Research on Beijing Manufacturing Green-Oriented Transition Path under “Double Carbon” Goal-Based on the GML-SD Model

Abstract

1. Introduction

2. Measurement of Green Total-Factor Energy Efficiency

2.1. Models and Methods

2.1.1. The SuperSBM Model

2.1.2. The GML Index

2.2. Indicator Selection and Data Sources

- 1.

- Capital Indicator—Annual Average Balance of Net Fixed Assets.

- 2.

- Labor Indicator—Annual Average Number of Employees.

- 3.

- Energy—Total Energy Consumption.

- 4.

- Desirable Output—Industrial Gross Output.

- 5.

- Undesirable Output—CO2 Emissions.

2.3. Empirical Results

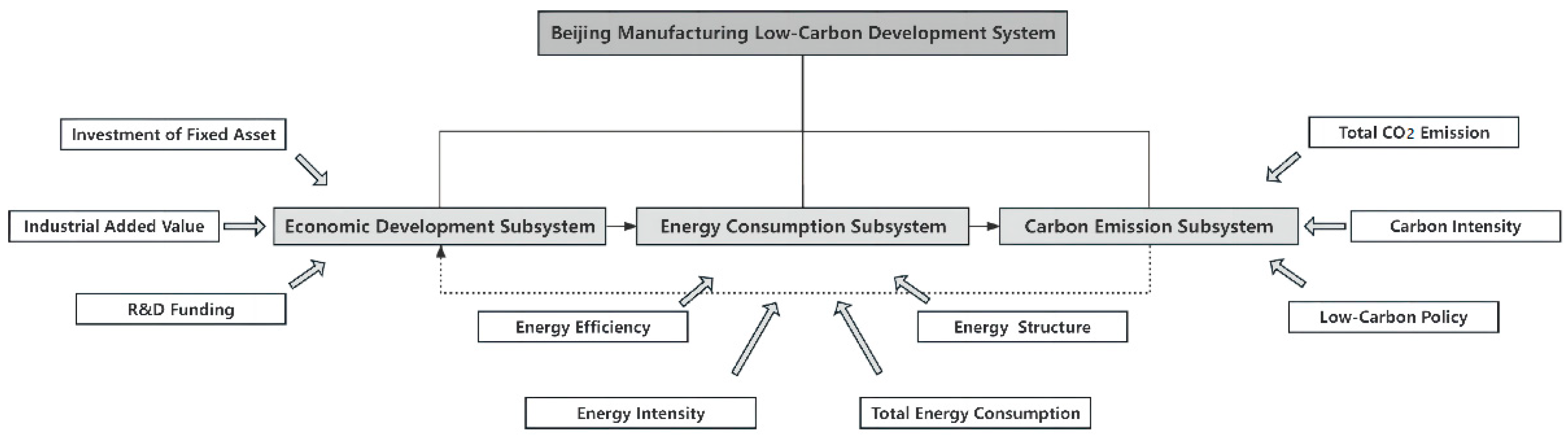

3. Modeling of Beijing Manufacturing Low-Carbon Development System Based on Green Total-Factor Energy Efficiency

3.1. Boundary and Influencing Factors of the System

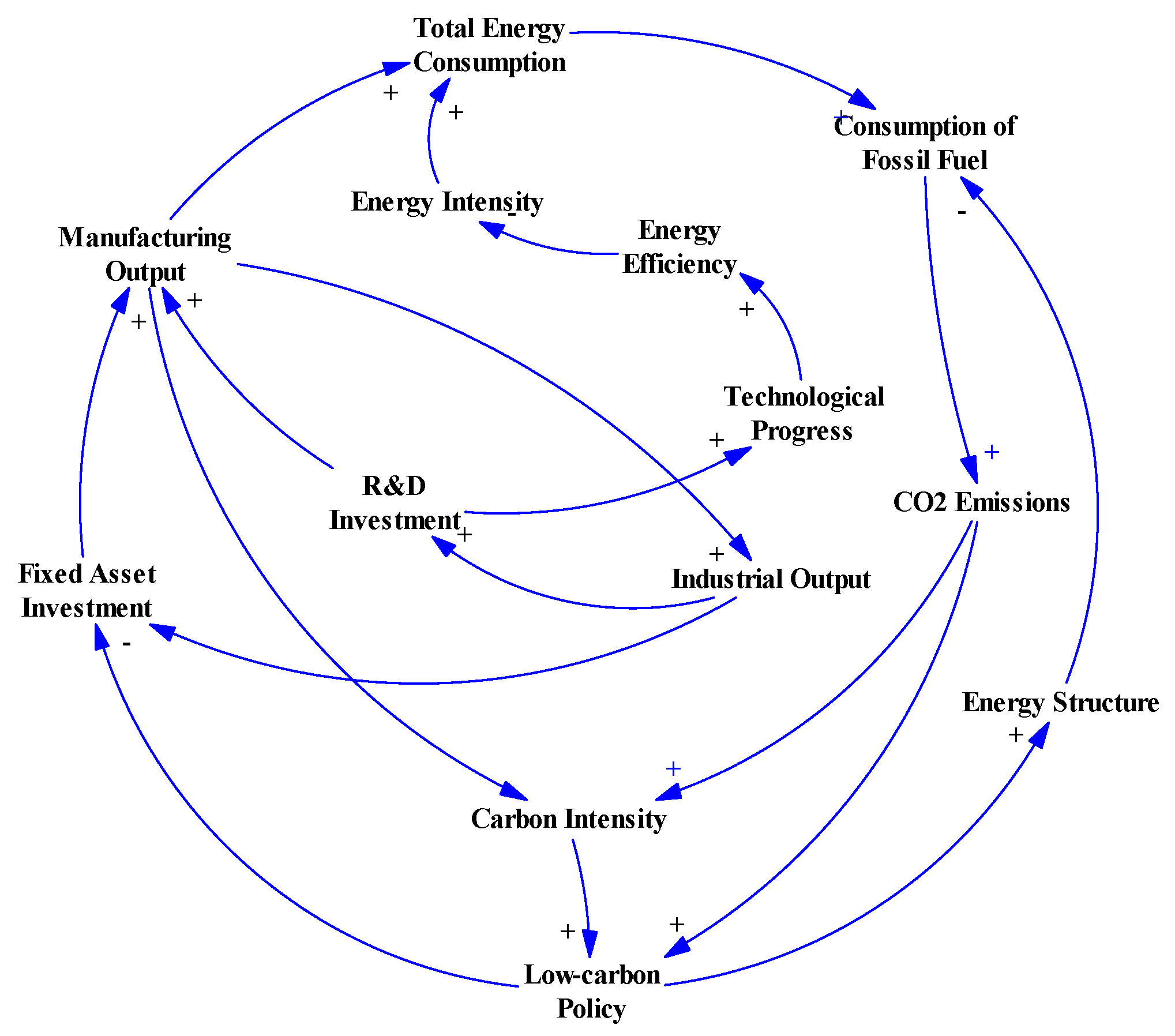

3.2. Causal Feedback Analysis of the System

3.3. Stock-Flow Relationship Analysis of the System

3.4. Parameter Setting of the System

3.4.1. Initial Value

3.4.2. Parameter Setting of Economic Development Subsystem

- 1.

- The manufacturing industry added value

3.4.3. Parameter Setting of Energy Consumption Subsystem

- 1.

- The Manufacturing Energy Consumption

- 2.

- The Energy Intensity

3.4.4. Parameter Setting of Carbon Emission Subsystem

- 1.

- The Manufacturing CO2 Emissions

- 2.

- The Carbon Intensity

3.5. Assumptions

- Assumption 1: In the initial scenario of the system, to obtain the predicted value of variables during the 14th Five-Year Plan period, the energy consumption structure is maintained at the same level as year 2020, and all other variables that require input values use the average annual growth rate to calculate predicted values.

- Assumption 2: Investment of fixed assets and R&D investment are the main influencing factors for the change of manufacturing added value.

- Assumption 3: The Beijing manufacturing final consumption of coke will hold at zero during the 14th Five-Year Plan period.

