A Traceability Platform for Monitoring Environmental and Social Sustainability in the Textile and Clothing Value Chain: Towards a Digital Passport for Textiles and Clothing

Abstract

:1. Introduction

- Spinning: A fiber processing technique where fibers undergo preparation, drafting, and twisting to transform them into yarn. During spinning, the fibers are drafted, or attenuated, to achieve consistent thickness, and simultaneously twisted to bind the fibers together, resulting in the formation of yarn;

- Weaving: A method of fabric production in which two sets of yarns, known as the warp and weft, interlace with each other at right angles to form a woven fabric. These interlacements create a stable and structured fabric.

- Knitting: A technique where loops of yarn are interlocked to create fabric. It involves manipulating a set of knitting needles or a knitting machine to form rows of interlocking loops.

- Printing, dyeing, and finishing: Printing involves adding colors, patterns, or designs to fabrics, enhancing their visual appeal. Dyeing provides fabrics with vibrant and consistent colors while finishing treatments improve their appearance, texture, and performance.

- Textile manufacturing: The process of transforming fabric into garments or textile products through cutting, sewing, and assembling. The final outcome is a completed garment or textile product ready for distribution or sale.

2. Research Methodology

3. Related Work

3.1. Literature Review

| Technology Used | Support for Circular Economy | Support for Traceability | Traceability of Sustainability Indicators | IoT Integration | B2B/B2C Apps | Measurement of Environmental and/or Social-Economic Impact | References | |

|---|---|---|---|---|---|---|---|---|

| Blockchain-based framework for supply chain traceability | Blockchain | - | ✓ | - | ✓ | B2B | No | [19] |

| A secured tag for implementation of traceability in textile and clothing supply chain | QR Code and Data Server | ✓ | ✓ | - | ✓ | B2B2C | No | [18] |

| Developing a framework for traceability implementation in the textile supply chain | RDBMS and XML | - | ✓ | - | ✓ | B2B2C | No | [17] |

| Applying integrated blockchain and big data technologies to improve supply chain traceability and information sharing in the textile sector | Blockchain and big data | - | ✓ | - | - | B2B | No | [21] |

| Traceability of ready-to-wear clothing through blockchain technology | Permissioned blockchain | ✓ | ✓ | - | ✓ | B2B2C | No | [20] |

| STVgoDigital proposal | Permissioned blockchain | ✓ | ✓ | ✓ | ✓ | B2B2C | Yes | — |

3.2. Solutions from the Industry

- Data Carrier Tag:

- Data carrier type refers to the tag that interconnects the physical product and the digital product. There are numerous product ID technologies available, including one-dimensional barcodes, QR codes, radio frequency identification (RFID), and near field communications (NFC). QR codes are two-dimensional codes that can be scanned with smartphones to convey product information. RFID uses radio waves to identify and monitor products in real time. Barcodes are also commonly used for product identification, with each product being issued a unique barcode that can be scanned using a barcode reader. NFC technology enables wireless data transfer between compatible devices.

- Traceability:

- The type of data that the platform is able to trace along the value chain. Environmental and circular and real and/or estimated data can provide information about a product’s environmental score (environmental and circular score (ECS)). Social and economic data can provide information about a company’s social and economic score (economic and social score (ESS)). These four dimensions (environmental, circular, social, economic) can comprise real or estimated values, such as, for the environmental dimension, water and energy consumption, effluent production, CO2e production and other environmental indicators, and life cycle assessment (LCA) indicators; for the circularity indicators, the percentage of recycled content, recyclability of products, and design for circularity and durability; for the economic dimension, company certifications, financial data, profitability and investments; for the social dimension, if workers’ rights are respected, if workers are justly paid and have safety at work, and community involvement.

- -

- Centralized: The practice of storing all data in one centralized location, such as a data center or a cloud server. Centralized storage makes it easier to scale up storage capacity as needed and ensures that all users have access to the same data, eliminating the need for duplicate copies of data to be stored in multiple locations. However, there are also potential drawbacks to centralized storage, e.g., the risk of data loss or corruption if the central storage location fails.

- -

- Decentralized: Decentralized data storage spreads data across numerous locations, such as the cloud or different servers. This makes it more resistant to system faults and increases data accessibility. However, because the data are dispersed, the data might be more difficult to manage and safeguard, requiring more complicated management systems.

