SDGs in the EU Steel Sector: A Critical Review of Sustainability Initiatives and Approaches

Abstract

1. Introduction

- Evaluate the status of activities related to the sustainability of the steel sector.

- Identify points of strength and weakness.

- Attempt to identify future directions for improvements.

ESTEP

2. The EU Steel-Making Context for SDGs and Sustainability

2.1. Main Sustainability Issues in the Steel Sector

- Home scraps: scraps that are internally generated in the steel production process and are consumed within the factory gate.

- New scraps: scraps generated by manufacturers of steel-containing products are transported from scrap dealers and, therefore, are likely to contain residuals.

- Old scraps: this is the highest share of scraps and comes from end-of-life of products that entered service (e.g., vehicles, buildings and infrastructure). This kind of scrap has an embodied product life.

2.2. The SDGs and Sustainability Approaches in the Steel Industry

2.3. Quantification Approaches for Sustainability

- Scope 1: Direct GHG emissions occur from sources that are owned or controlled by the company.

- Scope 2: This accounts for GHG emissions from the generation of purchased electricity consumed by the company.

- Scope 3: This is an optional reporting category that allows for the treatment of all other indirect emissions, such as the consequences of the activities of the company but occur from sources not owned or controlled by the company.

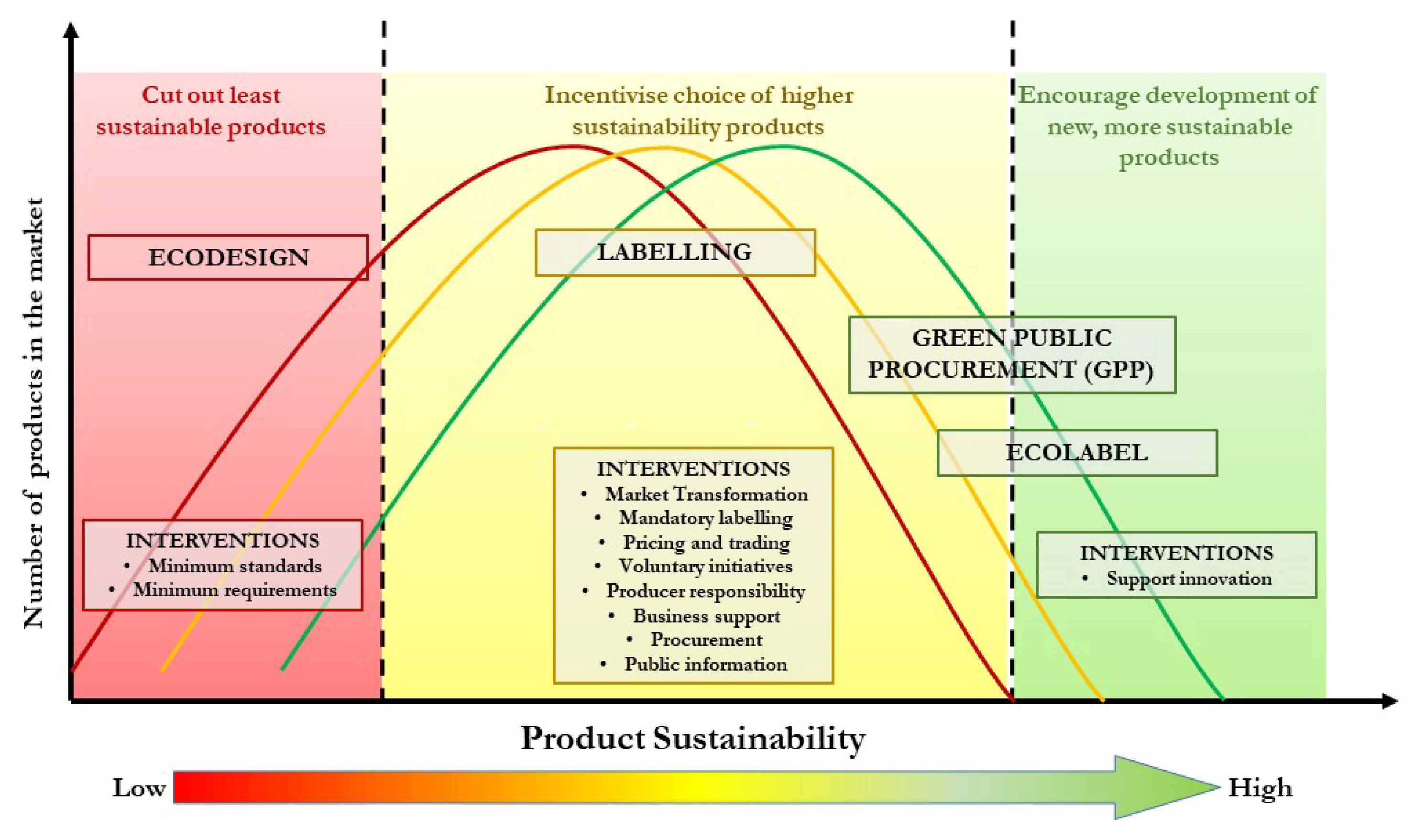

2.4. Main EU Policy Schemes and Initiatives

- Waste Framework Directive: Steel promotes measures to reuse products, reduce waste generation and increase preparation for reuse.

- Waste Shipment Regulation: it tackles illegal shipments of wastes to countries with more forgiving waste policies supported by well-defined procedures and audits to avoid these shortcuts.

- End-of-Life Vehicles (ELV): it represents a crucial, partially untapped scrap source for secondary steel-making, expanding the quantity of material that can be utilised.

- Regulation of Ecodesign requirements for sustainable and green products: the complexity of the definition about what sustainable and green mean and related terms allow space for several implications; therefore, proposals for more stringent definitions must be found.

- Industrial Emissions Directive (IED): leaning on the EU green deal framework, it tackles the theme of emissions. Further revisions of the Directive must integrate together multiple SDGs to achieve a comprehensive view of the topic.

- Develop technologies reducing CO2 emissions from steel production by 50% by 2030.

- Develop deployable technologies that can reduce CO2 by 80–95% by 2050, ultimately achieving climate neutrality and Technology Readiness Level (TRL) 8.

3. Initiatives in the Steel Sector

3.1. Roadmapping

- Step up: An important strategic programme to improve the efficiency of mill operations through the following:

- 1.1.

- Optimal raw material selection and use.

- 1.2.

- Increasing energy efficiency and minimising waste.

- 1.3.

- Improving yield.

- 1.4.

- Improving process reliability.

- Maximisation of scrap usage: In this way, the BF/BOF path will slowly leave space for a wider diffusion of the EAF path.

