How Do Uncertainties Affect Supply-Chain Resilience? The Moderating Role of Information Sharing for Sustainable Supply-Chain Management

Abstract

:1. Introduction

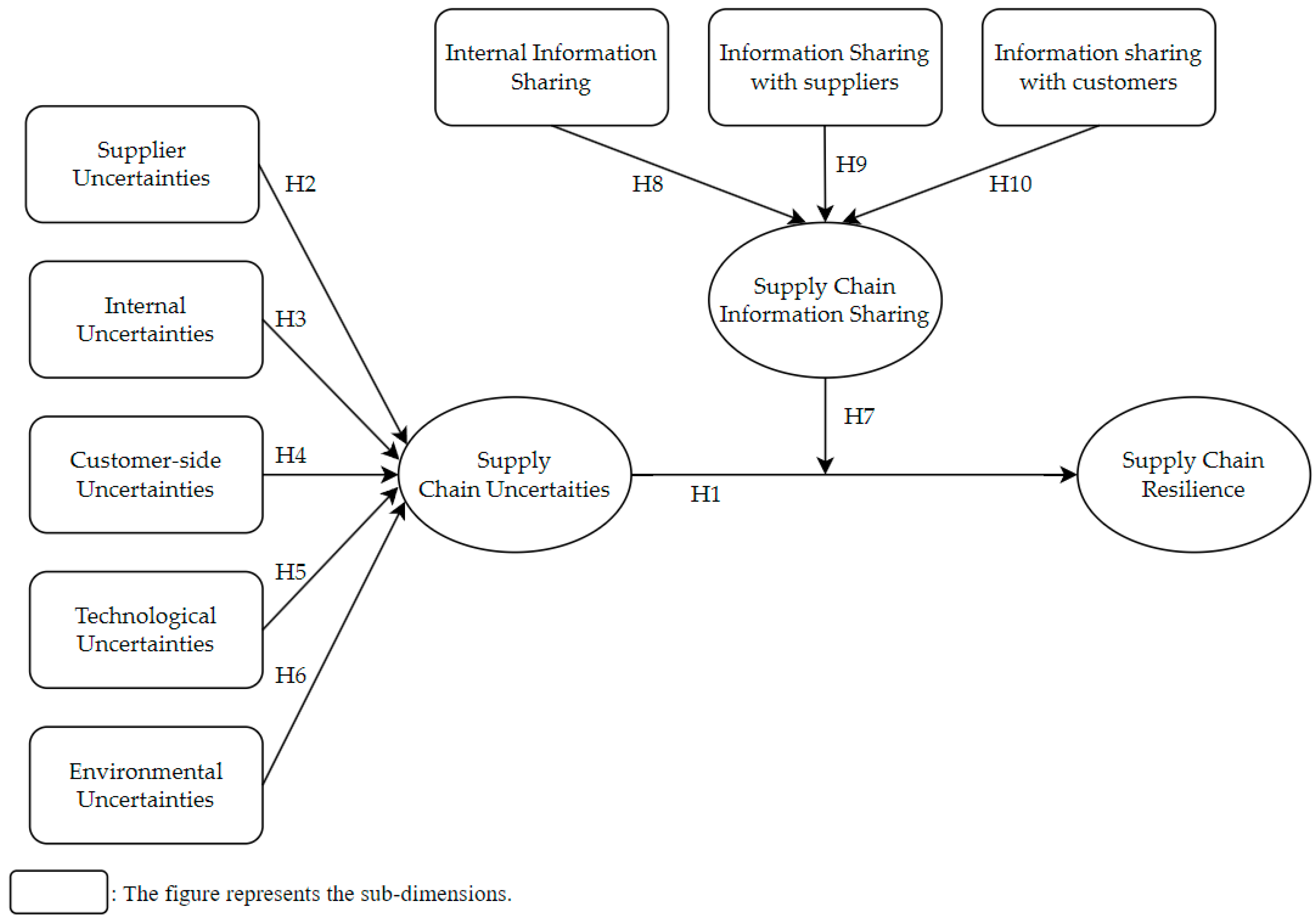

2. Conceptual Framework and Hypotheses

2.1. Supply-Chain Uncertainty (SCU)

2.2. Supply-Chain Resilience

2.3. Supply-Chain Information Sharing (SCIS)

2.4. Theoretical Background and Hypotheses Development

2.4.1. Contingency Theory

2.4.2. Resource-Based Theory

2.4.3. Contingent Resource-Based Theory

2.4.4. The Impact of SCU on SCRES

2.4.5. Moderating Effect of SCIS

3. Research Methodology

3.1. Sample and Data Collection

3.2. Instrument Design

4. Results

4.1. Validity and Reliability Check

4.2. Assessment of the Structural Model

5. Discussion

5.1. Theoretical Implications

5.2. Practical Implications

- Differing from the SCU scales in the literature, the fact that the scale used in this research is more inclusive will provide managers with a wider perspective in their observations and will make it easier for them to identify areas that they will have difficulty seeing;

- Taking into account the COVID-19 pandemic, which has recently caused radical changes around the world, businesses will have the opportunity to make a more detailed self assessment, taking into account the strategic information provided by this research;

- By adapting the strategies revealed in this research on SCRES, it will serve as a guide in determining the methods to overcome the fluctuations caused by unforeseen events;

- By integrating the information-sharing parameter with the field of management information systems, innovation-based information-sharing mechanisms can be created to improve SCRES in public- and private-sector organizations;

- By demonstrating that information exchanged among supply-chain members strengthens SCRES, this study offers managerial benefits.

