

3.2.4. Durability Property

Rapid Chloride Permeability Testing

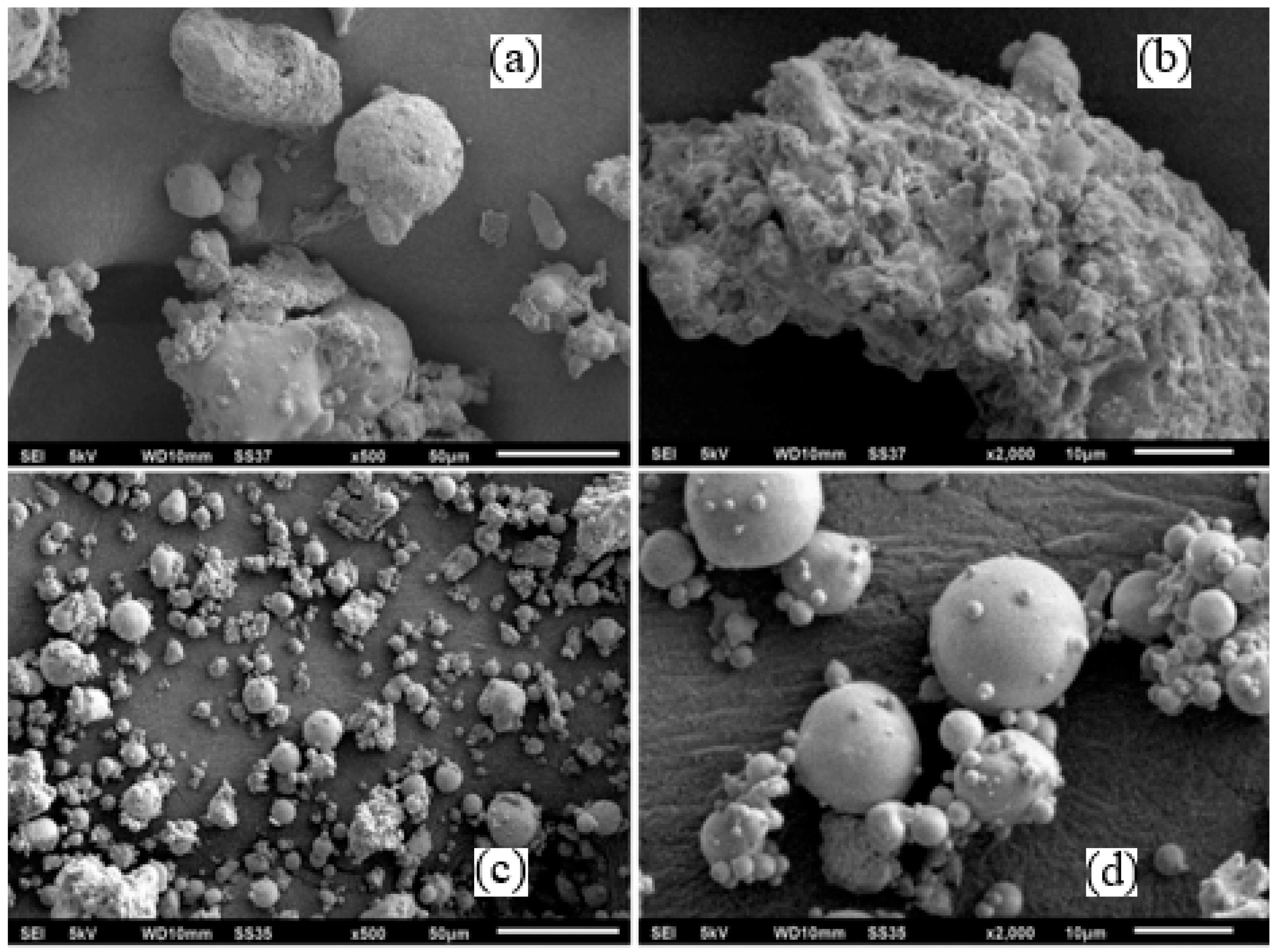

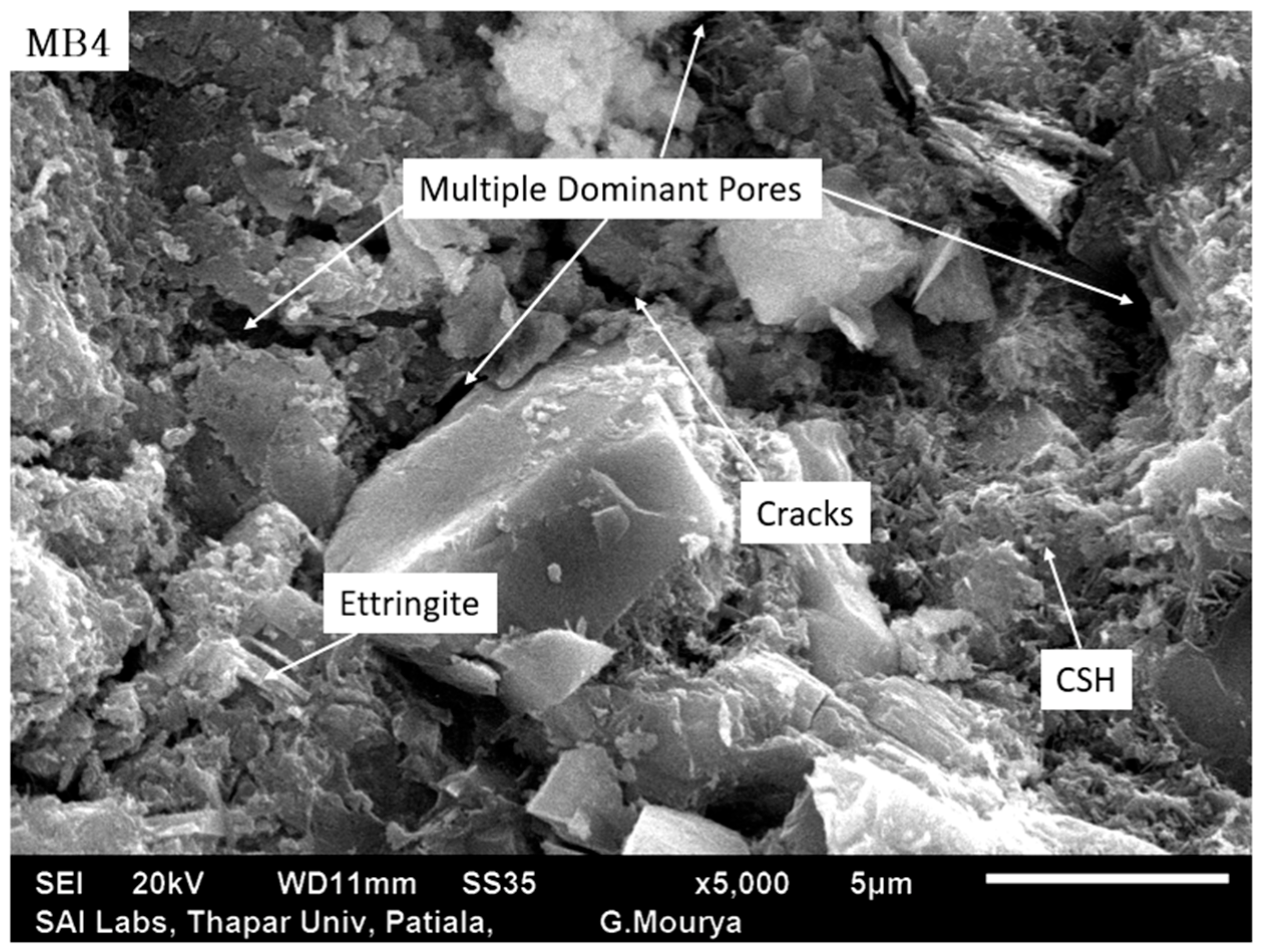

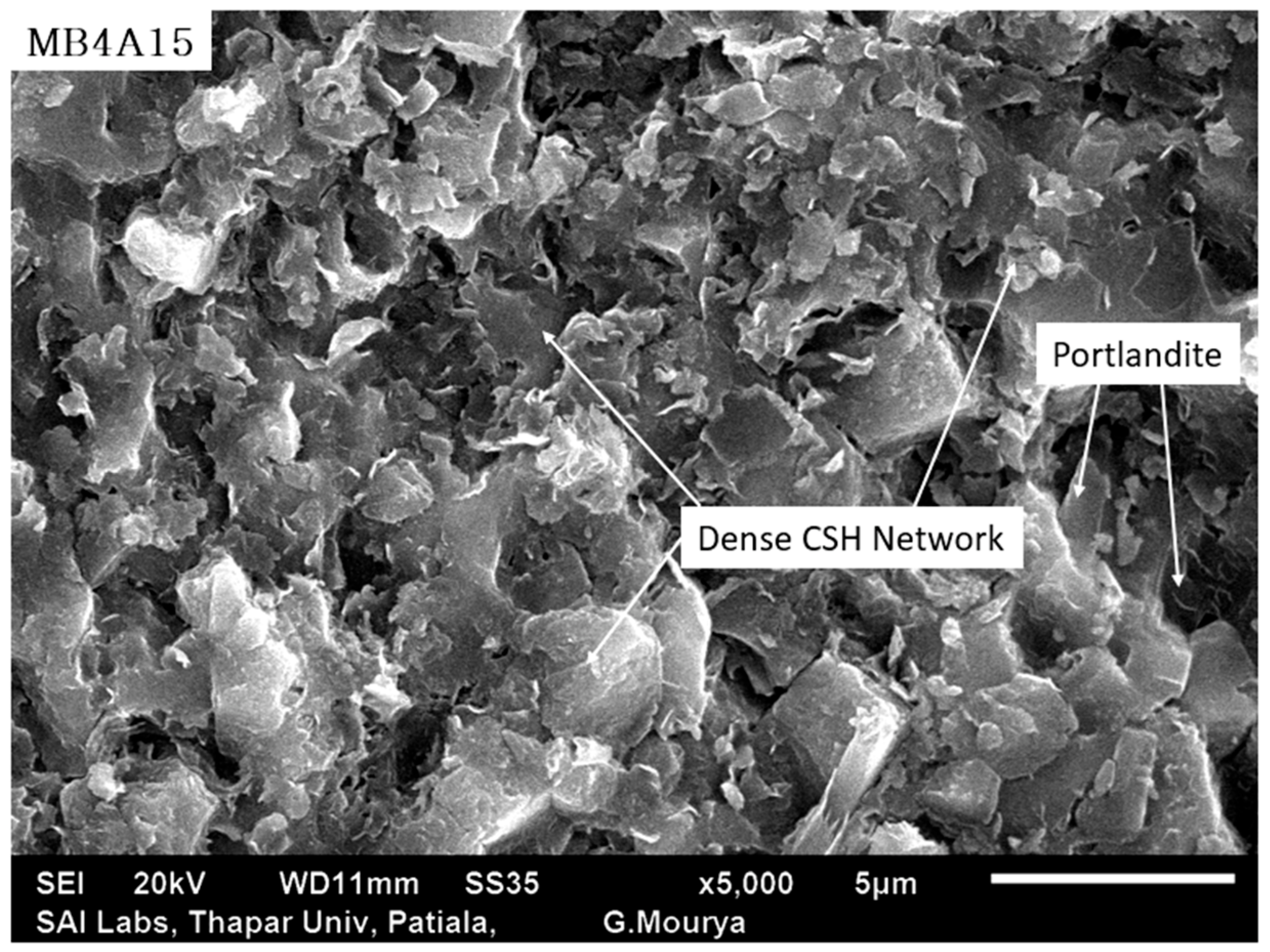

3.3. Scanning Electron Microscopy

