Effect of Modifiers on the Disintegration Characteristics of Red Clay

Abstract

:1. Introduction

2. Materials and Methods

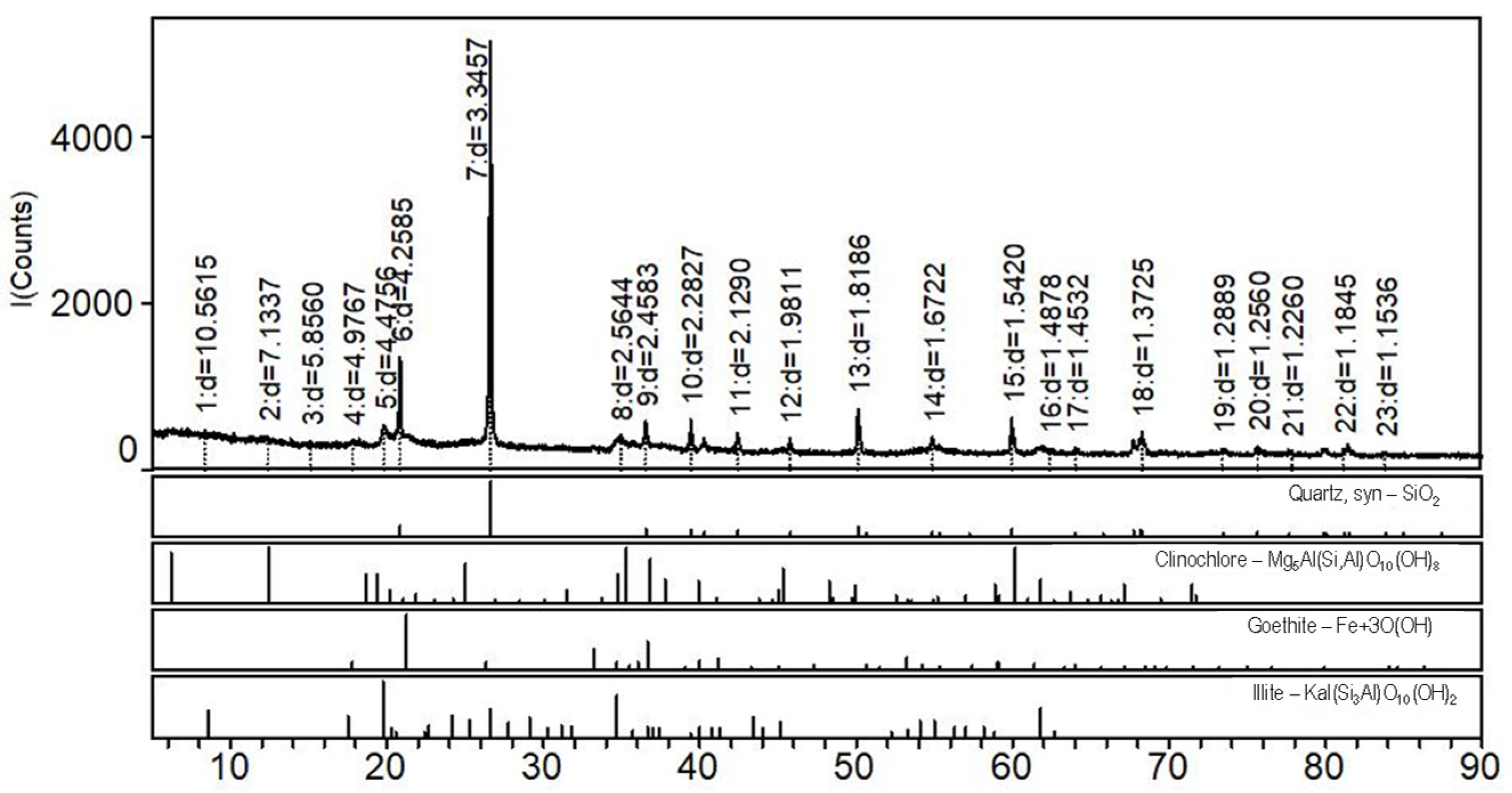

2.1. Experimental Materials

2.2. Experimental Method

3. Experiment Results and Analysis

3.1. Test Disintegration Phenomenon

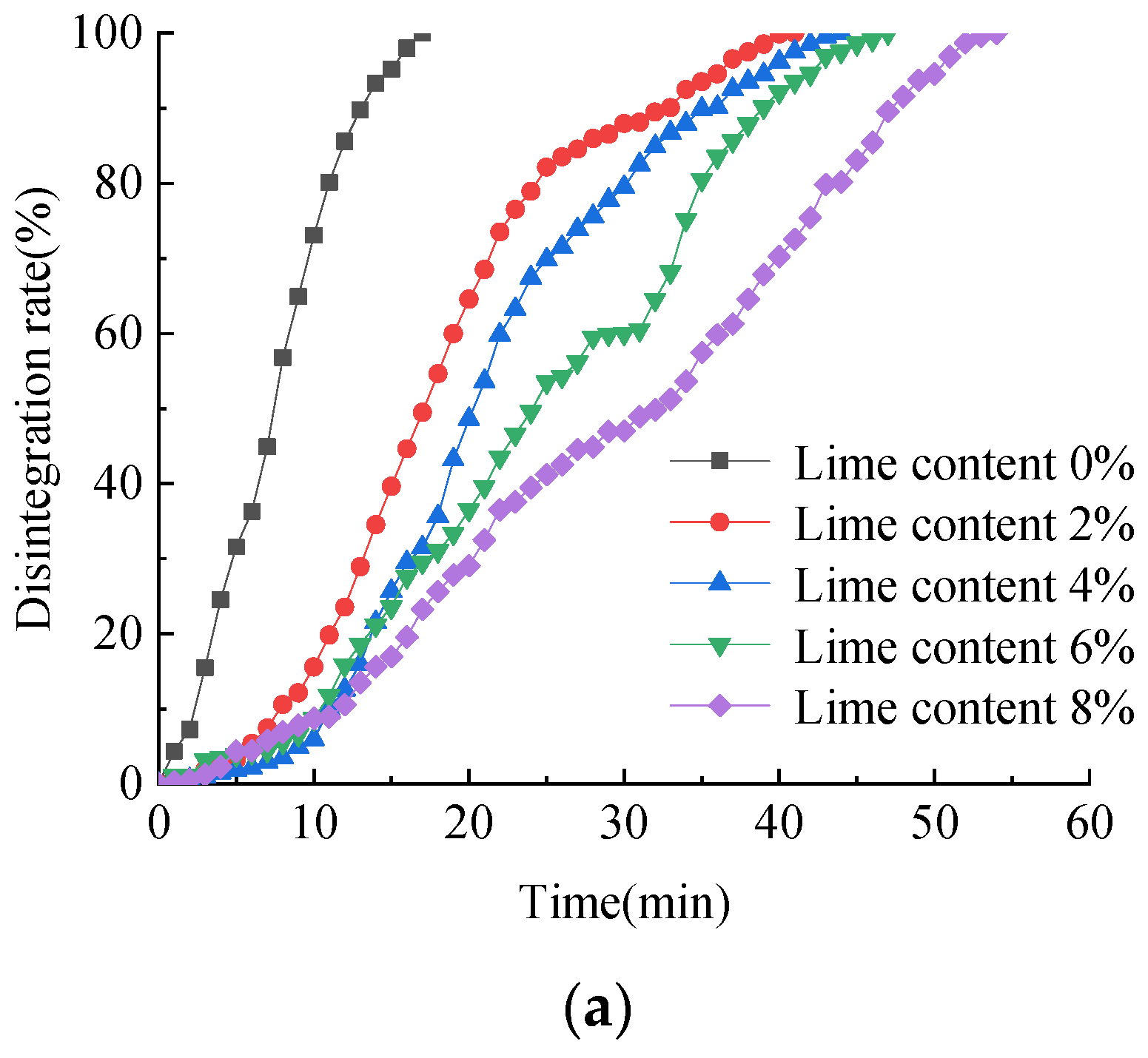