4. Results

4.1. Environmental, Circular, economic and social Indicators

- A: greater than 85%;

- B: between 75% and 85%;

- C: between 65% and 75%;

- D: between 55% and 65%;

- E: between 45% and 55%;

- F: lower than 45%.

4.2. Architecture of the Proposed Solution for Traceability in the T&C Value Chain

- A security layer, represented by the blue arrow in Figure 2, ensures that the user is authenticated and has authorization to perform the intended operations;

- Data insertion operations are put into a message queue (message layer in Figure 2), to be handled sequentially by the business layer, which calls the smart contract’s/chaincode’s methods for inserting traceability data onto the blockchain;

- Data query operations are directly sent to the business layer, which calls the chaincode’s methods for querying traceability data from the blockchain;

- The chaincode, which is installed on every non-orderer peer and channel, directly reads, writes or deletes the assets represented as documents on the CouchDB key-value-based database (Hyperledger Fabric’s World State database). This database contains the world state, meaning the latest and up-to-date representation of the items of the blockchain network’s ledger;

- If the transaction consensus is reached, the ledger and the world state database update themselves (if this was an invoke/put transaction). Query/get transactions do not need consensus approval.

4.3. On-Chain and Off-Chain Data Models

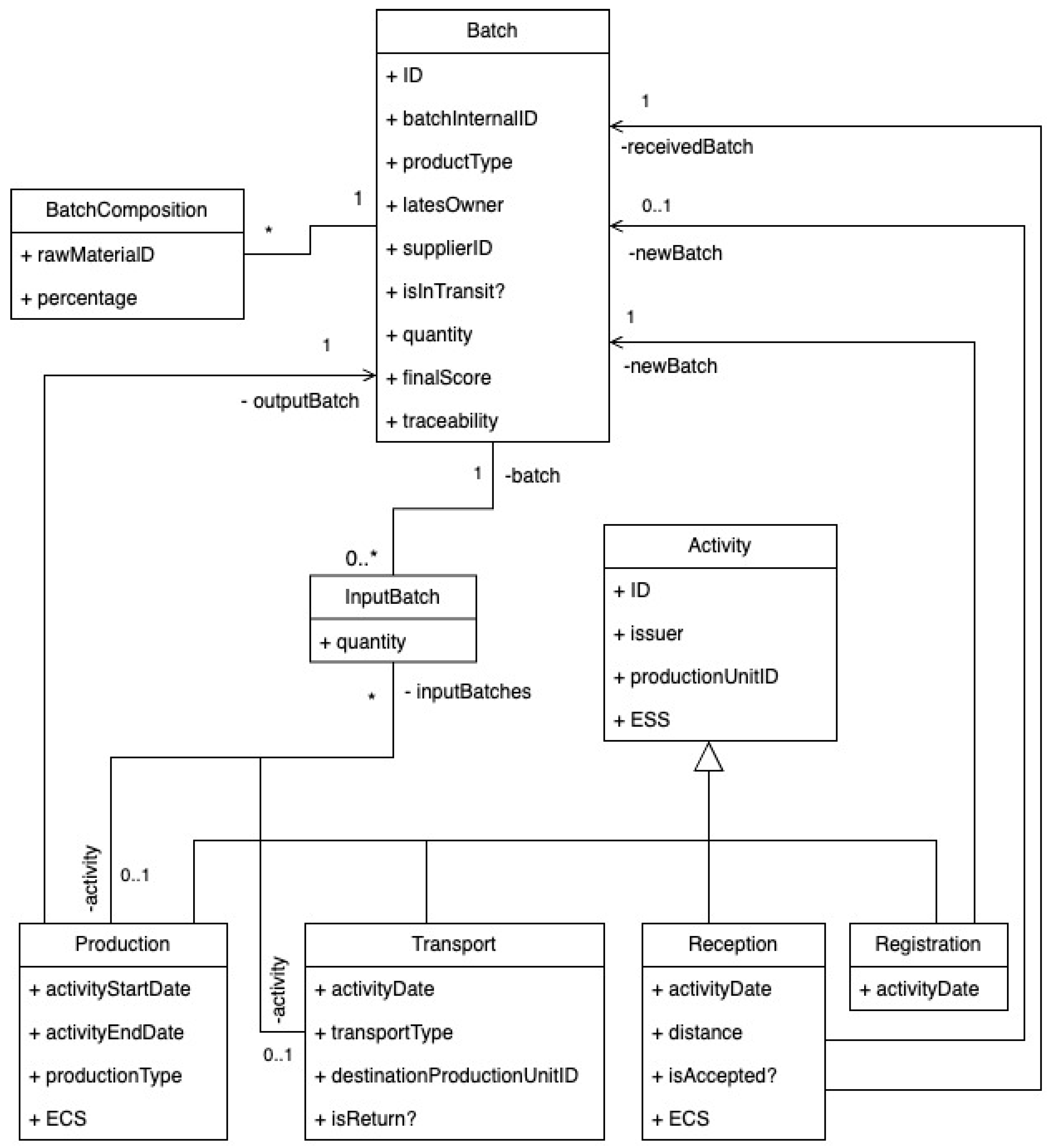

4.3.1. On-Chain Data

- Batch: The main asset to be tracked on which the value chain operations work on. The batch definition contains an identification of its (productType). A batch has attributes to reference off-chain entities, such as the production unit that owns it, supplier and internal batch identifiers, for referencing a batch within the scope of a single company-productionUnitID, supplierID and batchInternalID, respectively. The attribute finalScore is what holds the final score and ranks the batch sustainability claims. The calculations to reach the final score of the batch are made off-chain by other modules of the system, registering on-chain just the final value, inside the batch entity. The boolean attribute isInTransit, with a default value of false upon batch creation, helps to truthfully represent the batch’s current owner state when it is being transported between production units. Lastly, the attribute Traceability will append the activities’ “objects” for each activity that a batch goes through, resulting in a recursive collection of activities and its input/output batches throughout the value chain activities until it reaches the current instance of a batch. Visually, a batch traceability’s representation results in an inverted tree, where the root is the current batch and the straight branches are activities with no aggregation.

- BatchComposition: The information about what materials and their percentages constitute a given batch (e.g., {cotton: 50%, polyester: 50%}). MaterialID references the off-chain entity RawMaterial.

