Abstract

The EU prioritizes transitioning to a circular economy, aiming to boost sustainable resource management through policies promoting recycling and reuse, benefiting both the environment and the economy. Many successful case studies demonstrate using various incineration waste by-products (ashes) as substitutes for natural materials, yielding environmental advantages and showcasing sustainable resource management practices. While extensive literature covers ash characterization and applications, the direct links between the properties of the main components, the amorphous phase, and research findings remain elusive. Analysis predominantly centers on microstructural phase development, influencing mechanical, physical, and chemical properties and guiding research interpretations. Existing standards for ash use primarily address coal-derived fly ash, with SIST EN 13282-2 allowing alternative sources like circulating fluidized bed and paper sludge incineration residues. Yet, beyond this standard, no regulations mandate using different ash types. Nonetheless, the applicability of ashes for the geotechnical composite materials has already been confirmed in the field since numerous geotechnical projects have been carried out in Slovenia. Such composites have been recognized as beneficial practices, and the majority of them also possess legal permission for usage according to the Slovenian Technical Approvals. Given the varying value and complexity of ashes, detailed characterization before use is crucial. Assessing the recycling potential of different ashes requires a precise definition of basic properties such as microstructure, minerals, and chemical composition. Emphasis should be placed on characterizing the hydraulic properties and gaining detailed insights into the amorphous phase, ensuring informed decision-making regarding their recycling processes.

1. Introduction

The economy of the European Union is transitioning from a linear to a circular model, aiming to maximize the lifecycle of materials, products, and resources within the economy, and to minimize the generation of waste. This is supported by targeted policies and strategies—the newest issued in March 2020—with aims at accelerating the transformational changes required by the European Green Deal. The circular economy paradigm requests the efficient and responsible use and management of raw materials and favors the use of alternative materials instead of virgin materials [1,2,3]. The most promising alternative materials are different types of recycled waste, especially in light of the long-term prediction that the annual waste generation globally is going to increase 70% by 2050. It is estimated that around 600 million tonnes of waste-based materials are available annually to be pumped back into productive use in the economy. This strategy also includes guidelines on how to turn waste into resources by improving and increasing recycling based on the promotion of industrial symbiosis [2,3]. Industrial landfills play an important role in the transition to sustainable, low-carbon, competitive, and resource-efficient societies. The ideal sector for the recycling of industrial by-products is the construction industry. In the construction sector, ashes can offer two synergistic effects: efficient utilization of large material quantities and simultaneous permanent immobilization of harmful elements—in the case of earthworks, achieved through the immobilization process leveraging the favorable properties of specific ashes. Anthropogenic construction products were introduced to the field of earthworks in April 2019 through the SIST EN 16907-2 [4] standard. In accordance with this standard, natural materials processed mechanically, manufactured materials (including secondary manufactured materials), and recycled materials can be implemented into construction composites.

Fly ashes, bottom ashes, cyclone, and bag filter ashes represent the by-products generated by air pollution control equipment during high-temperature processes in industry and energetics. In addition to the classification of ashes according to the type of process they are formed in, they can also be classified based on the material used as fuel (i.e., coal ash, biomass ash, agricultural ash, municipal waste incineration ash, and ash from the co-combustion of different fuels). With the gradual reduction of the use of fossil fuels (decision to abandon coal use), the quantity of ash generated during coal combustion decreases [5], while the quantities of ashes from co-combustion and biomass incineration increase. The Integrated National Energy and Climate Plan (NEPN) of the Republic of Slovenia [5] forecasts a shift to at least 27% renewable energy by 2030. A large part of generated ash is disposed of, while only a small part is used in recycling processes.

Ash is a complex material that exhibits considerable variability in compositions [6]. Each type of ash has its own characteristics. Not all thermal processes are similar, nor do all incineration plants share the same working practices, which give rise to variations in the composition of ash at different incineration facilities and even at the same plant. Furthermore, the type and source of incineration material, local conditions, batch synthesis, and collection mechanisms employed also affect the composition of the ash produced [6]. Another aspect is the physical or practical procedure of dealing with the logistics of ash. Ashes from different processes are sometimes mixed together before being transported to the ash yard. Last but not least is the question of the handling of the ash at the ash yard. Water is often used to avoid the formation of dust. The exposure time of ash stockpiles to the atmosphere must also be taken into account. This means that every different ash must be considered as a case study, as all of these factors lead to fluctuations in performance and ineffective recycling processes [7].

