Characterization and Application of Rice Straw-Based Polyurethane Foam Blocks for Soil Erosion Control

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. RSPF Block Preparation

2.3. RSPF Characterization

2.3.1. Physical Properties

2.3.2. Mechanical Property

2.3.3. Morphology of RSPF

2.3.4. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.5. Thermogravimetric Analysis (TGA)

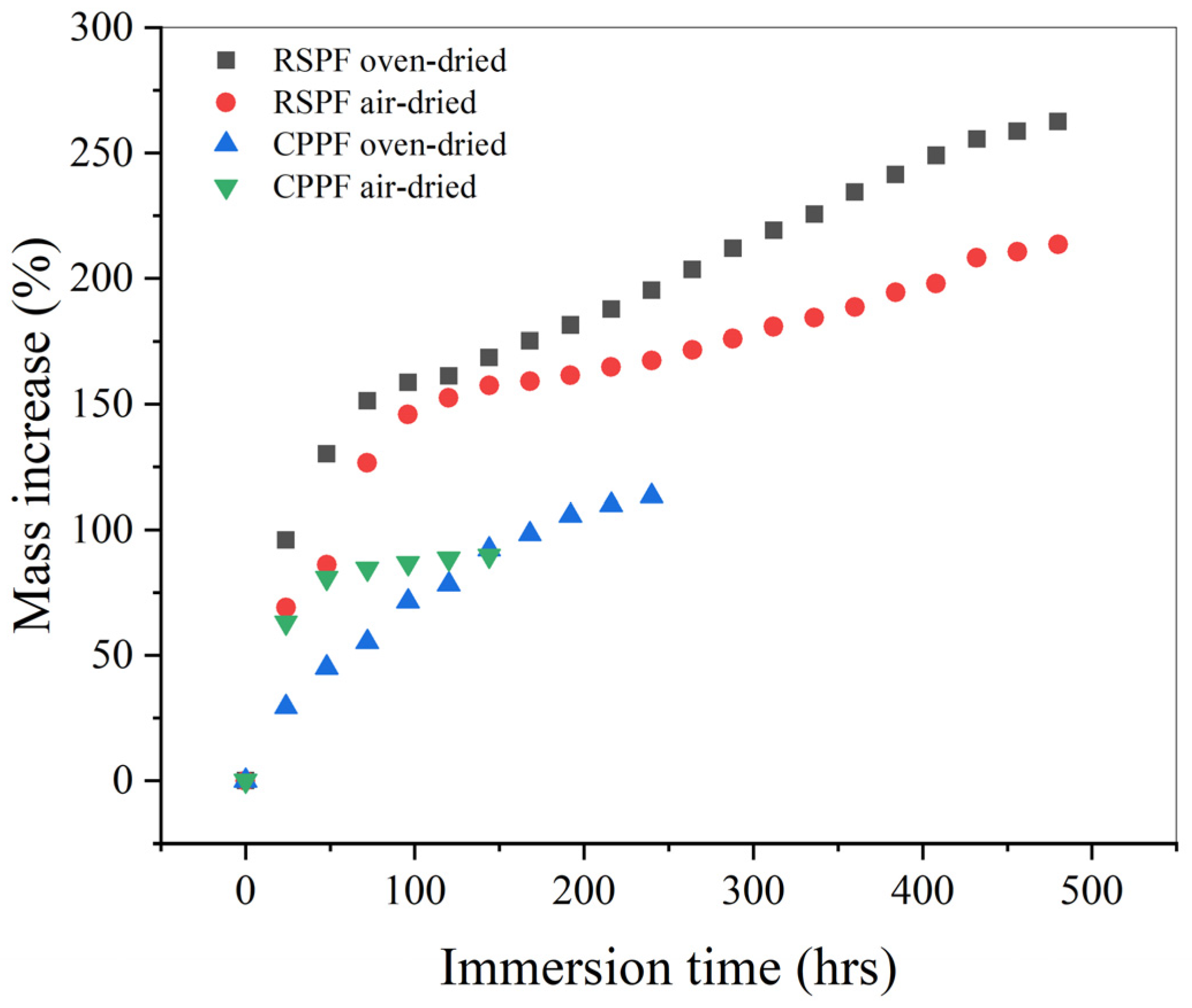

2.3.6. Water Absorption