- Activity: A value chain activity. It is executed by a production unit of a company, which has a given economic-social score (ESS). The ESS assesses the company level relative to its social impact on its workers and operators. An activity may be of one of four types (Registration, Production, Transport, or Reception).

- Registration: An activity used when a production unit wants to register a batch that is created outside of the developed system. This may be used to register a batch of raw material, not resulting from a production activity, that needs to enter the value chain traceability system to be used as an input batch for production activities.

- Production: An activity that consumes input batch(es) and creates a batch, making it the only activity that can converge the history of one or more batches’ with a new batch, by using them as Input Batches. For timing purposes, activityStartDate and activityEndDate represent the start and finish date and times of the production activity. Finally, ECS is a value of the computed environmental-circular score that assesses the sustainability level of the batch, until this point in the value chain.

- Transport: An activity used to register the transportation of a batch to another participant in the value chain. To support this functionality, this entity has an off-chain identifier (ID) for specifying the origin and destination for the transport (roductionUnitID and destinationProductionUnitID, respectively). Even though a transportation may carry more than a single batch, the transaction on-chain to log the transport activity only registers one batch per activity. The reasoning behind this decision is to decouple the batches’ traceability in the shipment from each other, maintaining a reliable tracking and tracing of each batch. Other attributes of this entity include predefined data related to its transportation type (transportType) and traveling distance (distance). A boolean isReturn attribute with a default value of false is also present to indicate if the shipment is a return transport in case the destination production unit rejects the batch upon receiving it (more in Reception activity below). Lastly, activityDate logs the timestamp of departure. The date and time of arrival are only registered when receiving the batch, leading to a Reception activity.

- Reception: An activity issued upon the arrival of batches to a production unit. This activity is required after a transport activity because the transported batch should be properly received and its quality assessed, to continue through the value chain. ECS score of the transportation is only registered, in the reception activity, upon reception of the transported batches.

4.3.2. Off-Chain Data

- Company, which is a company that performs value chain activities;

- Logistics activity, which corresponds to transportation between two production units;

- Registration activity, which models a registration of a new batch from outside the traceability system;

- Production activity, which corresponds to a value chain activity, such as spinning, weaving, dyeing, etc.;

- Batch, corresponding to a product batch created and handled by the identified value chain activities.