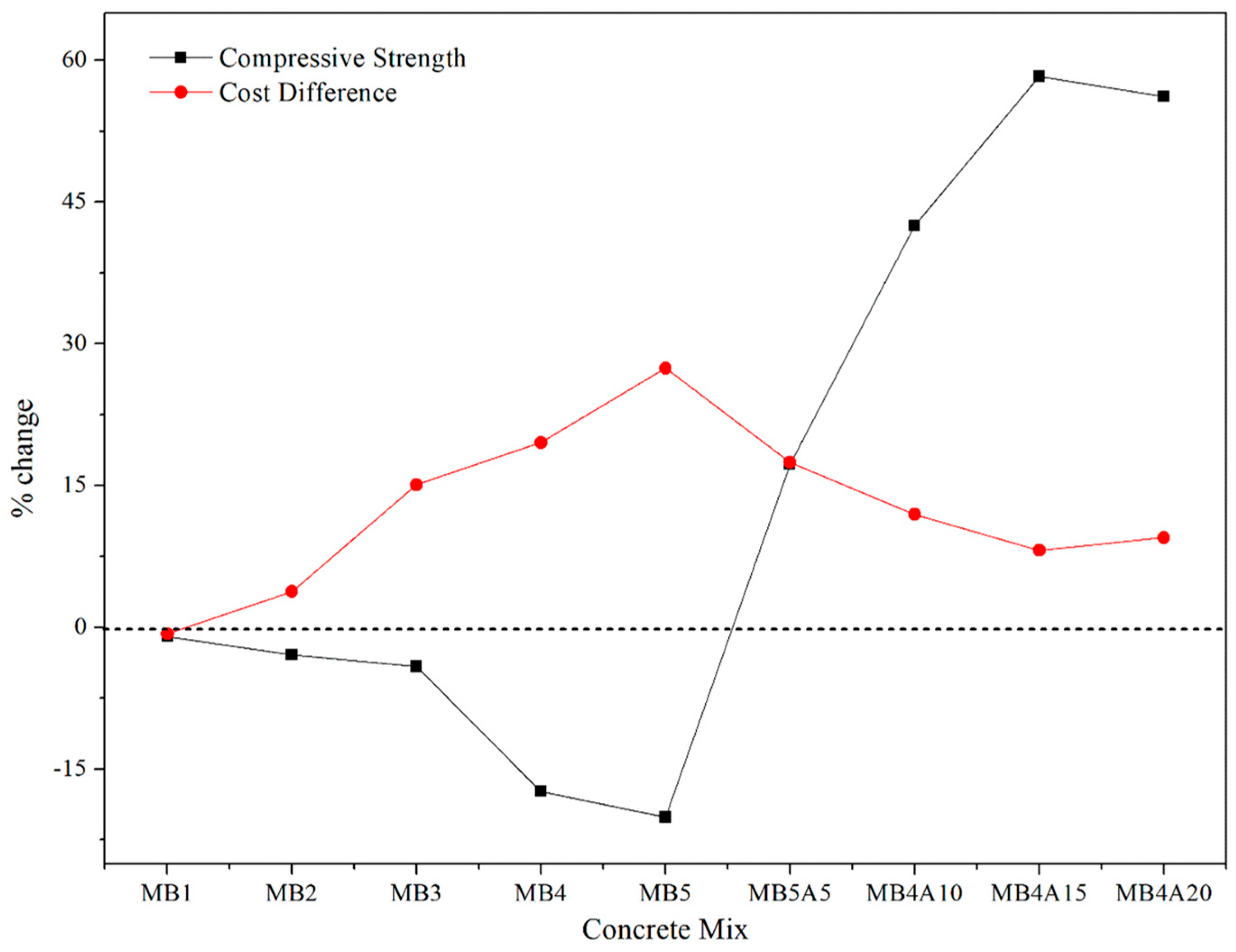

4. Cost Analysis

5. Statistical Studies

5.1. Empirical Relationships for Coal Bottom Ash Concrete

5.2. Empirical Relationships for Alccofine-Assisted Coal Bottom Ash Concrete

