Abstract

This study focused on the smart factory, one of the critical paradigms in the digital transformation in manufacturing, and attempted a meta-analysis to systematically integrate statistical results from existing empirical analysis studies. An integration model, key factors—smart manufacturing adoption—performances, was established from collecting 42 Korean examples of literature. To compare effect sizes between domestic and foreign empirical study results, 11 foreign articles were added, and the moderating effect verification was conducted. As a result of the analysis, (1) the key factors of the adoption and continuous use of smart manufacturing were the network effect, social influences, finances, performance expectancy, facilitating condition, technological capabilities, and entrepreneurship. (2) The adoption and continuous use of smart manufacturing had a significant impact on business performances, especially the financial performance. (3) The impacts of entrepreneurship and the network effect as factors influencing the decision making of smart manufacturing adoption in Korea can be seen to be significantly higher than those of foreign countries. (4) The impact of smart manufacturing adoption on performances in Korea was higher than other countries. The findings of this study will provide practical implications for practitioners optimizing digital transformation manufacturing policies and supporting the adoption of smart manufacturing systems.

1. Introduction

The Fourth Industrial Revolution emerged as a hot topic at the World Economic Forum (WEF) in 2016, as efforts were being made to create hyper-connected and super-intelligence-based added-value items by incorporating new innovative information and communications technology (ICT) across industries. In the manufacturing sector, industrial, academic, and research entities have been making joint efforts to move beyond process automation and help the industry build intelligent factories that autonomously recognize and control the work situation by incorporating technologies such as AI, cloud, big data, and 5G with existing manufacturing processes. Providing a fillip to these efforts, the government is making the distribution of smart factories to manufacturing small- and medium-sized enterprises (SMEs) a national task, while expanding strategic support with the aim of supplying 30,000 factories by the end of 2022 [1]. According to the Korea Federation of SMEs, SMEs account for 99.9% of all Korean companies and 82.7% of total, while manufacturing accounts for 27.1% of Korea’s gross domestic product [2], ranking second among Organization for Economic Co-operation and Development countries (OECD) [3]. Therefore, intelligence and high value-added manufacturing SMEs are important goals at the national economic level.

The top priority of Korea’s manufacturing innovation strategy is the smartization of factories. Since the launch of “Manufacturing Innovation 3.0 Strategy’” in 2014 to enhance the competitiveness of manufacturing SMEs, the Korean government has supported a huge budget. In 2022, KRW 249.5 billion was supported to build intelligent and digitalized factories, aiming to supply 30,000 units [4]. Contrary to the government’s expectations, however, only 19,799 smart factory projects out of the targeted 30,000 were completed, and its achievement rate has only been 66% [5]. Despite the large budget and efforts of the government, the adoption of smart manufacturing by SMEs fell short of the target. If the adoption of smart manufacturing is critical, it is imperative to conduct an in-depth analysis of the decision-making process behind the adoption of smart factories at the manufacturing sites, which is a policy consumer. The decision to adopt smart factories from a management strategy perspective requires not only replacement and improvement of physical systems, such as existing manufacturing equipment, facilities, and networks, but also large-scale changes and investments in intangible assets, such as human resources, software, operating systems, and research and development (R&D). An in-depth consideration of the decision-making process on smart factories can form the basis for the successful implementation of dissemination and diffusion policies.

Many researchers have attempted an empirical analysis of factors affecting the adoption and use of smart factories, such as the unified theory of acceptance and use of technology (UTAUT) or by considering various individual factors, such as technology, organization, environment, and strategy. In this regard, there have been several studies analyzing the factors related to technology adoption in the context of the Fourth Industrial Revolution [6,7], but studies focusing specifically on smart factories have been lacking. Furthermore, previous studies have addressed the factors influencing the adoption of smart factories in Korea [8,9,10] but the results were somewhat fragmented or heterogeneous. Meanwhile, the adoption of smart factories can bring not only quantitative benefits, such as cost savings, production optimization, quality improvement, and flexibility, but also social influence and ecological sustainability from an environmental perspective [11]. Several studies have shown that the adoption of smart factories increases the financial performance of SMEs [10,12] and creates nonfinancial performances, such as innovation performances, internal satisfaction, environmental performances, and corporate competitiveness [10,13,14,15].

Despite such various studies, no study has presented a comprehensive decision-making framework that includes the factors that induce smart factory adoption and the performance that comes from the adoption of smart factories. In addition, there is a limitation that the individual empirical analysis results cannot be compared to which factor has a higher effect within the overall decision-making framework. In this study, therefore, previous empirical studies will be collected to derive the overall framework including the factors and performances of smart factories. With this framework, meta-analysis, which is a statistical technique that can systematically and quantitatively synthesize figures reported by individual empirical analysis studies will be attempted to comprehensively show the impact and the performances of smart factory adoption and statistically review the status of smart factories in relation to practical strategies. Additionally, the study will investigate the specificity of domestic smart factory factors and performances with an analysis of overseas literature on this topic.

Providing policy supports and incentives for companies that are still using traditional manufacturing technologies to adopt smart factories is a desirable direction for national economic growth and sustainability. If the factors that motivate companies to adopt smart factories are comprehensively identified, especially in countries with high value-added manufacturing industries, such as Korea, the results can provide important insights for latecomer countries in the manufacturing industry.

The structure of this paper is as follows: Section 1 serves the background information and the purpose of the study; Section 2 reviews previous studies and derives research questions related to this topic; Section 3 introduces the research framework, empirical analysis models, and data collection and covers the meta-analysis methodology; Section 4 presents the meta-analysis results, including verification of publication bias, effect sizes of factors, and performances of smart factory adoption; Section 5 discusses the research results; and Section 6 proposes policy recommendations based on the results.

2. Literature Review and Research Question

2.1. Smart Factory

The concept of smart factories emerged in the late 1990s in the wake of the rapid growth of information technology (IT) presenting the basis for further discourse by naming the entire variable hardware, software, and structure that can rapidly reconfigure manufacturing capabilities and functions in response to sudden changes in the market and the regulatory environment [16]. In the 2010s, the paradigm expanded to intelligent smart factories with the advancement of technologies such as artificial intelligence (AI), sensor networks, big data, and cloud. When Internet of Things (IoT) technology, which connects all objects at the manufacturing site to a network, was applied to intelligent technology, which can make autonomous judgments and controls, the concept of “factory-of-things” was proposed [17]. Furthermore, by applying the idea of ubiquitous access to a network anytime anywhere, the concept of ubiquitous factory was proposed [18]. Here, ubiquitous factories have certain key requirements, such as transparency that can collect, exchange, and monitor a wide range of data in real time, autonomy that can judge and control itself, and sustainability that can manage energy in real time.

Recently, a smart factory referred to a factory that extends the concept of factory automation and is modularized for each individual process to enable active production of customized products. The public–private joint smart manufacturing innovation team, Korea Smart Manufacturing Office (KOSMO), which oversees policies related to the dissemination and advancement of smart factories, defines smart factories as “people-centered intelligent factories that produce customized products at minimum cost and time by integrating all production processes from product planning to sales with information communication technology (ICT)” [19]. Here, “smartization” can be applied to all areas, including premanufacturing stages such as planning, design, production, distribution, and sales. Furthermore, it is applied to application systems, control automation, and field automation. In terms of the level of “smartization,” the scope of smart factories includes the basic stage of process logistics management or performance aggregation automation to the advanced stage of IoT and Internet of Services-based Cyber-Physical System (CPS) and big-data-based diagnosis and operation. Nevertheless, there are minimum requirements to form a smart factory, and the Smart Manufacturing Innovation Promotion Team considers digitalization of 4M + 1E (Man, Machine, Material, Method, and Energy), algorithm or AI-based intelligence, horizontal and vertical integration, creation of data-based engineering knowledge, and connection with smart systems. These smart factory concepts and standards are constructed by public–private experts based on domestic and foreign manufacturing status and previous studies, so these concepts and standards are widely accepted, and this study will also apply these to concepts and standards to develop related discussions.