The main aim of the review is to emphasize the importance of the detailed characterization of incineration waste by-products (coal ash, biomass ash, ash from the co-combustion of different fuels) before their recycling in various applications, particularly in the context of transitioning to a circular economy in the EU. This involves understanding the properties of the main component, the amorphous phase, and its direct links to research findings. The research highlights the need for the precise definition of basic properties such as microstructure, mineral, and chemical composition to assess the recycling potential of ash and to make informed decisions regarding their recycling in sustainable resource management practices.

2. Recycling of Ashes and EU Standards

The results of numerous studies on the characterization of the ashes and their potential applications are described in the literature, but the direct links between the properties of the ashes’ main component (glassy phase) and the reported results are not established. Interpretations of the reported results are based mainly on the analysis of the development of phases at the microstructural level and their influence on mechanical, physical, and chemical properties. The majority of the research work reports the usage of ashes in the cement industry (ash used as a cement supplement), in concrete as a partial replacement for cement, in the production of lightweight aggregates, as a component of backfill materials, as a raw material in the panel board industry, in earthworks for soil treatment, etc. [8,9,10,11,12,13,14,15].

Standardization is crucial across diverse arenas, covering the maintenance of industrial by-product management quality, the enhancement of both the caliber and volume of recycling initiatives, and the assurance of enduring characteristics in materials containing industrial by-products. European standards defining the use of ash refer to concrete (SIST EN 450-1) [16], cement (SIST EN 197-1) [17], bricks (SIST EN 771-3) [18] + A1 (SIST EN 771-1 + A1) [19], hydraulic binders for road structures (SIST EN 13282-1, SIST EN 13282-2, SIST EN 13282-3) [20,21,22], roads (SIST EN 14227-3, SIST EN 14227-4, SIST EN 14227-14, SIST EN 14227-15) [23,24,25,26], and earthworks (SIST EN 16907-4) [27]. Requirements, criteria, and test procedures (for e.g., hydraulically bound aggregates) are in addition to the SIST EN 14227-3 [23] standard specified by the Slovenian technical specification TSPI—PGV.06.325 [28], but specifications differ between each other. While the Technical Specification for Transport Infrastructure (TSPI) [28] primarily defines cement as a hydraulic binder (though it also mentions other hydraulic binders without detailed definitions), SIST EN 14227-3 [23] specifies requirements and procedures for stabilization with ash. The existing standards covering the use of ash apply only to fly ash produced from coal combustion. The exception is SIST EN 13282-2 [20], which, in addition to the fly ash from coal combustion, allows the usage of ‘circulating fluidized bed’ ash and ash from incineration of paper sludge as the main component. No other standard prescribes the usage of any different type of ash. However, examples of good practices of the usage of ashes in earthworks, for which Slovenian technical approvals have been issued, offer added value to the usage of different ashes. The fact is that the high content of lime (free CaO) in ash is not desirable for its use in cement composites. Exceeding the prescribed limits of CaO content leads to instability (soundness) in the resulting cement composite. However, if the ash containing lime and/or portlandite is used for earthworks or hydraulically bound mixtures, this characteristic is positive (ash in a function of an alternative binder). On the basis of those facts, specific types of ash can also be successfully recycled as efficient immobilization additives of potentially toxic elements, which also enhances the geotechnical characteristics of remediated materials to be used for earthworks. The mechanisms of ion exchange, adsorption, encapsulation, the formation of solid solutions in minerals, and control of Eh/pH conditions are involved in this process [9].

An illustrative case of effective practice is showcased by the combination of paper mill ash and contaminated soil utilized as in situ backfill material for remediating polluted soil at the Old Zinc-works site in Celje, Slovenia. Drawing from this exemplary case underscores the necessity for deliberately preparing building composites rather than solely relying on empirical data. This emphasizes the need for deeper insights into the characteristics and the development of tailored procedures.

