A Front Advancing Adaptive Triangular Mesh Dynamic Generation Algorithm and Its Application in 3D Geological Modeling

Abstract

1. Introduction

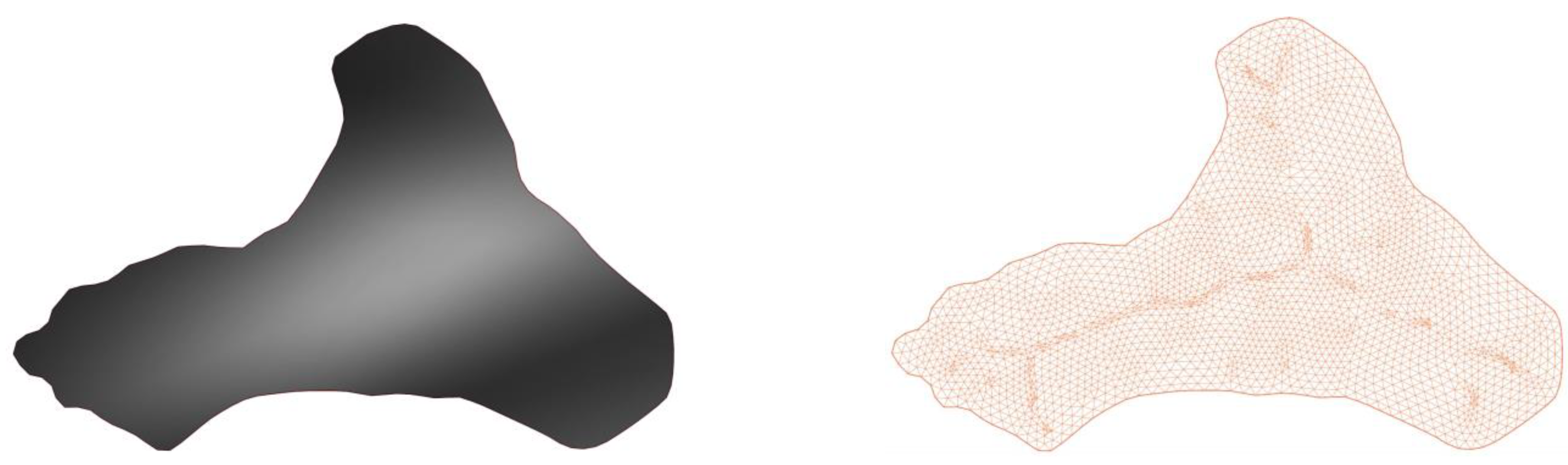

2. Front Edge Morphology Types and Mesh Cell Dynamic Generation Strategies

2.1. Divergence of the Mesh with a Threshold Hierarchical Yielding Mechanism

