Co-Digestion-Based Circular Bio-Economy to Improve Biomethane Generation and Production of Nutrient-Enriched Digestate in Bangladesh

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Description

2.2. Collection of Substrate and Inoculum

2.3. Analytical Methods

2.4. Experimental Setup

2.5. Kinetic Analysis

2.6. Electricity and Heat Production

2.7. Nutrient Analysis of Digestate

3. Results and Discussion

3.1. Characterization of Substrate during ACoD

3.2. Analysis of Biogas Composition

3.3. Daily Biogas and Methane Production

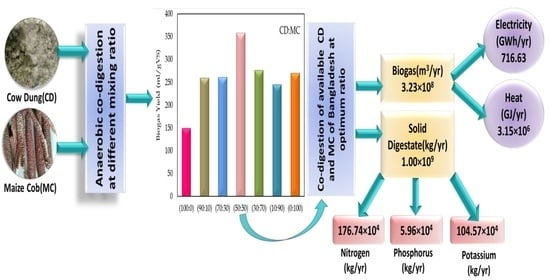

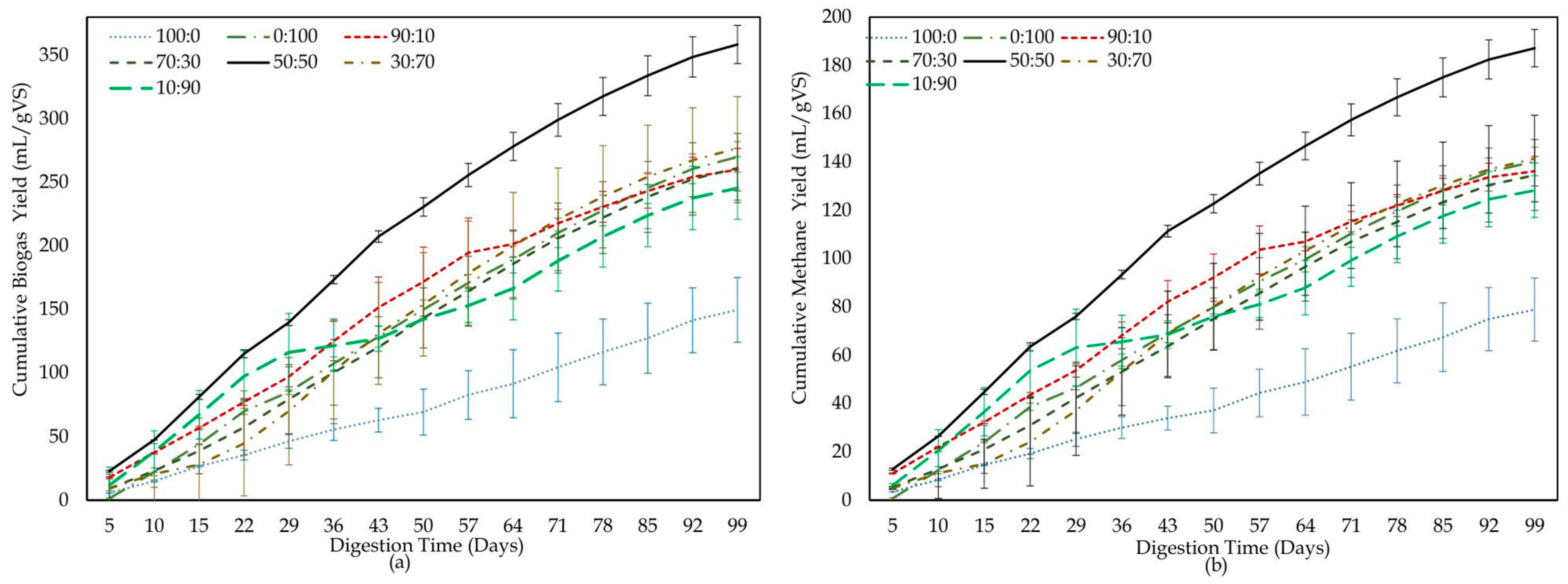

3.4. Biogas and Methane Production Potential from ACoD

3.5. Prediction of ACoD of CD and MC from Kinetic Modeling

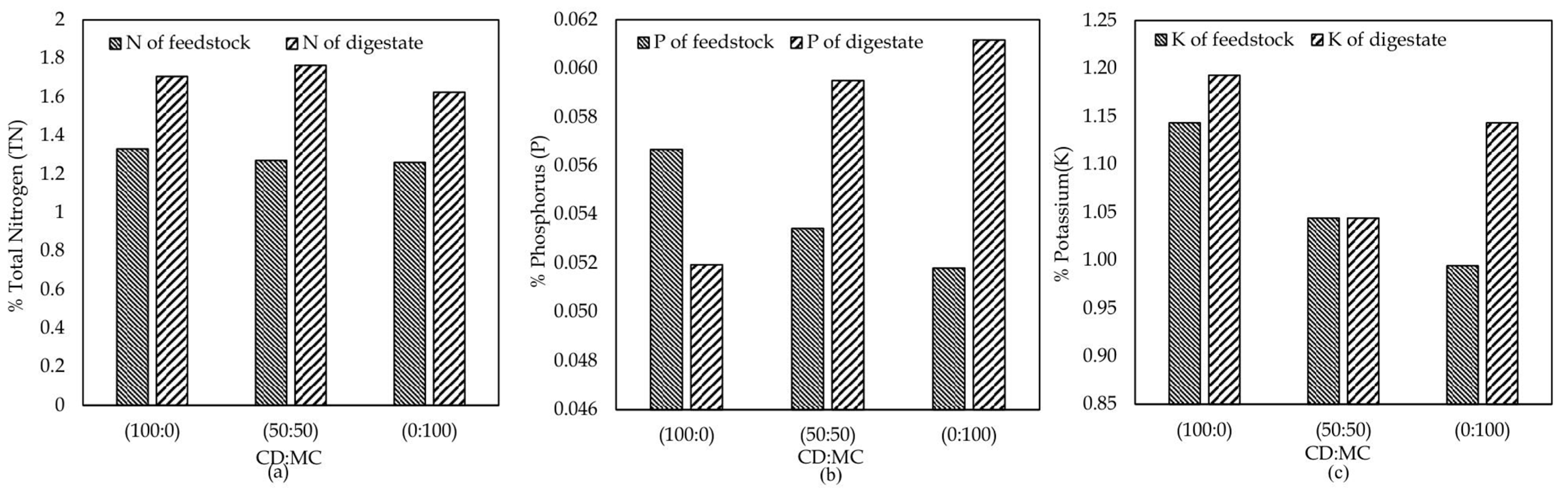

3.6. Nutrient Increments of Digestate from ACoD

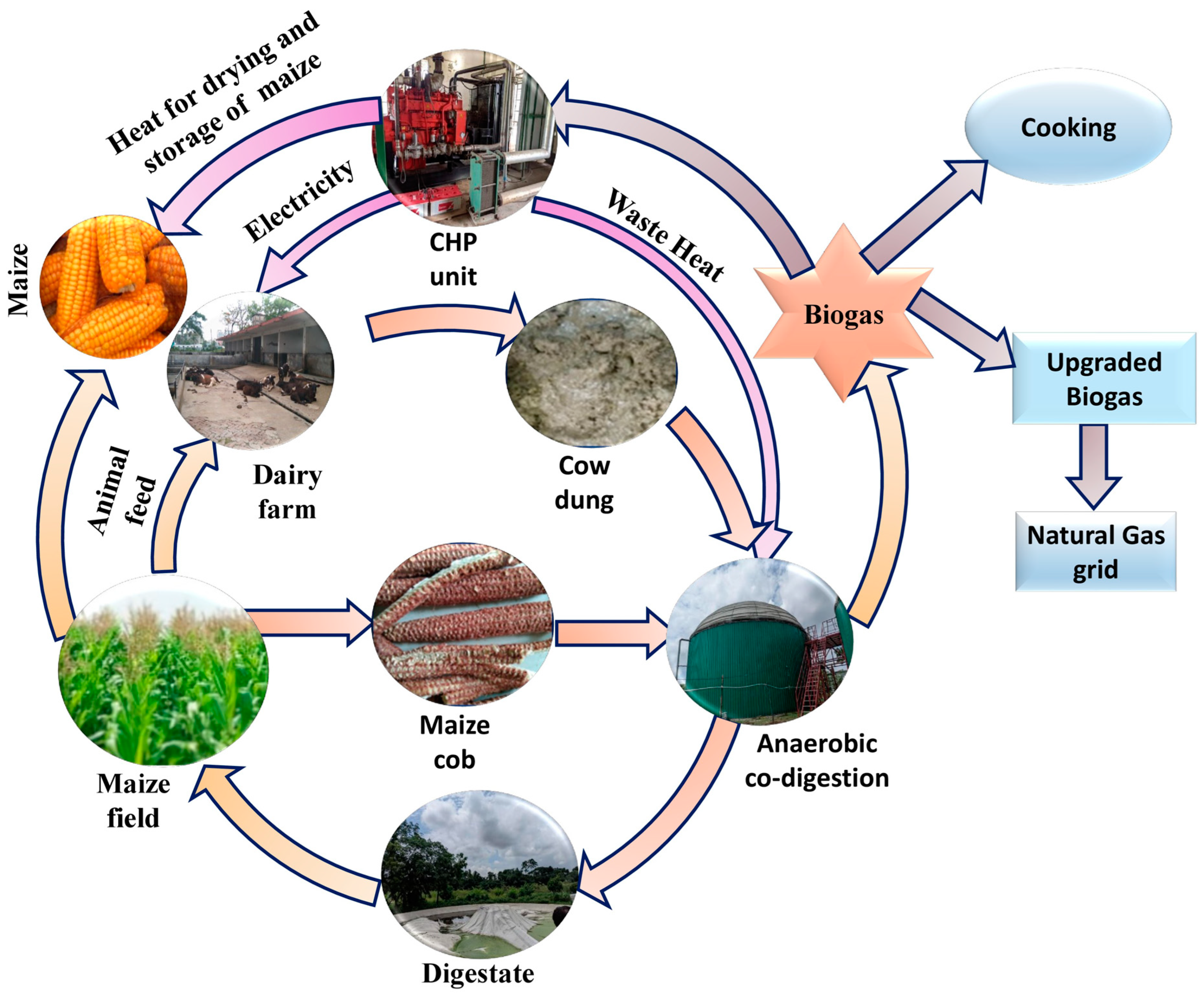

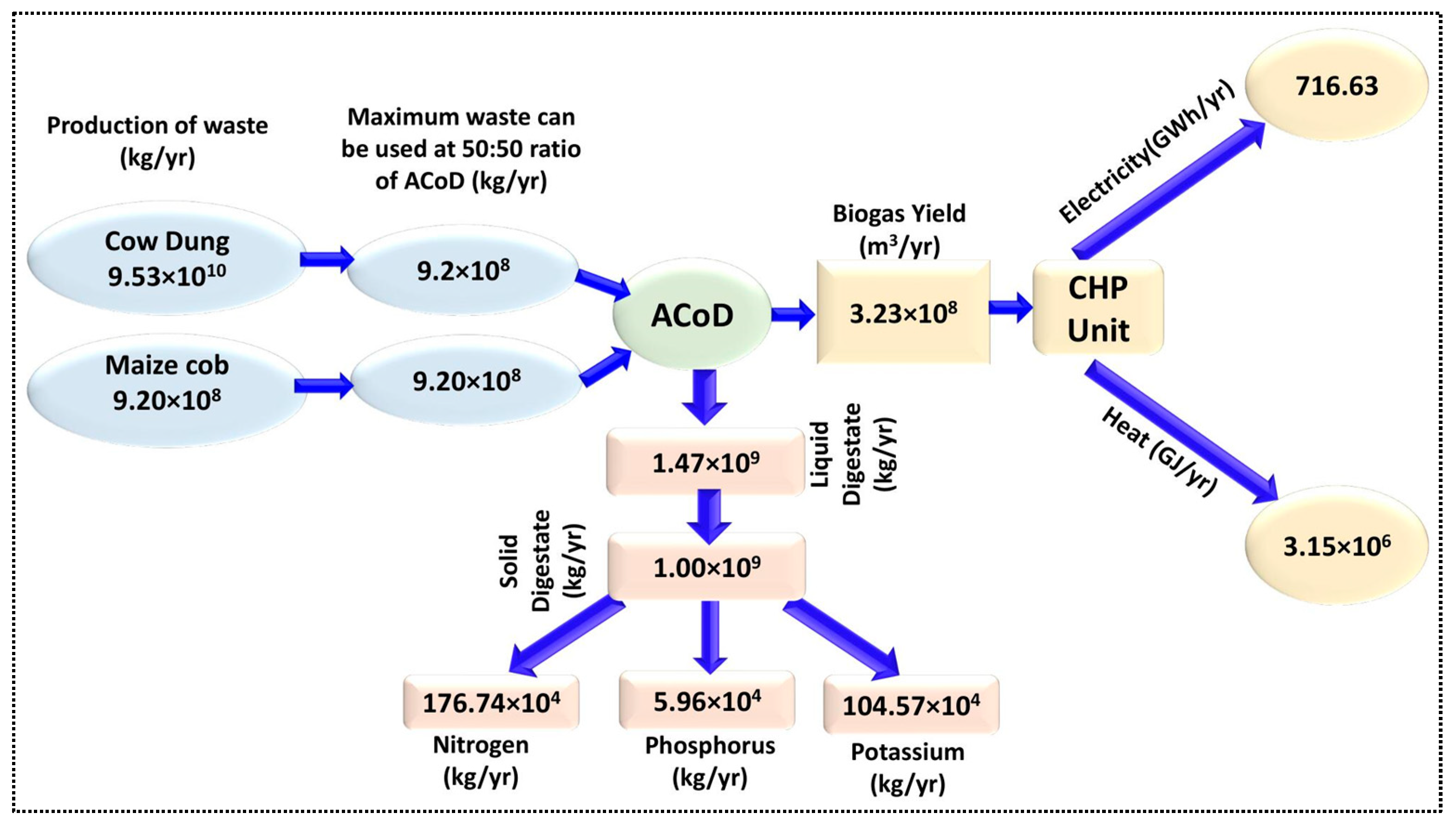

3.7. Circular Bio-Economy and Anaerobic Co-Digestion of CD and MC

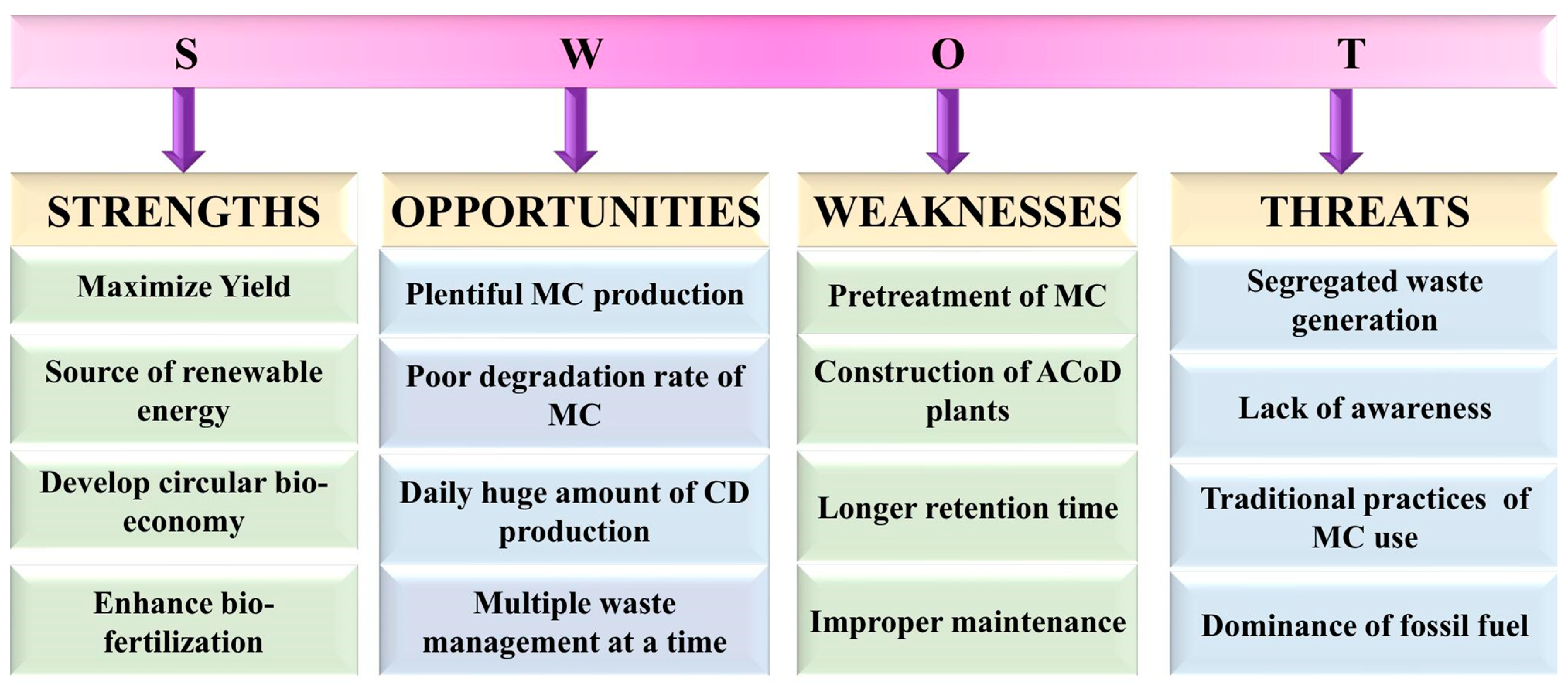

3.8. SWOT Analysis of Anaerobic Co-Digestion of CD and MC

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moller, K.; Eeswaran, R.; Nejadhashemi, A.P.; Hernandez-Suarez, J.S. Livestock and Aquaculture Farming in Bangladesh: Current and Future Challenges and Opportunities. Cogent Food Agric. 2023, 9, 2241274. [Google Scholar] [CrossRef]

- BBS. Statistical Yearbook Bangladesh 2022. Available online: https://bbs.portal.gov.bd/sites/default/files/files/bbs.portal.gov.bd/page/b2db8758_8497_412c_a9ec_6bb299f8b3ab/2023-06-26-09-19-2edf60824b00a7114d8a51ef5d8ddbce.pdf (accessed on 3 October 2023).