3. (Latent Hydraulic) Reactivity of Ashes

Ash is a fine-grained material composed of various different components. The ashes contain a variable proportion of the amorphous (vitreous) phase resulting from high temperatures during the incineration process. In addition to amorphous and non-hydraulic phases, hydraulically active phases may also be present in the ash in small quantities, such as mineral phases from the melilite group (akermanite, gehlenite), brownmillerite, etc. [14].

Hydraulic material/phases achieve adhesion and solidification through a chemical reaction with water, with cement being the most widely used type. Given the urgent imperative to reduce the global carbon footprint, integrating supplementary cementing materials with latent hydraulic activity holds significant importance [29].

Some ashes are defined as a latent hydraulic material or so-called pozzolan, which does not possess (pure) hydraulic properties, but they need an activator (such as CaO and/or Ca (OH)2) to react with water and to form hydration products, identical to those formed during the cement hydration [29,30]. The degree of latent hydraulic activity of individual ashes varies. On the other hand, some ashes are defined as a hydraulically active material that sets in the presence of water on account of the formation of crystalline products (those ashes containing CaO and/or Ca(OH)2 as their primary component; water enters directly to the ash solidification reaction), and they do not demand an activator for the reaction. Some ashes, however, are found to be hydraulically inert (the reaction with water does not occur even in the presence of activators) [31,32].

The component of the ashes that reacts in the presence of an ‘activator’ is the amorphous phase [31,33]. The amorphous phase in ash forms from a subcooled melt that has not crystallized. The form of a substance in a solid state affects its physical, chemical, and mechanical properties, such as solubility, stability, etc. In contrast to the crystalline phases, the amorphous phases do not possess a periodically arranged internal structure as the strict structural order is limited only to small areas—the local surroundings of individual atoms. Due to the high structural disorder, the amorphous solids possess higher enthalpy, entropy, and Gibbs free energy [34]. On account of its lower thermodynamic stability, it shows a crystallization tendency. Molecules of amorphous solids have a tendency to achieve equilibrium, which is a very slow process. Consequently, crystalline solids have lower surface energy than the amorphous form of the same solid (the amorphous form of a solid is the form of the substance with the highest energy). The amorphous form, with its disordered structure and higher energy, tends to be more reactive and dissolve more readily than its crystalline counterpart [34,35]. When the amorphous phase is exposed to higher pH values in the water–activator system (lime/portlandite), it starts to dissociate (over time) [31]. When the solution is saturated, equilibrium is reached in the pore solution, and the crystallization of the phases characteristic of cement hydration (calcium silicate hydrates (C-S-H) and calcium aluminate hydrates (C-A-H)) occurs. The C-S-H phase is the principal binding phase (primary factor of the development of mechanical strength) in cement composites. The C-A-H phases (primary ones) also contribute to the increase in the strength development of the composites by filling the pores during their growth [29,31,33]. In addition to the increase in the strength of the composites in such systems, the formation of those phases is also extremely important in the case where the ash (or the component to which the ash is added) is not inert. Especially for those industrial residues that are not environmentally inert, recycling in composites in which C-S-H and/or C-A-H phases are formed simultaneously represents an effective remediation process, which fixes the pollutants in the composite matrix (immobilizes them) [9].

In all systems, ashes interact with the environment with their grain surfaces. The presence of various impurities, grain size distribution, particle shape, polymorphism, degree of crystallinity, and degree of (pre) hydration are very important parameters. As certain impurities are surface active, they change the properties of the grains. This is because they can be arranged in higher or lower concentrations on the surface than in the core of the (amorphous phases) grains, which is reflected in differences in the behavior of presumed identical ashes or ash components. An important phenomenon in crystallography is that the same chemical solid compound exhibits different amorphous modifications, which are reflected in different properties due to the bonding and structural characteristics of the same solid compound. Similarly to the case of crystalline solids (polymorphism), it is also known for amorphous solids (polyamorphism). Polyamorphism is the ability of an amorphous solid to exist in several different amorphous modifications [35].

Defining the degree of ash reactivity in correlation with the in-depth characterization of their amorphous phase is feasible only on the basis of the use of various complementary methods [36,37].