3.2. Effect of Modifier on Disintegration Curve of Red Clay

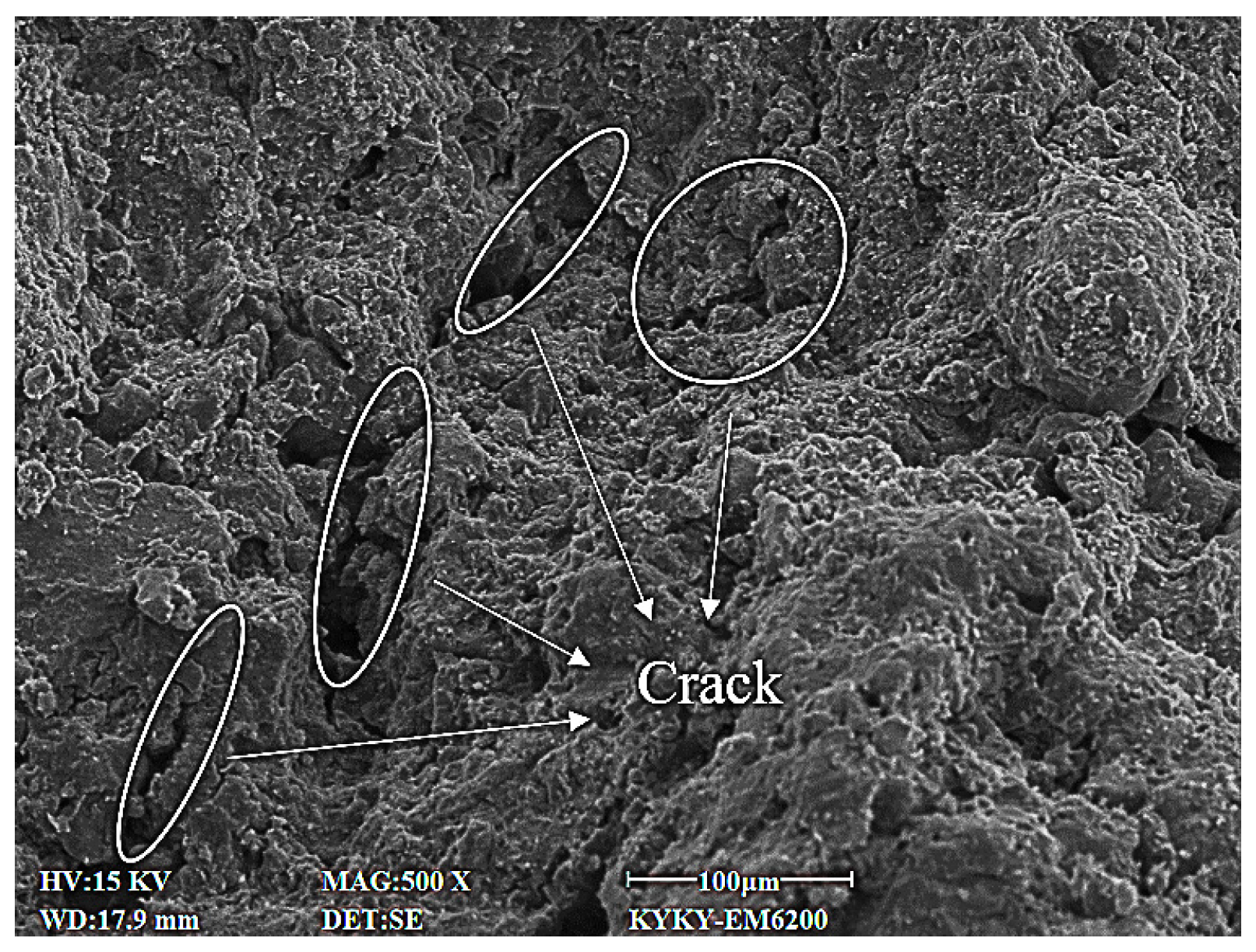

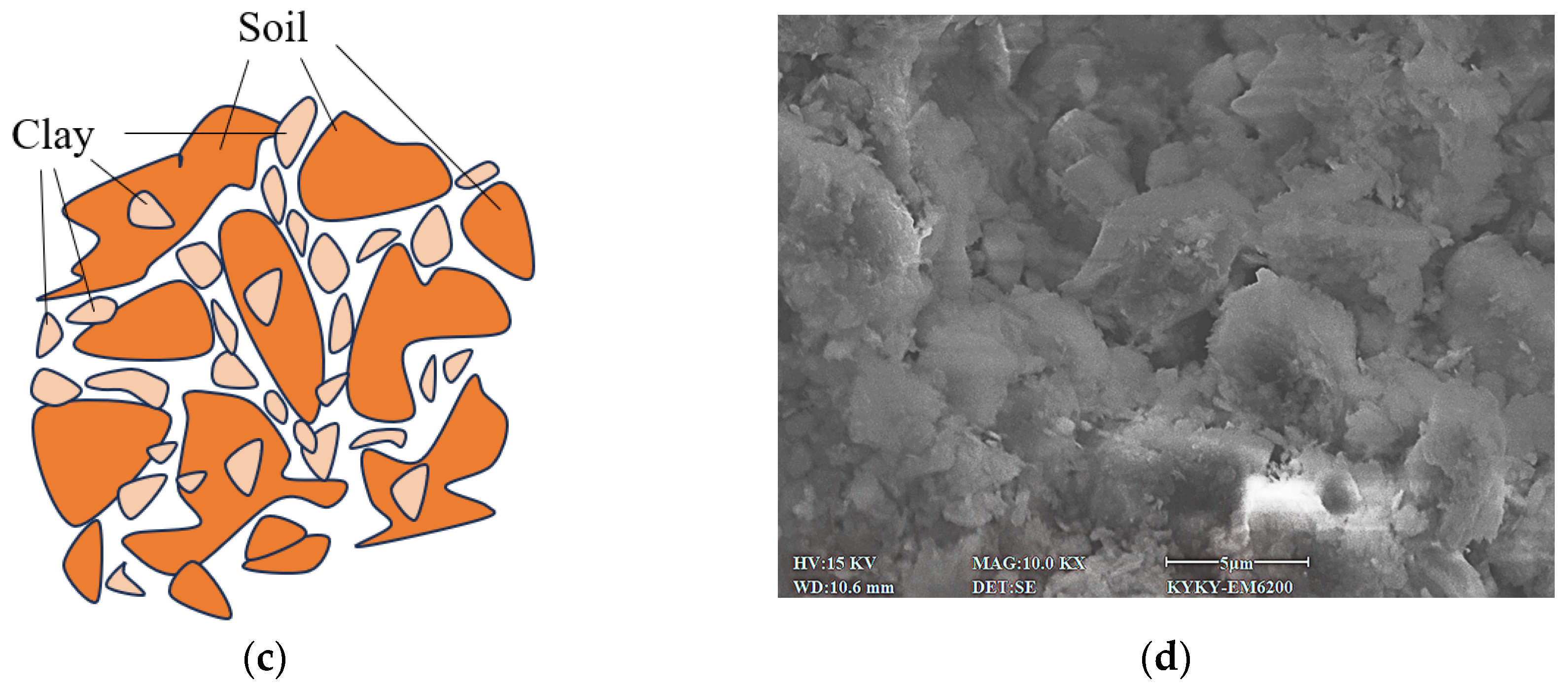

3.3. Effect of Modifier on Microstructure of Red Clay

3.4. Effect of Modifier Types on Saturated Moisture Content of Red Clay

3.5. Microscopic Porosity Analysis

4. Conclusions