- Assumption 4: All CO2 emissions calculated in the model are produced by fossil fuel and are emitted as CO2.

- Assumption 5: Simulation is performed only using the variables within the system.

3.6. Model Validity Test

4. Simulation and Analysis of Beijing Manufacturing Low-Carbon Development System

- Target 1: energy intensity reduction rate ≥12%.

- Target 2: carbon reduction rate ≥20%.

- Target 3: the proportion of manufacturing added value in GDP is back up to 13%, striving to reach approximately 15%.

4.1. Scenario Setting of the System

- Scenario 1 (initial model): the energy structure is maintained at the level of 2020 and all other variables are projected using average annual growth rates.

- Scenario 2 (energy restructuring priority model): comparing the 2025 energy consumption target value with the actual value in 2020 and considering the Beijing 14th Five-Year Plan of “reducing coal, stabilizing gas, and reducing oil”, the final parameter is set to reduce coal consumption while maintaining the proportion of oil and gas consumption at the level of 2020. Other variables are maintained at the same level as the initial model.

- Scenario 3 (industrial investment priority model): manufacturing R&D investment is prioritized, with fixed asset investment concerning the year-on-year growth rate of real data in 2020 and 2021 to determine the parameters. Other variables are maintained at the level of the initial model.

- Scenario 4 (low-carbon technological progress priority model): the green total-factor energy efficiency index calculated in Section 2 is used as a proxy variable for low-carbon technological progress. Systematic changes in this scenario are examined by increasing the average annual growth rates of the EC and TC index. In addition, other variables are maintained at the level of the initial model.

- Scenario 5 (comprehensive development model): this scenario conducts integrated and optimal regulation of energy consumption restructuring, industrial investment, and low-carbon technological progress.