- DLS. Livestock Economy at a Glance. 2023. Available online: https://dls.portal.gov.bd/sites/default/files/files/dls.portal.gov.bd/page/ee5f4621_fa3a_40ac_8bd9_898fb8ee4700/2023-07-23-12-04-afbcccb96f8b27d4bab6501aa8c2c2ff.pdf (accessed on 23 July 2023).

- Datta, A.K.; Haider, M.Z.; Ghosh, S.K. Economic Analysis of Dairy Farming in Bangladesh. Trop. Anim. Health Prod. 2019, 51, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.A.; Saha, C.K.; Wahid, R.; Feng, L. Optimal Ratio for Anaerobic Co-Digestion of Poultry Droppings and Lignocellulosic-Rich Substrates for Enhanced Biogas Production. Energy Sustain. Dev. 2017, 39, 59–66. [Google Scholar] [CrossRef]

- Gupta, K.K.; Aneja, K.R.; Rana, D. Current Status of Cow Dung as a Bioresource for Sustainable Development. Bioresour. Bioprocess. 2016, 3, 28. [Google Scholar] [CrossRef]

- Mudway, I.S.; Duggan, S.T.; Venkataraman, C.; Habib, G.; Kelly, F.J.; Grigg, J. Combustion of Dried Animal Dung as Biofuel Results in the Generation of Highly Redox Active Fine Particulates. Part. Fibre Toxicol. 2005, 2, 6. [Google Scholar] [CrossRef]

- Cathy, M. Importance of Cow Manure Management: Environmental Challenges and Solutions. Int. Sched. J. 2023, 11, 001. [Google Scholar]

- Wang, K.; Yun, S.; Ke, T.; An, J.; Abbas, Y.; Liu, X. Use of bag-filter gas dust in anaerobic digestion of cattle manure for boosting the methane yield and digestate utilization. Bioresour. Technol. 2022, 348, 126729. [Google Scholar] [CrossRef]

- Olaoye, R.A.; Olalere, A.S.; Oluremi, J.R.; Ojoawo, S.O. Sustainable Management of Cow Dung From Slaughter Houses. LAUTECH J. Eng. Technol. 2018, 12, 36–42. [Google Scholar]

- Shaibur, M.R.; Husain, H.; Arpon, S.H. Utilization of Cow Dung Residues of Biogas Plant for Sustainable Development of a Rural Community. Curr. Res. Environ. Sustain. 2021, 3, 100026. [Google Scholar] [CrossRef]

- Onwukeme, V.I.; Etienajirhevwe, O.F.; Mokobia, E.K. Production of Biogas from Cow Dung, Weeds and Domestic Wastes. Ethiop. J. Environ. Stud. Manag. 2017, 10, 482–491. [Google Scholar] [CrossRef]

- Putri, D.A.; Saputro, R.R.; Budiyono, B. Production from Cow Manure. Int. J. Renew. Energy Dev. 2012, 1, 61–64. [Google Scholar] [CrossRef]

- Ukpai, P.A.; Nnabushi, M.N. Comparative Study of Biogas Production from Cow Dung, Cow Pea and Cassava Peeling using 45 Litres Biogas Digester. Adv. Appl. Sci. Res 2012, 3, 1864–1869. [Google Scholar]

- Abbas, Y.; Yun, S.; Mehmood, A.; Ali, F.; Wang, K.; Tag, E.; Al-qahtani, W.H.; Ali, S.; Bocchetta, P. Chemosphere Co-digestion of Cow Manure and Food Waste for Biogas Enhancement and Nutrients Revival in Bio-Circular Economy. Chemosphere 2023, 311, 137018. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Xing, T.; Wang, Y.; Chen, R.; Han, F.; Zhang, C.; Zou, M. Mineral Residue Accelerant-Enhanced Anaerobic Digestion of Cow Manure: An Evaluation System of Comprehensive Performance. Sci. Total Environ. 2023, 858, 159840. [Google Scholar] [CrossRef] [PubMed]

- Abbas, Y.; Yun, S.; Wang, Z.; Zhang, Y.; Zhang, X.; Wang, K. Recent Advances in Bio-Based Carbon Materials for Anaerobic Digestion: A Review. Renew. Sustain. Energy Rev. 2021, 135, 110378. [Google Scholar] [CrossRef]

- Li, B.; Yun, S.; Xing, T.; Wang, K.; Ke, T.; An, J. A Strategy for Understanding the Enhanced Anaerobic Co-Digestion via Dual-Heteroatom Doped Bio-Based Carbon and Its Functional Groups. Chem. Eng. J. 2021, 425, 130473. [Google Scholar] [CrossRef]

- Xing, T.; Yun, S.; Li, B.; Wang, K.; Chen, J.; Jia, B.; Ke, T.; An, J. Coconut-Shell-Derived Bio-Based Carbon Enhanced Microbial Electrolysis Cells for Upgrading Anaerobic Co-Digestion of Cow Manure and Aloe Peel Waste. Bioresour. Technol. 2021, 338, 125520. [Google Scholar] [CrossRef]

- Liu, L.; Yun, S.; Ke, T.; Wang, K.; An, J.; Liu, J. Dual Utilization of Aloe Peel: Aloe Peel-Derived Carbon Quantum Dots Enhanced Anaerobic Co-Digestion of Aloe Peel. Waste Manag. 2023, 159, 163–173. [Google Scholar] [CrossRef]