- ESS_score, which stores the calculated economic and social score (ESS) for a company/year;

- SocialEconIndAttValue, which stores values of a company’s economic and social indicator (c.f. Table 4) for calculating the ESS;

- SocialEconAttValue, which stores other values of a company’s data;

- company_certification, which stores a company’s certificates yielded by a certifying entity;

- EvironIndAttValue, which stores temporary values of an activity’s environmental indicator (c.f. Table 3);

- FinalEnvIndAttValue, which stores the final/end values of an activity’s environmental indicator (c.f. Table 3);

4.4. Smart Contract/Chaincode

4.5. Backend, API and User Applications

5. Analysis and Discussion of Results

5.1. Test Scenario 1: A Home Textile Product (Towel)

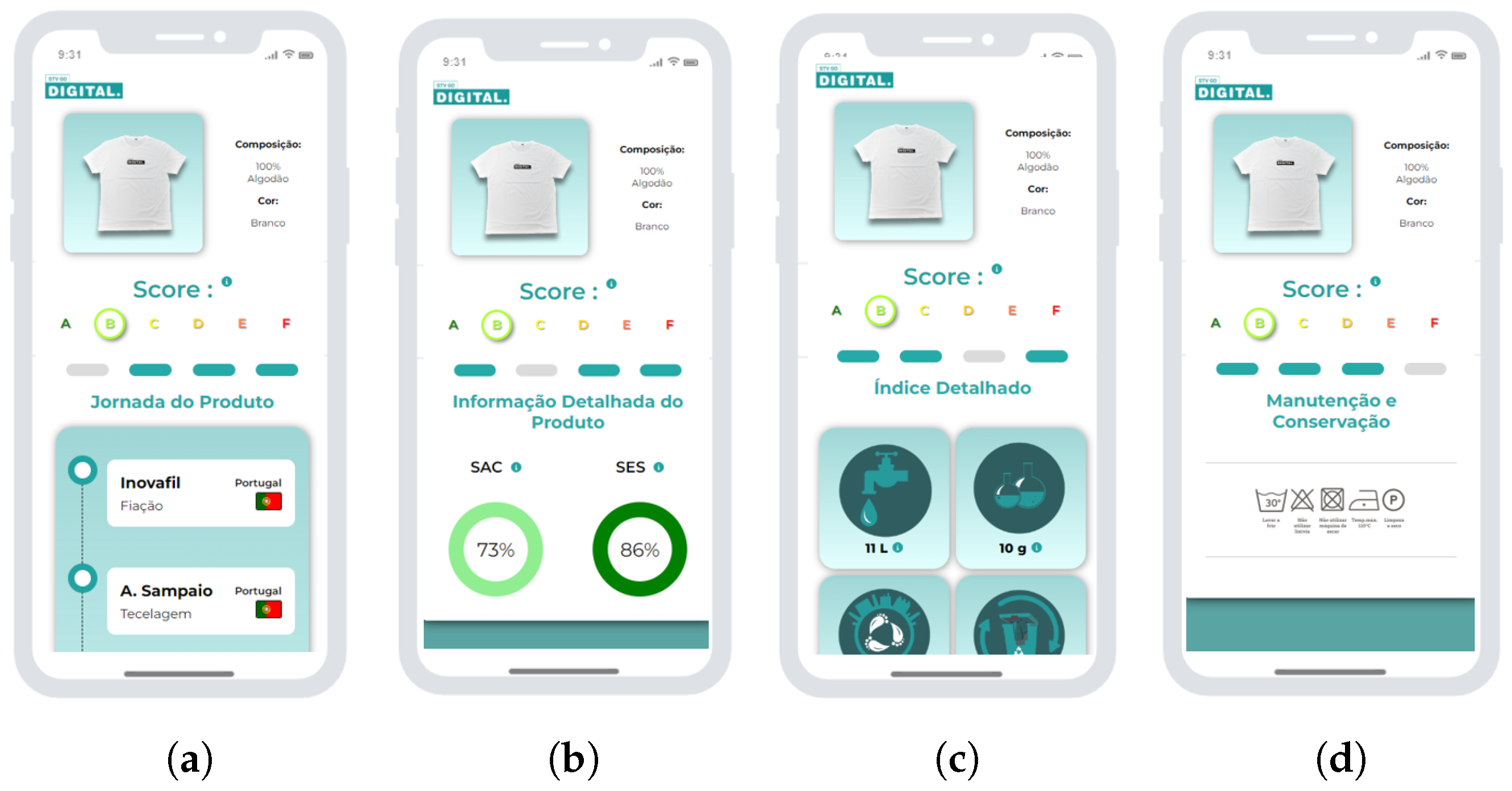

5.2. Test Scenario 2: A Garment (T-Shirt)

6. Conclusions and Future Work

- Providing environmental and social traceability information for every business partner in the value chain: The platform enables any industry or logistics company in the value chain, through their ERP/MRP applications integrated with the platform, to know the origin and monitored indicators values of any product batch, when it was manufactured, stored, transported, who was responsible for each activity, and which previous product batches have been used in producing that batch. This enables any business partner in the T&C value chain to make informed choices when buying from their suppliers.

- Providing traceability information to the end customer: The platform allows assessing the environmental impact of every product batch, and the socio-economic impact of every company. This enables every end costumer to know when, where and how the final product that is for sale in a retail store has impacted the environment, and how the involved companies support social welfare. This enables the end costumer to make an informed selection of T&C products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| API | Application programming interface |

| ATP | Textile and Clothing Association of Portugal |

| BLL | Business logic layer |

| CA | Certificate authority |

| CE | Circular economy |

| CLI | Command line interface |

| CRUD | Create, retrieve, update and delete |

| DPP | Digital product passport |