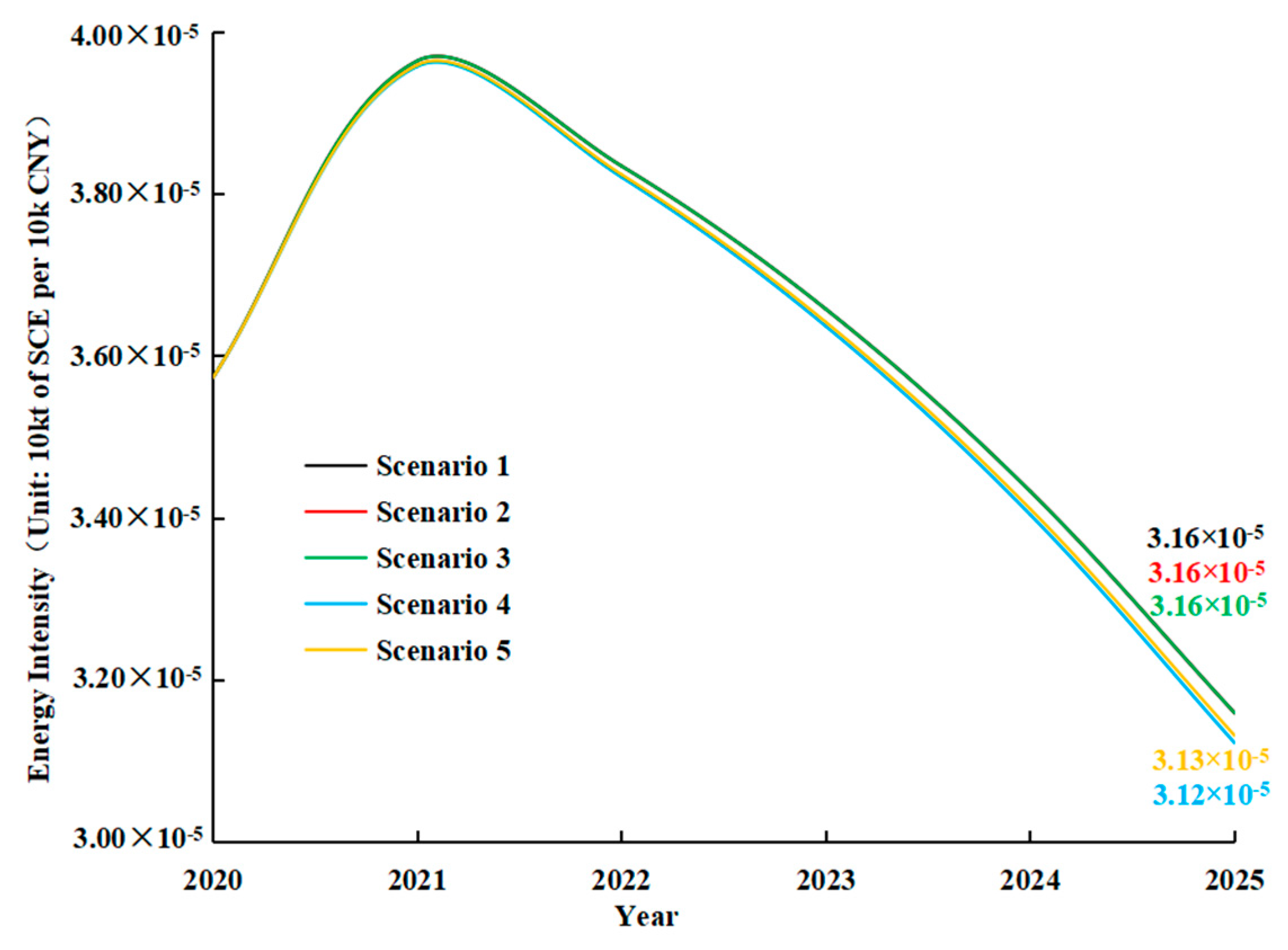

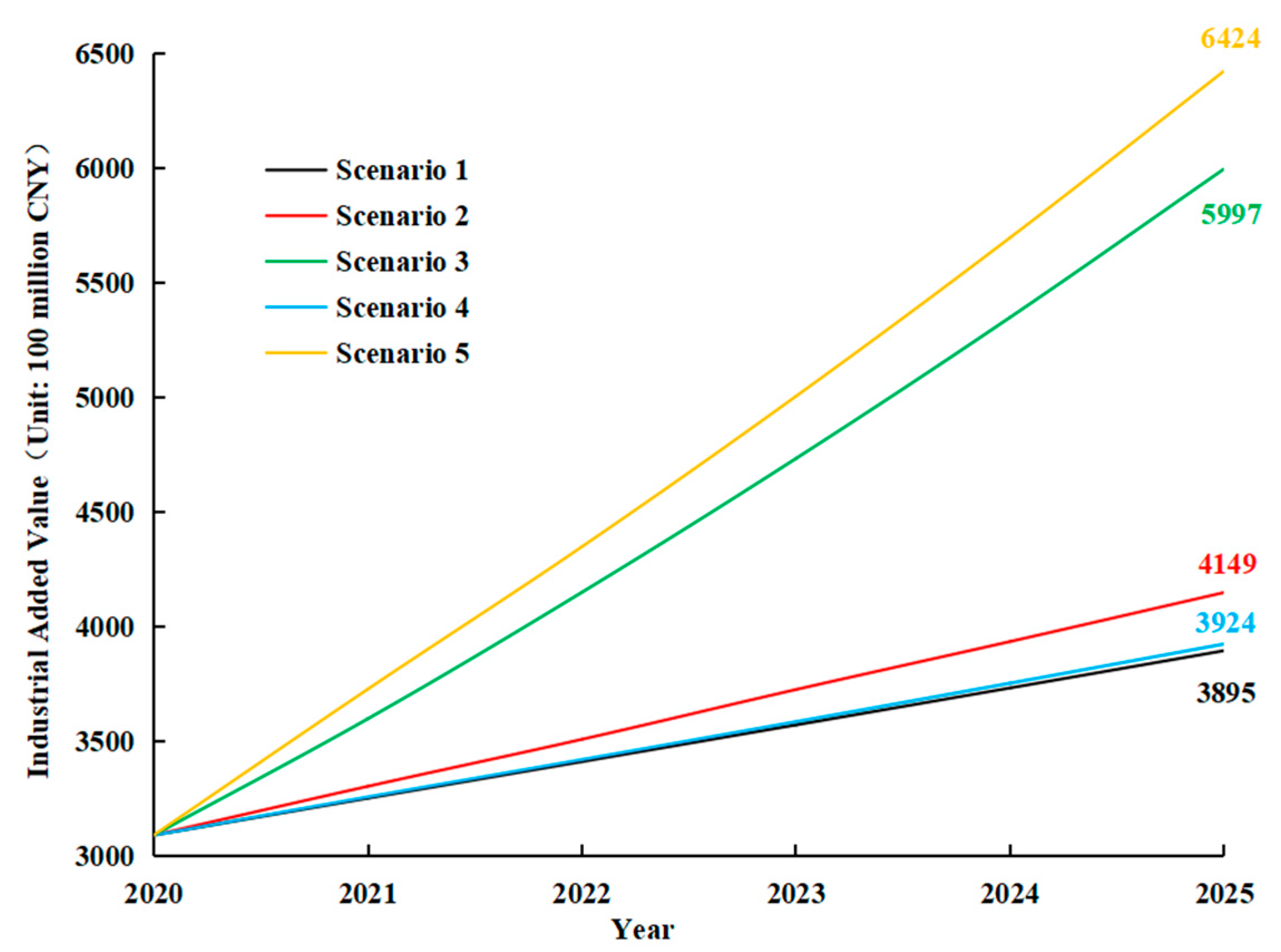

4.2. Results of Simulation

- Scenario 1 (initial model): In the initial scenario, the energy intensity in Beijing’s manufacturing industry will be reduced to 3.16 × 10−5 10 kt of SCE per 10k CNY by 2025, down 11.58% from 2020, and the carbon intensity will drop to 1.01 × 10−5 10 kt per 10k CNY by 2025, which also cannot reach the target value. In addition, due to the low average annual growth rate of R&D investment and fixed asset investment, the proportion of manufacturing added value to GDP in 2025 is 8.45% (The predicted value of GDP in 2025 is calculated on the basis of the Outline for the 14th Five-Year Plan for Beijing’s Economic and Social Development and Long-Range Objectives through the Year 2035), which cannot rise back to the expected level of 13%.

- Scenario 2 (energy restructuring priority model): With regard to energy restructuring priority, the energy consumption structure is regulated concerning the projects of energy development in the Beijing Energy Development Plan for the 14th Five-Year Plan Period. The simulation results show that with the reduction of coal consumption, CO2 emissions, and carbon intensity decrease. Under this scenario, the CO2 emissions of Beijing in 2025 will be 2,723,200 tons, which is 23.13% lower than that in 2020; additionally, the carbon intensity in 2025 will reach 6.96 × 10−6 10 kt per 10k CNY, which is 39.26% lower than that in 2020, and it will reach the target value. However, the model still has some shortcomings preventing the manufacturing economic output from reaching the planned value.

- Scenario 3 (industry investment priority model): In 2020 and 2021, the real data in Beijing Statistic Book show that R&D and fixed asset investment in Beijing’s manufacturing industry grows rapidly over the years, so this paper refers to historical data for selecting parameter settings. In this scenario, the manufacturing added value will increase to 599.70 billion CNY, and its proportion of GDP will reach 13.02%, which can achieve the requirements of Target 3. However, the increase in R&D and fixed asset investment promotes the rise in manufacturing added value while the increase in the manufacturing added value is accompanied by higher levels of energy consumption, which further leads to a higher level of CO2 emissions. The results show that regulation from a single investment perspective still has many drawbacks.

- Scenario 4 (priority model for technological progress in energy conservation and emission reduction): When focusing on technological progress in energy conservation and emission reduction, the energy intensity will be reduced to 3.12 × 10−5 10 kt of SCE per 10k CNY in 2025, which is 12.62% lower than that in 2020; however, this scenario can only satisfy Target 1. Thus, multi-variable regulation for optimization is still required.

