Investigating New Environmentally Friendly Zeotropic Refrigerants as Possible Replacements for Carbon Dioxide (CO2) in Car Air Conditioners

Abstract

:1. Introduction

2. Refrigerant Blends’ Thermodynamic Properties

2.1. Environmental and Physical Properties

2.2. Pressure–Enthalpy, P–h Envelopes

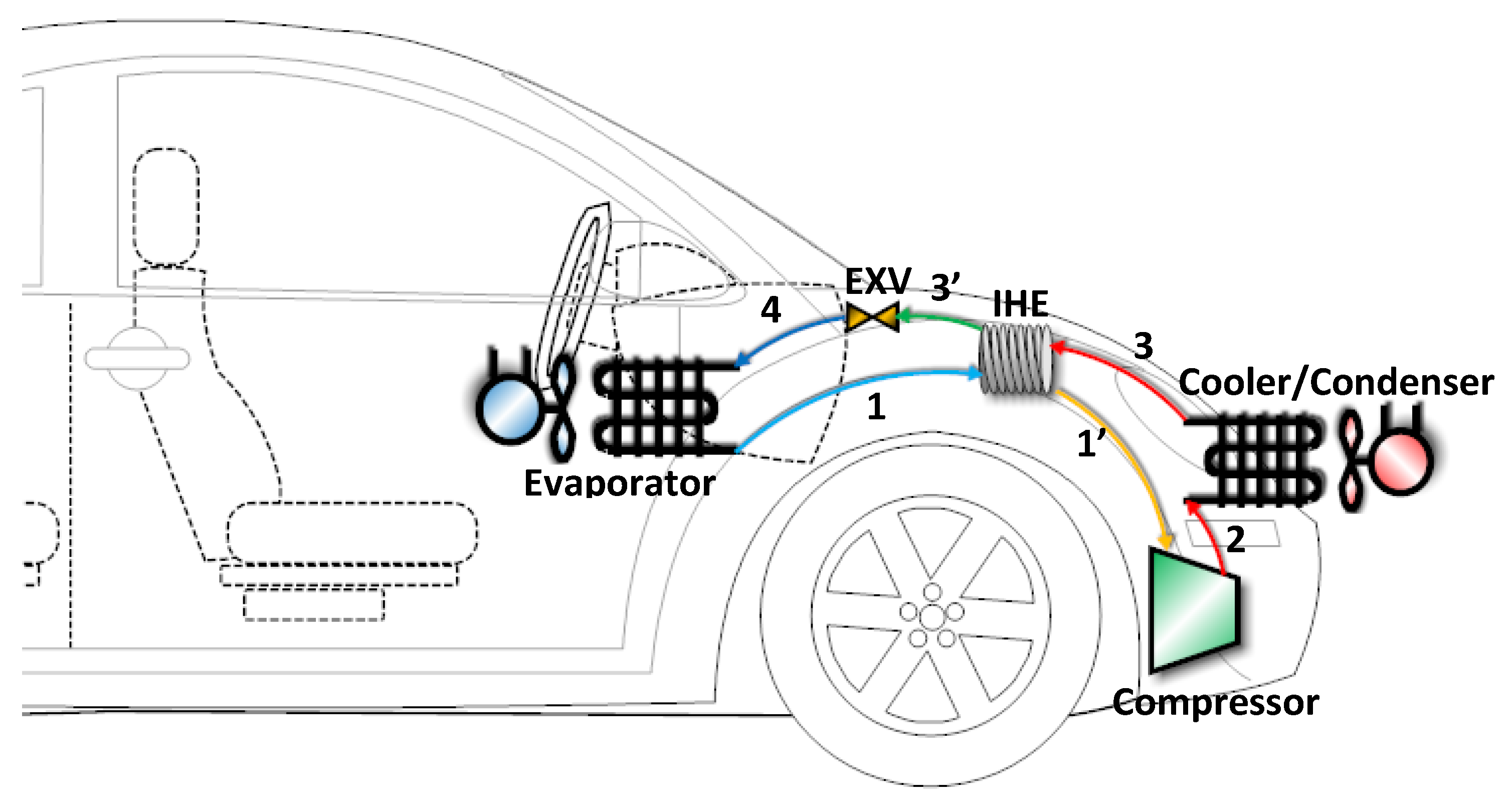

3. System Description

- From points 1 to 2: Non-isentropic compression.

- From point 2 to 3: Heat release at constant pressure in the cooler/condenser.

- From point 3 to 3’: Subcooling within the IHE.

- From point 3’ to 4: Isenthalpic throttling at the EXV.

- From point 4 to 1: Heat absorption at constant pressure within the evaporator.

- From point 1 to 1’: Superheating within the IHE.

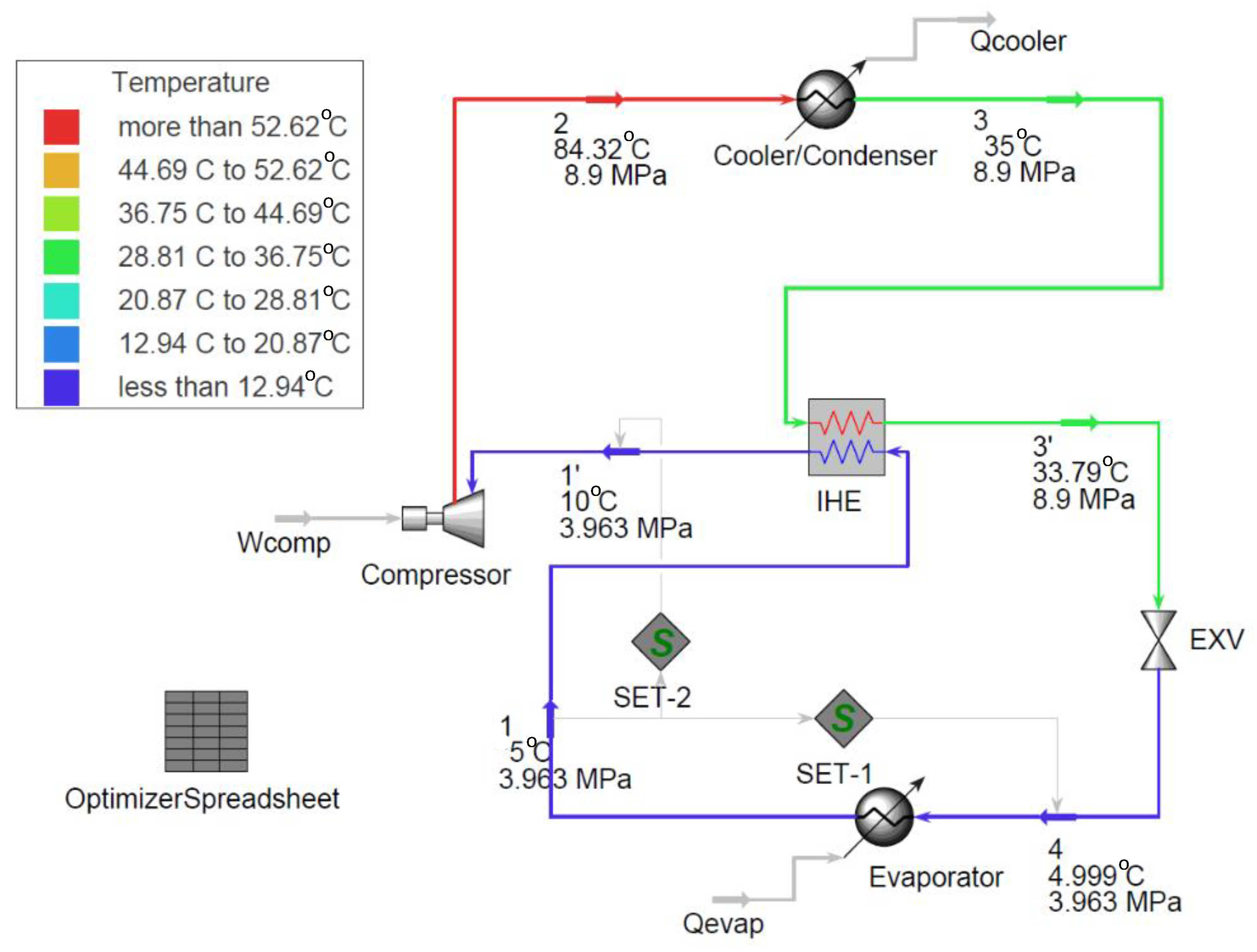

4. Modeling and Assumptions

4.1. System Assumptions

- The entire system operates under steady-state conditions.

