Abstract

Fuel cells have drawn a lot of interest in recent years as one of the most promising alternative green power sources in microgrid systems. The operating conditions and the integrated components greatly impact the quality of the fuel cell’s voltage. Energy management techniques are required in this regard to regulate the fuel cell’s power in a microgrid. The active/reactive power in the microgrid should be adjusted in line with US Energy Star’s regulations whereas the grid current needs to follow the standard set by IEEE 519 2014 to enhance the power quality of the electrical energy injected into the microgrid. Uncontrolled energy injection from the fuel cell can have serious impacts including superfluous energy demand, overloading, and power losses, especially in high power and medium voltage systems. Although fuel cells have many advantages, they cannot yet produce high voltages individually to compensate for the demand of a microgrid system. Due to these reasons, the fuel cell must be interfaced with a DC-DC converter. This research proposes a novel high voltage gain converter integrated 1.26 kW fuel cell for microgrid power management that can boost the fuel cell’s voltage up to 20 times. Due to this high voltage gain, the voltage and current ripple of the fuel cell is also reduced substantially. According to the analysis, the proposed converter demonstrated optimal performance when compared to the other converters due to its high voltage gain and extremely low voltage ripple. As a result, the harmonic profile of the microgrid current persists with a reduced THD of 3.22% and a very low voltage ripple of 4 V. To validate the converter’s performance, along with extensive simulation, a hardware prototype was also built. The voltage of the fuel cell is regulated using a simplified proportional integral controller. The operating principle of the converter integrated fuel cell along with its application in microgrid power management is demonstrated. A comparative analysis is also shown to verify how the proposed converter is improving the system’s performance when compared against other converters.

1. Introduction

Due to their high fuel conversion efficiency, high reliability, zero carbon emissions, and low temperature operation, fuel cells, particularly proton exchange membrane fuel cells (PEMFCs, are increasingly being acknowledged as a preferred means of generating energy for distributed electrical power generation units [1]. Fuel cells are becoming more popular as a direct energy conversion technology, especially in microgrid [2]. The significance of hydrogen energy and PEMFCs in microgrid is gradually growing as a result of the increased global energy demand [3]. Hydrogen energy from PEMFCs offers a significant means to manage and balance power flows, as opposed to other renewable energy sources like solar and wind, which have intermittency issues, power balancing issues, and high maintenance costs [4]. In recent years, an increasing number of PEMFCs are getting connected to various electrical networks, with microgrid applications being one of the most rapid advancements [5]. The primary objective of PEMFCs is to provide support for the microgrid to compensate the power requirements of the electrical loads.

In order to provide a steady supply of power to the microgrid, PEMFCs are usually interfaced with electrical loads [6]. This integration improves the performance and safety of the microgrid while also reducing the impact of load variations. However, in PEMFCs, it is necessary to amplify the DC voltage and power to a certain level where it can effectively compensate the power management of the microgrid. This is generally because a conventional PEMFC can only produce 24 V to 32 V, which is not enough for the microgrid’s power management [7]. Some advanced PEMFCs are available in the market that can produce up to 54 V, however, they are very expensive and more applicable in high-power industries [8]. Therefore, various power electronic interface devices are connected to the PEMFC in order to make it applicable for microgrid applications. Two such power electronic devices that are frequently being interfaced with the PEMFC are the DC-DC converter and the DC-AC inverter. The DC-AC inverter is primarily used to convert the DC voltage from the PEMFC to AC voltage and inject it to the microgrid. It should be noted that the inverter can also amplify the voltage level produced by the PEMFCs through utilizing step-up transformers or multilevel inverters [9]. Both of these alternatives are expensive and have control intricacies [10], qualities that are not aligned with the objective of this article. The most simplified way of boosting the PEMFCs voltage is to use a boost DC-DC converter [11]. Nevertheless, conventional boost DC-DC converters cannot amplify the voltage to the level required by the microgrid. For instance, the output voltage of 1.26 kW PEMFCs can be boosted from 24 V to 50 V using a conventional boost converter under normal circumstances, which is not enough for the power compensation of the microgrid. Higher voltage gain can be achieved by changing the duty cycle; however, it can cause massive switching stress and power losses [12]. Moreover, at low voltage gain, the boost converter also struggles to generate ripple-free DC voltages. The proper operation and reliability of the PEMFC integrated into the microgrid can be negatively impacted by these limitations. Advanced high voltage gain DC-DC converters thus offer the best solution for these issues [13].

In general, DC-DC converters can be classified into two categories: isolated converters and non-isolated converters [14]. Although both of these converter families have distinctive features and advantages, non-isolated converters offer more characteristic superiorities over isolated converters. In terms of voltage operation, these converters can be further classified into step down (buck), step up (boost, and step down/up (buck-boost) converters [15]. In recent studies, several converter-integrated PEMFC models have been investigated to address the issues presented by conventional converters. In one study [16], a DC-DC converter is proposed for PEMFC and electric vehicles (EV) application that has the ability to switch between buck and boost mode. Although buck mode can be a valuable option to have for EV applications where voltage step down is required, in microgrid it does not have usage. Due to the buck/boost configuration, the converter’s voltage gain is very limited, and it cannot be applied for microgrid power compensation [17]. A multiphase interleaved converter is proposed in [18] for PEMFC application. Although the voltage gain is improved compared to the converter from [16], it requires a high number of power components since it can only function as a multiphase unit. Moreover, the voltage gain is still not enough to be implemented for microgrid power compensation. Huangfu et al. proposed a floating interleaved boost converter (FIBC) in [19] for PEMFC application. The unique structure of this converter allowed it to reduce the voltage ripple of the PEMFC substantially. The voltage amplification ratio of this converter is almost three times that of the input voltage, which is better than both converters proposed in [16,18]. An auxiliary circuit-based boost converter was developed by Wang et al. in [20] for PEMFC and EV application. This converter has a higher voltage gain than all the previously mentioned converters. The converter can function in both continuous conduction mode (CCM) and discontinuous conduction mode (DCM), giving it higher flexibility in terms of operation. Two novel DC-DC converters with an identical voltage gain of four are proposed in [21,22]. The later converter’s voltage gain can be boosted by increasing the transformer turn ratio. However, the converter is very expensive because of transformer use. A high step-up DC-DC converter integrated with quadratic boost-cuk is proposed in [23] for EV applications. Although the converter can boost the voltage required by the microgrid, the duty cycle ratio needs to be increased to 0.7, which can cause high switching losses. A transformer-less simplified boost converter is proposed in [24] for EV applications. However, the voltage gain of the converter is only four times that of the input voltage, which is not enough for the active/reactive power compensation. A boost converter with a high voltage gain of 10 times is proposed in [25], which can be used for power management of the microgrid. However, the converter has a very high number of power electronic components, making it expensive to build. A single inductor, single switch converter is proposed in [26], having a voltage gain of six times the input voltage. The converter reduced the voltage stress on the switch and capacitors. The converter’s voltage gain can be increased by increasing the duty cycle; however, it will increase the switching stress significantly. An improved version of the quadratic converter in [23] is proposed in [27] based on voltage lift technique. This converter utilizes a high number of components. In [28], an improved dual switch non-isolated high gain boost converter is presented for DC microgrid application, and although it has a voltage gain of 10.5%, it has the disadvantage of having a significantly higher component count of 16.