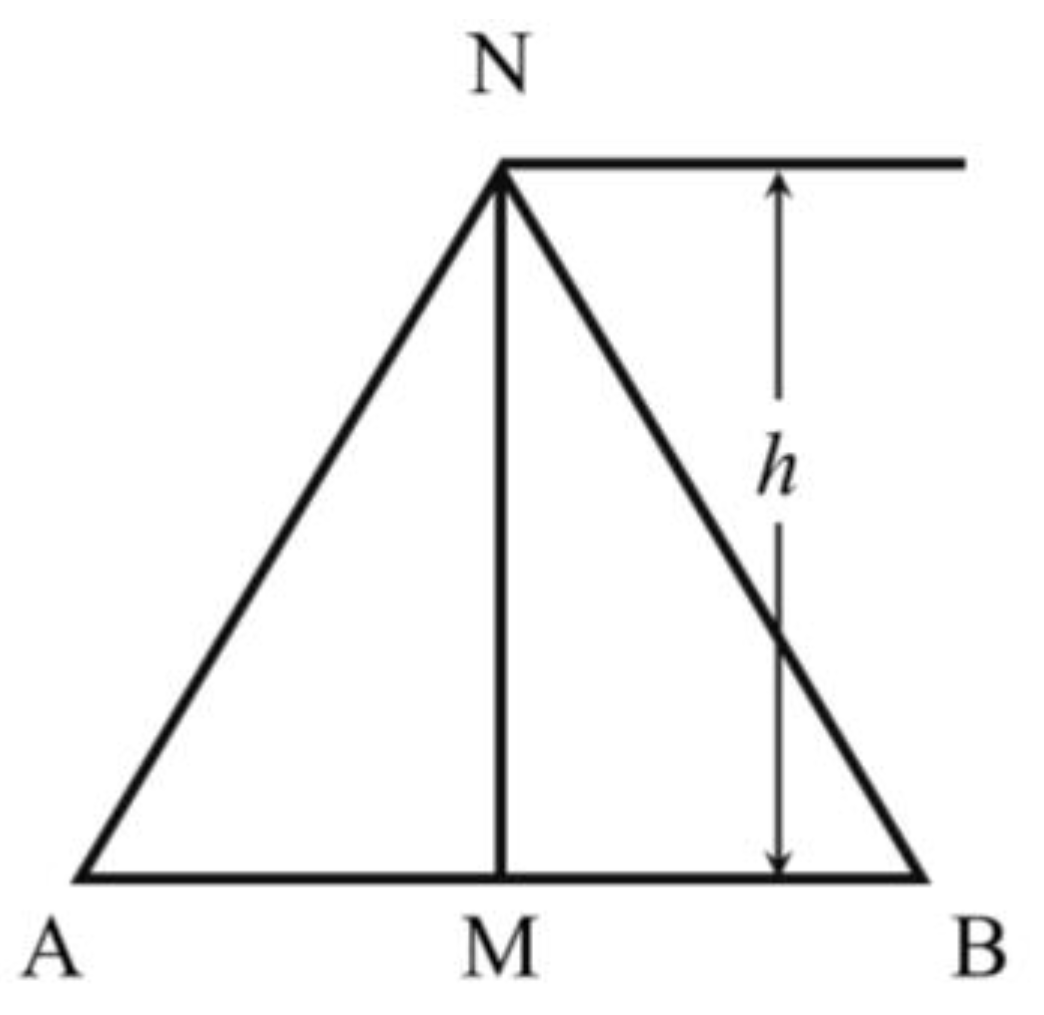

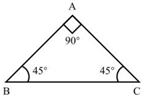

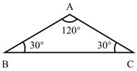

2.2. Basic Pattern and Strategy Analysis

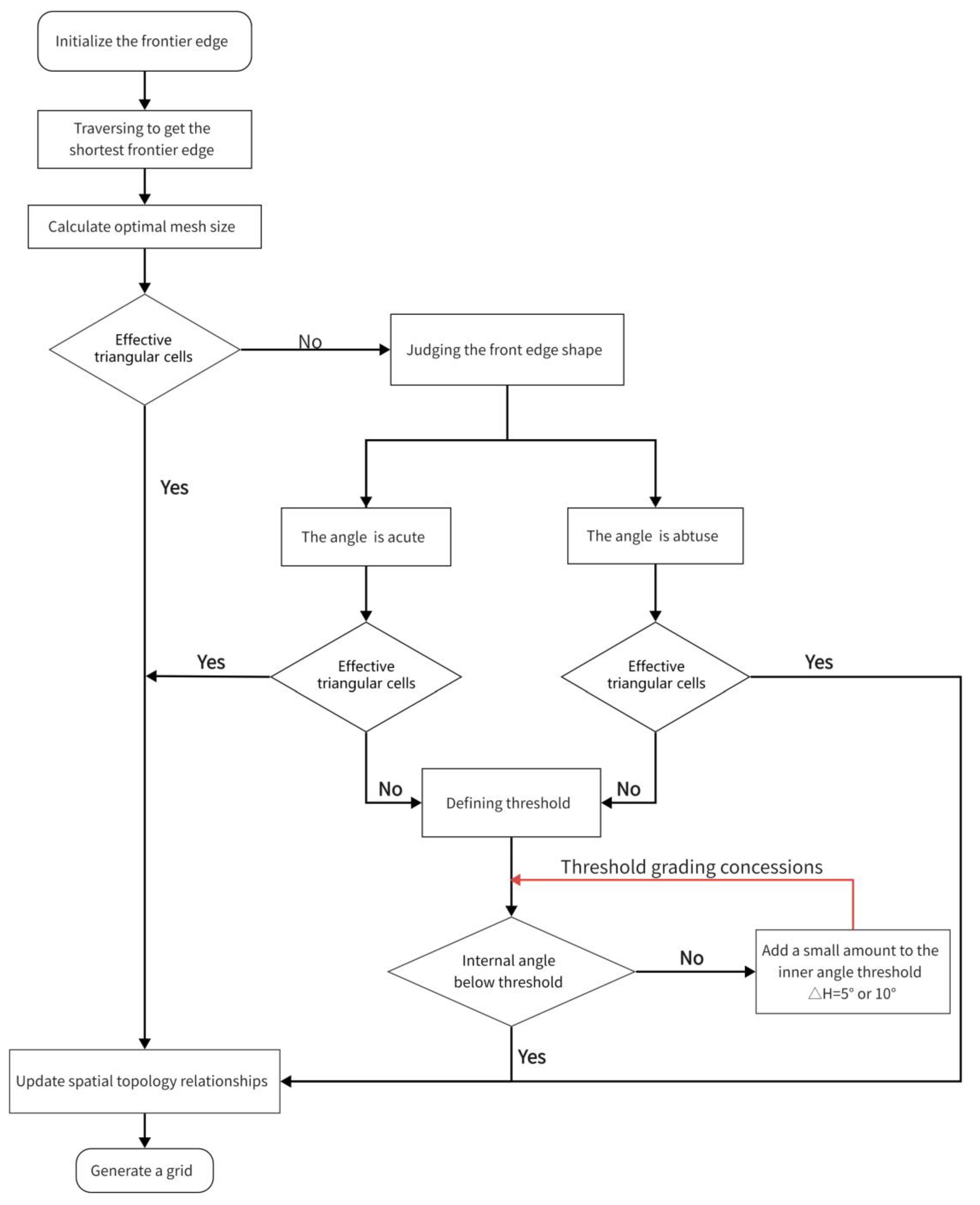

2.3. Adaptive Mesh Generation Algorithm Flow

