The Effect of Green Supply Chain Management Practices on the Sustainability Performance of Turkish Shipyards

Abstract

:1. Introduction

2. Literature Review

3. Methodology

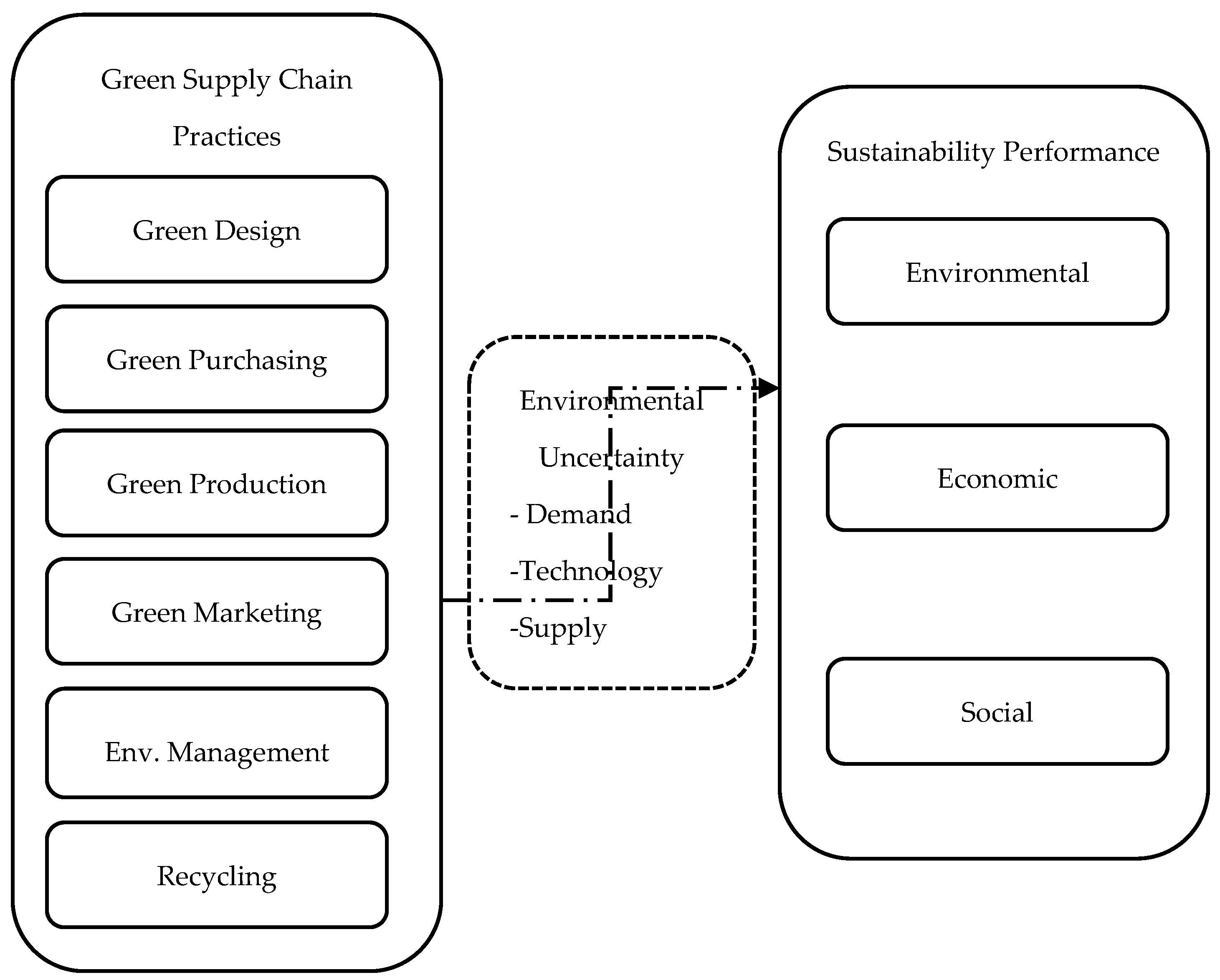

3.1. Research Model Construct

3.2. Survey Design and Application

3.3. Sample Size Constraint

4. Results

4.1. Demographic Statistics

4.2. Reliability and Validity

4.3. Structural Model Assessment

4.4. Common Method Bias

5. Discussion

6. Conclusions

7. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Survey Design

| Category | ID | Question | References |

| Green Design | S1 | We use more environmentally friendly materials and systems in the design phase than before | Çankaya [36], Dizaji [31], Lee, et al. [39] |

