The Impact of Manufacturing Intelligence on Green Development Efficiency: A Study Based on Chinese Data

Abstract

:1. Introduction

2. Mechanistic Analysis and Research Hypothesis

2.1. Direct Impact

2.2. Indirect Effects

2.3. Non-Linear Effects

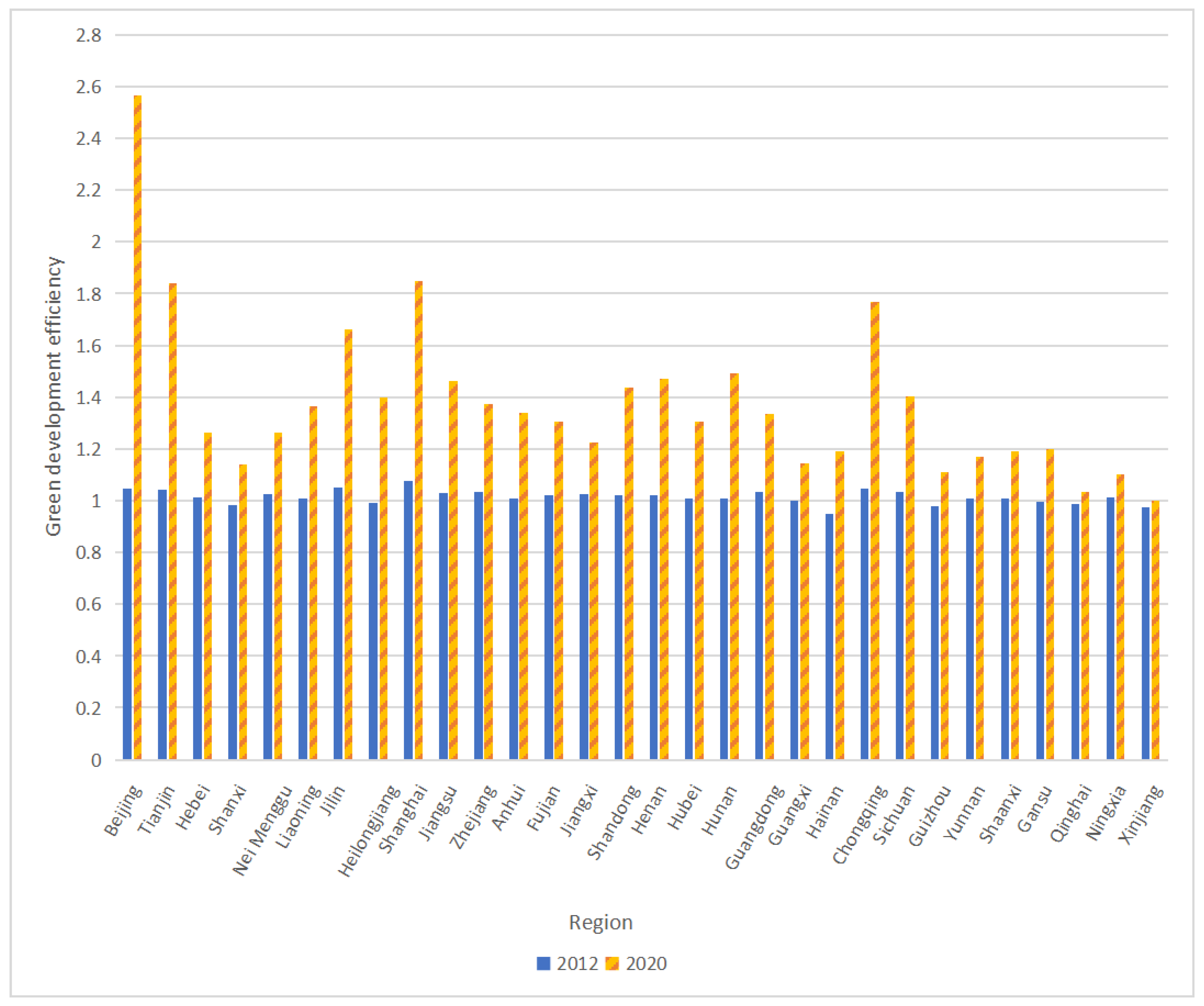

3. Measurement of Manufacturing Intelligence and Green Development Efficiency

3.1. Measurement of Manufacturing Intelligence

3.2. Measurement of Green Development Efficiency

4. Materials and Methods

4.1. Model Setting

4.2. Variable Description and Data Source

4.2.1. Variables Selection

4.2.2. Data Sources

5. Empirical Results and Discussion

5.1. Benchmark Regression Results

The Effect of Manufacturing Intelligence on Green Development Efficiency

5.2. Endogeneity and Robustness Testing

5.2.1. Replacement of Core Explanatory Variables

5.2.2. Regression with Reduced Tails

5.2.3. Exclude Provinces

5.3. A Mechanistic Test of Manufacturing Intelligence’s Effect on Green Development Efficiency

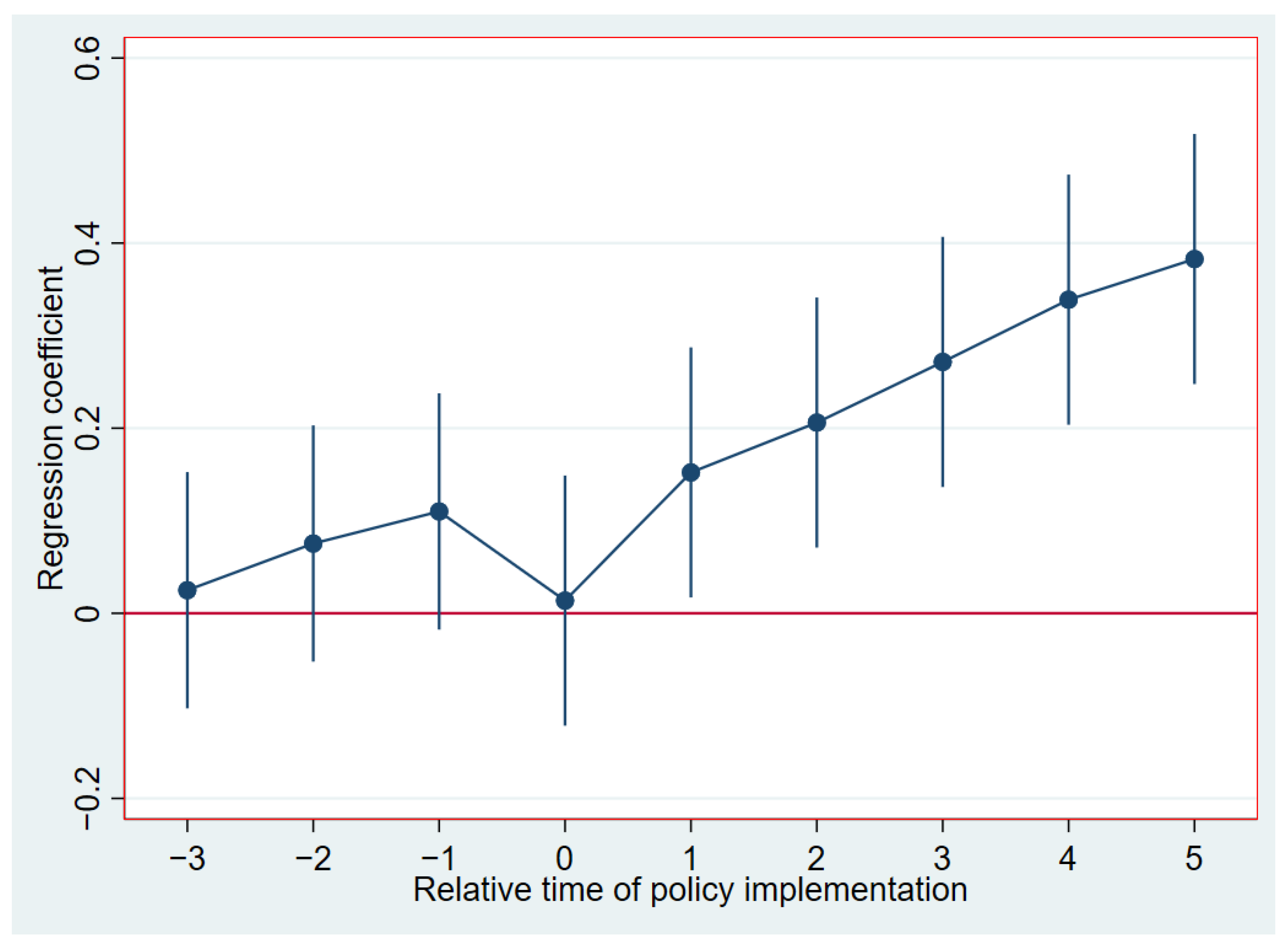

5.3.1. Policy Effects of the “Guidelines for the Construction of the National Intelligent Manufacturing Standard System”

5.3.2. The Parallel Trend Test

5.3.3. The Transmission Path of Technological Innovation and Energy Efficiency