4. Defining the Degree of Ash Reactivity

Testing methods aimed at assessing or predicting the reactivity of industrial waste by-products is a significant area of research [38]. Traditionally, the approach involves evaluating the compressive strength development when these by-products are blended with Portland cement at the mortar level. However, chemical tests have emerged as an alternative to compressive strength evaluations.

One category of chemical tests involves measuring the rate and extent of reaction of the industrial by-product when combined with portlandite and water. An early method measured the decrease in lime (Ca) concentration in a slaked lime (Ca(OH)2) suspension as an indicator of reactivity. This method aimed to correlate lime consumption by industrial by-products with compressive strength. However, no consistent correlation was found between test results and compressive strength across various industrial by-products. While these tests can generally differentiate between active and inert materials, they struggle to accurately classify different active materials [38]. A modified version of this test is utilized in France to evaluate the reactivity of calcined clays [39]. Frattini introduced the “pozzolanicity” test, comparing lime concentrations in a suspension of an industrial by-product and Portland cement to those in a Ca(OH)2-saturated solution of the same alkalinity (SIST EN 196-5) [40]. However, the results of this test are only used qualitatively.

One limitation of using lime consumption as a measure of reactivity is that not all industrial by-products require the same amount of lime to react. For example, CaO-rich slags or Class C fly ash consume less lime compared to Class F fly ashes for the same degree of reaction. Similarly, Class F fly ash may consume less lime than Al2O3-rich metakaolin. Therefore, measuring the degree of reaction of an industrial by-product would be preferable. However, methods for measuring the active phase content are challenging and difficult to define for individual different materials.

In the second category of chemical tests, the reactivity of industrial by-products is evaluated based on their bulk chemical composition. Previous studies have shown that even though fly ash may have similar bulk chemical compositions, their performance in concrete can vary significantly [7]. Bulk chemical composition can be meaningful only for one-phase—amorphous materials such as blast-furnace slag [7,38]. The reactivity of ashes depends mainly on the characteristics of the amorphous phase [31,37,41]. It was suggested that methods be used to measure the active phase content in ashes.

Alongside the traditional dissolution method used to determine the reactive proportions of SiO2 and Al2O3 (SIST EN 196-2) [42], advanced techniques for analyzing amorphous phases have gained prominence. These techniques include XRD, SEM/EDS, multispectral image analysis, X-ray photoelectron spectroscopy (XPS), FT-IR, MAS-NMR, acidolysis, and calorimetric analysis [13,37,38]. The calculation procedures were proposed to quantify the reaction degree of coal fly ash in blended cement systems [43]. There is ongoing progress in acquiring quantitative insights into reactive structures and their correlation with reactivity, with a focus on studying detailed reactive amorphous chemistries [14,37].

Quantitative XRD analysis using the Rietveld refinement method (QXRD) represents a methodology that is increasingly recognized as effective and accurate for the determination of the amount of amorphous phase in ashes, regardless of the complex phase composition of ashes. Because of the non-crystalline nature of amorphous phases, XRD does not reflect the diffraction peak positions recorded at the detected angle. QXRD requires additional refinement steps that take into account a broader group of parameters, which can be implemented only on the basis of competent in-depth knowledge in the field of crystallography and solid-state chemistry [7]. For characterization of the type and polyamorphism of amorphous phases, XRD radiation sources with a short wavelength (such as Mo and Ag XRD tube or synchrotron) should be adopted.

Comprehensive electron microscopy with energy dispersion spectroscopy (SEM/EDS) analysis is described as somewhat time-consuming but provides information on the chemical composition of individual (morphologically different) components. The results of the XPS analysis reveal the qualitative and quantitative elemental composition of the surfaces of the grains, the energy of the chemical bond, and the oxidation states of the elements on the surfaces. The results provide the identification of the surface of the amorphous phase grains. Based on this data, whether the surface of the grain acts as an inhibitor or accelerator of reactions can be defined. In 2020, a standard for determining the reactivity of supplementary cementitious materials (ASTM C-1897) [44] was issued. It defines the application of calorimetric analysis and an analysis of the amount of bound water. The results of the methodology covered by this standard show an excellent correlation with the results of the development of strength.

