Study on the Pseudo-Slope Length Effect of Buried Pipe Extraction in Fully Mechanized Caving Area on Gas Migration Law in Goaf

Abstract

:1. Introduction

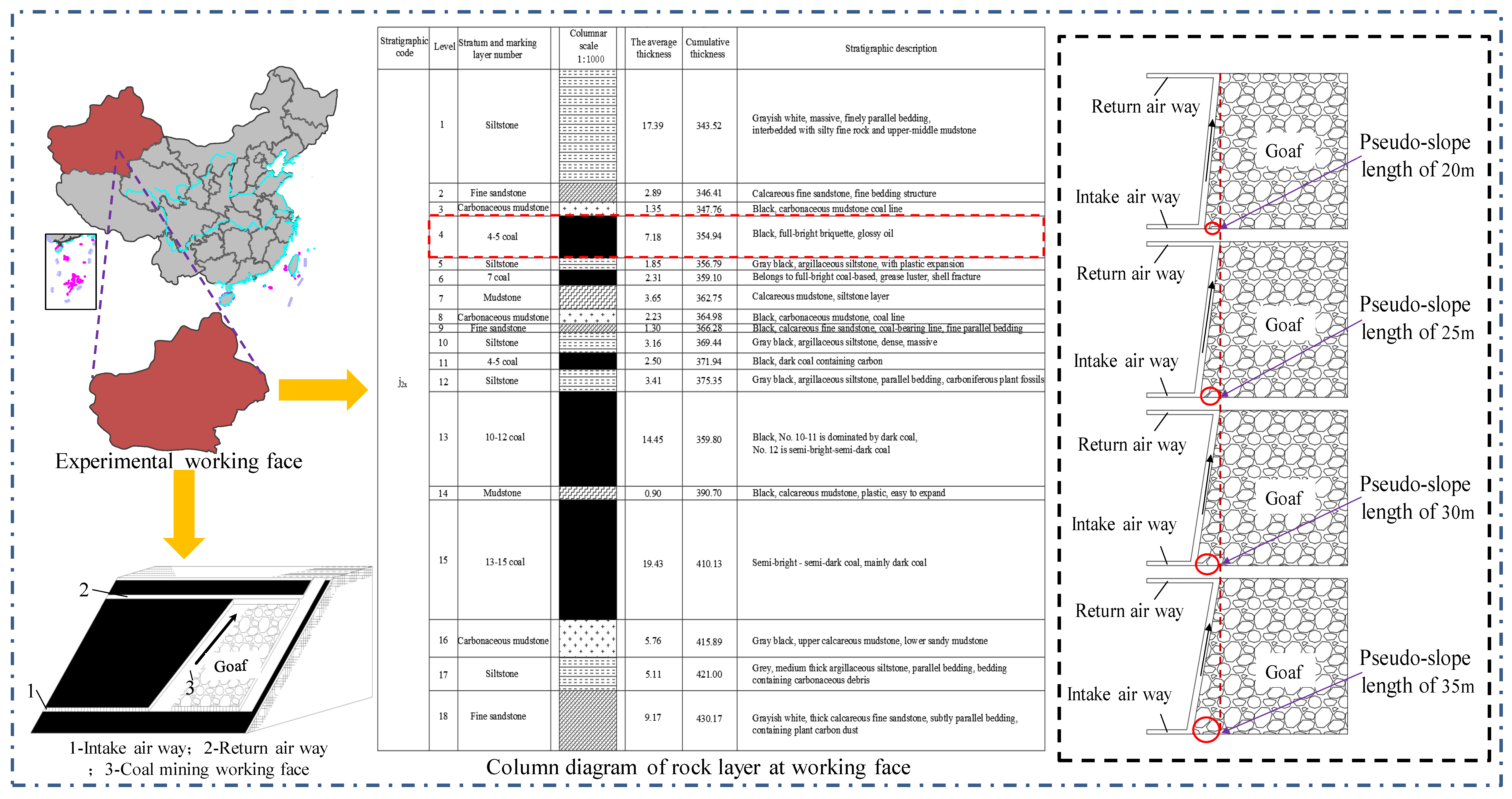

2. Experimental Design

2.1. Overview of the Experimental Working Area

2.2. Model Building

2.2.1. Geometric Modeling

2.2.2. Boundary Conditions and Parameter Setting

- (1)

- Flow model selection

- (2)

- Source item settings

- (3)