2.4. Application of RSPF Blocks in Soil Loss Reduction

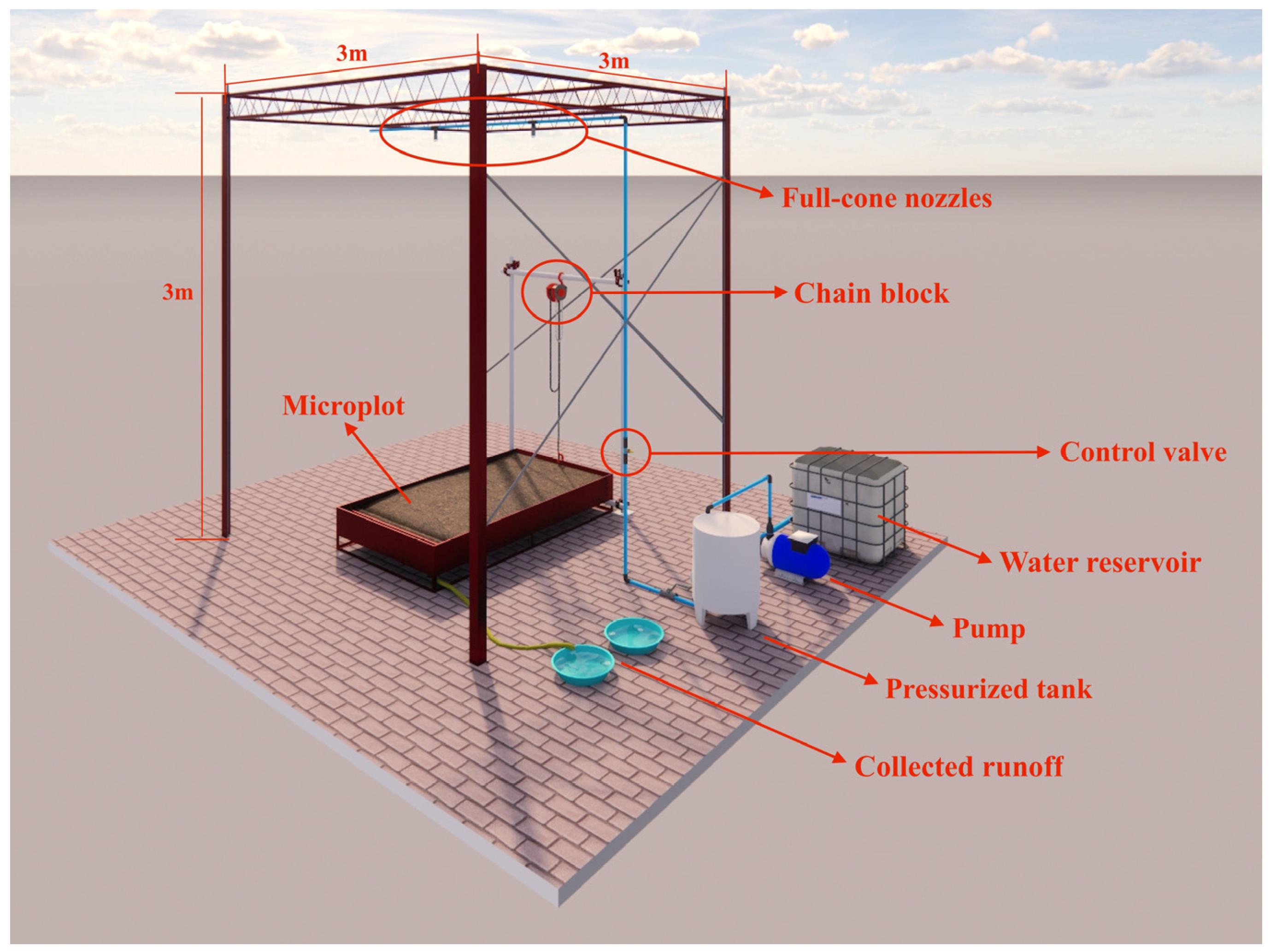

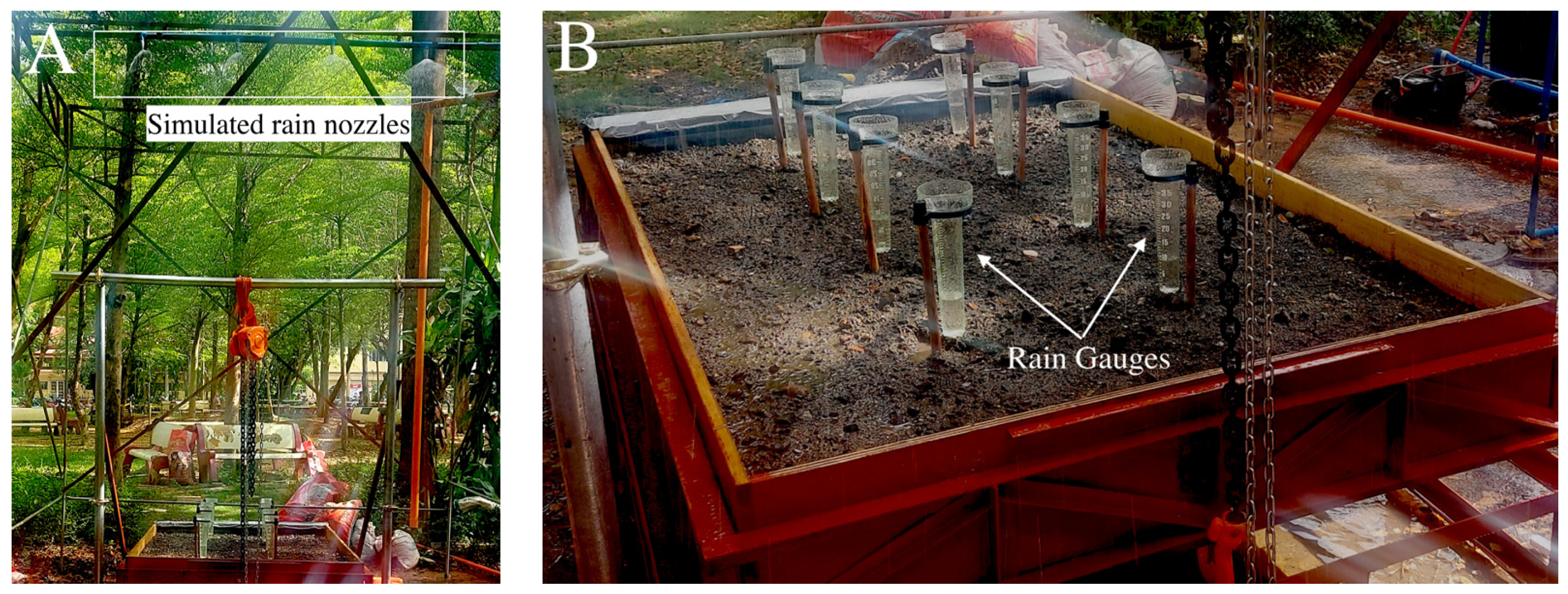

2.4.1. Rainfall Simulator Construction and Calibration

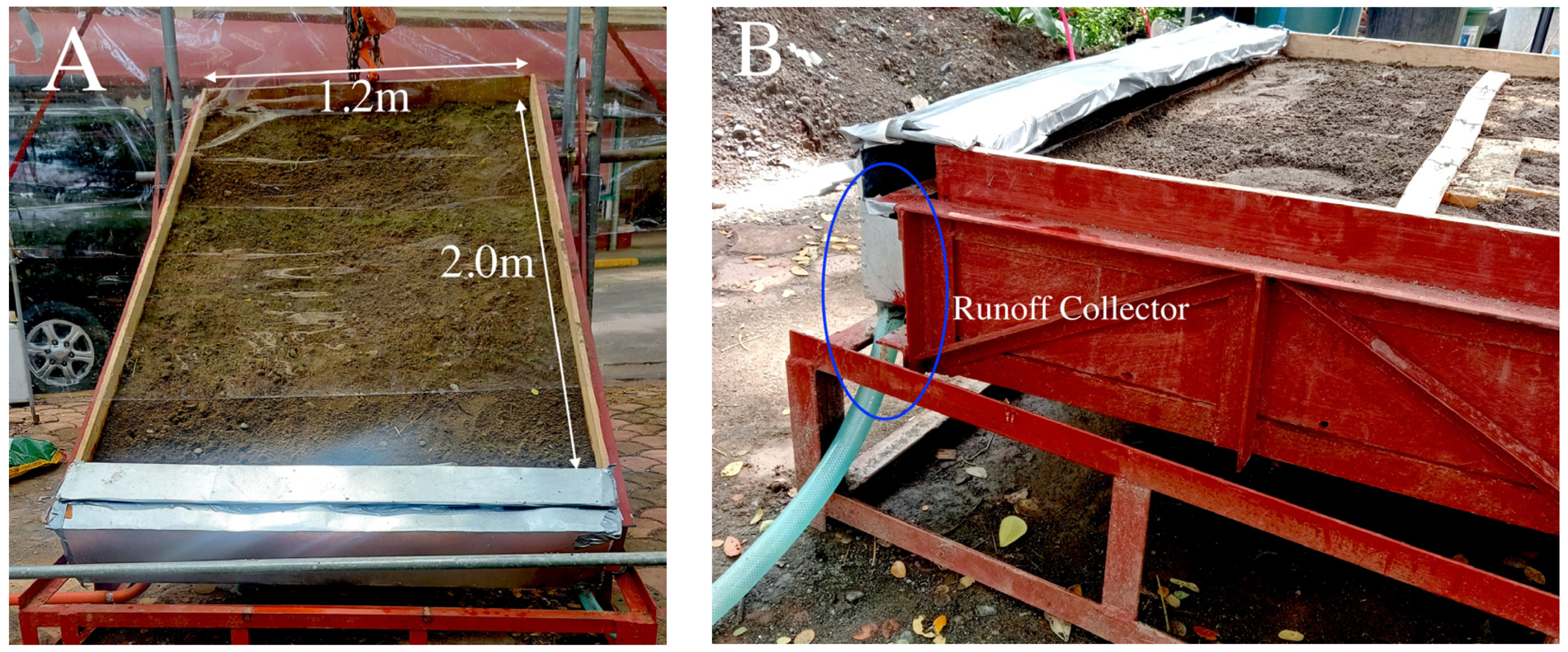

2.4.2. Experimental Microplot Preparation

2.4.3. Runoff and Sediment Collection

2.4.4. Best Fit Model

3. Results and Discussion

3.1. Rice Straw-Based Polyurethane Foam (RSPF) Properties

3.1.1. Physical and Mechanical Characteristics