| S2 | We design systems/products that will consume less energy than before | Çankaya [36], Dizaji [31], Lee, et al. [39] | |

| S3 | We design systems/products to generate less waste than before | Çankaya [36], Dizaji [31], Lee, et al. [39], Green, et al. [40] | |

| Green Purchasing | S4 | The technical specifications for the inputs demanded from suppliers contain the request for environmental protection. | Çankaya [36] |

| S5 | We also use environmental criteria in evaluating suppliers | Authors | |

| S6 | We cooperate with suppliers for goals related to protecting the natural environment. | Green et al. [40] | |

| Green Production | S7 | We minimize wastage, waste, and noise pollution in the production process. | Çankaya [36], Islam, et al. [56] |

| S8 | The use of products and production processes harmful to nature and human health is reduced or abandoned. | Çankaya [36], Islam, et al. [56] | |

| S9 | We pay attention to using recyclable raw materials in our production activities. | Dizaji [31], the authors | |

| Green Marketing | S10 | There are also environmental criteria in the technical specifications of our products. | Authors |

| S11 | Customer demands positively affect our company’s green policy | Bedük [42] | |

| S12 | In our promotional activities, the environmental aspects of our products are highlighted. | Çankaya [36] | |

| Environmental Management | S13 | An effective environmental management system has been established in our company. | Çankaya [36] |

| S14 | An environmental performance index is created on recycling, reducing harmful emissions, and saving energy. | Çankaya [36], Karabulut [57] | |

| S15 | Regular environmental training is organized for the personnel within the company. | Çankaya [36], Green, et al. [40] | |

| Recycling | S16 | Scrap and used materials/tools are sold and evaluated | Çankaya [36] |

| S17 | A recycling system has been established for used and defective products | Eltayeb et al. [41] | |

| S18 | We pay attention to the recycling of the materials to be used | Dizaji [31] | |

| Demand uncertainty | S19 | Demand for our products is often very volatile | Çankaya [36] |

| S20 | Customers want different features for each new product | Zhao et al. [38], Authors | |

| Technology uncertainty | S21 | We can foresee the development of green technology | Zhao et al. [38], Authors |

| S22 | We can anticipate new product/service offerings from competitors | Çankaya [36], Authors | |

| Supply uncertainty | S23 | The performance of our suppliers is difficult to predict. | Çankaya [36] |

| S24 | Suppliers offer products/services of desired quality and delivery time. | Zhao et al. [38], Authors | |

| Environmental Performance | S25 | Hazardous and harmful material consumption is reduced | Çankaya [36], Kalpande and Toke [43] |

| S26 | Pollution (wastewater and solid waste disposal, noise emission) decreased | Çankaya [36] | |

| S27 | Environmental accidents have decreased | Kalpande and Toke [43], Authors | |

| Economic Performance | S28 | Revenue and profitability increased | Çankaya [36], Kalpande and Toke [43], Authors |

| S29 | Energy consumption costs decreased | Çankaya [36] | |

| S30 | Waste disposal and treatment costs reduced | Kalpande and Toke [43], Authors | |

| Social Performance | S31 | Work accidents and work-related diseases have decreased | Authors |

| S32 | There has been an increase in the welfare of all stakeholders (employees, partners, customers, suppliers) | Çankaya [36], Authors | |

| S33 | Investments in social and environmental projects have increased | Çankaya [36], Caniëls, et al. [58] |

Appendix B. Survey

| Prof. Dr. Hatice CAMGÖZ AKDAĞ | Mehmet TANTAN |

| Faculty of Business Administration, Istanbul Technical University Department of Management Engineering Head of the department | Department of Management Engineering Istanbul Technical University Ph.D. Student, Graduate School of Education tantan18@itu.edu.tr |

| DEMOGRAPHIC QUESTIONS General Information about the company 1-Name of the company: ________________________________________________ 2-Please indicate the average number of employees (permanent/subcontractor) in your company: ____________/_______________ 3-Please indicate the year of establishment of your company: _______________ 4-Please specify the main ship types that the company produces: ____________ 5-Please select the quality and environmental certificates the company has: [ ] ISO 9001 [ ] ISO 14001 [ ] ISO 45001 6-Does the company have a department responsible for environmental activities? [ ] Yes [ ] No 7-If yes, please indicate which department is responsible for environmental activities and how many people work in this department. Name of the Department ________________ Number of Employees ________________ 8-Please indicate the region (district/province) where your company is located _____________ 9-Please indicate the department you work at __________________ |