- (4)

- Porosity setting of mining area module

- (5)

- Parameters of the inlet and return air lanes

2.3. Monitoring Point Layout Program

3. Gas Concentration Distribution Pattern under Different PSLS

3.1. Variation in the Working Area’s Gas Spewing Location while Using Various PSLs

3.2. Gas Concentration Distribution in the Upper Corner at Various PSLs

4. The Effect of the Coupling Mechanism of the BPDs of the Extraction Port and PSLs on the Gas Concentration Distribution in the Working Area

4.1. Influence of BPDs and PSLs on the Gas Concentration Distribution in the Extraction Zone

4.2. Influence of the Combined Effect of BPDs and PSLs on the Distribution Pattern of Gas Concentration in the Upper Corner

5. Engineering Practices

6. Conclusions

- (1)

- The influence law of PSLs on the wind flow in the mine area was obtained by Fluent simulation. With the increased PSL, the air leakage area gradually changed from the upper corner to the middle of the working area and the upper corner. The abnormal gas concentration area shifted to the inlet side. In contrast the gas concentration in the upper corner gradually decreased. The numerical simulation results showed that the optimal PSL was 25 m when there was no extraction measure.

- (2)

- When PSLs and BPD work together, the gas concentration in the corner of the working area can be effectively reduced. When the extraction opening was buried shallowly, the negative pressure formed by extraction would form a low gas concentration zone with air leakage. With the increase in BPD, the effect of BPD on the control of gas concentration in the upper corner gradually decreased. The results show that when PSL was 25 m and BPD was 20 m, it had the best effect on the gas control in the upper corner.

- (3)

- The change of PSLs and the depth of the extraction port significantly affected the gas concentration distribution on the working area. When the PSLs exceeded 25 m, the measured gas concentration in the field caused a gas anomaly at the 122# frame, and when the PSLs increased to 35 m, the measured gas concentration in the area caused a gas anomaly at the 108# frame. Therefore, the PSLs should be, at most, 25 m. Combined with the numerical simulation results, the gas concentration in the upper corner gradually decreased with the increase in the PSL. Therefore, the best PSL should be 25 m. When the gas concentration in the upper corner was low, no abnormal gas zone appeared in the working area. Based on the numerical simulation results, the maximum gas concentration in the upper corner was 0.46%, with the extraction port of BPD-20 m arranged in the return air tunnel. The numerical simulation was consistent with the engineering practice results. The gas concentration at the working area was effectively controlled by adjusting the PSLs and BPDs to realize the efficient production of the inclined coal seam extended release working area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, L. Scientific problem and countermeasure for precision mining of coal and associated resources. J. China Coal Soc. 2019, 44, 1–9. [Google Scholar]

- Yuan, L. Concept of gas control and simultaneous extraction of coal and gas. J. China Coal 2010, 36, 5–12. [Google Scholar]

- Qian, M.; Xu, J.; Wang, J. Further on the sustainable mining of coal. J. China Coal Soc. 2018, 43, 1–13. [Google Scholar]

- Qin, B.; Shi, Z.; Hao, J.; Ye, D.; Liang, B.; Sun, W. Analysis of the Space-Time Synergy of Coal and Gas Co-mining. ACS Omega 2022, 7, 13737–13749. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; From, F. Coal-gas compound dynamic disasters in China: A review. Process Saf. Environ. Prot. 2020, 133, 1–17. [Google Scholar] [CrossRef]

- Jia, L.; Peng, S.; Xu, J.; Yan, F.; Chen, J.; Wu, B.; Chen, Y. On the evolution mechanism of permeability during gas drainage: Insights from deformation field, gas pressure field and temperature field. Process Saf. Environ. Prot. 2022, 162, 825–836. [Google Scholar] [CrossRef]

- Tang, M.; Jiang, B.; Zhang, R.; Yin, Z.; Dai, G. Numerical analysis on the influence of gas extraction on air leakage in the gob. J. Nat. Gas Sci. Eng. 2016, 33, 278–286. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, T.; Cheng, Y. Numerical investigations of methane flow characteristics on a longwall face Part II: Parametric studies. J. Nat. Gas Sci. Eng. 2017, 43, 254–267. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Li, X. Simulation of the hazard arising from the coupling of gas explosions and spontaneously combustible coal due to the gas drainage of a gob. Process Saf. Environ. Prot. 2018, 118, 296–306. [Google Scholar] [CrossRef]