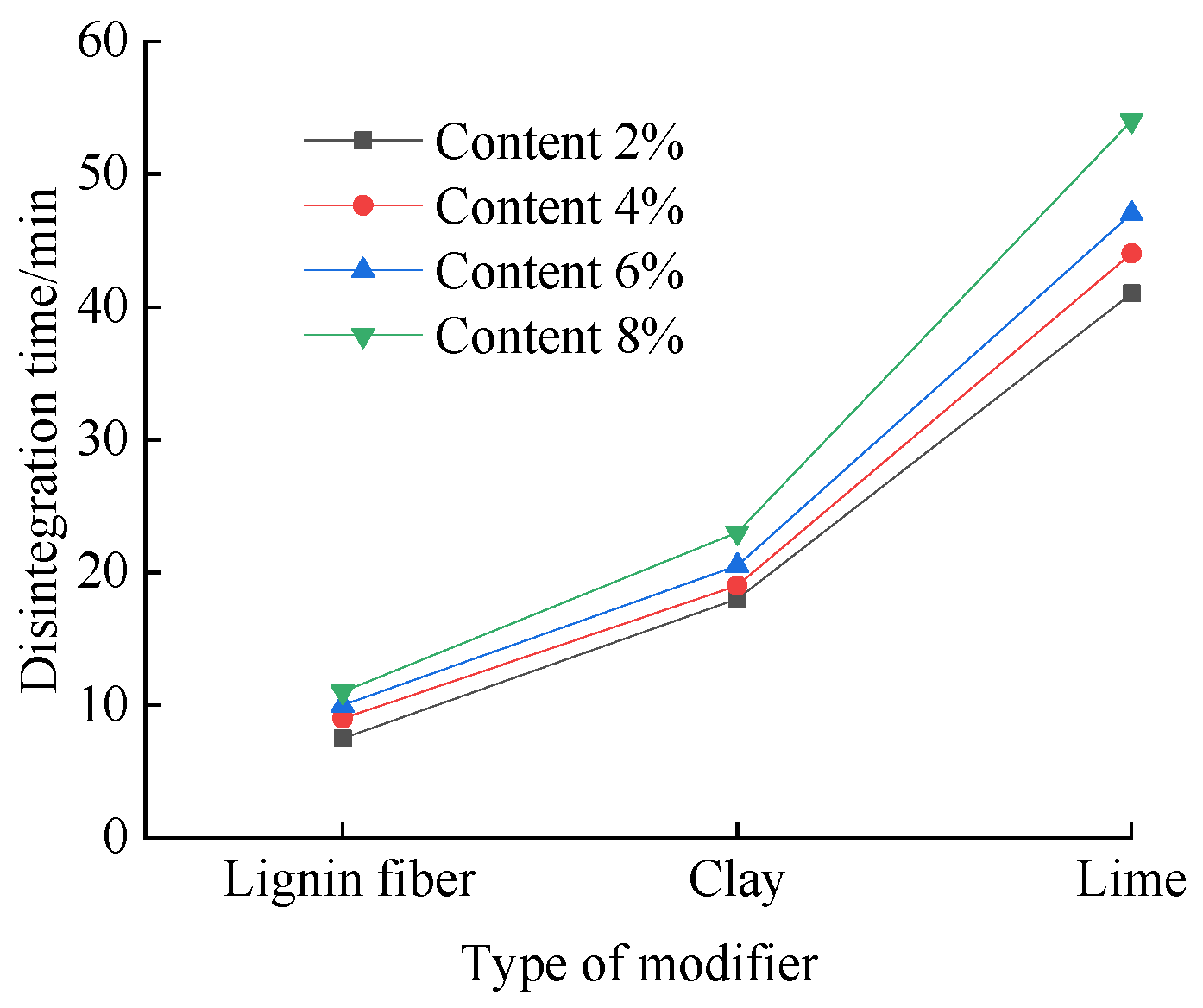

- After adding lignin, the water-holding capacity of red clay decreases, the anti-disintegration ability of soil decreases, and the water stability decreases. The water sensitivity of red clay is improved after adding clay, and the disintegration time increases with the increase of clay content. The water-holding capacity of red clay increases after structural lime treatment, and this water-holding capacity increases with the increase in its content. Comparing and analyzing the anti-disintegration ability of the three modifiers, lime can effectively improve the immersion of red clay in water, and the water stability is improved.