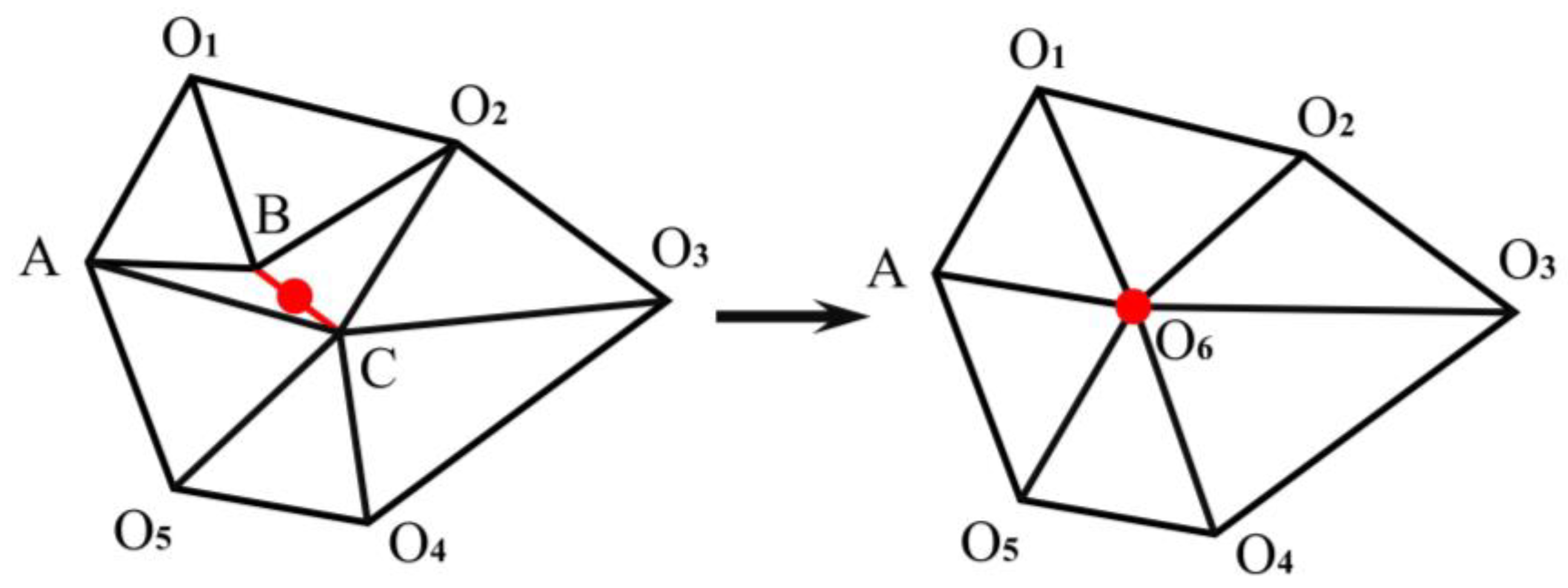

3. Mesh Optimization and Smoothing

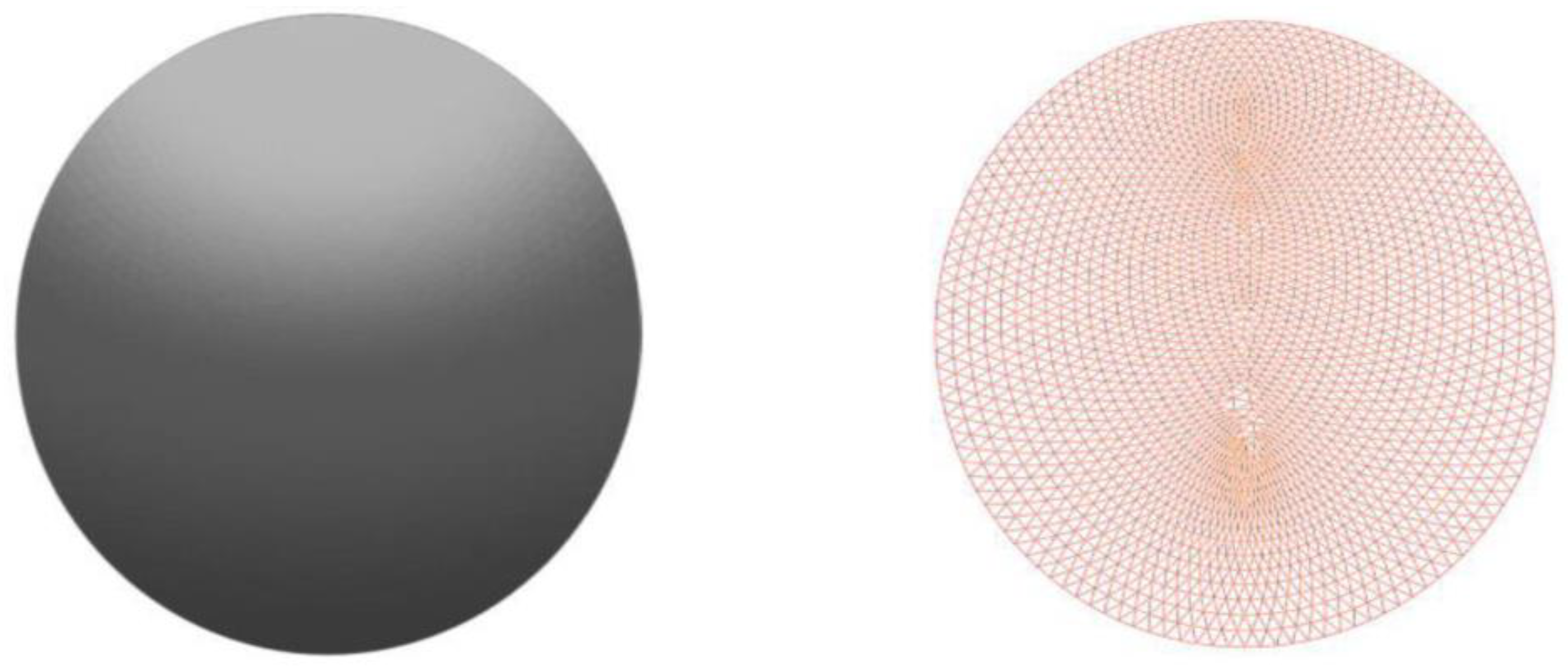

4. Results and Discussion

4.1. Algorithm and Algorithm Efficiency Analysis

4.2. Execution Time Analysis

4.3. Mesh Quality Analysis

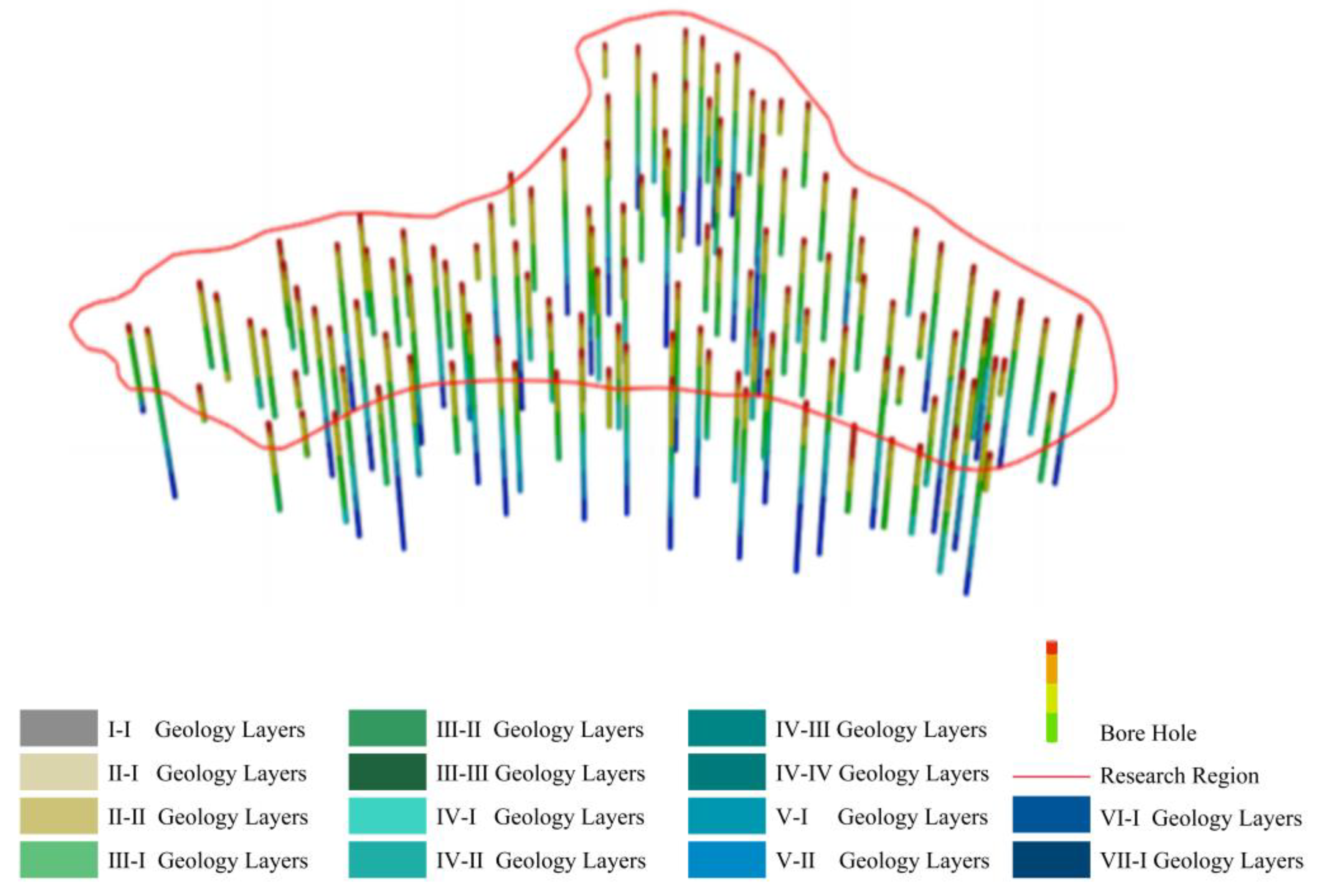

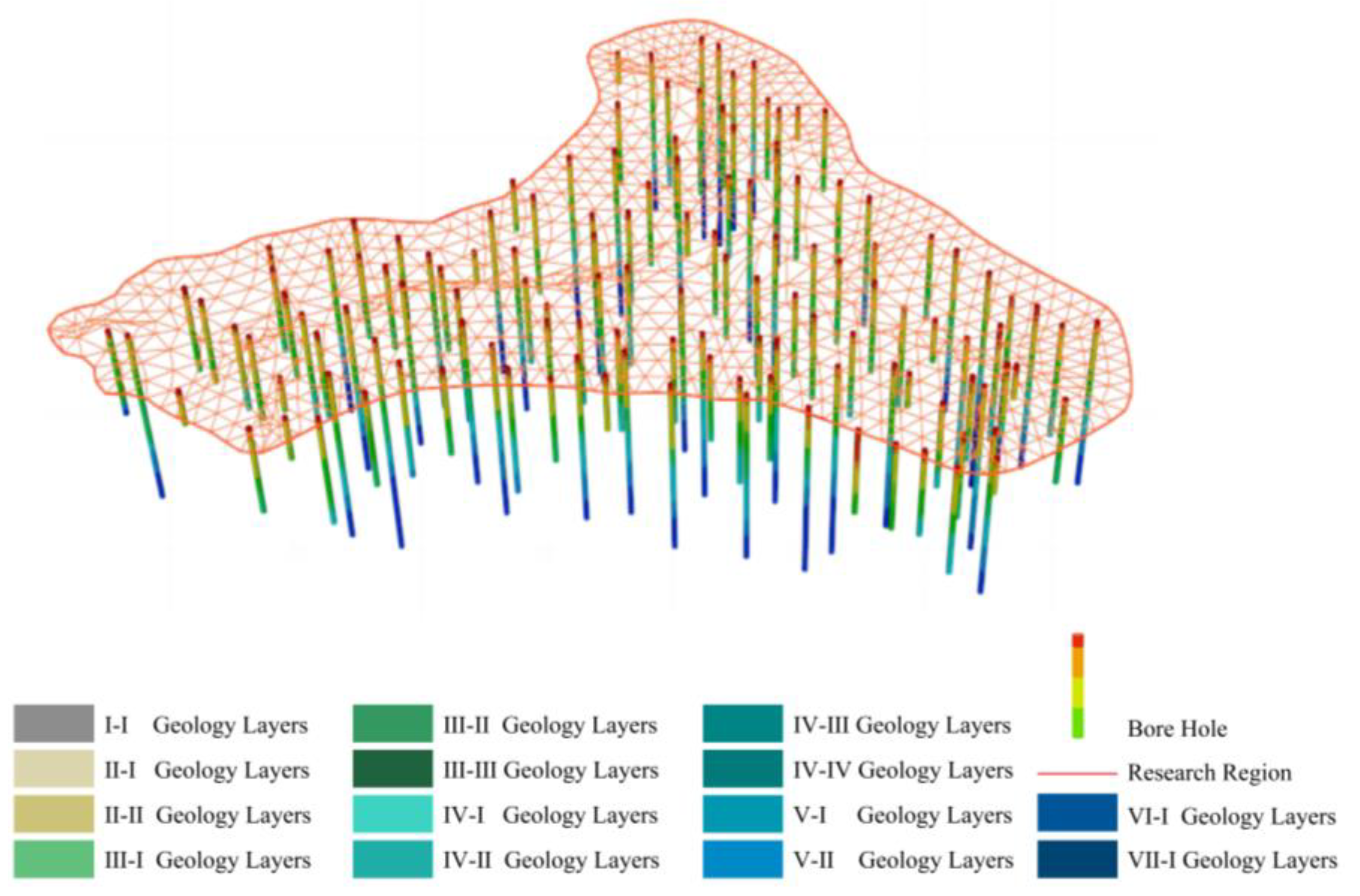