- Liu, L.; Yun, S.; Wang, K.; Ke, T.; Liu, J.; Gao, Y.; Zhang, X. Enhanced Anaerobic Co-Digestion under a Magnetic Field by a Synergistic Host–Guest Strategy: Focusing on Accelerant, Biogas Yield, Fertilization and Coupled Effect. Chem. Eng. J. 2023, 476, 146508. [Google Scholar] [CrossRef]

- Huang, X.; Yun, S.; Zhu, J.; Du, T.; Zhang, C.; Li, X. Mesophilic Anaerobic Co-Digestion of Aloe Peel Waste with Dairy Manure in the Batch Digester: Focusing on Mixing Ratios and Digestate Stability. Bioresour. Technol. 2016, 218, 62–68. [Google Scholar] [CrossRef]

- Rabii, A.; Aldin, S.; Dahman, Y.; Elbeshbishy, E. A Review on Anaerobic Co-Digestion with a Focus on the Microbial Populations and the Effect of Multi-stage Digester Configuration. Energies 2019, 12, 1106. [Google Scholar] [CrossRef]

- Khatun, M.L.; Nime, J.; Nandi, R.; Alam, M.M.; Saha, C.K. Co-digestion of Poultry Droppings and Banana Waste for Maximizing Biogas Production in Bangladesh. Fuel 2023, 346, 128346. [Google Scholar] [CrossRef]

- Rahman, M.A.; Møller, H.B.; Saha, C.K.; Alam, M.M.; Wahid, R.; Feng, L. Anaerobic Co-Digestion of Poultry Droppings and Briquetted Wheat Straw at Mesophilic and Thermophilic Conditions: Influence of Alkali Pretreatment. Renew. Energy 2018, 128, 241–249. [Google Scholar] [CrossRef]

- Hamzah, A.F.A.; Hamzah, M.H.; Mazlan, F.N.A.; Jamali, N.S.; Siajam, S.I.; Man, H.C. Anaerobic Co-digestion of Pineapple Wastes with Cow Dung: Effect of Different Total Solid Content on Bio- methane Yield. Adv. Agric. Food Res. J. 2020, 1, a0000109. [Google Scholar] [CrossRef]

- Kumar, V.; Khayum, N.; Sivalingam, M.; Subramanian, A. Biogas Production from Anaerobic Co-Digestion of Cow Dung and Waste Leaf and Its Purification. In Proceedings of the National Conference on Waste to Energy Carbon Capture and Storage (NCWECCS-17), Rourkela, India, 3–5 August 2017; Available online: https://www.researchgate.net/publication/324182575_Biogas_Production_from_Anaerobic_Co-Digestion_of_Cow_Dung_and_Waste_Leaf_and_Its_Purification (accessed on 4 April 2018).

- Haryanto, A.; Hasanudin, U.; Afrian, C.; Zulkarnaen, I. Biogas Production from Anaerobic Codigestion of Cowdung and Elephant Grass (Pennisetum purpureum) Using Batch Digester. IOP Conf. Ser. Earth Environ. Sci. 2018, 141, 012011. [Google Scholar] [CrossRef]

- Hilmi, N.A.M.; Zakarya1, I.A.; Gunny, A.A.N.; Izhar, T.N.T.; Zaaba, S.K.; Samah, M.F.; Daud, Z.A.A.M.; Beson, M.R.C. Co-digestion of Food Waste with Cow Dung by Anaerobic Digestion for Biogas Production. In Proceedings of the IOP Conference Series: Earth and Environmental Science, International Conference on Civil and Environmental Engineering, Penang, Malaysia, 29–30 August 2022. [Google Scholar] [CrossRef]

- Khan, S.I.; Aftab, S.; Chaudhry, T.A.; Younis, M.N. Production of Biogas by the Co-Digestion of Cow Dung and Crop Residue at University of the Punjab, Lahore, Pakistan. Afr. J. Environ. Sci. Technol. 2018, 12, 91–95. [Google Scholar] [CrossRef]

- Tasnim, F.; Iqbal, S.A.; Chowdhury, A.R. Biogas Production from Anaerobic Co-Digestion of Cow Manure with Kitchen Waste and Water Hyacinth. Renew. Energy 2017, 109, 434–439. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Himan, M. Prospects of Bioethanol from Agricultural Residues in Bangladesh. Energies 2023, 16, 4657. [Google Scholar] [CrossRef]

- Surra, E.; Bernardo, M.; Lapa, N.; Esteves, I.A.A.C.; Fonseca, I.; Mota, J.P.B. Biomethane Production Through Anaerobic Co-Digestion with Maize Cob Waste Based on a Biorefinery Concept: A Review. J. Environ. Manag. 2019, 249, 109351. [Google Scholar] [CrossRef]

- Jivini, Z.S.; Ikwebe, J.; Abah, M.A.; Okoli, E.C.; Habibu, B.; Saaku, A.S. Biochemical Generation of Biogas from Corn Cobs using Cow Dung as a Source of Microbial Catalyst. Glob. Sci. J. 2021, 9, 1875–1879. [Google Scholar]

- Chojnacka, K.; Moustakas, K.; Witek-Krowiak, A. Bio-based Fertilizers: A Practical Approach towards Circular Economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef] [PubMed]

- Abdoli, M.A.; Amiri, L.; Baghvand, A.; Nasiri, J.; Madadian, E. Methane Production from Anaerobic Co-Digestion of Maize and Cow Dung. Environ. Prog. Sustain. Energy 2014, 33, 597–601. [Google Scholar] [CrossRef]

- Adebayo, A.O.; Jekayinfa, S.O.; Linke, B. Effect of Co-Digestion on Biogas Production—A Case Study of Cow Slurry with Maize Cob. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting 2012, Dallas, TX, USA, 29 July–1 August 2012; pp. 3890–3906. [Google Scholar] [CrossRef]

- Adbeayo, A.O.; Jekayinfa, S.O.; Linke, B. Effect of Co-Digestion on Anaerobic Digestion of Cattle Slurry with Maize Cob at Mesophilic Temperature. J. Energy Technol. Policy 2013, 3, 47–55. [Google Scholar]