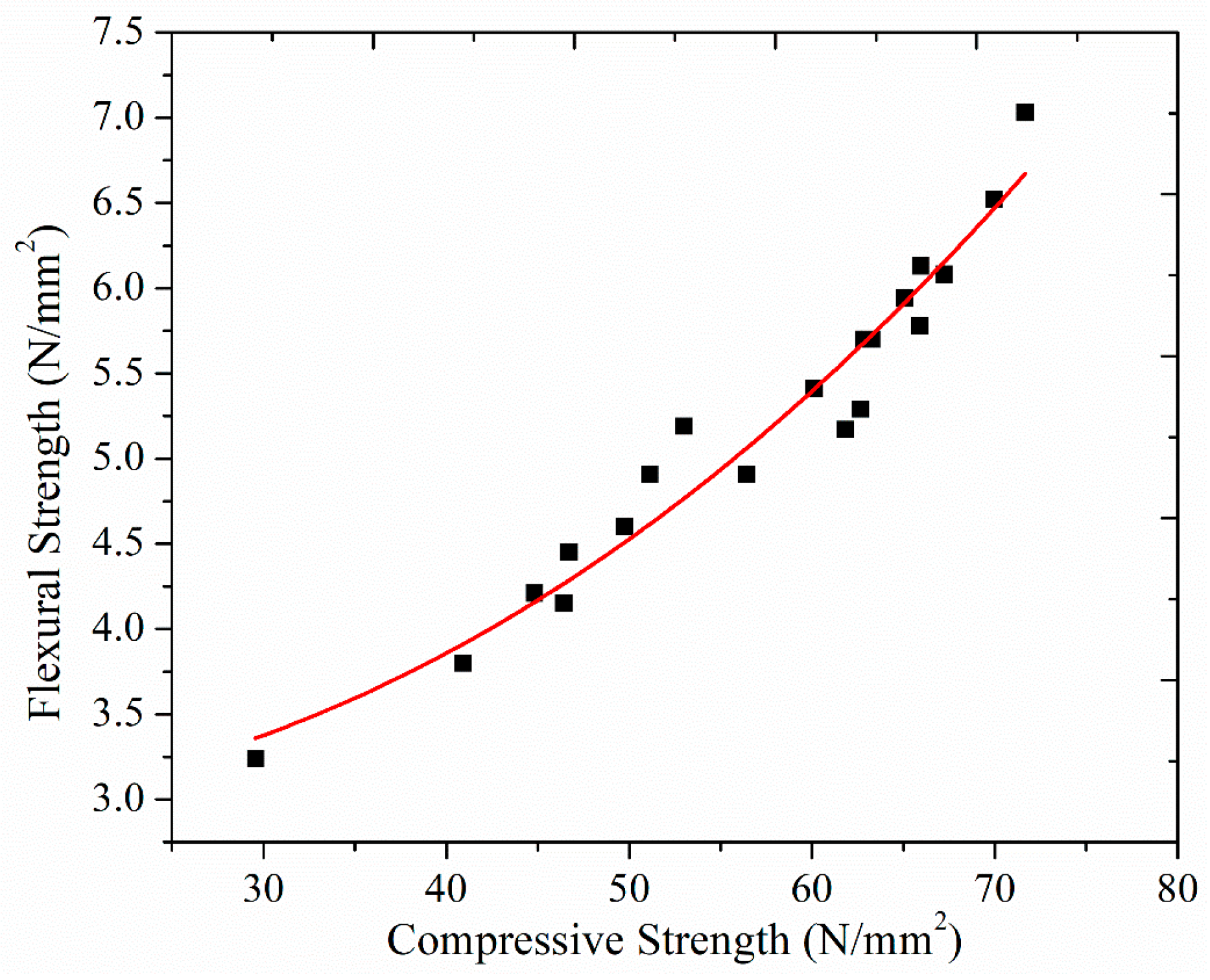

5.3. Association among Strength Properties

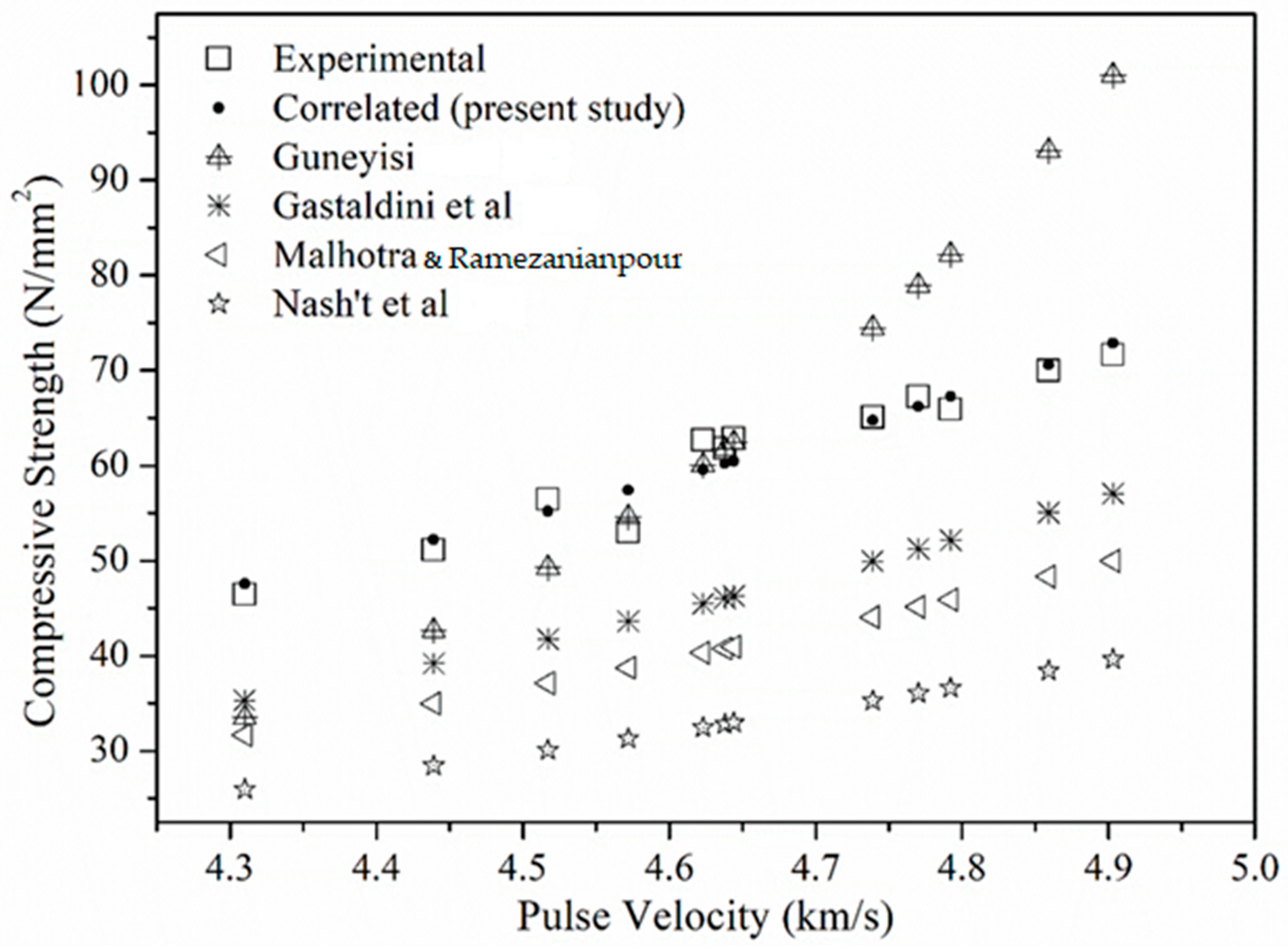

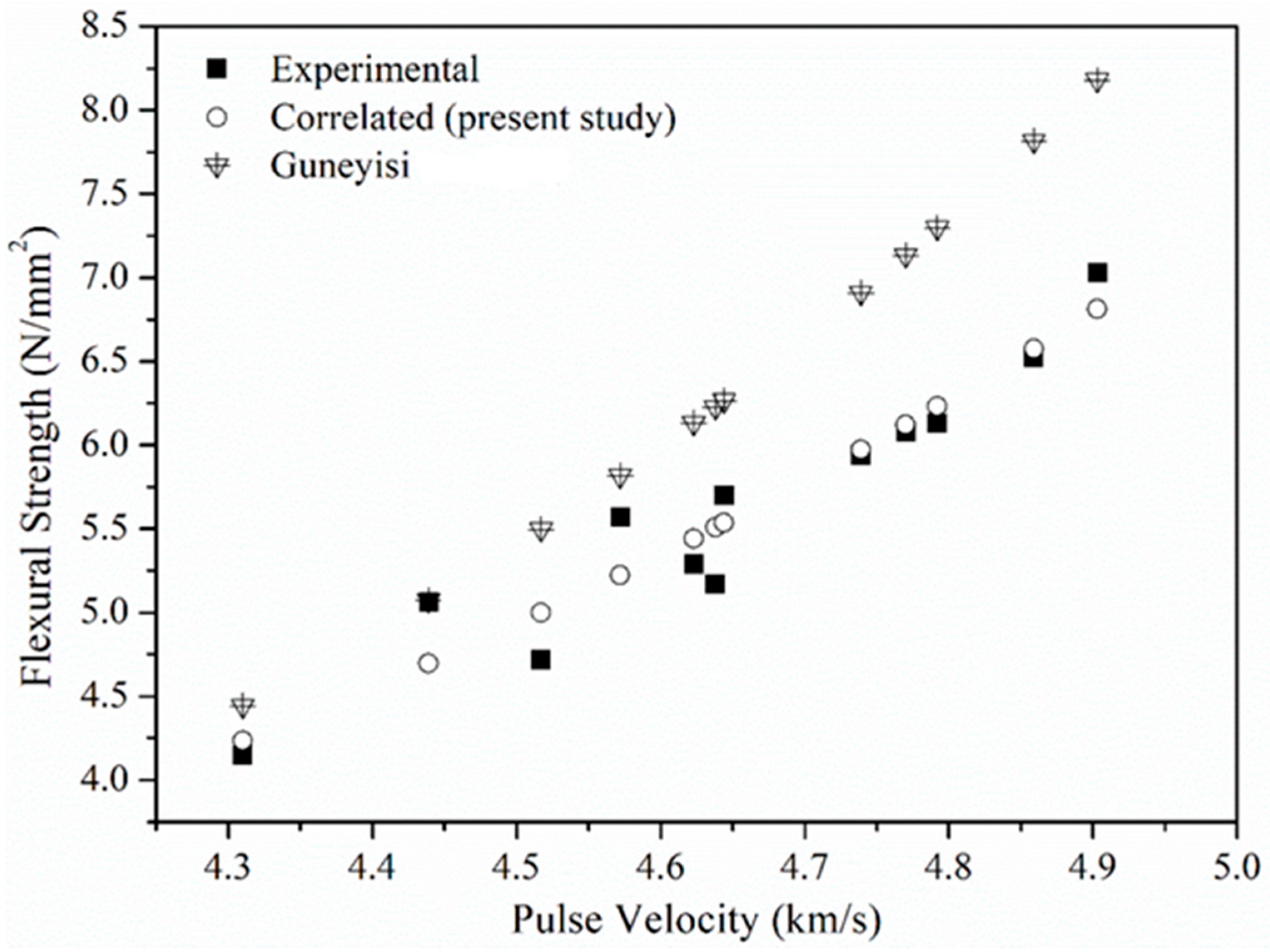

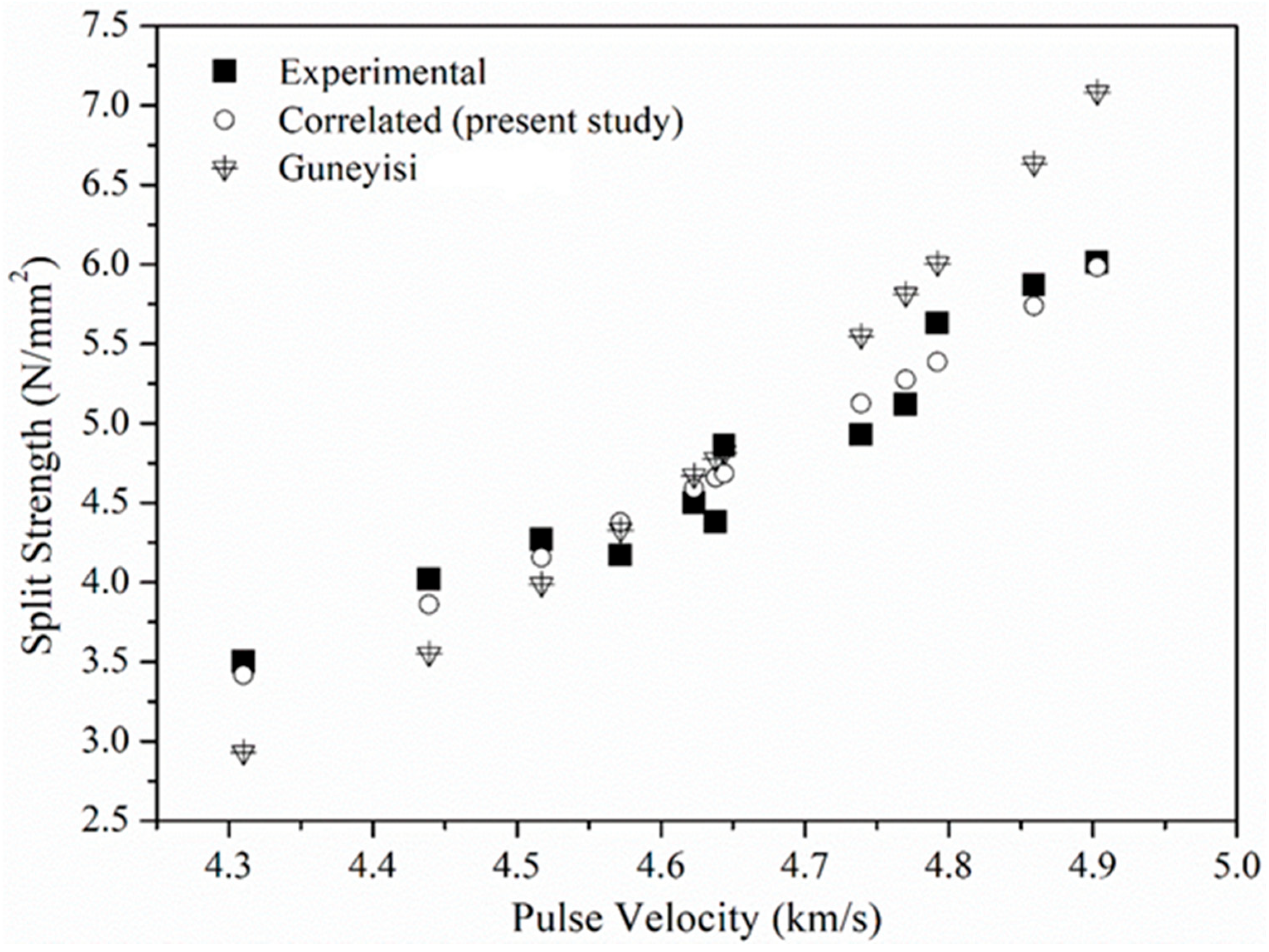

5.4. Relationship between Pulse Velocity and Strength Properties

6. Conclusions

- ✓

- Compared to the controlled concrete mix, the strength properties have shown a significant decline for all the concentrations of CBA (10% to 50%);