It is clear from the literature review that current configurations of the DC-DC converters present in the literature are not capable of compensating and managing active/reactive power in fuel cell integrated microgrid systems. Although a limited number of DC-DC converters such as the ones presented in [22,23,25] can boost the fuel cell voltage required by the microgrid power compensation, they all have various deficiencies that may hinder their usefulness in real-time applications. These characteristic limitations will be further discussed in a later section. Therefore, the current research gaps in terms of DC-DC converter configuration necessitates a new converter topology that can boost the fuel cell voltage to the level required for microgrid’s power management. Considering this research gap, this article proposes an interleaved DC-DC converter that uses a voltage doubler circuit that can significantly boost the PEMFC’s voltage. The major contributions of the paper can be outlined as follows:

- Proposed a novel configuration of high gain interleaved DC-DC converter consisting of a voltage doubler circuit that can boost the output voltage of the fuel cell to almost 20 times in nominal circumstances.

- The proposed converter can achieve high voltage gain without using any transformer and can operate with a small duty cycle ratio, ensuring reduced switching losses and voltage/current ripple. Moreover, it persists with a maximum switching voltage stress of almost 50% of the output voltage and a maximum the diode voltage stress of nearly 25% of the output voltage.

- Integration of the proposed converter with PEMFC allowed the microgrid to reduce the current harmonics (THD) to 3.22% along with minimal voltage ripple of 4V. Furthermore, integration properly managed the power requirements of the electrical loads, ensuring an improvement of the system’s power factor.

- The mathematical model and the results of the system are extensively analyzed, compared, and verified using proper simulation and hardware results.

2. High Gain Interleaved DC-DC Converter

This section elaborates on the circuit configuration and the operating principle of the proposed interleaved DC-DC converter. The mathematical model along with the different modes of operation are discussed in this section to demonstrate how the converter unit is obtaining high voltage gain.

2.1. Circuit Configuration

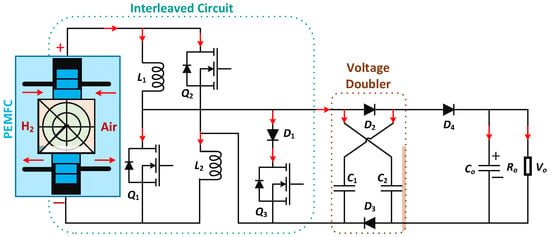

The proposed DC-DC converter is developed utilizing three semiconductor switches which are depicted as Q1, Q2, and Q3, and four semiconductor diodes symbolized as D1, D2, D3, and D4. It also consists of five energy storing elements that includes two interleaved inductors, L1 and L2, two crisscrossed capacitors, C1 and C2, and one output capacitor, Co. The schematic diagram of the proposed converter integrated with a PEMFC is shown in Figure 1.

Figure 1.

Circuit configuration of high gain interleaved DC-DC converter integrated to PEMFC.

The converter is primarily designed by combining an interleaved circuit and a voltage doubler circuit, as illustrated in Figure 1. The interleaved circuit is the main driving agent of the proposed converter, which consists of the three semiconductor switches (Q1–Q3), two inductors (L1 and L2), and one diode, D1. The primary function of the interleaved circuit is to provide high voltage gain with reduced switching stress. Because of its unique circuit arrangement, it makes the current switching stress equal to the PEMFC current and reduces current ripples substantially [29]. Moreover, it also splits the PEMFC current into two paths and therefore reduces the core losses of the inductors.

The voltage doubler circuit consists of two diodes (D2 and D3) and two capacitors (C1 and C2). It is one of the most simplified and effective ways of increasing the voltage gain of DC-DC converters. Generally, voltage double can be implemented in two ways. Firstly, it can be implemented at the initial part of a converter to reduce the stress on the switches. This type of voltage doubler circuit is not required in this configuration as the interleaved circuit already reduces the switching stress effectively. Secondly, the voltage doubler can be implemented at the end of circuit to effectively increase the voltage gain of the DC-DC converter [30]. The proposed converter has adopted the latter type of voltage doubler circuit. These circuits have gained popularity because they can be used on a variety of DC-DC converters. Additionally, since large capacitors are not required for high frequency operation, the implemented circuits do not make the converter design bulky or expensive. A small inductor can also be used in this circuit to obtain zero current switching (ZCS). Nevertheless, this option is not considered for the proposed design since it will not add any advantages to the converter [31].

2.2. Circuit Operation

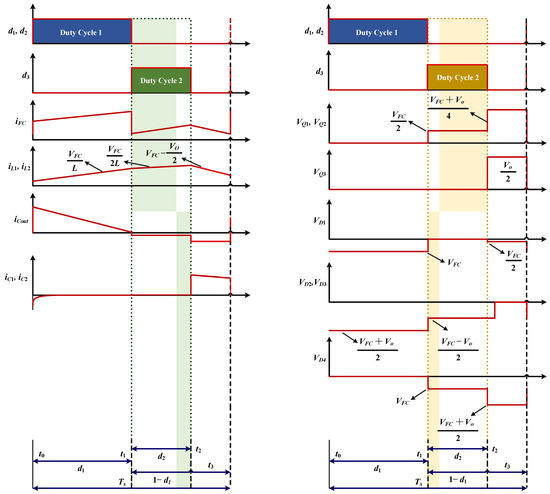

This section demonstrates the operating principle in the steady state response and the mathematical models of the proposed converter. Before developing the mathematical model, some assumptions were considered such as: the semiconductor and energy storing components are all ideal. This means that forward voltage drops of the diodes, equivalent and on series resistance of the inductors, and capacitors are not considered. The steady state operation of the converter is analyzed while it operates in continuous conduction mode (CCM) as shown in Figure 2. During CCM, the converter operates in three modes of operation over a complete cycle.

Figure 2.

Steady state analysis of the proposed DC-DC converter in CCM.

