Stability Analysis of the Tailings Dam for the Purpose of Closing, Greening, and Ensuring Its Safety—Study Case

Abstract

1. Introduction

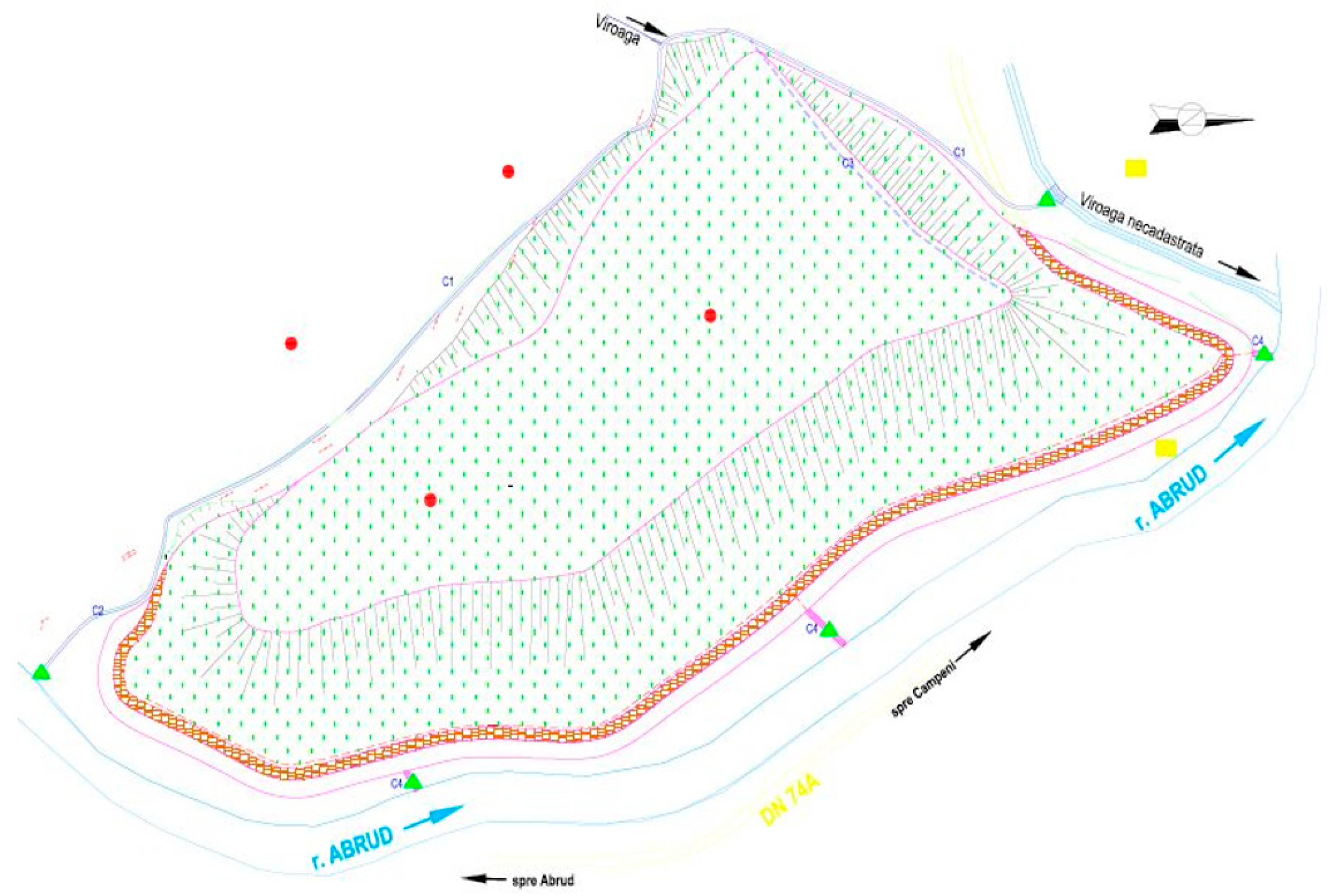

2. General Data Regarding the Tailings Dam

2.1. Constructive Elements

- contour dike (priming): It was built on two sides of the tailings dam, namely on the NW side and on the side parallel to the Abrudel stream. The other sides of the dam are natural slope areas. The dike was made of stone and river ballast. Made in this way, it also fulfills the role of a “reverse filter”, allowing the water to be filtered from the body of the pond. The constructive elements of the contour dam are the width of the crest (2 m); maximum height (5 m); and declivity of the slopes (approx. 1:1).

- the system of transporting and depositing the sterile material: It has the role of transporting and distributing the sterile material in all areas in which it is needed, for the uniform loading of the available storage volume, to ensure the material necessary to build the elevation dams, and to ensure the best conditions for water clearing.

- waste warehouse itself: This warehouse was formed behind the priming dam and has three compartments (1, 2, and 3). The first compartment has not been used for a long time and has remained at a much lower share than compartments 2 and 3 (Figure 1 and Figure 2). Compartments 2 and 3 are in preservation and were used only in exceptional situations, when damage would occur in the Selistei Valley. The maximum height of the deposit in these compartments is about 45 m. It was made by the “elevation inward” method, and the elevation dams were built from deposited and sediment waste in the previous stage.

- the drainage system: There is no information on the existence and functioning of this system.

- water evacuation system: For this pond, there was a unique system for the evacuation of water from rainfall and from the clearing slime pulp. This system is based on a reverse probe (Figure 5), which evacuates the water through an underground metal pipe (Ø = 400 mm) in the Abrudel stream (Figure 6). The pond was provided with quasi-parallel compartments to the Abrudel stream for the interception of tailings released by the seepage waters from the slopes of the pond, thus avoiding discharge into the emissary. Based on the observations made in the field, the following aspects were noted:

- There were only two systems of reverse wells: one was in operation and the other was clogged with branches, stones, etc.

- There was no access to the only working probe system, and the probe was not protected against clogging with floats.

- The discharge pipe of the water captured by the reverse probe is metallic, underground, and has been in an acidic environment for a very long time.

- the system for monitoring the construction behavior: the Gura Roşiei tailings dam has class and category of importance II, respectively, B; there is no information about the system for monitoring the behavior of this tailings dam.

2.2. Emission Sources

- water discharges: direct discharges of polluted water into natural surface receptors; exfiltration of polluted water from the pond into the groundwater in the area; direct discharge of stored waste into surface waters (occurred during current operation but can also occur in the event of an accident or outcome);

- emissions to the atmosphere: suspended dust blown by the wind from the material deposited in the tailings dam;

- direct discharge of tailings from the tailings dam onto the land surface located downstream of the settling pond (in case of accidents or damages).