- Impacts related to kinetic energy and gravity have been omitted.

- A reference situation is created with a 25 °C ambient temperature and a 101.325 kPa atmospheric pressure.

- During the process of heat transfer, heat loss and pressure drop are not taken into account.

- It is assumed that the refrigerant at the outlet of the evaporator is in a saturated state.

4.2. Thermodynamic Model Analysis

4.2.1. Analysis of Energy

4.2.2. Exergy Analysis

4.2.3. Model Validation

5. Results and Discussion

5.1. Environmental Effects of Studied Zeotropic Refrigerants

5.2. Parametric Studies

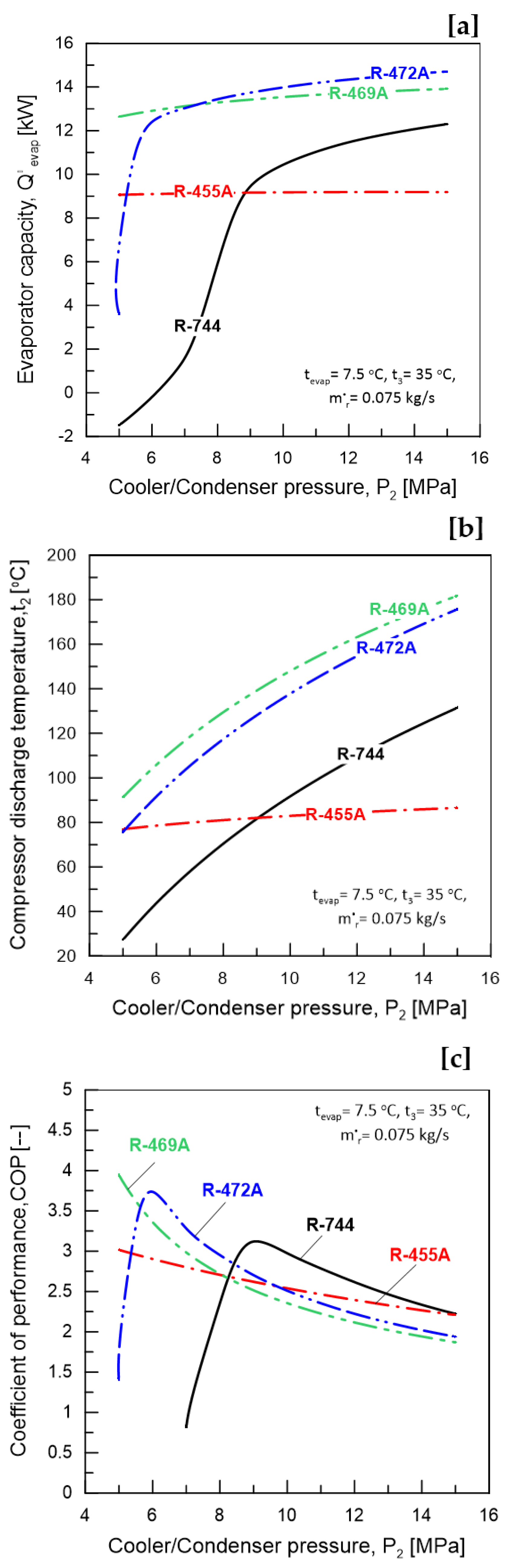

5.2.1. Effect of Condenser/Cooler Pressure, P2

5.2.2. Effect of Average Evaporator Temperature, tevap

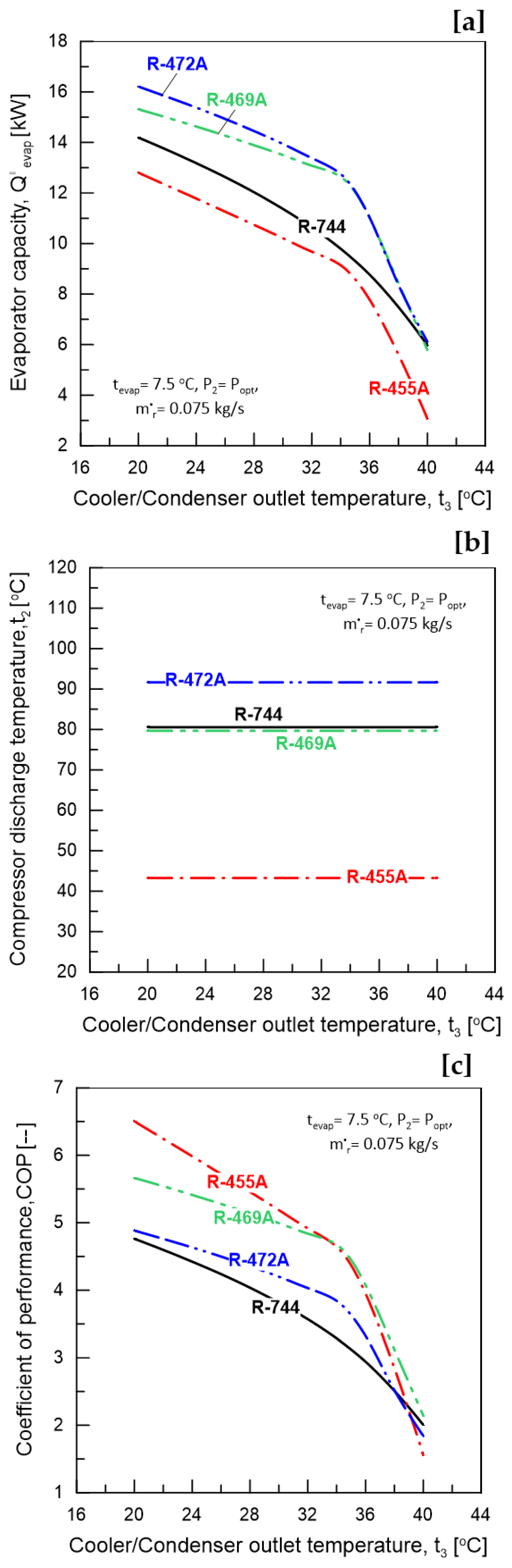

5.2.3. Effect of Condenser/Cooler Outlet Temperature, t3

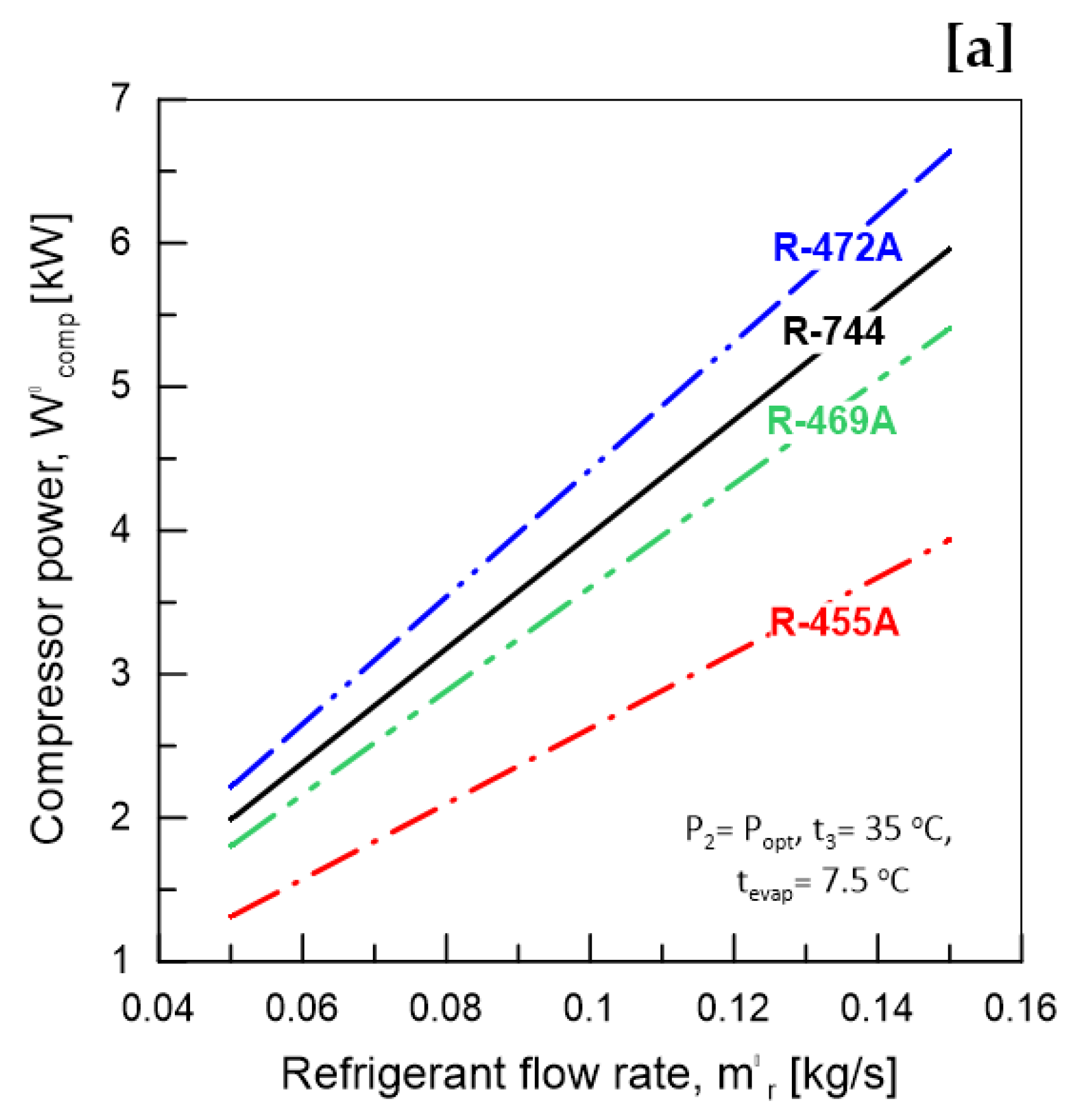

5.2.4. Effect of Refrigerant Mass Flow Rate, m•r

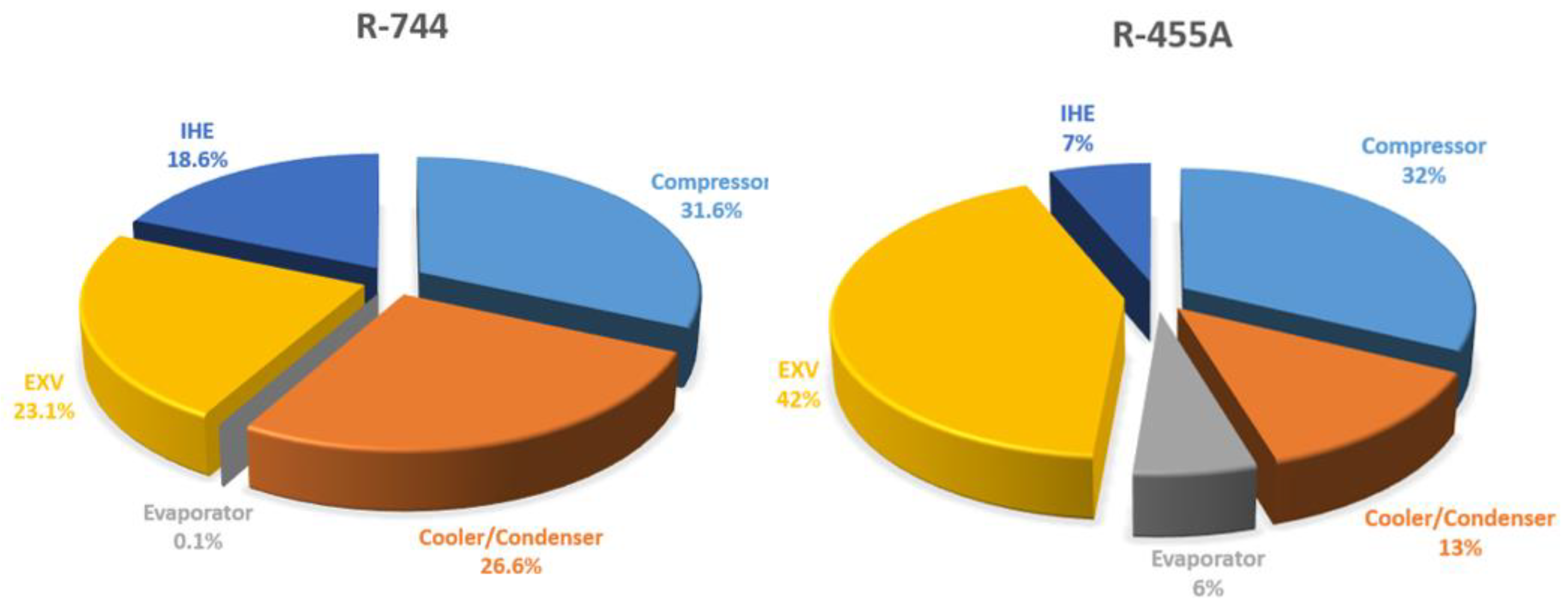

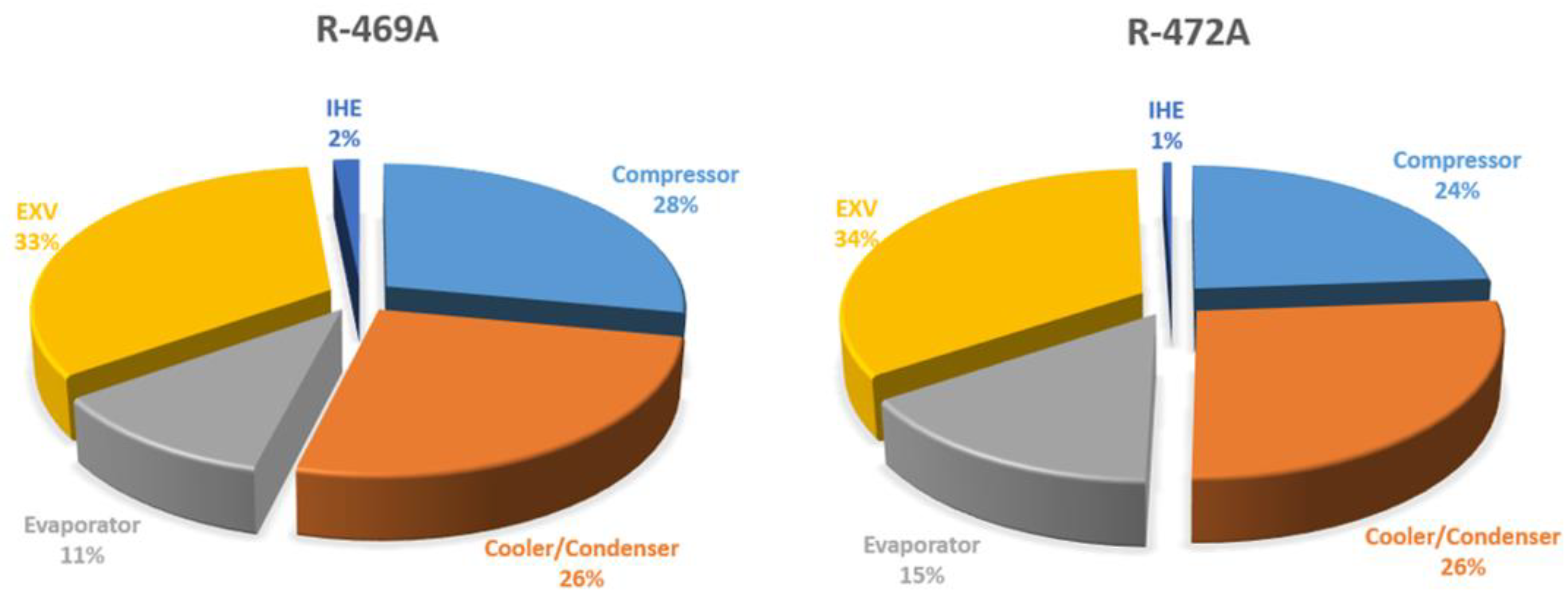

5.3. Comparisons and Evaluations of Analyzed Refrigerant Blends

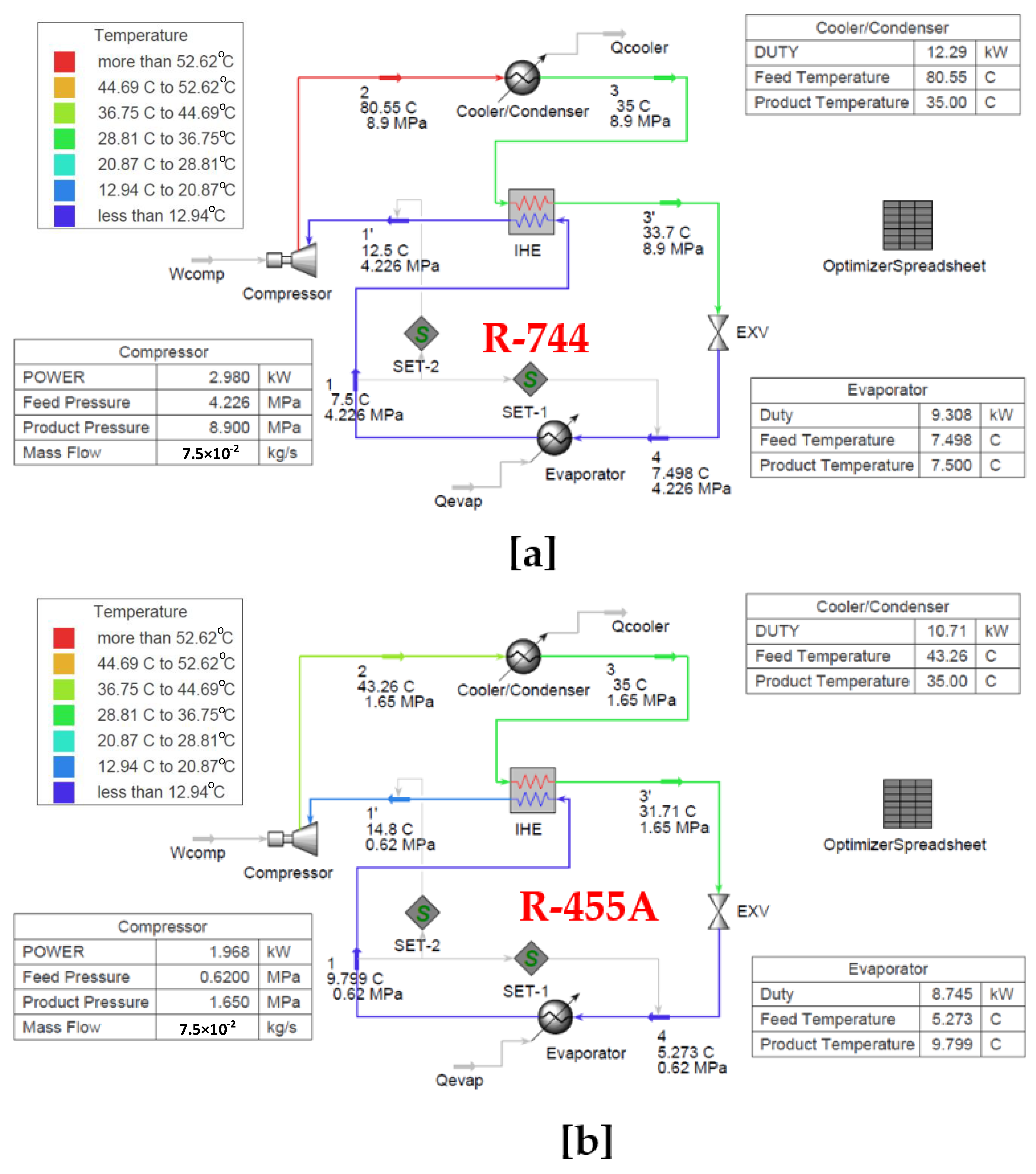

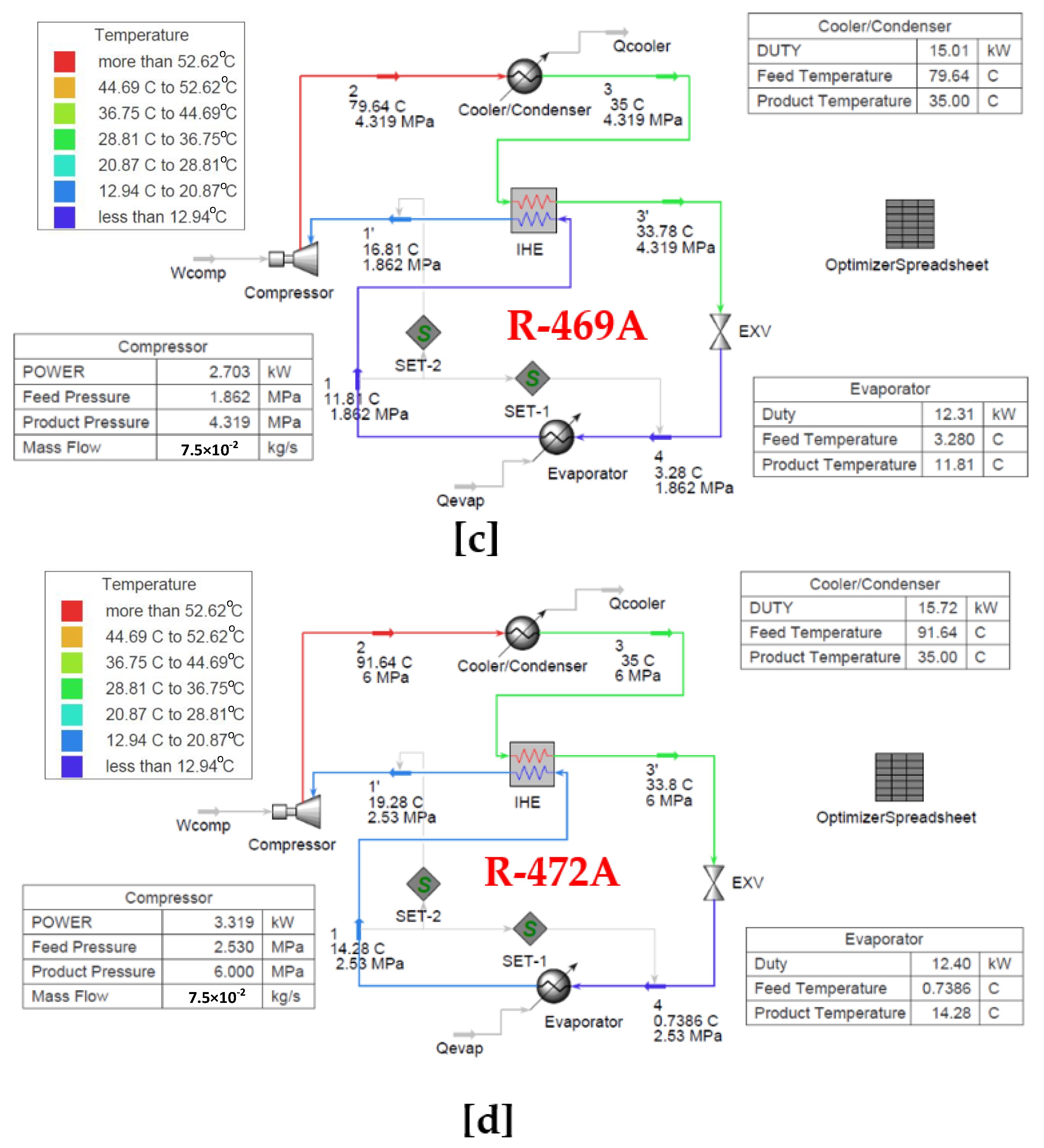

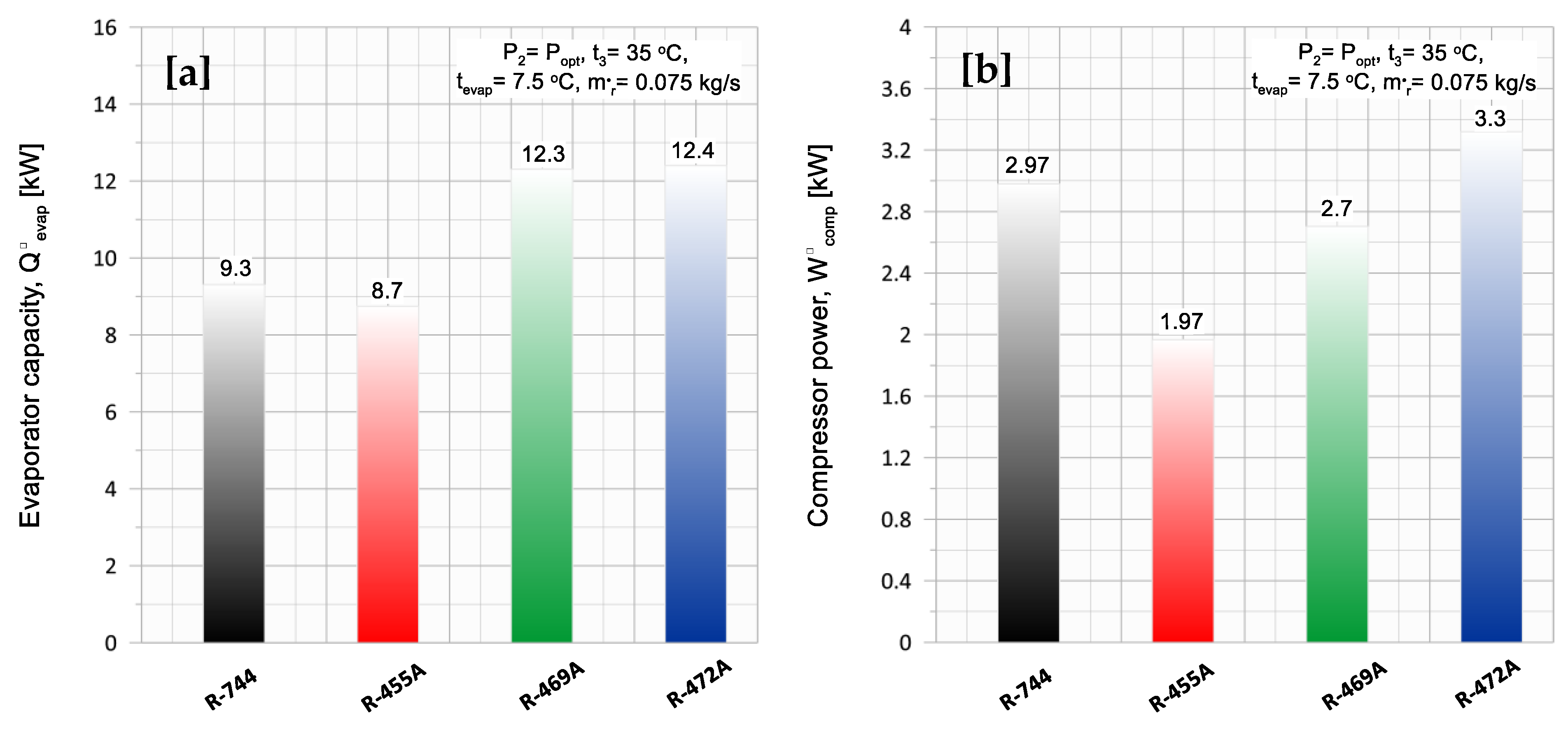

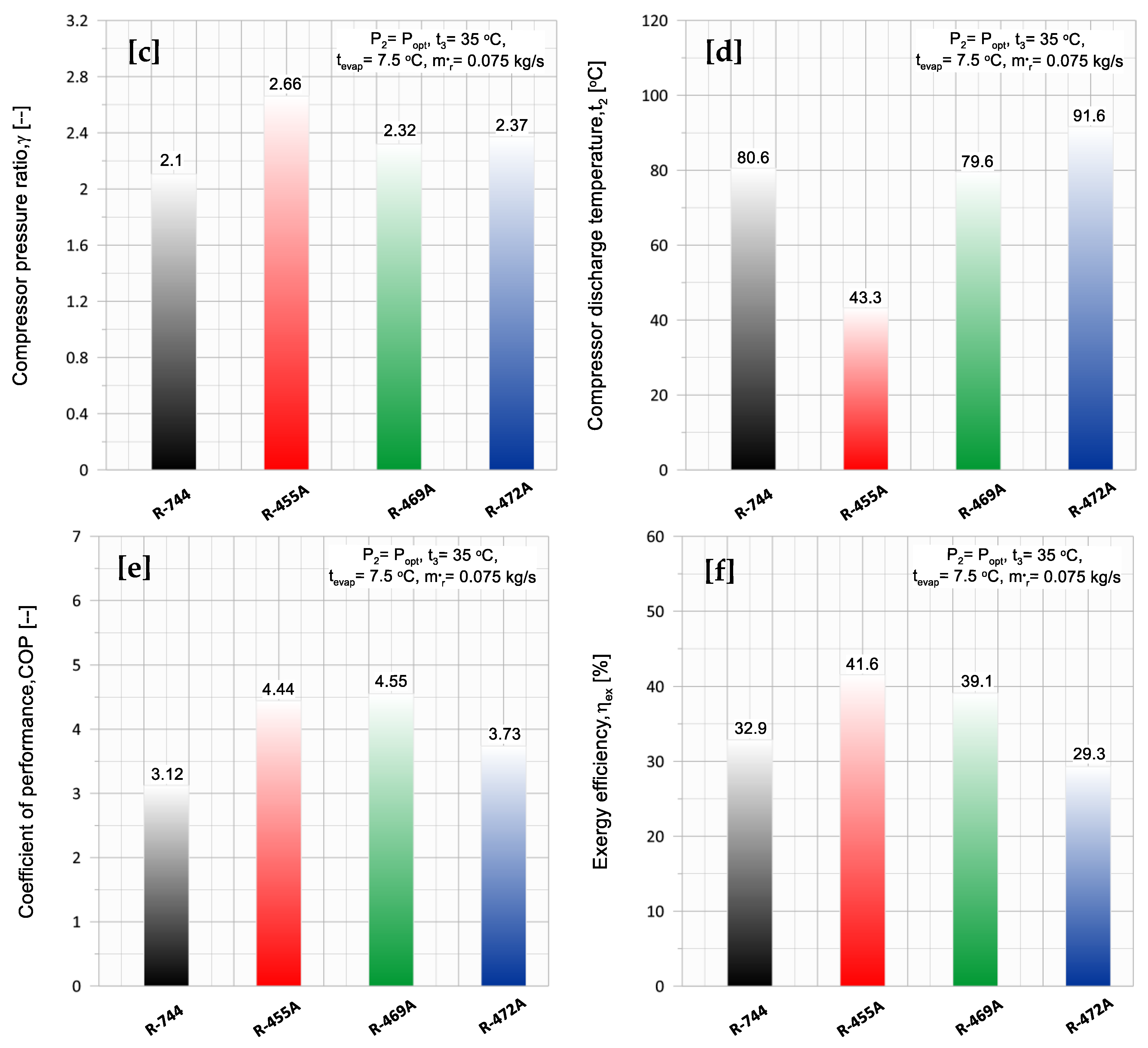

5.4. Systems’ Optimization Conditions

6. Conclusions

- The maximum coefficient of performance (COP) values for R744, R455A, R469A, and R472A were 3.1, 4.25, 4.3, and 5.48, respectively, at optimal pressures of 8.9, 1.65, 4.319, and 6 MPa.