5.3. Limitations and Future Research

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davis, K.F.; Downs, S.; Gephart, J.A. Towards Food Supply Chain Resilience to Environmental Shocks. Nat. Food 2021, 2, 54–65. [Google Scholar] [CrossRef] [PubMed]

- Ehrenhuber, I.; Treiblmaier, H.; Nowitzki, C.E.; Gerschberger, M. Toward a Framework for Supply Chain Resilience. Int. J. Supply Chain Oper. Resil. 2015, 1, 339–350. [Google Scholar] [CrossRef]

- Mensah, P.; Merkuryev, Y. Developing a Resilient Supply Chain. Procedia-Soc. Behav. Sci. 2014, 110, 309–319. [Google Scholar] [CrossRef]

- Salam, M.A.; Bajaba, S. The Role of Supply Chain Resilience and Absorptive Capacity in the Relationship between Marketing–Supply Chain Management Alignment and Firm Performance: A Moderated-Mediation Analysis. J. Bus. Ind. Mark. 2023, 38, 1545–1561. [Google Scholar] [CrossRef]

- ur Rehman, O.; Ali, Y. Enhancing Healthcare Supply Chain Resilience: Decision-Making in a Fuzzy Environment. Int. J. Logist. Manag. 2022, 33, 520–546. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The Role of Collaboration in Supply Chain Resilience. Supply Chain Manag. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Schroeder, M.; Lodemann, S. A Systematic Investigation of the Integration of Machine Learning into Supply Chain Risk Management. Logistics 2021, 5, 62. [Google Scholar] [CrossRef]

- Lawrence, P.R.; Lorsch, J.W. Differentiation and Integration in Complex Organizations. Adm. Sci. Q. 1967, 12, 1–47. [Google Scholar] [CrossRef]

- Miller, D. Environmental Fit Versus Internal Fit. Organ. Sci. 1992, 3, 159–178. [Google Scholar] [CrossRef]

- Thompson, J.D.; Zald, M.N.; Scott, W.R. Organizations in Action; Routledge: New York, NY, USA, 2017; ISBN 9781315125930. [Google Scholar]

- Schwark, B. Toward a Contingent Resource-Based View of Nonmarket Capabilities under Regulatory Uncertainty. In Proceedings of the 2nd Annual Conference on Competition and Regulation in Network Industries, Brussels, Belgium, 19 November 2010. [Google Scholar]

- Aragón-Correa, J.A.; Sharma, S. A Contingent Resource-Based View of Proactive Corporate Environmental Strategy. Acad. Manag. Rev. 2003, 28, 71. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Towards a Theory of Supply Chain Management: The Constructs and Measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Vahlne, J.E.; Hamberg, M.; Schweizer, R. Management under Uncertainty—The Unavoidable Risk-Taking. Multinatl. Bus. Rev. 2017, 25, 91–109. [Google Scholar] [CrossRef]

- Galbraith, J. Designing Complex Organizations; Addison-Wesley Publishing Company: Reading, MA, USA, 1973. [Google Scholar]

- Yang, B.; Burns, N.D.; Backhouse, C.J. Management of Uncertainty through Postponement. Int. J. Prod. Res. 2004, 42, 1049–1064. [Google Scholar] [CrossRef]

- Davis, T. Effective Supply Chain Management. Sloan Manag. Rev. 1993, 34, 35–46. [Google Scholar]

- Hult, G.T.M.; Craighead, C.W.; Ketchen, D.J., Jr.; Ketchen, D.J. Risk Uncertainty and Supply Chain Decisions: A Real Options Perspective. Decis. Sci. 2010, 41, 435–458. [Google Scholar] [CrossRef]

- Van Der Vorst, J.G.A.J.; Beulens, A.J.M. Identifying Sources of Uncertainty to Generate Supply Chain Redesign Strategies. Int. J. Phys. Distrib. Logist. Manag. 2002, 32, 409–430. [Google Scholar] [CrossRef]

- Simangunsong, E.; Hendry, L.C.; Stevenson, M. Supply-Chain Uncertainty: A Review and Theoretical Foundation for Future Research. Int. J. Prod. Res. 2012, 50, 4493–4523. [Google Scholar] [CrossRef]

- Flynn, B.B.; Koufteros, X.; Lu, G. On Theory in Supply Chain Uncertainty and Its Implications for Supply Chain Integration. J. Supply Chain Manag. 2016, 52, 3–27. [Google Scholar] [CrossRef]

- de Lima, F.A.; Seuring, S.; Sauer, P.C. A Systematic Literature Review Exploring Uncertainty Management and Sustainability Outcomes in Circular Supply Chains. Int. J. Prod. Res. 2022, 60, 6013–6046. [Google Scholar] [CrossRef]

- Peng, H.; Shen, N.; Liao, H.; Xue, H.; Wang, Q. Uncertainty Factors, Methods, and Solutions of Closed-Loop Supply Chain—A Review for Current Situation and Future Prospects. J. Clean. Prod. 2020, 254, 120032. [Google Scholar] [CrossRef]