3. The Hydrogeotechnical and Stability Study of the Tailings Dam

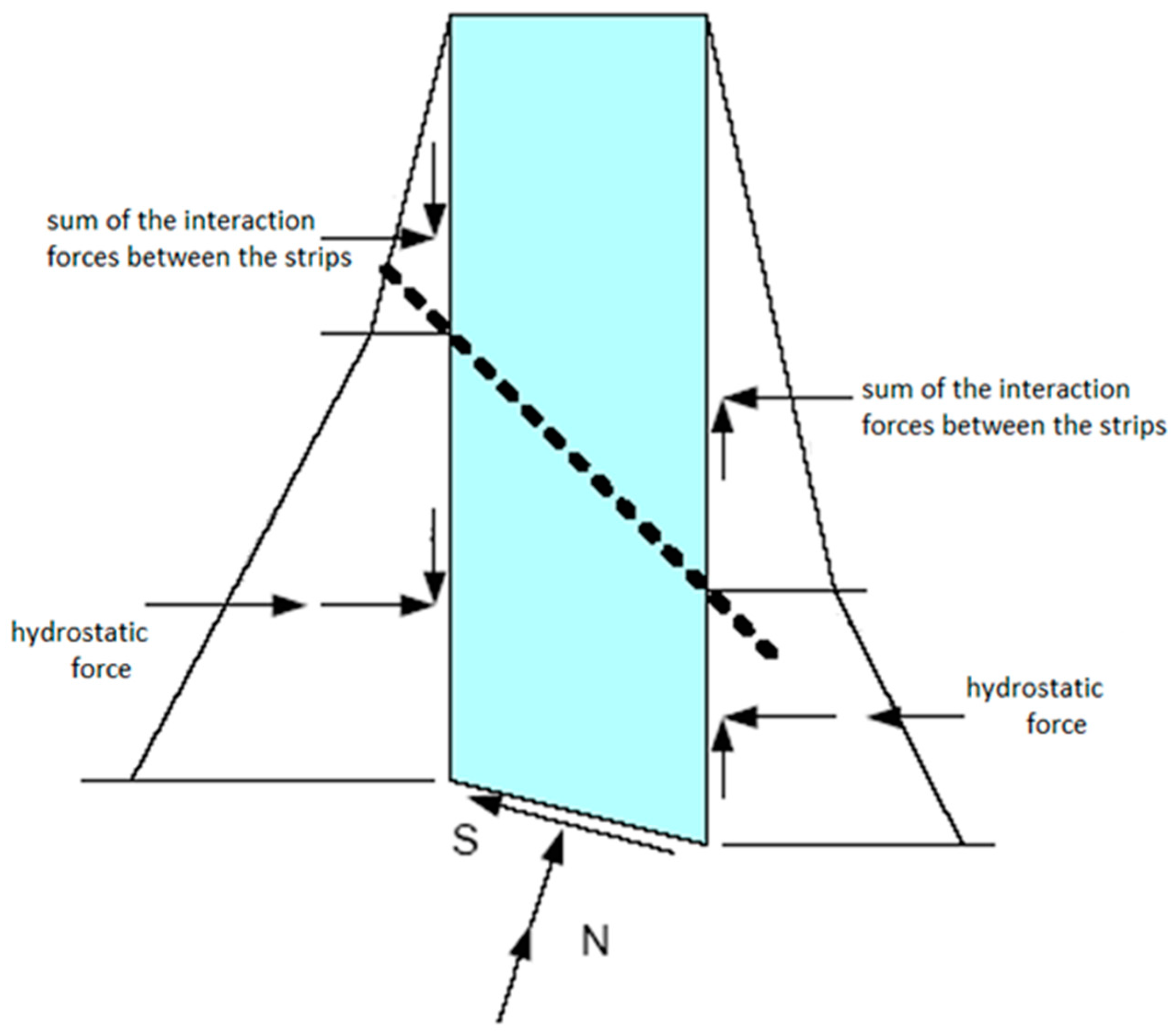

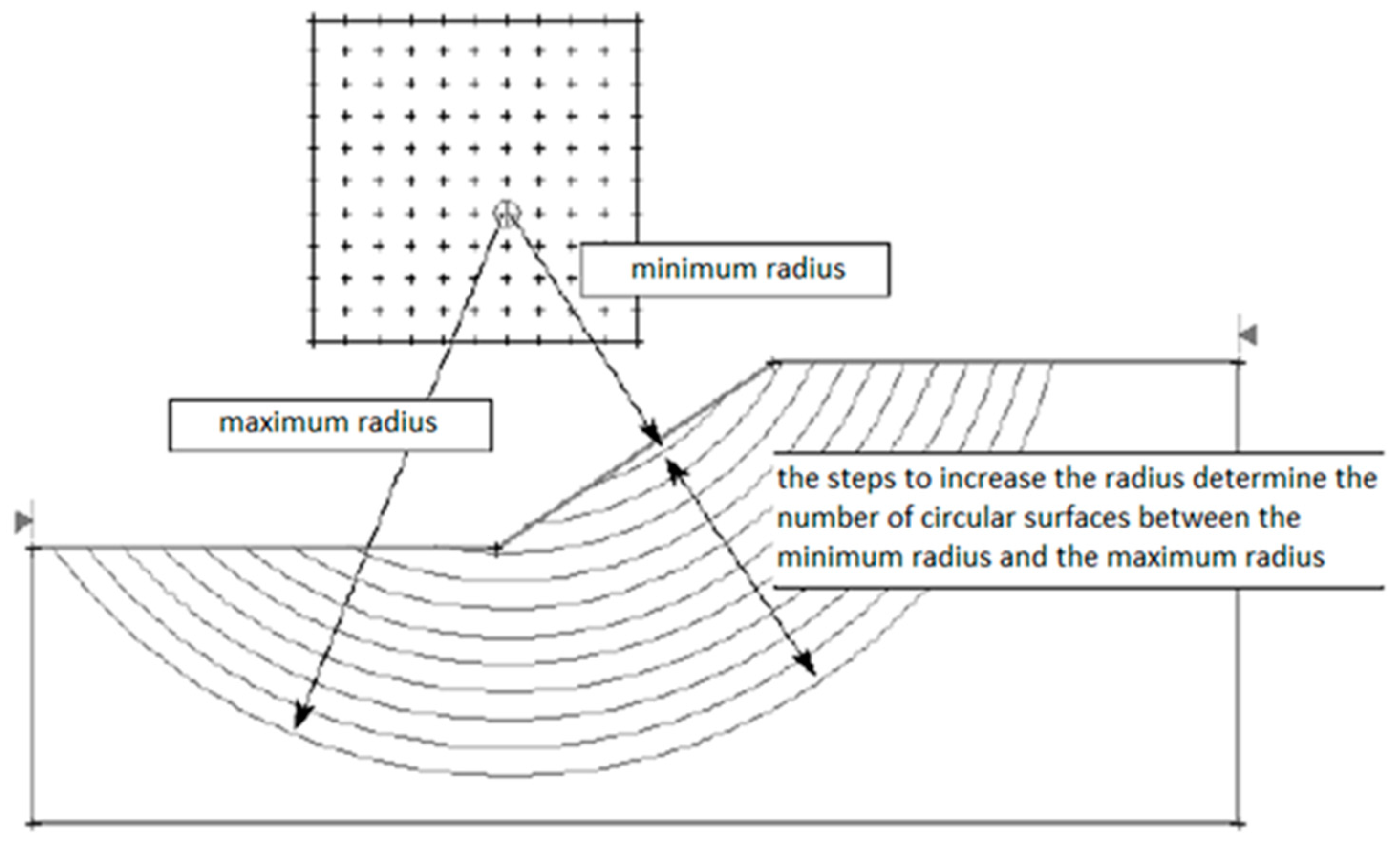

3.1. Methods Used in the Evaluation of the Safety Factor

- The static equilibrium of each strip is ensured by the equilibrium of the projections in two orthogonal directions and the equilibrium of the moments of the forces with respect to any point.

- Total vertical equilibrium is ensured when the vertical component of the resistance forces on the sliding surface balances the entire weight of the body (including external forces) and the vertical forces on the contour.

- Total horizontal equilibrium is ensured when the horizontal component of the resistance forces acting on the sliding surface is in equilibrium with the horizontal forces acting on the contour.

- The equilibrium of the total moments is ensured when the sum of the moments of the differential forces between the slices is in equilibrium with the moments of the forces acting on the contour.