| DSR | Design science research |

| ECS | Environmental and circular score |

| ERDF | European Regional Development Fund |

| ERP | Enterprise resource planning |

| ESS | Economic and social score |

| EU | European Union |

| ID | Identifier |

| IoT | Internet of Things |

| LCA | Life cycle assessment |

| NFC | Near field communications |

| REST | Representational state transfer |

| R&D | Research and development |

| RDBMS | Relational database management system |

| QR | Quick response |

| RFID | Radio frequency identification |

| T&C | Textile and clothing |

| XML | Extensible markup language |

References

- EURATEX, Economic and Statistics. FACTS and KEY FIGURES 2022 OF THE EUROPEAN TEXTILE AND CLOTHING INDUSTRY, 2022. August Update. Available online: https://euratex.eu/wp-content/uploads/EURATEX_FactsKey_Figures_2022rev-1.pdf (accessed on 27 April 2023).

- Cura, K.; Sheenam, J.; Niinimäki, K. Transparency and Traceability in the Textile Value Chain; Technical Report; Aalto University: Espoo, Finland, 2022. [Google Scholar]

- Alves, L.; Ferreira Cruz, E.; Lopes, S.I.; Faria, P.M.; Rosado da Cruz, A.M. Towards circular economy in the textiles and clothing value chain through blockchain technology and IoT: A review. Waste Manag. Res. 2022, 40, 3–23. [Google Scholar] [CrossRef] [PubMed]

- Toprak, T.; Anis, P. Textile industry’s environmental effects and approaching cleaner production and sustainability, an overview. J. Text. Eng. Fash. Technol. 2017, 2, 429–442. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2022, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Lehmann, M.; Arici, D.; Boger, E.; Martinez-Pardo, A.; Krueger, N.; Schneider, L.; Carrière-Pradal, M.; Schou, K. Pulse of the Fashion Industry. Report, 2019. Global Fashion Agenda, Boston Consulting Group, and Sustainable Apparel Coalition. Available online: https://www.bcg.com/2019-pulse-of-the-fashion-industry (accessed on 30 April 2023).

- Fashion Revolution. Fashion Transparency Index; 2022 edition; Fashion Revolution: London, UK, 2022; Available online: https://www.fashionrevolution.org/about/transparency/ (accessed on 30 April 2023).

- European Comission. A New Circular Economy Action Plan For a Cleaner and More Competitive Europe. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 27 April 2023).