| GREEN SUPPLY CHAIN APPLICATIONS | |||||

| Green Design | 1 | 2 | 3 | 4 | 5 |

| 1. We use more environmentally friendly materials and systems in the design phase than before | |||||

| 2. We design systems/products that will consume less energy than before | |||||

| 3. We design systems/products to generate less waste than before | |||||

| Green Purchasing | 1 | 2 | 3 | 4 | 5 |

| 1. The technical specifications for the inputs demanded from suppliers contain the request for the environmental protection | |||||

| 2. We also use environmental criteria in evaluating suppliers | |||||

| 3. We cooperate with suppliers for goals related to protecting the natural environment. | |||||

| Green Production | 1 | 2 | 3 | 4 | 5 |

| 1. We take action to minimize waste, waste, and noise pollution during production. | |||||

| 2. The use of products and production processes harmful to nature and human health is reduced or abandoned. | |||||

| 3. We pay attention to using recyclable raw materials in our production activities. | |||||

| Green Marketing | 1 | 2 | 3 | 4 | 5 |

| 1. Environmental criteria are also in the technical specifications of the products we produce. | |||||

| 2. Customer demands positively affect our company’s green policy. | |||||

| 3. In our promotional activities, the environmental aspects of our products are highlighted. | |||||

| Environmental Management | 1 | 2 | 3 | 4 | 5 |

| 1. An effective environmental management system has been established in our company. | |||||

| 2. An environmental performance index is created on recycling, reduction of harmful emissions, and energy saving. | |||||

| 3. Regular environmental training is organized for the personnel within the company. | |||||

| Recycling | 1 | 2 | 3 | 4 | 5 |

| 1. Scrap and used materials/tools are sold and evaluated. | |||||

| 2. A recycling system has been established for used and defective products | |||||

| 3. We pay attention to the recycling of the materials to be used | |||||

| ENVIRONMENTAL UNCERTAINTY | |||||

| Demand Uncertainty | 1 | 2 | 3 | 4 | 5 |

| 1. Demand for our products is often very volatile | |||||

| 2. Customers want different features for each new product | |||||

| Technological Uncertainty | 1 | 2 | 3 | 4 | 5 |

| 1. We can foresee the development of green technology. | |||||

| 2. We can anticipate new product/service offerings from competitors | |||||

| Supply Uncertainty | 1 | 2 | 3 | 4 | 5 |

| 1. The performance of our suppliers is difficult to predict. | |||||

| 2. Suppliers offer products/services of desired quality and delivery time. | |||||

| SUSTAINABILITY PERFORMANCE | |||||

| Environmental Performance | 1 | 2 | 3 | 4 | 5 |

| 1. Hazardous and harmful material consumption is reduced. | |||||

| 2. Pollution (wastewater and solid waste disposal, noise emission) decreased | |||||

| 3. Environmental accidents have decreased | |||||

| Economic Performance | 1 | 2 | 3 | 4 | 5 |

| 1. Revenue and profitability increased. | |||||

| 2. Energy consumption costs decreased | |||||

| 3. Waste disposal and treatment costs reduced | |||||

| Social Performance | 1 | 2 | 3 | 4 | 5 |

| 1. Work accidents and work-related diseases have decreased | |||||

| 2. There has been an increase in the welfare of all stakeholders (employees, partners, customers, suppliers) | |||||

| 3. Investments in social and environmental projects have increased | |||||

References

- Musmarra, D.; Zafeirakou, A.; Manakou, V.; Emmanouil, C. Efficient and sustainable environmental management as a means of addressing current pollution issues. Environ. Sci. Pollut. Res. Int. 2019, 26, 14703–14705. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Yuen, K.F.; Wong, Y.D.; Li, K.X. How can the maritime industry meet Sustainable Development Goals? An analysis of sustainability reports from the social entrepreneurship perspective. Transp. Res. Part D Transport Environ. 2020, 78, 102173. [Google Scholar] [CrossRef]

- Zapelloni, G.; Garcia Rellan, A.; Bello Bugallo, P.M. Sustainable production of marine equipment in a circular economy: Deepening in material and energy flows, best available techniques and toxicological impacts. Sci. Total Environ. 2019, 687, 991–1010. [Google Scholar] [CrossRef] [PubMed]