5.4. The Threshold Effect of Manufacturing Intelligence on Green Development Efficiency

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.L.; Wen, H.W. Research on the Excess Capacity over Chinese Manufacturing Sector. Stat. Res. 2017, 34, 76–83. [Google Scholar]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4. 0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology of the People’s Republic of China; China’s National Development and Reform Commission; Ministry of Education of the People’s Republic of China; Ministry of Science and Technology of the People’s Republic of China; Ministry of Finance of the People’s Republic of China; Ministry of Human Resources and Social Security of the People’s Republic of China; China’s State Administration for Market Regulation; China’s State-owned Assets Supervision and Administration Commission of the State Council. 14th Five-Year Plan for the Development of Intelligent Manufacturing. Available online: http://www.gov.cn/zhengce/zhengceku/2021-12/28/content_5664996.htm (accessed on 25 July 2022).

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart Manufacturing, Manufacturing Intelligence and Demand-dynamic Performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Lv, W.J.; Chen, J.; Liu, J. Intelligent Manufacturing and Firm-Level Platform Building in Industrial Internet: A Case Study of Haier. China Soft Sci. 2019, 34, 1–13. [Google Scholar]

- Lee, C.C.; Lee, C.C. How Does Green Finance Affect Green Total Factor Productivity? Evidence from China. Energy Econ. 2022, 107, 105863. [Google Scholar] [CrossRef]

- Liu, D.D.; Zhu, X.Y.; Wang, Y.F. China’s Agricultural Green Total Factor Productivity based on Carbon Emission: An Analysis of Evolution Trend and Influencing Factors. J. Clean. Pract. 2021, 278, 123692. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Liu, J. Natural Resource Abundance, Resource Industry Dependence and Economic Green Growth in China. Resour. Policy 2020, 68, 101734. [Google Scholar] [CrossRef]

- Lv, C.C.; Shao, C.H.; Lee, C.C. Green Technology Innovation and Financial Development: Do Environmental Regulation and Innovation Output Matter? Energy Econ. 2021, 98, 105237. [Google Scholar] [CrossRef]

- Wu, H.T.; Li, Y.W.; Hao, Y.; Ren, S.Y.; Zhang, P. Environmental Decentralization, Local Government Competition, and Regional Green Development: Evidence from China. Sci. Total Environ. 2020, 708, 135085. [Google Scholar] [CrossRef]

- Li, B.; Wu, S.S. Effects of Local and Civil Environmental Regulation on Green Total Factor Productivity in China: A Spatial Durbin Econometric Analysis. J. Clean. Pract. 2017, 153, 342–353. [Google Scholar] [CrossRef]