- The maximum Q•evap and COP values for R744, R455A, R469A, and R472A are 12.2, 9.9, 14.5 kW, and 3.15 and 3, 3.95, and 3.5, respectively.

- The maximum values of W•comp and γ for R744, R455A, R469A, and R472A are 3.3, 2.15, 3, and 3.65 kW and 2.25, 2.9, 2.5, and 2.58, respectively.

- At P2 = 5 MPa, the increase in W•comp for R744, R469A, and R472A is 53.5, 39.5, and 69.8% compared to R455A.

- The compressor power (W•comp) for R744, R455A, R469A, and R472A all decrease by 36.6%, 30.0%, 40%, and 35.6%, respectively, within the investigated range of P2.

- The highest recorded values for compressor power (W•comp) occur at 6, 4, 5.4, and 6.5 kW for R744, R455A, R469A, and R472A, respectively, with a refrigerant flow rate (ṁr) of 0.15 kg/s.

- The maximum refrigeration capacities and system performance capabilities can be reached for R744, R455A, R469A, and R472A, yielding respective values of 14.21, 15.05, 14.41, and 15.43 kW, respectively, and the corresponding values of the COP attain their maximum values at 14.58, 12.86, 11.66, and 7.55, respectively.

- In the context of environmental impact, both R455A and R472A exhibited relatively minimal adverse effects on the environment, as evidenced by their low global warming potential (GWP) values. Nonetheless, it is worth noting that this came with a slightly diminished COP in comparison to R744 and R469A.