In Korea, smart factories are divided into five stages according to the level of manufacturing innovation capabilities [19]. Stage 1 is the nonapplied stage in which all manufacturing processes are performed manually; Stage 2 is the basic stage with the application of point of production (POP), individually operated corporate resource management systems, etc.; Stage 3 is the first intermediate stage that applies a real-time decision-making operation system, automatic facility data aggregation system, etc.; Stage 4 is the second intermediate stage with the application of a facility control automation system, real-time factory control system, integrated operation system, etc.; and Stage 5 is an advanced stage that enables Internet of Things (IoT)- and Internet of Service (IoS)-based big data diagnosis and operation. It is reasonable that the adoption of smart factories should be implemented gradually depending on the level of a company’s manufacturing abilities. However, companies’ decision making on smart factory adoption by companies can be influenced by various other factors, such as management and environmental situations. In addition, it will be possible to attract more companies considering the transition to smart factories only when the feasibility of smart factory adoption is increased by confirming the high performances of using smart factories. Therefore, it is more necessary to identify factors that affect the decision making on adoption and effects caused by the adoption of smart factories to induce their adoption.

From a management perspective, research related to smart factories is focused not only on factors that affect decision making, but also the management performance due to adoption of smart factories. This study includes both subjects and derives research questions from the previous literature.

2.2. Factors of Smart Factory Adoption

Internal and external factors can affect the adoption of smart factories and attempts have been made to identify the factors through various empirical analyses and case studies. These studies generally identified the internal and external motives of the analysis unit based on the Technology Acceptance Model (TAM) proposed by Davis [20,21] and its subsequent models. The usefulness and ease of specific technologies are at the core of TAM. The degree to which a specific technology is found useful or easy to use is a decisive factor in the acceptance of technology by a specific entity. This model has been supplemented by TAM2 [22] and TAM3 [23] and has recently been developed as an integrated technology acceptance model (UTAUT) by combining and extending eight prominent models, including motivational models, planned behavioral theory, and social cognition theory. In this model, performance expectancy, effort expectancy, social influence, and facilitating conditions are considered major factors in technology acceptance, and demographic factors, such as gender and age, and experience and voluntariness of use intervene as control variables in the technology acceptance process. Recently, UTAUT2 with the addition of hedonic motivation, price value, and habit has been proposed for the existing UTAUT model [24]. Studies that applied TAM to organizational units, such as companies, cited competition and industrial environment [25,26] as external factors and the pursuit of efficiency and competitive advantages as internal factors [27,28].

According to Stocker et al. [6], who qualitatively reviewed previous studies on conditions for successful introduction of technologies related to the Fourth Industrial Revolution on a wider scale than smart factories, social factors, such as culture and working environment, and organizational factors, such as management and process, are believed to be important for the successful adoption of technologies. In terms of culture, communication, openness, and innovation-friendly culture are important and, with regard to the working environment, digitalization capabilities should be built and developed. Regarding management, efforts should be made to establish and disseminate digital strategies and establish a company-wide digital culture. As for the process, incorporating digital processes into the working environment is important. Touriki et al. [29], who analyzed the integration trend of smart, eco-friendly, resilient, and lean production, analyzed that the rise in regulatory and environmental issues, innovation of business models, changes in the labor market, and efforts to enhance corporate image are some of the factors that encourage the integration of smart factories. Expectations of efficiency and competitive advantages in accepting technologies related to the Fourth Industrial Revolution have a positive effect, while competitor and supplier factors have no statistically significant effect [30]. In Japan, relative advantages as technological factors, support from top executives as organizational factors, and market uncertainty as environmental factors were found to be the main factors in SMEs’ acceptance of technologies for the Fourth Industrial Revolution [7].

Empirical studies on factors affecting the adoption and continuous use of smart factories in Korea were actively conducted with various variables. In many studies, among the factors considered in UTAUT, performance expectancy and social influence were positive variables in the decision-making process for introducing smart factories [8,31,32,33]. It was confirmed that the expectation of effort was generally not statistically significant, except in some studies [12,34]. Other variables that UTAUT include are the relative advantages of smart manufacturing technology [35], technology readiness [36], and supplier technology [34], while entrepreneurs’ willingness and support level were also confirmed as elements for introducing smart factories [8,34]. Other external factors, such as government support [8,13,35,36] and co-operation with external entities [37,38], were also confirmed as components for the adoption of smart factories. These analysis results show that various factors within and outside the organization are closely involved in the introduction of smart factories by SMEs. Therefore, it is necessary to review the importance of various factors and strategically focus and support the adoption of smart factories. In addition, the need for meta-analysis arises, as there have been no statistical attempts to analyze the factors systematically and comprehensively behind the adoption of smart factories, despite the diversity of various empirical analyses.

- Q1: What factors affect the adoption and continuous use of smart factories and what level of influence does each factor have?

2.3. Performances of Smart Factory Adoption

For companies, the ultimate purpose of converting manufacturing processes into ICT-based smart factories, despite budget and time constraints, is to maximize productivity and streamline costs to generate profits. There are various ripple effects at the mid to long term and it may impact a firm’s financial performance. Consequently, smart factory performance can be broadly defined as achieving production efficiency or creating and propagating social value. According to Kamble et al. (2020) [11], who developed a Smart Manufacturing Performance Measurement System (SMPMS) for small- and medium-sized enterprises by combining 98 previous studies and two surveys at industrial sites, smart factory performance can be redefined in 10 big-picture ways: cost, real-time diagnosis, production optimization, quality, integration, flexibility, computing, time, social performance, and ecological performance. By applying 59 detailed performance indicators, performance can be diagnosed in multifaceted ways according to the perspective and purpose that is desired to be measured.

Previous empirical studies in Korea also reported that smart factories at manufacturing SMEs had a statistically significant effect on multidimensional management performance. In general, many studies have confirmed that the promotion of smart factories had a positive effect on management performance by integrating financial and nonfinancial performance [10,12,39]. Some studies have integrated productivity performance, such as cost reduction, automation facility introduction, quality improvement, and visibility, into management performance [15]. Furthermore, it presented environmental performance as an indicator, considering that sustainability and social responsibility had become significant topics of interest at manufacturing sites. In addition, there were studies that presented net benefits [35] or corporate competitiveness [14] as performance indicators, which signify the degree to which a company’s productivity and flexibility have improved, driven by smart factories.

Various performance indicators and measurement methodologies have been proposed, but many studies suggest that smart factories generally have a positive effect on management performance, which can serve as empirical evidence for the government to promote these factories. However, a generalized conclusion has not been drawn as to which factors smart factories contribute more among the multidimensional performance indicators of a company, and there is a need for meta-analysis that integrates existing studies.

- Q2: What is the level of impact of smart factories on management performance, and is there a difference by performance type?