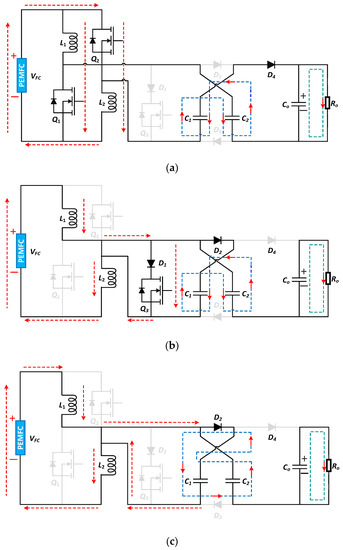

2.2.1. Mode 1

The time interval of this mode is between t0 – t1. This mode is operated with duty cycle d1, where semiconductor switches Q1 and Q2 are turned on and Q3 is turned off. The current path of this mode is illustrated in Figure 3a for clarification. Initially, the PEMFC current (iFC) is supplied to the inductors L1 and L2 while the output capacitor Co supplies the stored energy to the inverter. Here, only diode D4 conducts while all the other diodes do not. It should be noted that in this mode of operation, diode D1 and D4 are reverse biased. On the other hand, the parallel diode of the switch Q3 is forward biased. This indicates that although the switch Q3 is turned off, it has voltage across it. Assuming the inductors have similar turn ratios, it can be concluded that they have identical voltages across them, and it is same as the PEMFC voltage (VFC) since they are parallelly connected to the PEMFC. Therefore, the inductor current and voltages can be determined in this mode as follows:

Furthermore, it can be mathematically understood that:

Figure 3.

Current path of the proposed DC-DC converter in: (a) Mode 1, (b) Mode 2, and (c) Mode 3.

2.2.2. Mode 2

This mode has a time interval between t1–t2. This mode is operated with duty cycle d2, where semiconductor switches Q1 and Q2 are turned off and Q3 is turned on. The current direction of this mode is illustrated in Figure 3b. In this mode, the PEMFC current is supplied to the inductor L1 which further flows through diode D1, switch Q3, and finally toward inductor L2. Because of the interleaved configuration, the deactivated switches Q1 and Q2 endure voltage stress of only half of the PEMFC voltage. Like Mode 1, since the diode D4 is reverse biased, the output capacitor Co delivers energy to the inverter. In contrast to Mode 1, the inductors are connected in series with the PEMFC. Therefore, the inductor current and voltages can be determined in this mode as follows:

2.2.3. Mode 3

This mode has a time interval between t2–t3. This mode is operated with duty cycle (1–d1–d2), where all the semiconductor switches are turned off. The current direction of Mode 3 is illustrated in Figure 3c. Here, the inverter is supplied by the PEMFC and the inductors directly. Moreover, diode D1 is in a reverse-biased state whereas D2 is forward biased and therefore, the output capacitor Co is charged. The switching stress of Q1 and Q2 in this mode is the average between the PEMFC voltage and the output voltage, while for Q3, the switching stress is half of the output voltage. Like Mode 2, the inductors are connected in series. The inductor current and voltages can be determined in this mode as follows:

2.3. Mathematical Modelling

2.3.1. Voltage Gain Calculation

To determine the voltage gain, a state-space averaging method is applied on Equations (3), (7) and (19) and the following equation can be obtained:

Simplifying Equation (11), the voltage gain of the proposed converter can be obtained as follows:

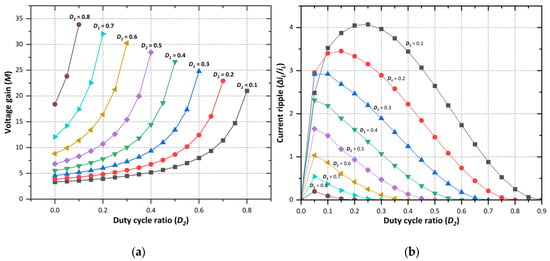

The voltage of the converter at different combinations of duty cycles is illustrated in Figure 4a. It is noticeable that the converter can generate low/high voltage gain depending on the duty cycle combinations of the switches. This ability gives the converter added flexibility in terms of PEMFC applications.

Figure 4.

Different combinations of duty cycle to determine the proposed converter’s: (a) voltage gain, and (b) current ripple.

2.3.2. Current Ripple Calculation

One of the major challenges of integrating a DC-DC converter with PEMFCs is to reduce the current ripple. This will ensure the maximum performance is obtained from the PEMFC. Furthermore, it can also optimize the entire performance of the microgrid. In the proposed converter, the phase is the same between switches Q1 and Q2 as they have same duty cycle. On the contrary, the phase difference between Q1, Q2, and Q3 is around 33° over one complete switching cycle. Due to this, the inductors of the converter charge twice and discharge once in one cycle of operation as depicted in Figure 2. By reducing the duty cycle of switch Q1 and Q2, the charging time of the inductors can be decreased.

Applying the ampere-second balance theory for the current of capacitors (iC1, iC2, iCO), the following expressions can be attained:

Using Equations (12) and (13), the average inductor current can be obtained as follows:

Since the inductor currents increase linearly during Mode 1, it can be stated that:

Here, fsw denotes the switching frequency and represents the ripple current of the proposed converter. Based on Equations (14) and (15), the ripple current ratio of the converter can be calculated as follows:

The current ripple of the converter at different combinations of duty cycles is illustrated in Figure 4b. It is evident that the converter’s duty cycle ratio can also impact the current ripple of the proposed converter.

3. Proton Exchange Membrane Fuel Cell (PEMFC)

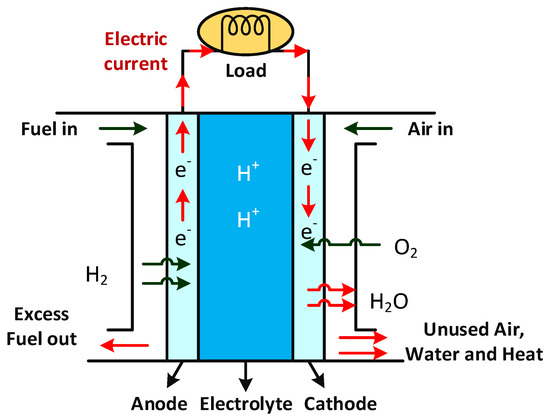

A PEMFC utilizes an electrochemical reaction between an oxidant (air oxygen) and a fuel to generate hydrogen energy. The generated hydrogen travels through the anode to produce an electric current whereas the oxidant continues to flow through the cathode [32]. The reaction results in the release of water and heat. Fuel cells are employed as a quiet and dependable source of electricity because they have no moving parts [33]. Figure 5 [34] provides specifics regarding the PEMFC’s overall configuration and equivalent circuit.

Figure 5.

Schematic diagram of a PEMFC.