3.1.2. Morphology and Cell Nature

3.1.3. FTIR Spectroscopy

3.1.4. Thermal Degradation

3.1.5. Water Absorption

3.2. Application of RSPF Blocks in Mitigating Soil Loss

3.2.1. Simulated Rainfall Coefficient of Uniformity ()

3.2.2. Runoff Coefficient and Soil Loss

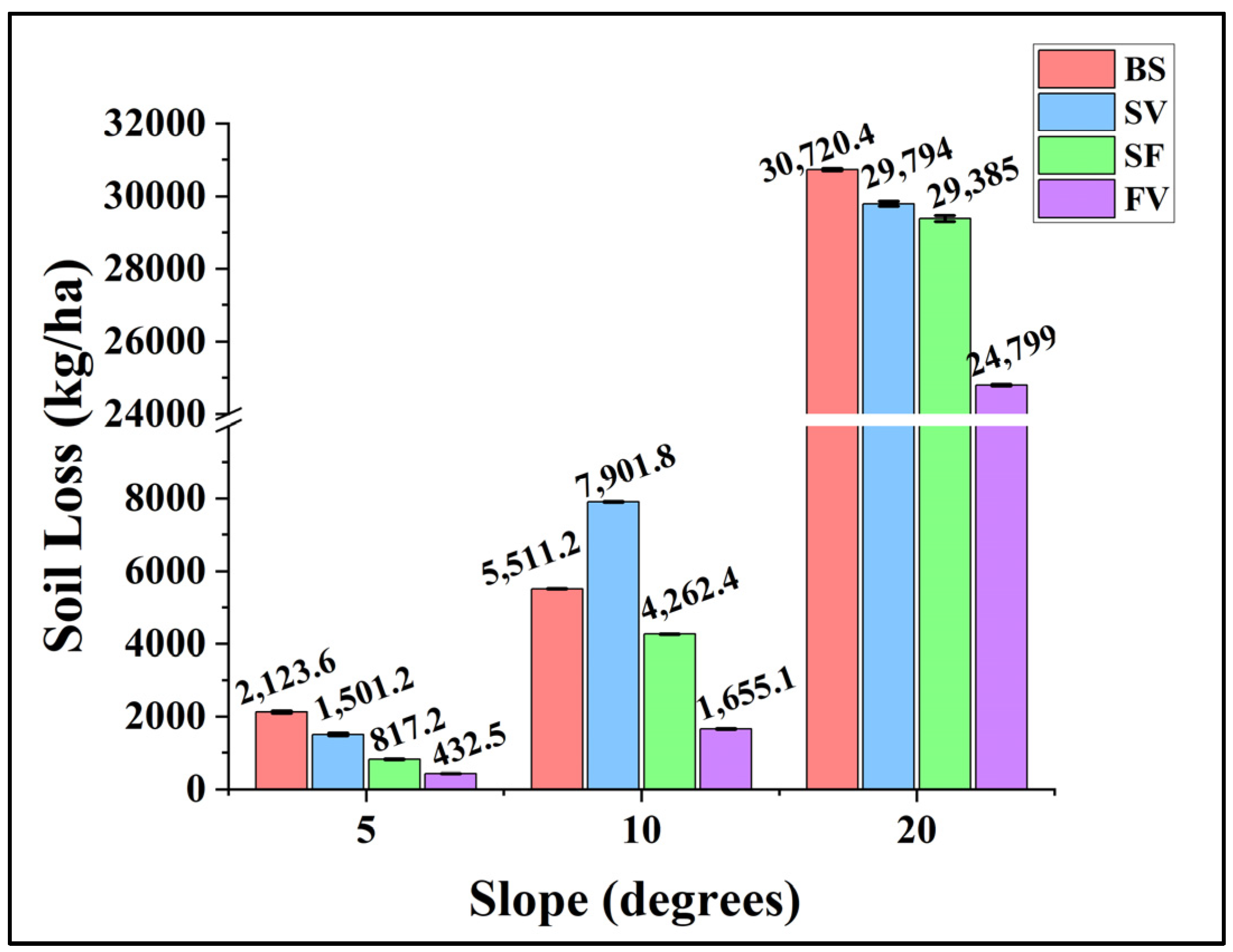

3.2.3. Relationship between Soil Loss and Land Slope

4. Conclusions

- RSPF blocks have a density of 43.29 kg/m3, compressive strength of 184.55 kPa, and water absorption capacity of up to 262% their mass.

- RSPF blocks in a simulated rainfall intensity of 80 mm/h reduced the soil loss by 61.5%, 22.7%, and 4.3% in 5°, 10°, and 20° of land slope, respectively, compared with bare soil. The reduction of soil loss was amplified when the RSPF block was used in combination with natural vegetation cover with 79.6%, 70%, and 19.3% reductions in 5°, 10°, and 20° land slopes, respectively.