- Huang, X.; Dong, Z.Q. How Does Artificial Intelligence Promote Economic Growth and Social Welfare? J. Cent. Univ. Financ. Econ. 2019, 39, 76–85, 128. [Google Scholar]

- Gasteiger, E.; Prettner, K. A Note on Automation, Stagnation, and the Implications of a Robot Tax. Macroecon. Dyn. 2022, 26, 218–249. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. The Race betw e en Machine and Man: Implications of Technology for Growth, Factor Shares and Employment. Am. Econ. Rev. 2018, 108, 1488–1542. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Hitt, L. Beyond Computation: Information Technology, Organizational Transformation and Business Performance. J. Econ. Perspect. 2000, 14, 23–48. [Google Scholar] [CrossRef]

- Lin, C.; Chen, X.L.; Chen, W.Z.; Chen, Y.B. Artificial Intelligence, Economic Growth and Residential Consumption Improvement: From the Perspective of Capital Structure Optimization. Chin. Ind. Econ. 2020, 38, 61–83. [Google Scholar]

- Mao, B.M.; Tang, F.X.; Kawamoto, Y.; Kato, N. AI Models for Green Communications towards 6G. IEE Commun. Surv. Tutor. 2022, 24, 210–247. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Robots at Work. Rev. Econ. Stat. 2018, 100, 753–768. [Google Scholar] [CrossRef]

- Chen, Y.B.; Lin, C.; Chen, X.L. Artificial Intelligence, Aging and Economic Growth. Econ. Res. 2019, 54, 47–63. [Google Scholar]

- Yang, G.; Hou, Y. The Usage of Industrial Robots, Technology Upgrade and Economic Growth. Chin. Ind. Econ. 2020, 38, 138–156. [Google Scholar]

- Lv, Y.; Gu, W.; Bao, Q. Artificial Intelligence and Chinese Enterprises’ Participate in the Global Value Chains. Chin. Ind. Econ. 2020, 38, 80–98. [Google Scholar]

- Shi, B. Interpretation of the Mechanism of Artificial Intelligence Boosting High-quality Economic Development. Reform 2020, 33, 30–38. [Google Scholar]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Han, J.; Chen, X.; Feng, X.H. The Real Challenge and Path of Enabling Green Development of Digital Economy. Reform 2022, 35, 11–23. [Google Scholar]

- Chen, Y.; Cheng, L.; Lee, C.C. How Does the Use of Industrial Robots Affect the Ecological Footprint? International Evidence. Ecol. Econ. 2022, 198, 107483. [Google Scholar] [CrossRef]

- Chen, F.; Liu, S.T. Can Artificial Intelligence Technology Become a New Engine of Urban Green Development. J. Nanjing Univ. Financ. Econ. 2022, 40, 78–86. [Google Scholar]

- Xu, X.C.; Ren, X.; Chang, Z.H. Big Data and Green Development. Chin. Ind. Econ. 2019, 37, 5–22. [Google Scholar]

- Tang, X.H.; Chi, Z.M. An Empirical Study on Industrial Intelligence to Improve the Efficiency of Industrial Green Development. Economist 2022, 34, 43–52. [Google Scholar]

- Yang, H.C.; Li, L.S.; Liu, Y.B. The Effect of Manufacturing Intelligence on Green Innovation Performance in China. Technol. Forecast. Soc. 2022, 178, 121569. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Frank, M.R.; Autor, D.; Bessen, J.E.; Brynjolfsson, E.; Cebrian, M.; Deming, D.J.; Feldman, M.; Groh, M.; Lobo, J.; Moro, E.; et al. Toward Understanding the Impact of Artificial Intelligence on Labor. Proc. Natl. Acad. Sci. USA 2019, 116, 6531–6539. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.H. Dongfang Electric Realizes the Integration and Development of Digitalization and Intelligence. Economic Information Daily, 17 October 2022; 7. [Google Scholar]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial Intelligence for Sustainability: Challenges, Opportunities, and a Research Agenda. Int. J. Inform. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Huang, X. To Select More than 300 Pilot Demonstration Projects by 2020—The Intelligent Manufacturing Promotion System Has Basically Formed. Economic Daily, 25 November 2017; 4. [Google Scholar]