- Scenario 5 (system coordination development model): This scenario is the comprehensive optimization scenario of Scenarios 2, 3, and 4. It considers the coordination relationship among all the selected variables and is determined after several simulations. As shown in Figure 4, Figure 5 and Figure 6, in this scenario, energy intensity decreases by 12.36%, carbon intensity decreases by 21.00%, and the share of added value in GDP rebounds to 13.94%, which means all low-carbon targets are achieved.

5. Conclusions and Policy Implications

- 1.

- Adjust the energy structure and synchronically promote green technology to help the manufacturing industry save energy and reduce carbon.

- 2.

- Increase investment in fixed assets and R&D funds to promote the development of high-end and green-oriented manufacturing.

- 3.

- Tackle key problems in technology while providing targeted assistance in certain manufacturing sub-sectors to improve energy efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Caves, D.W.; Christensen, L.R.; Diewert, W.E. The Economic Theory of Index Numbers and the Measurement of Input, Output, and Productivity. Econometrica 1982, 50, 1393–1414. [Google Scholar] [CrossRef]

- Hu, J.L.; Wang, S.C. Total-factor energy efficiency of regions in China. Energy Policy 2006, 34, 3206–3217. [Google Scholar] [CrossRef]

- Liu, Y. Does international trade degrade total-factor energy efficiency: An empirical analysis in China. China Popul. Resour. Environ. 2018, 28, 20–29. [Google Scholar]

- Wu, J.; Li, M.; Zhu, Q.; Zhou, Z.; Liang, L. Energy and environmental efficiency measurement of China’s industrial sectors: A DEA model with nonhomogeneous inputs and outputs. Energy Econ. 2019, 78, 468–480. [Google Scholar] [CrossRef]

- Jiang, L.; Zhou, H.; He, S. Does energy efficiency increase at the expense of output performance: Evidence from manufacturing firms in Jiangsu province, China. Energy 2021, 220, 119704. [Google Scholar] [CrossRef]

- Gong, X.; Mi, J.; Wei, C.; Yang, R. Measuring Environmental and Economic Performance of Air Pollution Control for Province-Level Areas in China. Int. J. Environ. Res. Public Health 2019, 16, 1378. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Liu, X.; Li, A. Evaluating the performance of Chinese fossil fuel power plants by data environment analysis: An application of three intermediate approaches in a time horizon. J. Clean. Prod. 2020, 277, 121992. [Google Scholar] [CrossRef]

- Newell, R.G.; Jaffe, A.B.; Stavins, R.N. The Induced Innovation Hypothesis and Energy-Saving Technological Change. Q. J. Econ. 1999, 114, 941–975. [Google Scholar] [CrossRef]

- Li, L.; Zhou, Y. Can Technological Progress Improve Energy Efficiency?-Empirical Test Based on China’s Industrial Sub-Sectors. J. Manag. World 2006, 10, 82–89. [Google Scholar] [CrossRef]

- Shi, D.; Wu, L.X.; Fu, X.X.; Wu, B. Research on Regional Differences of China’s Energy Efficiency and Its Cause-Variance Decomposition Based on Stochastic Frontier Production Function. J. Manag. World 2008, 2, 35–43. [Google Scholar] [CrossRef]

- Zheng, L.L. Energy Efficiency, Factor Inputs and Economic Growth-An Empirical Analysis Based on Panel Threshold Regression. J. Cent. Univ. Financ. Econ. 2012, 9, 48–53. [Google Scholar]

- Angus, M. Growth and Slowdown in Advanced Capitalist Economies: Techniques of Quantitative Assessment. J. Econ. Lit. 1987, 25, 649–698. [Google Scholar]

- Zhang, W.S. Energy Efficiency, Industrial Structure and Regional Economic Development Gap in China. J. Shanxi Financ. Econ. Univ. 2010, 32, 28–34. [Google Scholar] [CrossRef]

- Wan, L.; Zhang, Y.; Qi, S.; Li, H.; Chen, X.; Zang, S. A study of regional sustainable development based on GIS/RS and SD model-Case of Hadaqi industrial corridor. J. Clean. Prod. 2016, 142, 654–662. [Google Scholar] [CrossRef]

- Xiao, S.; Dong, H.; Geng, Y.; Tian, X.; Liu, C.; Li, H. Policy impacts on Municipal Solid Waste management in Shanghai: A system dynamics model analysis. J. Clean. Prod. 2020, 262, 121366. [Google Scholar] [CrossRef]

- Bai, J.; Nie, L. Energy Efficiency, Environmental Pollution and the Transformation of China’s Economic Development Mode. J. Financ. Res. 2018, 10, 1–18. [Google Scholar]

- Tong, H.; Yang, Y.; Wang, J.; Feng, Y. Modeling China’s Green Economy 2050: Scenario Analysis Based on the System Dynamics Model. China Soft Sci. Mag. 2015, 6, 20–34. [Google Scholar]

- Liu, C.; Tu, G. The Analysis and Simulation of National Strategy on Low Carbon Energy Development Based on System Dynamics. Syst. Eng. 2015, 33, 100–106. [Google Scholar]

