Impact of Underground Coal Seam Mining on Stability and Slippage of the Loess Slope

Abstract

:1. Introduction

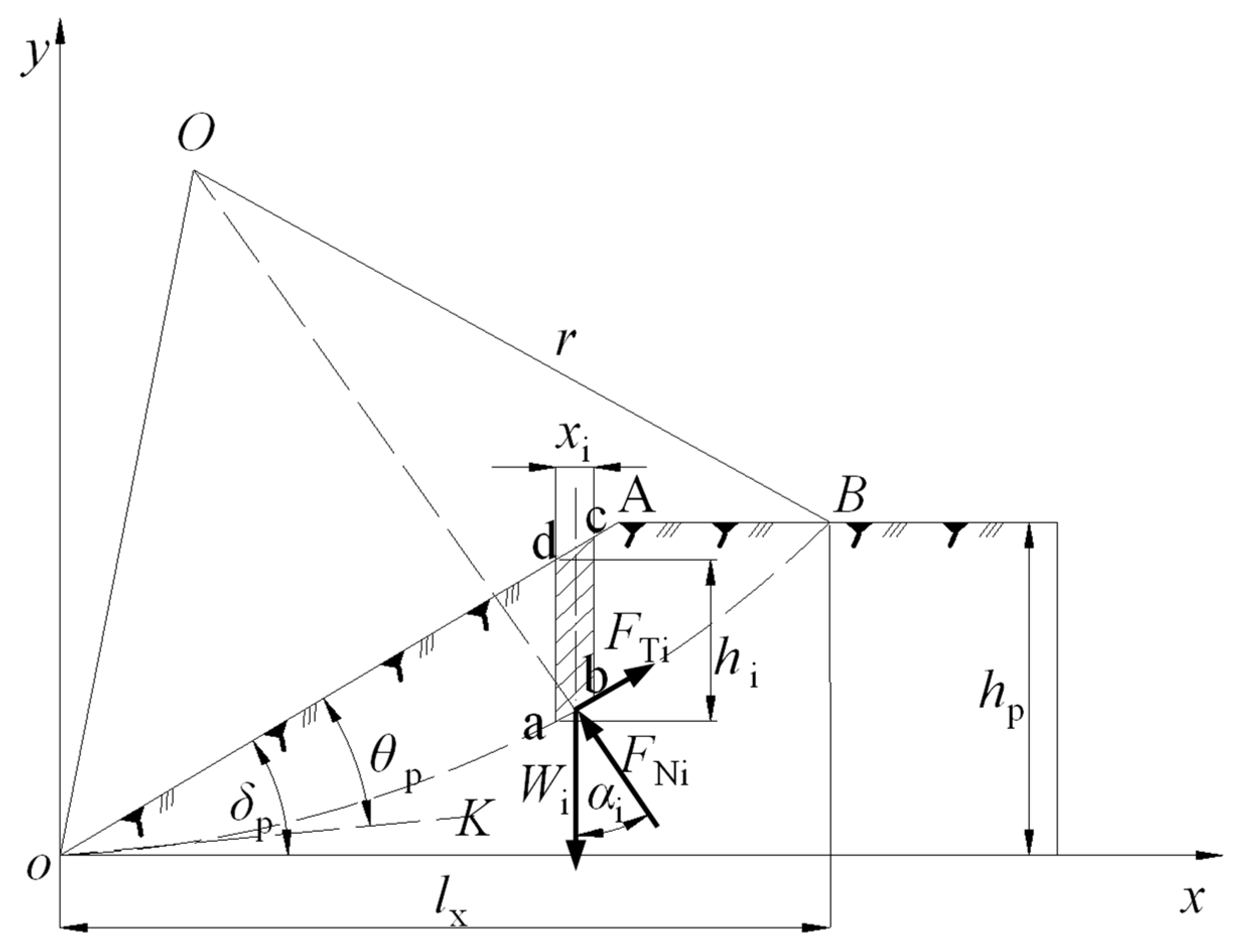

2. Theoretical Analysis of Slope Stability before Mining

3. Numerical Simulation of Mining Slope Stability

3.1. Mining Factors Affecting Slope Stability

3.2. Numerical Simulation Design

3.2.1. Numerical Simulation Scheme