- Ran, R.C.; Wu, L.M. Promoting the Construction of a Strong Industrial Area in Banan District of Chongqing City-transformation and Upgrading to Strengthen the Industrial Pillar. Economic Daily, 17 October 2022; 12. [Google Scholar]

- Yu, J.D. The Output of Yema Batteries in the First half of the Year Exceeded 800 Million Units—The Upgrade of the Smart Factory Brings Galloping Power. Economic Daily, 12 August 2022; 10. [Google Scholar]

- Li, X.Z.; Xu, Y. Research on the Promoting Effect and Threshold Effect of Government Subsidies on Enterprise Innovation Performance—Based on the Data of Listed Companies of Electronic and Information Industry in Shanghai and Shenzhen. China Soft Sci. 2019, 34, 31–39. [Google Scholar]

- Sun, Z.; Hou, Y.L. How Does Industrial Intelligence Reshape the Employment Structure of Chinese Labor Force. Chin. Ind. Econ. 2019, 37, 61–79. [Google Scholar]

- Liu, J.; Cao, Y.R.; Bao, Y.F.; Zhao, Y.H. Research on the Impact of Manufacturing Intelligence on Income Gap. China Soft Sci. 2021, 36, 43–52. [Google Scholar]

- Chung, Y.H.; Fare, R. Productivity and Undesirable Outputs: A Directional Distance Function Approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef]

- Tone, K. A Slacks-based Measure of Efficiency in Data Envelopment Analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, G.Y.; Zhang, J.P. The Estimation of China’s provincial Capital Stock: 1952–2000. Econ. Res. 2004, 39, 35–44. [Google Scholar]

- Qiu, B.; Yang, S.; Xin, P.J. Research on FDI Technology Spillover Channels and China’s Manufacturing Productivity Growth: Analysis Based on Panel Data. World Econ. 2008, 31, 20–31. [Google Scholar]

- Ministry of Industry and Information Technology of the People’s Republic of China; China’s Standardization Administration. Guidelines for the Construction of the National Intelligent Manufacturing Standard System. Available online: http://www.gov.cn/xinwen/2015-12/30/content_5029681.htm (accessed on 29 July 2022).

- Li, J.J.; Han, X. The Effect of Financial Inclusion on Income Distribution and Poverty Alleviation: Policy Framework for Efficiency and Equity. J. Financ. Res. 2019, 62, 129–148. [Google Scholar]

- Yao, D.M.; Ning, J.; Wei, S.Y. How Does the Population Aging Affect Technology Innovation. World Econ. 2017, 40, 105–128. [Google Scholar]

| Level 1 Indicators | Secondary Indicators | Metrics |

|---|---|---|

| Basic input layer | R&D funding input | High-tech manufacturing R&D expenditure |

| Smart device input | Fixed asset investment in information transmission, software and information technology services | |

| Internet infrastructure investment | Fibre optic cable length/provincial area | |

| Staff input | Number of employees in high-tech manufacturing | |

| Number of people in information transmission, software and information technology services | ||

| Production application layer | Software development and service situation | Software business revenue |

| The degree of industrialization of intelligent technology | High-tech manufacturing new product output value | |

| High-tech manufacturing valid invention patent | ||

| Market benefit layer | Smart device market profit | Total profit of high-tech manufacturing industry |

| Smart device market efficiency | High-tech manufacturing main business income/employees | |

| Environmental improvement | Industrial solid waste generation/GDP | |

| Energy intensity | Energy consumption/GDP |

| Variables | Sample Size | Average | Standard Deviation | Minimum Value | Maximum Value |