- ✓

- Alccofine addition has recovered the workability and strength properties significantly as it contains a finer pore structure which reduces the void space in concrete. In particular, the MB4A15 concrete mix has shown the peak properties; thus, it is recommended to use Alccofine in place of cement as per the current investigation;

- ✓

- RCPT test results empower the MB4A15 concrete mix, as it showed very low chloride-ion penetration due to its dense pore structure and chemical stability. Therefore, it has been concluded that 40% of the industrial waste, i.e., coal bottom ash with a combination of 15% Alccofine material, as a replacement of cement, is a desirable combination in order to accomplish enhanced properties of concrete at a fresh as well as hardened stage;

- ✓

- SEM analysis has depicted the formation of extra C-S-H, due to the excellent pozzolanic reactions, projected dense pore structure and ultimately higher strength gain at all ages for the MB4A15 mix;

- ✓

- It has been concluded that for the MB4A15 mix, the cost has increased to 8.14% compared to control concrete; however, a significant increase of 58.3% in compressive strength can be observed, which is very large compared to the cost involved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poudyal, L.; Adhikari, K. Environmental sustainability in cement industry: An integrated approach for green and eco-nomical cement production. Resour. Environ. Sustain. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Scope, C.; Vogel, M.; Guenther, E. Greener, cheaper, or more sustainable: Reviewing sustainability assessments of maintenance strategies of concrete structures. Sustain. Prod. Consum. 2020, 26, 838–858. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S.; Nikbakht, E. Incorporation of waste materials in the manufacture of masonry bricks: An update review. J. Build. Eng. 2018, 21, 37–54. [Google Scholar] [CrossRef]

- Shahidan, S.; Tayeh, B.A.; Jamaludin, A.A.; Bahari, N.A.; Mohd, S.S.; Ali, N.Z.; Khalid, F.S. Physical and mechanical properties of self-compacting concrete containing superplasticizer and me-takaolin. Mater. Sci. Eng. 2017, 271, 12004. [Google Scholar]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Muthusamy, K.; Rasid, M.H.; Jokhio, G.; Budiea, A.M.A.; Hussin, M.W.; Mirza, J. Coal bottom ash as sand replacement in concrete: A review. Constr. Build. Mater. 2019, 236, 117507. [Google Scholar] [CrossRef]

- Tian, Y.; Zhou, X.; Yang, Y.; Nie, L. Experimental analysis of air-steam gasification of biomass with coal-bottom ash. J. Energy Inst. 2019, 93, 25–30. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2013, 47, 1055–1065. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement in-dustry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Aggarwal, Y.; Siddique, R. Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 2014, 54, 210–223. [Google Scholar] [CrossRef]

- Polydorou, T.; Constantinides, G.; Neocleous, K.; Kyriakides, N.; Koutsokeras, L.; Chrysostomou, C.; Hadjimitsis, D. Effects of pre-treatment using waste quarry dust on the adherence of recycled tyre rubber particles to cementitious paste in rubberised concrete. Constr. Build. Mater. 2020, 254, 119325. [Google Scholar] [CrossRef]

- Febin, G.K.; Abhirami, A.; Vineetha, A.; Manisha, V.; Ramkrishnan, R.; Sathyan, D.; Mini, K. Strength and durability properties of quarry dust powder incorporated concrete blocks. Constr. Build. Mater. 2019, 228, 116793. [Google Scholar] [CrossRef]

- Zafar, M.S.; Javed, U.; Khushnood, R.A.; Nawaz, A.; Zafar, T. Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Constr. Build. Mater. 2020, 250, 118878. [Google Scholar] [CrossRef]

- Jain, K.L.; Sancheti, G.; Gupta, L.K. Durability performance of waste granite and glass powder added concrete. Constr. Build. Mater. 2020, 252, 119075. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.I.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Çelik, A.I.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- dos Santos, L.; Magalhães, R.; Barreto, S.; Santos, G.; de Paiva, F.; de Souza, A.; Teixeira, S. Characterization and reuse of spent foundry sand in the production of concrete for interlocking pavement. J. Build. Eng. 2020, 36, 102098. [Google Scholar] [CrossRef]

- Mushtaq, S.M.; Siddique, R.; Goyal, S.; Kaur, K. Experimental studies and drying shrinkage prediction model for concrete containing waste foundry sand. Clean. Eng. Technol. 2021, 2, 100071. [Google Scholar] [CrossRef]

- Lo, F.-C.; Lee, M.-G.; Lo, S.-L. Effect of coal ash and rice husk ash partial replacement in ordinary Portland cement on pervious concrete. Constr. Build. Mater. 2021, 286, 122947. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Strength properties and micro-structural properties of concrete containing coal bottom ash as partial replacement of fine aggregate. Constr. Build. Mater. 2014, 50, 246–256. [Google Scholar] [CrossRef]

- Singh, N.; Bhardwaj, A. Reviewing the role of coal bottom ash as an alternative of cement. Constr. Build. Mater. 2019, 233, 117276. [Google Scholar] [CrossRef]

- Kara, I.B. Effects of cooling regimes on limestone rock and concrete with limestone aggregates at elevated temperatures. Int. J. Rock Mech. Min. Sci. 2021, 138, 104618. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Huang, J.; Zhang, W.; Liu, X. Experimental and numerical study of hooked-end steel fiber-reinforced concrete based on the meso- and macro-models. Compos. Struct. 2023, 309, 116750. [Google Scholar] [CrossRef]

- Zhang, W.; Kang, S.; Huang, Y.; Liu, X. Behavior of Reinforced Concrete Beams without Stirrups and Strengthened with Basalt Fiber–Reinforced Polymer Sheets. J. Compos. Constr. 2023, 27, 04023007. [Google Scholar] [CrossRef]

- Qi, B.; Gao, S.; Xu, P. The Application of Rubber Aggregate-Combined Permeable Concrete Mixture in Sponge City Con-struction. Coatings 2023, 13, 87. [Google Scholar] [CrossRef]

- Qi, B.; Gao, S.; Xu, P. The Application of Recycled Epoxy Plastic Sheets Waste to Replace Concrete in Urban Construction and Building. Processes 2023, 11, 201. [Google Scholar] [CrossRef]

- Bai, B.; Bai, F.; Nie, Q.; Jia, X. A high-strength red mud–fly ash geopolymer and the implications of curing temperature. Powder Technol. 2023, 416, 118242. [Google Scholar] [CrossRef]

- Amin, M.; Agwa, I.S.; Mashaan, N.; Mahmood, S.; Abd-Elrahman, M.H. Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability 2023, 15, 3085. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri Sabri, M.M. Performance evaluation of fi-ber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 692. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Özkılıç, Y.O.; Sabri, M.M.S. Effects of Waste Powder, Fine and Coarse Marble Aggregates on Concrete Compressive Strength. Sustainability 2022, 14, 14388. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban, E.M.; Stel’Makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Shcherban, E.M.; Stel’Makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’Nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Zhao, F.; Huo, T.; Chen, E.; Tang, S. Comparison between the Influence of Finely Ground Phosphorous Slag and Fly Ash on Frost Resistance, Pore Structures and Fractal Features of Hydraulic Concrete. Fractal Fract. 2022, 6, 598. [Google Scholar] [CrossRef]