- Marcos, J.T.; Scheller, C.; Godina, R.; Spengler, T.S.; Carvalho, H. Sources of Uncertainty in the Closed-Loop Supply Chain of Lithium-Ion Batteries for Electric Vehicles. Clean. Logist. Supply Chain 2021, 1, 100006. [Google Scholar] [CrossRef]

- Sato, Y.; Tse, Y.K.; Tan, K.H. Managers’ Risk Perception of Supply Chain Uncertainties. Ind. Manag. Data Syst. 2020, 120, 1617–1634. [Google Scholar] [CrossRef]

- Angkiriwang, R.; Pujawan, I.N.; Santosa, B. Managing Uncertainty through Supply Chain Flexibility: Reactive vs. Proactive Approaches. Prod. Manuf. Res. 2014, 2, 50–70. [Google Scholar] [CrossRef]

- Hoffmann, P.; Schiele, H.; Krabbendam, K. Uncertainty, Supply Risk Management and Their Impact on Performance. J. Purch. Supply Manag. 2013, 19, 199–211. [Google Scholar] [CrossRef]

- Sreedevi, R.; Saranga, H. Uncertainty and Supply Chain Risk: The Moderating Role of Supply Chain Flexibility in Risk Mitigation. Int. J. Prod. Econ. 2017, 193, 332–342. [Google Scholar] [CrossRef]

- Gokarn, S.; Kuthambalayan, T.S. Creating Sustainable Fresh Produce Supply Chains by Managing Uncertainties. J. Clean. Prod. 2019, 207, 908–919. [Google Scholar] [CrossRef]

- Tse, Y.K.; Zhang, M.; Zeng, W.; Ma, J. Perception of Supply Chain Quality Risk: Understanding the Moderation Role of Supply Market Thinness. J. Bus. Res. 2021, 122, 822–834. [Google Scholar] [CrossRef]

- Sopha, B.M.; Jie, F.; Himadhani, M. Analysis of the Uncertainty Sources and SMEs’ Performance. J. Small Bus. Entrep. 2021, 33, 1–27. [Google Scholar] [CrossRef]

- Tse, Y.K.; Matthews, R.L.; Tan, K.H.; Sato, Y.; Pongpanich, C. Unlocking Supply Chain Disruption Risk within the Thai Beverage Industry. Ind. Manag. Data Syst. 2016, 116, 21–42. [Google Scholar] [CrossRef]

- Asbjørnslett, B.E.; Rausand, M. Assess the Vulnerability of Your Production System. Prod. Plan. Control 1999, 10, 219–229. [Google Scholar] [CrossRef]

- Rice, J.B.; Caniato, F. Building a Secure and Resilience Supply Chain. Supply Chain Manag. Rev. 2003, 5, 22–30. [Google Scholar]

- Holling, C.S. Resilience and Stability of Ecological Systems. Annu. Rev. Ecol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef]

- Sheffi, Y. The Resilient Enterprise: Overcoming Vulnerability for Competitive Advantage; MIT Press: Cambridge, MA, USA; Paperback: London, UK, 2005; ISBN 9788578110796. [Google Scholar]

- Shuai, Y.; Wang, X.; Zhao, L. Research on Measuring Method of Supply Chain Resilience Based on Biological Cell Elasticity Theory. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011; pp. 264–268. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring Supply Chain Resilience: Development of a Conceptual Framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- van Hoek, R. Research Opportunities for a More Resilient Post-COVID-19 Supply Chain—Closing the Gap between Research Findings and Industry Practice. Int. J. Oper. Prod. Manag. 2020, 40, 341–355. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Johnson, N.; Elliott, D.; Drake, P. Exploring the Role of Social Capital in Facilitating Supply Chain Resilience. Supply Chain Manag. 2013, 18, 324–336. [Google Scholar] [CrossRef]

- Emenike, S.N.; Falcone, G. A Review on Energy Supply Chain Resilience through Optimization. Renew. Sustain. Energy Rev. 2020, 134, 110088. [Google Scholar] [CrossRef]

- Sabahi, S.; Parast, M.M. Firm Innovation and Supply Chain Resilience: A Dynamic Capability Perspective. Int. J. Logist. Res. Appl. 2020, 23, 254–269. [Google Scholar] [CrossRef]

- Wieland, A.; Stevenson, M.; Melnyk, S.A.; Davoudi, S.; Schultz, L. Thinking Differently about Supply Chain Resilience: What We Can Learn from Social-Ecological Systems Thinking. Int. J. Oper. Prod. Manag. 2023, 43, 1–21. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Soni, U.; Chandra, C. Supply Chain Resilience: Model Development and Empirical Analysis. Int. J. Prod. Res. 2017, 55, 6779–6800. [Google Scholar] [CrossRef]

- Brusset, X.; Teller, C. Supply Chain Capabilities, Risks, and Resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.; Agarwal, R. Supply Chain Resilience for Performance: Role of Relational Practices and Network Complexities. Supply Chain Manag. 2019, 24, 659–676. [Google Scholar] [CrossRef]

- Qader, G.; Junaid, M.; Abbas, Q.; Mubarik, M.S. Industry 4.0 Enables Supply Chain Resilience and Supply Chain Performance. Technol. Forecast. Soc. Chang. 2022, 185, 122026. [Google Scholar] [CrossRef]