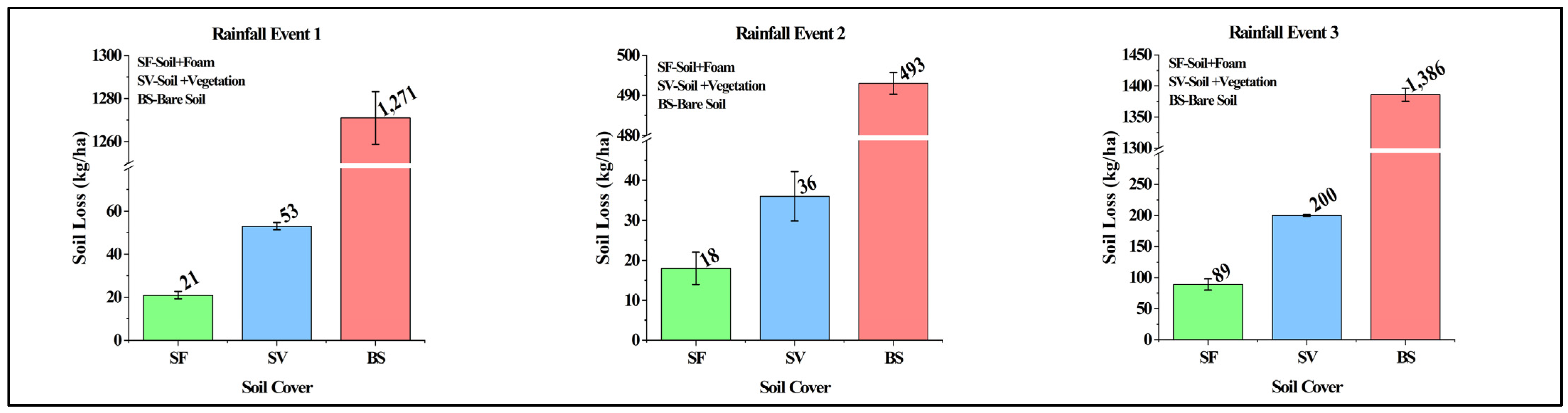

- Microplots in actual fields were also studied under natural rainfall events with an average rainfall intensity of 16.26 mm/h and slope of 20°. Soil loss was reduced by 93.6–98.8% in microplots embedded with RSPF compared with bare soil.

- Curve fitting of the available data generated a linear regression correlation between soil loss and slope across all types of microplot. The coefficients of determination (R2) of the models were calculated to fall between 0.92 and 0.99, suggesting that the equations have a high degree of accuracy in predicting soil loss at different slopes up to 20°.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wuepper, D.; Borrelli, P.; Finger, R. Countries and the global rate of soil erosion. Nat. Sustain. 2019, 3, 51–55. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Gu, K.; Jiang, H.; Inyang, H.I. Effect of polyurethane on the stability of sand–clay mixtures. Bull. Eng. Geol. Environ. 2012, 71, 537–544. [Google Scholar] [CrossRef]

- Iii, J.M.G. Effectiveness of vegetation in erosion control from forest road sideslopes. Trans. ASAE 2002, 45, 681. [Google Scholar] [CrossRef]

- Gholami, L.; Hasanzadeh, N.; Darvishan, A.K. Effect of sawdust on splash erosion in laboratory condition. J. Agric. For. 2018, 64, 51–56. [Google Scholar] [CrossRef]

- Bakr, N.; Weindorf, D.C.; Zhu, Y.; Arceneaux, A.E.; Selim, H. Evaluation of compost/mulch as highway embankment erosion control in Louisiana at the plot-scale. J. Hydrol. 2012, 468–469, 257–267. [Google Scholar] [CrossRef]

- Buchanan, J.R.; Yoder, D.C.; Denton, H.P.; Smoot, J.L. Wood chips as a soil cover for construction sites with steep slopes. Appl. Eng. Agric. 2002, 18, 679. [Google Scholar] [CrossRef]

- Cao, S.; Xu, C.; Ye, H.; Zhan, Y.; Gong, C. The use of air bricks for planting roadside vegetation: A new technique to improve landscaping of steep roadsides in China’s Hubei Province. Ecol. Eng. 2010, 36, 697–702. [Google Scholar] [CrossRef]

- Kavian, A.; Gholami, L.; Mohammadi, M.; Spalevic, V.; Soraki, M.F. Impact of Wheat Residue on Soil Erosion Processes. Not. Bot. Horti Agrobot. Cluj-Napoca 2018, 46, 553–562. [Google Scholar] [CrossRef]

- Kumar, N.; Das, D. Nonwoven geotextiles from nettle and poly(lactic acid) fibers for slope stabilization using bioengineering approach. Geotext. Geomembr. 2018, 46, 206–213. [Google Scholar] [CrossRef]

- Luo, H.; Zhao, T.; Dong, M.; Gao, J.; Peng, X.; Guo, Y.; Wang, Z.; Liang, C. Field studies on the effects of three geotextiles on runoff and erosion of road slope in Beijing, China. CATENA 2013, 109, 150–156. [Google Scholar] [CrossRef]

- Javellonar, R.P.; Taylan, V.T.; Agulto, I.C.; Aguinaldo, T.G.; Sicat, E.V.; Gavino, H.F. Rice Straw Geotextile as Ground Cover for Soil Erosion Mitigation. J. Energy Technol. Policy 2013, 3, 195–204. [Google Scholar]