3. Research Model, Data, and Methodology

3.1. Research Model and Variables

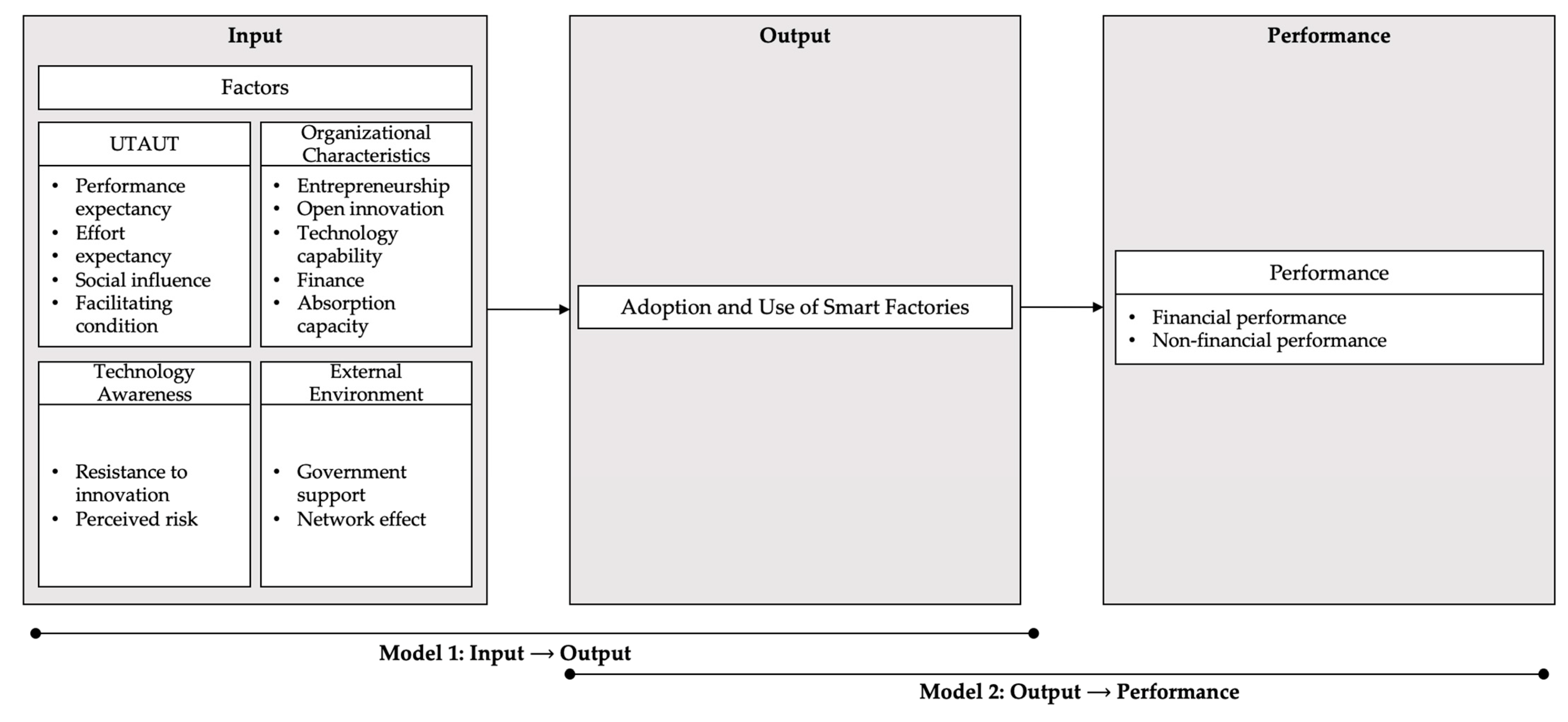

As a result of extracting the factors of adoption and continuous use of smart factories by synthesizing individual empirical analysis studies, it was determined that internal and external factors affect the adoption of smart factories. Specifically, organizational characteristics, technology recognition, and external environment can be classified as higher-level factors and sub-factors can be extracted from these higher-level factors. However, since many studies have adopted the theoretically established UTAUT model, UTAUT factors were classified into independent higher-level factors for empirical investigation of this model. Accordingly, 13 sub-factors from the four higher-level factors were defined as factors for smart factory adoption and continuous use. In addition, significant achievements were made following the adoption of smart factories and empirical analysis studies were synthesized, and these achievements were classified into financial and nonfinancial achievements. Therefore, the overall framework of this research model includes variables of input, output, and performance. Input includes factors that affect the adoption of smart factories, output is the adoption and use of smart factories, and performance refers to business performance resulting from the adoption and use of smart factories. A schematic expression of this model is shown in Figure 1.

Figure 1.

Research model.

A meta-analysis uses a statistical approach to derive pooled estimates close to the common truth of existing studies. The patterns of results of previous studies can be provided. The following research process is conducted to perform a meta-analysis. First, previous empirical analysis studies are searched and collected. Among them, statistical estimate values related to variables of this research model are extracted. The collected data are analyzed according to the above framework in Figure 1. Here, the framework is divided into two analytical models. Model 1 is the relationship between the factors influencing the adoption and use of smart factories and Model 2 is about the impact of the adoption and use of smart factories on management performances.

In Figure 1, each variable is defined as shown in Table 1. The variables were defined by applying the verbatim definitions provided by previous studies subject to meta-analysis.

Table 1.

Definition of variables.

3.2. Data Collection

This study statistically integrated previous studies on factors for the adoption of smart factories and examined the relationship between smart factories and management performance. To analyze the statistics reported by individual empirical studies in an integrated way and to integrate them so that they are not biased to a specific type of study, an objective document securing procedure that is not biased must be secured.

To systematically collect domestic academic literature, four representative academic databases in Korea were used, including RISS (www.riss.kr accessed on 30 December 2021 to 11 January 2022), DBpia (www.dbpia.co.kr accessed on 30 December 2021 to 11 January 2022), Korean journal Citation Index (KCI: www.kci.go.kr accessed on 30 December 2021 to 11 January 2022), and ScienceOn (scienceon.kisti.re.kr accessed on 30 December 2021 to 11 January 2022). Search engines such as Google were also used, considering that various policy research reports and certain publications would not be available in academic databases. The search phrases included “smart factory or smart manufacturing”.

The first research list compiled by academic databases and search engine included 8937 items, but 1482 unique research lists were built because of consolidating the lists to exclude duplicate items. Here, studies unrelated to meta-analysis were excluded through title and abstract review, and a total of 218 texts were secured by additionally excluding studies with no original text or inappropriate form and content. Coding was conducted on each one through consensus among researchers, and studies that were unrelated to the content, involved qualitative research, or had empirical analysis without statistical values were additionally excluded. Consequently, 58 empirical analysis studies were coded and, by reidentifying studies with analyzable variables after constructing a research model, 42 studies were selected for meta-analysis.

For coding, information such as researchers, year of publication, sub-research classification, factor variables, smart factory adoption and continuous use variables, performance variables, effect size, and number of samples in the targeted analysis literature were entered.

3.3. Methodology

This study performed meta-analysis by integrating Pearson’s momentum correlation coefficient r among the effect sizes reported by various empirical analysis studies. r is the most intuitive statistic showing the linear relationship between two variables and is widely used in various empirical analysis studies. However, this value basically has the characteristic of indicating an asymmetric distribution, so, in meta-analysis, it is common to convert it to Fisher’s Z to calculate the average effect size. Fisher’s Z is considered suitable for integrating correlation coefficients reported in different studies, because it tends to follow a normal distribution in comparison to r. The effect size calculated by Fisher’s Z was converted back to Pearson’s correlation coefficient r and reported to enhance the reader’s understanding [60]. The equations for calculating Fisher’s Z (1) and converting it back to r (2) are as follows [61]:

The formulas for calculating the variance (3) and standard deviation of Fisher’s Z (4) are as follows:

If the analyzed study did not report the correlation coefficient, the regression coefficient β was converted to r using the following Formula (5) and then analyzed [62]:

In calculating the average effect size, studies with a larger number of samples were weighted to individual effect sizes on the premise that they were reliable statistics that could better represent the population. Here, the inverse variable weight (, 6) and the weighted average (M, 7) were calculated according to the following equations [63]:

For coding and the calculation of effect size, “Comprehensive Meta-analysis (CMA) 3.0”, a statistical package specialized for meta-analysis, was used. In accordance with Cohen [64], the calculated effect size was interpreted as a minor effect size when it was 0.1 or lower, an intermediate effect size if it was around 0.3, and a large effect size if it was 0.5 or more.