The output voltage of the PEMFC can be obtained mathematically as follows:

Here, Voc, Vact, Vconc, and VΩ symbolize open circuit voltage, activation voltage, concentration voltage, and ohmic voltage of the PEMFC unit, respectively. Furthermore, a PEMFC’s current and voltage relationship can be mathematically realized by the following equation [35]:

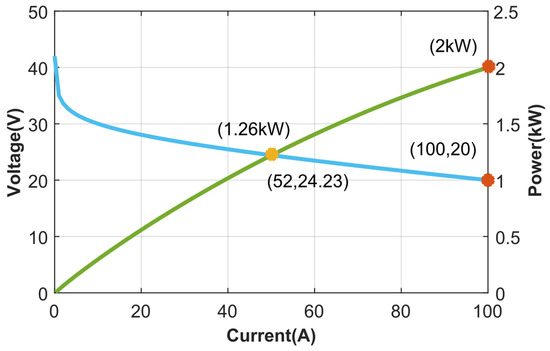

Here, Aact and Ccon represent the activation coefficient and concentration coefficient, respectively, of the PEMFC. On the other hand, Tk represents the Tafael Slope, and IFC, Io, and Ilim symbolize the nominal current, exchange current, and limiting current of the PEMFC unit, respectively. Finally, RFC represents the internal resistance of the PEMFC. The design specifications of the 1.26 kW PEMFC used in this paper is summarized in Table 1. The operating characteristics of the PEMFC unit are shown in Figure 6.

Table 1.

Design Specifications of the 1.26 kW Fuel Cell.

Figure 6.

Characteristic curves of the 1.26 kW PEMFC.

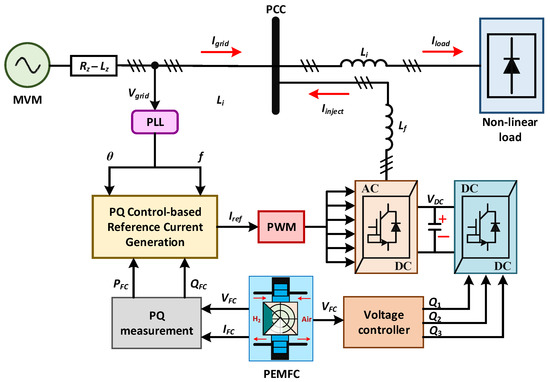

4. PEMFC Integrated Microgrid

The primary objective of this research is to manage the power of the microgrid using the novel interleaved DC-DC converter integrated PEMFC. Therefore, special design consideration is also given to the development of the entire microgrid system. The circuit configuration of the PEMFC integrated microgrid is illustrated in Figure 7. Although controlling the proposed DC-DC converter or the DC-AC inverter is not the focus of the paper, they play a substantial role in ensuring that the system’s performance is optimized. Thus, the controls of both the converter and the inverter are briefly discussed in the following section to demonstrate the working principle of the entire PEMFC integrated microgrid system.

Figure 7.

Circuit diagram of the PEMFC integrated microgrid.

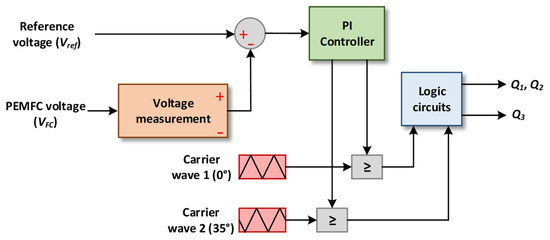

4.1. Control of the Proposed DC-DC Converter

The ripple in the output current has a substantial impact on a PEMFC’s lifespan [36]. The two most common types of ripples that can be observed in the output current of a PEMFC are high frequency and low frequency ripple. High frequency ripples are generated due to the switching operation of the DC-DC converter. Thus, the converter is operated using a triangular PWM, and as a result, high frequency ripples are significantly reduced. Subsequently, the active power injection and filtration is done by the inverter. Since the inverter does not have constant output power, DC bus voltage persists with low frequency voltage ripple. Due to these voltage ripples, low frequency current ripples are generated in the PEMFC’s output if no proper voltage controller is implemented for the converter [13]. Thus, it is necessary to implement an effective voltage control mechanism to reduce the voltage ripple. The voltage control diagram for the proposed converter is depicted in Figure 8. The active power of the PEMFC is determined by the preset voltage reference (Vref). Voltage measurements are utilized for detecting the PEMFC’s output voltage. The reference voltage and the measured voltage are delivered to a subtractor, and then the output response from the subtractor is delivered to a proportional integral (PI) controller. Then this controller’s output is delivered to PWM circuit to compare with two triangular carrier signals respectively. Moreover, a combination of different logic circuits is applied to generate the desired switching pulses. Finally, these switching pulses are used to control the operation of the three switches of the proposed converter module.

Figure 8.

Control diagram for the proposed DC-DC converter.

4.2. Control of the DC-AC Inverter

A DC-AC inverter is also an important interfacing device for the fuel cell integrated microgrid alongside the DC-DC converter. The DC-AC inverter is capable of power conversion from the DC-DC converter as well as active power filtration. While using the fuel cell for the power generation system, the microgrid current (Igrid) needs to be sinusoidal and in-phase with the microgrid voltage (Vgrid) [4]. These two tasks are done by the controller of the DC-AC inverter. In this paper, for phase synchronization, a phase-locked loop (PLL) controller is utilized, while for active power filtration, a conventional PQ-based reference current generation method is utilized. The reference current generated from the PQ controller is then sent to a PWM block to generate the switching pulses for the DC-AC inverter. The implementation of the PLL and the PQ controller is discussed elaborately in [37,38], respectively.

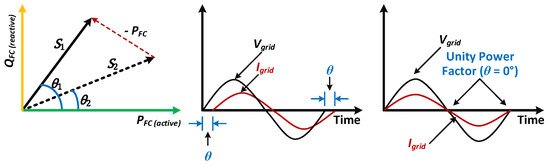

4.3. Active/Reactive Power Management

The operation of traditional active/reactive (PQ) power techniques is dependent on the actual power and the reference power, whereas the calculated power value is utilized to maintain the power flow between the fuel cells and the microgrid. The proposed system compares the actual active power with the active power injected from the fuel cell inside the PQ controller in order to maintain the power flow from the power generation side to the load side. Therefore, the fuel cell must have the ability to support the microgrid in order to support the load side power demand when the grid is unavailable. Generally, it is assumed that during load transients, active power is completely delivered by the microgrid in electrical load and thus, inside the PQ controller, power management is required. However, in a practical scenario when the microgrid needs support, the fuel cell must have the ability to deliver the required power through electrical loads. If not, the voltage and current of the microgrid become out-of-phase resulting in power factor deterioration. Therefore, to resolve these issues, a fuel cell’s injected power needs to be injected alongside the microgrid for power factor correction to improve the system’s performance. Hence, the interfacing devices including the DC-DC converter and the AC-DC inverter of the fuel cell are integrated into the power system to manage the power and ensure an optimal grid-side power factor. The relation between the active power, reactive power, and power factor along with the phase analysis of the microgrid’s voltage/current and how the injected active/reactive power from the fuel cell is helping to keep the power factor unity is shown in the phasor diagram of Figure 9. The system parameters utilized to develop the PEMFC integrated microgrid are summarized in Table 2.

Figure 9.

Phasor diagram of the PEMFC integrated microgrid.

Table 2.

Parameters of the Microgrid.