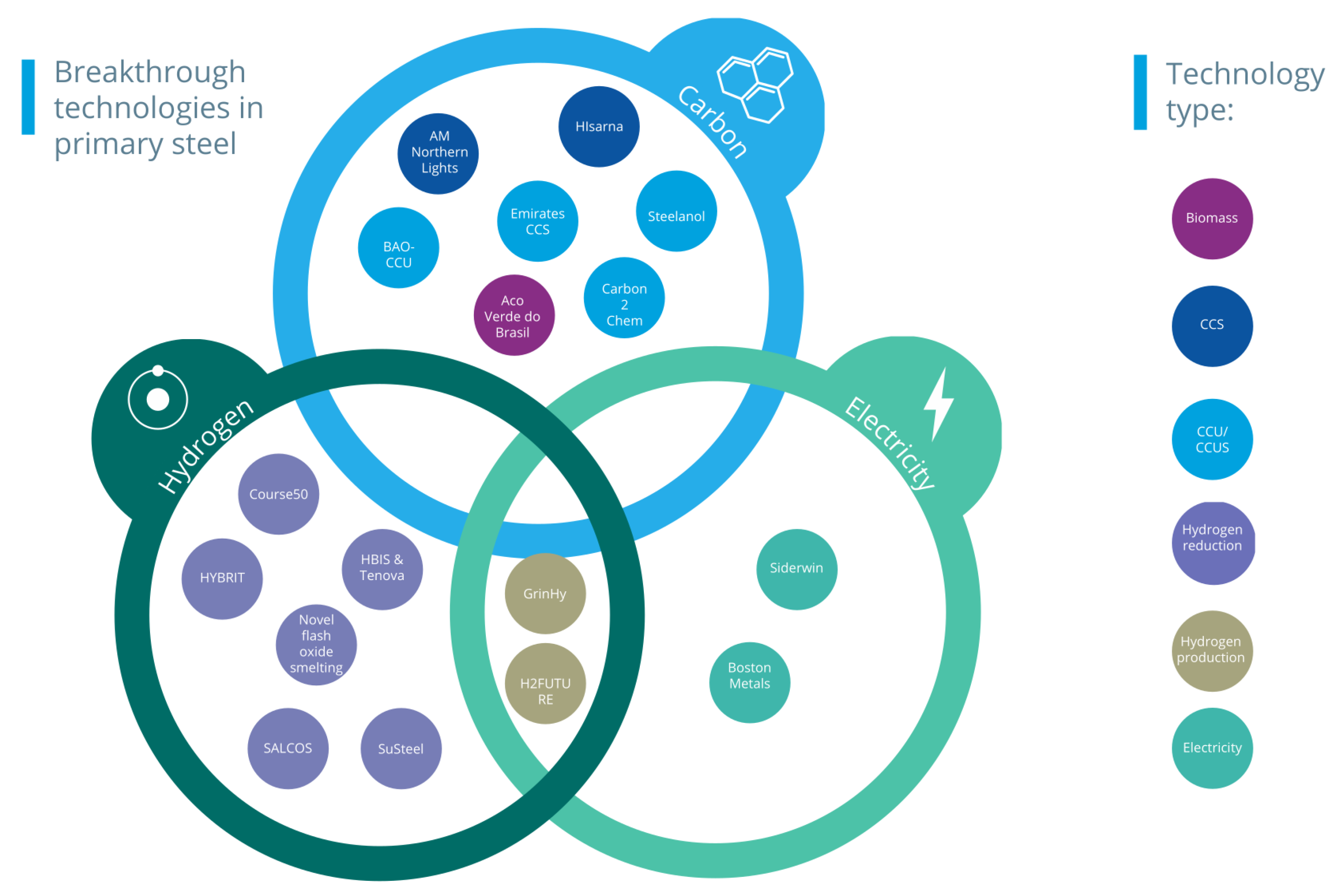

- Use of breakthrough technology:

- 3.1.

- Use of carbon as a reducing agent and preventing CO2 fossil emissions using carbon capture and utilization (CCU)/carbon capture and storage (CCS) and/or sustainable biomass (e.g., biocharcoal) [91].

- 3.2.

- Substitute hydrogen for carbon as a reducing agent, producing, in this way, H2O instead of CO2.

- 3.3.

- Use of electricity through an electrolysis-based process.

3.2. Labelling and Claiming

- Type I—environmental labels: applied for ecolabelling schemes in which the product criteria are clearly defined (e.g., Nordic Swan, EU Ecolabel and Blue Angel) and regulated by ISO 14024. An ecolabel identifies products or services proven to be environmentally preferable within a specific category.

- Type II—Self-declared environmental claims: labels made by the manufacturers themselves where there are neither criteria or labelling schemes (compostability and recyclability). Regulated by ISO 14021.

- Type III—Environmental declarations: labels produced using a life cycle approach through specific programs managed by dedicated organizations (Environmental Product Declaration (EPD)) and regulated by ISO 14025.

3.3. Reporting and Initiatives

- Life cycle data, including the results of LCA analysis for different impact categories or single ones.

- Data about the best practices or internal policies of companies in terms of specific projects (e.g., European frontiers projects or internal projects).

- Environmental and social claims supported by real data and compared with specific targets, such as SDGs.