- R455A and R469A obtain the greatest COP and exergy efficiency (ηex) values, measuring 4.44 and 4.55, respectively, at the identical operating conditions with optimal condenser/cooler pressures of the examined blends.

- Eco-friendly refrigerants R455A and R472A are recommended for integration into AAC systems in vehicles, as they help combat global warming and protect natural surroundings and leakage issues.

- Zeotropic blends, HFO-based, such as R1234yf, are recommended as upcoming work on automotive air conditioning performance studies.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| exergy (kW) | |

| h | specific enthalpy (kJ/kg) |

| exergy destruction (kW) | |

| mass flow rate (kg/s) | |

| M | Molar mass (kg/kmol) |

| P | Working fluid pressure (MPa) |

| heat transfer rate (kW) | |

| s | specific entropy (kJ/kg K) |

| t | temperature (°C) |

| T | temperature (K) |

| Tb | normal boiling point (°C) |

| Tc | critical temperature (°C) |

| power (kW) | |

| P | critical pressure (MPa) |

| Greek symbols | |

| η | efficiency |

| compressor pressure ratio | |

| Subscripts | |

| cond | condenser |

| comp | compressor |

| cv | control volume |

| en | energy |

| ex | exergy |

| evap | evaporator |

| I = 1, 2, 3, … | index referring to various positions in the system |

| in | inlet |

| is | isentropic e |

| j | boundary |

| max | maximum |

| o | outlet |

| r | refrigerant |

| ref | refrigeration |

| 0 | Environmental state |

| 1,2,3, … | working fluid state points |