3.2. In Situ and Laboratory Studies

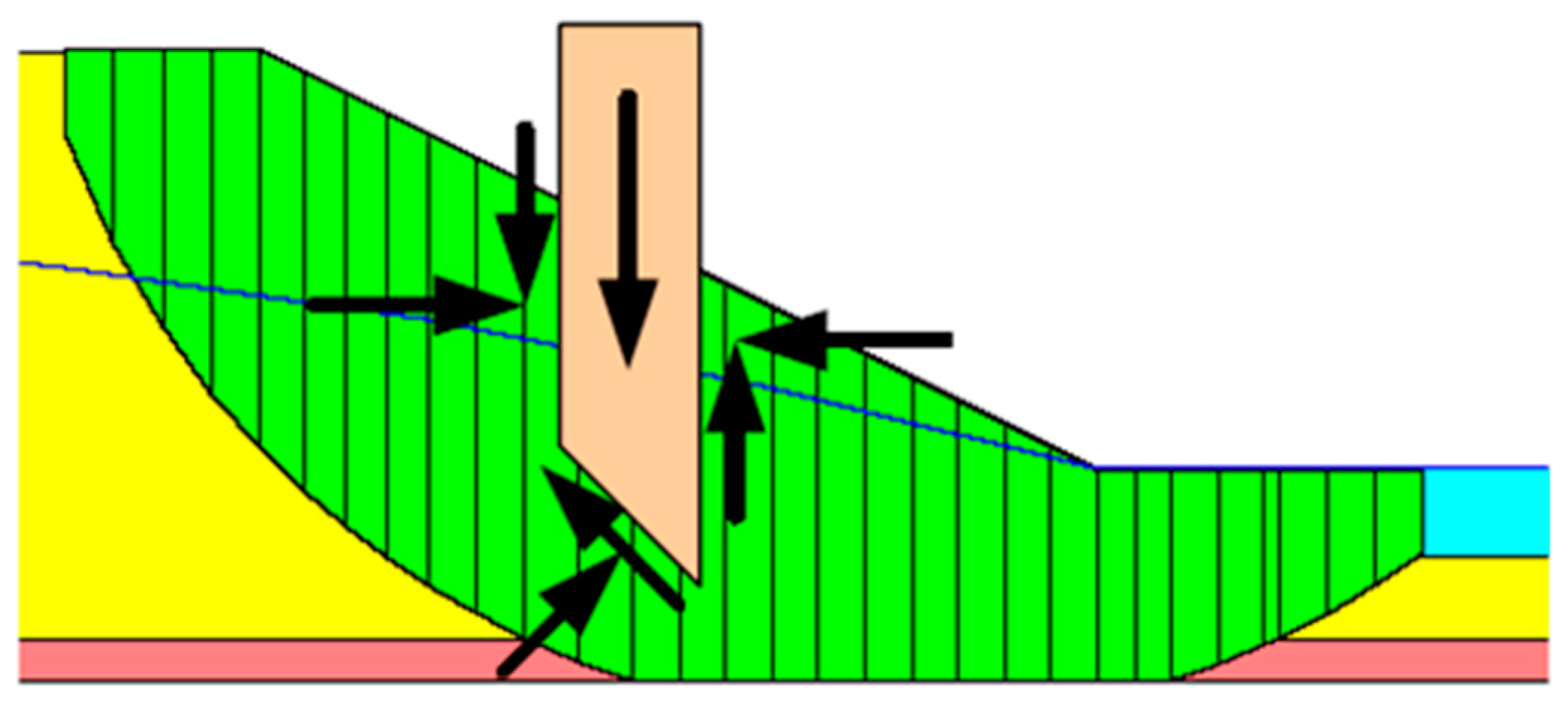

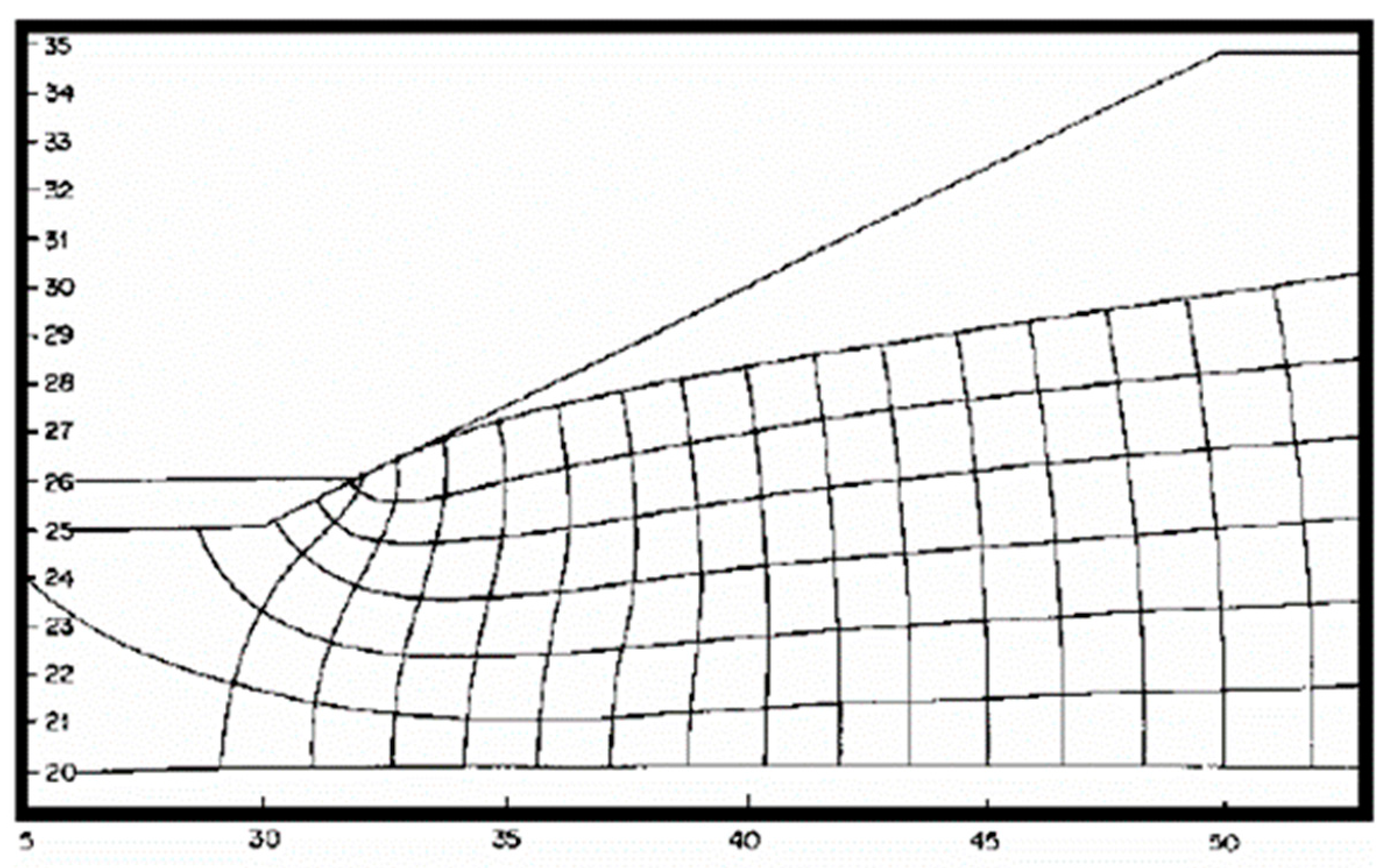

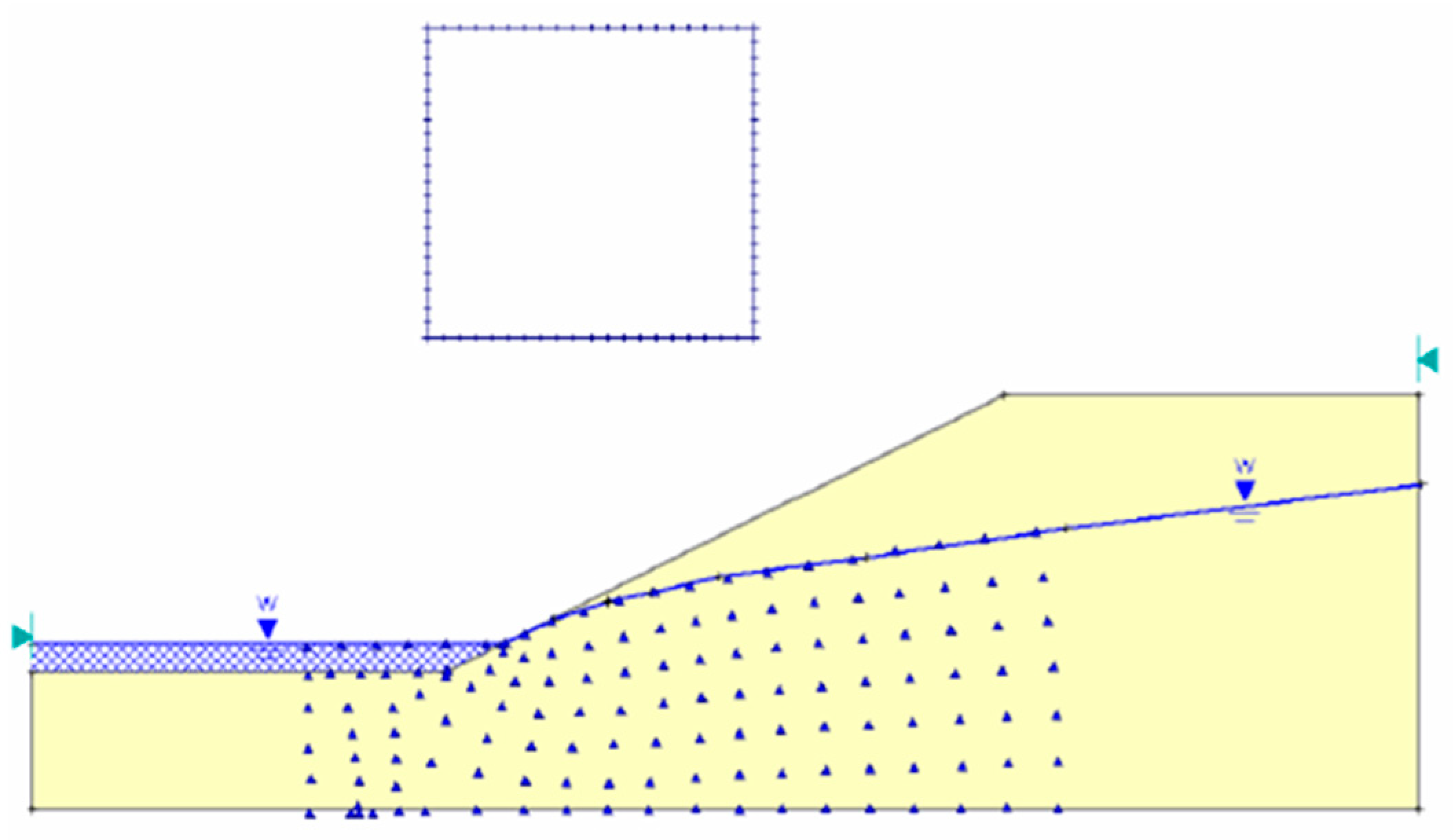

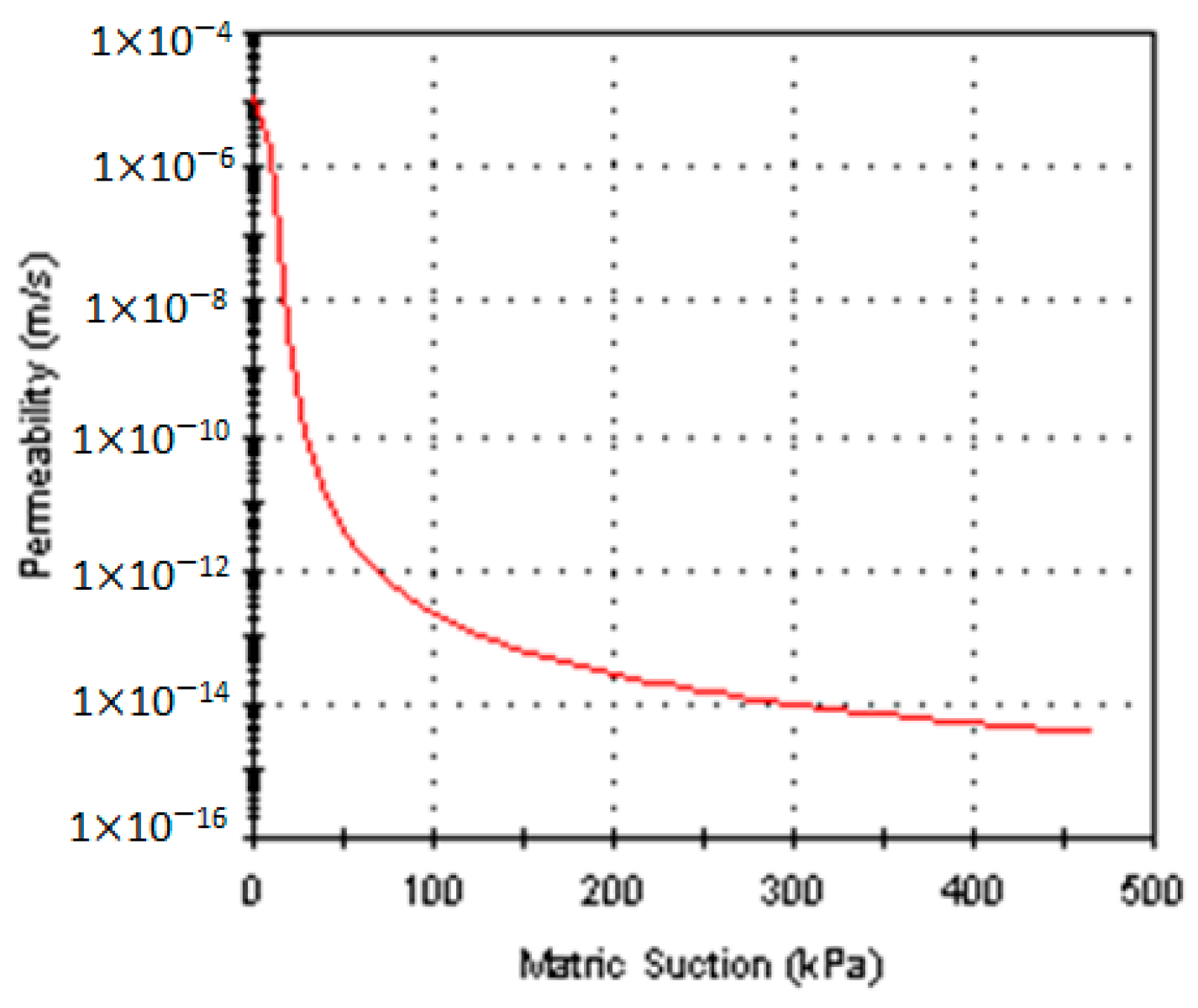

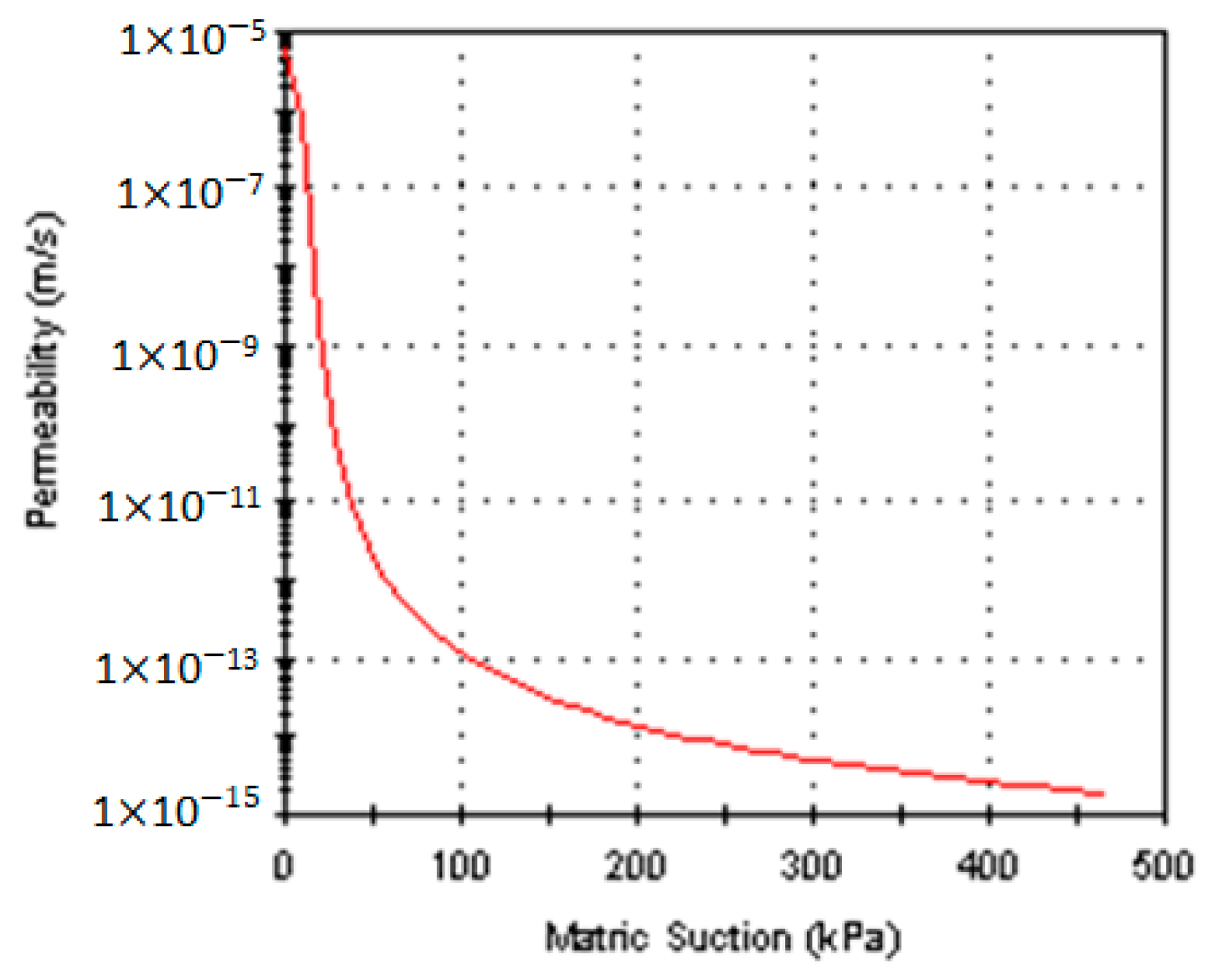

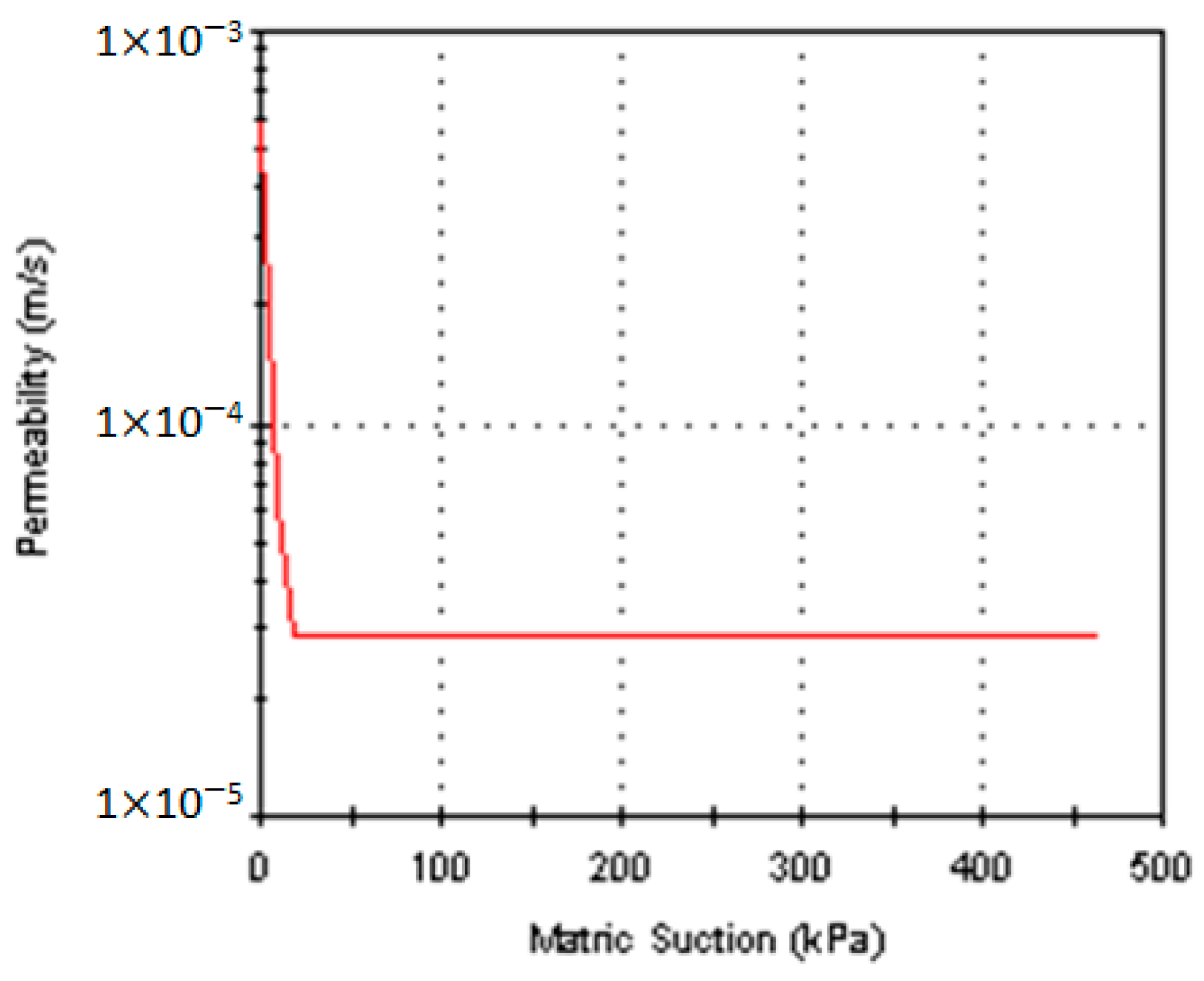

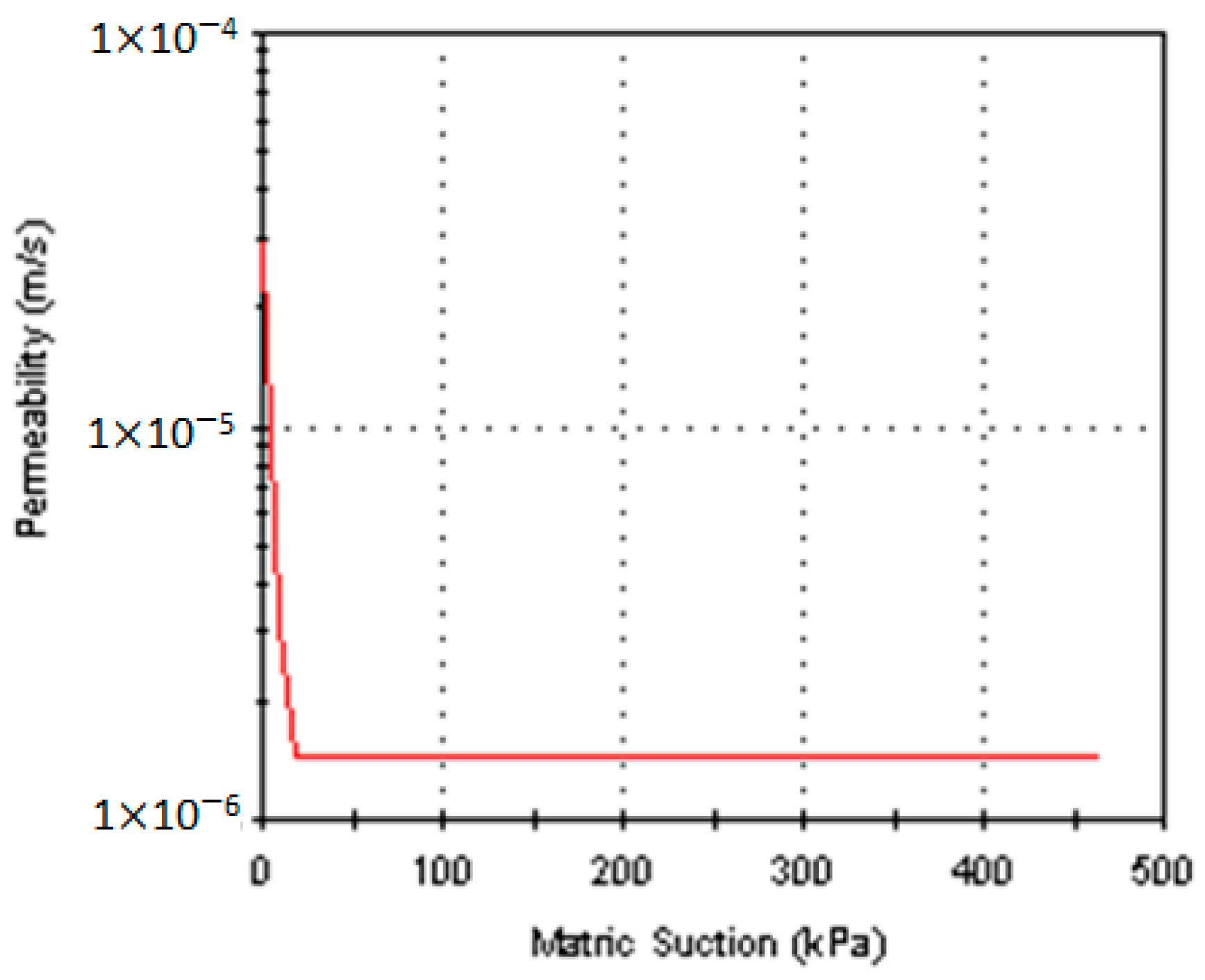

3.3. Calculation of Seepage in the Dikes’ Body of the Dams and through the Foundation Using the Finite Element Method

4. Risk Analysis

- Qualitative analyses are used to identify hazards (Hazard and Operability Study—HAZOP). The qualitative analysis has as its main objective the establishment of the list of possible hazards; it makes it possible to rank the events in order of risk and presents the first step in the methodology of performing the quantitative risk analysis.

- Quantitative analyses are used to assess hazards to decide how to act in order to eliminate or reduce the risk (Hazard Analysis—HAZAN).