- Moreno-Ramón, H.; Quizembe, S.J.; Ibáñez-Asensio, S. Coffee husk mulch on soil erosion and runoff: Experiences under rainfall simulation experiment. Solid Earth 2014, 5, 851–862. [Google Scholar] [CrossRef]

- Orts, W.J.; Sojka, R.E.; Glenn, G.; Gross, R.A. Preventing soil erosion with polymer additives. Polym. News 1999, 24, 406–413. [Google Scholar]

- Prats, S.A.; Martins, M.A.d.S.; Malvar, M.C.; Ben-Hur, M.; Keizer, J.J. Polyacrylamide application versus forest residue mulching for reducing post-fire runoff and soil erosion. Sci. Total Environ. 2014, 468–469, 464–474. [Google Scholar] [CrossRef] [PubMed]

- Foltz, R.B.; Dooley, J.H. Comparison of erosion reduction between wood strands and agricultural straw. Trans. ASAE 2003, 46, 464–474. [Google Scholar] [CrossRef]

- Ghadir, P.; Ranjbar, N. Clayey soil stabilization using geopolymer and Portland cement. Constr. Build. Mater. 2018, 188, 361–371. [Google Scholar] [CrossRef]

- Rickson, R. Geotextiles in land reclamation. In Land Reclamation—Extending Boundaries; Taylor & Francis: Abingdon, UK, 2003. [Google Scholar] [CrossRef]

- Smoltczyk, U.; Malcharek, K. Slope protection by membrane structures. Geotext. Geomembr. 1985, 2, 323–336. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.H.; Oh, K.W. Bio-Based Polyurethane Foams with Castor Oil Based Multifunctional Polyols for Improved Compressive Properties. Polymers 2021, 13, 576. [Google Scholar] [CrossRef]

- Pinzi, S.; Dorado, M.P. Vegetable-based feedstocks for biofuels production. In Handbook of Biofuels Production; Elsevier: Amsterdam, The Netherlands, 2011; pp. 61–94. [Google Scholar] [CrossRef]

- Akay, O.; Özer, A.; Fox, G. Assessment of EPS block geofoam with internal drainage for sandy slopes subjected to seepage flow. Geosynth. Int. 2014, 21, 364–376. [Google Scholar] [CrossRef]

- Artidteang, S.; Tanchaisawat, T.; Bergado, D.T.; Chaiyaput, S. Natural Fibers in Reinforcement and Erosion Control Applications with Limited Life Geosynthetics. In Ground Improvement Case Histories; Elsevier: Amsterdam, The Netherlands, 2015; pp. 717–740. [Google Scholar] [CrossRef]

- García-Ruiz, J.M.; Beguería, S.; Nadal-Romero, E.; González-Hidalgo, J.C.; Lana-Renault, N.; Sanjuán, Y. A meta-analysis of soil erosion rates across the world. Geomorphology 2015, 239, 160–173. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, K.; Kong, Y.; Chen, J.; Yu, B. Effectiveness of erosion control measures along the Qinghai–Tibet highway, Tibetan plateau, China. Transp. Res. Part D Transp. Environ. 2006, 11, 302–309. [Google Scholar] [CrossRef]

- Pioquinto, W.P.C.; Caranto, J.A.; Bayrante, L.F.; Zarco, M.H.; Catane, S.G. Mitigating a Deep-Seated Landslide Hazard- the Case of 105 Mahiao Slide Area, Leyte Geothermal Production Field, Philippines. In Proceedings of the World Geothermal Congress, Bali, Indonesia, 25–30 April 2010; pp. 25–29. [Google Scholar]

- ASTM Standard D1622; Standard Test Method for Apparent Density of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM Standard C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM Standard D1621; Standard Test Method for Compressive Properties of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM Standard D6226; Standard Test Method for Open Cell Content of Rigid Cellular Plastics. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM Standard C272/C272M; Standard Test Method for Water Absorption of Core Materials for Sandwich Constructions. ASTM International: West Conshohocken, PA, USA, 2018.

- Keya, D.R.; Karim, T.H. Simulation of Rainfall Intensity and Slope Gradient to Determination the Soil Runoff Coefficient at Microplot Scale. Polytech. J. 2020, 10, 12–17. [Google Scholar] [CrossRef]

- Bortolini, L.; Martello, M. Effects of Water Distribution Uniformity on Waxy Corn (Zea mays L.) Yield: Preliminary Results. J. Water Resour. Prot. 2014, 6, 1037–1044. [Google Scholar] [CrossRef]

- Quan, X.; He, J.; Cai, Q.; Sun, L.; Li, X.; Wang, S. Soil erosion and deposition characteristics of slope surfaces for two loess soils using indoor simulated rainfall experiment. Soil Tillage Res. 2020, 204, 104714. [Google Scholar] [CrossRef]

- Legout, C.; Leguédois, S.; Le Bissonnais, Y.; Issa, O.M. Splash distance and size distributions for various soils. Geoderma 2005, 124, 279–292. [Google Scholar] [CrossRef]