- Zhou, H.; Bhattarai, R.; Li, Y.; Si, B.; Dong, X.; Wang, T.; Yao, Z. Towards sustainable coal industry: Turning coal bottom ash into wealth. Sci. Total. Environ. 2021, 804, 149985. [Google Scholar] [CrossRef] [PubMed]

- Jaturapitakkul, C.; Cheerarot, R. Development of bottom ash as pozzolanic material. J. Mater. Civ. Eng. 2003, 15, 48–53. [Google Scholar] [CrossRef]

- Kurama, H.; Kaya, M. Usage of coal combustion bottom ash in concrete mixture. Constr. Build. Mater. 2008, 22, 1922–1928. [Google Scholar] [CrossRef]

- Yıldırım, H.; Özturan, T. Impact resistance of concrete produced with plain and reinforced cold-bonded fly ash aggregates. J. Build. Eng. 2021, 42, 102875. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Altan, I.; Öz, H. Utilization of cold bonded fly ash lightweight fine aggregates as a partial substitution of natural fine aggregate in self-compacting mortars. Constr. Build. Mater. 2015, 74, 9–16. [Google Scholar] [CrossRef]

- Oren, O.H.; Gholampour, A.; Gencel, O.; Ozbakkaloglu, T. Physical and mechanical properties of foam concretes containing granulated blast furnace slag as fine aggregate. Constr. Build. Mater. 2019, 238, 117774. [Google Scholar] [CrossRef]

- Mengasini, L.; Mavroulidou, M.; Gunn, M.J. Alkali-activated concrete mixes with ground granulated blast furnace slag and paper sludge ash in seawater environments. Sustain. Chem. Pharm. 2021, 20, 100380. [Google Scholar] [CrossRef]

- Chand, G.; Happy, S.K.; Ram, S. Assessment of the properties of sustainable concrete produced from quaternary blend of portland cement, glass powder, metakaolin and silica fume. Clean. Eng. Technol. 2021, 4, 100179. [Google Scholar] [CrossRef]

- Habibi, A.; Ramezanianpour, A.M.; Mahdikhani, M.; Bamshad, O. RSM-based evaluation of mechanical and durability properties of recycled aggregate concrete containing GGBFS and silica fume. Constr. Build. Mater. 2020, 270, 121431. [Google Scholar] [CrossRef]

- Jindal, B.B.; Singhal, D.; Sharma, S.K.; Ashish, D.; Parveen, P. Improving compressive strength of low calcium fly ash geopolymer concrete with alccofine. Adv. Concr. Constr. 2017, 5, 17–29. [Google Scholar] [CrossRef]

- Singhal, D.; Jindal, B.B.; Garg, A. Mechanical properties of ground granulated blast furnace slag based geopolymer con-crete incorporating alccofine with different concentration and curing temperature. Adv. Sci. Eng. Med. 2017, 9, 948–958. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Effect of incorporation of metakaolin and recycled coarse aggregate on properties of concrete. J. Clean. Prod. 2018, 209, 398–414. [Google Scholar] [CrossRef]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of silica fume, metakaolin & SBR latex on strength and durability performance of pervious concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar] [CrossRef]

- Tangadagi, R.B.; Manjunatha, M.; Seth, D.; Preethi, S. Role of mineral admixtures on strength and durability of high strength self compacting concrete: An experimental study. Materialia 2021, 18, 101144. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R.G. Effect of Coal Bottom Ash on Strength and Durability Properties of Concrete. Ph.D. Thesis, Thapar Institute of Engineering & Technology, Punjab, India, 2015. [Google Scholar]

- Argiz, C.; Moragues, A.; Menéndez, E. Use of ground coal bottom ash as cement constituent in concretes exposed to chloride environments. J. Clean. Prod. 2018, 170, 25–33. [Google Scholar] [CrossRef]

- Gooi, S.; Mousa, A.A.; Kong, D. A critical review and gap analysis on the use of coal bottom ash as a substitute constituent in concrete. J. Clean. Prod. 2020, 268, 121752. [Google Scholar] [CrossRef]

- Jang, J.; Kim, H.; Lee, H. Resistance of coal bottom ash mortar against the coupled deterioration of carbonation and chloride penetration. Mater. Des. 2016, 93, 160–167. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Das, L. Concrete mix proportioning as per IS 10262: 2009–Comparison with IS 10262: 1982 and ACI 211.1-91. Indian Concr. J. 2010, 2010, 64–70. [Google Scholar]

- IS 10262-2009; Recommended Guidelines for Concrete Mix Design. Bureau of Indian Standards: New Delhi, India, 2009.

- Gunasekaran, K.; Kumar, P.; Lakshmipathy, M. Mechanical and bond properties of coconut shell concrete. Constr. Build. Mater. 2010, 25, 92–98. [Google Scholar] [CrossRef]

- Chun, L.B.; Sung, K.J.; Sang, K.T.; Chae, S.T. A study on the fundamental properties of concrete incorporating pond-ash in Korea. In Proceedings of the 3rd ACF international conference-ACF/VCA, Ho Chi Minh City, Vietnam, 11–13 November 2008; pp. 401–408. [Google Scholar]

- Aggarwal, P.; Aggarwal, Y.; Gupta, S.M. Effect of bottom ash as replacement of fine aggregates in concrete. Asian J. Civ. Eng. 2007, 8, 49–62. [Google Scholar]

- Kim, H.; Lee, H. Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete. Constr. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Irassar, E. Sulfate attack on cementitious materials containing limestone filler—A review. Cem. Concr. Res. 2009, 39, 241–254. [Google Scholar] [CrossRef]

- Brown, P.W. An evaluation of the sulfate resistance of cements in a controlled environment. Cem. Concr. Res. 1981, 11, 719–727. [Google Scholar] [CrossRef]

- Ouyang, C.; Nanni, A.; Chang, W.F. Internal and external sources of sulfate ions in portland cement mortar: Two types of chemical attack. Cem. Concr. Res. 1988, 18, 699–709. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, S.; Shi, Y.; Huang, Y.; Zhao, F.; Huo, T.; Tang, S. The Influence of Fly Ash Dosages on the Permeability, Pore Structure and Fractal Features of Face Slab Concrete. Fractal Fract. 2022, 6, 476. [Google Scholar] [CrossRef]

- Wang, L.; Yu, Z.; Liu, B.; Zhao, F.; Tang, S.; Jin, M. Effects of Fly Ash Dosage on Shrinkage, Crack Resistance and Fractal Characteristics of Face Slab Concrete. Fractal Fract. 2022, 6, 335. [Google Scholar] [CrossRef]

- Guneyisi, E. Effect of Binding Material Composition on Strength and Chloride Permeability of High Strength Concrete. Master’s Thesis, Department of Civil Engineering, Bogazic University, Istanbul, Türkiye, 1999. [Google Scholar]

- Gastaldini, A.; Isaia, G.; Gomes, N.; Sperb, J. Chloride penetration and carbonation in concrete with rice husk ash and chemical activators. Cem. Concr. Compos. 2007, 29, 176–180. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Malhotra, V.M. Effect of curing on the compressive strength, resistance to chloride-ion pene-tration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Compos. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Naik, T.R.; Singh, S.S.; Ramme, B.W. Mechanical properties and durability of concrete made with blended fly ash. Mater. J. 1998, 95, 454–462. [Google Scholar]