5. Results and Discussion

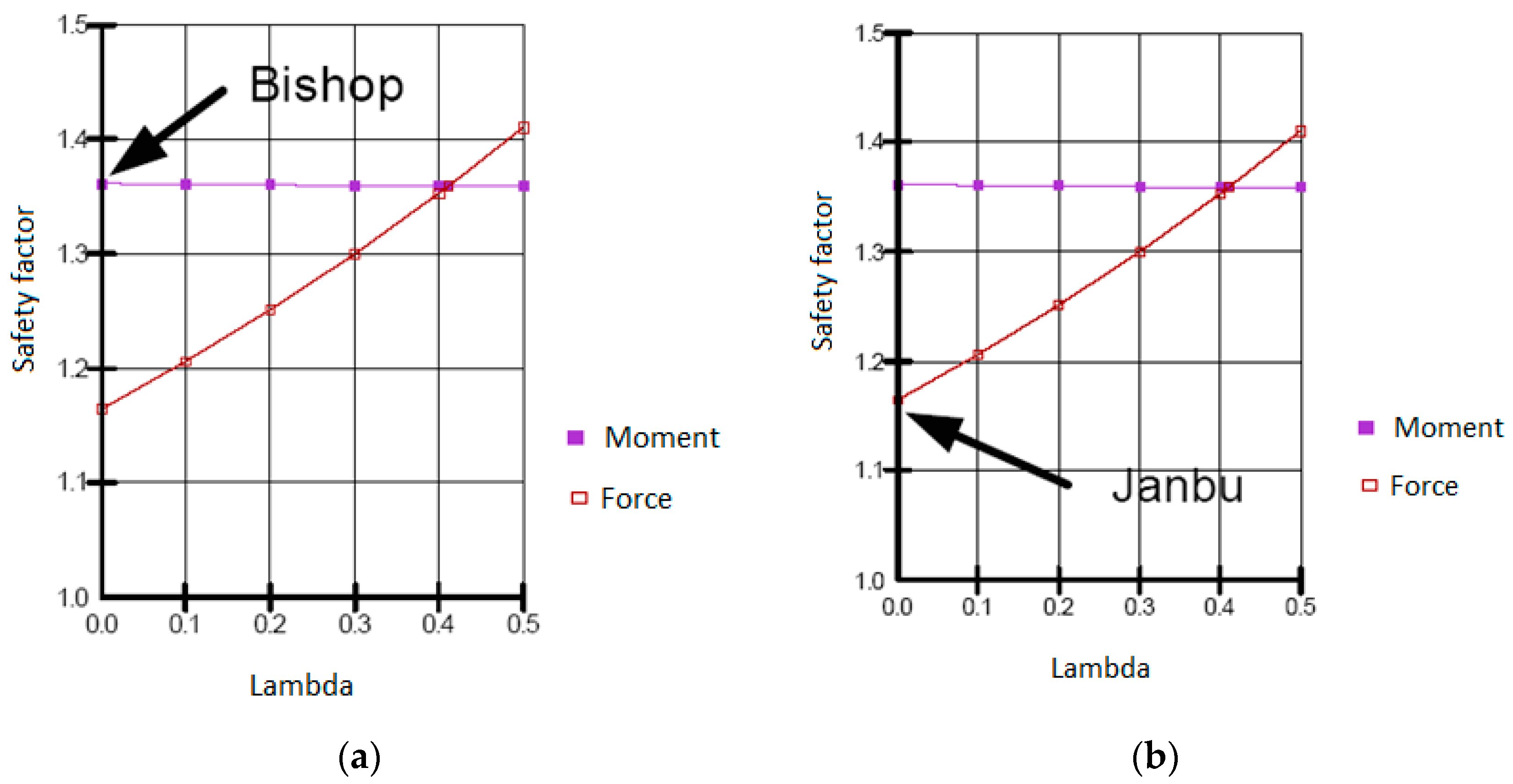

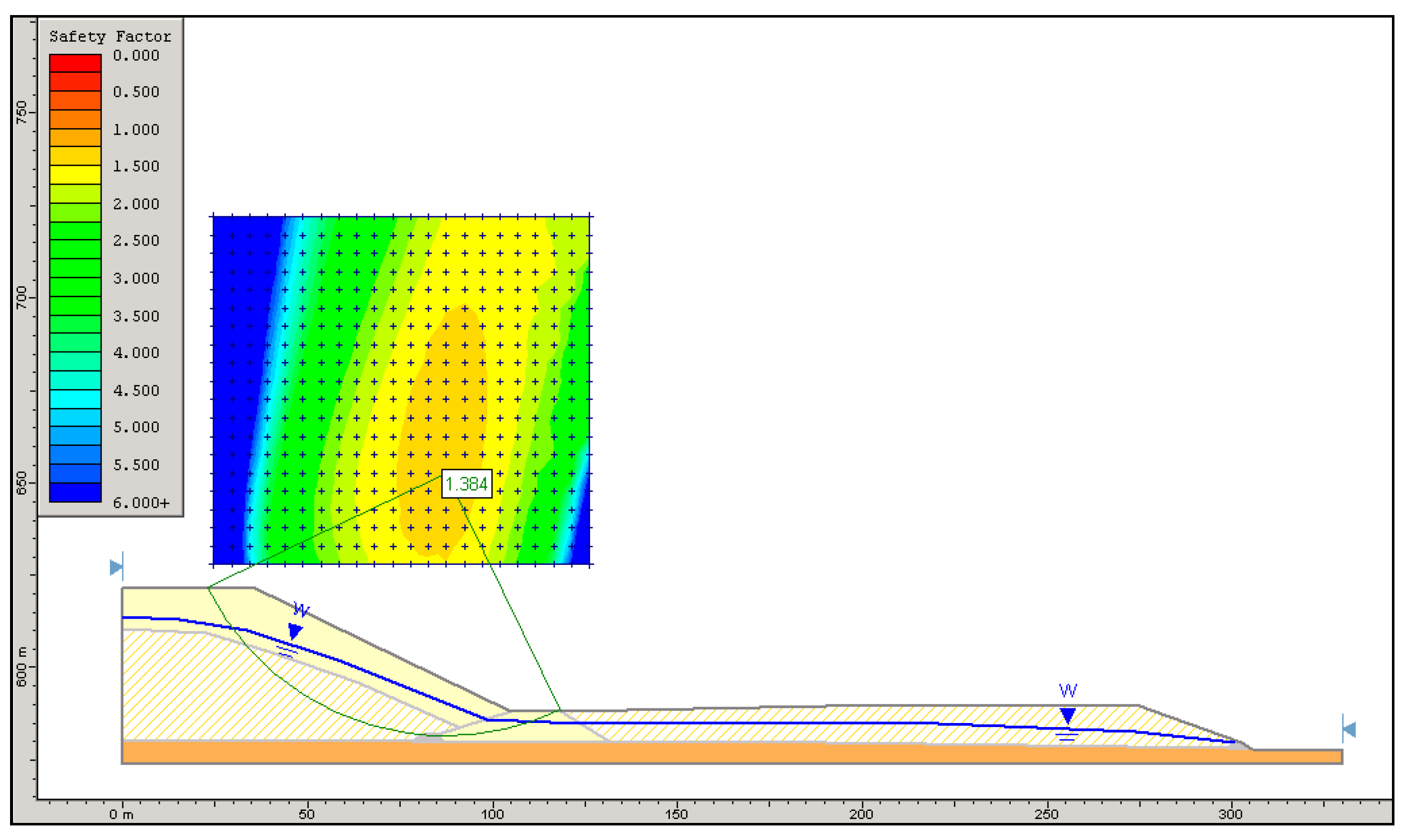

5.1. Stability Study Results

- Compartment 1: Section I-I′ S-N; Section II-II′ W-E;

- Compartment 2: Section III-III′ NE-SW; Section IV-IV′ NW-SE;

- Compartment 3: Section V-V′ NE-SW; Section VI-VI′ E-W; Section VII-VII′ SE-NW.

5.2. Infiltration Modeling

- The terrace deposit (clogged up in the digging area), K = 2.90 × 10−5 m/s;

- The priming dike, K = 15.80 × 10−5 m/s;

- Dam material (medium–fine sand), K = 1.16 × 10−5 m/s;

- Dam material (dusty sand), K = 5.80 × 10−5 m/s.

- Dam No. 3 cannot be used because it does not have the mechanical characteristics necessary for this type of hydrotechnical construction.

- Currently, there is only one clear water evacuation system (in dam number 2).

- Any elevation of these dams requires a corresponding occupation of the land surface on the coast on which the deposit rests, namely, on privately owned land where expropriation may lead to negotiations with uncertain results.

- Due to the weak geotechnical characteristics of the land on which a new dam would be located (represented by the three existing dams), particularly expensive work will be necessary, as well as taking a long time to complete.

6. Technical Proposals

- carrying out a specialized study and an analysis of the physical–chemical composition of the material that makes up the deposit in order to accurately establish whether in its composition there are elements and useful mineral substances profitable from an economic, strategic, and social point of view in order to recover them with the technologies existing at that time;

- during the design and construction of the tailings dam, it must be taken into account that there are surfaces of the deposit that will be in contact with the natural land and whose size differs depending on the type of dam. Thus, it is indicated that even from this phase, an isolation or waterproofing of this contact surface should be carried out, so as to avoid the penetration of water from the natural land into the body of the dam because this will contribute to the phenomenon of its instability, but also vice versa, to avoid infiltrating harmful and dangerous substances from the warehouse into the natural land, causing pollution of the groundwater in the area.

7. Conclusions

- From the point of view of the stability calculations performed in the hypothesis in which the three ponds become active for the storage of tailings, assuming a corresponding piezometric level, the resulting safety factors are relatively close to the standard values (Fs ≥ 1.4) for the static analysis, and in seismic conditions, they are at the limit of equilibrium. In some areas, the slope shows values below the standard safety limit for this type of work. The calculations showed that one of the compartments of the sedimentation pond is totally unsuitable for elevation. From the results obtained, it was found that the location formed by the three compartments that make up the Gura Roşiei settling pond presents major disadvantages for the future storage of the flotation tailings and is at the same time an imminent danger for the environment. A solution for greening the dam in its dry version without the presence of water accumulations on its surface can be provided.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References and Notes

- Singer, P.C.; Stumm, W. Acidic Mine Drainage: The Rate-Determining Step. Science 1970, 167, 1121–1123. [Google Scholar] [CrossRef] [PubMed]

- Kossoff, D.; Dubbin, W.E.; Alfredsson, M.; Edwards, S.J.; Macklin, M.G.; Hudson-Edwards, K.A. Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Appl. Geochem. 2014, 51, 229–245. [Google Scholar] [CrossRef]

- Owen, J.R.; Kemp, D.; Lèbre, É.; Svobodova, K.; Murillo, G.P. Catastrophic tailings dam failures and disaster risk disclosure. Int. J. Disaster Risk Reduct. 2020, 42, 101361. [Google Scholar] [CrossRef]

- Pissarra, T.C.T.; Costa, R.C.A.; Valle Junior, R.F.d.; Silva, M.M.A.P.d.M.; Costa, A.M.d.; Sanches Fernandes, L.F.; Carvalho de Melo, M.; Valera, C.A.; Pacheco, F.A.L. Role of Mine Tailings in the Spatio-Temporal Distribution of Phosphorus in River Water: The Case of B1 Dam Break in Brumadinho. Water 2022, 14, 1572. [Google Scholar] [CrossRef]

- Wang, C.G.; Zhang, J.S. Experimental study on physical and mechanical properties of tailings. Min. Metall. Eng. 2005, 25, 19–22. [Google Scholar]

- Wang, F.J.; Wang, L.G. Hazards of tail reservior and its engineering control. Chin. J. Geol. Hazard Control 2003, 14, 76–80. [Google Scholar]

- Liu, T.F.; Zhang, P.W.; Hu, L.M. Experimental study on mechanical characteristics of copper tailing materials with sulfur content. Chin. J. Geotech. Eng. 2013, 35, 166–169. [Google Scholar]

- Liu, W.L.; Zhang, X.L.; Yan, D.Y.; Li, H.; Yu, S. A preliminary study on new prospecting technology of larger tailings-dam and engineering property of tailings. J. Eng. Geol. 2004, 12, 523–528. [Google Scholar]

- Zhang, C.; Yang, C.H.; Kong, L.W. Study on mechanical characteristics of tailing dam of a copper mine and stability analysis of tailing dam. Rock Soil Mech. 2003, 24, 858–862. [Google Scholar]

- James, M.; Aubertin, M.; Wijewickreme, D.; Wilson, G.W. A laboratory investigation of the dynamic properties of tailings. Can. Geotech. J. 2011, 48, 1587–1600. [Google Scholar] [CrossRef]

- Yin, G.Z.; Yang, Z.Y.; Wei, Z.A.; Tan, Q. Physical and mechanical properties of YangLa-copper’s tailings. J. Chongqing Univ. (Nat. Sci. Ed.) 2007, 30, 117–122. [Google Scholar]

- Hatje, V.; Pedreira, R.M.A.; de Rezende, C.E.; Augusto, C.; Schettini, F.; de Souza, G.C.; Canaver Marin, D.; Hackspacher, P.C. The environmental impacts of one of the largest tailing dam failures worldwide. Sci. Rep. 2017, 7, 10706. [Google Scholar] [CrossRef] [PubMed]

- Macklin, M.G.; Brewer, P.A.; Hudson-Edwards, K.A.; Bird, G.; Coulthard, T.J.; Dennis, I.A.; Lechler, P.J.; Miller, J.R.; Turner, J.N. A geomorphological approach to the management of rivers contaminated by metal mining. Geomorphology 2006, 79, 423–447. [Google Scholar] [CrossRef]

- Olías, M.; Moral, F.; Galván, L.; Cerón, J.C. Groundwater contamination evolution in the Guadiamar and Agrio aquifers after the Aznalcóllar spill: Assessment and environmental implications. Environ. Monit. Assess. 2012, 184, 3629–3641. [Google Scholar] [CrossRef]

- Segura, F.R.; Nunes, E.A.; Paniz, F.P.; Paulelli, A.C.C.; Rodrigues, G.B.; Braga, G.Ú.L.; Dos Reis Pedreira Filho, W.; Barbosa, F., Jr.; Cerchiaro, G.; Silva, F.F.; et al. Potential risks of the residue from Samarco’s mine dam burst (Bento Rodrigues, Brazil). Environ. Pollut. 2016, 218, 813–825. [Google Scholar] [CrossRef]

- Lottermoser, B. Mine Wastes: Characterisation, Treatment and Environmental Impacts; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2007. [Google Scholar]