- Khalilmoghadam, B.; Afyuni, M.; Abbaspour, K.; Jalalian, A.; Dehghani, A.; Schulin, R. Estimation of surface shear strength in Zagros region of Iran—A comparison of artificial neural networks and multiple-linear regression models. Geoderma 2009, 153, 29–36. [Google Scholar] [CrossRef]

- Yu, X.; Huang, Y.; Li, E.; Li, X.; Guo, W. Effects of rainfall and vegetation to soil water input and output processes in the Mu Us Sandy Land, northwest China. CATENA 2018, 161, 96–103. [Google Scholar] [CrossRef]

- Bahat, Y.; Grodek, T.; Lekach, J.; Morin, E. Rainfall–runoff modeling in a small hyper-arid catchment. J. Hydrol. 2009, 373, 204–217. [Google Scholar] [CrossRef]

- Stark, T.; Bartlett, S.; Arellano, D. Expanded Polystyrene (EPS) Geofoam Applications and Technical Data; The EPS Industry Alliance: Crofton, MD, USA, 2012; Volume 1298. [Google Scholar]

- Salcedo, M.L.D.; Omisol, C.J.M.; Maputi, A.O.; Estrada, D.J.E.; Aguinid, B.J.M.; Asequia, D.M.A.; Erjeno, D.J.D.; Apostol, G.; Siy, H.; Malaluan, R.M.; et al. Production of Bio-Based Polyol from Coconut Fatty Acid Distillate (CFAD) and Crude Glycerol for Rigid Polyurethane Foam Applications. Materials 2023, 16, 5453. [Google Scholar] [CrossRef]

- ASTM Standard D6817/D6817M-17; Standard Specification for Rigid Cellular Polystyrene Geofoam. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 4898; Rigid Cellular Plastics—Thermal Insulation Products for Buildings—Specifications. ISO: Geneva, Switzerland, 2018.

- Chadha, A.; Florentine, S.K.; Chauhan, B.S.; Long, B.; Jayasundera, M. Influence of soil moisture regimes on growth, photosynthetic capacity, leaf biochemistry and reproductive capabilities of the invasive agronomic weed; Lactuca serriola. PLoS ONE 2019, 14, e0218191. [Google Scholar] [CrossRef]

- Gravit, V.M.; Ogidan, O.; Znamenskaya, E. Methods for determining the number of closed cells in rigid sprayed polyurethane foam. MATEC Web Conf. 2018, 193, 03027. [Google Scholar] [CrossRef]

- Kurańska, M.; Malewska, E.; Polaczek, K.; Prociak, A.; Kubacka, J. A Pathway toward a New Era of Open-Cell Polyurethane Foams—Influence of Bio-Polyols Derived from Used Cooking Oil on Foams Properties. Materials 2020, 13, 5161. [Google Scholar] [CrossRef] [PubMed]

- Prociak, A.; Kurańska, M.; Cabulis, U.; Ryszkowska, J.; Leszczyńska, M.; Uram, K.; Kirpluks, M. Effect of bio-polyols with different chemical structures on foaming of polyurethane systems and foam properties. Ind. Crop. Prod. 2018, 120, 262–270. [Google Scholar] [CrossRef]

- Trovati, G.; Sanches, E.A.; Neto, S.C.; Mascarenhas, Y.P.; Chierice, G.O. Characterization of polyurethane resins by FTIR, TGA, and XRD. J. Appl. Polym. Sci. 2010, 115, 263–268. [Google Scholar] [CrossRef]

- Gu, R.; Sain, M.M. Effects of Wood Fiber and Microclay on the Performance of Soy Based Polyurethane Foams. J. Polym. Environ. 2012, 21, 30–38. [Google Scholar] [CrossRef]

- Luo, M.-T.; Li, H.-L.; Huang, C.; Zhang, H.-R.; Xiong, L.; Chen, X.-F.; Chen, X.-D. Cellulose-Based Absorbent Production from Bacterial Cellulose and Acrylic Acid: Synthesis and Performance. Polymers 2018, 10, 702. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Ko, T.; Jeong, H.; Ye, S. The Development of a Methodology for Calibrating a Large-Scale Laboratory Rainfall Simulator. Atmosphere 2018, 9, 427. [Google Scholar] [CrossRef]

- Ngasoh, F.G.; Mbajiorgu, C.C.; Kamai, M.B.; Okoro, G.O. A Revisit of Rainfall Simulator as a Potential Tool for Hydrological Research. In Agrometeorology; IntechOpen: Rijeka, Croatian, 2021. [Google Scholar] [CrossRef]

- Machado, R.E.; Cardoso, T.O.; Mortene, M.H. Determination of runoff coefficient (C) in catchments based on analysis of precipitation and flow events. Int. Soil Water Conserv. Res. 2021, 10, 208–216. [Google Scholar] [CrossRef]