- Tiong, J.S.M.; Chan, Y.J.; Lim, J.W.; Mohamad, M.; Ho, C.D.; Ur Rahmah, A.; Kiatkittipong, W.; Sriseubsai, W.; Kumakiri, I. Simulation and Optimization of Anaerobic Co-digestion of Food Waste with Palm Oil Mill Effluent for Biogas Production. Sustainability 2021, 13, 13665. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Bremner, J.M.; Mulvaney, C.S. Nitrogen-Total. In Methods of Soil Analysis, Part 2; American Society of Agronomy Inc.: Madison, WI, USA, 1982; pp. 595–622. [Google Scholar]

- Page, A.L.; Miller, R.H.; Keeney, D.R. Methods of Soil Analysis, Part 11; American Society of Agronomy Inc.: Madison, WI, USA, 1982. [Google Scholar]

- Ghosh, A.B.; Bajaj, J.C.; Hasan, R.; Singh, D. Soil and Water Testing Method: A Laboratory Manual; Division of Soil Science and Agricultural Chemisiry, IARI: New Delhi, India, 1983; pp. 221–226. [Google Scholar]

- Nandi, R.; Saha, C.K.; Sarker, S.; Huda, M.S.; Alam, M.M. Optimization of Reactor Temperature for Continuous Anaerobic Digestion of Cow Manure: Bangladesh Perspective. Sustainability 2020, 12, 8772. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Experimental and Kinetic Study on Anaerobic Digestion of Food Waste: The Effect of Total Solids and pH. J. Renew. Sustain. Energy 2015, 7, 063104. [Google Scholar] [CrossRef]

- Zhang, H.; An, D.; Cao, Y.; Tian, Y.; He, J. Modeling the Methane Production Kinetics of Anaerobic Co-Digestion of Agricultural Wastes Using Sigmoidal Functions. Energies 2021, 14, 258. [Google Scholar] [CrossRef]

- Wang, K.; Yun, S.; Xing, T.; Li, B.; Abbas, Y.; Liu, X. Binary and ternary trace elements to enhance anaerobic digestion of cattle manure: Focusing on kinetic models for biogas production and digestate utilization. Bioresour. Technol. 2021, 323, 124571. [Google Scholar] [CrossRef]

- Rahman, M.A.; Møller, H.B.; Alam, M.M. Assessing the Energy Potential of Agricultural Residues and an Approach to Meet the Rural Energy Demand: The Bangladesh Perspective. Biomass Convers. Biorefinery 2018, 8, 925–934. [Google Scholar] [CrossRef]

- Akhter, T.; Ashraf, M.A.; Hassan, M.M.; Akhter, F.; Riza, A.N. Agricultural Waste Management Practices in Trishal Upazilla, Mymensingh. Res. Agric. Livest. Fish. 2016, 3, 395–402. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, X.; Shang, D.; Bao, D.; Zhang, S.; Zheng, T. Energetic-environmental-economic assessment of the biogas system with three utilization pathways: Combined heat and power, biomethane and fuel cell. Bioresour. Technol. 2016, 214, 722–728. [Google Scholar] [CrossRef] [PubMed]

- Suhartini, S.; Lestari, Y.P.; Nurika, I. Estimation of methane and electricity potential from canteen food waste. IOP Conf. Ser. Earth Environ. Sci. 2019, 230, 012075. [Google Scholar] [CrossRef]

- Berber-Villamar, N.K.; Netzahuatl-Muñoz, A.R.; Morales-Barrera, L.; Chávez-Camarillo, G.M.; Flores-Ortiz, C.M.; Cristiani-Urbina, E. CornCob as an Effective, Eco-Friendly, and Economic Biosorbent for Removing the Azo Dye Direct Yellow 27 from Aqueous Solutions. PLoS ONE 2018, 13, e0196428. [Google Scholar] [CrossRef] [PubMed]

- Okewale, A.O.; Babayemi, K.A.; Adesina, O. Biogas Production from Anaerobic Co–Digestion of Corn Cobs, Pig and Poultry Droppings. J. Eng. Res. Dev. 2018, 1, 273–282. [Google Scholar]

- TG, I.; Haq, I.; Kalamdhad, A.S. 14—Factors affecting anaerobic digestion for biogas production: A review. In Advanced Organic Waste Management: Sustainable Practices and Approaches; Elsevier: Amsterdam, The Netherlands, 2022; pp. 223–233. ISBN 978-0-323-85792-5. [Google Scholar] [CrossRef]

- Maramba, F.D. Biogas and Waste Recycling—The Phillipine Experience; Maya Farms Division, Liberty Flour Mills: Manila, Phillipines, 1978; p. 43. [Google Scholar]

- Budiyono, I.S.; Sumardiono, S. Kinetic model of biogas yield production from vinasse at various initial pH: Comparison between modified gompertz model and first order kinetic model. Res. J. Appl. Sci. Eng. Technol. 2014, 13, 2798–2805. [Google Scholar] [CrossRef]

- Guarino, G.; Carotenuto, C.; Di Cristofaro, F.; Papa, S.; Morrone, B.; Minale, M. Does the C/N Ratio Really Affect the Bio-Methane Yield? A Three Years Investigation of Buffalo Manure Digestion. Chem. Eng. Trans. 2016, 49, 463–468. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Bojarski, W. Characteristics of Substrates Used for Biogas Production in Terms of Water Content. Fermentation 2023, 9, 449. [Google Scholar] [CrossRef]

- Fagerstrom, A.; Al Seadi, T.; Rasi, S.; Briseid, T. The Role of Anaerobic Digestion and Biogas in the Circular Economy; IEA Bioenergy Task 37; IEA Bioenergy: Paris, France, 2018; Available online: https://www.ieabioenergy.com/wp-content/uploads/2018/08/anaerobic-digestion_web_END.pdf (accessed on August 2018).

- Kavuma, C. Variation of Methane and Carbon Dioxide Yield in a Biogas Plant. Master’s Thesis, Department of Energy Technology, KTH Royal Institute of Technology, Stockholm, Sweden, 2013; pp. 1–46. Available online: http://www.diva-portal.org/smash/get/diva2:604559/FULLTEXT02 (accessed on 29 January 2013).