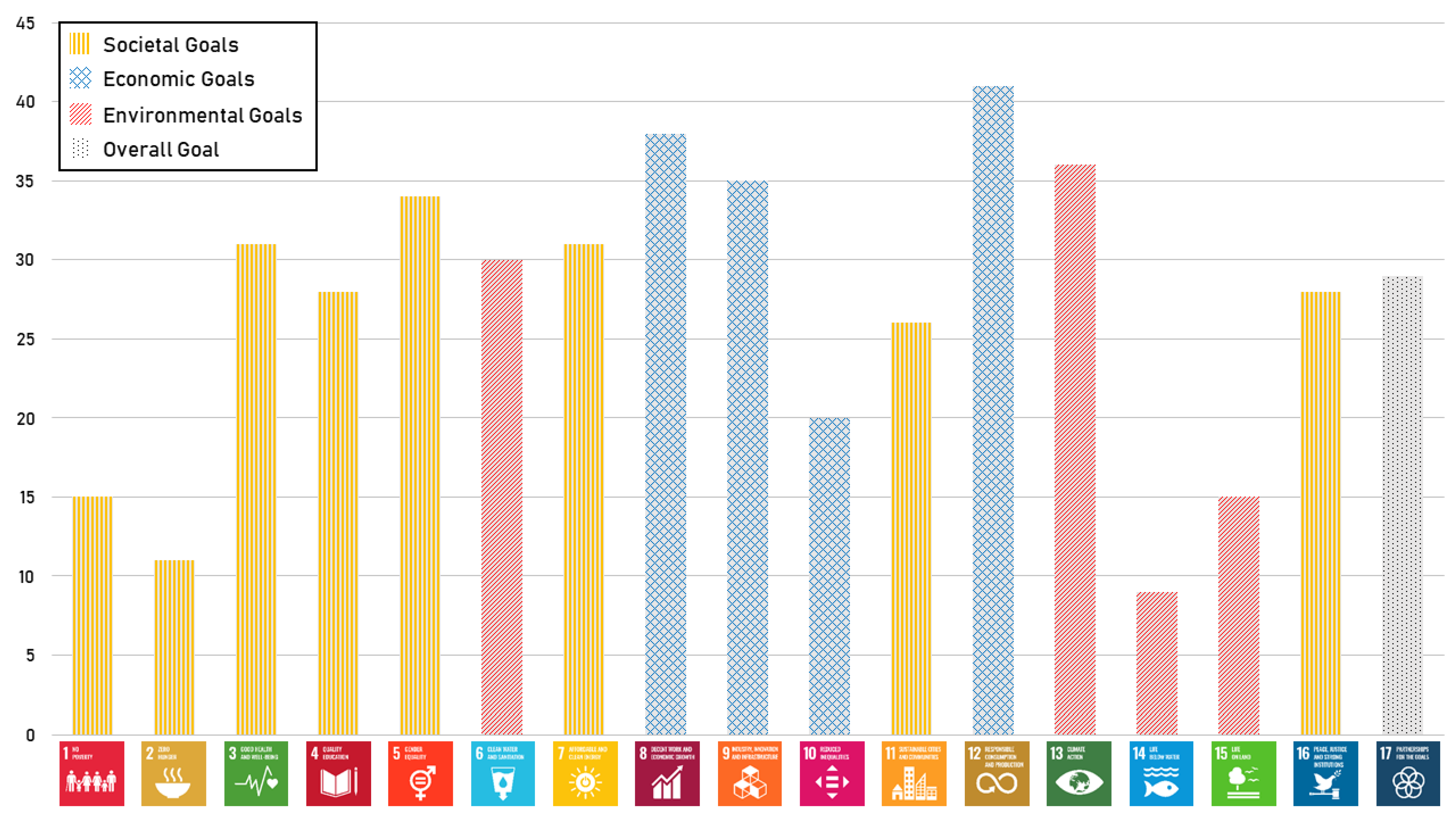

- Goal 3—Good Health and Well-Being: through the decarbonization of the steel industry, CSP aims to contribute to the reducing the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination.

- Goal 8—Decent Work and Economic Growth: additional circularity of materials and improved productivity and efficiency in steel-making contribute to sustainable growth and better working conditions.

- Goal 9—Industry, Innovation and Infrastructure: technical developments in the steel sector bring huge potentials for less resource-intensive infrastructure solutions and contribute to the transformative innovation in other industrial sectors, leading to growth, high-value technology, innovation and resource efficiency.

- Goal 12—Responsible Consumption and Production: the enhancement of circularity in the steel industry contributes to the promotion of responsible consumption and production patterns.

- Goal 13—Climate Action: CSP will facilitate research, development and demonstration of technologies that eliminate CO2 emissions in the steel sector.

- Science-Based Target initiative (SBTi) [116]: This is a partnership between Carbon Disclosure Project (CDP), the United Nations Global Compact, World Resources Institute (WRI) and the World Wide Fund for Nature (WWF). Its main scope is related to climate through the definition of a path to reduce emissions in line with the Paris Agreement goals. The steel sector has a dedicated path that is currently under development due to different stakeholders’ support. The focus of SBTi is on the operation phase.

- Energy Transitions Commission (ETC): This is “a global coalition of leaders from across the energy landscape committed to achieving net-zero emissions by mid-century”, in line with the Paris climate objectives. The aim is to develop potential roadmaps for operational activities to support different sectors. Within these roadmaps, ETC aims to merge different methodologies, initiatives and corporate targets.

- Responsible Steel: this initiative focuses on steel aiming to define and promote responsible practices in different phases (i.e., sourcing, operations and products). In addition to the standards, they also produce a certification verifying compliance with the program.

- Centre for Climate-Aligned Finance: The focus is on the financial sector to help high-emitting sectors to overcome decarbonisation barriers. The development of the IMPACT+ Principles for Climate-Aligned Finance aims to support the private financial institutions in the identification of strategies aligned with sustainability targets.

- Operations: a review of the requirements for companies to report and disclose emissions through the EU Pollutant Release and Transfer Register (E-PRTR).

- Products: with the support of proper digitalisation tools, it is possible to include environmental performance aspects, tracked in several ways, such as LCA or the carbon footprint in a product in the framework of the Sustainable Products Initiative and Digital Product Passport.

3.4. Innovation

4. Discussion

4.1. General Outcomes

4.2. Specific Issues for Sustainability Implementation

- Availability of renewable energy: Several initiatives rely on the foreseen availability of a huge quantity of renewable energy (210–355 TWh according to the report of Material economics [13] and over 350 TWh following for the Joint Research Center (JRC) and the European Commission [88]); however, first, while writing this, there is no such availability, and, secondly, the associated cost is not competitive compared to fossil-based electricity. One of the key challenges will be ensuring the availability of this clean energy (wind, solar and hydro) and ensuring its stability through accumulators to avoid potential blackout of the lines if adverse conditions or situations occur.

- Carbon capture usage and storage (CCU, CCS and CCUS): the technology for carbon capture actually can only act on a small share of the emissions that distinguish the steel-making process. Ref. [5] infers that, “in the Sustainable Development Scenario the iron and steel sector is projected to cumulatively capture 3.5 Gt CO2 of its direct emissions by 2050, i.e., 6% of total direct emissions generated in the sector from 2020 until 2050”. One of the main constraints is linked to differences in deploying these technologies at different geographic locations and the high costs associated with the development and utilization [98].Another critical aspect is related to the efficiency of such technologies related to carbon capture that perform reasonably well if directly linked to the steel-making process. However, extensive process modifications are required [88] and with lower performance for free air carbon sequestration. The usage in other sectors of the CO2 captured may reduce emissions related to its production by dedicated producers giving value to a by-product of the steel-making process. However, a significant investment in developing the necessary infrastructure for adopting industrial symbiosis solutions are required to optimize these exchanges further.

- High-quality steel scrap: one of the conditions to reduce the primary steel production (and, therefore, the associated impacts) relies upon the availability of scraps characterized by their reuse in sectors extremely demanding from the quality point of view. Due to the longevity of steel, its availability from decommissioned infrastructures, buildings and vehicles is limited. It may not satisfy standard requirements when reused due to several aspects, such as corrosion, new types of alloys utilized or impurities. Scraps are usually down-cycled to lower quality steel keeping the demand for primary steel high [88]. According to [95], in 2020, the proportion of steel scrap used in the EU’s crude steel production was 55.7% with a significant difference compared to China, the world’s largest steel scrap user, whose share was 20.7%.

- Green market: products that take into consideration sustainability aspects usually also have higher costs and, therefore, embody a competitive disadvantage. Based on this, products of companies that invest on specific projects or initiatives aiming at sustainability in different aspects should be safeguarded by specific policies, such as the ones already in place (e.g., CBAM and ETS market) provided that the requirements are feasible and agreed within the stakeholders and not only imposed. This situation may arise if policies are integrated or changed over the years in response to modified factors and conditions setting more ambitious goals with a stricter deadline.