- Hussain, G.; Nazir, M.S.; Rashid, M.A.; Sattar, M.A. From Supply Chain Resilience to Supply Chain Disruption Orientation: The Moderating Role of Supply Chain Complexity. J. Enterp. Inf. Manag. 2023, 36, 70–90. [Google Scholar] [CrossRef]

- Lin, J.; Lin, S.; Benitez, J.; Luo, X.; Ajamieh, A. How to Build Supply Chain Resilience: The Role of Fit Mechanisms between Digitally-Driven Business Capability and Supply Chain Governance. Inf. Manag. 2023, 60, 103747. [Google Scholar] [CrossRef]

- Lotfi, Z.; Mukhtar, M.; Sahran, S.; Zadeh, A.T. Information Sharing in Supply Chain Management. Procedia Technol. 2013, 11, 298–304. [Google Scholar] [CrossRef]

- Samaddar, S.; Nargundkar, S.; Daley, M. Inter-Organizational Information Sharing: The Role of Supply Network Configuration and Partner Goal Congruence. Eur. J. Oper. Res. 2006, 174, 744–765. [Google Scholar] [CrossRef]

- Barua, A.; Ravindran, S.; Whinston, A.B. Enabling Information Sharing within Organizations. Inf. Technol. Manag. 2007, 8, 31–45. [Google Scholar] [CrossRef]

- Lee, H.L.; Whang, S. Information Sharing in a Supply Chain. Int. J. Manuf. Technol. Manag. 2000, 1, 79–93. [Google Scholar] [CrossRef]

- Erturgut, R. Lojistik ve Tedarik Zinciri Yönetimi; Nobel Yayıncılık: Ankara, Turkey, 2016. [Google Scholar]

- Chen, F.; Drezner, Z.; Ryan, J.K.; Simchi-Levi, D. Quantifying the Bullwhip Effect in a Simple Supply Chain: The Impact of Forecasting, Lead Times, and Information. Manag. Sci. 2000, 46, 436–443. [Google Scholar] [CrossRef]

- Ouyang, Y. The Effect of Information Sharing on Supply Chain Stability and the Bullwhip Effect. Eur. J. Oper. Res. 2007, 182, 1107–1121. [Google Scholar] [CrossRef]

- Tran, T.T.H.; Childerhouse, P.; Deakins, E. Supply Chain Information Sharing: Challenges and Risk Mitigation Strategies. J. Manuf. Technol. Manag. 2016, 27, 1102–1126. [Google Scholar] [CrossRef]

- Colicchia, C.; Creazza, A.; Noè, C.; Strozzi, F. Information Sharing in Supply Chains: A Review of Risks and Opportunities Using the Systematic Literature Network Analysis (SLNA). Supply Chain Manag. 2019, 24, 5–21. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, J. Coordination of Information Sharing in a Supply Chain. Int. J. Prod. Econ. 2013, 143, 178–187. [Google Scholar] [CrossRef]

- Khan, M.; Hussain, M.; Saber, H.M. Information Sharing in a Sustainable Supply Chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar] [CrossRef]

- Han, G.; Dong, M. Trust-Embedded Coordination in Supply Chain Information Sharing. Int. J. Prod. Res. 2015, 53, 5624–5639. [Google Scholar] [CrossRef]

- Shang, W.; Ha, A.Y.; Tong, S. Information Sharing in a Supply Chain with a Common Retailer. Manag. Sci. 2016, 62, 245–263. [Google Scholar] [CrossRef]

- Huang, S.; Guan, X.; Chen, Y.J. Retailer Information Sharing with Supplier Encroachment. Prod. Oper. Manag. 2018, 27, 1133–1147. [Google Scholar] [CrossRef]

- Jeong, K.; Hong, J.D. The Impact of Information Sharing on Bullwhip Effect Reduction in a Supply Chain. J. Intell. Manuf. 2019, 30, 1739–1751. [Google Scholar] [CrossRef]

- Gruzauskas, V.; Burinskiene, A.; Krisciunas, A. Application of Information-Sharing for Resilient and Sustainable Food Delivery in Last-Mile Logistics. Mathematics 2023, 11, 303. [Google Scholar] [CrossRef]

- Wang, M.; Jie, F.; Abareshi, A. The Measurement Model of Supply Chain Uncertainty and Risk in the Australian Courier Industry. Oper. Supply Chain Manag. An Int. J. 2014, 7, 89–96. [Google Scholar] [CrossRef]

- Han, Z.; Huo, B.; Zhao, X. Backward Supply Chain Information Sharing: Who Does It Benefit? Supply Chain Manag. An Int. J. 2021. [Google Scholar] [CrossRef]

- Bai, C.; Govindan, K.; Huo, B. The Contingency Effects of Dependence Relationship on Supply Chain Information Sharing and Agility. Int. J. Logist. Manag. 2023, 34, 1808–1832. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, F.; Tan, K.H. Effects of Managerial Ties and Trust on Supply Chain Information Sharing and Supplier Opportunism. Int. J. Prod. Res. 2014, 52, 7046–7061. [Google Scholar] [CrossRef]

- Burns, T.; Stalker, G.M. The Management of Innovation; Oxford University Press: London, UK, 1961. [Google Scholar]

- Kembro, J.; Selviaridis, K.; Näslund, D. Theoretical Perspectives on Information Sharing in Supply Chains: A Systematic Literature Review and Conceptual Framework. Supply Chain Manag. 2014, 19, 609–625. [Google Scholar] [CrossRef]