- Oh, B.H.; Cha, S.W.; Jang, B.S.; Jang, S.Y. Development of high-performance concrete having high resistance to chloride penetration. Nucl. Eng. Des. 2002, 212, 221–231. [Google Scholar] [CrossRef]

- Feng, N.; Feng, X.; Hao, T.; Xing, F. Effect of ultrafine mineral powder on the charge passed of the concrete. Cem. Concr. Res. 2002, 32, 623–627. [Google Scholar] [CrossRef]

- Yang, C.; Chiang, C. On the relationship between pore structure and charge passed from RCPT in mineral-free cement-based materials. Mater. Chem. Phys. 2005, 93, 202–207. [Google Scholar] [CrossRef]

- Gu, P.; Beaudoin, J.J.; Zhang, M.-H.; Malhotra, V.M. Performance of steel reinforcement in portland cement and high-volume fly ash concretes. Mater. J. 1999, 96, 551–559. [Google Scholar]

- Cheriaf, M.; Rocha, J.; Péra, J. Pozzolanic properties of pulverized coal combustion bottom ash. Cem. Concr. Res. 1999, 29, 1387–1391. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Properties of concrete containing high volumes of coal bottom ash as fine aggregate. J. Clean. Prod. 2015, 91, 269–278. [Google Scholar] [CrossRef]

- Onprom, P.; Chaimoon, K.; Cheerarot, R. Influence of Bottom Ash Replacements as Fine Aggregate on the Property of Cellular Concrete with Various Foam Contents. Adv. Mater. Sci. Eng. 2015, 2015, 381704. [Google Scholar] [CrossRef]

- Sagar, B.; Sivakumar, M.V.N. Mechanical and Microstructure Characterization of Alccofine Based High Strength Concrete. Silicon 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Zanni, H.; Cheyrezy, M.; Maret, V.; Philippot, S.; Nieto, P. Investigation of hydration and pozzolanic reaction in Reactive Powder Concrete (RPC) using 29Si NMR. Cem. Concr. Res. 1996, 26, 93–100. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Kavyateja, B.V.; Jawahar, J.G.; Sashidhar, C. Effect of alccofine and fly ash on analytical methods of self-compacting concrete. Innov. Infrastruct. Solut. 2020, 5, 1–11. [Google Scholar] [CrossRef]

- Reddy, P.N.; Naqash, J.A. Properties of Concrete Modified with Ultra-Fine Slag. Karbala Int. J. Mod. Sci. 2019, 5, 4. [Google Scholar] [CrossRef]

- Elaty, M.A.A.A. Compressive strength prediction of Portland cement concrete with age using a new model. HBRC J. 2014, 10, 145–155. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Clean. Prod. 2016, 112, 620–630. [Google Scholar] [CrossRef]

- Turgut, P. Research into the correlation between concrete strength and UPV values. NDT Net 2004, 12, 1–9. [Google Scholar]

- Nash’t, I.H.; A’bour, S.H.; Sadoon, A.A. Finding an unified relationship between crushing strength of concrete and non-destructive tests. In Proceedings of the Middle East Nondestructive Testing Conference & Exhibition, Manama, Bahrain, 27–30 November 2005; pp. 27–30. [Google Scholar]

| Sr. No. | Constituents | Specific Gravity | Fineness Modules |

|---|---|---|---|

| 1. | Cement | 3.13 | - |

| 2. | Coarse aggregates | 2.66 | 6.68 |

| 3. | Fine aggregates (river sand) | 2.63 | 2.53 |

| 4. | Coal Bottom ash | 1.71 | 1.37 |

| 5. | Alccofine 1203 | 2.98 | - |

| Chemical Composition | Physical Properties | ||||

|---|---|---|---|---|---|

| Composition | Test Result | BIS Value | Property | Test Result | BIS Value |

| Lime saturation factor (lsf) | 0.877 | 0.66 < lsf < 1.02 | Fineness (m2/kg) | 278.6 | >225 |

| Ratio of Alumina and Iron oxide | 1.51 | >0.66 | Initial setting time (min) | 125 | >30 |

| Loss on ignition (%) | 1.93 | <5.0 | Final setting time (min) | 175 | <600 |

| Compound | Percentage (CBA) | Percentage (Alccofine) |

|---|---|---|

| SiO2 | 35.13 | 35.05 |

| Al2O3 | 25.63 | 24.34 |

| MgO | 0.54 | 9.66 |

| CaO | 0.46 | 28.86 |

| Fe2O3 | 7.92 | 1.97 |

| Mix Design | Alccofine% | CBA% | Cement (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregates (kg/m3) | Alccofine (kg/m3) | CBA (kg/m3) | Water Content (kg/m3) | Dosage of Superplasticizer to Achieve 100 mm Slump Value (wt% of Cement) |

|---|---|---|---|---|---|---|---|---|---|

| MB0 | 0 | 0 | 415 | 779.89 | 782.27 | 0 | 0 | 157.73 | 1.2 |

| MB1 | 0 | 10 | 415 | 779.89 | 704.04 | 0 | 78.22 | 157.73 | 1.2 |

| MB2 | 0 | 20 | 415 | 779.89 | 625.81 | 0 | 156.45 | 157.73 | 1.5 |

| MB3 | 0 | 30 | 415 | 779.89 | 547.59 | 0 | 234.68 | 157.73 | 2.2 |

| MB4 | 0 | 40 | 415 | 779.89 | 469.36 | 0 | 312.91 | 157.73 | 2.5 |

| MB5 | 0 | 50 | 415 | 779.89 | 391.14 | 0 | 234.68 | 157.73 | 3 |

| MB4A5 | 5 | 40 | 394.25 | 779.89 | 469.36 | 20.75 | 312.91 | 157.73 | 2.4 |

| MB4A10 | 10 | 40 | 373.5 | 779.89 | 469.36 | 41.5 | 312.91 | 157.73 | 2.1 |

| MB4A15 | 15 | 40 | 352.75 | 779.89 | 469.36 | 62.25 | 312.91 | 157.73 | 1.9 |

| MB4A20 | 20 | 40 | 332 | 779.89 | 469.36 | 83 | 312.91 | 157.73 | 2 |

| SLUMP (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mix | Phase I | Phase II | |||||||||

| Dosage of Superplasticizer | MB0 | MB1 | MB2 | MB3 | MB4 | MB5 | MB4A5 | MB4A10 | MB4A15 | MB4A20 | |

| 0% | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0.6% | 30 | 25 | 15 | 0 | 0 | 0 | 0 | 5 | 10 | 10 | |

| 0.8% | 50 | 50 | 30 | 15 | 0 | 0 | 5 | 15 | 25 | 20 | |

| 1% | 80 | 70 | 55 | 25 | 10 | 0 | 15 | 25 | 40 | 35 | |

| 1.2% | 105 | 100 | 80 | 40 | 25 | 10 | 25 | 35 | 45 | 40 | |

| 1.4% | - | - | 90 | 50 | 30 | 25 | - | - | - | - | |

| 1.6% | - | - | 115 | 60 | 40 | 35 | - | - | - | - | |

| 1.8% | - | - | - | 65 | 45 | 40 | 55 | 70 | 85 | 75 | |

| 2% | - | - | - | 85 | 60 | 55 | 75 | 85 | 110 | 105 | |

| 2.2% | - | - | - | 100 | 70 | 65 | 85 | 115 | - | - | |

| 2.4% | - | - | - | - | 85 | 80 | 105 | - | - | - | |

| 2.6% | - | - | - | - | 110 | 85 | - | - | - | - | |

| 2.8% | - | - | - | - | - | 95 | - | - | - | - | |

| 3% | - | - | - | - | - | 105 | - | - | - | - | |

| Mix | Ultrasonic Pulse Velocity (m/s) | Standard Value IS: 13311-92 [29] Part-I (m/s) | Concrete Grading | ||