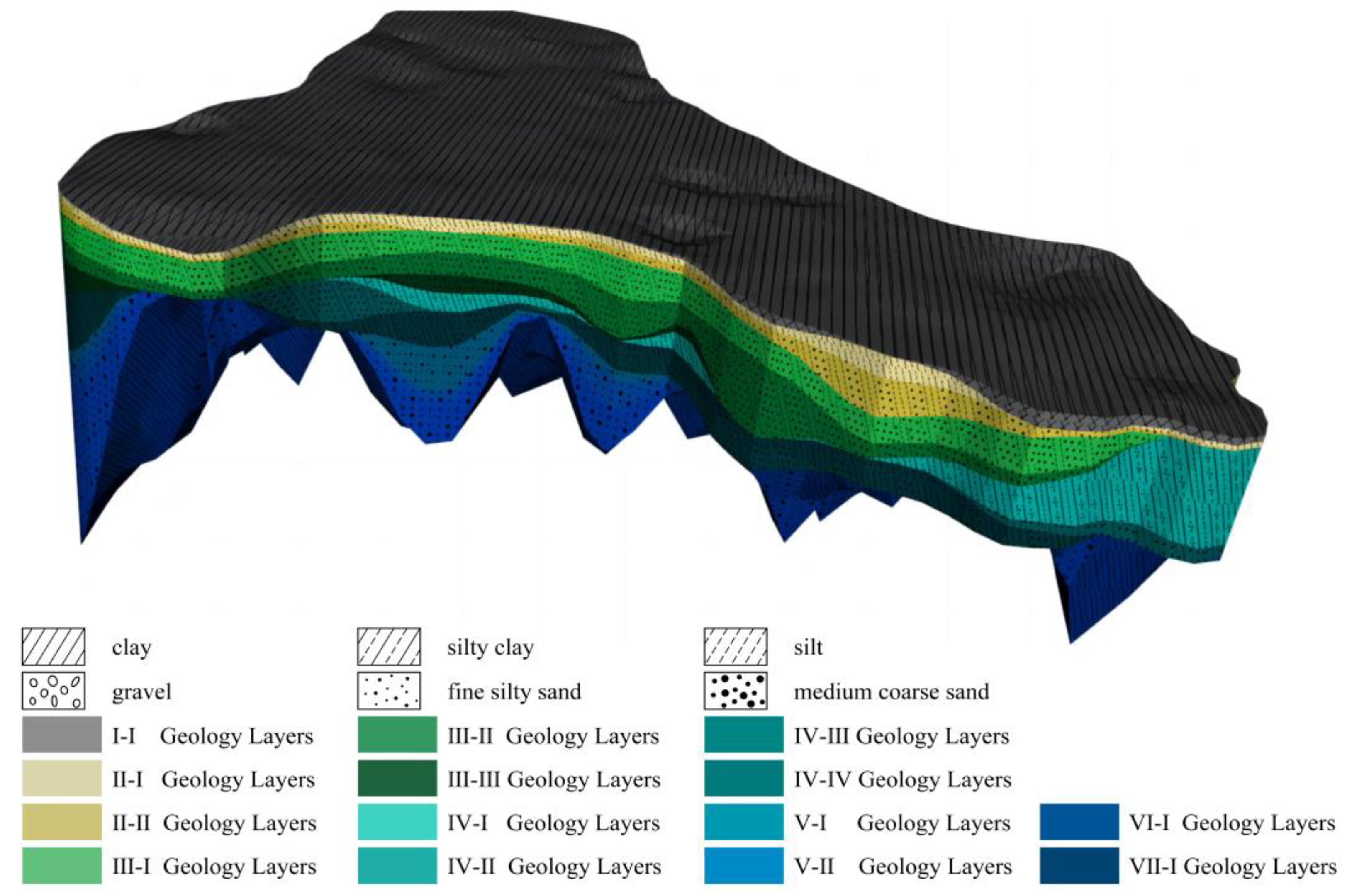

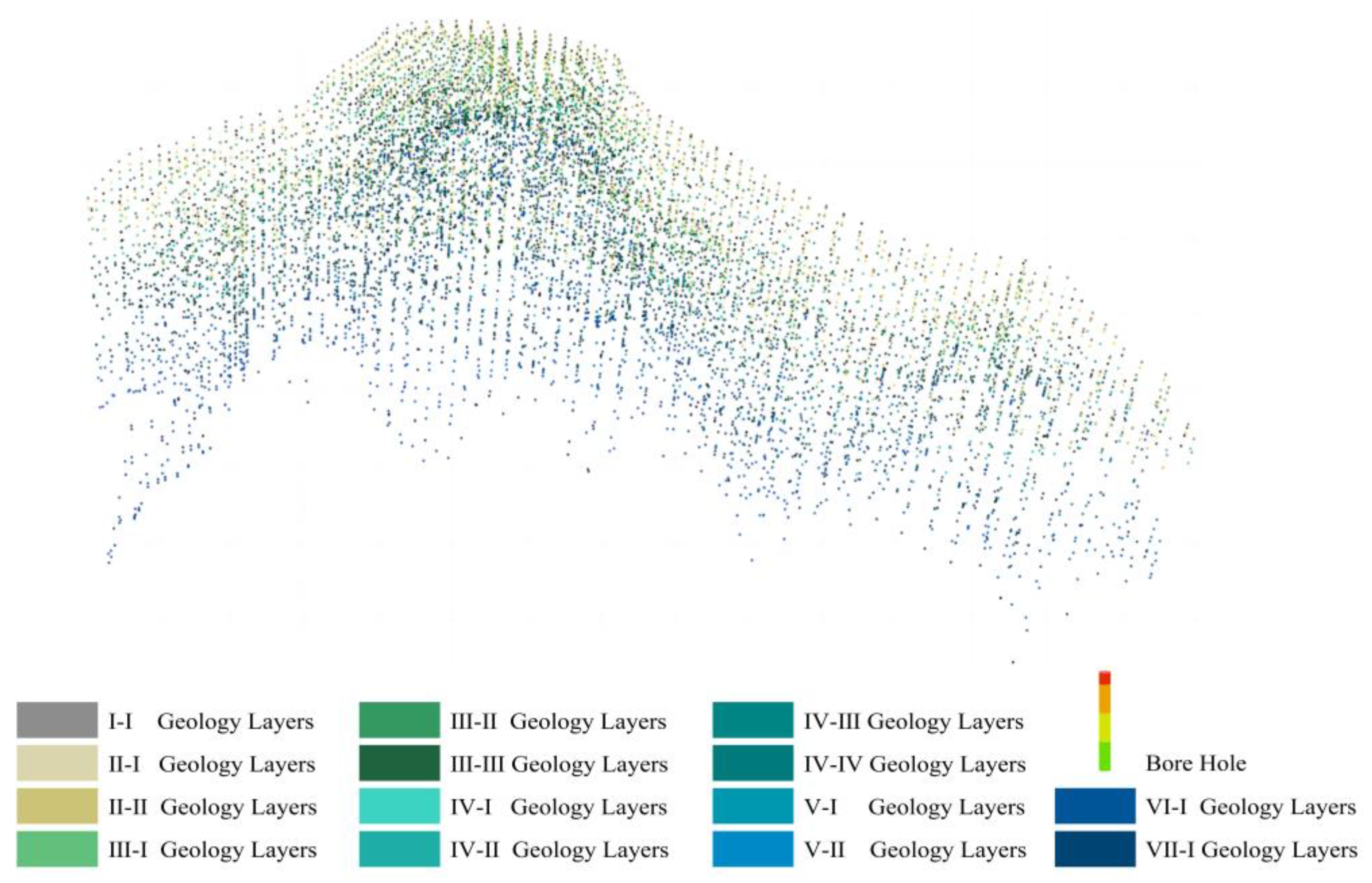

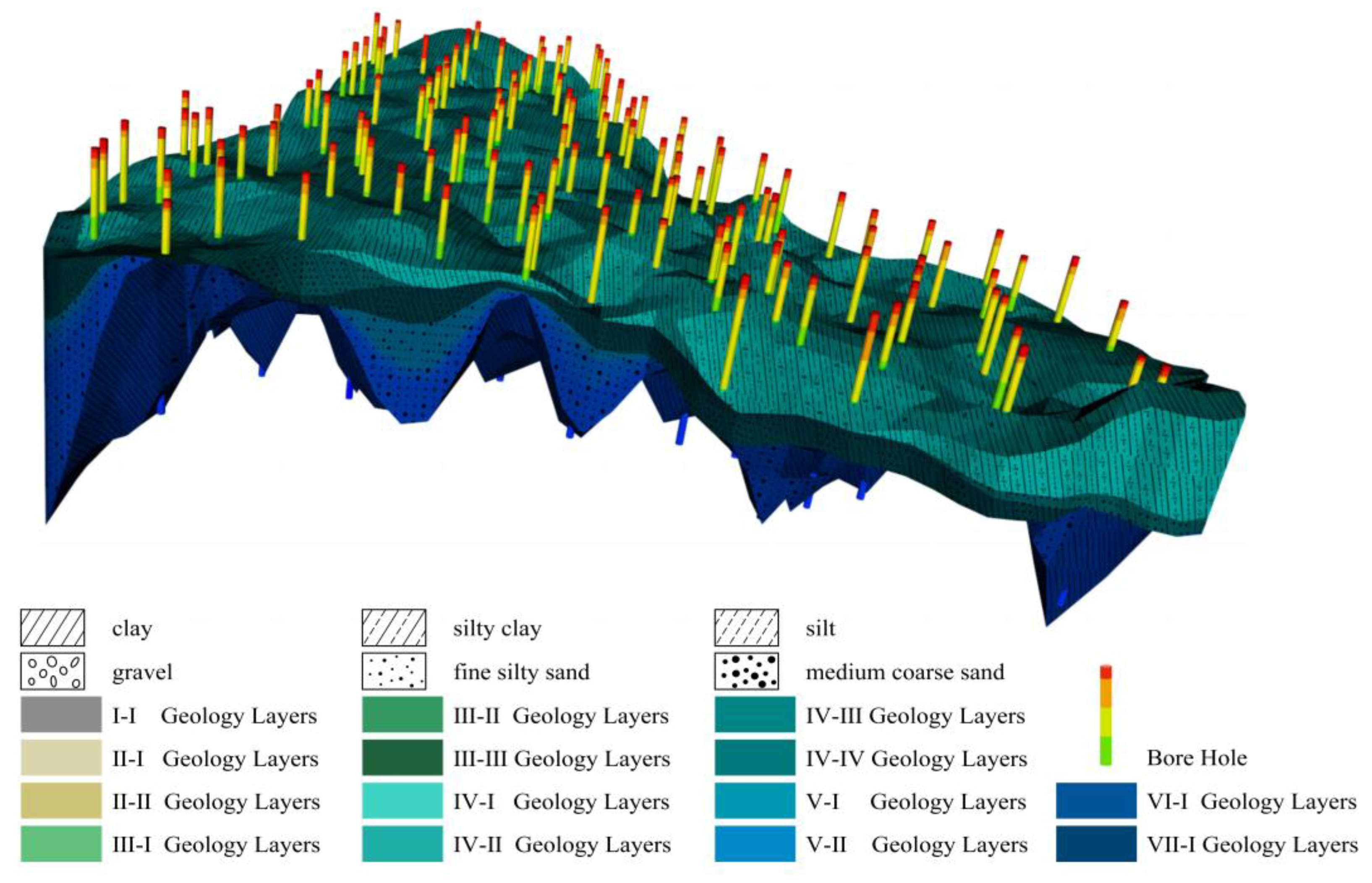

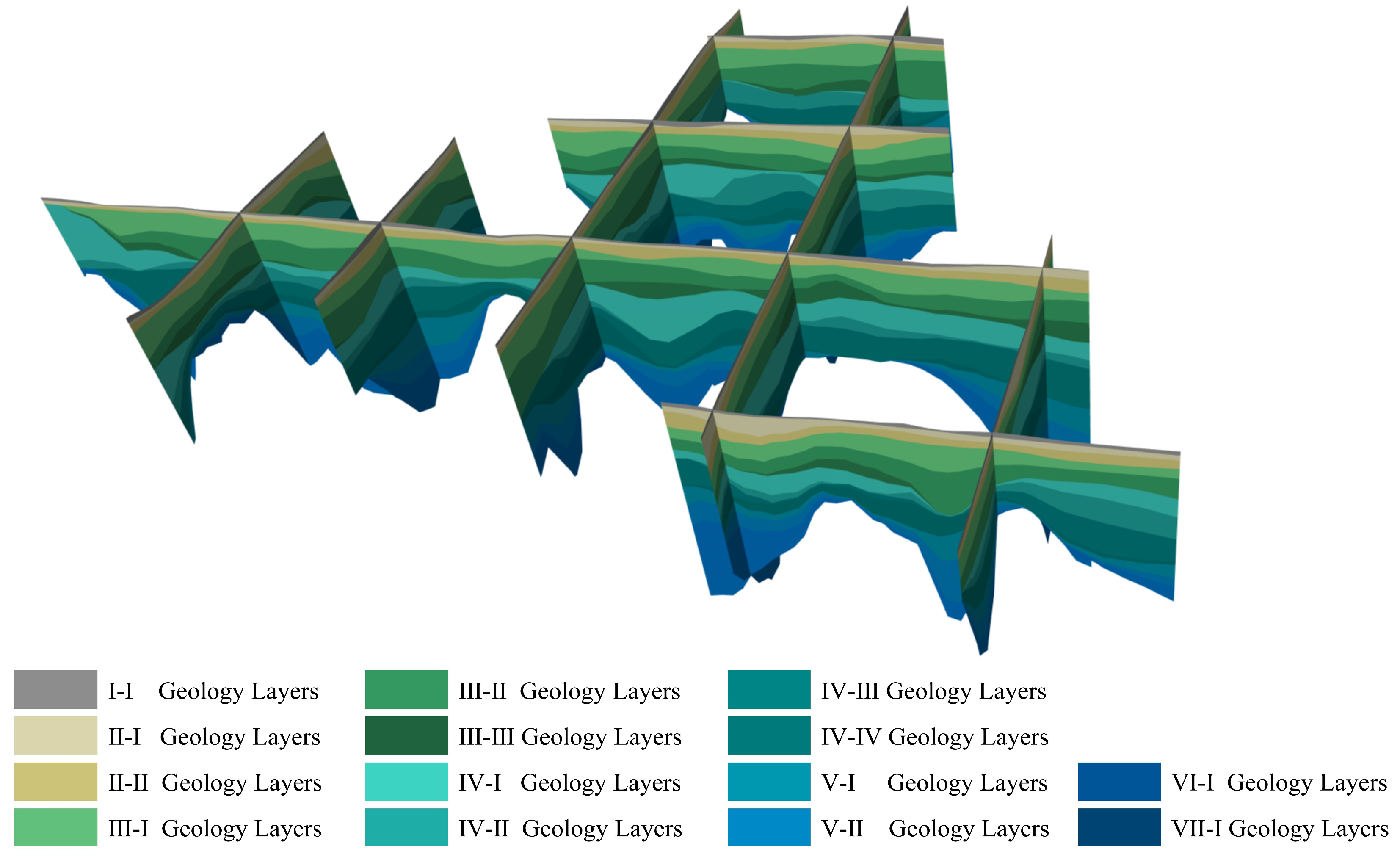

5. Application of Algorithms in 3D Geological Modeling

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, M.; Scott, M.H. A PFEM Background Mesh for Simulating Fluid and Frame Structure Interaction. J. Struct. Eng. 2022, 148, 04022051. [Google Scholar] [CrossRef]

- Luo, T.X.; Yuan, P.; Zhu, S. Automatic modelling of urban subsurface with ground-penetrating radar using multi-agent classification method. Geo-Spat. Inf. Sci. 2022, 25, 588–599. [Google Scholar] [CrossRef]

- Zhang, M.; Xie, Z.; He, L. Does the scarcity of urban space resources make the quality of underground space planning more sustainable? A case study of 40 urban underground space master plans in China. Front. Environ. Sci. 2022, 10, 2162. [Google Scholar] [CrossRef]