|---|---|---|---|---|---|

| Green development efficiency | 300 | 1.1689 | 0.2241 | 0.8958 | 2.5642 |

| Intelligent level of manufacturing | 300 | 0.0949 | 0.1233 | 0.0023 | 0.8794 |

| Human capital level | 300 | 9.2529 | 0.9169 | 7.4739 | 12.7820 |

| GDP per capita | 300 | 10.8406 | 0.4361 | 9.7058 | 12.0130 |

| Openness to the outside | 300 | 0.0192 | 0.0150 | 0.0004 | 0.0796 |

| Industrial structure | 300 | 1.2187 | 0.6960 | 0.5180 | 5.2968 |

| Telecommunications development level | 300 | 13.4669 | 0.8961 | 10.8325 | 15.1993 |

| Variables | Fixed-Effects Model | Random-Effects Model | Replacement of Core Explanatory Variables | Regression with Reduced Tails | Exclude Provinces |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | |

| Intelligent level of manufacturing | 0.7312 *** (0.1592) | 0.3577 *** (0.1291) | 0.1035 *** (0.0244) | 1.0497 *** (0.1847) | 0.5479 *** (0.1180) |

| Human capital level | 0.0464 * (0.0261) | 0.0215 (0.0229) | 0.0472 * (0.0262) | 0.0480 * (0.0255) | 0.0107 (0.0196) |

| GDP per capita | 0.1819 *** (0.0574) | 0.1364 *** (0.0445) | 0.2067 *** (0.0563) | 0.1439 ** (0.0575) | 0.0047 (0.0462) |

| Openness to the outside | −2.6027 *** (0.7159) | −2.4490 *** (0.7050) | −2.6601 *** (0.7191) | −2.5140 *** (0.7025) | −0.8082 (0.6509) |

| Industrial structure | 0.3752 *** (0.0331) | 0.2246 *** (0.0244) | 0.3799 *** (0.0333) | 0.3667 *** (0.0326) | 0.1172 *** (0.0319) |

| Telecommunications development level | −0.0780 *** (0.0282) | 0.0410 *** (0.0156) | −0.0805 *** (0.0283) | −0.0739 *** (0.0276) | 0.1009 *** (0.0254) |

| Constant term | −0.6578 (0.4301) | −1.3211 *** (0.3696) | −0.8983 ** (0.4151) | −0.3367 (0.4326) | −0.5537 * (0.3255) |

| Ra2 | 0.4803 | 0.5778 | 0.4680 | 0.4820 | 0.4300 |

| F value | 121.65 | 119.82 | 128.15 | 93.89 | |

| Wald value | 576.46 | ||||

| Fixed effect | YES | YES | YES | YES | |

| Observations | 300 | 300 | 300 | 300 | 260 |

| Hausman test | 0.0000 | ||||

| Variables | Double-Difference Model |

|---|---|

| Did × T | 0.1597 *** (0.0256) |

| Human capital level | 0.0218 (0.0221) |

| GDP per capita | 0.2157 *** (0.0440) |

| Openness to the outside | −0.7994 (0.7096) |

| Industrial structure | 0.2116 *** (0.0247) |

| Telecommunications development level | 0.0494 *** (0.0164) |

| Constant term | −2.2047 *** (0.3796) |

| Ra2 | 0.6609 |

| Wald value | 673.74 |

| Fixed effect | YES |

| Observations | 300 |

| Variables | Technological Innovation | Green Development Efficiency | Energy Efficiency | Green Development Efficiency |

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| Did × T | 0.0281 *** (0.0100) | 0.1023 *** (0.0228) | 0.0543 *** (0.0122) | 0.0817 *** (0.0225) |

| Energy efficiency | 0.5130 *** (0.1095) | |||

| Technological innovation | 0.2580 * (0.1386) | |||

| Human capital level | −0.0487 *** (0.0114) | 0.0773 *** (0.0266) | −0.0184 (0.0140) | 0.0742 *** (0.0250) |

| GDP per capita | 0.0279 (0.0237) | 0.2435 *** (0.0536) | 0.5725 *** (0.0291) | −0.0430 (0.0812) |