5. Case/Preliminary Studies from Slovenia

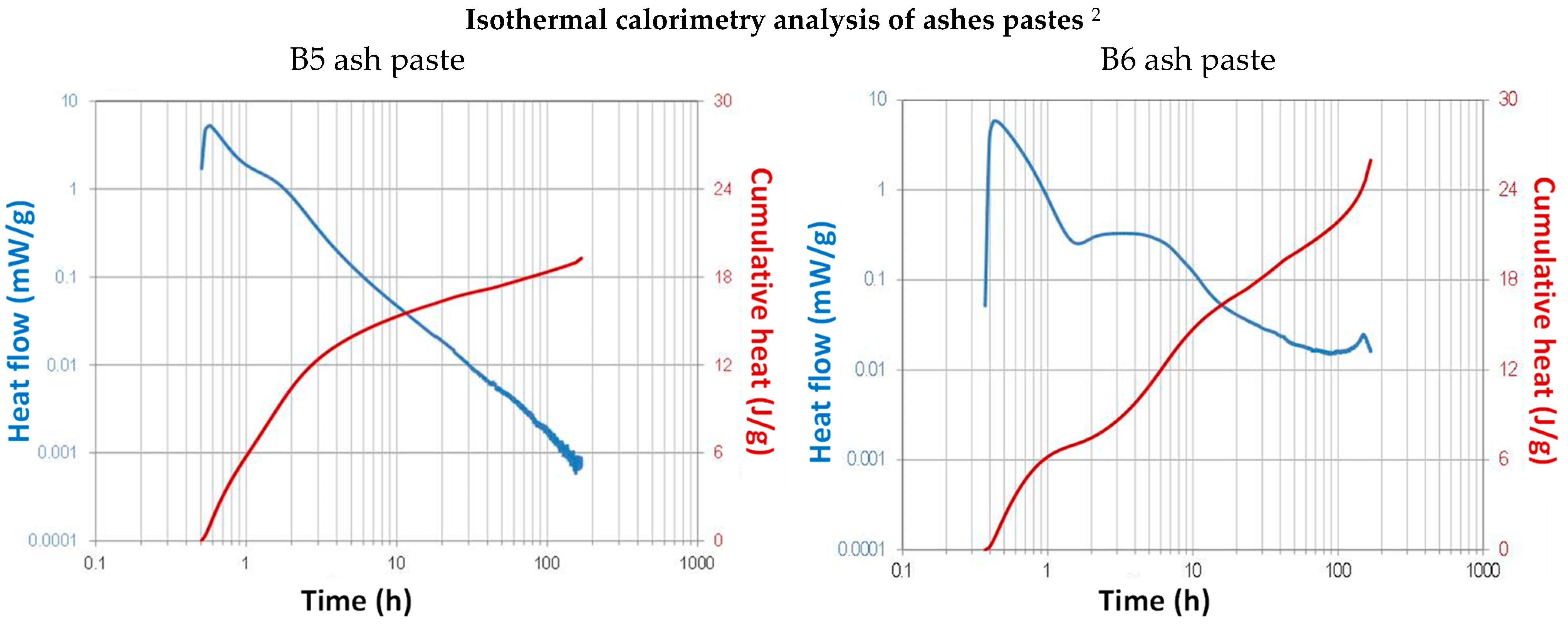

The preliminary results of analyses of the hydraulic activity of eight ash samples from five different thermal processes [45,46,47] confirmed the literature findings. The chemical and mineralogical analyses showed comparable results according to the type of fuel used in the incineration process for each ash, while their mechanical and physical properties (hydraulic activity index and porosity of composites) varied to a greater extent within each group, especially at longer time intervals [32,45]. These results underscore the importance of detailed phase characterization with an emphasis on defining the compositional and structural properties of the amorphous phase. The time interval of exposure to the atmospheric conditions is also an important factor influencing the characteristics of ashes [46,47]. The next study was conducted on two ash types resulting from the same thermal process during coal combustion (labeled B5 and B6). Based on the results of physical, chemical, and mineralogical (Table 1) investigations, the differences between both of the investigated ashes could not be revealed. The differences reflected in the mechano–physical characteristics of both ash pastes (a mixture of ash with water) could only be detected by measuring the heat release (Figure 1) during their hydration (calorimetric analysis).