- Rico, M.; Benito, G.; Salgueiro, A.R.; Díez-Herrero, A.; Pereira, H.G. Reported tailings dam failures: A review of the European incidents in the worldwide context. J. Hazard. Mater. 2008, 152, 846–852. [Google Scholar] [CrossRef]

- Miranda, L.S.; Marques, A.C. Hidden impacts of the Samarco mining waste dam collapse to Brazilian marine fauna—An example from the staurozoans (Cnidaria). Biota Neotrop. 2016, 16, 1–3. [Google Scholar] [CrossRef]

- Hudson-Edwards, K.A.; Macklin, M.G.; Miller, J.R.; Lechler, P.J. Sources, distribution and storage of heavy metals in the Rio Picomayo, Bolivia. J. Geochem. Explor. 2001, 72, 229–250. [Google Scholar] [CrossRef]

- Blight, G.; Steffen, D. Geotechnics of gold mine waste disposal. In Current Geotechnical Practice in Mine Waste Disposal; ASCE: New York, NY, USA, 1979; pp. 1–52. [Google Scholar]

- Martin, T.E.; McRoberts, E.C. Some considerations in the stability analysis of upstream tailings dams. In Proceedings of the sixth International Conference on Tailings and Mine Waste ‘99, Fort Collins, CO, USA, 24–27 January 1999; A.A Balkema: Rotterdam, The Netherlands, 1999; pp. 1–17. [Google Scholar]

- Morgenstern, N.R. Geotechnics and Mine Waste Management—An Update. In Proceedings of the ICME/UNEP Workshop on Risk Assessment and Contingency Planning in the Management of Mine Tailings, Buenos Aires, Argentina, 5–6 November 1998; pp. 172–175. [Google Scholar]

- Sengupta, M. Environmental Impacts of Mining: Monitoring, Restoration and Control; Lewis Publishers: Boca Raton, FL, USA, 1993. [Google Scholar]

- Burd, B.J. Evaluation of mine tailings effects on a benthic marine infaunal community over 29 years. Mar. Environ. Res. 2002, 53, 481–519. [Google Scholar] [CrossRef]

- Koval, V.; Mikhno, I.; Udovychenko, I.; Gordiichuk, Y.; Kalina, I. Sustainable natural resource management to ensure strategic environmental development. TEM J. 2021, 10, 1022–1030. [Google Scholar] [CrossRef]

- Bazaluk, O.; Ashcheulova, O.; Mamaikin, O.; Khorolskyi, A.; Lozynskyi, V.; Saik, P. Innovative activities in the sphere of mining process management. Front. Environ. Sci. 2022, 10, 878977. [Google Scholar] [CrossRef]

- Brinkgreve, R.B.J. Selection of soil models and parameters for geotechnical engineering application. In Proceedings of the Geo-Frontiers Conference, ASCE, Austin, TX, USA, 24–26 January 2005; American Society of Civil Engineers: Reston, VA, USA, 2005; pp. 69–98. [Google Scholar]

- Desai, C.S.; Shao, C.; White, D.; Davis, S. Stability analysis for consolidation and dynamic response of mine tailing dam. In Proceedings of the Fifth International Conference on Tailings and Mine Waste ‘98, Fort Collins, CO, USA, 26–28 January 1998; A.A Balkema Publishers: Rotterdam, The Netherlands, 1998; pp. 193–200. [Google Scholar]

- Prodromos, N.; Psarropoulos, P.N.; Psarropoulos and Yiannis Tsompanakis; Tsompanakis, Y. Stability of tailings dams under static and seismic loading. Can. Geotech. J. 2008, 45, 663–675. [Google Scholar]

- Toderas, M.; Ionica, A. Greening Solutions of Gura Rosiei Tailing Dam. Int. J. Environ. Sci. 2007, 2, 80–83. [Google Scholar]

- Gupta, G.; Sharma, S.K.; Singh, G.S.P.; Kishore, N. Numerical Modelling-Based Stability Analysis of Waste Dump Slope Structures in Open-Pit Mines-A Review. J. Inst. Eng. (India) Ser. D 2021, 102, 589–601. [Google Scholar] [CrossRef]

- Ecoind Bucuresti, Bilant de mediu nivel I pentru exploatarea miniera Rosia Montana-judetul Alba, Bucuresti, 2003. (In Romanian)

- SC West Construct Company SRL Baia Mare, Proiect Tehnic, Închiderea şi ecologizarea minei Roşia Montană, judeţul Alba—Etapa I iazul de decantare Gura Roşiei, Baia Mare, 2008. (In Romanian)

- SC Ipromin SA Bucuresti, Studiu hidrogeotehnic şi de stabilitate a iazurilor de decantare nr. 1, 2 şi 3 Gura Rosiei-judetul Alba, Bucureşti, 2005. (In Romanian)

- SC Phobos Soft Co SRL Bucuresti, Studiu de stabilitate al iazului de decantare Gura Rosiei-Judeţul Alba, Bucuresti, 2008–2011.

- RMGC. Rosia Montana Gold Corporation S.A.—Report on Environmental Impact Assessment Study; RMGC: Melbourne, Australia, 2006. [Google Scholar]

- Sakurai, S.; Shimizu, N. Assessment of rock slope stability by fuzzy set theory. In Proceedings of the 6th Congress of the International Society for Rock Mechanics, Montreal, QC, Canada, 30 August 1987; pp. 503–506. [Google Scholar]

- Gens, A.; Alonso, E.E. Aznalcóllar dam failure. Part 2: Stability conditions and failure mechanism. Géotechnique 2006, 56, 185–201. [Google Scholar] [CrossRef]

- He, H.W.; Long, J.H.; Lü, Y.Q. Experimental study of dynamic characteristics of tailings material at Mijiangou dam. J. Eng. Geol. 2007, 15, 817–822. [Google Scholar]

- Spencer, E. A method of analysis of the stability of embankments assuming parallel inter-slice forces. Geotechnique 1967, 17, 11–26. [Google Scholar] [CrossRef]

- Morgenstern, N.R.; Price, V.E. The analysis of the stability of general slip surfaces. Geotechnique 1965, 15, 79–93. [Google Scholar] [CrossRef]

- Griffiths, D.V.; Lane, P.A. Slope stability analysis by finite elements. Géotechnique 1999, 49, 387–403. [Google Scholar] [CrossRef]

- Luo, X.H.; Bai, S.W.; Wan, K.J. Static stability analysis of seepage of tailings dam. Rock Soil Mech. 2004, 25, 560–565. [Google Scholar]

- Jing, X.F.; Yin, G.Z.; Wei, Z.A.; Li, X.S.; Wang, M.L. Model experimental study of collapse mechanism and broken mode of tailings dam. Rock Soil Mech. 2011, 32, 1377–1385. [Google Scholar]

- Li, H.R.; Hu, Z.Q.; Chen, C.L.; Dang, F.N. Numerical simulation and slope stability analysis in Jingduicheng tailings dam to be designed to increase the dam height. Rock Soil Mech. 2008, 29, 1138–1142. [Google Scholar]

- Liu, Y.; Zhao, X.T.; Wu, S.C. Analysis of Static Liquefaction and Numerical simulation for tailings pond under high depositing rates. Chin. J. Rock Mech. Eng. 2014, 33, 1158–1168. [Google Scholar]

- Yu, S.Y.; Shao, L.T.; Liu, S.Y. Stability analysis of tailings dam based on finite element limit equilibrium method. Rock Soil Mech. 2012, 34, 1185–1190. [Google Scholar]

- Salmasi, F.; Pradhan, B.; Nourani, B. Prediction of the sliding type and critical factor of safety in homogeneous finite slopes. Appl. Water Sci. 2019, 9, 158. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, A.; Sitharam, T.G. Stability Analysis of Tailings Dam Using Finite Element Approach and Conventional Limit Equilibrium Approach. In Stability of Slopes and Underground Excavations; Satyanarayana Reddy, C.N.V., Muthukkumaran, K., Vaidya, R., Eds.; Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 185. [Google Scholar] [CrossRef]

- Ning, H.D.; Yu, Z.; Zhu, L.Z.; Ye, F. Stability analysis of the dam of Baogang West Mine Tailings Pond. J. Eng. Geol. 2014, 22, 37–42. [Google Scholar]

- Li, Q.; Zhang, L.T.; Qi, Q.L.; Zhou, Z. Instability characteristics and stability analysis of a tailings dam based on fluid-solid coupling theory. Rock Soil Mech. 2012, 33, 243–250. [Google Scholar]

- Li, Q.M.; Zhang, X.K.; Wang, Y.H.; Zhang, R.Y. Risk index system and evaluation model for failure of tailings dams. J. Hydraul. Eng. 2009, 40, 989–994. [Google Scholar]

- Sitharam, T.G.; Hegde, A. Stability analysis of rock-fill tailing dam: An Indian case study. Int. J. Geotech. Eng. 2017, 11, 332–342. [Google Scholar] [CrossRef]

- Johari, A.; Mousavi, S.; Hooshmand Nejad, A. A seismic slope stability probabilistic model based on Bishop’s method using analytical approach. Sci. Iran. A 2015, 22, 728–741. [Google Scholar]

- Johari, A.; Khodaparast, A.R. Analytical stochastic analysis of seismic stability of infinite slope. Soil Dyn. Earthq. Eng. 2015, 79 Pt A, 17–21. [Google Scholar]

- Johari, A.; Rahmati, H. System reliability analysis of slopes based on the method of slices using sequential compounding method. Comput. Geotech. 2019, 114, 103116. [Google Scholar] [CrossRef]

- Signoret, J.P.; Leroy, A. Hazard and Operability Study (HAZOP). In Reliability Assessment of Safety and Production Systems; Springer Series in Reliability Engineering; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Kletz, T.A. Hazop & Hazan: Identifying and Assessing Process Industry Hazards, 4th ed.; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar] [CrossRef]

- Chakrabarti, U.K.; Parikh, J.K. Applying HAZAN methodology to hazmat transportation risk assessment. Process Saf. Environ. Prot. 2012, 90, 368–375. [Google Scholar] [CrossRef]

- Muram, F.U.; Javed, M.A.; Punnekkat, S. System of Systems Hazard Analysis Using HAZOP and FTA for Advanced Quarry Production. In Proceedings of the 4th International Conference on System Reliability and Safety (ICSRS), Rome, Italy, 20–22 November 2019; pp. 394–401. [Google Scholar]

- Sofri, S.; Prasad, D.M.R.; Azri, M.H.B. Analysis of chemical engineering curriculum to improve process safety competency. Int. J. Occup. Saf. Ergon. 2023, 29, 642–650. [Google Scholar] [CrossRef] [PubMed]