- Funding and associated costs: the research on new technologies, the investments in the building of new factories, ensuring tracking of the different raw materials and sources of energies and better safety and occupational conditions of workers involve high costs. Private initiatives as part of the R&D department of companies are one of the main activities to find new applications and methodologies but, real effective substitution and game changer technologies require firm commitments, substantial funding and collaboration between different entities (companies, RTOs, universities and public bodies).Therefore, relying on all the initiatives of private sector cannot be feasible both for the utmost importance for the steel sector in the EU (and worldwide) both in terms of production and direct and indirect employment and for the amounts required to follow the development of specific technologies from a low TRL level to practical application. Moreover, another important aspect is related to the long development time required (even 20–30 years) for most technologies. Companies’ decisions and initiatives cannot rely only on private funds that are susceptible to market dynamics (e.g., global crises in the last few years) as this can lead to interruptions in the development. A similar argument was recently proposed for the deployment of large-scale CCS in the Netherlands, claiming a leading role for governments [119].

- Public policies and regulations: several directives, regulations and laws are spreading both in the national and international spheres with ambitious targets, especially in terms of reducing GHG emissions to tackle IPCC objectives (e.g., the Green New Deal and Fit for 55), enhancing the availability and share of renewable energy in EU market. However, a critical aspect is the feasibility of the target defined especially when modified over the years toward more ambitious ones (e.g., switching from 2030 and 2040 as important dates to 2025 and 2035 [98]. The urgency of taking practical actions identified by public bodies should be complemented by discussions with the sectors involved in substantial modifications not to take the risk of companies’ negative impact. Sustainability comprises three pillars, and every policy aimed to embrace this term must consider and consider all these.

5. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roy, K.; Dani, A.A.; Ichhpuni, H.; Fang, Z.; Lim, J.B.P. Improving Sustainability of Steel Roofs: Life Cycle Assessment of a Case Study Roof. Appl. Sci. 2022, 12, 5943. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Meadows, D.H.; Meadows, D.L.; Randers, J.; Behrens, W.W., III. The Limits to Growth. A Report for the Club of Rome’s Project on the Predicament of Mankind; Universe Books: New York, NY, USA, 1972. [Google Scholar]

- Eurofer. European Steel in Figures; Technical Report; Eurofer: Brussels, Belgium, 2022. [Google Scholar]

- International Energy Agency. Iron and Steel Technology Roadmap—Towards More Sustainable Steelmaking; International Energy Agency: Paris, France, 2020; p. 190. [Google Scholar]

- Kim, J.; Sovacool, B.K.; Bazilian, M.; Griffiths, S.; Lee, J.; Yang, M.; Lee, J. Decarbonizing the iron and steel industry: A systematic review of sociotechnical systems, technological innovations, and policy options. Energy Res. Soc. Sci. 2022, 89, 102565. [Google Scholar] [CrossRef]

- Cormos, C.C. Evaluation of reactive absorption and adsorption systems for post-combustion CO2 capture applied to iron and steel industry. Appl. Therm. Eng. 2016, 105, 56–64. [Google Scholar] [CrossRef]

- Association, W.S. Steel’s Contribution to a Low Carbon Future and Climate Resilient Societies; World Steel Association: Brussels, Belgium, 2020; pp. 1–6. [Google Scholar]

- Conejo, A.N.; Birat, J.P.; Dutta, A. A review of the current environmental challenges of the steel industry and its value chain. J. Environ. Manag. 2020, 259, 109782. [Google Scholar] [CrossRef] [PubMed]

- Shatokha, V. Post-Soviet issues and sustainability of iron and steel industry in Eastern Europe. Miner. Process. Extr. Metall. 2017, 126, 62–69. [Google Scholar] [CrossRef]

- International Iron and Steel Institute; United Nations Environment Programme. Iron and Steel: A Report; United Nations Digital Library: Paris, France, 2002. [Google Scholar]

- The World Steel Association. Climate Change and the Production of Iron and Steel: An Industry View. 2021. Available online: https://worldsteel.org/wp-content/uploads/Climate-and-the-production-of-iron-and-steel-presentation-2021_Asa-Ekdahl-2.pdf?x25904 (accessed on 4 November 2022).

- Material Economics. Industrial Transformation 2050—Pathways to Net-Zero Emissions from EU Heavy Industry; Technical Report; Material Economics: Stockholm, Sweden, 2019. [Google Scholar]

- Yellishetty, M.; Mudd, G.M.; Ranjith, P.; Tharumarajah, A. Environmental life-cycle comparisons of steel production and recycling: Sustainability issues, problems and prospects. Environ. Sci. Policy 2011, 14, 650–663. [Google Scholar] [CrossRef]

- American Iron and Steel Institute and Steel Manufacturers Association. Determination of Steel Recycling Rates in the United States; Technical Report; American Iron and Steel Institute and Steel Manufacturers Association: Washington, DC, USA, 2021. [Google Scholar]

- Lee, B.; Sohn, I. Review of innovative energy savings technology for the electric arc furnace. JOM 2014, 66, 1581–1594. [Google Scholar] [CrossRef]

- Gao, C.; Wang, D.; Dong, H.; Cai, J.; Zhu, W.; Du, T. Optimization and evaluation of steel industry’s water-use system. J. Clean. Prod. 2011, 19, 64–69. [Google Scholar] [CrossRef]

- Zhang, S.; Worrell, E.; Crijns-Graus, W.; Wagner, F.; Cofala, J. Co-benefits of energy efficiency improvement and air pollution abatement in the Chinese iron and steel industry. Energy 2014, 78, 333–345. [Google Scholar] [CrossRef]

- Mele, M.; Magazzino, C. A Machine Learning analysis of the relationship among iron and steel industries, air pollution, and economic growth in China. J. Clean. Prod. 2020, 277, 123293. [Google Scholar] [CrossRef]

- Xu, F.; Cui, F.; Xiang, N. Roadmap of green transformation for a steel-manufacturing intensive city in China driven by air pollution control. J. Clean. Prod. 2021, 283, 124643. [Google Scholar] [CrossRef]

- Geny, P.; Dohen, E. Measures against water pollution in the iron and steel industry. Pure Appl. Chem. 1972, 29, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Bramer, H.C. Pollution control in the steel industry. Environ. Sci. Technol. 1971, 5, 1004–1008. [Google Scholar] [CrossRef]

- Proctor, D.M.; Shay, E.C.; Fehling, K.A.; Finley, B.L. Assessment of Human Health and Ecological Risks Posed by the Uses of Steel-Industry Slags in the Environment. Hum. Ecol. Risk Assess. Int. J. 2002, 8, 681–711. [Google Scholar] [CrossRef]