| Openness to the outside | 0.3154 (0.3307) | −1.8697 ** (0.7462) | 0.6544 (0.4050) | −2.1240 *** (0.7239) |

| Industrial structure | −0.0070 (0.0149) | 0.3534 *** (0.0336) | −0.1325 *** (0.0182) | 0.4195 *** (0.0355) |

| Telecommunications development level | −0.0059 (0.0124) | −0.0890 *** (0.0278) | −0.1168 *** (0.0151) | −0.0306 (0.0298) |

| Constant term | 0.3844 ** (0.1691) | −1.4464 *** (0.3847) | −3.7547 *** (0.2071) | 0.5789 (0.5519) |

| Ra2 | 0.2194 | 0.4705 | 0.1858 | 0.5711 |

| F value | 6.31 | 107.01 | 89.61 | 117.05 |

| Fixed effect | YES | YES | YES | YES |

| Observations | 300 | 300 | 300 | 300 |

| Threshold Variable | Threshold | Threshold Value | F Value | p Value | 10% Critical Value | 5% Critical Value | 1% Critical Value |

|---|---|---|---|---|---|---|---|

| Technological innovation | Single threshold | 0.3472 | 56.71 | 0.0000 *** | 24.1243 | 27.9323 | 36.6306 |

| Double sill | 0.3472, 0.1136 | 10.54 | 0.3867 | 69.1699 | 84.3016 | 144.4616 | |

| Government’s role | Single threshold | 0.1765 | 60.61 | 0.0000 *** | 30.8952 | 37.3986 | 48.3053 |

| Double sill | 0.1765, 0.1954 | 16.12 | 0.4167 | 26.8287 | 31.7205 | 47.9296 |

| Explanatory Variables | Threshold Variable | Explanatory Variables | Threshold Variable |

|---|---|---|---|

| Technological Innovation | Government’s Role | ||

| Intelligent level of manufacturing (Technological innovation ≤ η) | 0.6008 *** (0.1470) | Intelligent level of manufacturing(Government’s role ≤ η) | 0.7047 *** (0.1451) |

| Intelligent level of manufacturing (Technological innovation > η) | 2.7770 *** (0.3204) | Intelligent level of manufacturing(Government’s role > η) | 2.6851 *** (0.3008) |

| Human capital level | 0.0431 * (0.0239) | Human capital level | 0.0328 (0.0238) |

| GDP per capita | 0.1264 ** (0.0531) | GDP per capita | 0.0772 (0.0541) |

| Openness to the outside | −3.2908 *** (0.6630) | Openness to the outside | −3.1918 *** (0.6572) |

| Industrial structure | 0.2599 *** (0.0344) | Industrial structure | 0.2808 *** (0.0328) |

| Telecommunications development level | −0.0044 (0.0278) | Telecommunications development level | −0.0508 * (0.0259) |

| Constant term | −0.8637 ** (0.3951) | _cons | 0.2735 (0.4115) |

| Ra2 | 0.5352 | Ra2 | 0.5545 |

| F value | 131.53 | F value | 133.44 |

| Observations | 300 | Observations | 300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ling, J. The Impact of Manufacturing Intelligence on Green Development Efficiency: A Study Based on Chinese Data. Sustainability 2023, 15, 7553. https://doi.org/10.3390/su15097553

Li X, Ling J. The Impact of Manufacturing Intelligence on Green Development Efficiency: A Study Based on Chinese Data. Sustainability. 2023; 15(9):7553. https://doi.org/10.3390/su15097553

Chicago/Turabian StyleLi, Xiaozhong, and Jun Ling. 2023. "The Impact of Manufacturing Intelligence on Green Development Efficiency: A Study Based on Chinese Data" Sustainability 15, no. 9: 7553. https://doi.org/10.3390/su15097553

APA StyleLi, X., & Ling, J. (2023). The Impact of Manufacturing Intelligence on Green Development Efficiency: A Study Based on Chinese Data. Sustainability, 15(9), 7553. https://doi.org/10.3390/su15097553