- Cheng, J.; Li, S.; Zhang, F.; Zhao, C.; Yang, S.; Ghosh, A. CFD modelling of ventilation optimization for improving mine safety in longwall working faces. J. Loss Prevent. Proc. 2016, 40, 285–297. [Google Scholar] [CrossRef] [Green Version]

- Shao, H.; Chen, K.; Zhao, H.; Li, M. Comparison Study of “U + L” and “Y + L” Working Face Ventilation Patterns on Gas Control in a Highly Gassy Mine. Teh. Vjesn. 2015, 22, 443–452. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Zhou, B.; Wang, C. Investigation on coal spontaneous combustion in the gob of Y type ventialtion caving face: A case study. Process Saf. Environ. Prot. 2021, 148, 590–603. [Google Scholar] [CrossRef]

- Li, H.; Liu, Z.; Yang, Y.; Zhu, D.; Yang, H.; Wang, W. Study on the evolution law of the gas flow field based on the distribution characteristics of voids in the overlying strata in a goaf. Arab. J. Geosci. 2021, 14, 1–8. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, S. Prediction of coal mine goaf self-heating with fluid dynamics in porous media. Fire Saf. J. 2017, 87, 49–56. [Google Scholar] [CrossRef]

- Wang, G.; Xu, H.; Wu, M.; Wang, Y.; Wang, R.; Zhang, X. Porosity model and air leakage flow field simulation of goaf based on DEM-CFD. Arab. J. Geosci. 2018, 11, 148. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, T.; Zhang, J. Numerical investigations of airflow patterns on a longwall face. Int. J. Oil Gas Coal Technol. 2020, 24, 321–344. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, Y.; Wei, L. Gas monitoring data anomaly identification based on spatio-temporal correlativity analysis. J. Coal Sci. Eng. 2013, 19, 8–13. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, S.; Qin, Y.; Hu, X.; Cheng, J. Experimental study on the goaf flow field of the “U+I” type ventilation system for a comprehensive mechanized mining face. Int. J. Min. Sci. Technol. 2015, 25, 1003–1010. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, G.; Wang, B. Study and Application of High-Level Directional Extraction Borehole Based on Mining Fracture Evolution Law of Overburden Strata. Sustainability 2023, 15, 2806. [Google Scholar] [CrossRef]

- Brigida, V.S.; Golik, V.I.; Dzeranov, B.V. Modeling of Coalmine Methane Flows to Estimate the Spacing of Primary Roof Breaks. Mining 2022, 2, 45. [Google Scholar] [CrossRef]

- Dzhioeva, A.K.; Brigida, V.S. Spatial non-linearity of methane release dynamics in underground boreholes for sustainable mining. J. Min. Inst. 2020, 245, 522–530. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, W.; Bian, Y.; Yang, M.; Luo, H. Influences of Gas Drainage Pipe Positions on Spontaneous Coal Combustion in the Gob: A Case Study of Baode Coal Mine in China. Combust. Sci. Technol. 2021, 194, 3357–3373. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, M.; Luo, H. Parameter Optimization and Application of Gas Extraction Technology by Buried Pipes in Goaf of Multi-roadway U-type Working Face. Combust. Sci. Technol. 2022, 1–18. [Google Scholar] [CrossRef]

- Li, Z.; Wang, F.; Ren, S.; Liu, G.; Xiong, H. Gas Distribution Mechanism in Goaf during Combined Drainage of Upper Corner Buried Pipeline and Intubation for Thick Coal Seams. Lithosphere 2021, 2021, 8308256. [Google Scholar] [CrossRef]

- Chen, X.; Dong, X.; Wang, L.; Huang, Z.; Cui, P. Gas Emergence Characteristics of the Upper Corner on the 215101 Mining Working Face of the Yue Nan Coal Mine. ACS Omega 2022, 7, 25663–25674. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, S.; Wang, X.; Chang, L.; Cui, G.; Zhou, F. Gas flow analysis for the impact of gob gas ventholes on coalbed methane drainage from a longwall gob. J. Nat. Gas Sci. Eng. 2017, 36, 1312–1325. [Google Scholar] [CrossRef]

- Chai, J. Study on Gas Control in Goaf of High Gas Coal Seam: A Case Study of Tingnan Coal Mine, China. Geofluids 2022, 2022, 5262173. [Google Scholar] [CrossRef]