- Guo, J.; Wang, X.; Wang, J.; Dai, X.; Wu, L.; Li, C.; Li, F.; Liu, S.; Jessell, M.W. Three-dimensional geological modeling and spatial analysis from geotechnical borehole data using an implicit surface and marching tetrahedra algorithm. Eng. Geol. 2021, 284, 106047. [Google Scholar] [CrossRef]

- Hao, M.; Li, M.; Zhang, J.; Liu, Y.; Huang, C.; Zhou, F. Research on 3D geological modeling method based on multiple constraints A case study of Huaying Mountain Kangyangju in Guang’an City. Earth Sci. Inform. 2021, 14, 291–297. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, X.; Flener, C.; Kukko, A.; Kaartinen, H.; Kurkela, M.; Vaaja, M.; Hyyppa, H.; Alho, P. 3D Modeling of Coarse Fluvial Sediments Based on Mobile Laser Scanning Data. Remote Sens. 2013, 5, 4571–4592. [Google Scholar] [CrossRef]

- Costantino, D.; Vozza, G.; Alfio, V.S.; Pepe, M. Strategies for 3D Modelling of Buildings from Airborne Laser Scanner and Photogrammetric Data Based on Free-Form and Model-Driven Methods: The Case Study of the Old Town Centre of Bordeaux (France). Appl. Sci. 2021, 11, 10993. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, C.; Li, M.; Pan, X.; Sun, J. Building 3D solid models of sedimentary stratigraphic systems from borehole data: An automatic method and case studies. Eng. Geol. 2012, 127, 1–13. [Google Scholar] [CrossRef]

- Robert, M.; Carmen, J.; Fritz, Z. A visual LISP program for voxelizing AutoCAD solid models. Comput. Geosci. 2015, 74, 110–120. [Google Scholar] [CrossRef]

- Spirou-Sioula, K.; Ioannidis, C.; Potsiou, C. Technical aspects for 3D hybrid cadastral model. Surv. Rev. 2013, 45, 419–427. [Google Scholar] [CrossRef]

- Martinez, J.L.; Raiber, M.; Cendon, D.I. Using 3D geological modelling and geochemical mixing models to characterise alluvial aquifer recharge sources in the upper Condamine River catchment, Queensland, Australia. Sci. Total Environ. 2017, 574, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wang, X.; Chen, M.; Wu, P.; Kim, M.J. Integration of BIM and GIS: IFC geometry transformation to shapefile using enhanced open-source approach. Autom. Constr. 2019, 106, 102859. [Google Scholar] [CrossRef]

- Luo, Y.-T.; Du, H.; Yan, Y.-M. MeshCNN-based BREP to CSG conversion algorithm for 3D CAD models and its application. Nucl. Sci. Tech. 2022, 33, 74. [Google Scholar] [CrossRef]

- Li, C.; Li, F.; Guo, J.; Liu, C.; Chen, F.; Liu, Y. 3D geological map modeling technology based on a geological route and geological object wireframe model. Acta Geol. Sin. 2019, 92, 231. [Google Scholar]

- Cheng, X. Algorithm of CAD Surface Generation for Complex Pipe Model in Industry 4.0 Background. Comput. Intell. Neurosci. 2022, 2022, 7062052. [Google Scholar] [CrossRef]

- Quan, Y.; Song, J.; Guo, X.; Miao, Q.; Yang, Y. Filtering LiDAR data based on adjacent triangle of triangulated irregular network. Multimed. Tools Appl. 2017, 76, 11051–11063. [Google Scholar] [CrossRef]

- Zhao, Z.; Cheng, C.; Jin, X.; Liu, L.; Yan, L. A MILP model for hydro unit commitment with irregular vibration zones based on the constrained Delaunay triangulation method. Int. J. Electr. Power Energy Syst. 2020, 123, 106241. [Google Scholar] [CrossRef]

- Hu, G.; Wang, C.; Li, S.; Dai, W.; Xiong, L.; Tang, G.; Strobl, J. Using vertices of a triangular irregular network to calculate slope and aspect. Int. J. Geogr. Inf. Sci. 2021, 36, 383–405. [Google Scholar] [CrossRef]

- Zhao, L.; Li, G.; Yao, X.; Ma, Y.; Cao, Q. An optimized hexagonal quadtree encoding and operation scheme for icosahedral hexagonal discrete global grid systems. Int. J. Digit. Earth 2022, 15, 975–1000. [Google Scholar] [CrossRef]

- Liang, X.; Ben, J.; Wang, R.; Liang, Q.; Huang, X.; Ding, J. Construction of rhombic triacontahedron discrete global grid systems. Int. J. Digit. Earth 2022, 15, 1760–1783. [Google Scholar] [CrossRef]

- Hu, G.; Xiong, L.; Lu, S.; Chen, J.; Li, S.; Tang, G.; Strobl, J. Mathematical vector framework for gravity-specific land surface curvatures calculation from triangulated irregular networks. GISci. Remote Sens. 2022, 59, 590–608. [Google Scholar] [CrossRef]

- Wang, S.; Gao, Z.; Wang, Z.; Wu, X.; An, Y.; Ren, X.; He, M.; Wang, W.; Liu, J. Hydrodynamic characteristics of groundwater aquifer system under recharge and discharge conditions. Arab. J. Geosci. 2020, 13, 859. [Google Scholar] [CrossRef]

- Vu, M.T.; Jardani, A.; Massei, N.; Fournier, M. Reconstruction of missing groundwater level data by using Long Short-Term Memory (LSTM) deep neural network. J. Hydrol. 2021, 597, 125776. [Google Scholar] [CrossRef]

- Sastry, S.P. A 2D advancing-front Delaunay mesh refinement algorithm. Comput. Geom. 2021, 97, 101772. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Wang, Q.; Yu, Z. SAFT: Shotgun advancing front technique for massively parallel mesh generation on graphics processing unit. Int. J. Numer. Methods Eng. 2022, 123, 4391–4406. [Google Scholar] [CrossRef]

- Lu, P.; Wang, N.; Chang, X.; Zhang, L.; Wu, Y.; Zhang, H. An Automatic Isotropic Triangular Grid Generation Technique Based on an Artificial Neural Network and an Advancing Front Method. Math. Probl. Eng. 2022, 2022, 8103813. [Google Scholar] [CrossRef]

- Meng, L.; Tong, X.; Fan, S.; Cheng, C.; Chen, B.; Yang, W.; Hou, K. A Universal Generating Algorithm of the Polyhedral Discrete Grid Based on Unit Duplication. ISPRS Int. J. Geo-Inf. 2019, 8, 146. [Google Scholar] [CrossRef]