- Götz, T.; Adisorn, T.; Tholen, L. Der Digitale Produktpass als Politik-Konzept; Technical Report; Wuppertal Institut für Klima, Umwelt, Energie: Wuppertal, Germany, 2021. [Google Scholar] [CrossRef]

- Götz, T.; Adisorn, T.; Tholen, L. Towards a Digital Product Passport Fit for Contributing to a Circular Economy. Energies 2021, 14, 2289. [Google Scholar] [CrossRef]

- Huang, S.; Wang, G.; Yan, Y.; Fang, X. Blockchain-based data management for digital twin of product. J. Manuf. Syst. 2020, 54, 361–371. [Google Scholar] [CrossRef]

- Alves, L.; Cruz, E.F.; Rosado Da Cruz, A.M. Tracing Sustainability Indicators in the Textile and Clothing Value Chain using Blockchain Technology. In Proceedings of the 2022 17th Iberian Conference on Information Systems and Technologies (CISTI), Madrid, Spain, 22–25 June 2022; pp. 1–7. [Google Scholar] [CrossRef]

- Nguyen, K.; Akbari, M.; Quang, H.T.; McDonald, S.; Hoang, T.H.; Yap, T.L.; George, M. Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability 2023, 15, 16720. [Google Scholar] [CrossRef]

- Akbari, M. Revolutionizing supply chain and circular economy with edge computing: Systematic review, research themes and future directions. Manag. Decis. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Peffers, K.; Tuunanen, T.; Gengler, C.E.; Rossi, M.; Hui, W.; Virtanen, V.; Bragge, J. Design Science Research Process: A Model for Producing and Presenting Information Systems Research. arXiv 2020, arXiv:2006.02763. [Google Scholar]

- Baskerville, R. What design science is not. Eur. J. Inf. Syst. 2008, 17, 441–443. [Google Scholar] [CrossRef]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a Framework for Traceability Implementation in the Textile Supply Chain. Systems 2017, 5, 33. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Koehl, L.; Campagne, C. A secured tag for implementation of traceability in textile and clothing supply chain. Int. J. Adv. Manuf. Technol. 2018, 99, 2563–2577. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based Framework for Supply Chain Traceability: A Case Example of Textile and Clothing Industry. Comput. Ind. Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Bullón Pérez, J.J.; Queiruga-Dios, A.; Gayoso Martínez, V.; Martín del Rey, Á. Traceability of Ready-to-Wear Clothing through Blockchain Technology. Sustainability 2020, 12, 7491. [Google Scholar] [CrossRef]

- Hader, M.; Tchoffa, D.; Mhamedi, A.E.; Ghodous, P.; Dolgui, A.; Abouabdellah, A. Applying integrated Blockchain and Big Data technologies to improve supply chain traceability and information sharing in the textile sector. J. Ind. Inf. Integr. 2022, 28, 100345. [Google Scholar] [CrossRef]

- Wiegand, T.; Wynn, M. Sustainability, the Circular Economy and Digitalisation in the German Textile and Clothing Industry. Sustainability 2023, 15, 9111. [Google Scholar] [CrossRef]

- Dahllöf, L. Life Cycle Assessment (LCA) applied in the Textile Sector: The Usefulness, Limitations and Methodological Problems—A Literature Review; Technical Report, Environmental Systems Analysis; Chalmers Tekniska Högskola: Göteborg, Sweden, 2003. [Google Scholar]

- ISO 105-C06:2010. Available online: https://www.iso.org/standard/51276.html (accessed on 19 June 2023).

- ISO 105-B02:2014. Available online: https://www.iso.org/standard/65209.html (accessed on 19 June 2023).

- ISO 12945-2:2020. Available online: https://www.iso.org/standard/75375.html (accessed on 19 June 2023).

- ISO 12947-2:2016. Available online: https://www.iso.org/standard/61058.html (accessed on 19 June 2023).

- Androulaki, E.; Barger, A.; Bortnikov, V.; Cachin, C.; Christidis, K.; De Caro, A.; Enyeart, D.; Ferris, C.; Laventman, G.; Manevich, Y.; et al. Hyperledger Fabric: A Distributed Operating System for Permissioned Blockchains. In Proceedings of the Thirteenth EuroSys Conference; Association for Computing Machinery: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

| Solution | Data Carrier Tag | Traceability | Data Storage | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Barcodes(s) | RFID | NFC | Product (ECS) | Company (ESS) | Sustainability Score | Centralized | Decentralized | |||