- Luo, L.; Wu, J.; Hu, H.; Chen, Y.; Xu, Z. Analysis and forecast of water supply and demand in Beijing through system dynamics modeling. Urban Water J. 2020, 17, 512–524. [Google Scholar] [CrossRef]

- Yang, H.; Li, X.; Ma, L.; Li, Z. Using system dynamics to analyse key factors influencing China’s energy-related CO2 emissions and emission reduction scenarios. J. Clean. Prod. 2021, 320, 128811. [Google Scholar] [CrossRef]

- Li, J.; Sun, K. Research on the Industrial Green Development of Beijing-Tianjin-Hebei Based on System Dynamics. Soft Sci. 2018, 32, 113–119. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, H.; Sun, D. Simulation of urban sustainability based on System Dynamics: A case study of Beijing-Tianjin-Hebei region. Sci. Geogr. Sin. 2021, 41, 1515–1524. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Tang, L.; Yu, A. The Simulation of Carbon Emission Trading System in Beijing-Tianjin-Hebei Region: An Analysis Based on System Dynamics. Chin. J. Manag. Sci. 2016, 24, 1–8. [Google Scholar] [CrossRef]

- Li, G.; Li, Y.; Jia, X.; Du, L.; Huang, D. Establishment and Simulation Study of System Dynamic Model on Sustainable Development of Water-Energy-Food Nexus in Beijing. Manag. Rev. 2016, 28, 11–26. [Google Scholar] [CrossRef]

- Chen, S. Energy Consumption, CO2 Emission and Sustainable Development in Chinese Industry. Econ. Res. J. 2009, 44, 41–55. [Google Scholar]

- Xu, G.; Deng, X.; Chen, X. Transformation and Upgrading of Manufacturing and High-Quality Economic Development-A Research Based on Total Factor Energy Efficiency. Econ. Theor. Bus. Manag. 2020, 12, 100–110. [Google Scholar]

- Kuang, L.; Han, X.; Liu, G. The Efficiency of Energy Infrastructure Investment and Its Regional Economic Impact. Int. J. Environ. Res. Public Health 2023, 20, 2125. [Google Scholar] [CrossRef]

- Xie, Z.; Li, Y.; Qin, Y. Allocation of control targets for PM2.5 concentration: An empirical study from cities of atmospheric pollution transmission channel in the Beijing-Tianjin-Hebei district. J. Clean. Prod. 2020, 270, 122545. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of super-efficiency in data envelopment analysis. Eur. J. Oper. Res. 2002, 143, 32–41. [Google Scholar] [CrossRef]

- Oh, D.H. A metafrontier approach for measuring an environmentally sensitive productivity growth index. Energy Econ. 2010, 32, 146–157. [Google Scholar] [CrossRef]

- Wu, Q.; Wu, C. Research on Evaluation Model of Energy Efficiency Based on DEA. J. Manag. Sci. 2009, 22, 103–112. [Google Scholar]

- Zhao, M.; Zhang, W.; Yu, L. Carbon Emissions from Energy Consumption in Shanghai City. Res. Environ. Sci. 2009, 22, 984–989. [Google Scholar] [CrossRef]

- Chen, S. Reconstruction of Sub-industrial Statistical Data in China (1980–2008). China Econ. Q. 2011, 10, 735–776. [Google Scholar] [CrossRef]

- Zeng, S.; Li, G.; Wu, S.; Dong, Z. The Impact of Green Technology Innovation on Carbon Emissions in the Context of Carbon Neutrality in China: Evidence from Spatial Spillover and Nonlinear Effect Analysis. Int. J. Environ. Res. Public Health 2022, 19, 730. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.; Wang, H.; Wang, B. Empirical Analysis of Carbon Emission Accounting and Influencing Factors of Energy Consumption in China. Int. J. Environ. Res. Public Health 2018, 15, 2467. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.; Lai, C. Abatement R&D, market imperfections, and environmental policy in an endogenous growth model. J. Econ. Dyn. Control 2014, 41, 20–37. [Google Scholar] [CrossRef]

- Grimaud, A.; Tournemaine, F. Why can an environmental policy tax promote growth through the channel of education? Ecol. Econ. 2007, 62, 27–36. [Google Scholar] [CrossRef]

- Hamaguchi, Y. Pollution havens and agglomeration: The effect of globalization and technological spillover. Appl. Econ. 2023. [Google Scholar] [CrossRef]

- Nakada, M. Does environmental policy necessarily discourage growth? J. Econ. 2004, 81, 249–275. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L. The Path of China’s Industrial Structure Adjustment from the Perspective of Added Value. Macroeconomics 2016, 7, 60–72+150. [Google Scholar] [CrossRef]

- Li, G.; Zeng, S.; Li, T.; Peng, Q.; Irfan, M. Analysing the Effect of Energy Intensity on Carbon Emission Reduction in Beijing. Int. J. Environ. Res. Public Health 2023, 20, 1379. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, S.; Wang, P. Key areas and pathways for carbon emissions reduction in Beijing for the “Dual Carbon” targets. Energy Policy 2022, 164, 112873. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, H. Do provincial energy policies and energy intensity targets help reduce CO2 emissions? Evidence from China. Energy 2022, 245, 123275. [Google Scholar] [CrossRef]