- Blackhurst, J.; Dunn, K.S.; Craighead, C.W. An Empirically Derived Framework of Global Supply Resiliency. J. Bus. Logist. 2011, 32, 374–391. [Google Scholar] [CrossRef]

- Olavarrieta, S.; Ellinger, A.E. Resource-Based Theory and Strategic Logistics Research. Int. J. Phys. Distrib. Logist. Manag. 1997, 27, 559–587. [Google Scholar] [CrossRef]

- Lai, K. Service Capability and Performance of Logistics Service Providers. Transp. Res. Part E Logist. Transp. Rev. 2004, 40, 385–399. [Google Scholar] [CrossRef]

- Gligor, D.M.; Holcomb, M. The Road to Supply Chain Agility: An RBV Perspective on the Role of Logistics Capabilities. Int. J. Logist. Manag. 2014, 25, 160–179. [Google Scholar] [CrossRef]

- Ralston, P.M.; Grawe, S.J.; Daugherty, P.J. Logistics Salience Impact on Logistics Capabilities and Performance. Int. J. Logist. Manag. 2013, 24, 136–152. [Google Scholar] [CrossRef]

- Peteraf, M.A. The Cornerstones of Competitive Advantage: A Resource-Based View. Strateg. Manag. J. 1993, 14, 179–191. [Google Scholar] [CrossRef]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Koç, E.; Delibaş, M.B.; Anadol, Y. Environmental Uncertainties and Competitive Advantage: A Sequential Mediation Model of Supply Chain Integration and Supply Chain Agility. Sustainability 2022, 14, 8928. [Google Scholar] [CrossRef]

- Wang, M.; Jie, F.; Abareshi, A. A Conceptual Framework for Mitigating Supply Chain Uncertainties and Risks in the Courier Industry. Int. J. Supply Chain Oper. Resil. 2015, 1, 319. [Google Scholar] [CrossRef]

- Roscoe, S.; Skipworth, H.; Aktas, E.; Habib, F. Managing Supply Chain Uncertainty Arising from Geopolitical Disruptions: Evidence from the Pharmaceutical Industry and Brexit. Int. J. Oper. Prod. Manag. 2020, 40, 1499–1529. [Google Scholar] [CrossRef]

- Barney, J.B.; Ketchen, D.J.; Wright, M. The Future of Resource-Based Theory: Revitalization or Decline? J. Manag. 2011, 37, 1299–1315. [Google Scholar] [CrossRef]

- Ahmed, W.; Khan, M.A.; Najmi, A.; Khan, S.A. Strategizing Risk Information Sharing Framework among Supply Chain Partners for Financial Performance. Supply Chain Forum Int. J. 2023, 24, 233–250. [Google Scholar] [CrossRef]

- Ling-yee, L. Marketing Resources and Performance of Exhibitor Firms in Trade Shows: A Contingent Resource Perspective. Ind. Mark. Manag. 2007, 36, 360–370. [Google Scholar] [CrossRef]

- Donaldson, L. The Contingency Theory of Organizations; Sage Publications: Thousand Oaks, CA, USA, 2001. [Google Scholar]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Fredericks, E. Infusing Flexibility into Business-to-Business Firms: A Contingency Theory and Resource-Based View Perspective and Practical Implications. Ind. Mark. Manag. 2005, 34, 555–565. [Google Scholar] [CrossRef]

- Birkie, S.E.; Trucco, P.; Fernandez Campos, P. Effectiveness of Resilience Capabilities in Mitigating Disruptions: Leveraging on Supply Chain Structural Complexity. Supply Chain Manag. 2017, 22, 506–521. [Google Scholar] [CrossRef]

- Agarwal, N.; Seth, N. Analysis of Supply Chain Resilience Barriers in Indian Automotive Company Using Total Interpretive Structural Modelling. J. Adv. Manag. Res. 2021, 18, 758–781. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s Resilience to Supply Chain Disruptions: Scale Development and Empirical Examination. J. Oper. Manag. 2015, 33–34, 111–122. [Google Scholar] [CrossRef]

- Christopher, M. Logistics & Supply Chain Management, 4th ed.; Pearson Education Limited: Dorchester, UK, 2011. [Google Scholar]

- Fiksel, J.; Polyviou, M.; Croxton, K.L.; Pettit, T.J. From Risk to Resilience: Learning to Deal with Disruption. MIT Sloan Manag. Rev. 2015, 56, 79–86. [Google Scholar]

- Liu, G. Three Essays on Mass Customization: Examining Impacts of Work Design, Supply Chain Uncertainty Management, and Functional Integration on Mass Customization. Ph.D. Dissertation, Faculty of the Graduate School of the University of Minnesota, UMI Microform, Ann Arbor, MI, USA, 2007. [Google Scholar]

- Gölgeci, I.; Ponomarov, S.Y. How Does Firm Innovativeness Enable Supply Chain Resilience? The Moderating Role of Supply Uncertainty and Interdependence. Technol. Anal. Strateg. Manag. 2015, 27, 267–282. [Google Scholar] [CrossRef]

- Tang, C.S. Perspectives in Supply Chain Risk Management. Int. J. Prod. Econ. 2006, 103, 451–488. [Google Scholar] [CrossRef]