Table 1.

Results of QXRD analysis of two ash samples from the same thermal process.

Figure 1.

Heat flow and cumulative amount of heat released in the first 7 days for samples of ash composites B5 and B6. 2 The rate of heat production of ash pastes was continuously measured in a TAM Air isothermal calorimeter (TA Instruments, New Castle, DE, USA).

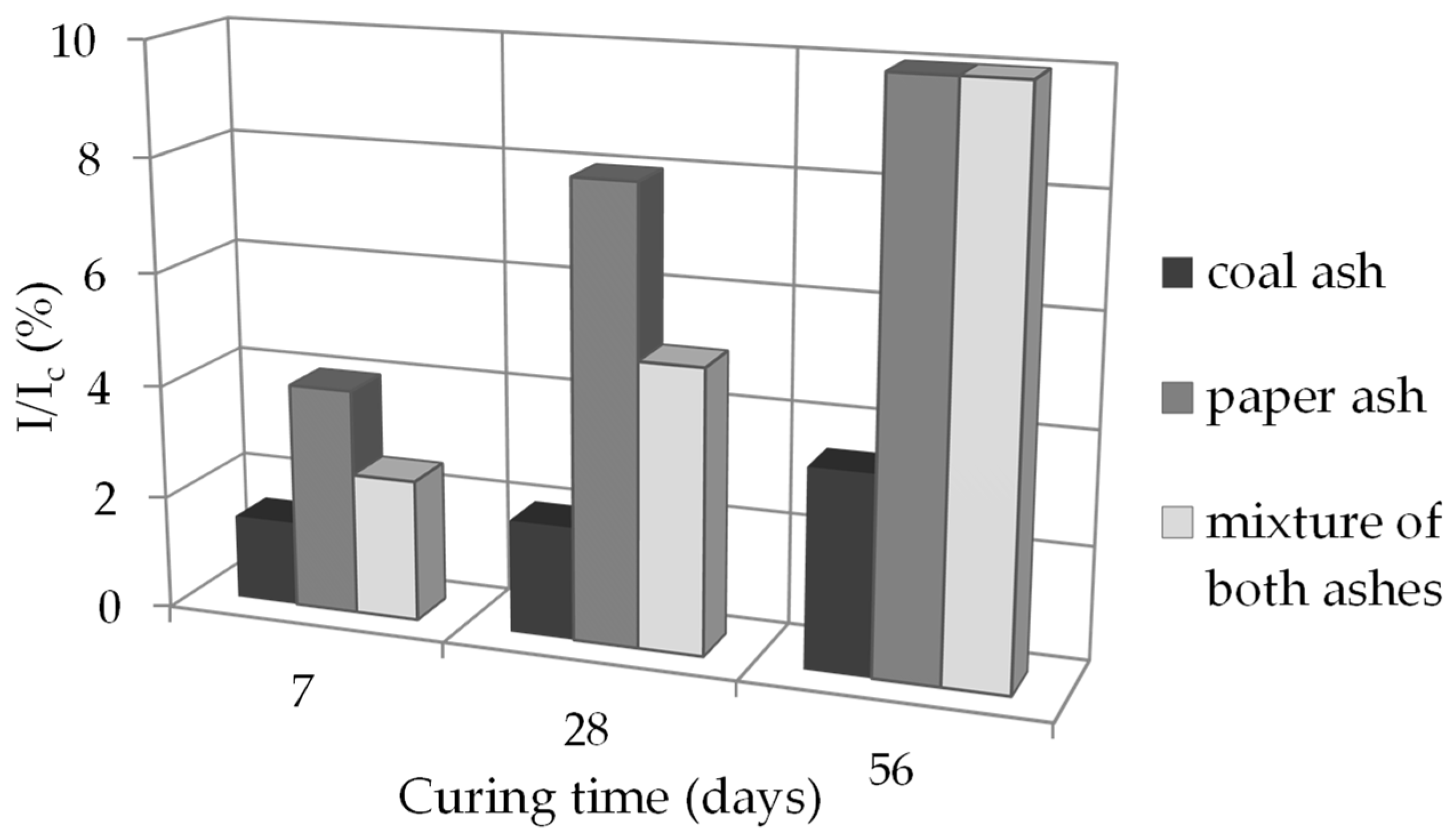

Lime and cement have long been the most commonly used additives for geotechnical composite preparation and waste immobilization. Some of the ashes have similar binding properties as lime and/or cement. The effectiveness of replacing the lime/cement with appropriate ash was confirmed by research work in which we used ash from the incineration of paper sludge for the remediation of contaminated soil [9] and good practices of the usage of paper ash for the environmentally acceptable composites from different non-hazardous and hazardous waste materials with the required mechanical properties [8,46]. Investigations of different ashes have shown that the reactivity of less active ashes can be increased by adding another suitable type of ash to the system. Figure 2 shows the quantity of hydration products formed during the hydration of less reactive ash (coal ash), more reactive ash (paper ash), and a combination of both. The amount of hydration products formed during the hydration over time confirms the reactivation of less reactive ash by blending it with a more reactive one.

Figure 2.

The quantity of hydration products formed at different time intervals during the hydration of two different ashes and their blend (QXRD results of C-A-H phases formed in ashes pastes).

The results further confirmed the need for a systematic analysis of all parameters crucial to the identification of the hydraulic properties of the ashes, with emphasis on the characterization of the amorphous phase. Current research has shown the need to gain additional basic knowledge regarding the characteristics of the amorphous phase for the purpose of designing precise formulations of composites in which ashes will be used. Such knowledge would enable the prediction of (long-term) characteristics of ash composites, which would not be based solely on the use of empirically determined amounts of ash needed on a case-by-case basis but on the carefully tailored mixing of various residues.

6. Conclusions

A key feature of ashes is their (latent) hydraulic reactivity, which mainly accounts for the amorphous phase in their complex composition.

The results of case studies from Slovenia shows the following:

- The reactivity of ashes cannot be determined solely on the basis of their overall chemical and phase composition;