- The incorporation of lignin fiber leads to the change in the internal pores of the sample; in the short term, there is no good cross-accumulation effect between the soil particles and the fiber in the sample, and the water easily immerses the soil, which leads to the decrease in the anti-disintegration ability of the soil. The clay particle size is small, and it is incorporated into the soil to fill the pores of the soil. The cementation of clay minerals in the clay particles enhances the disintegration resistance of the soil, and the disintegration time increases with the increase in clay content. The hydration of lime changes the original pore structure and material composition of red clay and improves the disintegration of the red clay.

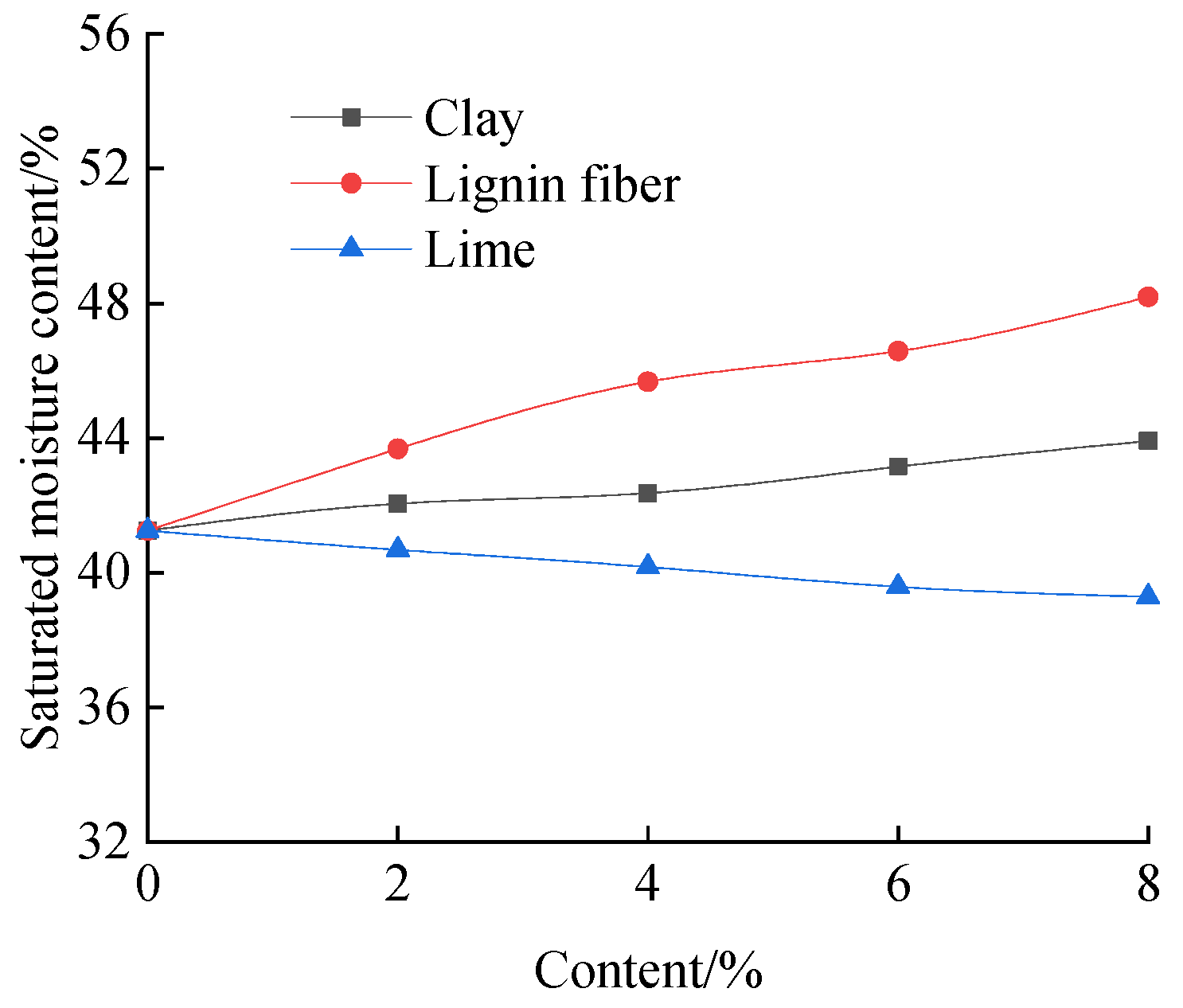

- The content of water-soluble minerals and the pore structure of the soil have a significant effect on the soil–water characteristic curve. In red clay, with the increase in wood fiber content, the saturated water content gradually increased from 43.68% to 48.91%, showing a significant upward trend. This change reflects the effect of wood fiber incorporation on the water-holding capacity of red clay. In contrast, the saturated water content of red clay increases slightly with the increase in clay content, which may be related to the specific properties of clay adsorption in water. On the other hand, the incorporation of lime will lead to a decrease in the number of pores in the internal structure of red clay, thus reducing its saturated water content. This finding reveals the modification effect of lime on the pore structure of red clay and its effect on water retention capacity.