- Qing, X.; Yutong, Z.; Shenggao, L. Assessment of heavy metal pollution and human health risk in urban soils of steel industrial city (Anshan), Liaoning, Northeast China. Ecotoxicol. Environ. Saf. 2015, 120, 377–385. [Google Scholar] [CrossRef]

- Tavakoli, H.; Azari, A.; Ashrafi, K.; Salimian, M.; Momeni, M. Human health risk assessment of arsenic downstream of a steel plant in Isfahan, Iran: A case study. Int. J. Environ. Sci. Technol. 2020, 17, 81–92. [Google Scholar] [CrossRef]

- Jeong, K.; Ji, C.; Kim, H.; Hong, T.; Cho, K.; Lee, J. An integrated assessment of the environmental, human health, and economic impacts based on life cycle assessment: A case study of the concrete and steel sumps. J. Clean. Prod. 2019, 239, 118032. [Google Scholar] [CrossRef]

- Elkington, J. Towards the Sustainable Corporation: Win-Win-Win Business Strategies for Sustainable Development. Calif. Manag. Rev. 1994, 36, 90–100. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Wu, J.; Pu, G.; Ma, Q.; Qi, H.; Wang, R. Quantitative environmental risk assessment for the iron and steel industrial symbiosis network. J. Clean. Prod. 2017, 157, 106–117. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Fujita, T.; Ohnishi, S.; Li, H.; Fujii, M.; Dong, H. Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J. Clean. Prod. 2013, 59, 226–238. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and Recycling of By-Products in the Steel Sector: Recent Achievements Paving the Way to Circular Economy and Industrial Symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef]

- Bleischwitz, R.; Hoff, H.; Spataru, C.; Van der Voet, E.; VanDeveer, S.D. Routledge Handbook of the Resource Nexus; Routledge: Abingdon, UK, 2018. [Google Scholar]

- Bleischwitz, R.; Spataru, C.; VanDeveer, S.D.; Obersteiner, M.; van der Voet, E.; Johnson, C.; Andrews-Speed, P.; Boersma, T.; Hoff, H.; van Vuuren, D.P. Resource nexus perspectives towards the United Nations Sustainable Development Goals. Nat. Sustain. 2018, 1, 737–743. [Google Scholar] [CrossRef]

- Hoff, H. Understanding the Nexus; Stockholm Environment Institute: Stockholm, Sweden, 2011. [Google Scholar]

- Andrews-Speed, P.; Bleischwitz, R.; Boersma, T.; Johnson, C.; Kemp, G.; VanDeveer, S.D. The Global Resource Nexus: The Struggles for Land, Energy, Food, Water, and Minerals; Transatlantic Academy: Washington, DC, USA, 2012. [Google Scholar]

- Andrews-Speed, P.; Bleischwitz, R.; Boersma, T.; Johnson, C.; Kemp, G.; VanDeveer, S.D. Want, Waste or War? The Global Resource Nexus and the Struggle for Land, Energy, Food, Water and Minerals; Routledge: London, UK, 2014. [Google Scholar]

- Liu, J.; Mooney, H.; Hull, V.; Davis, S.J.; Gaskell, J.; Hertel, T.; Lubchenco, J.; Seto, K.C.; Gleick, P.; Kremen, C.; et al. Systems integration for global sustainability. Science 2015, 347, 1258832. [Google Scholar] [CrossRef] [PubMed]

- Tsalis, T.A.; Malamateniou, K.E.; Koulouriotis, D.; Nikolaou, I.E. New challenges for corporate sustainability reporting: United Nations’ 2030 Agenda for sustainable development and the sustainable development goals. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1617–1629. [Google Scholar] [CrossRef]

- Johnsson, F.; Karlsson, I.; Rootzén, J.; Ahlbäck, A.; Gustavsson, M. The framing of a sustainable development goals assessment in decarbonizing the construction industry—Avoiding “Greenwashing”. Renew. Sustain. Energy Rev. 2020, 131, 110029. [Google Scholar] [CrossRef]

- Kornieieva, Y. Non-financial Reporting Challenges in Monitoring SDG`s Achievement: Investment Aspects for Transition Economy. Int. J. Econ. Bus. Adm. 2020, VIII, 62–71. [Google Scholar] [CrossRef]

- Hatayama, H. The metals industry and the Sustainable Development Goals: The relationship explored based on SDG reporting. Resour. Conserv. Recycl. 2022, 178, 106081. [Google Scholar] [CrossRef]

- Long, Y.; Pan, J.; Farooq, S.; Boer, H. A sustainability assessment system for Chinese iron and steel firms. J. Clean. Prod. 2016, 125, 133–144. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.; Gupta, S.; Dikshit, A. Development of composite sustainability performance index for steel industry. Ecol. Indic. 2007, 7, 565–588. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.C.; van Erck, R.P. Assessing the sustainability performances of industries. J. Clean. Prod. 2005, 13, 373–385. [Google Scholar] [CrossRef]

- Schrettle, S.; Hinz, A.; Scherrer -Rathje, M.; Friedli, T. Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance. Int. J. Prod. Econ. 2014, 147, 73–84. [Google Scholar] [CrossRef]

- Strezov, V.; Evans, A.; Evans, T. Defining sustainability indicators of iron and steel production. J. Clean. Prod. 2013, 51, 66–70. [Google Scholar] [CrossRef]

- Fruehan, R.J. Research on Sustainable Steelmaking. Metall. Mater. Trans. B 2009, 40, 123–133. [Google Scholar] [CrossRef]

- Heijungs, R.; Suh, S. The Computational Structure of Life Cycle Assessment; Springer: Dordrecht, The Netherlands, 2002. [Google Scholar] [CrossRef]

- Roos, S.; Zamani, B.; Sandin, G.; Peters, G.M.; Svanström, M. A life cycle assessment (LCA)-based approach to guiding an industry sector towards sustainability: The case of the Swedish apparel sector. J. Clean. Prod. 2016, 133, 691–700. [Google Scholar] [CrossRef]

- BS EN ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. Technical Report. British Standards Institute: London, UK, 2006.

- BS EN ISO 14044:2006+A1:2018; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Technical Report. British Standards Institute: London, UK, 2018.