- Analyses of ashes with very similar chemical and mineral compositions showed large differences in the properties/behavior of the composites in which they were incorporated.

The literature data involving the amorphous phase studies of specific ashes highlights the specificity of such analyses, as they are (due to the presence of several types of amorphous phases in single ash), on the one hand, very complex (and time-consuming) and, on the other hand, they require specific analytical equipment (XRD sources with short wavelengths, synchrotron) together with the in-depth competent knowledge. Due to the nature of the amorphous phase, additional systematic investigations of ashes are crucial for their characterization, which will bring new knowledge into the field of hydraulic activity analysis, possible levels of hydration, and thus define useful potentials and increase ash recycling potential in the construction sector. Recycling is recognized as one of the tools for improving material efficiency in all sectors, which is a key measure for the transition to a climate-neutral society.

Based on the known good practices of the usage of different ashes, the aim of future work is to answer the question of how to optimize the type and amount of ash, as well as a more precise definition of relationships in multi-component systems for different construction purposes. This will allow the improvement and spread of the use of ash, which presents a social and applicative advantage for the research field.

Funding

This work was financially supported by the Slovenian Research and Innovation Agency (ARIS): ARIS Program Group P2-027 and ARIS Project ARRS J1-4413.

Acknowledgments

Special acknowledgment to Ana Mladenovič and Primož Oprčkal for their expertise and data contribution, to Mateja Štefančič for performing isothermal calorimetry analysis, and to Primož Pavšič for his comments on the manuscript.

Conflicts of Interest

The author declares no conflict of interest.

References

- European Commission. The Raw Materials Initiative—Meeting Our Critical Needs for Growth and Jobs in Europe; 699 Final; COM: Brussels, Belgium, 2008. [Google Scholar]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; 614 Final; COM: Brussels, Belgium, 2015. [Google Scholar]

- European Commission. Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; 474 Final; COM: Brussels, Belgium, 2020. [Google Scholar]

- SIST EN 16907-2; Zemeljska Dela—2. Del: Klasifikacija Materialov. European Committee for Standardization: Brussels, Belgium, 2019.

- Government of the Republic of Slovenia. Celoviti Nacionalni Energetski in Podnebni Načrt Republike Slovenije(NEPN); no. 35400-18/2019/22; Government of Slovenia: Ljubljana, Slovenia, 2020.