4. Results

4.1. Verification of Publication Bias

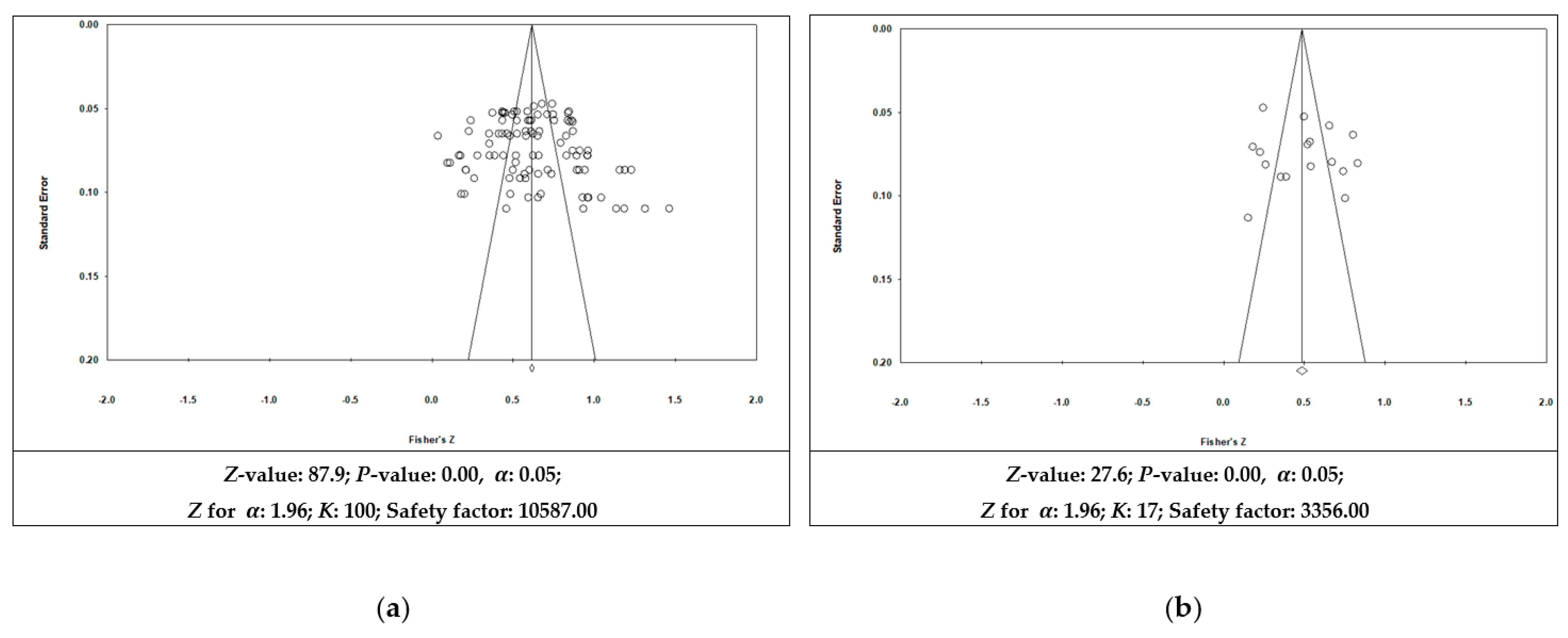

Publication bias was analyzed in Figure 2 to verify that empirical analysis studies subject to meta-analysis were collected without bias to specific trends. First, a funnel plot was plotted to visually verify the convenience of publication, and it was judged that the bias was low because the effect size was generally distributed in a symmetrical form. By calculating the safety coefficient to numerically verify the convenience of publication, 10,587 were identified in Model 1 and 3356 in Model 2. This figure is sufficiently larger than the 5K + 10 in each model, so it can be evaluated that the concerns of publication convenience are generally low [65].

Figure 2.

Funnel plots, fail-safe N for verification of publication bias: each circle means effect size/standard error, (a) Model 1, factors influencing the adoption and continuous use of smart factories; (b) Model 2, performances of smart factory adoption.

4.2. Homogeneity Verification and Average Effect Size

In Table 2, homogeneity verification was attempted to understand the level of heterogeneity of the average effect size (ES) calculated by synthesizing individual empirical analysis studies. The size of the test statistic Q value, which is the total variance of all effect sizes included in the analysis model, is significant enough, and the value was more than 75%. Therefore, the heterogeneity of the model was substantial [66]. In a model with substantial heterogeneity in effect size, it is appropriate to analyze it as a random effect model, which assumes heterogeneity in effect size and recognizes variance between studies, rather than a fixed effect model [61].

Table 2.

Results of homogeneity verification and average effect size.

The average effect size was 0.562 in Model 1, which was larger than Model 2 (0.456). The impact of internal and external factors on the adoption of smart factories was greater than the impact of smart factories on management performance. However, the difference was not significant and it can be interpreted that both models showed a large effect size.

4.3. Factors Affecting Adoption of Smart Factories

Table 3 compiles the meta-analysis results of how much internal and external factors affect the adoption and continuous use of smart factories. Thirteen detailed factors were identified across four larger factors, which included UTAUT, organizational characteristics, technology recognition, and external environment. The analyses of 21,211 samples from 100 research models were incorporated into the meta-analysis model. Among the 13 factors, innovation resistance and perceived risk corresponding to technology recognition had a negative (−) sign. However, if they were merged into the models, they were distorted in the direction of decreasing the overall average effect size due to the offset effect. The calculated average effect sizes were distributed over the range of 0.145 to 0.714, and all effect sizes were statistically significant within the 95% confidence interval.

Table 3.

Results of factors affecting adoption and use of smart factories (Model 1).

Considering the influential factors based on effect size, it was found that network effect (0.714), social influence (0.672), finance (0.628), performance expectancy (0.627), facilitating condition (0.606), technology capability (0.573), and entrepreneurship (0.547) had a significant impact on the adoption and use of smart factories. These factors were interpreted as having a large effect size of 0.5 or more. In addition, government support (0.526) and effort expectancy (0.518) were confirmed to have a large effect size. At the policy level, appropriate management of these factors is necessary to promote the conversion of SMEs to smart factories.

4.4. Performances of Smart Factory Adoption

Table 4 compiles meta-analyses of the effect of adoption, use, and advancement of smart factories on management performance. The results of 17 analysis models and 3387 samples were incorporated. Six models were compiled for financial performance and seven for nonfinancial performance. In cases where financial performance is analyzed for each study, in cases where nonfinancial performance was analyzed, and in cases where multiple models are presented at the same time, simple compilation violates the assumption of independence, so the shifting unit of analysis was applied so that the analytical sample was not redundant [67]. Consequently, the sum of the number of studies and samples of financial and nonfinancial performance is not consistent with the compiled model.

Table 4.

Results of performances of smart factory adoption (Model 2).

As a result of the analysis, the adoption and continuous use of smart factories had a positive effect on management performance (0.456), which was less than 0.5, but it nevertheless had a relatively large effect size. For all types of management performance, the magnitude of the effect size was above average and all figures were statistically significant in the 95% confidence interval.

The adoption and continuous use of smart factories had a greater impact on financial performance between the two types of performance, and this effect size (0.464) was larger than that of compiled management performance (0.456). In addition, this effect size had intermediate I2 value (58.641), which showed heterogeneity. Therefore, it demonstrated that many studies consistently support large effect sizes.