3.2.2. Model Parameters and Boundary Conditions

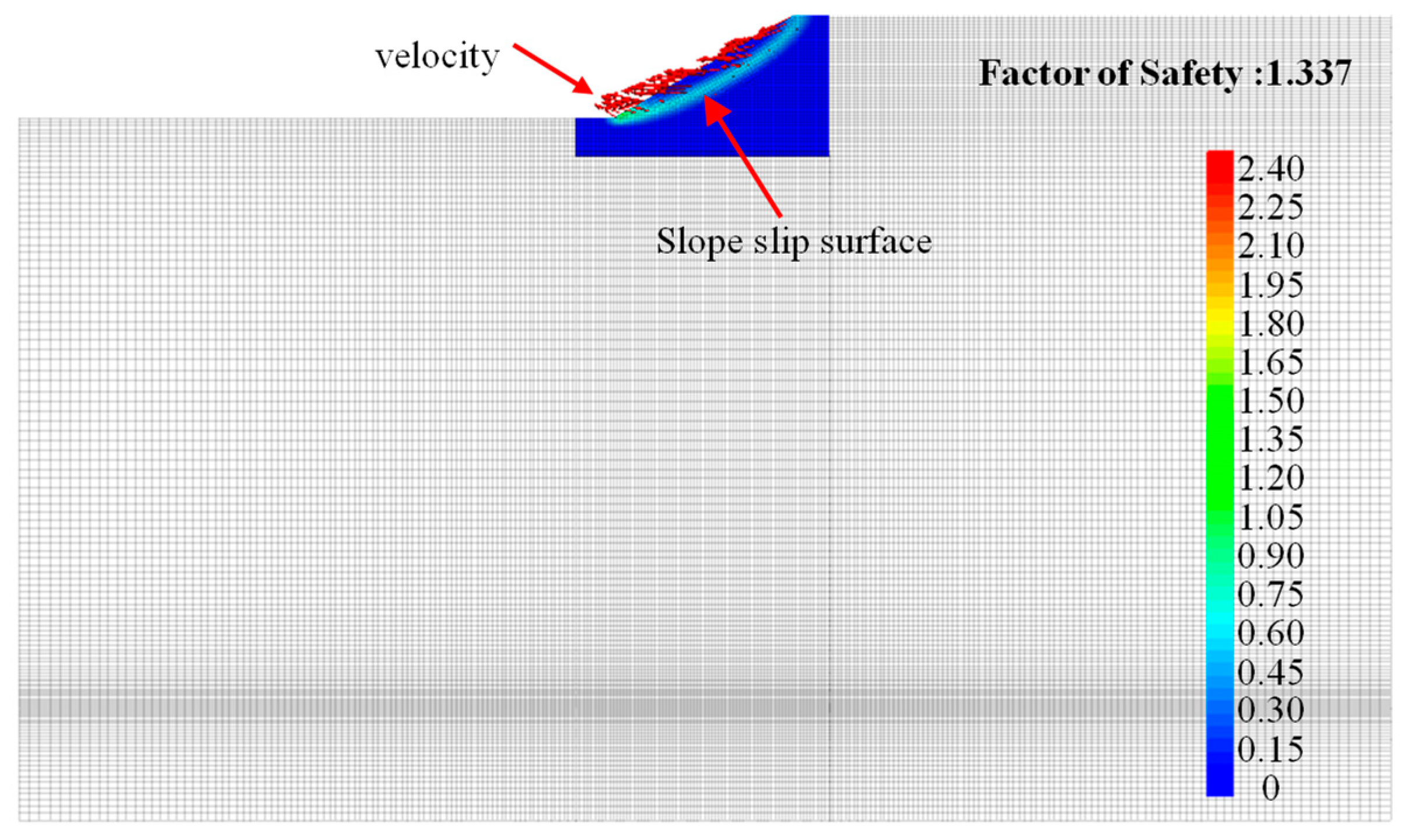

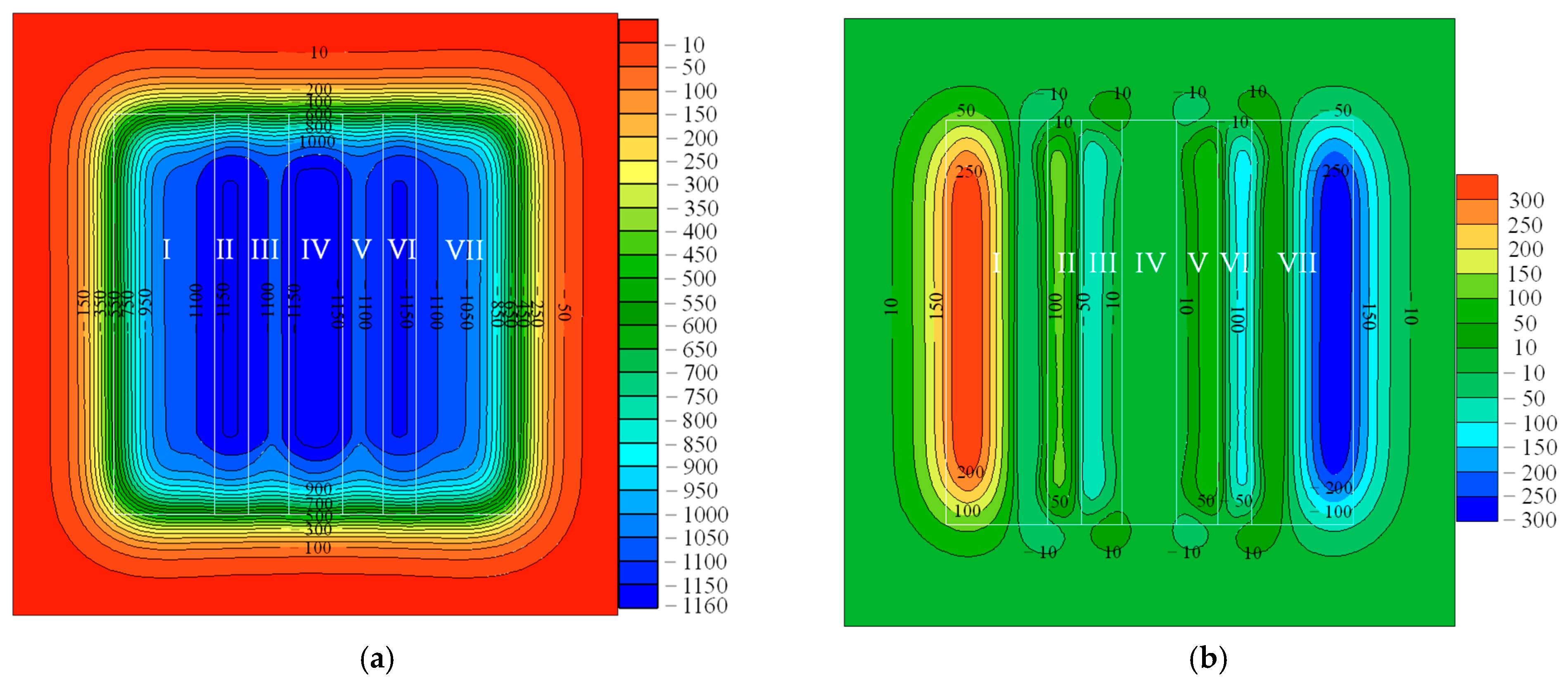

3.2.3. Numerical Inversion Results

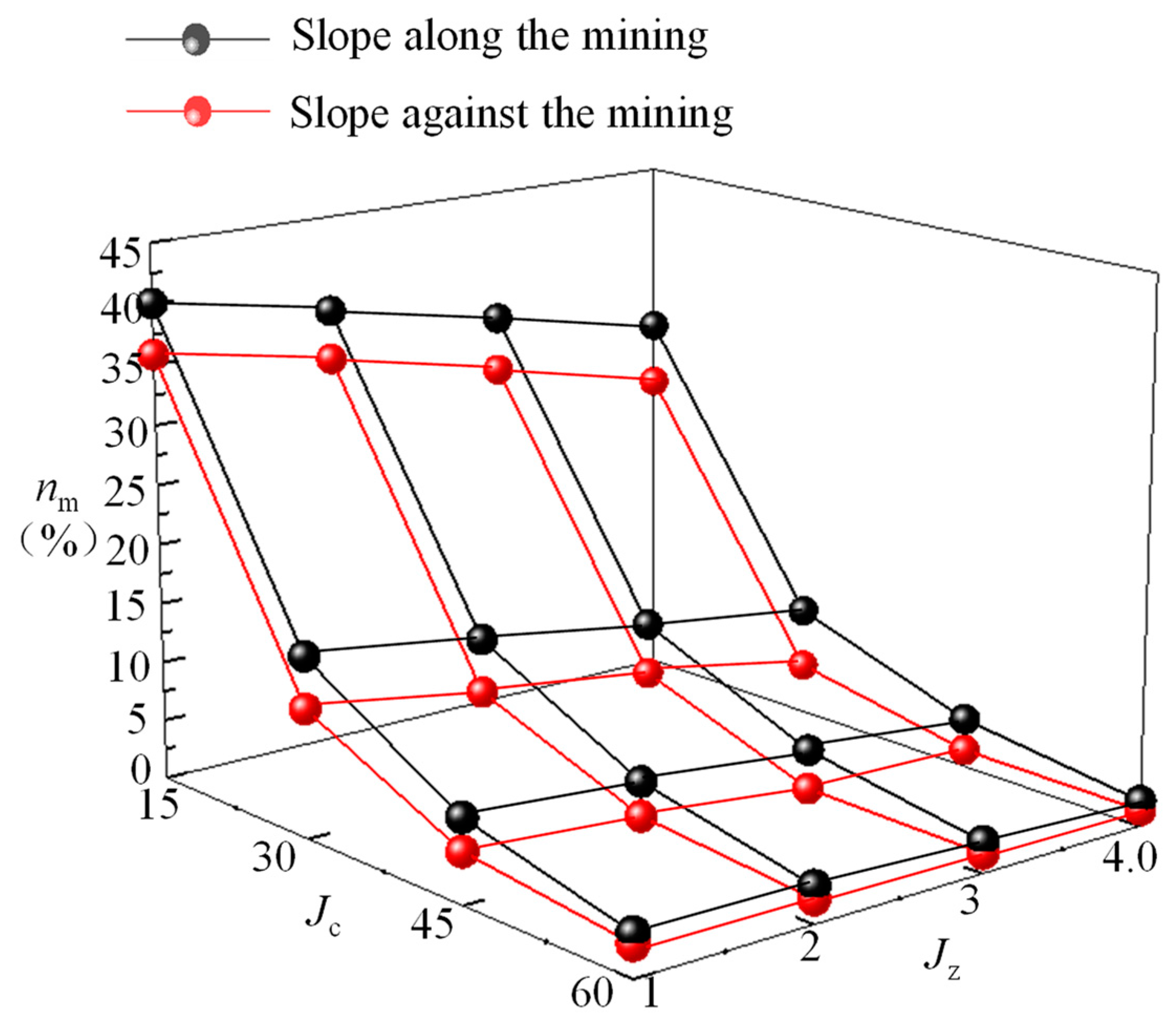

3.3. The Influence Degree of Underground Mining on Slope Stability

4. Theoretical Analysis of the Correlation between Influencing Factors and Kms

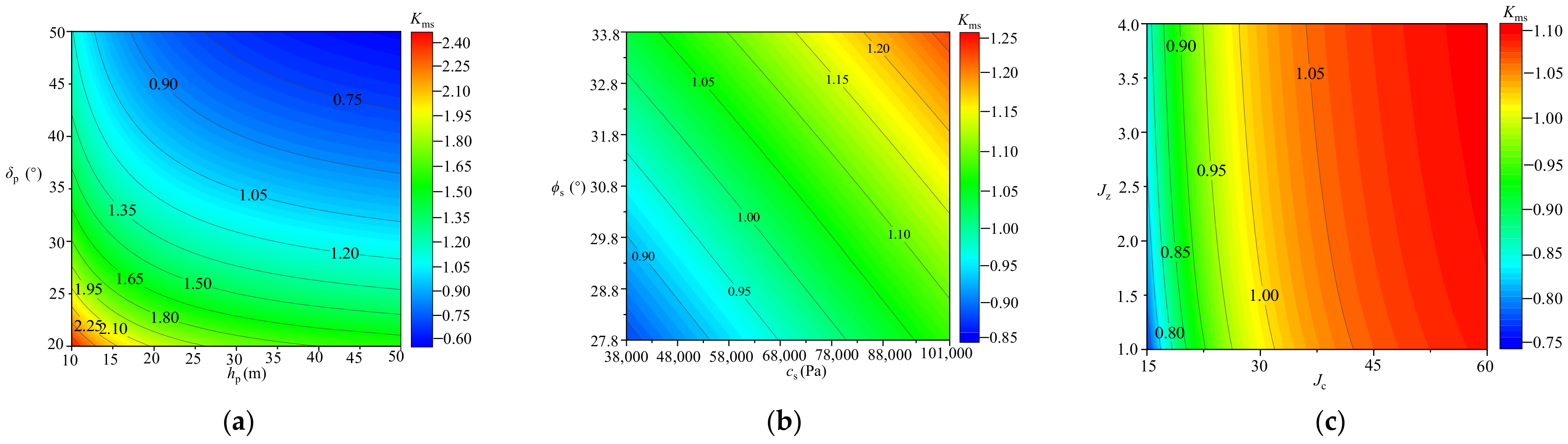