- Lei, Y.; Tong, X.; Qu, T.; Qiu, C.; Wang, D.; Sun, Y.; Tang, J. A scale-elastic discrete grid structure for voxel-based modeling and management of 3D data. Int. J. Appl. Earth Obs. Geoinf. 2022, 113, 103009. [Google Scholar] [CrossRef]

- Rangarajan, R.; Kabaria, H.; Lew, A. An algorithm for triangulating smooth three-dimensional domains immersed in universal meshes. Int. J. Numer. Methods Eng. 2019, 117, 84–117. [Google Scholar] [CrossRef]

- Adamoudis, L.D.; Koini, G.; Nikolos, I.K. Heuristic repairing operators for 3D tetrahedral mesh generation using the advancing-front technique. Adv. Eng. Softw. 2012, 54, 49–62. [Google Scholar] [CrossRef]

- Ding, H.; Xu, X.; Luo, Y. Generating Free-Form Grid Truss Structures from 3D Scanned Point Clouds. Math. Probl. Eng. 2017, 2017, 5818627. [Google Scholar] [CrossRef]

- Isailovic, V.; Filipovic, N. An algorithm for finding and adding boundary conditions with the aim of solving the contact problem in computational mechanics. Simul. Model. Pract. Theory 2021, 108, 102247. [Google Scholar] [CrossRef]

- Liu, Z.; Lv, H.; Li, M.; Li, Z.; Huang, Z. A Novel Self-adaptive Grid-partitioning Noise Optimization Algorithm Based on Differential Privacy. Comput. Sci. Inf. Syst. 2019, 16, 915–938. [Google Scholar] [CrossRef]

- Letnik, T.; Bozicnik, S.; Spacapan, S.; Mencinger, M. Optimal covering of the equidistant square grid network. Discret. Appl. Math. 2021, 296, 85–89. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Richard, J.-P.P.; Tawarmalani, M. Convexification techniques for linear complementarity constraints. J. Glob. Optim. 2021, 80, 249–286. [Google Scholar] [CrossRef]

- Chandra, A.; Tawarmalani, M. Probability estimation via policy restrictions, convexification, and approximate sampling. Math. Program. 2022, 196, 309–345. [Google Scholar] [CrossRef]

- Khademloo, S. A Multiplicity Result for Quasilinear Problems with Nonlinear Boundary Conditions in Bounded Domains. Int. J. Math. Math. Sci. 2011, 2011, 419341. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Wang, W.M.; Wang, L.H.; Yan, J.X. Analytical Solution of Interface Effect on the Strength of Combined Model Composed of Different Geologic Bodies. Math. Probl. Eng. 2014, 2014, 549–566. [Google Scholar] [CrossRef]

- He, L.; Zhang, J.; Chen, S.; Hou, M.; Chen, J. Three-dimensional hydrogeological modeling method and application based on TIN-GTP-TEN. Earth Sci. Inform. 2022, 15, 337–350. [Google Scholar] [CrossRef]

- Wu, L. Topological relations embodied in a generalized tri-prism (GTP) model for a 3D geoscience modeling system. Comput. Geosci. 2004, 30, 405–418. [Google Scholar] [CrossRef]

- Sun, L.; Wei, Y.; Cai, H.; Xiao, J.; Yan, J.; Wu, S. Adaptive Interpolation Method for Generalized Triangular Prism (GTP) Geological Model Based on the Geometric Smoothness Rule. Front. Earth Sci. 2022, 10, 254. [Google Scholar] [CrossRef]

- Shi, C.; Wang, Y. Data-driven construction of Three-dimensional subsurface geological models from limited Site-specific boreholes and prior geological knowledge for underground digital twin. Tunn. Undergr. Space Technol. 2022, 126, 104493. [Google Scholar] [CrossRef]

- Wu, L.; Shi, W. GTP-based Integral Real-3D Spatial Model for Engineering Excavation GIS. Geo-Spat. Inf. Sci. 2004, 7, 123–128. [Google Scholar] [CrossRef]

- Kim, H.-S.; Ji, Y. Three-dimensional geotechnical-layer mapping in Seoul using borehole database and deep neural network-based model. Eng. Geol. 2022, 297, 106489. [Google Scholar] [CrossRef]

- Liu, J.B.; Fang, L.L. Several Topological Indices of Two Kinds of Tetrahedral Networks. J. Math. 2021, 2021, 9800246. [Google Scholar] [CrossRef]

| Unit form Mass | 1.0 | 0.98 | 0.72 | 0.45 |

| Unit geometry form |  |  |  |  |

| Example | Total Number of Units | Overall Time Consumption (s) | Generating Mesh Time Consuming (s) | Optimizing Mesh Time Consuming (s) | Smoothing Mesh Time Consuming (s) | Before Optimization Mesh Quality | After Optimization Mesh Quality |

|---|---|---|---|---|---|---|---|

| Example 1 | 3898 | 15.225 | 0.415 | 12.458 | 0.352 | 0.891 | 0.920 |

| Example 2 | 4042 | 28.414 | 0.504 | 27.546 | 0.364 | 0.884 | 0.918 |

| Example | Programs | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Example 1 | R-TIN Algorithm | 0.415 | 4676 | 0.89 | 1.00 | 0.28 | 2.59% | 26.21% | 71.20% |

| Traditional Algorithm | 0.840 | 4636 | 0.83 | 1.00 | 0.02 | 2.14% | 35.06% | 62.80% | |

| Example 2 | R-TIN Algorithm | 0.504 | 4042 | 0.89 | 1.00 | 0.12 | 4.74% | 24.36% | 70.90% |

| Traditional Algorithm | 0.915 | 4021 | 0.83 | 1.00 | 0.04 | 4.35% | 34.20% | 61.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Li, X.; Lei, S.; Bi, B.; Chen, S. A Front Advancing Adaptive Triangular Mesh Dynamic Generation Algorithm and Its Application in 3D Geological Modeling. Sustainability 2023, 15, 7214. https://doi.org/10.3390/su15097214

He L, Li X, Lei S, Bi B, Chen S. A Front Advancing Adaptive Triangular Mesh Dynamic Generation Algorithm and Its Application in 3D Geological Modeling. Sustainability. 2023; 15(9):7214. https://doi.org/10.3390/su15097214

Chicago/Turabian StyleHe, Liang, Xiaoqing Li, Shaohua Lei, Bo Bi, and Suozhong Chen. 2023. "A Front Advancing Adaptive Triangular Mesh Dynamic Generation Algorithm and Its Application in 3D Geological Modeling" Sustainability 15, no. 9: 7214. https://doi.org/10.3390/su15097214

APA StyleHe, L., Li, X., Lei, S., Bi, B., & Chen, S. (2023). A Front Advancing Adaptive Triangular Mesh Dynamic Generation Algorithm and Its Application in 3D Geological Modeling. Sustainability, 15(9), 7214. https://doi.org/10.3390/su15097214