- Backes, J.G.; Suer, J.; Pauliks, N.; Neugebauer, S.; Traverso, M. Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability 2021, 13, 3443. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Ramli, M.Z. A comparative life cycle assessment (LCA) of concrete and steel-prefabricated prefinished volumetric construction structures in Malaysia. Environ. Sci. Pollut. Res. 2020, 27, 43186–43201. [Google Scholar] [CrossRef] [PubMed]

- Burchart-Korol, D. Life cycle assessment of steel production in Poland: A case study. J. Clean. Prod. 2013, 54, 235–243. [Google Scholar] [CrossRef]

- Burchart-Korol, D. Significance of environmental life cycle assessment (LCA) method in the iron and steel industry. Metalurgija 2011, 50, 205–208. [Google Scholar]

- Buyle, M.; Maes, B.; Van Passel, S.; Boonen, K.; Vercalsteren, A.; Audenaert, A. Ex-ante LCA of emerging carbon steel slag treatment technologies: Fast forwarding lab observations to industrial-scale production. J. Clean. Prod. 2021, 313, 127921. [Google Scholar] [CrossRef]

- Chisalita, D.A.; Petrescu, L.; Cobden, P.; van Dijk, H.E.; Cormos, A.M.; Cormos, C.C. Assessing the environmental impact of an integrated steel mill with post-combustion CO2 capture and storage using the LCA methodology. J. Clean. Prod. 2019, 211, 1015–1025. [Google Scholar] [CrossRef]

- Chubbs, S.T.; Steiner, B.A. Life cycle assessment in the steel industry. Environ. Prog. 1998, 17, 92–95. [Google Scholar] [CrossRef]

- Dlamini, N.G.; Fujimura, K.; Yamasue, E.; Okumura, H.; Ishihara, K.N. The environmental LCA of steel vs. HDPE car fuel tanks with varied pollution control. Int. J. Life Cycle Assess. 2011, 16, 410–419. [Google Scholar] [CrossRef]

- Gul, E.; Riva, L.; Nielsen, H.K.; Yang, H.; Zhou, H.; Yang, Q.; Skreiberg, Ø.; Wang, L.; Barbanera, M.; Zampilli, M.; et al. Substitution of coke with pelletized biocarbon in the European and Chinese steel industries: An LCA analysis. Appl. Energy 2021, 304, 117644. [Google Scholar] [CrossRef]

- Norgate, T.E.; Jahanshahi, S.; Rankin, W.J. Alternative Routes to Stainless Steel—A Life Cycle Approach; Document Transformation Technologies: Cape Town, South Africa, 2004; pp. 1–4. [Google Scholar]

- Rovelli, D.; Brondi, C.; Andreotti, M.; Abbate, E.; Zanforlin, M.; Ballarino, A. A Modular Tool to Support Data Management for LCA in Industry: Methodology, Application and Potentialities. Sustainability 2022, 14, 3746. [Google Scholar] [CrossRef]

- Xing, S.; Xu, Z.; Jun, G. Inventory analysis of LCA on steel- and concrete-construction office buildings. Energy Build. 2008, 40, 1188–1193. [Google Scholar] [CrossRef]

- Yingjun, H.; Zheng, Z.; Suqin, L.; Daqiang, C. A Case Study of LCA for Environmental Protection in Steel Company. In Proceedings of the 2012 Third International Conference on Digital Manufacturing & Automation, Guilin, China, 31 July–2 August 2012; pp. 13–16. [Google Scholar] [CrossRef]

- Ma, X.; Ye, L.; Qi, C.; Yang, D.; Shen, X.; Hong, J. Life cycle assessment and water footprint evaluation of crude steel production: A case study in China. J. Environ. Manag. 2018, 224, 10–18. [Google Scholar] [CrossRef]

- Worldsteel. Sustainability Indicators 2021 Report; Technical Report; Worldsteel: Brussels, Belgium, 2021. [Google Scholar]

- Eurofer. Annual Report 2022; Technical report; Eurofer: Brussels, Belgium, 2022. [Google Scholar]

- Chesnokov, Y.N.; Lisienko, V.G.; Lapteva, A.V. Evaluating the Carbon Footprint from the Production of Steel in an Electric-Arc Furnace. Metallurgist 2014, 57, 774–778. [Google Scholar] [CrossRef]

- Qi, Z.; Gao, C.; Na, H.; Ye, Z. Using forest area for carbon footprint analysis of typical steel enterprises in China. Resour. Conserv. Recycl. 2018, 132, 352–360. [Google Scholar] [CrossRef]

- Suer, J.; Traverso, M.; Ahrenhold, F. Carbon footprint of scenarios towards climate-neutral steel according to ISO 14067. J. Clean. Prod. 2021, 318, 128588. [Google Scholar] [CrossRef]

- Suer, J.; Ahrenhold, F.; Traverso, M. Carbon Footprint and Energy Transformation Analysis of Steel Produced via a Direct Reduction Plant with an Integrated Electric Melting Unit. J. Sustain. Metall. 2022, 8, 1532–1545. [Google Scholar] [CrossRef]

- BS EN ISO 14067; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification and Communication. Technical Report. British Standards Institute: London, UK, 2018.

- World Resources Institute (WRI); World Business Council on Sustainable Development (WBCSD). Product Life Cycle Accounting and Reporting Standard. Technical Report; Green House Gas Protocol. 2011. Available online: https://ghgprotocol.org/ (accessed on 22 February 2023).

- Ranganathan, J.; Bhatia, P. The Greenhouse Gas Protocol: A Corporate Accounting and Reporting Standard, Revised Edition; Technical Report; Green House Gas Protocol. 2004. Available online: https://ghgprotocol.org/ (accessed on 22 February 2023).

- Martin, O. Sustainability Report 2021. Available online: https://www.orimartin.it/public/download/ORI_Martin_Bilancio_di_Sostenibilit%C3%A0_2021.pdf (accessed on 4 November 2022).

- voestalpine. Corporate Responsibility Report 2021/22. Available online: https://reports.voestalpine.com/2022/cr-report/environment/air-emissions.html (accessed on 4 November 2022).

- Outokumpu. Outokumpu Sustainability Data on Climate Change. 2022. Available online: https://www.outokumpu.com/en/sustainability/reporting-and-data/sustainability-data/climate-change (accessed on 4 November 2022).

- TUV India. Tata Steel—Greenhouse Gases Verification. 2021. Available online: https://www.tatasteel.com/media/14071/ghg-verification-statement-tata-steel-group-fy21.pdf (accessed on 4 November 2022).

- Apple. Apple-Environmental Progress Report 2021. 2022. Available online: https://www.apple.com/environment/pdf/Apple_Environmental_Progress_Report_2021.pdf (accessed on 4 November 2022).

- Huawei. Sustainability Report 2021. 2022. Available online: https://www-file.huawei.com/-/media/corp2020/pdf/sustainability/sustainability-report-2021-en.pdf (accessed on 4 November 2022).

- Enel. Sustainability Report 2021. 2022. Available online: https://www.enel.com/content/dam/enel-com/documenti/investitori/sostenibilita/2021/sustainability-report_2021.pdf (accessed on 4 November 2022).

- Ferrero. Sustainability Report 2021. 2022. Available online: https://www.ferrerosustainability.com/int/sites/ferrerosustainability_int/files/2022-07/ferrero_book_1307_interactive-compressed.pdf (accessed on 4 November 2022).

- Unilever. Annual Report and Accounts 2021. 2022. Available online: https://www.unilever.com/files/92ui5egz/production/e582e46a7f7170fd10be32cf65113b738f19f0c2.pdf (accessed on 4 November 2022).