- Shah, T.A.; Tabassum, R. Enhancing Biogas Production from Lime Soaked Corn Cob Residue. Int. J. Renew. Energy Res. 2018, 8, 761–766. [Google Scholar] [CrossRef]

- Li, Y.; Achinas, S.; Zhao, J.; Geurkink, B.; Krooneman, J.; Euverink, G.J.W. Co-digestion of Cow and Sheep Manure: Performance Evaluation and Relative Microbial Activity. Renew. Energy 2020, 153, 553–563. [Google Scholar] [CrossRef]

- Orhorhoro, E.K.; Ebunilo, P.O.; Sadjere, G.E. Experimental Determination of Effect of Total Solid (TS) and Volatile Solid (VS) on Biogas Yield. Am. J. Mod. Energy 2017, 3, 131–135. [Google Scholar] [CrossRef]

- Raposo, F.; Fernández-Cegrí, V.; de la Rubia, M.A.; Borja, R.; Béline, F.; Cavinato, C.; Demirer, G.; Fernández, B.; Fernández-Polanco, M.; Frigon, J.C.; et al. Biochemical Methane Potential (BMP) of Solid Organic Substrates: Evaluation of Anaerobic Biodegradability Using Data from an International Interlaboratory Study. J. Chem. Technol. Biotechnol. 2011, 86, 1088–1098. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of Anaerobic Digestion on Digestate Nutrient Availability and Crop Growth: A Review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Edith, K.-K.N.; Francis, K.Y.; Martin, K.K.; Felix, K.K. Characterization of Digestates from Anaerobic Co-Digestion of Manioc Effluent, Human Urine and Cow Dung. J. Water Resour. Prot. 2019, 11, 777–788. [Google Scholar] [CrossRef]

- Zhang, C.; Yun, S.; Li, X.; Wang, Z.; Xu, H.; Du, T. Low-Cost Composited Accelerants for Anaerobic Digestion of Dairy Manure: Focusing on Methane Yield, Digestate Utilization and Energy Evaluation. Bioresour. Technol. 2018, 263, 517–524. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Yun, S.; Wang, C.; Wang, Z.; Han, F.; Jia, B.; Chen, J.; Li, B. Improving Performance and Phosphorus Content of Anaerobic Co-Digestion of Dairy Manure with Aloe Peel Waste Using Vermiculite. Bioresour. Technol. 2020, 301, 122753. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Fang, W.; Du, T.; Hu, X.; Huang, X.; Li, X.; Zhang, C.; Lund, P.D. Use of Bio-Based Carbon Materials for Improving Biogas Yield and Digestate Stability. Energy 2018, 164, 898–909. [Google Scholar] [CrossRef]

- Yun, S.; Zhang, C.; Wang, Y.; Zhu, J.; Huang, X.; Du, T.; Li, X.; Wei, Y. Synergistic Effects of Fe Salts and Composite Additives on Anaerobic Digestion of Dairy Manure. Int. Biodeterior. Biodegrad. 2019, 136, 82–90. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Determination of Business Strategies Using SWOT Analysis; Planning and Managing the Organizational Resources to Enhance Growth and Profitability. Macro Manag. Public Policies 2021, 3, 19–22. [Google Scholar] [CrossRef]

- Nsair, A.; Cinar, S.O.; Alassali, A.; Qdais, H.A.; Kuchta, K. Operational Parameters of Biogas Plants: A Review and Evaluation Study. Energies 2020, 13, 3761. [Google Scholar] [CrossRef]

- Saha, C.K.; Nandi, R.; Rahman, M.A.; Alam, M.M.; Møller, H.B. Biogas Technology in Commercial Poultry and Dairy Farms of Bangladesh: Present Scenario and Future Prospect. Biomass Convers. Biorefin. 2022. [Google Scholar] [CrossRef]

| Characteristics of raw substrates | ||||||||

| Substrates | pH | TS (%) | VSwb (%) | Ash (%) | TAN (g/L) | N (%) | C/N | |

| CD | 7.59 ± 0.02 | 13.45 ± 0.37 | 11.30 ± 0.31 | 15.98 ± 0.05 | 4.15 ± 0 | 1.49 | 32.15 ± 0.92 | |

| MC | 6.55 ± 0.04 | 87.77 ± 1.42 | 83.16 ± 1.29 | 5.26 ± 1.24 | 0.68 ± 0 | 1.26 | 42.72 ± 0.64 | |

| Inoculum | 7.29 ± 0.02 | 7.01 ± 0.29 | 4.85 ± 0.15 | 30.83 ± 0.16 | 2.18 ± 0.01 | 1.26 | 31.19 ± 0.93 | |

| Characteristics of feedstock | ||||||||

| Mixing Ratio | pH | TS (%) | VSwb (%) | Ash (%) | TAN (g/L) | N (%) | C/N | |

| CD:MC | 100:0 | 7.41 ± 0.05 | 9.07 ± 0.15 | 6.75 ± 0.30 | 2.32 ± 0.15 | 2.75 ± 0.02 | 1.328 | 31.83 ± 0.94 |

| 90:10 | 7.34 ± 0.04 | 8.65 ± 0.34 | 6.56 ± 0.22 | 2.09 ± 0.12 | 2.65 ± 0.01 | 1.300 | 33.13 ± 0.22 | |

| 70:30 | 7.28 ± 0.07 | 9.10 ± 0.14 | 7.42 ± 0.08 | 1.68 ± 0.05 | 2.33 ± 0.03 | 1.280 | 36.18 ± 0.19 | |

| 50:50 | 7.32 ± 0.03 | 9.24 ± 0.05 | 7.74 ± 0.04 | 1.51 ± 0.01 | 1.98 ± 0.02 | 1.270 | 37.44 ± 0.03 | |

| 30:70 | 7.24 ± 0.06 | 10.00 ± 16 | 8.62 ± 0.04 | 1.38 ± 0.02 | 1.83 ± 0.01 | 1.265 | 38.71 ± 0.02 | |