|---|---|---|---|---|---|

| 28 Days | 90 Days | 180 Days | |||

| MB0 | 4564 | 4692 | 4810 | <3000 | Doubtful |

| MB4 | 4286 | 4419 | 4544 | 3000–3500 | Medium |

| MB4A5 | 4310 | 4439 | 4572 | 3500–4500 | Good |

| MB4A10 | 4517 | 4644 | 4792 | >4500 | Excellent |

| MB4A15 | 4623 | 4770 | 4903 | ||

| MB4A20 | 4638 | 4739 | 4859 | ||

| Material | Rate (INR) at Source | Rate per Kg | Phase I Mixtures | Phase II Mixtures | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MB0 | MB1 | MB2 | MB3 | MB4 | MB5 | MB4A5 | MB4A10 | MB4A15 | MB4A20 | |||

| OPC-43 Grade | INR 400/per 50 kg bag | 8 | 3320 | 3320 | 3320 | 3320 | 3320 | 3320 | 3154 | 2988 | 2822 | 2656 |

| Alccofine 1203 | INR 177/ per 25 kg bag | 7.08 | 0 | 0 | 0 | 0 | 0 | 0 | 146.91 | 293.82 | 440.73 | 587.64 |

| Fine aggregate | INR 3400 per cu ft | 0.45 | 352.02 | 316.81 | 281.91 | 246.41 | 211.21 | 176.01 | 211.21 | 211.21 | 211.21 | 211.21 |

| Coal Bottom Ash | (available free of cost) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Coarse Aggregate | INR 2900 per cu ft | 0.38 | 415.19 | 415.19 | 415.19 | 415.19 | 415.19 | 415.19 | 415.19 | 415.19 | 415.19 | 415.19 |

| Superplasticizer | 212.40 per kg | 212.4 | 1057.75 | 1057.75 | 1322.19 | 1939.21 | 2203.65 | 2644.38 | 2115.5 | 1851.06 | 1674.77 | 1762.92 |

| Total cost per cum | 5144.96 | 5109.75 | 5339.29 | 5920.81 | 6150.05 | 6555.58 | 6042.81 | 5759.28 | 5563.9 | 5632.96 | ||

| % change from control concrete (Cost difference) | - | −0.6844 | 3.77709 | 15.0798 | 19.5354 | 27.4175 | 17.4511 | 11.9402 | 8.14273 | 9.48501 | ||

| Correlation Coefficient | Coal Bottom Ash Concrete | Alccofine-Assisted Coal Bottom Ash Concrete | ||||

|---|---|---|---|---|---|---|

| Compressive Strength | Flexural Strength | Splitting Tensile Strength | Compressive Strength | Flexural Strength | Splitting Tensile Strength | |

| 7 days | ||||||

| a | 20.49411 | 3.91341 | 3.27722 | 2.88589 | 0.83337 | 0.93784 |

| b | 34.0307 | −0.07049 | −0.0997 | 0.11878 | 0.0765 | 0.0355 |

| c | 4.01332 | −0.07575 | −1.5873 × 10−4 | −0.00365 | −0.00229 | −0.00107 |

| d | −0.35364 | 0.01148 | 9.25926 × 10−5 | |||

| R2 | 0.967 | 0.957 | 0.995 | 0.999 | 0.87 | 0.855 |

| 28 days | ||||||

| a | 38.18893 | 4.80421 | 3.94413 | 3.52878 | 1.17826 | 0.96304 |

| b | 47.34086 | 0.06089 | −0.02132 | 0.07189 | 0.05511 | 0.07009 |

| c | 3.49315 | −0.12341 | −0.08647 | −0.0021 | −0.00158 | −0.00223 |

| d | −1.43526 | 0.01657 | 0.01231 | |||

| R2 | 0.974 | 0.995 | 0.995 | 0.997 | 0.932 | 0.98 |

| 56 days | ||||||

| a | 41.29 | 5.42294 | 4.48937 | 3.59113 | 1.28096 | 1.08961 |

| b | 49.475 | 0.00935 | 0.08733 | 0.07428 | 0.05802 | 0.05576 |

| c | 3.95374 | −0.12016 | −0.16444 | −0.00232 | −0.00175 | −0.00158 |

| d | −8.76299 | 0.01676 | 0.02093 | |||

| R2 | 0.975 | 0.992 | 0.965 | 0.995 | 0.999 | 0.99 |

| 90 days | ||||||

| a | 43.86 | 5.9273 | 4.74056 | 3.6213 | 1.42085 | 1.10325 |

| b | 51.305 | −0.0613 | −0.01763 | 0.07508 | 0.04684 | 0.06959 |

| c | 3.90417 | −0.10175 | −0.12504 | −0.00237 | −0.00144 | −0.00226 |

| d | −8.71209 | 0.01352 | 0.01648 | |||

| R2 | 0.986 | 0.997 | 0.97 | 0.994 | 0.991 | 0.988 |

| 180 days | ||||||

| a | 46.086 | 5.98111 | 4.90365 | 3.64156 | 1.45464 | 1.02052 |

| b | 54.79033 | 0.09164 | 0.09519 | 0.07827 | 0.05813 | 0.0998 |

| c | 3.69594 | −0.14901 | −0.15337 | −0.0024 | −0.00183 | −0.00313 |

| d | −1.74554 | 0.01713 | 0.01843 | |||

| R2 | 0.988 | 0.997 | 0.983 | 0.998 | 0.65 | 0.95 |

| Correlation Coefficient | Compressive Strength and Flexural | Compressive Strength and Splitting | |

|---|---|---|---|

| a | 2.85951 | 2.93665 | 0.1223 [81] |

| b | 2.0869 × 10-4 | 2.96229 × 10-7 | 0.8769 [81] |

| c | 2.2971 | 3.77727 | |

| R2 | 0.943 | 0.941 | |

| Correlation Coefficient | Compressive Strength | Flexural Strength | Splitting Tensile Strength |

|---|---|---|---|

| a | 0.76311 | −2.01407 | −2.8417 |

| b | 7.19018 × 10−4 | 8.02136 | 9.44419 × 10-4 |

| R2 | 0.925 | 0.911 | 0.943 |

| Strength property correlation coefficients (previous studies–Equation (10)) | |||

| a | 0.0111 [64] | 0.0525 [64] | 0.0048 [64] |

| 1.0741 [65] | |||

| 1.146 [66] | |||

| 1.19 [83] | |||

| b | 1.8593 [64] | 1.0297 [64] | 1.4882 [64] |

| 0.8102 [65] | |||

| 0.77 [66] | |||

| 0.715 [83] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganesan, H.; Sachdeva, A.; Petrounias, P.; Lampropoulou, P.; Sharma, P.K.; Kumar, A. Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete. Sustainability 2023, 15, 6076. https://doi.org/10.3390/su15076076

Ganesan H, Sachdeva A, Petrounias P, Lampropoulou P, Sharma PK, Kumar A. Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete. Sustainability. 2023; 15(7):6076. https://doi.org/10.3390/su15076076

Chicago/Turabian StyleGanesan, Halan, Abhishek Sachdeva, Petros Petrounias, Paraskevi Lampropoulou, Pushpendra Kumar Sharma, and Abhinav Kumar. 2023. "Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete" Sustainability 15, no. 7: 6076. https://doi.org/10.3390/su15076076

APA StyleGanesan, H., Sachdeva, A., Petrounias, P., Lampropoulou, P., Sharma, P. K., & Kumar, A. (2023). Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete. Sustainability, 15(7), 6076. https://doi.org/10.3390/su15076076