| Abbreviations | |

| AAC | automotive air conditioning |

| COP | coefficient of performance |

| EOS | Peng–Robinson equation of state |

| EXV | Expansion valve |

| GWP | global warming potential |

| HEX | internal heat exchanger |

| HFC | Hydrofluorocarbon |

| HFO | Hydrofluro-Olefins |

| ODP | ozone depletion potential |

| VLE | vapor-liquid equilibrium |

References

- Pérez-Lombard, L.; Ortiz, J.; Coronel, J.F.; Maestre, I.R. A review of HVAC systems requirements in building energy regulations. Energy Build. 2011, 43, 255–268. [Google Scholar] [CrossRef]

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions, and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Uddin, K.; Arakaki, S.; Saha, B.B. Thermodynamic analysis of low-GWP blends to replace R410A for residential building air conditioning applications. Environ. Sci. Pollut. Res. 2021, 28, 2934–2947. [Google Scholar] [CrossRef] [PubMed]

- European Union. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006 (1). Official Journal of European Union L 150/195. 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014R0517&from=EN (accessed on 25 October 2023).

- Lee, Y.; Jung, D. Brief performance comparison of R1234yf and R134a in a bench tester for automobile applications. Appl. Therm. Eng. 2012, 35, 240–242. [Google Scholar] [CrossRef]