4.5. Further Analysis: Comparison of Domestic and Foreign Literatures

The meta-analysis of this study is basically limited to domestic empirical analysis literature, but additional analysis was attempted by comparing the effect size in overseas empirical analysis literature to compare the analysis results.

The collection of overseas literature was conducted by consulting with literature information experts, selecting search databases, securing search terms and search formulas, obtaining the literature databases suitable for analysis, determining literature candidates for analysis through content review, and coding. For literature databases, Scopus and Web of Science (WoS) were selected owing to the range of research topics, public confidence, volume of literature secured, and possibility for redundancy. Furthermore, search formula was set in consideration of research topics and methodologies. The first search literature was 4915 in Scopus and 2554 in WoS, and a total of 7469 documents were secured. Furthermore, 5561 first overseas literature databases were established by deleting the redundant literature in both databases. Among the 5561 publications, 11 were secured by eliminating studies with unrelated topic matter (3437), engineering-based modeling and simulation studies (1221), qualitative (562) and systematic literature reviews (173), and studies without variables that can be analyzed (157). Overseas literature that was subject to analysis included surveys, comprising the results of analysis from eight countries: China (3), India (3), Germany (1), Pakistan (1), South Africa (1), Saudi Arabia (1), Malaysia (1), and Iran (1).

Among the analyzed literature, five factor variables—performance expectancy, effort expectancy, entrepreneurship, technology capability, and network effect—could be put through meta-analysis, since the number of effect sizes corresponding to Model 1 were two or more (Table 5).

Table 5.

Variables of foreign literature.

After classifying the countries of origin in each literature as domestic or foreign, whether the country of origin of the literature was domestic or foreign act as regulatory variables, as shown in Table 6 below.

Table 6.

Comparison of Model 1 between domestic and foreign literatures.

Since the result of Cochran’s Q test indicates that the effect size of each model is statistically heterogeneous, it suggests that there are significant differences between the domestic and foreign models in four variables (effort expectancy, entrepreneurship, technological capability, and network effect). In other words, the effect sizes of these variables differ between the two models. The foreign literature suggests a larger effect size for effort expectancy, while the domestic literature shows a larger effect size for entrepreneurship, technological capability, and network effect. These characteristics are likely unique to Korea and may differentiate it from other countries in terms of introducing smart factories, among other factors.

Regarding the impact of the adoption and continuous use of smart factories on management performance, the effect size was compared by inputting domestic and foreign literature as control variables (Table 7).

Table 7.

Comparison of Model 2 between domestic and foreign literature.

Domestic literature was 0.456 and overseas literature was 0.304, and the impact of smart factories on management performance was higher for domestic companies. However, the p-value, which shows the statistical significance of the difference in effect size, was 0.097, and the statistical difference was recognized at 90% confidence level but there was no statistically significant difference at the 95% confidence level. Under the assumption that statistical significance has not been sufficiently secured, in Korea, smart factories contribute to management performance significantly in comparison to those seen in overseas analyses. This is a result that supports the legitimacy of domestic policies pursuing the distribution of smart factory technology.

5. Discussion

In the results of Model 1 Table 3, this phenomenon in which network and social effects have the greatest influence, rather than internal organizational factors, suggests that manufacturing SMEs, the main topic of smart factory research, closely influence companies in terms of value chain. It is estimated that more than 60% of Korean SMEs conduct management activities through direct and indirect subcontracting relationships with larger companies [79]. Considering this, relationships with other companies connected by the value chain, such as suppliers, competitors, customers, and partners, have a profound impact on management decision making. Regarding the adoption of smart factories, decisions by partners and competitors can lead one to conform to another. Furthermore, decisions by related companies can lead to expectations for network effects, and customers may directly or indirectly demand the adoption of smart factories for reasons such as cost reduction and reliability. The fact that the influence of external players is significant suggests that consortium-type distribution policies at the corporate level may be more useful than smart factory distribution policies at individual companies.

Usefulness can be considered more important but the difference is not significant because the error range of the effect size partially overlaps. Companies are likely to introduce smart factories when they recognize that smart factories will improve their production efficiency and finances. Consequently, the prospect of ease of adoption of technology and proficiency is a secondary factor. In terms of policies that supply and distribute smart factories, it is necessary to focus on the practical effects more so than the ease of application.

Among the variables of organizational characteristics, the influence of finances, entrepreneurship, and technology capability were significant. Companies with sufficient financial capacity could seek to upgrade their technology capabilities, and the expansion of technology capabilities could lead to further financial performance, creating a positive cycle. Companies that have generated results based on technology are likely to introduce innovative new technologies and solutions for smart factories. Furthermore, the leadership and strategic will of top executives—the founders of the company—could serve as a catalyst in these decisions.

Conversely, innovation resistance (0.426) and perceived risk (0.145), which were factors hindering the adoption of smart factories, had actual negative (−) signs, and the effect size was relatively small. Furthermore, perceived risk was interpreted to have a relatively low effect size. As innovation resistance had an intermediate effect size, efforts to improve the understanding and acceptability of new technologies for smart factories for management and the public should be continued.

Among the external environmental variables, the network effect that demonstrated the relationship among companies was the most influential factor. Although government support (0.526) had a large effect size, it only had intermediate-to-low influence. This suggests that policy support only plays an auxiliary role in the decision-making process of smart factory introduction, and it is not a decisive factor. The most important factors were the interaction among companies on the value chain, level of readiness to accept technology within the company, and strategic decision making.

In the comparative analysis results of Model 1 (Table 6), in terms of performance expectancy and effort expectancy, the effect size of performance expectancy was not statistically significant. However, for domestic companies, the expectation that smart factories would affect performance had great influence on whether smart factories were introduced. For foreign companies, the expectation that it would be easy to introduce and utilize smart factories had a great influence on whether smart factories were introduced.

Entrepreneurship and network effects were significantly higher than those of overseas companies as factors influencing domestic companies’ decision making to introduce smart factories. This result reflects the tendency of domestic SMEs to rely heavily on decision making of the entrepreneur and the interdependent influence with related companies.

In Table 4, the effect of smart factories on nonfinancial performance was found to have a normal size effect, and heterogeneity was also substantial. This difference stems from the fact that financial performance can be generalized to financial indicators, while nonfinancial performance is a multi-layered concept that encompasses satisfaction, efficiency, value, and efficacy. Since the nature of the two performance indicators is different, the comparison of the two effect sizes does not have much significance. However, the analysis clearly shows that smart factories have a significant impact on management performance, especially on financial performance, which is critical for a company’s existence. These analyses can be a source for empirical argument for a government to implement policies that supply and distribute smart factories.

6. Conclusions

6.1. Research Conclusions and Policy Implications

This study focused on smart factories, one of the key digital transformation paradigms in the manufacturing industry, and attempted a meta-analysis that systematically compiled statistical figures of existing empirical analyses on their factors and performance. A comprehensive research framework of the impact of internal and external factors on the adoption of smart factories and the impact of smart factories on financial and nonfinancial management performance was constructed by compiling the correlation coefficient effect size according to the protocol of meta-analysis. In addition, 11 overseas publications on the research topic were additionally analyzed to investigate the specificity of domestic smart factory factors and performance.

According to the analysis, the key factors of the adoption and continuous use of smart factories were network effect (0.714), social influence (0.672), finance (0.628), performance expectancy (0.627), facilitating conditions (0.606), technology capabilities (0.573), and entrepreneurship (0.547). With respect to research question 1 (Q1), we can explain that the above variables play a significant role in the adoption of smart factories within the Korean context. While the significance of these variables has been established in prior individual studies [8,9,31,32,33,34,38,46], this study is the first to provide a comprehensive and quantitative comparison of their relative importance.