4.1. The Correlation between Individual Factors and Mining Slope Stability

4.2. The Sensibility between Associated Factors and Mining Slope Stability

5. Theoretical Analysis and Similar Simulation of Mining Slope Slippage

5.1. Additional Deformation of Mining Slope Slip

5.2. Theoretical Prediction

5.2.1. Theoretical Prediction Model

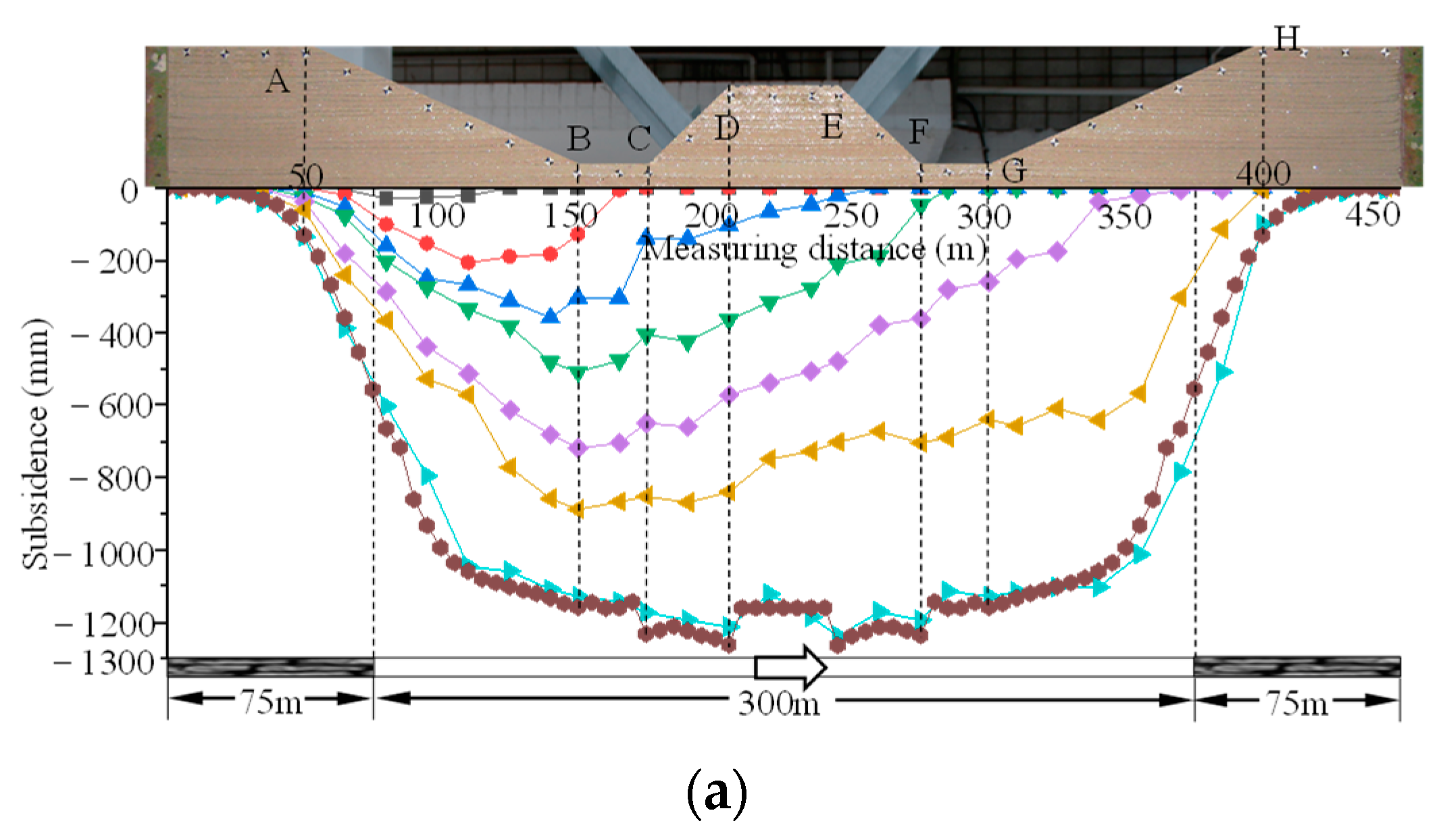