- Ding, X.; Zhai, C.; Xu, J.; Yu, X.; Sun, Y. Study on Coal Seepage Characteristics and Secondary Enhanced Gas Extraction Technology under Dual Stress Disturbance. Sustainability 2022, 14, 15118. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Fan, X. Current situation and development trend of theories and technologies for coal and CBM co-mining in China. Nat. Gas Ind. 2022, 42, 130–145. [Google Scholar]

- Tutak, M. The Influence of the Permeability of the Fractures Zone Around the Heading on the Concentration and Distribution of Methane. Sustainability 2020, 12, 16. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Gao, J.; Yang, M.; Wang, D.; Wang, L. Numerical Simulation of Parameters Optimization for Goaf Gas Boreholes. Adv. Civ. Eng. 2019, 2019, 3891080. [Google Scholar] [CrossRef]

- Wang, S.; Wang, D.; Cao, K.; Wang, S. Distribution law of 3D fracture field of goaf and overlying strata. J. Cent. South Univ. Sci. Technol. 2014, 45, 833–839. [Google Scholar]

- Liu, Z. Analysis of the effect of buried pipe extraction at the integrated working face of sharply inclined extra-thick coal seam. Coal Sci. Technol. 2017, 45, 74–76. [Google Scholar]

| Lithology | Coal Seam |

|---|---|

| Hard (40~80 MPa, quartz sandstone, limestone, conglomerate) | |

| Medium-hard (20~40 MPa, sandstone, muddy tuff, shale) | |

| Soft (10~20 MPa, mudstone, muddy shale) |

| Remaining Coal Seam | Inbreak Zone | Fractured Zone | ||||

|---|---|---|---|---|---|---|

| Natural Accumulation Area | Influence Area of Coal Wall on the Return Wind Side | Compaction Stabilization Zone | Inlet Side Coal Wall Influence Area | |||

| P0(%) | 0.2 | 0.4 | 0.25 | 0.13 | 0.22 | 0.2 |

| PSL 20 m | PSL 25 m | PSL 30 m | PSL 35 m | |||||

|---|---|---|---|---|---|---|---|---|

| Gas Concentration Anomaly Zone (m) | Maximum Gas Concentration (%) | Gas Concentration Accumulation Area (m) | Maximum Gas Concentration (%) | Gas Concentration Anomaly Zone (m) | Maximum gas Concentration (%) | Gas Concentration Anomaly Zone (m) | Maximum Gas Concentration (%) | |

| Upper Level | 84.9~159.7 | 1.76% | 156.4~160.6 | 0.98% | 64.1~161.1 | 3.05% | 23.6~163.1 | 4.90% |

| Middle Level | - | - | 160.1~161.1 | 0.81% | 65.3~73.6 | 1.46% | 29.9~126.6 | 3.28% |

| 149.4~160.1 | 1.58% | 155.4~163.1 | 2.57% | |||||

| Lower level | - | - | - | - | - | - | 35.2~102.3 | 2.19% |

| 160.2~161.7 | 1.88% | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; An, X.; Li, S.; Kang, X.; Huang, Y.; Yang, J.; Jin, S. Study on the Pseudo-Slope Length Effect of Buried Pipe Extraction in Fully Mechanized Caving Area on Gas Migration Law in Goaf. Sustainability 2023, 15, 6628. https://doi.org/10.3390/su15086628

Zhao P, An X, Li S, Kang X, Huang Y, Yang J, Jin S. Study on the Pseudo-Slope Length Effect of Buried Pipe Extraction in Fully Mechanized Caving Area on Gas Migration Law in Goaf. Sustainability. 2023; 15(8):6628. https://doi.org/10.3390/su15086628

Chicago/Turabian StyleZhao, Pengxiang, Xingbao An, Shugang Li, Xinpeng Kang, Yitong Huang, Junsheng Yang, and Shikui Jin. 2023. "Study on the Pseudo-Slope Length Effect of Buried Pipe Extraction in Fully Mechanized Caving Area on Gas Migration Law in Goaf" Sustainability 15, no. 8: 6628. https://doi.org/10.3390/su15086628

APA StyleZhao, P., An, X., Li, S., Kang, X., Huang, Y., Yang, J., & Jin, S. (2023). Study on the Pseudo-Slope Length Effect of Buried Pipe Extraction in Fully Mechanized Caving Area on Gas Migration Law in Goaf. Sustainability, 15(8), 6628. https://doi.org/10.3390/su15086628