The analyses of overseas literature demonstrated that entrepreneurship, technology capabilities, and network effects were important variables for introducing smart factories in Korea in comparison to factories overseas. Conversely, the influence on effort expectancy was relatively low for factories in Korea in comparison to factories overseas. The results of the meta-analysis conducted to explore the relationship between smart factories and performance, in response to research question 2 (Q2), indicated a positive impact of smart factories on performance. The analysis revealed that the impact on financial performance (0.464) was larger and more consistent than the impact on nonfinancial performance (0.340). These findings lend support to the legitimacy of policies aimed at promoting the adoption of smart factories by firms.

Policy implications of this analysis are as follows.

First, the most influential factor in companies’ decision to introduce smart factories was network and social effects, suggesting that a policy approach considering these effects is needed rather than individual company-level smart factory supply and distribution policies. In particular, the profound influence of the network effect was prominent in supplementary analysis when compared to results shown in overseas literature. Since domestic manufacturing SMEs are greatly influenced by stakeholders in the value chain, such as suppliers, competitors, and partners, it is possible to consider ways to support the adoption of smart factory joint platforms, solutions, and technology development, especially focusing on the value chain consortium. In addition, these results are in line with a previous study which suggests that the diversity of knowledge among actors participating in innovation networks can be a key factor in driving positive collaborations and partnerships among innovation partners [80].

Second, since the level of performance expectancy of smart factory technology has a profound impact on decision making to accept smart factories, it is necessary to provide companies with success stories of smart factories to raise expectations and further promote the adoption of smart factories. The fact that smart factories have a positive effect on financial performance is firmly supported by the analysis results of Model 2 of this study. The effort expectancy (0.518) was lower than performance expectancy (0.627), suggesting that, if the technology is useful with a clear expectation of performance, the question of whether it is easy to introduce the technology is a secondary consideration. Although statistical significance for the moderating effect is yet to be established, the level of effect size of performance expectancy in the analysis of domestic companies exceeded the analysis result (0.569) shown in overseas literature. Therefore, it is necessary to focus policy capabilities on strengthening the acceptability of high-level models that can achieve strong results rather than exert policy efforts to spread a basic factory automation system, which is a low-level smart factory.

Third, internal factors, such as strategic will, management support, financial capacity, and technology capabilities have a profound impact on the decision to introduce smart factories. Since policy-led support from the government has been identified as a secondary factor, governments need to reorganize effective smart factory supply policies, and it is necessary to focus on providing conducive conditions for smart factories rather than providing direct support. It is necessary to ease the requirements for public demonstration test beds, expand financial support programs related to technology, facilities, and manpower, and strengthen education and promotional communication on the usefulness of smart factories. Since innovation resistance has a huge negative impact on the adoption of smart factories, it is necessary to equip companies with technology, through job training support on manufacturing innovation along with the spread of test beds. Among the variables of organizational characteristics, the role of entrepreneurship is particularly important, which is clearly shown through the analysis of the moderating effects in overseas literature. Therefore, efforts should be made to promote success cases and factors through management councils in respective regions, technologies, and industries.

From a managerial perspective, the following implications can be drawn. Firstly, the positive impact of smart factories on business performance suggests that companies re-lying on traditional manufacturing technologies should consider transitioning to smart factories. Secondly, given the significant influence of network effects on the adoption of smart factories, companies can facilitate a smoother transition by collaborating with other firms in the value chain. Finally, the importance of executive capabilities and entrepreneurship in the adoption of smart factories highlights the need for managers to prioritize manufacturing innovation and allocate resources accordingly.

6.2. Limitations and Future Directions of Research

This meta-analysis is the first to deal with factors and performance of smart factories, and it is significant that the effect size of various factors was empirically compiled and identified. Based on this empirical compilation and identification, policy implications were presented. However, this study has certain limitations.

First, domestic literature was used to analyze the factors and performance of smart factories, and additional analysis was attempted by adding 11 overseas studies for comparison between countries. However, the number of overseas studies and the distribution of countries that were part of the analysis did not reach the level where academic generalization was possible. Although 5,561 overseas studies were considered for meta-analysis, only 11 overseas studies included variables that could be compared in the same line as variables in domestic literature used for analysis. In addition, there was difficulty in generalization because the research target countries of overseas studies were developing countries.

Second, no further analysis has been attempted to explain the heterogeneity of the effect size. Effect sizes may vary depending on a company’s characteristics, such as type of company and industry, analysis methodologies, etc.

Third, the research model was overly simplified into a three-step process. The intention to introduce a smart factory, the actual adoption behavior, and the initial and ultimate management performance in terms of production efficiency from the adoption of smart factories can be precisely classified, but this classification was limited in this study. This is because of a lack of previous studies that conducted domestic and foreign empirical analysis.

Through the limitations found in this study, the following directions for future research were derived.

First, the quantitative difference between domestic and foreign studies is due to the difference in policy importance and methodological approach for the supply and distribution of smart factories by country. This limitation can be overcome by verifying regulatory variables by continent, industry, and company size after sufficient empirical analysis studies related to overseas smart factories are accumulated in the future.

Second, it is necessary to supplement this through moderating effect analysis or meta-regression analysis, which can identify differences in effect size according to research characteristics, corporate and industry types, analysis methodologies, and data attributes.

Third, the factors of smart factory adoption considered in this framework were simplified due to the lack of previous studies. If enough previous empirical studies are added in the future, the scope of the framework can be expanded.

Author Contributions

Conceptualization, J.K.; methodology, J.K. and H.P.; software, J.K. and H.P.; validation, J.K. and H.P.; formal analysis, J.K.; investigation, J.K. and H.P.; resources, J.K. and H.P.; data curation, J.K. and H.P.; writing—original draft preparation, J.K.; writing—review and editing, J.K., H.-r.J. and H.P.; visualization, J.K., H.-r.J. and H.P.; supervision, J.K. and H.P.; project administration, J.K. and H.P.; funding acquisition, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Korea Institute of S&T Evaluation and Planning (KISTEP) funded by the Ministry of Science and ICT (MSIT) in 2022, under grant number KISTEP-2022-011 and AV22060. The title of the project is ‘Science, Technology, and Innovation Policy Agenda of Digital Transformation: 10 Strategic Imperatives on Accelerating Industry and Creation of New Convergence Markets’.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ministry of SMEs and Startups. Available online: https://www.mss.go.kr/site/smba/ex/bbs/View.do?cbIdx=86&bcIdx=1031335&parentSeq=1031335 (accessed on 10 June 2022).

- Korea Federation of SMEs (KBIZ). Available online: https://www.kbiz.or.kr/ko/contents/bbs/view.do?mnSeq=325&seq=151412#none (accessed on 10 June 2022).

- Korean Statistical Information Service (KOSIS). Available online: https://kosis.kr/statHtml/statHtml.do?orgId=101&tblId=DT_2KAA906_OECD (accessed on 10 June 2022).

- Korea Policy Brief. Available online: https://www.korea.kr/news/pressReleaseView.do?newsId=156491717 (accessed on 10 June 2022).

- Korea Smart Manufacturing Office (KOSMO). Available online: https://library.smart-factory.kr/SDL/main/cnstc (accessed on 17 January 2023).