5. Result and Discussion

The performance of the proposed system is verified in this section utilizing simulation and experimental results. The discussion and analysis of these results are provided below:

5.1. Performance of The Proposed DC-DC Converter

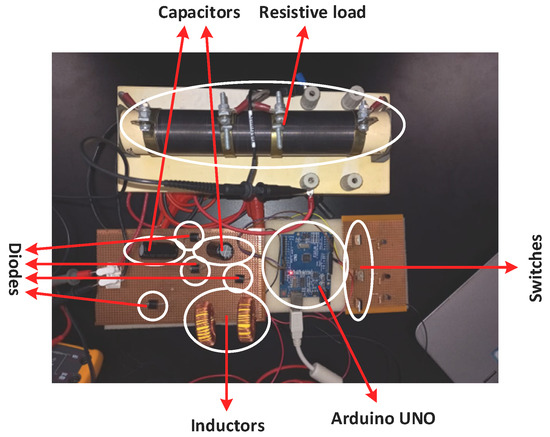

The performance verification of the proposed converter is evaluated by building a hardware prototype as illustrated in Figure 10. Table 3 includes the hardware specifications of the hardware prototype for the proposed converter topology. An Arduino UNO controller is integrated with the proposed converter topology for adequate switching control that includes phase delay, duty ratio, and switching gale pulses.

Figure 10.

Hardware prototype of the proposed interleaved DC-DC converter.

Table 3.

Proposed Converter’s Design Parameters.

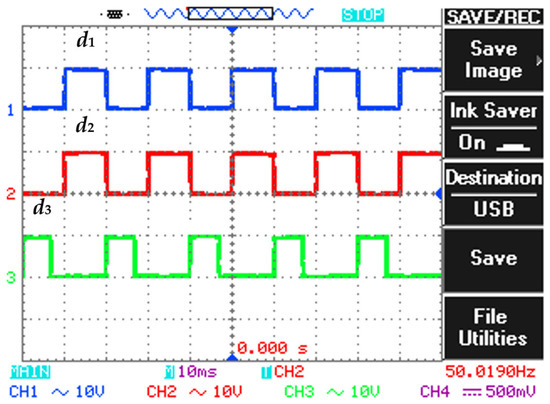

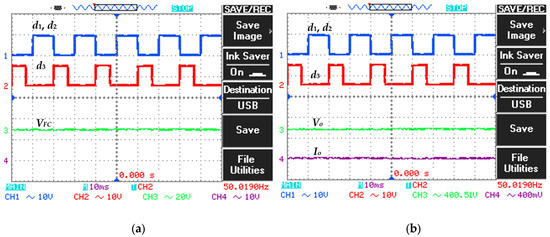

Figure 11 depicts the switching pulse patterns of VGQ1, VGQ2, and VGQ3 that are utilized to control the switches Q1, Q2, and Q3. The first two switches Q1 and Q2 are coupled with the inductors and operated using a switching frequency of 25 kHz with a duty ratio, d1, of 0.5. The third switch Q3 is operated by a duty ratio, d2, of 0.35 with a switching frequency of 25 kHz. The input voltage of the converter topology from the PEMFC (VFC), is shown in Figure 12a. The evaluated output voltage gain for the proposed converter topology is 20 when integrated to a PEMFC voltage of 20 V. Hence, the voltage gain theoretically and experimentally is verified by implementing the hardware prototype for the proposed converter topology. The output voltage/DC-link voltage, VDC, and the output current, IDC, with switching operation are depicted in Figure 12b. Experimental setup has achieved an output voltage of 400.51 V with an average current of 400 mA.

Figure 11.

Switching pulses of the proposed DC-DC converter.

Figure 12.

Voltage and current waveforms of the proposed DC-DC converter: (a) input, and (b) output.

5.2. Performance of The PEMFC Integrated Microgrid

The performance of the PEMFC integrated microgrid is justified in this section from the perspective of the DC-DC converter since it is the primary objective of this manuscript. The performance is compared while applying the proposed DC-DC converter and a conventional boost converter. The rest of the components of the PEMFC integrated microgrid are considered to be similar as demonstrated in Table 2. In this manner, the comparison will be justified. A simulation-based performance analysis is conducted using MATLAB Simulink.

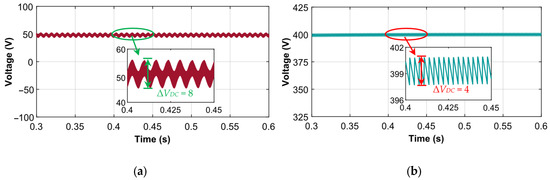

The DC-link voltage ripple of the PEMFC integrated microgrid for the conventional boost converter and the proposed converter are illustrated in Figure 13a,b, respectively. It is evident that the conventional boost converter’s voltage ripple is around 8 V, which is almost 16% of the output voltage. On the contrary, the voltage ripple of the proposed converter is around 4 V, which is only 1% of the output voltage. Moreover, it can be observed that the voltage of the boost converter also contains oscillations. The presence of the voltage ripple can significantly hamper the PEMFC integrated microgrid’s injected current and hence, creates distortions in the microgrid current.

Figure 13.

Output voltage and voltage ripple of: (a) conventional boost converter, and (b) proposed converter.

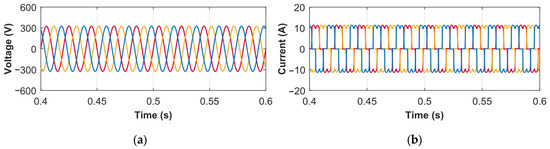

The impact of the voltage ripple produced by the conventional boost converter can be realized while analyzing the harmonic profile of the microgrid current. Here, the PEMFC integrated microgrid is feeding a bridge rectifier connected to a non-linear resistive inductive load (50 Ω–5 mH). The three-phase microgrid voltage (Vgrid) and the non-linear load current (Iload) are depicted in Figure 14a,b, respectively. Moreover, the grid current and its harmonic profile are illustrated in Figure 15 and Figure 16, while the PEMFC is integrated with a conventional boost converter and the proposed interleaved converter, respectively. The red-yellow-blue (RYB) color represent phase a, phase b and phase c, respectively.

Figure 14.

Results of the PEMFC integrated microgrid: (a) microgrid voltage (Vgrid), and (b) load current (Iload).

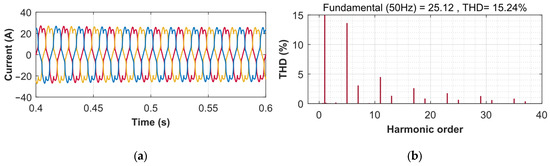

Figure 15.

PEMFC integrated microgrid’s performance when a conventional boost converter is applied: (a) microgrid current (Igrid), and (b) harmonic profile.

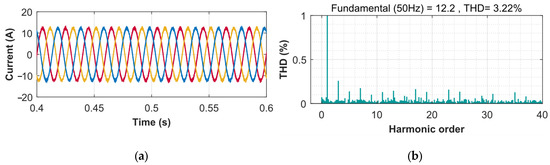

Figure 16.