- Gu, M.; Yang, L.; Huo, B. The Impact of Information Technology Usage on Supply Chain Resilience and Performance: An Ambidexterous View. Int. J. Prod. Econ. 2021, 232, 107956. [Google Scholar] [CrossRef]

- Spiegler, V.L.M.; Naim, M.M.; Wikner, J. A Control Engineering Approach to the Assessment of Supply Chain Resilience. Int. J. Prod. Res. 2012, 50, 6162–6187. [Google Scholar] [CrossRef]

- Ramanathan, U.; Aluko, O.; Ramanathan, R. Supply Chain Resilience and Business Responses to Disruptions of the COVID-19 Pandemic. Benchmarking 2022, 29, 2275–2290. [Google Scholar] [CrossRef]

- Williams, T.A.; Gruber, D.A.; Sutcliffe, K.M.; Shepherd, D.A.; Zhao, E.Y. Organizational Response to Adversity: Fusing Crisis Management and Resilience Research Streams. Acad. Manag. Ann. 2017, 11, 733–769. [Google Scholar] [CrossRef]

- Ghosh, S.; Bhowmick, B. Technological Uncertainty: Exploring Factors in Indian Start-Ups. In Proceedings of the IEEE Global Humanitarian Technology Conference (GHTC 2014), San Jose, CA, USA, 10–13 October 2014; pp. 425–432. [Google Scholar]

- Al-Hakimi, M.A.; Borade, D.B.; Saleh, M.H.; Nasr, M.A.A. The Moderating Role of Supplier Relationship on the Effect of Postponement on Supply Chain Resilience under Different Levels of Environmental Uncertainty. Prod. Manuf. Res. 2022, 10, 383–409. [Google Scholar] [CrossRef]

- Trkman, P.; McCormack, K. Supply Chain Risk in Turbulent Environments-A Conceptual Model for Managing Supply Chain Network Risk. Int. J. Prod. Econ. 2009, 119, 247–258. [Google Scholar] [CrossRef]

- Sydow, J.; Müller-Seitz, G.; Provan, K.G. Managing Uncertainty in Alliances and Networks—From Governance to Practice. In Managing Knowledge in Strategic Alliances; Das, T.K., Ed.; Information Age Publishing: Charlotte, NC, USA, 2013; pp. 1–43. [Google Scholar]

- Tan, H.-C.; Soh, K.L.; Wong, W.P.; Tseng, M.-L. Enhancing Supply Chain Resilience by Counteracting the Achilles Heel of Information Sharing. J. Enterp. Inf. Manag. 2022, 35, 817–846. [Google Scholar] [CrossRef]

- Zhou, H.; Benton, W.C. Supply Chain Practice and Information Sharing. J. Oper. Manag. 2007, 25, 1348–1365. [Google Scholar] [CrossRef]

- Li, S.; Lin, B. Accessing Information Sharing and Information Quality in Supply Chain Management. Decis. Support Syst. 2006, 42, 1641–1656. [Google Scholar] [CrossRef]

- Darkow, P.M. Beyond “Bouncing Back”: Towards an Integral, Capability-Based Understanding of Organizational Resilience. J. Contingencies Cris. Manag. 2019, 27, 145–156. [Google Scholar] [CrossRef]

- Li, G.; Li, X.; Liu, M. Inducing Supplier Backup via Manufacturer Information Sharing under Supply Disruption Risk. Comput. Ind. Eng. 2023, 176, 108914. [Google Scholar] [CrossRef] [PubMed]

- Syed, M.W.; Li, J.Z.; Junaid, M.; Ye, X.; Ziaullah, M. An Empirical Examination of Sustainable Supply Chain Risk and Integration Practices: A Performance-Based Evidence from Pakistan. Sustainability 2019, 11, 5334. [Google Scholar] [CrossRef]

- Chen, C.; Gu, T.; Cai, Y.; Yang, Y. Impact of Supply Chain Information Sharing on Performance of Fashion Enterprises: An Empirical Study Using SEM. J. Enterp. Inf. Manag. 2019, 32, 913–935. [Google Scholar] [CrossRef]

- Cachon, G.P.; Fisher, M. Supply Chain Inventory Management and the Value of Shared Information. Manag. Sci. 2000, 46, 1032–1048. [Google Scholar] [CrossRef]

- Yang, L.; Huo, B.; Gu, M. The Impact of Information Sharing on Supply Chain Adaptability and Operational Performance. Int. J. Logist. Manag. 2022, 33, 590–619. [Google Scholar] [CrossRef]

- Krejcie, R.V.; Morgan, W.D. Determining Sample Size for Research Activities. Educ. Psychol. Meas. 1970, 30, 607–610. [Google Scholar] [CrossRef]

- Sekaran, U. Research Methods for Business: A Skill-Building Approach, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2003; ISBN 9781119111931. [Google Scholar]

- Haider, S.N.; Siddiqui, D.A. Impact of Logistics Capabilities on Mitigation of Supply Chain Uncertainty and Risk in Courier Firms in Pakistan. SSRN Electron. J. 2018. [Google Scholar] [CrossRef]

- Fynes, B.; de Búrca, S.; Marshall, D. Environmental Uncertainty, Supply Chain Relationship Quality and Performance. J. Purch. Supply Manag. 2004, 10, 179–190. [Google Scholar] [CrossRef]

- Huo, B.; Zhao, X.; Zhou, H. The Effects of Competitive Environment on Supply Chain Information Sharing and Performance: An Empirical Study in China. Prod. Oper. Manag. 2014, 23, 552–569. [Google Scholar] [CrossRef]