- After comparing the saturated water content of the three additives, it was found that the porosity of lignin-remolded soil was the highest, followed by clay-remolded soil, and lime-remolded soil was the lowest. The damage analysis showed that the damage factor was negatively correlated with the disintegration resistance. The damage factor of lignin-remolded soil was the largest and the disintegration resistance was the worst. Clay-remolded soil was second; the lime-remolded soil had the smallest damage factor and the best disintegration resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.H.; Gao, Q.F.; Yu, G.T.; Zhou, Q.S.; Cao, S.P. Water Retention and Strength Properties of Red Clay Containing Cracks. Sci. Technol. Eng. 2023, 23, 5278–5284. [Google Scholar]

- Yang, E.J.; Zeng, S.S.; Mo, H.Y.; Yang, C.L.; Chen, C.; Wang, Y.F. Analysis of the Mineral Compositions of Lateritic Clay in Guangxi and their Influence. Adv. Mater. Sci. Eng. 2022, 2022, 4068773. [Google Scholar] [CrossRef]

- Ilyas, A.; Shahid, A. Determination of collapse and consolidation behavior of cohesionless soils. Bull. Eng. Geol. Environ. 2022, 81, 458–475. [Google Scholar]

- Zhang, S.; Xu, Q.; Hu, Z. Effects of rainwater softening on red mudstone of deep-seated landslide, Southwest China. Eng. Geol. 2016, 204, 1–13. [Google Scholar] [CrossRef]

- Fu, J.W.; Yang, J.M.; Guo, H.C.; Zhang, F. Study on rock mechanics response and permeability characteristics of crack grouting under hydraulic-mechanics coupling. GOLD 2023, 44, 12–17. [Google Scholar]

- Jia, D.Q.; Pei, X.J.; Zhang, X.C.; Zhou, L.H. A test study of the microscopic mechanism of modified glutinous rice mortar solidified loess. Hydrogeol. Eng. Geol. 2019, 46, 90–96. [Google Scholar]

- Wu, J.H.; Ren, M. Effect of hydroxypropyl methyl cellulose as soil modifier on solute migration in soil. Trans. Chin. Soc. Agric. Eng. 2019, 35, 141–147. [Google Scholar]

- Wu, J.H.; Tao, W.H.; Wang, H.Y.; Wang, Q.J. Influence of sodium carboxyl methyl cellulose on soil aggregate structure and soil water movement. Trans. Chin. Soc. Agric. Eng. 2015, 31, 117–123. [Google Scholar]

- Feng, R.Y.; Wang, H.J.; Guo, F.; Yang, Y.; Che, L.; Gu, X.H.; Chen, W.L. Effects of Modified Straw Soil Amendment on Soil Structure and Water Characteristics. J. Irrig. Drain. 2015, 34, 44–48+65. [Google Scholar]

- Shang, Y.N.; Hu, F.N.; Zhao, S.W.; Huo, N.; Chang, W.Q. Effects of Cementing Materials on the Formation of Loessial Soil Aggregates. J. Soil Water Conserv. 2017, 31, 204–208+239. [Google Scholar]

- Zhang, Y.; Feng, H.; Wang, Y.K.; Du, J.; Zhao, X.N.; Xu, X.P.; Wang, Y. Preliminary Research on Moisture Characteristic of New Soil Conditioner and its Influences on Seeding Stage of Corn. Water Sav. Irrig. 2008, 5, 6–9. [Google Scholar]

- Zhang, S.; Tang, H.M. Experimental study of disintegration mechanism for unsaturated granite residual soil. Rock Soil Mech. 2013, 34, 1668–1674. [Google Scholar]

- Chen, S.-M.; Yilmaz, E.; Wang, W.; Wang, Y.-M. Curing stress effect on stability, microstructure, matric suction and electrical conductivity of cementitious tailings backfills. Constr. Build. Mater. 2022, 360, 1–10. [Google Scholar] [CrossRef]

- Wang, T.; Hu, B.; Liu, J.; Chen, P.Z. Experimental Study on Shear Strength of a Root-Soil Composite of a Modified Expansive Soil. Soil Eng. Found. 2023, 37, 835–840. [Google Scholar]

- Chen, W.H.; Qu, S.H.; Lin, L.B.; Luo, Q.; Wang, T.F. Ensemble Learning Methods for Shear Strength Prediction of Fly Ash-Amended Soils with Lignin Reinforcement. J. Mater. Civ. Eng. 2023, 35, 22–37. [Google Scholar] [CrossRef]

- Hu, X.Q.; Hong, L.; Xu, G.L.; Yang, X.; Jiang, G.W. Impacts of Fiber Content and Fiber Length on the Strength and Deformation of Fiber Reinforced Soil. Saf. Environ. Eng. 2015, 22, 139–143. [Google Scholar]

- Liu, J.F.; Su, Y.H. Analyses of the Strength Characteristics of Solidified Desert Aeolian Sandy Soil. J. Highw. Transp. Res. Dev. 2017, 11, 32–36. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Soil Test Method. China Planning Press: Beijing, China, 2019.