- Strandhagen, J.W.; Buer, S.-V.; Semini, M.; Alfnes, E.; Strandhagen, J.O. Sustainability challenges and how Industry 4.0 technologies can address them: A case study of a shipbuilding supply chain. Prod. Plan. Control 2020, 33, 995–1010. [Google Scholar] [CrossRef]

- Özler, M. Research on the Sustainability Conditions of Turnover of Shipbuilding Industry in Turkey. Master’s Thesis, Beykent University, Istanbul, Turkey, 2010. [Google Scholar]

- Almajali, D.A. Diagnosing the effect of green supply chain management on firm performance: An experiment study among Jordan industrial estates companies. Uncertain Supply Chain Manag. 2021, 9, 897–904. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Abu Seman, N.A. Green Supply Chain Management: A Review and Research Direction. Int. J. Manag. Value Supply Chains 2012, 3, 1–18. [Google Scholar] [CrossRef]

- Samekto, A.A.; Kristiyanti, M. Green Supply Chains and Sustainable Maritime Transportation in Covid-19 Pandemic. Int. J. Mech. Eng. 2022, 7, 1512–1517. [Google Scholar]

- Noordin, N.; Salleh, Z. Green Shipbuilding Technology for Boustead Naval Shipyard Sdn Bhd Towards Sustainable Shipbuilding Development. Adv. Struct. Mater. 2022, 166, 99–110. [Google Scholar] [CrossRef]

- Hossain, K.A.; Zakaria, N.M.G. A Study on Global Shipbuilding Growth, Trend and Future Forecast. Procedia Eng. 2017, 194, 247–253. [Google Scholar] [CrossRef]

- Lister, J.; Poulsen, R.T.; Ponte, S. Orchestrating transnational environmental governance in maritime shipping. Glob. Environ. Chang. 2015, 34, 185–195. [Google Scholar] [CrossRef] [Green Version]

- Buyukozkan, G.; Karabulut, Y. Sustainability performance evaluation: Literature review and future directions. J. Environ. Manag. 2018, 217, 253–267. [Google Scholar] [CrossRef] [PubMed]

- MacNeil, J.L.; Adams, M.; Walker, T.R. Evaluating the Efficacy of Sustainability Initiatives in the Canadian Port Sector. Sustainability 2022, 14, 373. [Google Scholar] [CrossRef]

- Vakili, S.; Ölçer, A.I.; Schönborn, A.; Ballini, F.; Hoang, A.T. Energy-related clean and green framework for shipbuilding community towards zero-emissions: A strategic analysis from concept to case study. Int. J. Energy Res. 2022, 46, 20624–20649. [Google Scholar] [CrossRef]

- Klymenko, O.; Lillebrygfjeld Halse, L. Sustainability practices during COVID-19: An institutional perspective. Int. J. Logist. Manag. 2021, 33, 1315–1335. [Google Scholar] [CrossRef]

- Ashari, R.; Soesilo, T.E.B.; Herdiansyah, H. Strategy for Shipyard Industrial Waste Management in Controlling Water and Air Pollution in Ship Repair. In Proceedings of the 1st Journal of Environmental Science and Sustainable Development Symposium, JESSD, Jakarta, Indonesia, 28–30 September 2020; pp. 1–10. [Google Scholar]

- Bono, G. Sustainability Report 2020; Fincanteri: Trieste, Italy, 2020. [Google Scholar]

- Letian, R. Sustainability Report; Yangzijiang Shipbuilding Holdings: Taizhou, China, 2019. [Google Scholar]

- Roppestad, R.T. 2020/2021 | Sustainability Report; Gard: Arendal, Norway, 2021. [Google Scholar]

- Pinto, L. Green supply chain practices and company performance in Portuguese manufacturing sector. Bus. Strateg. Environ. 2020, 29, 1832–1849. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Cruz Machado, V. The influence of green practices on supply chain performance: A case study approach. Transp. Res.Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Felício, J.A.; Rodrigues, R.; Caldeirinha, V. Green Shipping Effect on Sustainable Economy and Environmental Performance. Sustainability 2021, 13, 4256. [Google Scholar] [CrossRef]

- Küçükoğlu, M.T. Investigating Turkish Companies from Sustainability and Green Innovation Perspective. Ph.D. Thesis, Istanbul University, Istanbul, Turkey, 2014. [Google Scholar]