PEMFC integrated microgrid’s performance when the proposed converter is applied: (a) microgrid current (Igrid), and (b) harmonic profile.

It can be observed from Figure 15a that when the conventional boost converter is applied for integrating the PEMFC with the microgrid, the microgrid’s current has high current ripple. Therefore, there are high harmonics of 15.24% present, as shown in Figure 15b. The resultant THD has violated the IEEE 519 2014 standard which states the THD of a grid-connected system must be less than 5%. This is because the conventional converter has high voltage ripple and thus, the injected current from the inverter is unable to accurately compensate the microgrid current. On the contrary, it can be observed from Figure 16a that when the proposed converter is applied, the microgrid’s current almost becomes distortion-free and the resulting THD is reduced to 3.22%. Thus, in this case the microgrid current has successfully followed the IEEE 519 standard. The significant improvement of the harmonic profile is due to the fact that the proposed converter’s voltage ripple was significantly less than the conventional boost converter and hence, the injected current from the inverter is able to accurately compensate the microgrid current. Moreover, this substantial reduction in the THD profile of the system due to utilizing the high gain converter can improve the power quality of the system.

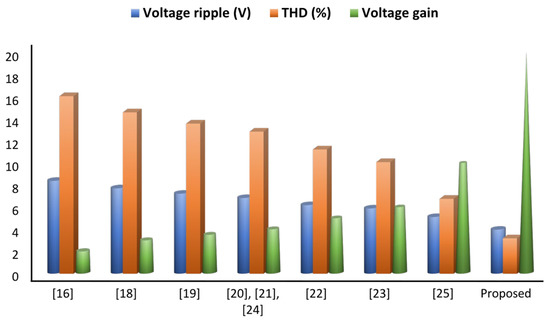

A comparative analysis in terms of the voltage ripple and harmonic profile of the grid current is also shown in Figure 17 while applying other recently developed DC-DC converters to interface the PEMFC with the microgrid. The analysis showed that because of the high voltage gain and very low voltage ripple, the proposed converter outperformed the other converters. Therefore, the harmonic profile of the microgrid current also showed the lowest THD of 3.22%, the lowest voltage ripple of 4 V, and the highest voltage gain of 20 while implementing the proposed converter. It should be noted that to justify the comparison, the systems’ parameters of the PEMFC and microgrid are considered similar to the ones shown in Table 1 and Table 2.

Figure 17.

Comparative analysis among various DC-DC converters in terms of voltage ripple, THD, and voltage gain [16,18,19,20,21,22,23,24,25].

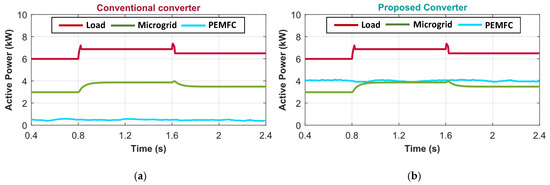

The performance of converters during load transients can be determined by analyzing the active/reactive power status and the power factor of the PEMFC integrated microgrid. The inability of the conventional converter to boost the voltage also impacts the active/reactive power management and hence, causes power factor deterioration of the microgrid. In most cases, the problem occurs during the active power injection from the PEMFC, whereas the reactive power injection remains unaffected since the required reactive power by the electrical loads is relatively small compared to the active power. The load transients are produced in the Simulink environment by three three-phase circuit breakers. The circuit breakers are switched on and off at different times of the simulation to connect the three different electrical loads with the microgrid and observe the performance.

The active power status of the PEMFC integrated microgrid is shown in Figure 18 and Figure 19 when the PEMFC is interfaced with the microgrid using a boost converter and the proposed converter, respectively. It can be observed from Figure 18a that because of the low active power of 500 W injected from the conventional converter interfaced PEMFC, the microgrid is unable to satisfy the power demand from any of the electrical loads. On the contrary, due to injecting a high active power of 4 kW from the proposed converter interfaced PEMFC, as observed from Figure 18b, the microgrid is able to satisfy the power demand from all three electrical loads. This inability to inject the required power from the PEMFC to support the microgrid can deteriorate the power factor of the microgrid substantially, as demonstrated in Table 4.

Figure 18.

Power flow statistics of the microgrid when PEMFC is interfaced by: (a) conventional converter, and (b) proposed converter.

Figure 19.

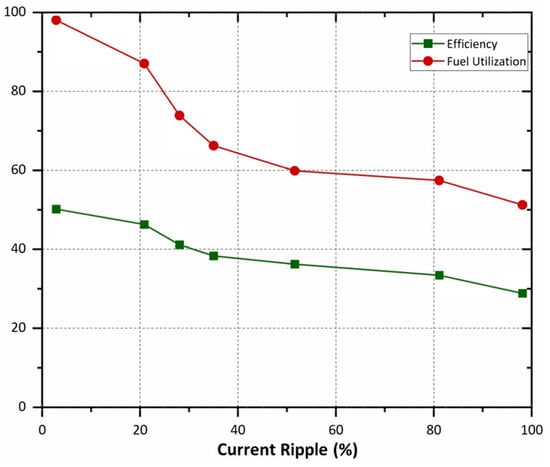

Fuel utilization and PEMFC’s efficiency in terms of current ripple.

Table 4.

Power flow and power factor statistics under different electrical loads.

5.3. Performance Asssessment of the PEMFC

This section elaborates on the performance assessment and evaluates the behavior of the PEMFC in terms of the microgrid current’s THD. The performance of the PEMFC is highly reliant on the microgrid integration along with the type of connected electrical loads. The efficiency of the fuel cell can be significantly enhanced by minimizing the harmonics caused by the microgrid interface or the non-linear electrical loads.

The high voltage gain and reduced voltage ripple of the proposed DC-DC converter ensures a reduction of the current ripple of the system that is caused by the non-linear electrical loads. The microgrid must eliminate the lower order harmonics, otherwise it can inject a low frequency AC current to the PEMFC and subsequently cause performance disorder by shifting its polarity region [39]. Thus, due to the implementation of the high voltage gain DC-DC converter, the lower order harmonics are eliminated from the microgrid’s current, which can also prevent the PEMFC from operating outside the polarization region. Consequently, it ensures the system operates with optimal conditions and the PEMFC operates without any malfunction. By reducing the current ripples in the microgrid, the PEMFC’s efficiency and fuel usage is significantly improved as depicted in Figure 18. It is apparent that interfacing the PEMFC using a conventional boost converter can induce a voltage ripple of 16% along with a current ripple of 35%. Hence, utilization of fuel is also limited to 66.25%, having a PEMFC efficacy of 38.32%. Conversely, by applying the proposed converter, the voltage ripple is significantly minimized to only 1% with a current ripple of 3.91%. Therefore, utilization of fuel increased to about 97.36% with an efficiency of 49.74%. By applying the proposed converter, the THD is effectively mitigated; and the flow of fuel can be sustained at a nominal rate that will ensure the optimal utilization of the fuel flow, a minimized cost, and increased efficacy of the PEMFC.