- Gu, Y.; Xu, J.; Keller, A.A.; Yuan, D.; Li, Y.; Zhang, B.; Weng, Q.; Zhang, X.; Deng, P.; Wang, H.; et al. Calculation of water footprint of the iron and steel industry: A case study in Eastern China. J. Clean. Prod. 2015, 92, 274–281. [Google Scholar] [CrossRef]

- Nezamoleslami, R.; Hosseinian, S.M. Data needed for assessing water footprint of steel production. Data Brief 2020, 30, 105461. [Google Scholar] [CrossRef]

- Mattila, H.P.; Hudd, H.; Zevenhoven, R. Cradle-to-gate life cycle assessment of precipitated calcium carbonate production from steel converter slag. J. Clean. Prod. 2014, 84, 611–618. [Google Scholar] [CrossRef]

- Vögele, S.; Grajewski, M.; Govorukha, K.; Rübbelke, D. Challenges for the European steel industry: Analysis, possible consequences and impacts on sustainable development. Appl. Energy 2020, 264, 114633. [Google Scholar] [CrossRef]

- European Commission. Joint Research Centre. Technologies to Decarbonise the EU Steel Industry; European Commission, Joint Research Centre Publications Office: Luxembourg, 2022. [Google Scholar]

- Stede, J.; Pauliuk, S.; Hardadi, G.; Neuhoff, K. Carbon pricing of basic materials: Incentives and risks for the value chain and consumers. Ecol. Econ. 2021, 189, 107168. [Google Scholar] [CrossRef]

- ESTEP. Clean Steel Partnership—Strategic Research and Innovation Agenda (SRIA). 2021. Available online: https://www.estep.eu/assets/CleanSteelMembersection/CSP-SRIA-Oct2021-clean.pdf (accessed on 15 January 2023).

- Kieush, L.; Rieger, J.; Schenk, J.; Brondi, C.; Rovelli, D.; Echterhof, T.; Cirilli, F.; Thaler, C.; Jaeger, N.; Snaet, D.; et al. A Comprehensive Review of Secondary Carbon Bio-Carriers for Application in Metallurgical Processes: Utilization of Torrefied Biomass in Steel Production. Metals 2022, 12, 2005. [Google Scholar] [CrossRef]

- Abbate, E.; Mirpourian, M.; Brondi, C.; Ballarino, A.; Copani, G. Environmental and Economic Assessment of Repairable Carbon-Fiber-Reinforced Polymers in Circular Economy Perspective. Materials 2022, 15, 2986. [Google Scholar] [CrossRef]

- European Commission. Joint Research Centre. Raw Materials Demand for Wind and Solar PV Technologies in the Transition towards a Decarbonised Energy System; Publications Office: European Commission, Joint Research Centre Publications Office: Luxembourg, 2020. [Google Scholar]

- Allwood, J.M. Transitions to material efficiency in the UK steel economy. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2013, 371, 20110577. [Google Scholar] [CrossRef]

- Bureau of International Recycling—Ferrous Division. World Steel Recycling in Figures 2016–2020; Technical Report. 2021. Available online: https://www.bir.org/publications/facts-figures/download/821/175/36?method=view (accessed on 22 February 2023).

- Emi, T. Optimizing Steelmaking System for Quality Steel Mass Production for Sustainable Future of Steel Industry. Steel Res. Int. 2014, 85, 1274–1282. [Google Scholar] [CrossRef]

- Directorate-General for research and innovation; Rossetti di Valdalbero, D.; Lucas, N. European Steel: The Wind of Change: Energy in Future Steelmaking, Steel in the Energy Market Applications, Greening European Steel; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- European Commission; European Research Executive Agency; Green Steel for Europe. Climate-Neutral Steelmaking in Europe: Decarbonisation Pathways, Investment Needs, Policy Conditions, Recommendations; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Gielen, D.; Saygin, D.; Taibi, E.; Birat, J. Renewables-based decarbonization and relocation of iron and steel making: A case study. J. Ind. Ecol. 2020, 24, 1113–1125. [Google Scholar] [CrossRef]

- Lee, H.; Sohn, I. Global Scrap Trading Outlook Analysis for Steel Sustainability. J. Sustain. Metall. 2015, 1, 39–52. [Google Scholar] [CrossRef]

- Pan, H.; Zhang, X.; Wu, J.; Zhang, Y.; Lin, L.; Yang, G.; Deng, S.; Li, L.; Yu, X.; Qi, H.; et al. Sustainability evaluation of a steel production system in China based on emergy. J. Clean. Prod. 2016, 112, 1498–1509. [Google Scholar] [CrossRef]

- Rieger, J.; Colla, V.; Matino, I.; Branca, T.A.; Stubbe, G.; Panizza, A.; Brondi, C.; Falsafi, M.; Hage, J.; Wang, X.; et al. Residue Valorization in the Iron and Steel Industries: Sustainable Solutions for a Cleaner and More Competitive Future Europe. Metals 2021, 11, 1202. [Google Scholar] [CrossRef]

- Shatokha, V. Environmental Sustainability of the Iron and Steel Industry: Towards reaching the climate goals. Eur. J. Sustain. Dev. 2016, 5, 289–300. [Google Scholar] [CrossRef]

- Yellishetty, M.; Ranjith, P.; Tharumarajah, A. Iron ore and steel production trends and material flows in the world: Is this really sustainable? Resour. Conserv. Recycl. 2010, 54, 1084–1094. [Google Scholar] [CrossRef]

- Bank, T.W. Sustainable Finance. 2022. Available online: https://www.worldbank.org/en/topic/financialsector/brief/sustainable-finance (accessed on 16 November 2022).

- European Commission. Overview of Sustainable Finance. 2022. Available online: https://finance.ec.europa.eu/sustainable-finance/overview-sustainable-finance_en (accessed on 16 November 2022).

- d’Italia, B. Bank of Italy—Sustainable Finance. 2022. Available online: https://www.bancaditalia.it/focus/finanza-sostenibile/https%3A%2F%2Fwww.bancaditalia.it%2Ffocus%2Ffinanza-sostenibile%2Findex.html%3Fcom.dotmarketing.htmlpage.language%3D1 (accessed on 16 November 2022).

- Claringbould, D.; Koch, M.; Owen, P. Sustainable finance: The European Union’s approach to increasing sustainable investments and growth—Opportunities and challenges. Vierteljahrshefte zur Wirtschaftsforschung 2019, 88, 11–27. [Google Scholar] [CrossRef]

- de Souza Cunha, F.A.F.; Meira, E.; Orsato, R.J. Sustainable finance and investment: Review and research agenda. Bus. Strategy Environ. 2021, 30, 3821–3838. [Google Scholar] [CrossRef]

- ABNT-Sustainability Portal. 2023. Available online: https://www.abntonline.com.br/sustentabilidade/ (accessed on 26 March 2023).