- Dilşad Güzel, O.D. An Investigation on the Relationship Among Supply Chain Integration, Green Supply Chain Implementations and Business Performance. Sos. Bilim. Enst. Derg. 2016, 6, 362–394. [Google Scholar]

- Praharsi, Y.; Jami’In, M.A.; Suhardjito, G.; Wee, H.M. Modeling of an industrial ecosystem at traditional shipyards in indonesia for the sustainability of the material supply chain. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management, IEEM 2020, Singapore, 14–17 December 2020; pp. 1–4. [Google Scholar]

- Rupa, R.A.; Saif, A.N.M. Impact of Green Supply Chain Management (GSCM) on Business Performance and Environmental Sustainability: Case of a Developing Country. Bus. Perspect. Res. 2021, 10, 140–163. [Google Scholar] [CrossRef]

- Vakili, S.; Schönborn, A.; Ölçer, A.I. Techno-economic feasibility of photovoltaic, wind and hybrid electrification systems for stand-alone and grid-connected shipyard electrification in Italy. J. Clean. Prod. 2022, 366, 132945. [Google Scholar] [CrossRef]

- Dizaji, B.S. Green Marketing Strategies in Manufacturing Operations, a Model Suggestion on Relationship with PERFORMANCe. Ph.D. Thesis, Ataturk University, Erzurum, Turkey, 2017. [Google Scholar]

- Derya Öztürk, E.O. Effect of Green Supply Chain Practices on Business Performance: A Case Study of Food-Packaging Sector in Region Tr83. In Proceedings of the Sosyal, Beşeri ve İdari Bİlimlerde Akademik Çalışmalar, Cetinje, Montenegro, September 2018. [Google Scholar]

- Günday, A.H. The Impact of Green Supply Chain Applications on Business Performance: An Empirical Analysis in the Chemical Sector. Ph.D. Thesis, Selçuk University, Konya, Turkey, 2018. [Google Scholar]

- Yildiz Çankaya, S.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Davoodi, s.m.r.; Sazegari, S. Identifying and Ranking the Barriers to Sustainable Supply Chain Management, Using a Hybrid Fuzzy ANP-DEMATEL Approach: A Case of shipyard in Bushehr. Iran. J. Trade Stud. 2021, 25, 105–130. [Google Scholar] [CrossRef]

- Çankaya, S.Y. Supply Chain Management from a Sustainability Perspective and Green Applications. Ph.D. Thesis, Gebze Technical University, Gebze, Turkey, 2015. [Google Scholar]

- Santos Álvarez, M.d.V.; García Merino, M.T. Environmental uncertainty: The side object of perception. Innovar 2008, 18, 65–74. [Google Scholar]

- Zhao, Y.; Feng, T.; Shi, H. External involvement and green product innovation: The moderating role of environmental uncertainty. Bus. Strateg. Environ. 2018, 27, 1167–1180. [Google Scholar] [CrossRef]

- Lee, S.J.; Woo, J.H.; Shin, J.G. New business opportunity: Green field project with new technology. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 471–483. [Google Scholar] [CrossRef] [Green Version]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- Bedük, S. An Exploratory Study of the Differences Between the Green Supply Chain Practices of Goods vs. Service Retailers. Ph.D. Thesis, Maltepe University, Istanbul, Turkey, 2017. [Google Scholar]

- Kalpande, S.D.; Toke, L.K. Assessment of green supply chain management practices, performance, pressure and barriers amongst Indian manufacturer to achieve sustainable development. Int. J. Prod. Perform. Manag. 2020, 70, 2237–2257. [Google Scholar] [CrossRef]

- Latif, K.F. Reflective-Reflective Higher Order Construct/Second Order Analysis and Reporting in SmartPLS. 2021. Available online: https://youtu.be/iDMXqqf-E2I (accessed on 16 April 2021).

- Hair, J.F., Jr.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Sarstedt, M.; Cheah, J.-H. Partial least squares structural equation modeling using SmartPLS: A software review. J. Mark. Anal. 2019, 7, 196–202. [Google Scholar] [CrossRef]

- Joseph, F.; Hair, J.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; SAGE: Los Angeles, CA, USA, 2017. [Google Scholar]

- Rigdon, E.E. Choosing PLS path modeling as analytical method in European management research: A realist perspective. Eur. Manag. J. 2016, 34, 598–605. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis. Curr. Dir. Psychol. Sci. 1992, 1, 98–101. [Google Scholar] [CrossRef]

- Ecorys Research and Consulting. Study on Competitiveness of the European Shipbuilding Industry. Rotterdam 2009. Available online: https://ec.europa.eu/docsroom/documents/10506/attachments/1/translations/en/renditions/native (accessed on 16 October 2022).