| 10:90 | 7.24 ± 0.03 | 11.22 ± 0.03 | 9.92 ± 0.01 | 1.30 ± 0.01 | 1.88 ± 0.03 | 1.261 | 39.84 ± 0.05 | |

| 0:100 | 7.20 ± 0.07 | 10.68 ± 0.06 | 9.02 ± 0.11 | 1.65 ± 0.05 | 2.08 ± 0.02 | 1.260 | 38.10 ± 0.29 | |

| Mixing Ratio | pH | TS (%) | VSwb (%) | Ash (%) | TAN (g/L) | N (%) | C/N | |

|---|---|---|---|---|---|---|---|---|

| CD:MC | 100:0± | 6.92 ± 03 | 7.22 ± 0.47 | 5.42 ± 0.47 | 1.80 ± 0.16 | 2.13 ± 0.02 | 1.71 | 24.96 ± 0.81 |

| 90:10± | 6.83 ± 0.08 | 6.30 ± 0.21 | 4.84 ± 0.17 | 1.46 ± 0.06 | 1.98 ± 0.01 | 1.48 | 29.40 ± 0.25 | |

| 70:30± | 6.73 ± 0.05 | 6.41 ± 0.19 | 4.93 ± 0.16 | 1.48 ± 0.06 | 1.75 ± 0.02 | 1.62 | 26.90 ± 0.24 | |

| 50:50± | 6.80 ± 0.06 | 6.82 ± 0.29 | 5.48 ± 0.0.28 | 1.33 ± 0.04 | 1.60 ± 0.03 | 1.76 | 25.91 ± 0.23 | |

| 30:70± | 6.86 ± 0.07 | 7.14 ± 7.14 | 5.74 ± 0.28 | 1.39 ± 0.02 | 1.78 ± 0.01 | 1.09 | 41.86 ± 0.16 | |

| 10:90± | 6.91 ± 0.04 | 7.86 ± 0.15 | 7.42 ± 0.24 | 1.47 ± 0.08 | 1.73 ± 0.02 | 1.57 | 29.46 ± 0.45 | |

| 0:100± | 6.87 ± 0.05 | 6.26 ± 0.36 | 4.94 ± 0.37 | 1.31 ± 0.02 | 1.78 ± 0.03 | 1.62 | 27.63 ± 0.47 | |

| Name of Kinetic Model | Parameters | 100:0 | 90:10 | 70:30 | 50:50 | 30:70 | 10:90 | 0:100 |

|---|---|---|---|---|---|---|---|---|

| First-Order Model | Bo | 100.00 | 229.00 | 200.10 | 316.50 | 177.80 | 195.50 | 602.40 |

| K | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 | |

| R2 | 0.94 | 0.97 | 0.96 | 0.98 | 0.93 | 0.96 | 0.99 | |

| RMSE | 6.42 | 7.79 | 9.33 | 9.94 | 13.66 | 8.49 | 5.25 | |

| Cone Model | Bo | 200.00 | 186.20 | 239.90 | 265.40 | 198.60 | 391.40 | 259.20 |

| K | 0.01 | 0.02 | 0.01 | 0.02 | 0.02 | 0.01 | 0.01 | |

| n | 1.31 | 1.54 | 1.52 | 1.47 | 1.92 | 0.94 | 1.42 | |

| R2 | 0.98 | 0.98 | 0.99 | 0.98 | 0.99 | 0.96 | 0.99 | |

| RMSE | 3.53 | 6.84 | 3.96 | 8.85 | 2.63 | 8.70 | 4.02 | |

| Modified Gompertz Model | Bo | 112.50 | 142.50 | 155.30 | 196.10 | 156.80 | 145.40 | 158.90 |

| Rmax | 0.90 | 2.09 | 1.83 | 2.79 | 2.12 | 1.50 | 1.89 | |

| λ | 6.85 | 3.92 | 8.37 | 3.45 | 11.87 | −3.53 | 6.76 | |

| R2 | 0.98 | 0.98 | 0.99 | 0.98 | 0.99 | 0.94 | 0.99 | |

| RMSE | 3.74 | 6.84 | 4.36 | 9.45 | 2.64 | 10.07 | 5.25 | |

| Logistic Model | Bo | 90.26 | 133.60 | 138.30 | 183.90 | 141.60 | 134.70 | 143.10 |

| Rmax | 0.97 | 2.15 | 1.96 | 2.84 | 2.29 | 1.49 | 1.99 | |

| λ | 11.11 | 6.04 | 11.99 | 5.33 | 15.40 | −2.22 | 10.02 | |

| R2 | 0.98 | 0.98 | 0.99 | 0.97 | 0.99 | 0.93 | 0.98 | |

| RMSE | 4.28 | 7.71 | 5.66 | 11.04 | 4.55 | 11.03 | 6.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saha, C.K.; Khatun, M.L.; Nime, J.; Kirtania, K.; Alam, M.M. Co-Digestion-Based Circular Bio-Economy to Improve Biomethane Generation and Production of Nutrient-Enriched Digestate in Bangladesh. Sustainability 2024, 16, 104. https://doi.org/10.3390/su16010104

Saha CK, Khatun ML, Nime J, Kirtania K, Alam MM. Co-Digestion-Based Circular Bio-Economy to Improve Biomethane Generation and Production of Nutrient-Enriched Digestate in Bangladesh. Sustainability. 2024; 16(1):104. https://doi.org/10.3390/su16010104

Chicago/Turabian StyleSaha, Chayan Kumer, Mst. Lucky Khatun, Jannatoon Nime, Kawnish Kirtania, and Md. Monjurul Alam. 2024. "Co-Digestion-Based Circular Bio-Economy to Improve Biomethane Generation and Production of Nutrient-Enriched Digestate in Bangladesh" Sustainability 16, no. 1: 104. https://doi.org/10.3390/su16010104

APA StyleSaha, C. K., Khatun, M. L., Nime, J., Kirtania, K., & Alam, M. M. (2024). Co-Digestion-Based Circular Bio-Economy to Improve Biomethane Generation and Production of Nutrient-Enriched Digestate in Bangladesh. Sustainability, 16(1), 104. https://doi.org/10.3390/su16010104