- ArcelorMittal Brazil. ABNT-Sustainability Portal. 2023. Available online: https://brasil.arcelormittal.com/en/sustainability/environment/long-carbon/ecolabel (accessed on 26 March 2023).

- Greenpro. 2023. Available online: https://ciigreenpro.com/ (accessed on 26 March 2023).

- Wirtschaftsvereinigung Stahl. Green Steel Definition—A Labelling System for Green Lead Markets. 2022. Available online: https://www.stahl-online.de/wp-content/uploads/2022-11-25_Green-Steel-Definition-A-Labelling-System-for-Green-Lead-Markets.pdf) (accessed on 1 December 2022).

- Cordella, M.; Alfieri, F.; Sanfelix, J.; Donatello, S.; Kaps, R.; Wolf, O. Improving material efficiency in the life cycle of products: A review of EU Ecolabel criteria. Int. J. Life Cycle Assess. 2019, 25, 921–935. [Google Scholar] [CrossRef]

- Rockström, J.; Sukhdev, P. How Food Connects All the SDGs; Stockholm Resilience Centre: Stockholm, Sweden, 2016; Volume 14. [Google Scholar]

- Science Based Targets. 2023. Available online: https://sciencebasedtargets.org/ (accessed on 26 March 2023).

- Nidheesh, P.; Kumar, M.S. An overview of environmental sustainability in cement and steel production. J. Clean. Prod. 2019, 231, 856–871. [Google Scholar] [CrossRef]

- Konietzko, J. Moving beyond Carbon Tunnel Vision with a Sustainability Data Strategy. 2022. Available online: https://digitally.cognizant.com/moving-beyond-carbon-tunnel-vision-with-a-sustainability-data-strategy-codex7121 (accessed on 16 December 2022).

- Akerboom, S.; Waldmann, S.; Mukherjee, A.; Agaton, C.; Sanders, M.; Kramer, G.J. Different This Time? The Prospects of CCS in the Netherlands in the 2020s. Front. Energy Res. 2021, 9, 644796. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

| Sector | Company | Scope 1 | Scope 2 | Scope 3 |

|---|---|---|---|---|

| Steel | Ori Martin [75] | 20% | 26% | 55% |

| Steel | voestalpine [76] | 53% | 2% | 45% |

| Steel | Outokumpu [77] | 22% | 34% | 44% |

| Steel | Tata Steel Group [78] | 69% | 6% | 25% |

| Information Technology | Apple [79] | <1% | 0% | >99% |

| Information Technology | Huawei [80] | 1% | 36% | 64% |

| Energy | Enel [81] | 41% | 4% | 55% |

| Energy | Equinor [80] | 5% | 95% | |

| Confectionery | Ferrero [82] | 7% | 1% | 92% |

| Consumer Goods | Unilever [83] | 1% | 0% | 99% |

| Company | Number of EPDs | Programme Operator |

|---|---|---|

| ArcelorMittal | 30 | Institut Bauen und Umwelt e.V. (IBU) |

| Salzgitter | 2 | Institut Bauen und Umwelt e.V. (IBU) |

| Tata Steel Europe | 11 | Tata Steel UK |

| Thyssenkrupp Steel Europe AG | 2 | Institut Bauen und Umwelt e.V. (IBU) |

| voestalpine | 8 | Institut Bauen und Umwelt e.V. (IBU) |

| Bauforumstahl | 4 | Institut Bauen und Umwelt e.V. (IBU) |

| Outokumpu | 4 | Institut Bauen und Umwelt e.V. (IBU) |

| Sidenor | 3 | Environdec |

| Vallourec | 2 | Environdec |

| Duferco | 2 | Environdec |

| Tenova | 1 | Environdec |

| Acciaierie di Sicilia | 1 | EPDItaly |

| AFV Accaierie Beltrame | 1 | EPDItaly |

| Alfa Acciai | 1 | EPDItaly |

| Alfa Acciai | 2 | EPDItaly |

| Feralpi Siderurgica | 2 | EPDItaly |

| Ferriere Nord | 4 | EPDItaly |

| Tenaris | 6 | Environdec |

| Ori Martin | 4 | Environdec |

| Celsa | 9 | Environdec |

| Aperam | 4 | UL |

| Liberty Steel Group | 4 | CENIA—Czech Environmental Information Agency |

| Worldsteel Key Topic | SDG | Objective |

|---|---|---|

| Climate Action | 7–13 | Proactively address climate change and take effective actions to minimise the industry’s GHG emissions |

| Circular Economy | 12 | Maximise the efficient use of resources throughout the life cycle of steel products and support society to achieve a circular economy |

| Environmental Care | 3–6–11–12–14–15 | Conduct operations in an environmentally responsible manner |

| Health and Safety | 3–8 | Maintain a safe and healthy workplace and act on health and safety incidents, risks and opportunities |

| People | 4–8 | Enable our people to realise their potential while providing them with an inclusive and fair working environment |

| Local Communities | 6–11 | Build trust and create constructive relationships with local communities |

| Responsible Value Chain | 12 | Lead responsible business practices through the value chain |

| Ethical and Transparent Operations | 8–12–16-17 | Conduct operations with high standards and transparent processes |

| Innovation and Prosperity | 1–8–9 | Pursue innovations for technologies and products to achieve sustainable economic development |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andreotti, M.; Brondi, C.; Micillo, D.; Zevenhoven, R.; Rieger, J.; Jo, A.; Hettinger, A.-L.; Bollen, J.; Malfa, E.; Trevisan, C.; et al. SDGs in the EU Steel Sector: A Critical Review of Sustainability Initiatives and Approaches. Sustainability 2023, 15, 7521. https://doi.org/10.3390/su15097521

Andreotti M, Brondi C, Micillo D, Zevenhoven R, Rieger J, Jo A, Hettinger A-L, Bollen J, Malfa E, Trevisan C, et al. SDGs in the EU Steel Sector: A Critical Review of Sustainability Initiatives and Approaches. Sustainability. 2023; 15(9):7521. https://doi.org/10.3390/su15097521

Chicago/Turabian StyleAndreotti, Michele, Carlo Brondi, Davide Micillo, Ron Zevenhoven, Johannes Rieger, Ayoung Jo, Anne-Laure Hettinger, Jan Bollen, Enrico Malfa, Claudio Trevisan, and et al. 2023. "SDGs in the EU Steel Sector: A Critical Review of Sustainability Initiatives and Approaches" Sustainability 15, no. 9: 7521. https://doi.org/10.3390/su15097521

APA StyleAndreotti, M., Brondi, C., Micillo, D., Zevenhoven, R., Rieger, J., Jo, A., Hettinger, A.-L., Bollen, J., Malfa, E., Trevisan, C., Peters, K., Snaet, D., & Ballarino, A. (2023). SDGs in the EU Steel Sector: A Critical Review of Sustainability Initiatives and Approaches. Sustainability, 15(9), 7521. https://doi.org/10.3390/su15097521