- Stocker, A.; Rosenberger, M.; Schmeja, M.; Schneider, G. Key success factors for the implementation of digital technologies in the context of Industry 4.0. In Proceedings of the International Federation for Information Processing/IEEE IM 2021—International Symposium on Integrated Network Management, Bordeaux, France, 17–21 May 2021. [Google Scholar]

- Prause, M. Challenges of Industry 4.0 technology adoption for SMEs: The case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Kim, S. A Study on the Factors Influencing the Introduction of Smart Factories: Focusing on the Moderating Effect of Innovation Resistance. Ph.D. Thesis, Incheon National University, Incheon, Republic of Korea, 2021. [Google Scholar]

- Park, C.; Seo, Y. A study on the intention to use smart factory-related technologies using extended UTAUT. Manag. Educ. Res. 2020, 35, 501–532. [Google Scholar]

- Lee, R.; Kim, C. The impact of application of smart factory technology by small and medium venture companies on quality and innovation performance. Venture Start-Up Res. 2020, 15, 59–71. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Ghadge, A.; Raut, R. A performance measurement system for industry 4.0 enabled smart manufacturing system in SMMEs—A review and empirical investigation. Int. J. Prod. Econ. 2020, 229, 107853. [Google Scholar] [CrossRef]

- Lee, J.; Gil, J. An empirical study on the effect of integrated technology acceptance theory (UTAUT) on the intention to introduce smart factories and management performance: The moderating effect of CEO’s. Korean Manag. Consult. Rev. 2021, 21, 61–84. [Google Scholar]

- Kim, S. Empirical Study on Big Data-Based Small and Medium-Sized Manufacturing Companies’ Intention to Accept Smart Factgories and Business Performance of Smart Factories. Ph.D. Thesis, Hansung University, Seoul, Republic of Korea, 2019. [Google Scholar]

- Choo, Y.; Lee, D.H. A study on factors for introducing smart factory to improve competitiveness of small and medium-sized metal processing companies. J. Korean Inst. Ind. Eng. 2019, 45, 70–80. [Google Scholar]

- Jang, S. A Study on the Effect of Smart Factory Manufacturing Data on Small and Medium Business Management Performance: Focusing on Small and Medium Manufacturing Industry. Master’s Thesis, Kyung Hee University, Seoul, Republic of Korea, 2021. [Google Scholar]

- Koren, Y.; Heisel, U.; Jovane, F.; Moriwaki, T.; Pritschow, G.; Ulsoy, G.; Van Brussel, H. Reconfigurable manufacturing systems. CIRP Ann. 1999, 48, 527–540. [Google Scholar] [CrossRef]

- Zühlke, D. Smart Factory-towards a factory-of-things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Yoon, J.S.; Shin, S.J.; Suh, S.H. A conceptual framework for the ubiquitous factory. Int. J. Prod. Res. 2012, 50, 2174–2189. [Google Scholar] [CrossRef]

- Korea Smart Manufacturing Office (KOSMO). Available online: https://www.smart-factory.kr/smartFactoryIntro (accessed on 10 June 2022).

- Davis, F.D. A Technology Acceptance Model for Empirical Testing New End-User Information System: Theory and Results; Massachusetts Institute of Technology: Cambridge, MA, USA, 1986. [Google Scholar]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–339. [Google Scholar] [CrossRef]

- Venkatesh, V.; Davis, F.D. A theoretical extension of the technology acceptance model: Four longitudinal field studies. Manag. Sci. 2000, 46, 186–204. [Google Scholar] [CrossRef]

- Venkatesh, V.; Bala, H. Technology acceptance Model 3 and a Research Agenda on Interventions. Decis. Sci. 2008, 39, 273–315. [Google Scholar] [CrossRef]

- Venkatesh, V.; Thong, J.Y.L.; Xu, X. Consumer acceptance and use of information technology: Extending the unified theory of acceptance and use of technology. MIS Q. 2012, 36, 157–178. [Google Scholar] [CrossRef]

- Gatignon, H.; Robertson, T.S. Technology diffusion: An empirical test of competitive effects. J. Mark. 1989, 53, 35–49. [Google Scholar] [CrossRef]

- Chwelos, P.; Benbasat, I.; Dexter, A.S. Research report: Empirical test of an EDI adoption model. Inform. Syst. Res. 2001, 12, 304–321. [Google Scholar] [CrossRef]

- Obal, M. What drives post-adoption usage? Investigating the negative and positive antecedents of disruptive technology continuous adoption intentions. Ind. Mark. Manag. 2017, 63, 42–52. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Touriki, F.E.; Benkhati, I.; Kamble, S.S.; Belhadi, A.; El Fezazi, S. An integrated SMART, Green, resilient, and lean manufacturing framework: A literature review and future research directions. J. Clean. Prod. 2021, 319, 128691. [Google Scholar] [CrossRef]

- Čater, T.; Čater, B.; Černe, M.; Koman, M.; Redek, T. Industry 4.0 technologies usage: Motives and enablers. J. Manuf. Technol. Manag. 2021, 32, 323–345. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S. A study on the factors influencing smart factory technology acceptance. J. Korean Stat. Soc. 2020, 27, 75–95. [Google Scholar]

- Lee, Y.; Park, C. Study on the policy direction for the acceptance and promotion of smart factories by small and medium businesses in Korea. Small Medium Bus. Res. 2020, 42, 251–283. [Google Scholar]

- Lee, Y.; Park, C.; Seo, Y. A study on the determinants of smart factory acceptance by small and medium enterprises. Bus. Manag. Res. 2020, 27, 157–182. [Google Scholar]

- Chung, S.; Park, H. The factors influencing small and medium businesses’ intention to accept smart factory advancement. J. Digit. Converg. 2021, 19, 199–211. [Google Scholar]

- Gil, H. Empirical Study on the Analysis of Smart Factory Acceptance Factors and Performance: Focusing on TOE and IS Success Models. Ph.D. Thesis, Hansung University, Seoul, Republic of Korea, 2019. [Google Scholar]

- Park, H. An Empirical Study on the Factors Affecting the Introduction of Smart Factories by SMEs: Focusing on the Effect of Controlling Innovation Characteristics. Ph.D. Thesis, Incheon National University, Incheon, Republic of Korea, 2021. [Google Scholar]

- Lee, J.; Kim, J. An empirical study on the degree of use of smart factories by small and medium-sized domestic metal processing companies. Humanit. Soc. 21 2020, 11, 269–284. [Google Scholar]

- Lee, C. Study on the Introduction of Smart Manufacturing According to Corporate Assets and Activities. Master’s Thesis, Kyungpook National University, Daegu, Republic of Korea, 2021. [Google Scholar]

- Han, S. The Effect of Managerial Competence and Organizational Characteristics of Companies Introducing Smart Factories on Management Performance: Mediating Effect of Product Innovation Performance and Moderating Effect of R&D Competency. Master’s Thesis, Hansung University, Seoul, Republic of Korea, 2021. [Google Scholar]

- Kim, Y. A Study on Factors Influencing the Continued Use of Smart Factories among Small and Medium Manufacturing Companies: Focusing on the Late Acceptance Model (PAM). Ph.D. Thesis, Hansung University, Seoul, Republic of Korea, 2021. [Google Scholar]

- Kim, J. A Study on the Effects of Smart Factory Service Quality on Acceptance Intention and Acceptance Behavior. Master’s Thesis, Kyung Hee University, Seoul, Republic of Korea, 2020. [Google Scholar]

- Kim, J.; Yu, G. The influence of the perceived quality of smart factory on the intention to advance. Res. Internet e-Commer. 2020, 20, 39–54. [Google Scholar]

- Kim, H. Empirical study on the continued use and conversion to smart factories. J. Korea Soc. Ind. Inf. 2019, 24, 65–80. [Google Scholar]

- Park, C.; Seo, Y. Study on the relationship between smart factory-related technology and innovation resistance and technology acceptance intention. Manag. Educ. Res. 2020, 35, 167–197. [Google Scholar]

- Seo, Y.; Park, C. Study on the intention of reactive supply chain companies using smart factory-related technologies: Focusing on the expanded UTAUT model. J. Korean SCM 2020, 20, 27–47. [Google Scholar]