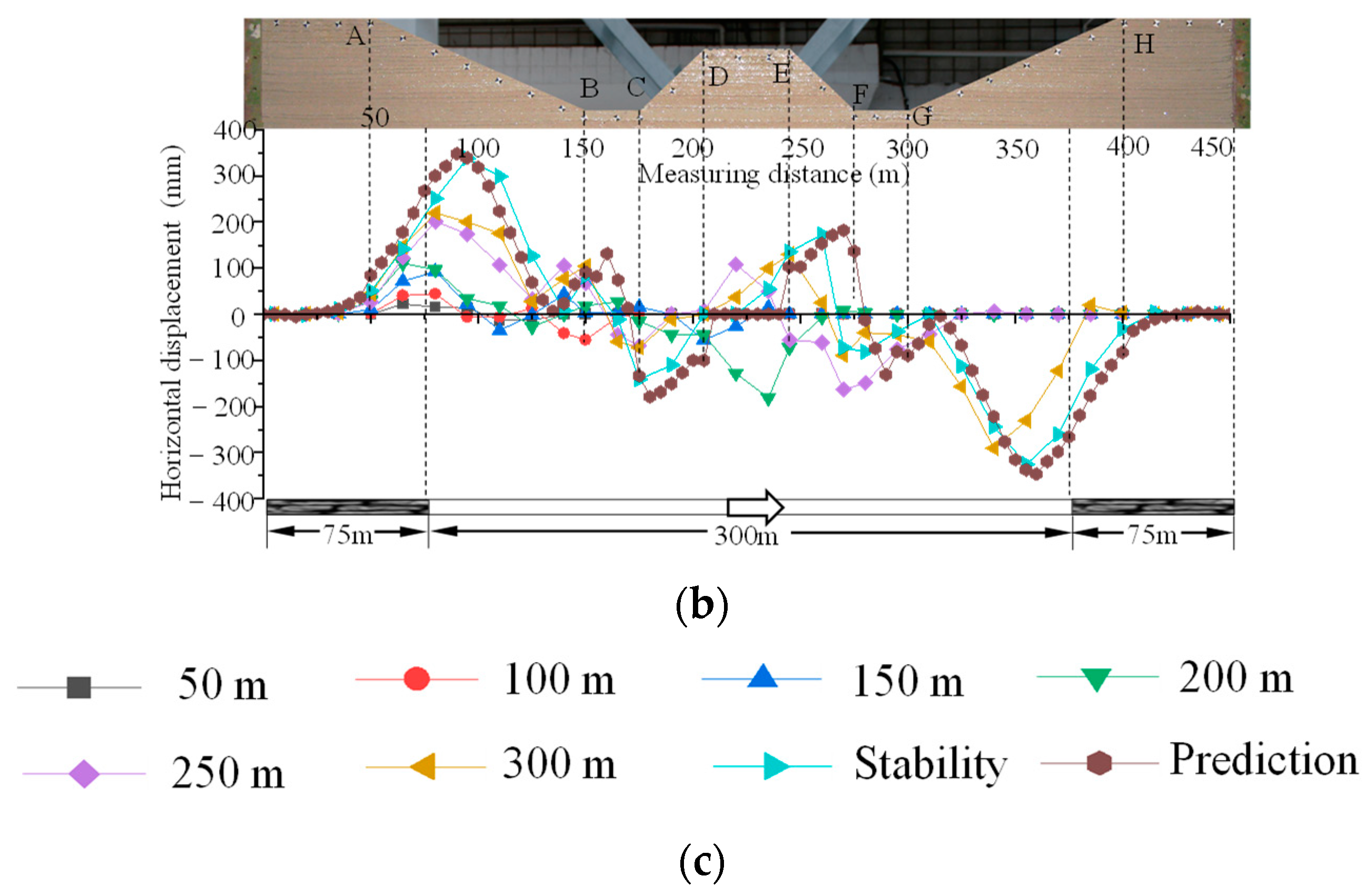

5.2.2. Theoretical Prediction Process and Results

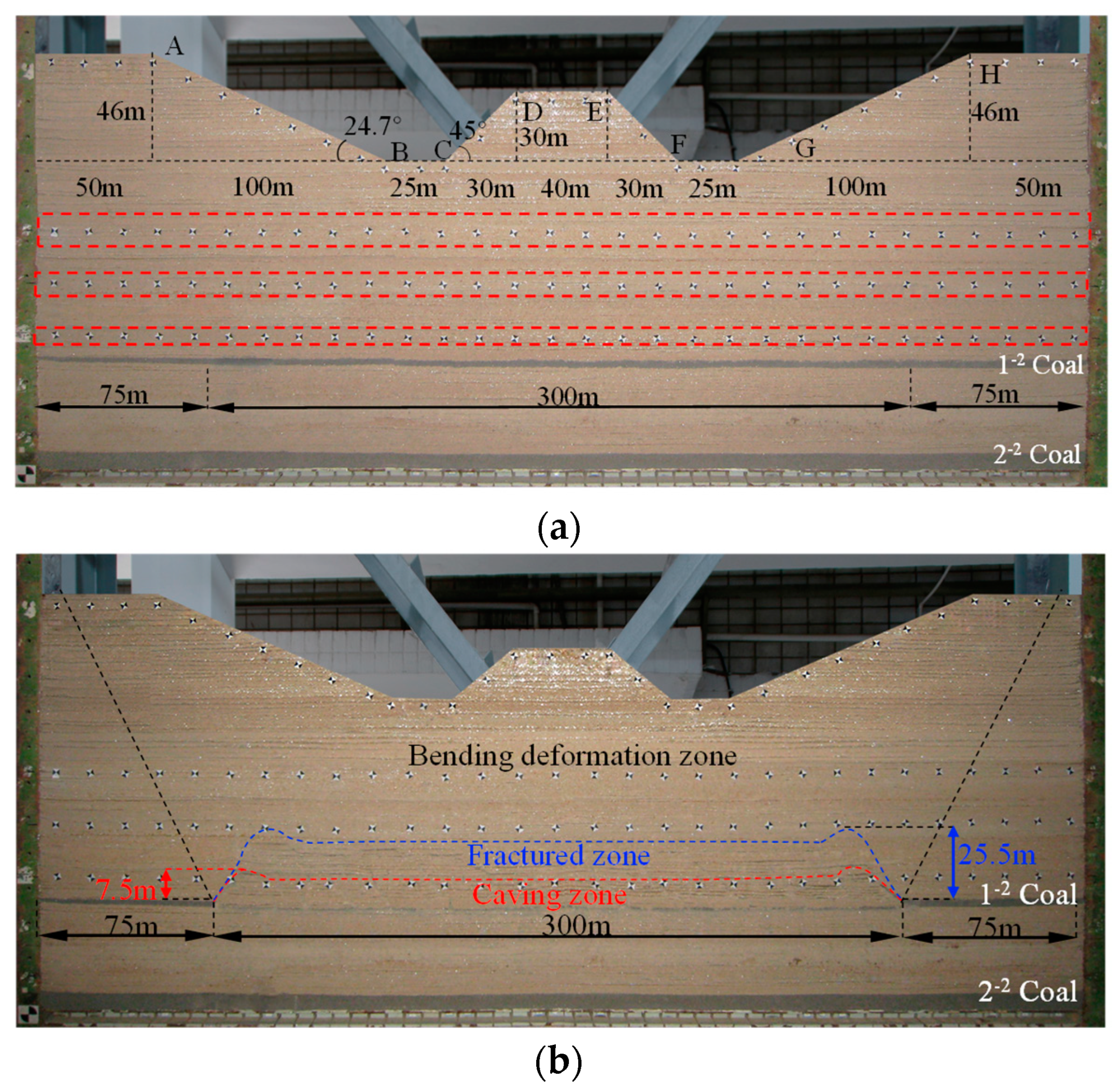

5.3. Similar Simulation Test

6. Conclusions

- (1)

- Based on the slope stability theory and numerical simulation results, the calculation equation of the mining slope stability coefficient of loess slope (Kms) with different mining directions is derived, and whether mining induces slope instability and landslide is judged. When Kms > 1, the stability is good; mining only causes the loess slope to slip and does not induce landslides. When 0.95 ≤ Kms ≤ 1, the stability is poor and there is a potential risk of loess slope landslide induced by mining. When Kms < 0.95, the stability is very poor and the risk of mining induced loess slope landslides is higher.