- Zeng, S.; Jin, G.; Tan, K.; Liu, X. Can low-carbon city construction reduce carbon intensity? Empirical evidence from low-carbon city pilot policy in China. J. Environ. Manag. 2023, 332, 117363. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Chen, X.; Li, Z.; Zeng, Z.; Zhang, M. Exploring the effect of a low-carbon city pilot policies on carbon dioxide emission intensity: Based on the PSM-DID method. Chin. J. Popul. Resour. Environ. 2022, 20, 209–216. [Google Scholar] [CrossRef]

- Vicente, S.E.; Javier, F.; Jaime, M.; Luis, J.M.; Margarita, M. Analysis of energy future pathways for Ecuador facing the prospects of oil availability using a system dynamics model. Is degrowth inevitable? Energy 2022, 259, 124963. [Google Scholar] [CrossRef]

- Hu, Y.; Chi, Y.; Zhou, W.; Li, J.; Wang, Z.; Yuan, Y. The interactions between renewable portfolio standards and carbon emission trading in China: An evolutionary game theory perspective. Energy 2023, 271, 127047. [Google Scholar] [CrossRef]

| Type | Indicator | |

|---|---|---|

| Input | Capital | Annual Average Balance of Net Fixed Assets |

| Labor | Annual Average Number of Employees | |

| Energy | Total Energy Consumption | |

| Output | Desirable Output | Gross Output Value of Industry |

| Undesirable Output | CO2 Emissions | |

| Item | NCV | CEF | COF | |||

|---|---|---|---|---|---|---|

| Value | Unit | Value | Unit | |||

| Raw Coal | Soft Coal | 20,908 | kj/kg | 26.10 | kg/gj | 0.930 |

| Anthracite | 27.40 | 0.940 | ||||

| Weighted Mean | 26.36 | 0.932 | ||||

| Coke | 28,435 | 29.50 | 0.930 | |||

| Crude Oil | 41,816 | 20.10 | 0.980 | |||

| Gasoline | 43,070 | 18.90 | ||||

| Kerosene | 43,070 | 19.60 | ||||

| Diesel | 42,652 | 20.20 | ||||

| Fuel Oil | 41,816 | 21.10 | ||||

| Liquefied Petroleum Gas | 50,179 | 17.20 | ||||

| Natural Gas | 38,931 | kj/m3 | 15.30 | 0.990 | ||

| Manufacturing Sub-Sector | Annual Average Value | Cumulative Value | ||||

|---|---|---|---|---|---|---|

| GML | EC | TC | GML | EC | TC | |

| Processing of Food from Agricultural Products | 0.964 | 0.944 | 1.035 | 0.576 | 0.405 | 1.424 |

| Manufacture of Foods | 0.982 | 0.961 | 1.037 | 0.755 | 0.513 | 1.471 |

| Manufacture of Liquor, Beverages, and Refined Tea | 1.004 | 0.972 | 1.045 | 0.922 | 0.557 | 1.656 |

| Manufacture of Textile | 1.054 | 1.031 | 1.035 | 1.386 | 1.002 | 1.383 |

| Manufacture of Textile, Wearing Apparel, and Accessories | 1.028 | 1.010 | 1.033 | 1.233 | 0.895 | 1.378 |

| Processing of Timber, Manufacture of Wood, Bamboo, Rattan Palm, and Straw Products | 1.259 | 1.522 | 1.080 | 8.493 | 9.136 | 0.930 |

| Manufacture of Furniture | 1.021 | 1.000 | 1.034 | 1.258 | 0.898 | 1.400 |

| Manufacture of Paper and Paper Products | 1.015 | 0.994 | 1.038 | 1.198 | 0.815 | 1.470 |

| Printing and Reproduction of Recording Media | 1.013 | 0.980 | 1.044 | 1.111 | 0.693 | 1.604 |

| Manufacture of Papers for Culture, Education, Arts and Crafts, Sports, and Entertainment Activities | 1.196 | 1.544 | 1.112 | 0.822 | 0.591 | 1.390 |

| Processing of Petroleum, Coal, and Other Fuels | 0.975 | 1.145 | 1.459 | 0.622 | 0.125 | 4.971 |

| Manufacture of Raw Chemical Materials and Chemical Products | 1.008 | 0.969 | 1.049 | 1.043 | 0.613 | 1.702 |

| Manufacture of Medicines | 1.066 | 1.037 | 1.045 | 2.318 | 1.407 | 1.647 |

| Manufacture of Rubber and Plastics Products | 1.002 | 0.978 | 1.036 | 0.975 | 0.685 | 1.423 |

| Manufacture of Non-metallic Mineral Products | 1.034 | 1.011 | 1.039 | 1.544 | 1.025 | 1.506 |

| Smelting and Pressing of Ferrous Metals | 1.106 | 1.044 | 1.052 | 2.068 | 1.159 | 1.784 |

| Smelting and Pressing of Non-ferrous Metals | 0.974 | 0.907 | 1.180 | 0.544 | 0.148 | 3.679 |