- Montreal Protocol on Substances that Deplete the Ozone Layer, “Assessment of Alternatives to HCFCS and HFCS and Update of the TEAP 2005 Supplement Report Data”. 2010. Available online: https://ozone.unep.org/treaties/montreal-protocol/montreal-protocol-substances-deplete-ozone-layer (accessed on 25 October 2023).

- Xu, Y.; Mao, C.; Huang, Y.; Shen, X.; Xu, X.; Chen, G. Performance evaluation and multi-objective optimization of a low-temperature CO2 heat pump water heater based on artificial neural network and new economic analysis. Energy 2021, 216, 119232. [Google Scholar] [CrossRef]

- Song, Y.; Cui, C.; Yin, X.; Cao, F. Advanced development and application of transcritical CO2 refrigeration and heat pump technology—A review. Energy Rep. 2022, 8, 7840–7869. [Google Scholar] [CrossRef]

- Yelishala, S.C.; Kannaiyan, K.; Wang, Z.; Hameed, M. Thermodynamic study on blends of hydrocarbons and carbon dioxide as zeotropic refrigerants. J. Energy Resour. Technol. Trans. ASME 2020, 142, 082304. [Google Scholar] [CrossRef]

- Llopis, R.; Toffoletti, G.; Nebot-Andrés, L.; Cortella, G. Experimental evaluation of zeotropic refrigerants in a dedicated mechanical subcooling system in a CO2 cycle. Int. J. Refrig. 2021, 128, 287–298. [Google Scholar] [CrossRef]

- Mostafa, M.; Ezzeldien, M.; Attalla, M.; Ghazaly, N.M.; Alrowaili, Z.A.; Hasaneen, M.F.; Shmroukh, A.N. Comparison of different adsorption pairs based on zeotropic and azeotropic mixture refrigerants for solar adsorption ice maker. Environ. Sci. Pollut. Res. 2021, 28, 41479–41491. [Google Scholar] [CrossRef]