- Afefy, I.H. Hazard Analysis and Risk Assessments for Industrial Processes Using FMEA and Bow-Tie Methodologies. Ind. Eng. Manag. Syst. 2015, 14, 379–391. [Google Scholar] [CrossRef]

| Chemical Element | Value (%) | Chemical Element | Value (%) |

|---|---|---|---|

| SiO2 | 65.31 | Pb | 0.06 |

| Al2O3 | 12.33 | Cu | 0.03 |

| Fe | 2.15 | Zn | 0.06 |

| CaO | 2.08 | V | 0.0003 |

| MgO | 1.49 | Cr | 0.0003 |

| S | 0.89 | Ni | 0.0003 |

| Mn | 0.10 | W | 0.003 |

| Method | Equilibrium of Moments | Equilibrium of Forces |

|---|---|---|

| Fellenius | YES | NO |

| Bishop simplified | YES | NO |

| Janbu simplified | NO | YES |

| Janbu corrected | YES (on the strip) | YES |

| Morgenstern–Price (GLE) | YES | YES |

| Spencer | YES | YES |

| US Army Corps of Engineers-1 | NO | YES |

| US Army Corps of Engineers-2 | NO | YES |

| Lowe–Karafiath | NO | YES |

| HAZOP Technique | HAZAN Technique |

|---|---|

| Identify hazards | Evaluate the hazards |

| It is preferred for use in every project | It is a selective technique used mainly for systems potentially exposed to major accidents |

| Qualitative technique | Quantitative technique |

| It is carried out by a team | It is made by one or two experts in the field |

| It is also called “But What If?” |

| No. | Risk Severity Level | Effects |

|---|---|---|

| 1 | Insignificant | For humans (the population): insignificant injuries. Ecosystems: some minor adverse effects on a few species or parts of the ecosystem, short-term and reversible. Socio-political: insignificant social effects without cause for concern for the community. |

| 2 | Minor | For humans (population): insignificant injuries. Ecosystems: some minor adverse effects on a few species or parts of the ecosystem, short-term and reversible. Socio-political: insignificant social effects without cause for concern for the community. |

| 3 | Moderate | For the population: medical certificates are required. Economic: reduction of production capacity. Emissions: emissions within the objective can be contained with external help. Ecosystems: temporary and reversible damage; damage to habitats and migration of animal populations; plants unable to survive; air quality affected by compounds with potential long-term health risks; possible damage to aquatic life; pollution requiring physical treatments; limited contamination of the soil which can be remedied quickly. Socio-political: Social effects of moderate concern for the community. |

| 4 | Major | For people (population): special injuries. Economic: interruption of production activity. Emissions: off-site emissions without harmful effects. Ecosystems: the death of some animals; large-scale damage; damage to local species; and the destruction of extensive habitats; air quality requiring “safe refuge” or the decision to evacuate; soil remediation only possible through long-term programs. Socio-political: Social effects of serious concern for the community. |

| 5 | Catastrophic | For people (population): death. Economic: stopping the production activity. Emissions: off-site toxic emissions with harmful effects. Ecosystems: the death of animals in large numbers; the destruction of flora species; the quality of the air requiring evacuation; permanent contamination of extensive areas of the soil. Socio-political: social effects of particular concern to the community. |

| No. | Probability | When It Can Be Produced | Frequency (Probability) of Occurrence |

|---|---|---|---|

| 1 | Rare | Only in exceptional conditions | 10−12 ani |

| 2 | Not probably | It could happen sometime | 10−8–10−12 ani |

| 3 | Posible | It can happen sometime | 10−6–10−8 ani |

| 4 | Probably | It can happen in most situations | 10−4–10−6 ani |

| 5 | Almost certainly | It is expected to happen in most situations | <10−4 ani |

| SEVERITY | |||||||

| Negligible | Medium | Grave | Very Grave | Catastrophic | |||

| 1 | 2 | 3 | 4 | 5 | |||

| PROBABILITY | Very frequently | 1 | 1 | 2 | 3 | 4 | 5 |

| Frequently | 2 | 2 | 4 | 6 | 8 | 10 | |

| Rare | 3 | 3 | 6 | 9 | 12 | 15 | |

| Extremely rare | 4 | 4 | 8 | 12 | 16 | 20 | |

| Improbable | 5 | 5 | 10 | 15 | 20 | 25 | |

| No. | Material Type | Volumetric Weight (kN/m3) | Internal Friction Angle (Degree) | Cohesion (kPa) |

|---|---|---|---|---|

| 1 | Fine–medium sandy pond material | 15.79 | 33 | 10 |

| 2 | Dusty sand pond material | 15.79 | 30 | 20 |

| 3 | Priming dike | 19.62 | 35 | 0 |

| 4 | Terrace deposit | 17.66 | 35 | 10 |

| 5 | Diluvial deposit | 18.00 | 20 | 30 1 |

| Computational Section | Computing Method 1 | |||||||

|---|---|---|---|---|---|---|---|---|

| Bishop | Janbu | Spencer | Morgenstern–Price | |||||

| Fstatic | Fseismic | Fstatic | Fseismic | Fstatic | Fseismic | Fstatic | Fseismic | |

| Compartment 1, Section 1 (C1S1) | 1.384 | 1.140 | 1.317 | 1.075 | 1.397 | 1.160 | 1.397 | 1.159 |

| Compartment 1, Section 1 new (C1S1N) | 1.372 | 1.132 | 1.302 | 1.067 | 1.381 | 1.151 | 1.380 | 1.149 |

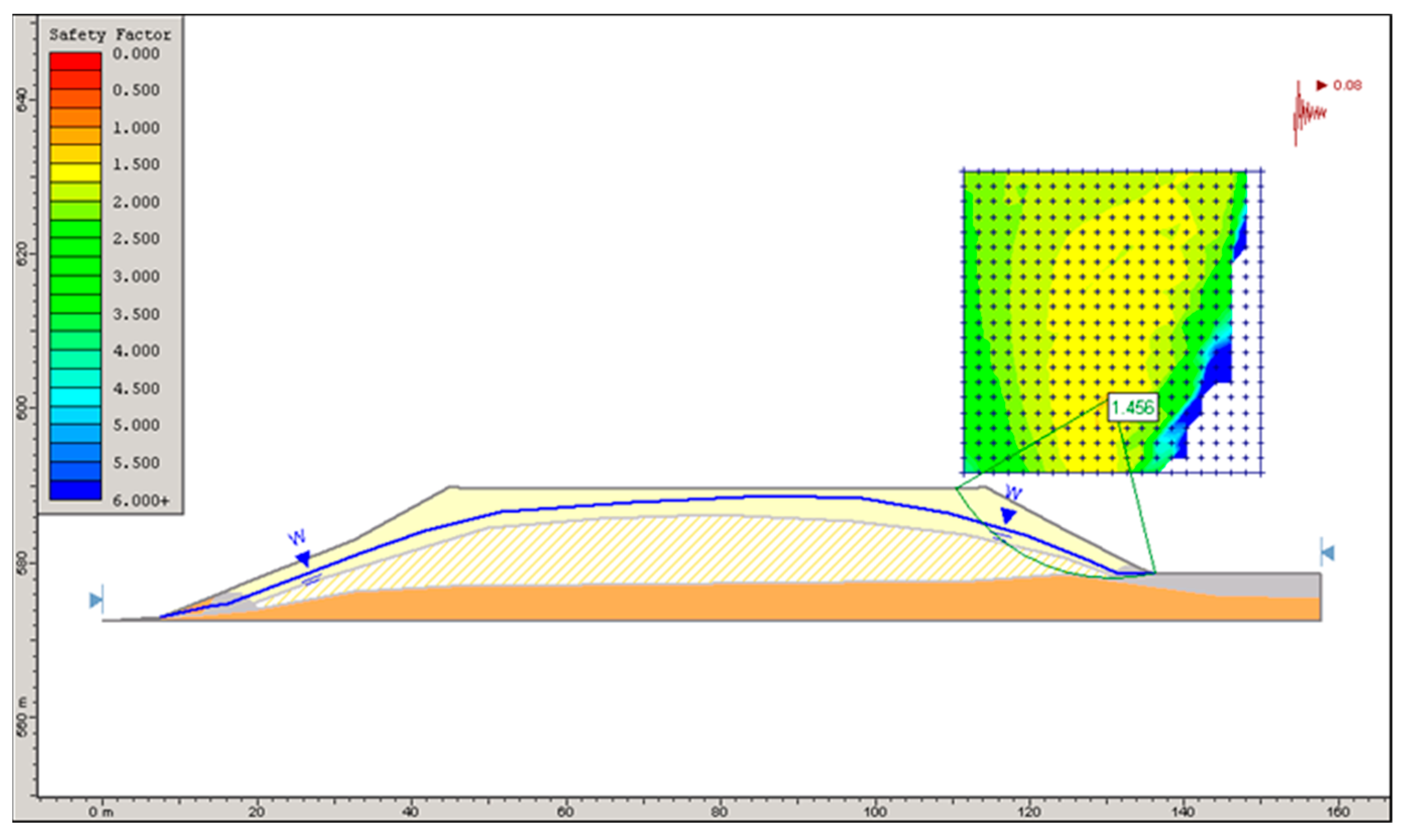

| Compartment 1, Section 2 (C1S2) | 1.752 | 1.456 | 1.722 | 1.411 | 1.761 | 1.471 | 1.762 | 1.474 |

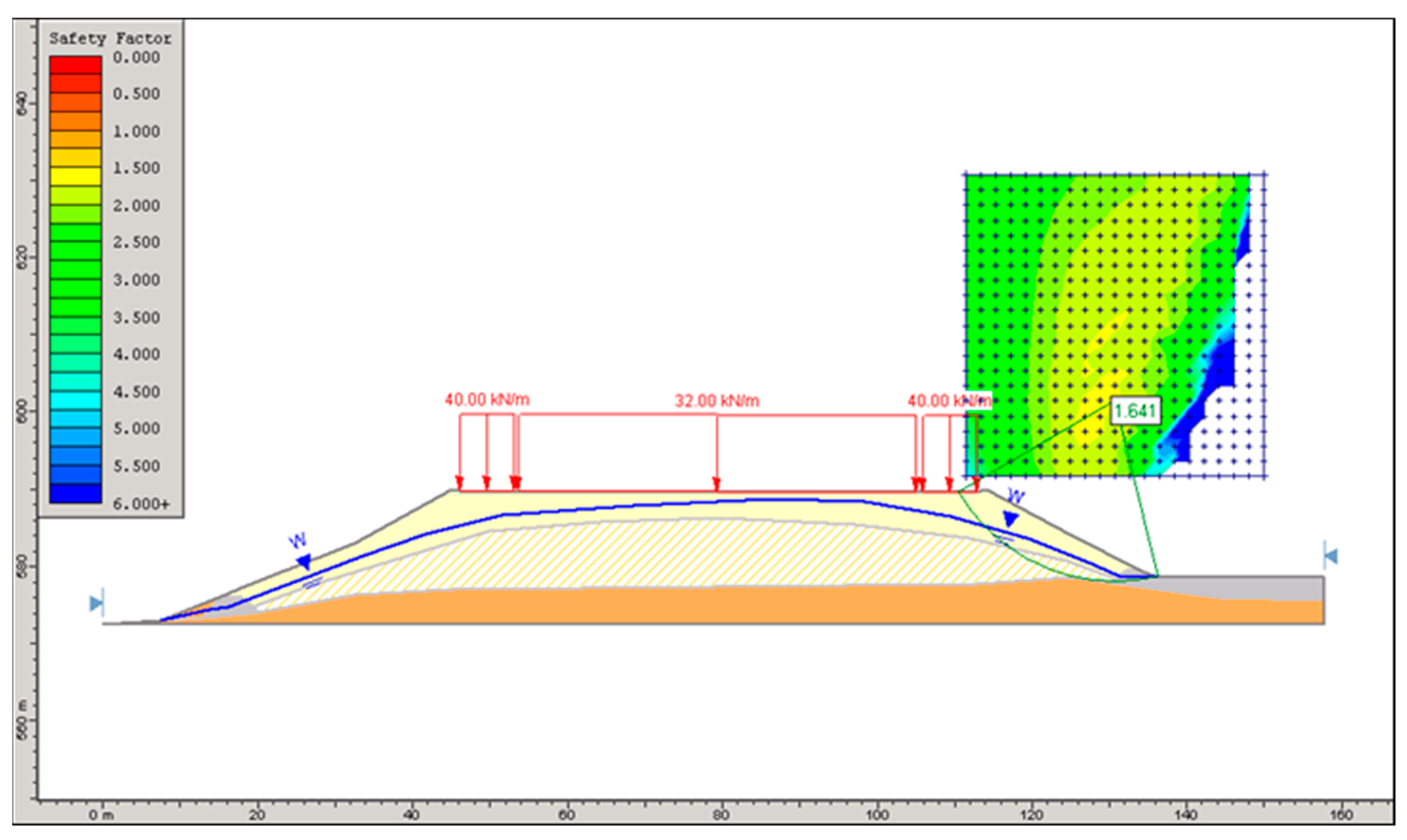

| Compartment 1, Section 2 new (C1S2N) | 1.641 | 1.386 | 1.570 | 1.317 | 1.648 | 1.399 | 1.652 | 1.405 |