- (2)

- The impact of mining along the slope and mining against the slope on Kms is basically the same. However, due to the superposition of slope movement caused by mining subsidence and slope slip tendency, the slope stability of mining against the slope is slightly higher than that of mining along the slope.

- (3)

- The sensitivity of different factors affecting the mining stability of loess slope from large to small is δp (0.828), hp (0.675), Jc (0.662), Jz (0.648), γs (0.615), φs (0.624) and cs (0.568). δp and hp are the main factors affecting Kms. Jc and Jz are positively correlated with Kms, and the correlation is relatively strong. The range of variation of the mechanical parameters of the loess slope (γs, φs and cs,) is small, and the influence on Kms is weak.

- (4)

- The calculation equation of mining loess slope slip with Kms as the key parameter is established by strata movement theory and probability integral theory, and a prediction method of loess slope surface movement and deformation in underground coal seam mining is designed. The deviation between the theoretical prediction results of the maximum subsidence value and the experimental results is 2.03%, the deviation of the maximum horizontal movement value is between 3.30% and 6.43% and the predicted results basically meet the engineering requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Latin characters | |

| cs | loess cohesion (Pa) |

| hp | slope height (m) |

| Jc | ratio of rock stratum thickness to mining height |

| Jz | ratio of rock stratum thickness to soil stratum thickness |

| Ks | stability coefficient of slope |

| Kms | stability coefficient of mining slope |

| H | mining depth (m) |

| m | mining height (m) |

| nm | rate of change of slope stability before and after mining |

| p(x) | influence function of slope height on mining slip |

| q(x) | influence function of slope angle on mining slip |

| r | mining influence range (m) |

| R(x) | influence function of additional value of the mining slope slip |

| w(x) | influence function of mining subsidence |

| Greek characters | |

| δp | slope angle (°) |

| γs | loess volume weight (N/m3) |

| φs | loess internal friction angle (°) |

| η | subsidence coefficient |

| Δu(x) | additional horizontal movement value (mm) |

| Δw(x) | additional subsidence value (mm) |

| Abbreviations | |

| FEM | Finite element method |

| LEM | Limit equilibrium method |

References

- Zhao, B.C.; Tong, C.; Liu, Z.R. Characteristics of mining-induced surface damage in western ecological fragile region. J. Cent. South Univ. 2017, 48, 2990–2997. [Google Scholar]

- Yu, X.Y.; Zhang, E.Q. Mining Damage Science; China Coal Industry Publishing House: Beijing, China, 2010. [Google Scholar]

- Feng, J.; Wang, S.J.; Hou, E.K.; Ding, X.; Duan, H.J. Determining the Height of Water-Flowing Fractured Zone in Bedrock-Soil Layer in a Jurassic Coalfield in Northern Shaanxi, China. Adv. Civ. Eng. 2021, 2021, 9718802. [Google Scholar] [CrossRef]

- Huang, Q.X. Research on roof control of water conservation mining in shallow seam. J. China Coal Soc. 2017, 42, 50–55. [Google Scholar] [CrossRef]

- Bai, Q.S.; Tu, S.H.; Yuan, Y.; Wang, F.T. Back analysis of mining induced responses on the basis of goaf compaction theory. J. China Univ. Min. Technol. 2013, 42, 355–369. [Google Scholar] [CrossRef]

- Ma, S.; Qiu, H.; Yang, D.; Wang, J.; Zhu, Y.; Tang, B.; Sun, K.; Cao, M. Surface multi-hazard effect of underground coal mining. Landslides 2023, 20, 39–52. [Google Scholar] [CrossRef]

- Yu, X.Y.; Mao, X.W. A preliminary discrimination model of a deep mining landslide and its application in the Guanwen coal mine. Bull. Eng. Geol. Environ. 2020, 79, 485–493. [Google Scholar] [CrossRef]

- Hou, H.P.; Ding, Z.Y.; Zhang, S.L.; Guo, S.C.; Yang, Y.J.; Chen, Z.X.; Mi, J.X.; Wang, X. Spatial estimate of ecological and environmental damage in an underground coal mining area on the Loess Plateau: Implications for planning restoration interventions. J. Clean. Prod. 2021, 287, 125061. [Google Scholar] [CrossRef]

- Guo, W.B.; Yu, X.Y.; Liu, Z.Y. Analysis of Mining Subsidence Disasters in Loess Gully Areas and its Control Countermeasures. Appl. Mech. Mater. 2015, 737, 456–460. [Google Scholar] [CrossRef]

- Liu, H.; Deng, K.Z.; Lei, S.G.; Bian, Z.F. Mechanism of formation of sliding ground fissure in loess hilly areas caused by underground mining. Int. J. Min. Sci. Technol. 2015, 25, 553–558. [Google Scholar] [CrossRef]

- Alimohammadlou, Y.; Najafi, A.; Yalcin, A. Landslide process and impacts: A proposed classification method. Catena 2013, 104, 219–232. [Google Scholar] [CrossRef]

- Huang, Y.H. Slope Stability Analysis by the Limit Equilibrium Method: Fundamentals and Methods; American Society of Civil Engineers: Reston, VA, USA, 2014. [Google Scholar] [CrossRef]

- Karthik, A.V.R.; Manideep, R.; Chavda, J.T. Sensitivity analysis of slope stability using finite element method. Innov. Infrastruct. Solut. 2022, 7, 184. [Google Scholar] [CrossRef]

- Ozbay, A.; Cabalar, A.F. FEM and LEM stability analyses of the fatal landslides at Çöllolar open-cast lignite mine in Elbistan, Turkey. Landslides 2015, 12, 155–163. [Google Scholar] [CrossRef]