- SY/T 5163-2018; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by X-ray Diffraction. Petroleum Industry Press: Beijing, China, 2018.

- Zhou, E.Q.; Ju, D.Y.; Cui, L.; Zhang, M.; Zuo, X. Unconfined compressive strength properties of lignin modified silt. J. Jiangsu Univ. (Nat. Sci. Ed.) 2023, 44, 614–620. [Google Scholar]

- Sun, Y.X.; Pang, X.F.; Li, X.Y.; Pang, J.Y.; Su, L. Study on Hydrophilic Modification of Lignin. China For. Prod. Indusfry 2020, 57, 15–18. [Google Scholar]

- Wang, F.C.; Qin, M.Q.; Li, D.; Sun, Q. Experimental Study on Permeability and Disintegration Performance of Carex Root Fiber Soil. J. Shenyang Jianzhu Univ. (Nat. Sci.) 2021, 37, 287–295. [Google Scholar]

- Ye, J.H.; Zhao, Q.L.; Wu, L.; Fu, S.Y.; Ma, K.C.; Xiong, Z.L. Preparation and Hydrophilicity of Lignin/Polyvinyl Chloride (PVC) Membrane. Chem. Ind. For. Prod. 2022, 42, 95–100. [Google Scholar]

- Zhang, X.; Du, D.; Man, T.; Ge, Z.; Huppert, H.E. Particle clogging mechanisms in hyporheic exchange with coupled lattice Boltzmann discrete element simulations. Phys. Fluids 2024, 36, 013312. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Q. Feature and mechanism analysis of dispersive soil disintegration impacted by soil water content, density, and salinity. Eur. J. Soil Sci. 2023, 74, e13353. [Google Scholar] [CrossRef]

- Han, Z.L.; Zhang, L.Q.; Zhou, J.; Wang, S. Effect of clay mineral grain characteristics on mechani-cal behaviours of hydrate-bearing sediments. J. Eng. Geol. 2021, 29, 1733–1743. [Google Scholar]

- Liang, C.Y.; Wu, Y.D.; Liu, J.; Wu, H.J. Influences of arrangement and cementation of soil particles on structure of artificial structural soil. Chin. J. Geotech. Eng. 2022, 44, 2135–2142. [Google Scholar]

- Tang, L.S.; Wang, Y.X.; Sun, Y.L. Test Study on Effect of Free Iron Oxide in Granite Laterite on cementation Characteristics of Laterite. Ind. Constr. 2023, 53, 137–143. [Google Scholar]

- Lu, X.M.; Fen, L.J.; He, N.; Lin, X. Experimental Study on Engineering Characteristics of Cement-Lime-Improving Silt in Eastern Henan Province. Coatings 2022, 12, 501. [Google Scholar] [CrossRef]

- Bian, J.M. Water Stability of Lime-treated Expansive Soil. J. Yangtze River Sci. Res. Inst. 2016, 33, 77–82. [Google Scholar]

- Haas, S.; Ritter, H. Soil improvement with quicklime—Long-time behaviour and carbonation. Road Mater. Pavement Des. 2019, 20, 1941–1951. [Google Scholar] [CrossRef]

- Zhang, X.J.; Liu, P.; Yang, X.Q.; Wang, Y. A Study of the Relationship Between Permeability and Pore Structure of Lime-treated Loess. J. Guangdong Univ. Technol. 2021, 38, 97–103. [Google Scholar]

- Tian, Y.C.; Zhang, H.B.; Wang, Y.L. Study on mechanical properties of carbonation curing fluorogypsum and slaked lime. J. Funct. Mater. 2024, 55, 2133–2141. [Google Scholar]

- Zhao, L.J. Study on Strength and Disintegration Characteristic of Improved Granite Eluvial Soil. Ph.D. Thesis, Hunan University of Science and Technology, Zhuzhou, China, 2015. [Google Scholar]

- Li, S.J.; Tao, S.; Wang, Q.F.; Luo, L.F.; Wang, L.Y.; Wan, M.G.; Liu, Q.L. Effect of clay on microstructure and mechanical properties of red clay. Technol. Innov. Appl. 2023, 13, 45–49+53. [Google Scholar]

- Wang, T.L.; Li, Y.L.; Su, L.J. Types and boundaries of bound water on loess particle surface. Chin. J. Geotech. Eng. 2014, 36, 942–948. [Google Scholar]

- Han, Z.F. Molecular Dynamics Study on the Micromechanical Properties of Clay Minerals. Master’s Thesis, China University of Mining & Technology-Beijing, Beijing, China, 2020. [Google Scholar]

- Wang, L.; Li, X.A.; Zhao, N.; Hong, B. Effect of clay content on physical and mechanical properties of loess soils. Chin. J. Geol. Hazard Control 2018, 29, 133–143. [Google Scholar]