| Environmental | Circular | Social | Economic | |||||||

| CIRPASS | QR | - | - | ✓ | ✓ | ✓ | - | - | - | - |

| French Initiative | - | - | - | ✓ | ✓ | ✓ | - | - | - | - |

| BCome | QR | - | - | ✓ | ✓ | - | - | - | - | - |

| circular.fashion | QR | ✓ | ✓ | ✓ | ✓ | ✓ | - | - | ✓ | ✓ |

| EON | 1D + QR | ✓ | ✓ | ✓ | ✓ | ✓ | - | - | ✓ | ✓ |

| TextileGenesis | 1D + QR | ✓ | - | - | - | - | - | - | - | ✓ |

| TRICK | QR | - | - | ✓ | ✓ | - | - | - | ✓ | ✓ |

| TrusTrace | QR | - | - | ✓ | ✓ | - | - | - | ✓ | ✓ |

| STVgoDigital | QR | - | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Data | Description |

|---|---|

| Water consumption | Water consumption for the product under evaluation, per batch |

| Quantity of recycled water | Quantity of recycled water, per batch |

| Electricity consumption, total | Electricity consumption for the product under evaluation, per batch |

| Renewable electricity bill | Annual average of the amount indicated in the monthly electricity bills and/or established in the contract |

| Self-consumption of renewable energy | Total consumption of own renewable electricity for the product under evaluation, per batch, as a percentage |

| Natural gas consumption | Consumption of natural gas for the product under evaluation, per batch |

| Steam consumption | Steam consumption for the product under evaluation, per batch |

| Steam pressure | Vapor pressure (gauge) of the acquired vapor |

| Hot water consumption | Hot water consumption for the product under evaluation, per batch |

| Hot water consumption | Average temperature of hot water acquired |

| Consumption of thick fuel oil | Consumption of thick fuel oil for the product under evaluation, per batch |

| Biomass consumption | Biomass consumption for the product under evaluation, per batch |

| Coal consumption | Coal consumption for the product under evaluation, per batch |

| Consumption of other types of energy | Consumption of another type of energy for the product under evaluation, per batch |

| Diesel consumption | Diesel consumption for the product under evaluation |

| Gasoline consumption | Gasoline consumption for the product under evaluation |

| Liquid petroleum gas (LPG) consumption | Consumption of propane gas for the product under evaluation, per batch |

| Consumption of chemicals | Consumption of chemicals for the product under evaluation, per batch |

| Quantity of recovered chemicals | Consumption of recovered chemicals, for the product under evaluation, per batch |

| Quantity of non-hazardous chemicals | Consumption of non-hazardous chemicals for the product under evaluation, per batch |

| SVHC quantity in products | SVHC consumption for the product under evaluation, per batch |

| Wastewater volume | Wastewater volume for the product under evaluation, per batch |

| COD concentration | Annual average of chemical oxygen demand (COD) concentration based on liquid effluent characterization reports |

| BOD5 concentration | Annual average of biochemical oxygen demand (BOD5) concentration based on liquid effluent characterization reports |

| TSS concentration | Annual average of total suspended solids (TSS) concentration based on liquid effluent characterization reports |

| Quantity of solid waste | Total amount of solid waste generated for the product under evaluation, per batch |

| Quantity of textile waste | Quantity of textile waste generated for the product under evaluation, per batch |

| Quantity of non-hazardous waste | Quantity of non-hazardous waste generated for the product under evaluation, per batch |

| Quantity of recovered waste | Quantity of total waste valued for the product under evaluation, per batch |

| Quantity of valued textiles | Quantity of textiles valued for the product under evaluation, per batch |

| Quality control to color changing | Color fastness to washing–color changing (ISO 105 C06) [24] |

| Quality control to staining | color fastness to washing–staining (ISO 105 C06) [24] |

| Quality control to artificial light | color fastness to artificial light (EN ISO 105 B02) [25] |

| Quality control to pilling resistance | Pilling resistance of the woven fabrics (EN ISO 12945-2) [26] |

| Quality control to abrasion resistance | Abrasion resistance of the woven fabrics (EN ISO 12947-2) [27] |

| Data | Description |

|---|---|

| Total number of employees | Paid and unpaid persons employed by the company |

| Total number of women | Women at the service of the company |

| Total number of men | Men at the service of the company |

| Number of women in functions other than top management | Employees who perform functions other than top management |

| Number of men in functions other than top management | Employees who perform functions other than top management |

| Number of women in top management | Number of women with positions in the administration and/or direction of the company |

| Number of men in top management | Number of men with positions in the administration and/or direction of the company |