- Latif, K.F.; Pérez, A.; Sahibzada, U.F. Corporate social responsibility (CSR) and customer loyalty in the hotel industry: A cross-country study. Int. J. Hosp. Manag. 2020, 89, 102565. [Google Scholar] [CrossRef]

- Kock, N. Common method bias in PLS-SEM: A full collinearity assessment approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Younis, H.; Sundarakani, B.; Vel, P. The impact of implementing green supply chain management practices on corporate performance. Compet. Rev. 2016, 26, 216–245. [Google Scholar] [CrossRef]

- Rahman, A.; Ho, J.; Rusli, K.A. Pressures, green supply chain management practices and performance of ISO 14001 certified manufacturers in Malaysia. Int. J. Econ. Manag. 2014, 8, 1–24. [Google Scholar]

- Yildiz Çankaya, S.; Sezen, B. Moderator effect of environmental uncertainty on the relationship between ecologic innovation and sustainability performance. Int. J. Manag. Econ. Bus. 2015, 11, 111–134. [Google Scholar] [CrossRef]

- Islam, S.; Karia, N.; Fauzi, F.B.A.; Soliman, M. A review on green supply chain aspects and practices. Manag. Mark. 2017, 12, 12–36. [Google Scholar] [CrossRef] [Green Version]

- Karabulut, E. İşletmelerde Çevre Bilinci ve Yeşil Yönetim Uygulamalarının Işletme Başarısına Katkısını Incelemeye Yönelik bir Araştırma. Ph.D. Thesis, Istanbul University, Istanbul, Turkey, 2003. [Google Scholar]

- Caniëls, M.C.J.; Cleophas, E.; Semeijn, J. Implementing green supply chain practices: An empirical investigation in the shipbuilding industry. Marit. Policy Manag. 2016, 43, 1005–1020. [Google Scholar] [CrossRef] [Green Version]

| GSCM Practices | Description |

|---|---|

| Green design | Design of products for reduced consumption of materials/energy, intend to reduce products’ adverse effects on the environment during its entire life cycle, Design of products for reuse, recycling, recovery of materials, parts, Design the products to be easily set up for the users in the most energy-saving ways, Design for reduction of environmentally hazardous substances, Design for recycling waste, and Design for remanufacturing aimed at returning it to a better condition. |

| Green purchasing | Choice of suppliers by considering the environmental criteria, buying environment-friendly raw materials, Pressuring supplier(s) to take environmental actions |

| Green production | Generate minimum waste and reduce environmental pollution, Re-manufacturing and lean production, Cleaner Production, Improved capacity utilization, Lower raw material costs, gain production efficiency, improve their corporate image, increase the number of goods delivered on time, do not use hazardous or restricted materials during manufacturing and minimize waste during production, Substituting toxic inputs with environmentally friendly ones. |

| Customer environmental collaboration | Collaborate with customers to develop environmental management solutions, collaborate with customers to manage, and reverse flows of materials and packaging. |

| Internal green management Environmental management | Environmental compliance monitoring and Auditing, Total quality environment management, Pollution prevention plans, Environmental manager, and employee training. Employee incentive programs for environmental suggestions |

| Reverse logistics Recycling | Recovery of the company’s end-of-life Items, Resale or reuse of used parts or components, Old/obsolete items being used or replaced, Recondition and refurbishing of used parts or components |