- Wang, Y.J.; Wang, Y.W.; Jin, F.Y.; Ma, T.T. Soil-water Characteristic Curve and Freezing Characteristic Curve of Lime Improved Soil. J. Disaster Prev. Mitig. Eng. 2020, 40, 967–973. [Google Scholar]

- Cheng, Y.L.; Huang, D. Influence of pore structure characteristics on soil-water characteristic curves under different stress states. Chin. J. Eng. 2017, 39, 147–154. [Google Scholar]

- Shao, Y.J.; Shi, B.; Liu, C.; Gu, K.; Tang, C.C. Temperature effect on hydro-physical properties of clayey soils. Chin. J. Geotech. Eng. 2011, 33, 1576–1582. [Google Scholar]

- Wang, C.H.; An, D.; Qu, H.; Han, C.; He, X.H. Influence of the Clay Mineral on Coal Freezing Adhesive Strength of Coal Transportation Equipment. Non-Met. Mines 2017, 40, 33–36. [Google Scholar]

- Li, M.Y. Study of Disintegration and Microstructural Change Patterns under the Action of Water in Soft Rocks of the Xujiahe Formation. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2022. [Google Scholar]

- Zuo, Q.J.; Wu, L.; Luo, T.; Bian, Y.S.; Tan, Y.Z. Macro disintegration characteristics and micro mechanism of slate in the Yaojia tunnel of the Shanghai-Kunming Passenger Dedicated Line. Hydrogeol. Eng. Geol. 2015, 42, 65–69. [Google Scholar]

- Fang, L.; Zhou, H.M.; Zhang, Y.H. Influence of Microcracks on Strength Parameters of Engineering Rock Mass. Chin. J. Rock Mech. Eng. 2011, 30, 2703–2709. [Google Scholar]

- Lu, Y.F.; Hou, K.P.; Sun, H.F.; Sun, W.; Jiang, J. Experimental study on disintegration resistance characteristics of different kinds of schist. J. Saf. Sci. Technol. 2022, 18, 114–120. [Google Scholar]

- Meng, X.X. Basic Experimental Study on the Damage Evolution Rule of Rock Mass under the Action of Water-Rock. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2020. [Google Scholar]

- Li, W.; Li, S.; Wang, H.Q. Experimental study on internal pore structure and energy dissipation of basalt fiber reinforced concrete under stress damage. Compos. Sci. Eng. 2023, 55–62. [Google Scholar] [CrossRef]

- Wu, X.H. Study on Physical and Mechanical Properties and Damage Mechanism of Granite at Different Heating Temperatures after Water-Cooling. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2022. [Google Scholar]

| Specific Gravity | Maximum Dry Density/g·cm3 | Optimum Moisture Content/% | Liquid Limit/% | Plastic Limit/% | Plasticity Index | Proportion/% | ||

|---|---|---|---|---|---|---|---|---|

| Particulate 0.075~2 mm | Powder Particle 0.075~0.005 mm | Clay Particle <0.005 mm | ||||||

| 2.68 | 1.54 | 27.5 | 53.4 | 32.7 | 20.7 | 7.53 | 50.10 | 42.37 |

| Modifier | Disintegration Characteristic | Initial Demise | Soaking Time |

|---|---|---|---|

| Control group | After soaking in water, a large number of bubbles escaped; the early disintegration was slow, the soil fell off in a block form, and the soil collapsed to the later stage. The soil accumulated on the grid, slowly disintegrated, and the water quality was clear. | Rapidly | Less than 20 min |

| Lignin fiber | After soaking, it immediately disintegrated, and the soil properties were loose. There was no obvious crack, and the soil fell in the form of debris. The continuous small-diameter bubbles escaped at a constant speed, the disintegration was complete, and the water quality was turbid. | Rapidly | Less than 13 min |

| Clay | After soaking, large-diameter bubbles escaped. There were obvious cracks and soil blocks scattered. When the disintegration was complete, the water quality was cloudy. | Faster | Less than 25 min |

| Lime | After soaking, a small number of large-diameter bubbles escaped. The cracks were obvious and continued to develop, and the surface collapsed into small-granular soil. Disintegration was slower, and the water quality was clear. | Slower | Less than 60 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Zhou, H.; Wang, X.; Lian, G.; Yang, B. Effect of Modifiers on the Disintegration Characteristics of Red Clay. Sustainability 2024, 16, 4551. https://doi.org/10.3390/su16114551

Liu B, Zhou H, Wang X, Lian G, Yang B. Effect of Modifiers on the Disintegration Characteristics of Red Clay. Sustainability. 2024; 16(11):4551. https://doi.org/10.3390/su16114551

Chicago/Turabian StyleLiu, Baochen, Haofeng Zhou, Xiaobo Wang, Guan Lian, and Bai Yang. 2024. "Effect of Modifiers on the Disintegration Characteristics of Red Clay" Sustainability 16, no. 11: 4551. https://doi.org/10.3390/su16114551