- Kumar, N.; Verma, A.K.; Sardana, S.; Sarkar, K.; Singh, T.N. Comparative analysis of limit equilibrium and numerical methods for prediction of a landslide. Bull. Eng. Geol. Environ. 2018, 77, 595–608. [Google Scholar] [CrossRef]

- Vanneschi, C.; Eyre, M.; Burda, J.; Žižka, L.; Francioni, M.; Coggan, J.S. Investigation of landslide failure mechanisms adjacent to lignite mining operations in North Bohemia (Czech Republic) through a limit equilibrium/finite element modelling approach. Geomorphology 2018, 320, 142–153. [Google Scholar] [CrossRef]

- Cheng, H.; Zhou, X.P. A novel displacement-based rigorous limit equilibrium method for three-dimensional landslide stability analysis. Can. Geotech. J. 2015, 52, 2055–2066. [Google Scholar] [CrossRef]

- Tolovkhan, B.; Demin, V.; Amanzholov, Z.; Smagulova, A.; Tanekeyeva, G.; Zairov, S.; Krukovskyi, O.; Cabana, E. Substantiating the rock mass control parameters based on the geomechanical model of the Severny Katpar deposit, Kazakhstan. Min. Miner. Depos. 2022, 16, 123–133. [Google Scholar] [CrossRef]

- Nie, L.; Li, Z.C.; Zhang, M.; Xu, L.N. Deformation characteristics and mechanism of the landslide in West Open-Pit Mine, Fushun, China. Arab. J. Geosci. 2015, 8, 4457–4468. [Google Scholar] [CrossRef]

- Xie, L.F.; Yan, E.C.; Ren, X.B.; Lu, G.D. Sensitivity analysis of bending and toppling deformation for anti-slope based on the grey relation method. Geotech. Geol. Eng. 2015, 33, 35–41. [Google Scholar] [CrossRef]

- Sun, S.G.; Zhang, Y.J.; Miao, Z.Z.; Wang, J.; Xie, Y. Effect of Slope Stability during Transition from Open-pit and Underground Mining. Met. Mine 2016, 45, 171–174. [Google Scholar] [CrossRef]

- Salmi, E.F.; Nazem, M.; Karakus, M. Numerical analysis of a large landslide induced by coal mining subsidence. Eng. Geol. 2017, 217, 141–152. [Google Scholar] [CrossRef]

- Fernández, P.R.; Granda, G.R.; Krzemień, A.; Cortés, S.G.; Valverde, G.F. Subsidence versus natural landslides when dealing with property damage liabilities in underground coal mines. Int. J. Rock Mech. Min. Sci. 2020, 126, 104175. [Google Scholar] [CrossRef]

- Marschalko, M.; Yilmaz, I.; Bednárik, M.; Kubečka, K.; Bouchal, T.; Závada, J. Subsidence map of underground mining influence for urban planning: An example from the Czech Republic. Q. J. Eng. Geol. Hydrogeol. 2012, 45, 231–241. [Google Scholar] [CrossRef]

- Yuan, M.Z.; Li, M.; Liu, H.; Lv, P.Y.; Li, B.; Zheng, W.B. Subsidence monitoring base on SBAS-InSAR and slope stability analysis method for damage analysis in mountainous mining subsidence regions. Remote Sens. 2021, 13, 3107. [Google Scholar] [CrossRef]

- Yang, D.D.; Qiu, H.J.; Ma, S.Y.; Liu, Z.J.; Du, C.; Zhu, Y.R.; Cao, M.M. Slow surface subsidence and its impact on shallow loess landslides in a coal mining area. Catena 2022, 209, 105830. [Google Scholar] [CrossRef]

- Tang, F.Q.; Huang, H.; Sun, X.Y.; Qiao, D.J.; Bai, F. The influence of mining subsidence on terrain factors in gully region of loess. J. Arid. Land Resour. Environ. 2016, 30, 124–128. [Google Scholar] [CrossRef]

- Sun, X.Y.; Zhang, H.X.; Lu, M.J.; Li, C.; Miao, L.T. The development law of surface cracks in shallow coal seam mining through doublegullies terrain. Coal Geol. Explor. 2021, 49, 212–229. [Google Scholar] [CrossRef]

- Liu, T.T.; Lu, G.B.; Tong, L.M. Numerical simulation study of the influence on stability of slope by underground mining under opencast coal mine slope. J. Coal Sci. Eng. 2011, 17, 397–400. [Google Scholar] [CrossRef]

- Zhao, B.C.; Guo, Y.X.; Mao, X.X.; Zhai, D.; Zhu, D.F.; Huo, Y.M.; Sun, Z.D.; Wang, J.J. Prediction Method for Surface Subsidence of Coal Seam Mining in Loess Donga Based on the Probability Integration Model. Energies 2022, 15, 2282. [Google Scholar] [CrossRef]

- Takhanov, D.; Muratuly, B.; Rashid, Z.; Kydrashov, A. Geomechanics substantiation of pillars development parameters in case of combined mining the contiguous steep ore bodies. Min. Miner. Depos. 2021, 15, 50–58. [Google Scholar] [CrossRef]