| Certificate | Quantity | Percentage |

|---|---|---|

| ISO 9001 | 2 | 5% |

| ISO 14001 & ISO 9001 | 13 | 30% |

| ISO 45001 & ISO 14001 & ISO 9001 | 28 | 65% |

| Indicators | LOC | Nomination | HOC |

|---|---|---|---|

| GrDESIGN | Green Design | GSCM | Green Supply Chain Management |

| GrPURCH | Green Purchasing | ||

| GrPROD | Green Production | ||

| GrMAR | Green Marketing | ||

| GrENVR | Environmental Management | ||

| GrRCYC | Recycling | ||

| UNDEMAND | Demand Uncertainty | ENVR-UNCER | Environmental Uncertainty |

| UNTEC | Technology Uncertainty | ||

| UNSUPPLY | Supply Uncertainty |

| Indicators | Outer Loadings > 0.708 | VIF < 5.000 | ||

|---|---|---|---|---|

| 1st cal. | 2nd cal. | 1st cal. | 2nd cal. | |

| Gr-DESIGN | 0.768 | 0.768 | 1.806 | 1.806 |

| Gr-ENVR | 0.690 | 0.687 | 1.761 | 1.761 |

| Gr-MAR | 0.833 | 0.834 | 2.458 | 2.458 |

| Gr-PROD | 0.827 | 0.828 | 2.099 | 2.099 |

| Gr-PURCH | 0.775 | 0.775 | 2.352 | 2.352 |

| Gr-RCYC | 0.823 | 0.822 | 2.624 | 2.624 |

| UN-DEMAND | 0.047 | extracted | 1.033 | extracted |

| UN-SUPPLY | 0.645 | 0.658 | 1.047 | 1.016 |

| UN-TEC | 0.833 | 0.829 | 1.017 | 1.016 |

| Cronbach’s Alpha > 0.600 | Composite Reliability > 0.700 | |||

|---|---|---|---|---|

| 1st cal. | 2nd cal. | 1st cal. | 2nd cal. | |

| ENVR-UNCER | 0.286 | 0.220 | 0.552 | 0.715 |

| GSCM | 0.878 | 0.878 | 0.907 | 0.907 |

| ECO-PER | 0.871 | 0.871 | 0.921 | 0.921 |

| ENVR-PER | 0.812 | 0.812 | 0.887 | 0.887 |

| SOC-PER | 0.599 | 0.599 | 0.778 | 0.778 |

| ECO-PER | ENVR-PER | ENVR-UNCER | GSCM | SOC-PER | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| FL | HTMT | FL | HTMT | FL | HTMT | FL | HTMT | FL | HTMT | |