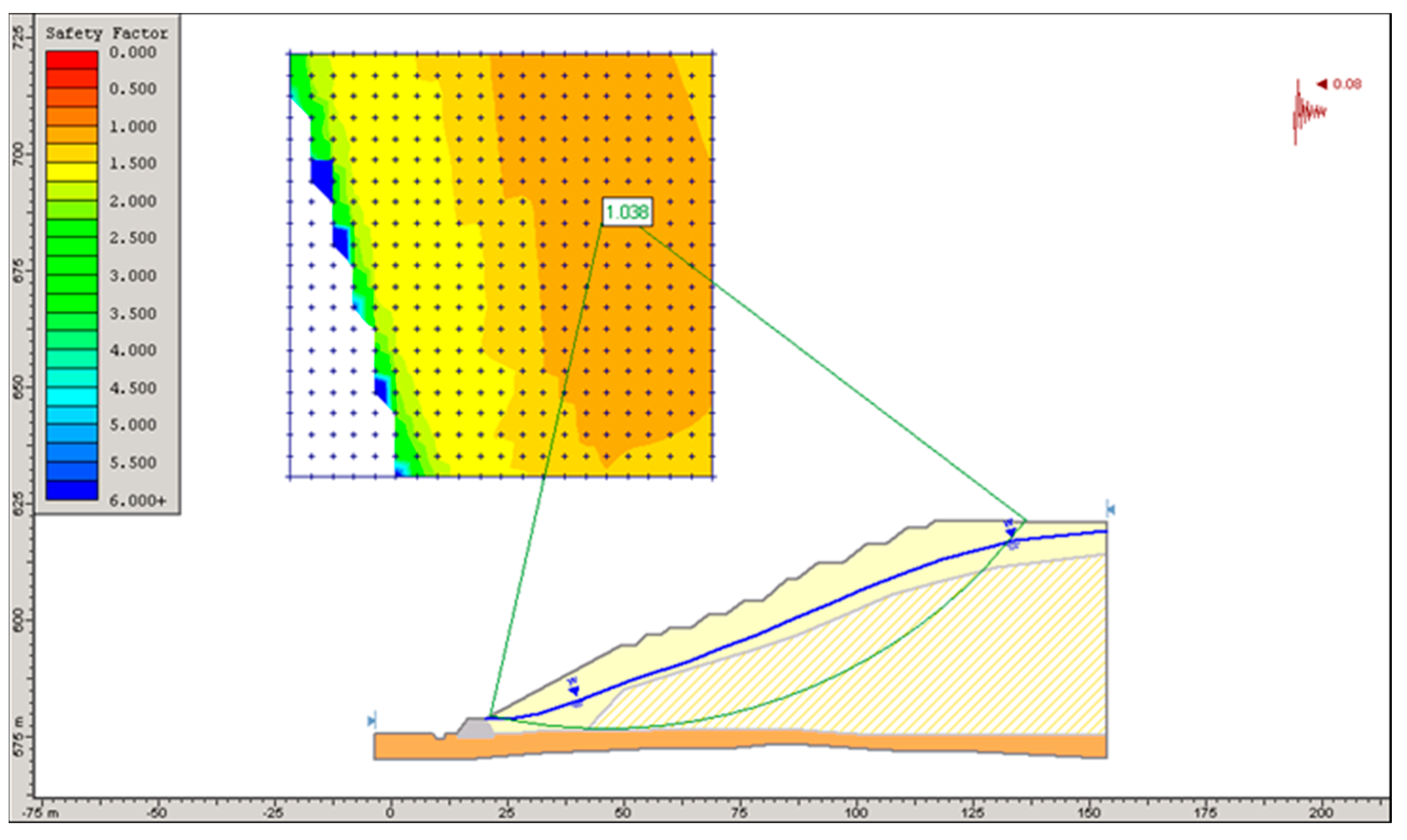

| Compartment 2, Section 3 (C2S3) | 1.284 | 1.038 | 1.260 | 1.008 | 1.298 | 1.056 | 1.296 | 1.057 |

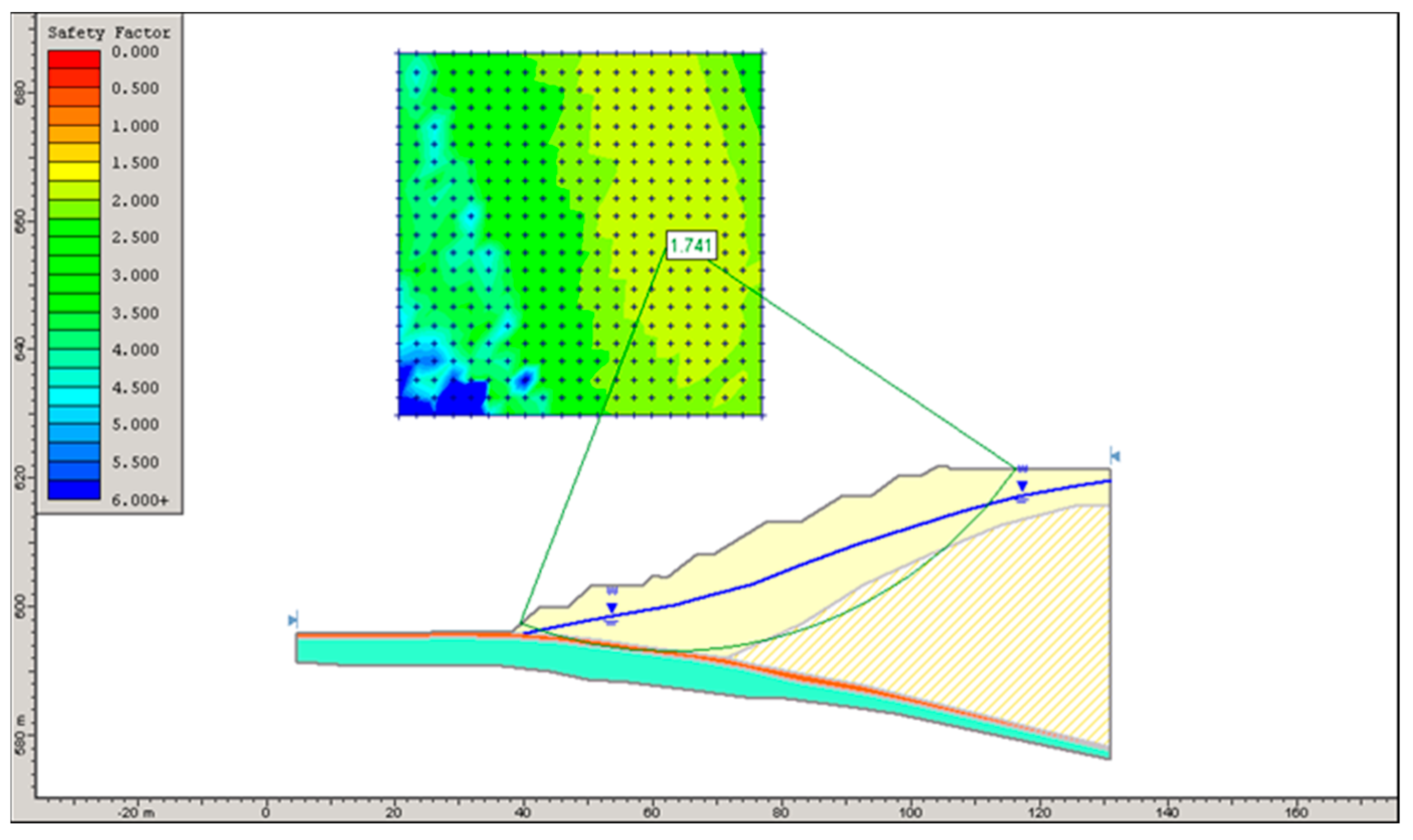

| Compartment 2, Section 4 (C2S4) | 1.741 | 1.369 | 1.698 | 1.325 | 1.729 | 1.359 | 1.725 | 1.352 |

| Compartment 3, Section 5 (C3S5) | 1.455 | 1.159 | 1.403 | 1.108 | 1.468 | 1.177 | 1.464 | 1.173 |

| Compartment 3, Section 6 (C3S6) | 1.537 | 1.219 | 1.519 | 1.203 | 1.542 | 1.234 | 1.540 | 1.230 |

| Compartment 3, Section 7 (C3S7) | 1.414 | 1.119 | 1.388 | 1.094 | 1.422 | 1.135 | 1.419 | 1.132 |

| Calculation Section | Infiltrations through the Dike | |

|---|---|---|

| (m3/s) | (m3/day) | |

| Initial Section 1 | 2.221 × 10−7 | 0.020 |

| Section 1 superelevation | 4.324 × 10−6 | 0.374 |

| Tailings Dam Compartment | Safety Coefficient 1 on: | |

|---|---|---|

| Static Load | Dynamic Load | |

| Compartment No. 1 | 1.31–1.76 | 1.07–1.47 |

| Compartment No. 2 | 1.24–1.72 | 1.008–1.35 |

| Compartment No. 3 | 1.39–1.54 | 1.09–1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toderaș, M.; Florea, V.A.; Itu, R.B. Stability Analysis of the Tailings Dam for the Purpose of Closing, Greening, and Ensuring Its Safety—Study Case. Sustainability 2023, 15, 7606. https://doi.org/10.3390/su15097606

Toderaș M, Florea VA, Itu RB. Stability Analysis of the Tailings Dam for the Purpose of Closing, Greening, and Ensuring Its Safety—Study Case. Sustainability. 2023; 15(9):7606. https://doi.org/10.3390/su15097606

Chicago/Turabian StyleToderaș, Mihaela, Vlad Alexandru Florea, and Răzvan Bogdan Itu. 2023. "Stability Analysis of the Tailings Dam for the Purpose of Closing, Greening, and Ensuring Its Safety—Study Case" Sustainability 15, no. 9: 7606. https://doi.org/10.3390/su15097606

APA StyleToderaș, M., Florea, V. A., & Itu, R. B. (2023). Stability Analysis of the Tailings Dam for the Purpose of Closing, Greening, and Ensuring Its Safety—Study Case. Sustainability, 15(9), 7606. https://doi.org/10.3390/su15097606