- Ponomarov, S.Y. Antecedents and Consequences of Supply Chain Resilience: A Dynamic Capabilities Perspective. Ph.D. Dissertation, The University of Tennessee, Knoxville, TN, USA, 2012. [Google Scholar]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Kenny, D.A., Little, T.D., Eds.; The Guilford Press: New York, NY, USA; London, UK, 2011; ISBN 9781606238776. [Google Scholar]

- Gefen, D.; Straub, D. A Practical Guide to Factorial Validity Using PLS-Graph: Tutorial and Annotated Example. Commun. Assoc. Inf. Syst. 2005, 16, 91–109. [Google Scholar] [CrossRef]

- Ho, R. Handbook of Univariate and Multivariate Data Analysis with IBM SPSS, 2nd ed.; CRC Press: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2014. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson Education Limited: Harlow, UK, 2014. [Google Scholar]

- Gray, C.D.; Kinnear, P.R. Psychology Press; IBM SPSS Statistics 19 Made Simple; New York, NY, USA, 2012; ISBN 9781848720695. [Google Scholar]

- Brown, T.A. Confirmatory Factor Analysis for Applied Research; Kenny, D.A., Ed.; The Guilford Press: New York, NY, USA, 2007; Volume 44. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39. [Google Scholar] [CrossRef]

- Raykov, T.; Grayson, D. A Test for Change of Composite Reliability in Scale Development. Multivariate Behav. Res. 2003, 38, 143–159. [Google Scholar] [CrossRef]

- Ab Hamid, M.R.; Sami, W.; Mohmad Sidek, M.H. Discriminant Validity Assessment: Use of Fornell & Larcker Criterion versus HTMT Criterion. J. Phys. Conf. Ser. 2017, 890, 012163. [Google Scholar] [CrossRef]

- Ullman, J.B.; Bentler, P.M. Structural Equation Modeling. In Handbook of Psychology; Weiner, I.B., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 661–690. ISBN 9781119111931. [Google Scholar]

- Cheng, J.H.; Lu, K.L. Enhancing Effects of Supply Chain Resilience: Insights from Trajectory and Resource-Based Perspectives. Supply Chain Manag. 2017, 22, 329–340. [Google Scholar] [CrossRef]

- Fiksel, J. From Risk to Resilience. In Resilient by Design; Island Press/Center for Resource Economics: Washington, DC, USA, 2015; pp. 19–34. ISBN 9781610915885. [Google Scholar]

- Akter, S.; Debnath, B.; Bari, A.B.M.M. A Grey Decision-Making Trial and Evaluation Laboratory Approach for Evaluating the Disruption Risk Factors in the Emergency Life-Saving Drugs Supply Chains. Healthc. Anal. 2022, 2, 100120. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Blome, C.; Luo, Z. Antecedents of Resilient Supply Chains: An Empirical Study. IEEE Trans. Eng. Manag. 2019, 66, 8–19. [Google Scholar] [CrossRef]

- Ruel, S.; Ouabouch, L.; Shaaban, S. Supply Chain Uncertainties Linked to Information Systems: A Case Study Approach. Ind. Manag. Data Syst. 2017, 117, 1093–1108. [Google Scholar] [CrossRef]

- Ho, C.F.; Chi, Y.P.; Tai, Y.M. A Structural Approach to Measuring Uncertainty in Supply Chains. Int. J. Electron. Commer. 2005, 9, 91–114. [Google Scholar] [CrossRef]

- Rodrigues, V.S.; Stantchev, D.; Potter, A.; Naim, M.; Whiteing, A. Establishing a Transport Operation Focused Uncertainty Model for the Supply Chain. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 388–411. [Google Scholar] [CrossRef]

- Wang, M. Impacts of Supply Chain Uncertainty and Risk on the Logistics Performance. Asia Pacific J. Mark. Logist. 2018, 30, 689–704. [Google Scholar] [CrossRef]

- Perdana, Y.R. Supply Chain Uncertainty: An Empirical Study of Indonesia’S Agro-Industry. Agrointek J. Teknol. Ind. Pertan. 2021, 15, 910–920. [Google Scholar] [CrossRef]

| Characteristics | Category | Frequency | % |

|---|---|---|---|

| Gender | Female | 78 | 32.8 |

| Male | 160 | 67.2 | |

| Age | 21–30 | 63 | 26 |

| 31–40 | 86 | 35.5 | |

| 41–50 | 62 | 25.6 | |

| 51–60 | 28 | 11.6 | |

| >61 | 3 | 1.2 | |

| Education | High School | 6 | 2.5 |

| Associate | 32 | 13.1 | |

| Undergraduate | 169 | 69.3 | |

| Graduate | 35 | 14.3 | |

| Seniority | <1 | 36 | 14.8 |

| 1–3 | 53 | 21.8 | |

| 3–7 | 66 | 27.2 | |

| >7 | 88 | 36.2 | |

| Age of the Company | <10 | 35 | 14.3 |

| 10–40 | 162 | 66.4 | |

| >40 | 46 | 18.9 | |

| Number of Employees | <50 | 63 | 25.8 |

| 51–100 | 22 | 9 | |

| 101–200 | 21 | 8.6 | |

| 201–500 | 54 | 22.1 | |

| 501–1000 | 36 | 14.8 | |

| >1000 | 48 | 19.7 |

| Construct | Mean | SD | Factor Loads (EFA) | Standardized Loads (CFA) | VIF | Cronbach Alpha | Skewness | Kurtosis |