- Zheng, H.; Miao, C.; Zhang, G.; Li, X.; Wang, S.; Wu, J.; Gou, J. Is the runoff coefficient increasing or decreasing after ecological restoration on China’s Loess Plateau? Int. Soil Water Conserv. Res. 2021, 9, 333–343. [Google Scholar] [CrossRef]

- Khadka, D.B. Experimental Study of Runoff Coefficients for Different Hill Slope Soil Profiles. Open J. Civ. Eng. 2019, 9, 157–171. [Google Scholar]

- Zhang, Z.; Sheng, L.; Yang, J.; Chen, X.-A.; Kong, L.; Wagan, B. Effects of Land Use and Slope Gradient on Soil Erosion in a Red Soil Hilly Watershed of Southern China. Sustainability 2015, 7, 14309–14325. [Google Scholar] [CrossRef]

| Components | Parts per Weight | |

|---|---|---|

| A | MDI | 110 |

| B | Rice straw-based polyol | 15 |

| VORANOL™ 490 | 85 | |

| POLYCAT® 8 | 1.0–1.5 | |

| DABCO® DC5357 | 0.5–1.0 | |

| Distilled water | 2.5 | |

| Parameters | Microplots | |

|---|---|---|

| Nature of rainfall | Simulated rainfall | natural Rainfall |

| Type of plot | Bare soil (BS) | |

| Soil with vegetation (SV) | ||

| Soil with foam (SF) | ||

| Soil with foam and vegetation (FV) | ||

| Land slope | 5°, 10°, 20° | 20° |

| Rainfall intensity | 80 mm/h | 16.26 mm/h a |

| Property | Expanded Polystyrene [40,41] | RSPF | Test | ||||||

|---|---|---|---|---|---|---|---|---|---|

| EPS 12 | EPS 15 | EPS 19 | EPS 22 | EPS 29 | EPS 39 | EPS 46 | |||

| Density (kg/m3) | 11.2 | 14.4 | 18.4 | 21.6 | 28.8 | 38.4 | 45.7 | 43.29 ± 1.86 | ASTM D1622 [26] |

| Thermal conductivity, W/m·K | 0.029–0.039 | 0.033 ± 0.005 | ASTM C518 [27] | ||||||

| Compressive strength at 10% strain, kPa | 40 | 70 | 110 | 135 | 200 | 276 | 345 | 184.55 ± 2.94 | ASTM D1621 [28] |

| Water absorption, % | 4.0 | 4.0 | 3.0 | 3.0 | 2.0 | 2.0 | 2.0 | 262 ± 7 | ASTM C272 [30] |

| Samples | Thermal Decomposition | % Weight Loss | ||

|---|---|---|---|---|

| Td1 (°C) | Td2 (°C) | m1 | m2 | |

| CPPF | 357.03 | 693.06 | 57.11 | 42.89 |

| RSPF | 352.44 | 690.30 | 53.48 | 46.52 |

| Type of Plot | Runoff Coefficient, C |

|---|---|

| BS | 0.35–2.20 |

| SV | 0.12–0.92 |

| SF | 0.10–0.15 |

| FV | 0.06–0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maravillas, F.P.; Omisol, C.J.M.; Abilay, G.Y.; Lasquite, N.L.; Aguinid, B.J.M.; Estrada, D.J.E.; Ruda-Bayor, R.J.; Cea, E.J.C.; Cavero, A.I.; Ahalajal, M.A.N.; et al. Characterization and Application of Rice Straw-Based Polyurethane Foam Blocks for Soil Erosion Control. Sustainability 2024, 16, 261. https://doi.org/10.3390/su16010261

Maravillas FP, Omisol CJM, Abilay GY, Lasquite NL, Aguinid BJM, Estrada DJE, Ruda-Bayor RJ, Cea EJC, Cavero AI, Ahalajal MAN, et al. Characterization and Application of Rice Straw-Based Polyurethane Foam Blocks for Soil Erosion Control. Sustainability. 2024; 16(1):261. https://doi.org/10.3390/su16010261

Chicago/Turabian StyleMaravillas, Felrose P., Christine Joy M. Omisol, Gerson Y. Abilay, Nicholas L. Lasquite, Blessy Joy M. Aguinid, Dave Joseph E. Estrada, Rosal Jane Ruda-Bayor, Evalyn Joy C. Cea, Applegen I. Cavero, Mary Ann N. Ahalajal, and et al. 2024. "Characterization and Application of Rice Straw-Based Polyurethane Foam Blocks for Soil Erosion Control" Sustainability 16, no. 1: 261. https://doi.org/10.3390/su16010261

APA StyleMaravillas, F. P., Omisol, C. J. M., Abilay, G. Y., Lasquite, N. L., Aguinid, B. J. M., Estrada, D. J. E., Ruda-Bayor, R. J., Cea, E. J. C., Cavero, A. I., Ahalajal, M. A. N., Lorenzo, G. A., Malaluan, R. M., Dumancas, G. G., & Lubguban, A. A. (2024). Characterization and Application of Rice Straw-Based Polyurethane Foam Blocks for Soil Erosion Control. Sustainability, 16(1), 261. https://doi.org/10.3390/su16010261