- Lee, Y. A Study on the Determinants of Smart Factory Acceptance Using the Extended Integrated Technology Model. Ph.D. Thesis, Geumo Technical University, Gumi, Republic of Korea, 2021. [Google Scholar]

- Kim, J.H.; Cho, J.; Lee, S. Analysis of factors influencing smart factory distribution on SME management. J. Korean Soc. Ind. Manag. Syst. 2019, 42, 76–83. [Google Scholar] [CrossRef]

- Park, J. Analysis of Relationship between the Intention to Establish Smart Factories and the Actual Implementation of Smart Factories: Focusing on the Moderating Effect of Government Subsidies and Corporate Contributions. Master’s Thesis, Busan National University, Busan, Republic of Korea, 2019. [Google Scholar]

- Choi, T. An Empirical Study on the Factors of Introduction and Acceptance of Smart Factories: Focusing on Shipbuilding Equipment Companies. Master’s Thesis, Busan National University, Busan, Republic of Korea, 2020. [Google Scholar]

- Hong, S. A Study on the Effect of Target Level and Managing Changes on the Intent to Continuously Use Smart Factories during the Introduction and Operation Stage of Smart Factories. Ph.D. Thesis, Hoseo University, Asan, Republic of Korea, 2021. [Google Scholar]

- Oh, J.; Kim, J. Study on strategic utilization of smart factory: Impact of the purpose and contents of construction on continuous utilization. Small Medium Bus. Res. 2019, 41, 1–36. [Google Scholar]

- Lee, R. An analysis of the structural relationship between management performance and continuous use intention of smart factory operation strategy. J. Korean Facil. Manag. Soc. 2020, 25, 59–72. [Google Scholar]

- Song, W. A Study on the Impact of Corporate Core Competencies on Corporate Performance: Focusing on the Mediating Effect of Smart Factories and the Perception of the Fourth Industrial Revolution. Ph.D. Thesis, Yeungnam University, Gyeongsan, Republic of Korea, 2021. [Google Scholar]

- Park, H.; Cho, I. The effect of small and medium manufacturing companies’ recognition of organizational support on the innovation behavior of organizational members. Glob. Manag. J. 2021, 18, 119–139. [Google Scholar]

- Park, C.; Kim, C. Impact of improving agility capacity for smart manufacturing and implementation of smart SCM in relation to the fourth industrial revolution on corporate and supply chain performance. Entrep. Ventur. Res. 2019, 22, 23–67. [Google Scholar]

- Park, H.; Cho, I. The effect of small and medium business executives and employees’ efforts to Smartify manufacturing on corporate performance from the perspective of BSC. Glob. Manag. J. 2020, 17, 103–121. [Google Scholar]

- Yeo, W. Interpretation of the Relationship between ICT Environment and Management Performance: Focusing on the Mediating Effect of Organizational Participation. Ph.D. Thesis, Mokwon University, Daejeon, Republic of Korea, 2019. [Google Scholar]

- Jung, B.A. Study on the Effect of the Introduction of Smart Factories on Corporate Performance and Job Satisfaction: Focusing on the Introduction of Smart Factories by Korean Companies. Master’s Thesis, Kyunghee University, Seoul, Republic of Korea, 2017. [Google Scholar]

- Jin, S.; Seo, Y. A study on the effect of technological innovation by environmental factors of companies on smart factory construction: Absorption capacity as a controlling variable. J. Korea Contents Assoc. 2019, 19, 407–420. [Google Scholar]

- Shadish, W.R.; Haddock, C.K. Combining estimates of effect size. In The Handbook of Research Synthesis; Cooper, H., Hedges, L.V., Eds.; Russell Publishing Sage Foundation: New York, NY, USA, 1994; pp. 261–281. [Google Scholar]

- Borenstein, M.; Hedges, L.V.; Higgins, J.P.T.; Rothstein, H.R. Introduction to Meta-Analysis; John Wiley & Sons: Chichester, UK, 2009. [Google Scholar]

- Peterson, R.A.; Brown, S.P. On the use of beta coefficients in meta-analysis. J. Appl. Psychol. 2005, 90, 175–181. [Google Scholar] [CrossRef]

- Hedges, L.V.; Olkins, I. Statistical Methods for Meta-Analysis; Academic Press: San Diego, CA, USA, 1985. [Google Scholar]

- Cohen, J. Statistical Power Analysis for the Behavioral Science, 2nd ed.; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1988. [Google Scholar]

- Rosenthal, R. The file drawer problem and tolerance for null results. Psychol. Bull. 1979, 86, 638–641. [Google Scholar] [CrossRef]

- Hunter, J.E.; Schmidt, F.L. Methods of Meta-Analysis: Correcting Error and Bias in Research Findings; Sage Publications: Newbury Park, CA, USA, 1990. [Google Scholar]

- Cooper, H. Research Synthesis and Meta-Analysis: A Step-by-Step Approach; SAGE Publication: Thousand Oaks, CA, USA, 2010. [Google Scholar]

- Hsu, M.W. An analysis of intention to use in innovative product development model through TAM model. Euras. J. Math. Sci. Technol. Educ. 2016, 12, 487–501. [Google Scholar] [CrossRef]

- Ullah, N.; Mugahed Al-rahmi, W.M.; Alkhalifah, A. Predictors for distributed ledger technology adoption: Integrating three traditional adoption theories for manufacturing and service operations. Prod. Manuf. Res. 2021, 9, 178–205. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Ching, N.T. Adoption of digital technologies of smart manufacturing in SMEs. J. Ind. Inf. Integr. 2019, 16, 100107. [Google Scholar] [CrossRef]

- Lin, D.P.; Lee, C.K.M.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Zhou, J.L.; Lan, S.L.; Liu, Y.; Rong, T.D.; Huisingh, D. Research on the relations between cognition and intelligent transformation of executive teams in small and medium-sized manufacturing enterprises. Adv. Eng. Inform. 2022, 52, 101539. [Google Scholar] [CrossRef]

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key resource for Industry 4.0 adoption and its effect on sustainable production and circular economy: An empirical study. J. Clean. Prod. 2021, 281, 125233. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R.; Vrontis, D.; Papadopoulos, T. Examining the impact of deep learning technology capability on manufacturing firms: Moderating roles of technology turbulence and top management support. Ann. Oper. Res. 2022, 1–21. [Google Scholar] [CrossRef]

- Dixit, A.; Jakhar, S.K.; Kumar, P. Does lean and sustainable manufacturing lead to industry 4.0 adoption: The mediating role of ambidextrous innovation capabilities. Technol. Forecast. Soc. Change 2022, 175, 121328. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Wuest, T.; Akarte, M. Factors Affecting Industry 4.0 Adoption: A hybrid SEM-ANN Approach. Comput. Ind. Eng. 2022, 168, 108062. [Google Scholar] [CrossRef]

- Sarbu, M. The impact of industry 4.0 on innovation performance: Insights from German manufacturing and service firms. Technovation 2022, 113, 102415. [Google Scholar] [CrossRef]

- Ghaithan, A.; Khan, M.; Mohammed, A.; Hadidi, L. Impact of Industry 4.0 and lean manufacturing on the sustainability performance of plastic and petrochemical organizations in Saudi Arabia. Sustainability 2021, 13, 11252. [Google Scholar] [CrossRef]

- Hankyung News. Available online: https://www.hankyung.com/news/article/2017030170261 (accessed on 4 July 2022).

- Cozzoni, E.; Passavanti, C.; Ponsiglione, C.; Primario, S.; Rippa, P. Interorganizational Collaboration in Innovation Networks: An Agent Based Model for Responsible Research and Innovation in Additive Manufacturing. Sustainability 2021, 13, 7460. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).