6. Conclusions

This paper introduces a novel DC-DC converter configuration utilizing three semiconductor switches. The proposed converter has numerous advantages, including high voltage gain of 20 times that of the input voltage without any transformer or magnetic DC-link, low voltage stress on the semiconductor devices with a maximum switching voltage stress of only 50% of the output voltage, and a maximum diode voltage stress of 25% of the output voltage. Due to these advantageous characteristics, the proposed converter is appropriate as an interfacing device for the PEMFC integrated microgrid. A 1.6 kW, 400 V prototype for the suggested topology was constructed, and the practical findings supported the theoretical analysis. By integrating the proposed converter, the microgrid current’s harmonic profile exhibited the lowest total harmonic distortion (THD) of 3.22%, and lowest voltage ripple of just 4 V while maintaining the voltage gain of 20 compared to other recently developed DC-DC converters. The high voltage gain and low voltage ripple of the converter substantially improved the power quality of the PEMFC integrated microgrid by reducing the current harmonics and keeping the power factor of the system close to unity. A comprehensive comparison with a conventional boost converter is also presented to demonstrate the superiority of the proposed device. The analysis and performance assessment of the PEMFC showed promising outcomes which further validates the industrial applicability of the proposed converter.

Author Contributions

Conceptualization, F.M. and S.T.M.; methodology, F.M. and S.T.M.; software, N.Z.Y. and S.T.M.; validation, N.Z.Y., M.S.H.L. and N.S.S.S.; formal analysis, M.S.R.; investigation, F.M.; resources, M.S.H.L. and N.S.S.S.; data curation, F.M. and M.S.R.; writing—original draft preparation, S.T.M.; writing—review and editing, F.M. and M.S.R.; visualization, S.T.M. and M.S.R.; supervision, N.Z.Y. and M.S.H.L.; project administration, N.Z.Y. and M.S.H.L.; funding acquisition, N.S.S.S. and M.S.H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge their great appreciation for the Department of Electrical and Electronics Engineering, Universiti Teknologi PETRONAS, Malaysia for conducting this research work. The authors also wish to extend their sincere thanks to the support of the Faculty of Data Science and Information Technology, INTI International University, Malaysia for providing the state-of-the-art research support to continue this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chakraborty, S.; Dash, S.K.; Elavarasan, R.M.; Kaur, A.; Elangovan, D.; Meraj, S.T.; Kasinathan, P.; Said, Z. Hydrogen Energy as Future of Sustainable Mobility. Front. Energy Res. 2022, 10. [Google Scholar] [CrossRef]

- İnci, M.; Türksoy, Ö. Review of fuel cells to grid interface: Configurations, technical challenges and trends. J. Clean. Prod. 2019, 213, 1353–1370. [Google Scholar] [CrossRef]

- Kalchschmid, V.; Erhart, V.; Angerer, K.; Roth, S.; Hohmann, A. Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies? Sustainability 2023, 15, 2994. [Google Scholar] [CrossRef]

- Meraj, S.T.; Yahaya, N.Z.; Hasan, K.; Lipu, M.H.; Elavarasan, R.M.; Hussain, A.; Hannan, M.A.; Muttaqi, K.M. A filter less improved control scheme for active/reactive energy management in fuel cell integrated grid system with harmonic reduction ability. Appl. Energy 2022, 312, 118784–118801. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Jordehi, A.R.; Marzband, M.; Tostado-Véliz, M.; Jurado, F.; Aguado, J.A. An IoT-enabled hierarchical decentralized framework for multi-energy microgrids market management in the presence of smart prosumers using a deep learning-based forecaster. Appl. Energy 2023, 333, 120560. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Ahmarinejad, A.; Sheidaei, F.; Javadi, M.S.; Jordehi, A.R.; Nezhad, A.E.; Catalao, J.P. A multi-stage joint planning and operation model for energy hubs considering integrated demand response programs. Int. J. Electr. Power Energy Syst. 2022, 140, 108103. [Google Scholar] [CrossRef]

- Shen, Q.; Hou, M.; Yan, X.; Liang, D.; Zang, Z.; Hao, L.; Shao, Z.; Hou, Z.; Ming, P.; Yi, B. The voltage characteristics of proton exchange membrane fuel cell (PEMFC) under steady and transient states. J. Power Sources 2008, 179, 292–296. [Google Scholar] [CrossRef]

- Bizon, N.; Thounthong, P. Real-time strategies to optimize the fueling of the fuel cell hybrid power source: A review of issues, challenges and a new approach. Renew. Sustain. Energy Rev. 2018, 91, 1089–1102. [Google Scholar] [CrossRef]

- Meraj, S.T.; Abd Rahman, M.S.; Yahaya, N.Z.; Ker, P.J.; Hossain, T.M.; Lipu, M.H.; Muttaqi, K.M.; Hannan, M.A. A Pencil Shaped 9-Level Multilevel Inverter with Voltage Boosting Ability: Configuration and Experimental Investigation. IEEE Access 2022, 10, 111310–111321. [Google Scholar] [CrossRef]

- Meraj, S.T.; Yu, S.S.; Rahman, M.S.; Hasan, K.; Lipu, M.S.H.; Trinh, H. Energy management schemes, challenges and impacts of emerging inverter technology for renewable energy integration towards grid decarbonization. J. Clean. Prod. 2023, 405, 137002–137034. [Google Scholar] [CrossRef]

- Kabalo, M.; Blunier, B.; Bouquain, D.; Miraoui, A. State-of-the-Art of DC-DC Converters for Fuel Cell Vehicles. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, VPPC 2010, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar]

- Overview. Step-Up DC—DC Converters: A Comprehensive Review of Voltage-Boosting Techniques. IEEE Trans. Power Electron. 2017, 32, 9143–9178. [CrossRef]

- Solsona, J.A.; Jorge, S.G.; Busada, C.A. Modeling and Nonlinear Control of DC-DC Converters for Microgrid Applications. Sustainability 2022, 14, 16889. [Google Scholar] [CrossRef]

- Kummara, V.G.R.; Zeb, K.; Muthusamy, A.; Krishna, T.N.V.; Kumar, S.V.P.; Kim, D.-H.; Kim, M.-S.; Cho, H.-G.; Kim, H.-J. A comprehensive review of DC–DC converter topologies and modulation strategies with recent advances in solar photovoltaic systems. Electronics 2020, 9, 31. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Rahim, N.A. Recent progress and development on power DC-DC converter topology, control, design and applications: A review. Renew. Sustain. Energy Rev. 2018, 81, 205–230. [Google Scholar] [CrossRef]