- Tian, H.; Zeng, W.; Gu, B.; Zhang, Y.; Yuan, X. Energy, exergy, and economic (3E) analysis of an organic Rankine cycle using zeotropic mixtures based on marine engine waste heat and LNG cold energy. Energy Convers. Manag. 2021, 228, 113657. [Google Scholar] [CrossRef]

- Mezentseva, N.N.; Mezentsev, I.V. Investigation of Heat Pump Efficiency on Zeotropic Refrigerants R32/R134a and R32/R152a. J. Eng. Thermophys. 2018, 27, 554–559. [Google Scholar] [CrossRef]

- Barraza, R.; Nellis, G.; Klein, S.; Reindl, D. Measured and predicted frictional pressure drop for boiling zeotropic mixed refrigerants in horizontal tubes. Int. J. Heat Mass Transf. 2016, 98, 285–298. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, P.; Li, M. Greenhouse effect and fourth generation refrigerant. Refrig. Technol. 2017, 5, 8–13. [Google Scholar]

- Chen, Y.; Xu, D.; Chen, Z.; Gao, X.; Ren, F.; Han, W. Performance Analysis and Evaluation of a Supercritical CO2 Rankine Cycle Coupled with an Absorption Refrigeration Cycle. J. Therm. Sci. 2020, 29, 1036–1052. [Google Scholar] [CrossRef]

- Robinson, D.M.; Groll, E.A. Eiciencies of transcritical CO2 cycles with and without an expansion turbine. Int. J. Refrig. 1998, 21, 577–589. [Google Scholar] [CrossRef]

- Yu, B.; Wang, D.; Xiang, W.; Yu, H.; Chen, J. Performance Analysis of Transcritical CO2 Electric Vehicle Air Conditioning System. J. Shanghai Jiaotong Univ. 2019, 53, 866–872. [Google Scholar]

- Sobieraj, M.; Rosiński, M. High Phase-Separation Efficiency Auto-Cascade System Working with a Blend of Carbon Dioxide for Low-Temperature Isothermal Refrigeration. Appl. Therm. Eng. 2019, 161, 114149. [Google Scholar] [CrossRef]

- Sun, Z.; Cui, Q.; Wang, Q.; Ning, J.; Guo, J.; Dai, B.; Liu, Y.; Xu, Y. Experimental study on CO2/R32 blends in a water-to-water heat pump system. Appl. Therm. Eng. 2019, 162, 114303. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, X.; Wen, X. Theoretical and Experimental Study on the Heat Transfer Temperature Difference Based on the Nonlinear Temperature Enthalpy of the R236fa/R32 Mixtures. Procedia Eng. 2017, 205, 2126–2132. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Gao, W.; Zhang, K.; Huang, L.; Bi, M. Hazard evaluation of R32/R1234ze(E) cloud explosion. Int. J. Refrig. 2020, 111, 159–167. [Google Scholar] [CrossRef]

- Wang, X.; Yan, Y.; Wright, E.; Hao, X.; Gao, N. Prospect Evaluation of Low-GWP Refrigerants R1233zd(E) and R1336mzz(Z) Used in Solar-Driven Ejector-Vapor Compression Hybrid Refrigeration System. J. Therm. Sci. 2020, 30, 1572–1580. [Google Scholar] [CrossRef]

- Abbood, M.H.; Hashim, H.T.; Amin, A.S. Investigation of Environmentally-Friendly Alternative Refrigerants for Automotive Air Conditioning Systems. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012139. [Google Scholar] [CrossRef]

- Vashisht, S.; Rakshit, D. Recent advances and sustainable solutions in automobile air conditioning systems. J. Clean. Prod. 2021, 329, 129754. [Google Scholar] [CrossRef]

- Zhang, N.; Dai, Y.; Feng, L.; Li, B. Study on environmentally friendly refrigerant R13I1/R152a as an alternative for R134a in automotive air conditioning system. Chin. J. Chem. Eng. 2022, 44, 292–299. [Google Scholar] [CrossRef]

- Savitha, D.C.; Ranjith, P.K.; Talawar, B.; Reddy, N.R.P. Refrigerants for sustainable environment—A literature review. Int. J. Sustain. Energy 2022, 41, 235–256. [Google Scholar] [CrossRef]

- Song, X.; Yuan, H.; Zhang, Y.; Yu, B.; Wang, D.; Shi, J.; Chen, J. Experimental study on improved performance of an automotive CO2 air conditioning system with an evaporative gas cooler. Int. J. Refrig. 2022, 140, 39–48. [Google Scholar] [CrossRef]

- Lei, L.; Song, X.; Yu, B.; Liu, C.; Shi, J.; Chen, J. Energetic performance evaluation of an automotive CO2 air conditioning system with a dual-evaporator configuration. Int. J. Refrig. 2023, in press. [CrossRef]

- Vaccaro, G.; Milazzo, A.; Talluri, L. Thermodynamic assessment of trans-critical refrigeration systems utilizing CO2-based mixtures. Int. J. Refrig. 2023, 147, 61–70. [Google Scholar] [CrossRef]

- Luo, J.; Ye, Z.; Zhao, Z.; Yang, K.; Zhang, S.; Wang, Q. Vapor-liquid equilibrium measurement and heating performance modeling on eco-friendly zeotropic blends of CO2/R1234ze(Z) and CO2/R1336mzz(E). Appl. Therm. Eng. 2023, 229, 120576. [Google Scholar] [CrossRef]

- Chen, B.-L.; Yang, T.-F.; Sajjad, U.; Ali, H.M.; Yan, W.-M. Deep learning-based assessment of saturated flow boiling heat transfer and two-phase pressure drop for evaporating flow. Eng. Anal. Bound. Elem. 2023, 151, 519–537. [Google Scholar] [CrossRef]

- Hussain, I.; Bibi, F.; Sajjad, U.; Sultan, M.; Kaushal, S.K.; Yan, W.-M. A new insight into two-phase flow pressure-drop estimation and optimization of the refrigerant R1234yf. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Al-Zahrani, A. Energy and Exergy Analysis on Zeotropic Refrigerants R-455A and R-463A as Alternatives for R-744 in Automotive Air-Conditioning System (AACs). Processes 2023, 11, 2127. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 34-2022; ASHRAE Standard 34, Designation and Safety Classification of Refrigerants. Refrigeration and Air-Conditioning Engineer Incorporation: Atlanta, GA, USA, 2016.

- Liao, S.; Zhao, T.; Jakobsen, A. A correlation of optimal heat rejection pressures in transcritical carbon dioxide cycles. Appl. Therm. Eng. 2000, 20, 831–841. [Google Scholar] [CrossRef]

- Aspen HYSYS V12.1. 2021. Available online: www.aspentech.com (accessed on 1 May 2023).