- Yanli, H.; Jixiong, Z.; Baifu, A.; Qiang, Z. Overlying strata movement law in fully mechanized coal mining and backfilling longwall face by similar physical simulation. J. Min. Sci. 2011, 47, 618–627. [Google Scholar] [CrossRef]

| KS | >1 | 0.95~1 | 0.87~0.95 | <0.87 |

|---|---|---|---|---|

| Slope stability | Excellent | Good | Poor | Very Poor |

| Type | Northern Shaanxi Loess |

|---|---|

| moisture content/(%) | 11.9~17.3 |

| volumetric weight/(N/m3) | 16,200~18,600 |

| ratio | 2.69~2.71 |

| void ratio | 0.62~0.88 |

| void degree/(%) | 38.3~46.9 |

| cohesion/(kPa) | 38~101 |

| angle of internal friction/(°) | 27.8~33.8 |

| coefficient of compressibility/(MPa−1) | 0.08~0.25 |

| modulus of compression/(MPa) | 7.0~22.1 |

| unconfined compression strength/(kPa) | 119~159 |

| Number | hp/(m) | δp/(°) | γs/(N/m3) | cs/(Pa) | ϕs/(°) | Jc | Jz | Kms |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 (10) | 1 (10) | 1 (16,200) | 1 (38,000) | 1 (27.8) | 1 (15.0) | 1 (1.0) | 1.29 |

| 2 | 1 (10) | 2 (30) | 2 (17,400) | 2 (69,500) | 2 (30.8) | 2 (37.5) | 2 (2.5) | 1.57 |

| 3 | 1 (10) | 3 (50) | 3 (18,600) | 3 (101,000) | 3 (33.8) | 3 (60.0) | 3 (4.0) | 1.61 |

| 4 | 2 (30) | 1 (10) | 1 (16,200) | 2 (69,500) | 2 (30.8) | 3 (60.0) | 3 (4.0) | 2.02 |

| 5 | 2 (30) | 2 (30) | 2 (17,400) | 3 (101,000) | 3 (33.8) | 1 (15.0) | 1 (1.0) | 0.81 |

| 6 | 2 (30) | 3 (50) | 3 (18,600) | 1 (38,000) | 1 (27.8) | 2 (37.5) | 2 (2.5) | 0.54 |

| 7 | 3 (50) | 1 (10) | 2 (17,400) | 1 (38,000) | 3 (33.8) | 2 (37.5) | 3 (4.0) | 1.84 |

| 8 | 3 (50) | 2 (30) | 3 (18,600) | 2 (69,500) | 1 (27.8) | 3 (60.0) | 1 (1.0) | 0.87 |

| 9 | 3 (50) | 3 (50) | 1 (16,200) | 3 (101,000) | 2 (30.8) | 1 (15.0) | 2 (2.5) | 0.49 |

| 10 | 1 (10) | 1 (10) | 3 (18,600) | 3 (101,000) | 2 (30.8) | 2 (37.5) | 1 (1.0) | 3.02 |

| 11 | 1 (10) | 2 (30) | 1 (16,200) | 1 (38,000) | 3 (33.8) | 3 (60.0) | 2 (2.5) | 1.40 |

| 12 | 1 (10) | 3 (50) | 2 (17,400) | 2 (69,500) | 1 (27.8) | 1 (15.0) | 3 (4.0) | 0.86 |

| 13 | 2 (30) | 1 (10) | 2 (17,400) | 3 (101,000) | 1 (27.8) | 3 (60.0) | 2 (2.5) | 1.98 |

| 14 | 2 (30) | 2 (30) | 3 (18,600) | 1 (38,000) | 2 (30.8) | 1 (15.0) | 3 (4.0) | 0.68 |

| 15 | 2 (30) | 3 (50) | 1 (16,200) | 2 (69,500) | 3 (33.8) | 2 (37.5) | 1 (1.0) | 0.77 |

| 16 | 3 (50) | 1 (10) | 3 (18,600) | 2 (69,500) | 3 (33.8) | 1 (15.0) | 2 (2.5) | 1.36 |

| 17 | 3 (50) | 2 (30) | 1 (16,200) | 3 (101,000) | 1 (27.8) | 2 (37.5) | 3 (4.0) | 0.95 |

| 18 | 3 (50) | 3 (50) | 2 (17,400) | 1 (38,000) | 2 (30.8) | 3 (60.0) | 1 (1.0) | 0.56 |

| Stratigraphic Regions | Soil Stratum Thickness (m) | Rock Stratum Thickness (m) | Subsidence Coefficient | Horizontal Displacement Coefficient | Integrated Moving Angle (°) | Deviation Distance of Inflection Point (m) |

|---|---|---|---|---|---|---|

| I | 33 | 64 | 0.58 | 0.266 | 62.3 | 13.5 |

| II | 10 | 64 | 0.58 | 0.286 | 66.8 | 10.3 |

| III | 25 | 64 | 0.58 | 0.272 | 63.6 | 12.4 |

| IV | 40 | 64 | 0.58 | 0.262 | 63.7 | 14.5 |

| V | 25 | 64 | 0.58 | 0.272 | 63.6 | 12.4 |

| VI | 10 | 64 | 0.58 | 0.286 | 66.8 | 10.3 |

| VII | 33 | 64 | 0.58 | 0.266 | 62.3 | 13.5 |

| Slope Region | Slope Parameters | Mining Parameter | Results | |||

|---|---|---|---|---|---|---|

| hp/(m) | δp/(°) | Mining Direction | Jc | Jz | Kms | |

| AB | 46.0 | 24.7 | Along slope | 32.0 | 1.94 | 1.37 |

| CD | 30.0 | 45.0 | Against slope | 32.0 | 2.56 | 0.80 |

| EF | 30.0 | 45.0 | Along slope | 32.0 | 2.56 | 0.78 |

| GH | 46.0 | 24.7 | Against slope | 32.0 | 1.94 | 1.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Guo, Y.; Wang, W.; He, S. Impact of Underground Coal Seam Mining on Stability and Slippage of the Loess Slope. Sustainability 2023, 15, 6485. https://doi.org/10.3390/su15086485

Zhao B, Guo Y, Wang W, He S. Impact of Underground Coal Seam Mining on Stability and Slippage of the Loess Slope. Sustainability. 2023; 15(8):6485. https://doi.org/10.3390/su15086485

Chicago/Turabian StyleZhao, Bingchao, Yaxin Guo, Wei Wang, and Shenglin He. 2023. "Impact of Underground Coal Seam Mining on Stability and Slippage of the Loess Slope" Sustainability 15, no. 8: 6485. https://doi.org/10.3390/su15086485

APA StyleZhao, B., Guo, Y., Wang, W., & He, S. (2023). Impact of Underground Coal Seam Mining on Stability and Slippage of the Loess Slope. Sustainability, 15(8), 6485. https://doi.org/10.3390/su15086485