- Gao, D.; Jin, Z.; Liu, J.; Ouyang, M. An interleaved step-up/step-down converter for fuel cell vehicle applications. Int. J. Hydrog. Energy 2016, 41, 22422–22432. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Ahmarinejad, A.; Nematbakhsh, E.; Javadi, M.S.; Jordehi, A.R.; Catalao, J.P.S. Energy hub design in the presence of P2G system considering the variable efficiencies of gas-fired converters. In Proceedings of the SEST 2021—4th International Conference on Smart Energy Systems and Technology, Vaasa, Finland, 6–8 September 2021. [Google Scholar] [CrossRef]

- Thounthong, P.; Davat, B. Study of a multiphase interleaved step-up converter for fuel cell high power applications. Energy Convers. Manag. 2010, 51, 826–832. [Google Scholar] [CrossRef]

- Huangfu, Y.; Zhuo, S.; Chen, F.; Pang, S.; Zhao, D.; Gao, F. Robust Voltage Control of Floating Interleaved Boost Converter for Fuel Cell Systems. IEEE Trans. Ind. Appl. 2018, 54, 665–674. [Google Scholar] [CrossRef]

- Wang, P.; Zhou, L.; Zhang, Y.; Li, J.; Sumner, M. Input-Parallel Output-Series DC-DC Boost Converter with a Wide Input Voltage Range, for Fuel Cell Vehicles. IEEE Trans. Veh. Technol. 2017, 66, 7771–7781. [Google Scholar] [CrossRef]

- Wu, J.C.; Der Wu, K.; Jou, H.L.; Wu, Z.H.; Chang, S.K. Novel power electronic interface for grid-connected fuel cell power generation system. Energy Convers. Manag. 2013, 71, 227–234. [Google Scholar] [CrossRef]

- Wu, Y.; Huangfu, Y.; Ma, R.; Ravey, A.; Chrenko, D. A strong robust DC-DC converter of all-digital high-order sliding mode control for fuel cell power applications. J. Power Sources 2018, 413, 222–232. [Google Scholar] [CrossRef]

- Pires, V.F.; Cordeiro, A.; Foito, D.; Silva, J.F. High step-up DC-DC converter for fuel cell vehicles based on merged quadratic boost-Cuk. IEEE Trans. Veh. Technol. 2019, 68, 7521–7530. [Google Scholar] [CrossRef]

- Elsayad, N.; Moradisizkoohi, H.; Mohammed, O.A. A Single-Switch Transformerless DC-DC Converter with Universal Input Voltage for Fuel Cell Vehicles: Analysis and Design. IEEE Trans. Veh. Technol. 2019, 68, 4537–4549. [Google Scholar] [CrossRef]

- Bi, H.; Wang, P.; Che, Y. A capacitor clamped H-Type Boost DC-DC converter with wide voltage-gain range for fuel cell vehicles. IEEE Trans. Veh. Technol. 2019, 68, 276–290. [Google Scholar] [CrossRef]

- Khan, S.; Mahmood, A.; Zaid, M.; Tariq, M.; Sadaf, S. A Single Inductor, Single Switch High Gain DC-DC Boost Converter. In Proceedings of the IEEE International Women in Engineering (WIE) Conference on Electrical and Computer Engineering (WIECON-ECE 2020), Bhubaneswar, India, 26–27 December 2020; pp. 98–101. [Google Scholar] [CrossRef]

- Khan, S.; Mahmood, A.; Zaid, M.; Tariq, M.; Lin, C.H.; Ahmad, J.; Alamri, B.; Alahmadi, A. A High Step-up DC-DC Converter Based on the Voltage Lift Technique for Renewable Energy Applications. Sustainability 2021, 13, 11059. [Google Scholar] [CrossRef]

- Khan, S.; Mahmood, A.; Tariq, M.; Zaid, M.; Khan, I.; Rahman, S. Improved Dual Switch Non-Isolated High Gain Boost Converter for DC microgrid Application. In Proceedings of the 2021 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2–5 February 2021. [Google Scholar] [CrossRef]

- Huangfu, Y.; Ma, Y.; Bai, H.; Xu, L.; Wang, A.; Ma, R. A family of high gain fuel cell front-end converters with low input current ripple for PEMFC power conditioning systems. Int. J. Hydrog. Energy 2021, 46, 27156–27172. [Google Scholar] [CrossRef]

- Mahmood, A.; Zaid, M.; Ahmad, J.; Khan, M.A.; Khan, S.; Sifat, Z.; Lin, C.-H.; Sarwar, A.; Tariq, M.; Alamri, B. A Non-Inverting High Gain DC-DC Converter with Continuous Input Current. IEEE Access 2021, 9, 54710–54721. [Google Scholar] [CrossRef]

- Schmitz, L.; Martins, D.C.; Coelho, R.F. Comprehensive conception of high step-Up DC-DC converters with coupled inductor and voltage multipliers techniques. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 2140–2151. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Y.; Fang, J.; Alkhayyat, A. An optimal methodology for optimal controlling of a PEMFC connected to the grid based on amended penguin optimization algorithm. Sustain. Energy Technol. Assess. 2022, 53, 102401. [Google Scholar] [CrossRef]

- Schumann, M.; Cosse, C.; Becker, D.; Vorwerk, D.; Schulz, D. Modeling and experimental parameterization of an electrically controllable PEM fuel cell. Int. J. Hydrog. Energy 2021, 46, 28734–28747. [Google Scholar] [CrossRef]

- Priya, M.; Ponnambalam, P. Circulating Current Control of Phase-Shifted Carrier-Based Modular Multilevel Converter Fed by Fuel Cell Employing Fuzzy Logic Control Technique. Energies 2022, 15, 6008. [Google Scholar] [CrossRef]

- Dhimish, M.; Vieira, R.G.; Badran, G. Investigating the stability and degradation of hydrogen PEM fuel cell. Int. J. Hydrog. Energy 2021, 46, 37017–37028. [Google Scholar] [CrossRef]

- Li, M.; Liu, H.; Yan, M.; Xu, H.; He, H. A Novel Multi-Objective Energy Management Strategy for Fuel Cell Buses Quantifying Fuel Cell Degradation as Operating Cost. Sustainability 2022, 14, 16190. [Google Scholar] [CrossRef]

- Hasan, K.; Meraj, S.T.; Othman, M.M.; Lipu, M.S.H.; Hannan, M.A.; Muttaqi, K.M. Savitzky–Golay Filter-Based PLL: Modeling and Performance Validation. IEEE Trans. Instrum. Meas. 2022, 71, 1–6. [Google Scholar] [CrossRef]

- Afonso, J.; Couto, C.; Martins, J. Active Filters with Control Based on the p-q Theory. IEEE Ind. Electron. Soc. Newsl. 2000, 47, 5–10. Available online: https://www.researchgate.net/publication/251506378 (accessed on 20 February 2023).

- Rahimi-Esbo, M.; Sangtabi, A.R.; Alizadeh, E. Manifold Design in a PEM Fuel Cell Stack to Improve Flow Distribution Uniformity. Sustainability 2022, 14, 15702. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).