- Moran, M.J.; Shapiro, H.N. Fundamentals of Engineering Thermodynamics; John Wiley and Sons: West Sussex, UK, 2006. [Google Scholar]

- Rigola, J.; Raush, G.; Pérez-Segarra, C.; Oliva, A. Numerical simulation and experimental validation of vapor compression refrigeration systems. Special emphasis on CO2 trans-critical cycles. Int. J. Refrig. 2005, 28, 1225–1237. [Google Scholar] [CrossRef]

- Mazyan, W.; Ahmadi, A.; Ahmed, H.; Hoorfar, M. Increasing the COP of a refrigeration cycle in natural gas liquefaction process using refrigerant blends of Propane-NH3, Propane-SO2, and Propane-CO2. Heliyon 2020, 6, 2405–8440. [Google Scholar] [CrossRef]

- Yu, B.; Ouyang, H.; Shi, J.; Liu, W.; Chen, J. Evaluation of low-GWP and mildly flammable mixtures as new alternatives for R410A in air-conditioning and heat pump system. Int. J. Refrig. 2020, 121, 95–104. [Google Scholar] [CrossRef]

- UNEP. Refrigeration, Air Conditioning, and Heat Pumps Technical Options Committee 2018 Assessment Report. 2019. Available online: https://ozone.unep.org/sites/default/files/2019-04/RTOC-assessment-report-2018_0.pdf (accessed on 1 May 2023).

| Pure Refrigerant | Kind | Safety Group (ASHRAE Standard 34), [35] | ODP | GWP | M [kg/kmol] | Tb [°C] | Tc [°C] | Pc [MPa] |

|---|---|---|---|---|---|---|---|---|

| R-134a | HFC | A1 | 0 | 1370 | 102 | −26 | 101 | 4 |

| R-32 | HFC | A2L | 0 | 677 | 52 | −51.7 | 78 | 5.8 |

| R-125 | HFC | A1 | 0 | 3170 | 120 | −48.5 | 66 | 3.6 |

| R-1234yf | HFO | A2L | 0 | <1 | 114 | −29.5 | 94.7 | 3.4 |

| R-744 | Natural | A1 | 0 | 1 | 44 | −78.5 | 31 | 7.4 |

| Refrigerant Designation | Composition (Mass %) | Glide Temperature (°C) | M (kg/kmol) | Tb/(Bubble/Dew) (°C) | Tc (°C) | Pc (MPa) | Safety Group (ASHRAE Standard 34), [35] | ODP | GWP |

|---|---|---|---|---|---|---|---|---|---|

| R-744 | R-744 (100) | -- | 44.01 | −78.51 | 31.05 | 7.38 | A1 | 0 | 1 |

| R-455A | R-744/32/1234yf (3.0/21.5/75.5) | 12.5 | 87.45 | −51.6/−39.1 | 85.48 | 4.32 | A2L | 0 | ~146 |

| R-469A | R-744/R-32/R-125 (35.0/32.5/32.5) | 17 | 59.14 | −78.5/−61.5 | 56.17 | 6.21 | A1 | 0 | 1250 |

| R-472A | R-744/32/134a (69.0/12.0/19.0) | 22.8 | 50.38 | −84.3/−61.5 | 48.22 | 7.31 | A1 | 0 | 342 |

| Parameter | Range/Value |

|---|---|

| The pressure of the cooler/condenser, P2 | 5–15 MPa |

| The average temperature of the evaporator, tevap | 5–15 °C |

| The outlet temperature of the cooler/condenser, t3 | 20–40 °C |

| a flow rate of refrigerant, | 0.05–0.15 kg/s |

| Optimum cooler/condenser pressure, Popt, R744 | 8.9 MPa |

| Optimum cooler/condenser pressure, Popt, R455A | 1.65 MPa |

| Optimum cooler/condenser pressure, Popt, R469A | 4.319 MPa |

| Optimum cooler/condenser pressure, Popt, R472A | 6 MPa |

| Element | Significant Equations [34] | Model Assumptions |

|---|---|---|

Compressor |

| |

Cooler/condenser |

| |

Expansion valve | ||

Evaporator |

| |

IHE |

|

| State Variables | Performance Metrics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Exp. Data, [39] | (W) | COP | |||||||||

| Qevap (W) | Tevap (°C) | Tcomp, in (°C) | Pcomp, out (bar) | Tcooler, out (°C) | ηcomp, overall (%) | Exp., [39] | Current Model | Error (%) | Exp., [39] | Current Model | Error (%) |

| 351.65 | −11.30 | 35.38 | 89.71 | 35.24 | 46.30 | 326.5 | 348 | 6.2 | 1.08 | 1.0 | 6.4 |

| 525.11 | −2.03 | 35.62 | 90.37 | 35.23 | 54.80 | 343.7 | 374 | 8.0 | 1.56 | 1.4 | 9.8 |

| 832.70 | 9.48 | 35.42 | 90.14 | 36.45 | 65.70 | 335 | 374 | 10.4 | 2.49 | 2.2 | 10.4 |

| 469.09 | −11.58 | 31.06 | 84.95 | 31.94 | 56.00 | 331.6 | 353.5 | 6.2 | 1.42 | 1.3 | 6.2 |

| 649.51 | −1.77 | 31.56 | 84.98 | 31.94 | 60.60 | 351.7 | 368.7 | 4.6 | 1.85 | 1.8 | 4.6 |

| 842.02 | 5.32 | 31.83 | 85.78 | 32.11 | 64.50 | 360.1 | 381.3 | 5.6 | 2.29 | 2.2 | 3.4 |

| Parameter | Unit | R-744 | R-455A | R-469A | R-472A |

|---|---|---|---|---|---|

| P1, P1′, P4 | Mpa | 5.09 | 0.793 | 2.31 | 2.73 |

| P2, P3, P3′ | Mpa | 6.3 | 1.243 | 3.46 | 4.51 |

| t1 | °C | 15 | 17.89 | 19.38 | 16.72 |

| t1′ | °C | 20 | 22.89 | 24.38 | 21.72 |

| t2 | °C | 38.63 | 33.57 | 54.568 | 63.21 |

| t3 | °C | 24 | 24.00 | 24.408 | 22 |

| t3′ | °C | 22.43 | 22.38 | 22.3 | 21.76 |

| t4 | °C | 15 | 10.29 | 9.05 | 2.41 |

| kg/s | 9.73 × 10−2 | 8.97 × 10−2 | 7.50 × 10−2 | 8.27 × 10−2 | |

| kW | 0.975 | 1.17 | 1.24 | 2.05 | |

| kW | 14.21 | 15.05 | 14.41 | 15.43 | |

| kW | 15.19 | 16.22 | 15.65 | 17.48 | |

| COPmax | --- | 14.58 | 12.86 | 11.66 | 7.55 |

| ηex | % | 45.4 | 26.8 | 19.8 | 29.3 |

| Term | Unit | R-744 | R-455A | R-469A | R-472A |

|---|---|---|---|---|---|

| kW | 0.23 | 0.23 | 0.23 | 0.36 | |

| kW | 0.078 | 0.289 | 0.357 | 0.513 | |

| kW | 0.0211 | 0.0127 | 0.0022 | 0.0045 | |

| kW | 0.20 | 0.15 | 0.15 | 0.43 | |

| kW | 5.27 × 10−8 | 1.82 × 10−1 | 2.52 × 10−1 | 4.73 × 10−1 | |

| kW | 0.975 | 1.17 | 1.24 | 2.05 | |

| ηex | % | 45.4 | 26.8 | 19.8 | 29.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Zahrani, A. Investigating New Environmentally Friendly Zeotropic Refrigerants as Possible Replacements for Carbon Dioxide (CO2) in Car Air Conditioners. Sustainability 2024, 16, 358. https://doi.org/10.3390/su16010358

Al-Zahrani A. Investigating New Environmentally Friendly Zeotropic Refrigerants as Possible Replacements for Carbon Dioxide (CO2) in Car Air Conditioners. Sustainability. 2024; 16(1):358. https://doi.org/10.3390/su16010358

Chicago/Turabian StyleAl-Zahrani, Ahmed. 2024. "Investigating New Environmentally Friendly Zeotropic Refrigerants as Possible Replacements for Carbon Dioxide (CO2) in Car Air Conditioners" Sustainability 16, no. 1: 358. https://doi.org/10.3390/su16010358

APA StyleAl-Zahrani, A. (2024). Investigating New Environmentally Friendly Zeotropic Refrigerants as Possible Replacements for Carbon Dioxide (CO2) in Car Air Conditioners. Sustainability, 16(1), 358. https://doi.org/10.3390/su16010358