| Manufacture of Metal Products | 1.037 | 1.004 | 1.039 | 1.489 | 1.003 | 1.485 |

| Manufacture of General-Purpose Machinery | 1.029 | 1.002 | 1.039 | 1.381 | 0.921 | 1.501 |

| Manufacture of Special-Purpose Machinery | 1.068 | 1.039 | 1.039 | 2.284 | 1.522 | 1.501 |

| Manufacture of Transport Equipment | 1.056 | 1.063 | 1.080 | 2.054 | 1.217 | 1.688 |

| Manufacture of Electrical Machinery and Apparatus | 1.164 | 1.217 | 1.116 | 4.612 | 3.005 | 1.535 |

| Manufacture of Computers, Communication, and Other Electronic Equipment | 1.121 | 1.005 | 1.115 | 2.802 | 1.063 | 2.636 |

| Manufacture of Measuring Instruments and Machinery | 1.013 | 0.981 | 1.178 | 1.091 | 0.345 | 3.157 |

| Utilization of Waste Resources | 0.980 | 0.945 | 1.048 | 0.523 | 0.323 | 1.620 |

| Average Value | 1.047 | 1.052 | 1.080 | 1.724 | 1.203 | 1.838 |

| Variables | Coef. | Robust Std. Err. | t | p > |t| | Collinearity Statistics | |

|---|---|---|---|---|---|---|

| 1/VIF | VIF | |||||

| IFA | 0.932 | 0.412 | 2.26 | 0.043 ** | 0.964 | 1.04 |

| RD | 7.960 | 0.807 | 9.86 | 0.000 *** | 0.964 | 1.04 |

| cons | 4,603,868 | 2,352,460 | 1.96 | 0.074 | ||

| R2 = 0.912 | F-statistic = 50.48 (0.000) | |||||

| Variables | Coef. | Robust Std. Err. | t | p > |t| | Collinearity Statistics | |

|---|---|---|---|---|---|---|

| 1/VIF | VIF | |||||

| IFA | −0.0001748 | 0.0000377 | −4.64 | 0.001 *** | 0.856 | 1.17 |

| RD | −0.0000866 | 0.0000308 | −2.78 | 0.017 *** | 0.856 | 1.17 |

| cons | 0.0004051 | 0.0000684 | 5.92 | 0.000 | ||

| R2 = 0.655 | F-statistic = 11.37 (0.0017) | |||||

| Variable | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | Scenario 5 |

|---|---|---|---|---|---|

| Energy Consumption Structure | Maintain at the level of the Year 2020 | On the basis of Scenario 1, the proportion of coal decreased by 1.2%, and the proportion of oil and natural gas remain unchanged. (The statistical population here is fossil fuels, and renewable energy is not included.) | Maintain at the level of Year 2020 | Maintain at the level of Year 2020 | On the basis of Scenario 1, the proportion of coal decreased by 1.2%, and the proportion of oil and natural gas remain unchanged |

| Fixed Asset Investment | AAG Rate: 6.28% | AAG Rate: 6.28% | AAG Rate: 30% | AAG Rate: 6.28% | AAG Rate: 30% |

| R&D Investment | AAG Rate: 5.58% | AAG Rate: 5.58% | AAG Rate: 15% | AAG Rate: 5.58% | AAG Rate: 15% |

| Green Total-factor Energy Efficiency Index | AAG Rate for EC: −2.81% AAG Rate for TC: 4.38% | AAG Rate for EC: −2.81% AAG Rate for TC: 4.38% | AAG Rate for EC: −2.81% AAG Rate for TC: 4.38% | AAG Rate for EC: −2.80% AAG Rate for TC: 4.41% | AAG Rate for EC: −2.80% AAG Rate for TC: 4.40% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chi, Y.; Xu, S.; Yang, X.; Li, J.; Zhang, X.; Chen, Y. Research on Beijing Manufacturing Green-Oriented Transition Path under “Double Carbon” Goal-Based on the GML-SD Model. Sustainability 2023, 15, 7716. https://doi.org/10.3390/su15097716

Chi Y, Xu S, Yang X, Li J, Zhang X, Chen Y. Research on Beijing Manufacturing Green-Oriented Transition Path under “Double Carbon” Goal-Based on the GML-SD Model. Sustainability. 2023; 15(9):7716. https://doi.org/10.3390/su15097716

Chicago/Turabian StyleChi, Yuanying, Situo Xu, Xiaolei Yang, Jialin Li, Xufeng Zhang, and Yahui Chen. 2023. "Research on Beijing Manufacturing Green-Oriented Transition Path under “Double Carbon” Goal-Based on the GML-SD Model" Sustainability 15, no. 9: 7716. https://doi.org/10.3390/su15097716

APA StyleChi, Y., Xu, S., Yang, X., Li, J., Zhang, X., & Chen, Y. (2023). Research on Beijing Manufacturing Green-Oriented Transition Path under “Double Carbon” Goal-Based on the GML-SD Model. Sustainability, 15(9), 7716. https://doi.org/10.3390/su15097716