| Average salary of women in roles other than top management | Average salary of female employees who perform functions other than top management |

| Average salary of men in positions other than top management | Average salary of male employees who perform functions other than top management |

| Average salary for women in top management | Average salary of female employees with positions in the administration and/or direction of the company |

| Average salary for men in top management | Average salary of male employees with positions in the administration and/or direction of the company |

| Lowest monthly salary (interpretative) | Lowest gross monthly remuneration, after removing the lowest 5% |

| Higher monthly salary (interpretative) | Highest gross monthly remuneration, after removing the top 5% |

| Number of employees with fixed-term contracts | Count of employees with fixed-term contracts |

| Number of employees with open-ended contracts | Count of employees with open-ended contracts |

| Age of the youngest employee | The age of the youngest employee in the company |

| Average number of weekly hours worked/employee | The average number of weekly hours worked per employee |

| Number of training hours/total number of employees | The total number of training hours per the total number of employees |

| Percentage of company profit distributed to social institutions | The percentage of company profit that is distributed to social institutions |

| Financial autonomy | Value resulting from the operation: (Equity/Assets)×100 |

| EBITDA | Earnings before interest, taxes, depreciation and amortization |

| Solvency | Value resulting from the operation: (Equity/Liabilities)×100 |

| Certifications | Certifications that the company holds (e.g., GOTS, GRS, STEP) |

| Transaction Method | Description | Automatic Arguments | Manual Arguments | Output |

|---|---|---|---|---|

| CreateRegistration | Creates a Registration activity | id,issuer, productionUnitID, activityDate | newBatch | registration, batch |

| ReadRegistration | Reads a Registration activity by id | - | id | registration |

| midrule CreateProduction | Creates a Production activity | id,issuer, productionUnitID, activityStartDate, activityEndDate, productionScore,ses | inputBatches, outputBatch, productionType | production, batch |

| ReadProduction | Reads a Production activity by id | - | id | production |

| CreateTransport | Creates a Transport activity | id,issuer, originProductionUnitID, activityDate, isReturn ** | transportType, destinationProductionUnitID, inputBatch, isReturn ** | transport, batch * |

| ReadTransport | Reads a Transport activity by id | - | id | transport |

| CreateReception | Creates a Reception activity | id,issuer, productionUnitID, isAccepted **, activityDate, transportScore,ses | receivedBatch, newBatch, isAccepted **, distance | reception, batch * |

| ReadReception | Reads a Reception activity by id | - | id | reception |

| ReadBatch | Reads a Batch by id | - | id | batch |

| TraceBatchByInternalID | Lists the batch and its activities, as well as its previous traceable batches’ activities | - | batchInternalID | batch.Traceability |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, L.; Sá, M.; Cruz, E.F.; Alves, T.; Alves, M.; Oliveira, J.; Santos, M.; Rosado da Cruz, A.M. A Traceability Platform for Monitoring Environmental and Social Sustainability in the Textile and Clothing Value Chain: Towards a Digital Passport for Textiles and Clothing. Sustainability 2024, 16, 82. https://doi.org/10.3390/su16010082

Alves L, Sá M, Cruz EF, Alves T, Alves M, Oliveira J, Santos M, Rosado da Cruz AM. A Traceability Platform for Monitoring Environmental and Social Sustainability in the Textile and Clothing Value Chain: Towards a Digital Passport for Textiles and Clothing. Sustainability. 2024; 16(1):82. https://doi.org/10.3390/su16010082

Chicago/Turabian StyleAlves, Luís, Miguel Sá, Estrela Ferreira Cruz, Toni Alves, Marcelo Alves, João Oliveira, Manuel Santos, and António Miguel Rosado da Cruz. 2024. "A Traceability Platform for Monitoring Environmental and Social Sustainability in the Textile and Clothing Value Chain: Towards a Digital Passport for Textiles and Clothing" Sustainability 16, no. 1: 82. https://doi.org/10.3390/su16010082

APA StyleAlves, L., Sá, M., Cruz, E. F., Alves, T., Alves, M., Oliveira, J., Santos, M., & Rosado da Cruz, A. M. (2024). A Traceability Platform for Monitoring Environmental and Social Sustainability in the Textile and Clothing Value Chain: Towards a Digital Passport for Textiles and Clothing. Sustainability, 16(1), 82. https://doi.org/10.3390/su16010082