| ECO-PER | 0.887 | |||||||||

| ENVR-PER | 0.122 | 0.139 | 0.851 | |||||||

| ENVR-UNCER | 0.132 | 0.375 | 0.310 | 0.924 | 0.914 | |||||

| GSCM | 0.367 | 0.371 | 0.388 | 0.327 | 0.636 | 1.389 | 0.715 | |||

| SOC-PER | 0.295 | 0.556 | 0.201 | 0.498 | 0.517 | 1.620 | 0.603 | 0.806 | 0.881 | |

| Indicators | ECO-PER | ENVR-PER | ENVR-UNCER | GSCM | SOC-PER |

|---|---|---|---|---|---|

| EcP1 | 0.895 | 0.107 | 0.212 | 0.360 | 0.285 |

| EcP2 | 0.934 | 0.111 | 0.010 | 0.293 | 0.303 |

| EcP3 | 0.844 | 0.147 | −0.005 | 0.208 | 0.168 |

| EnP1 | 0.052 | 0.742 | 0.233 | 0.123 | 0.032 |

| EnP2 | 0.188 | 0.952 | 0.477 | 0.297 | 0.193 |

| EnP3 | 0.051 | 0.847 | 0.282 | 0.285 | 0.242 |

| Gr-DESIGN | 0.285 | 0.179 | 0.602 | 0.767 | 0.486 |

| Gr-ENVR | 0.351 | 0.206 | 0.254 | 0.684 | 0.323 |

| Gr-MAR | 0.253 | 0:331 | 0.577 | 0.833 | 0.524 |

| Gr-PROD | 0.283 | 0.371 | 0.601 | 0.828 | 0.597 |

| Gr-PURCH | 0.249 | 0.134 | 0.461 | 0.777 | 0.455 |

| Gr-RCYC | 0.135 | 0.077 | 0.427 | 0.823 | 0.515 |

| SoP2 | 0.380 | 0.199 | 0.521 | 0.475 | 0.859 |

| SoP3 | 0.153 | 0.150 | 0.570 | 0.620 | 0.904 |

| UN-SUPPLY | −0.020 | 0.310 | 0.677 | 0.408 | 0.405 |

| UN-TEC | 0.129 | 0.317 | 0.814 | 0.544 | 0.516 |

| Hypothesis | β | t Statistics | p Values | Result |

|---|---|---|---|---|

| H1: GSCM -> ENVR-PER | 0.049 | 0.209 | 0.835 | Insignificant |

| H2: GSCM -> ECO-PER | 0.459 | 2.299 | 0.022 | Significant |

| H3: GSCM -> SOC-PER | 0.409 | 2.479 | 0.013 | Significant |

| H4a: ENVR-UNCER -> GSCM & ENVR-PER | 0.120 | 0.851 | 0.395 | Insignificant |

| H4b: ENVR-UNCER -> GSCM & ECO-PER | −0.092 | 0.503 | 0.615 | Insignificant |

| H4c: ENVR-UNCER -> GSCM & SOC-PER | −0.049 | 0.408 | 0.683 | Insignificant |

| RAND | |

|---|---|

| ECO-PER | 0.892 |

| ENVR-PER | 0.134 |

| ENVR-UNCER | 0.108 |

| GSCM | 0.329 |

| RAND | |

| SOC-PER | 0.344 |

| Authors | Research Subject | Sector | Result |

|---|---|---|---|

| Existing study | Six GSCM practices’ (green production, green marketing, green purchasing, green design, recycling) effects on three sustainability performances (environmental, social, economic) | Turkish shipyards | GSCM significantly affect social and economic but not environmental performance |

| Yildiz Çankaya and Sezen [34] | Seven GSCM practices’ (green purchasing, green manufacturing, green packaging and distribution, green marketing, investment recovery, internal environmental management, and environmental education) effects on three sustainability performances (environmental, social, economic) | Automotive, electronics, and chemical sectors | 5 of 7 GSCM practices effects positively environmental, 3 of 7 GSCM practices effects positively economic, 4 of 7 GSCM practices effects positively social performance |

| Dizaji [31] | Four green marketing strategies’ (green marketing mix, green supply chain, green innovation, green brand) effects on the food industry’s performance | Food sector | Except for green brands, all three of marketing strategies positively affect food sector performance |

| Green et al. [40] | Six GSCM practices’ (internal environmental management, green information system, green purchasing, cooperation with customers, eco-design, and investment recovery) effects on the environmental, operational, and organizational performance | Manufacturing managers | Green purchasing significantly affects economic performance but not environmental performance. Cooperation with customers affects environmental but not economic performance. Investment recovery affects environmental performance but not economic performance. |

| Eltayeb et al. [42] | Green Supply Chain Initiatives’ (Eco-Design, Green Purchasing, Reverse Logistics) effects on the environmental, economic, cost reduction, and intangible outcomes | Malaysian certified companies | Only eco-design significantly affects environmental, economic outcomes and intangible outcomes. Eco-design and reverse logistic effects positively cost reduction outcome. |

| Younis et al. [53] | Four GSCM practices’ (eco-design, green purchasing, environmental cooperation, and reverse logistics) effects on the four dimensions of corporate performance (operational performance, environmental performance, economic performance, and social performance) | all ISO 14001-certified and non-certified manufacturing firms in the UAE | None of the four GSCM practices were found to have any impact on the environmental performance, green purchasing, and environmental cooperation effects significantly on the operational performance. Only green purchasing effects significantly economic performance, and only reverse logistics practice effects significantly social performance. |

| Rahman et al. [54] | GSCM Practices’ (green purchasing, investment recovery, eco-design, reverse logistics, cooperation with the customer, and internal environmental practices) effect on environmental and firm performance | EMS ISO 14001-certified manufacturing firms registered as members of the Federation of Malaysian Manufacturers | GSCM practices significantly affect firm performance but are not significant for environmental performance. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tantan, M.; Akdağ, H.C. The Effect of Green Supply Chain Management Practices on the Sustainability Performance of Turkish Shipyards. Sustainability 2023, 15, 6677. https://doi.org/10.3390/su15086677

Tantan M, Akdağ HC. The Effect of Green Supply Chain Management Practices on the Sustainability Performance of Turkish Shipyards. Sustainability. 2023; 15(8):6677. https://doi.org/10.3390/su15086677

Chicago/Turabian StyleTantan, Mehmet, and Hatice Camgöz Akdağ. 2023. "The Effect of Green Supply Chain Management Practices on the Sustainability Performance of Turkish Shipyards" Sustainability 15, no. 8: 6677. https://doi.org/10.3390/su15086677

APA StyleTantan, M., & Akdağ, H. C. (2023). The Effect of Green Supply Chain Management Practices on the Sustainability Performance of Turkish Shipyards. Sustainability, 15(8), 6677. https://doi.org/10.3390/su15086677