|---|---|---|---|---|---|---|---|---|

| SCU-I | 1.579 | 0.556 | 0.841–0.505 | 0.825–0.656 | 1.046 | 0.740 | 0.668 | −0.248 |

| SCU-CS | 2.365 | 0.874 | 0.788–0.652 | 0.915–0.490 | 1.104 | 0.720 | 0.354 | −0.588 |

| SCU-TECH | 3.737 | 0.983 | 0.857–0.615 | 0.918–0.555 | 1.069 | 0.748 | −0.705 | −0.065 |

| SCU-ENV | 2.417 | 0.788 | 0.729–0.576 | 0.712–0.457 | 1.052 | 0.769 | 0.662 | 0.089 |

| ISI | 3.862 | 0.887 | 0.898–0.753 | 0.882–0.700 | 1.147 | 0.877 | −0.718 | 0.070 |

| ISS | 3.397 | 0.971 | 0.888–0.582 | 0.910–0.603 | 1.116 | 0.877 | −0.667 | 0.083 |

| SCRES | 3.823 | 0.730 | 0.863–0.731 | 0.819–0.620 | 0.880 | −0.549 | −0.037 |

| Structure | AVE | Square Root of AVE | CR | SCU-I | SCU-CS | SCU-TECH | SCU-ENV | ISI | ISS |

|---|---|---|---|---|---|---|---|---|---|

| (1) SCU-I | 0.518 | 0.720 | 0.745 | ||||||

| (2) SCU-CS | 0.507 | 0.711 | 0.761 | 0.045 (0.101) | |||||

| (3) SCU-TECH | 0.545 | 0.738 | 0.768 | −0.048 (0.109) | 0.168 ** (0.288) | ||||

| (4) SCU-ENV | 0.364 | 0.603 | 0.770 | 0.036 (0.081) | 0.204 ** (0.297) | 0.035 (0.220) | |||

| (5) ISI | 0.649 | 0.806 | 0.881 | −0.188 ** | −0.018 | 0.182 ** | −0.048 | ||

| (6) ISS | 0.574 | 0.758 | 0.890 | −0.124 | −0.158 * | −0.014 | 0.023 | 0.263 ** (0.324) | |

| (7) SCRES | 0.550 | 0.742 | 0.879 | −0.227 ** | −0.134 * | 0.035 | −0.123 | 0.667 ** | 0.334 ** |

| Hypothesis | Paths | Std. Estimates (β) | p-Value | Results |

|---|---|---|---|---|

| H1 | SCU→SCRES | −0.169 | 0.008 ** | Supported |

| H3 | SCU-I→SCRES | −0.216 | *** | Supported |

| H4 | SCU-CS→SCRES | −0.134 | 0.034 * | Supported |

| H5 | SCU-TECH→SCRES | 0.035 | 0.588 | Not Supported |

| H6 | SCU-ENV→SCRES | −0.096 | 0.045 * | Supported |

| H7 | SCU×IS→SCRES | −0.079 | 0.115 | Not Supported |

| H8 | SCU×ISI→SCRES | 0.01 | 0.826 | Not Supported |

| H8a | SCU-I×ISI→SCRES | 0.05 | 0.433 | Not Supported |

| H8b | SCU-CS×ISI→SCRES | 0.012 | 0.795 | Not Supported |

| H8c | SCU-TECH×ISI→SCRES | −0.129 | 0.044 * | Supported |

| H8d | SCU-ENV×ISI→SCRES | 0.075 | 0.145 | Not Supported |

| H9 | SCU×ISS→SCRES | −0.098 | 0.040 * | Supported |

| H9a | SCU-I×ISS→SCRES | −0.215 | 0.525 | Not Supported |

| H9b | SCU-CS×ISS→SCRES | −0.124 | 0.77 | Not Supported |

| H9c | SCU-TECH×ISS→SCRES | −0.128 | 0.033 * | Supported |

| H9d | SCU-ENV×ISS→SCRES | 0.067 | 0.287 | Not Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coşkun, A.E.; Erturgut, R. How Do Uncertainties Affect Supply-Chain Resilience? The Moderating Role of Information Sharing for Sustainable Supply-Chain Management. Sustainability 2024, 16, 131. https://doi.org/10.3390/su16010131

Coşkun AE, Erturgut R. How Do Uncertainties Affect Supply-Chain Resilience? The Moderating Role of Information Sharing for Sustainable Supply-Chain Management. Sustainability. 2024; 16(1):131. https://doi.org/10.3390/su16010131

Chicago/Turabian StyleCoşkun, Artuğ Eren, and Ramazan Erturgut. 2024. "How Do Uncertainties Affect Supply-Chain Resilience? The Moderating Role of Information Sharing for Sustainable Supply-Chain Management" Sustainability 16, no. 1: 131. https://doi.org/10.3390/su16010131

APA StyleCoşkun, A. E., & Erturgut, R. (2024). How Do Uncertainties Affect Supply-Chain Resilience? The Moderating Role of Information Sharing for Sustainable Supply-Chain Management. Sustainability, 16(1), 131. https://doi.org/10.3390/su16010131