- Singh, G.B.; Subramaniam, K.V. Quantitative XRD study of amorphous phase in alkali activated low calcium siliceous fly ash. Constr. Build. Mater. 2016, 124, 139–147. [Google Scholar] [CrossRef]

- Zhao, P.; Liu, X.; De La Torre, A.G.; Lu, L.; Sobolev, K. Assessment of the quantitative accuracy of Rietveld/XRD analysis of crystalline and amorphous phases in fly ash. Anal. Methods 2017, 9, 2415–2424. [Google Scholar] [CrossRef]

- Bizjak, K.F.; Likar, B.; Mladenovič, A.; Zalar Serjun, V. Valorized deinking paper residue as fill material for geotechnical structures. Sci. Rep. 2021, 11, 22363. [Google Scholar] [CrossRef] [PubMed]

- Oprčkal, P.; Mladenovič, A.; Zupančič, N.; Ščančar, J.; Milačič, R.; Zalar Serjun, V. Remediation of contaminated soil by red mud and paper ash. J. Clean. Prod. 2020, 256, 120440. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ.-Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Aboustait, M.; Kim, T.; Ley, M.T.; Davis, J.M. Physical and chemical characteristics of fly ash using automated scanning electron microscopy. Constr. Build. Mater. 2016, 106, 1–10. [Google Scholar] [CrossRef]

- Wei, G.; Dong, B.; Fang, G.; Wang, Y. Understanding reactive amorphous phases of fly ash through the acidolysis. Cem. Concr. Compos. 2023, 140, 105102. [Google Scholar] [CrossRef]

- Ding, X.; Du, H.; Wu, E.; Yi, P.; Li, Y.; Luo, Y.; Liu, W. Investigating the Hydration, Mechanical Properties, and Pozzolanic Activity of Cement Paste Containing Co-Combustion Fly Ash. Buildings 2024, 14, 1305. [Google Scholar] [CrossRef]

- SIST EN 450-1; Elektrofiltrski Pepel—1. Del: Definicije, Specifikacije in Merila Skladnosti in EN 450-2 Elektrofiltrski Pepel—2. del: Vrednotenje Skladnosti. European Committee for Standardization: Brussels, Belgium, 2012.

- SIST EN 197-1; Cement—1. Del: Sestava, Zahteve in Merila Skladnosti za Običajne Cemente. European Committee for Standardization: Brussels, Belgium, 2011.

- SIST EN 771-3; A1 (2015): Specifikacija za Zidake—3. Del: Betonski Zidaki (Kompaktni in Lahki Agregati). European Committee for Standardization: Brussels, Belgium, 2015.

- SIST EN 771-1; A1 (2015): Specifikacija za Zidake—1. Del: Opečni Zidaki. European Committee for Standardization: Brussels, Belgium, 2015.

- SIST EN 13282-2; Hidravlična Veziva za Ceste—2. Del: Hidravlična Veziva za Ceste, ki se Normalno Strjujejo—Sestava, Zahteve in Merila Skladnosti. European Committee for Standardization: Brussels, Belgium, 2015.

- SIST EN 13282-1; Hidravlična Veziva za Ceste—1. Del: Hidravlična Veziva za Ceste, ki se Hitro Strjujejo—Sestava, Zahteve in Merila Skladnosti. European Committee for Standardization: Brussels, Belgium, 2013.

- SIST EN 13282-3; Hidravlična Veziva za Ceste—3. del: Ovrednotenje Skladnosti. European Committee for Standardization: Brussels, Belgium, 2015.

- SIST EN 14227-3; Hidravlično Vezane Zmesi—Specifikacije—3. Del: Z Elektrofiltrskim Pepelom Vezane Zmesi. European Committee for Standardization: Brussels, Belgium, 2013.

- SIST EN 14227-4; Hidravlično Vezane Zmesi—Specifikacije—4. Del: Elektrofiltrski Pepel za Hidravlično Vezane Zmesi. European Committee for Standardization: Brussels, Belgium, 2013.

- SIST EN 14227-14; Hidravlično Vezane Zmesi—Specifikacije—14. Del: Izboljšanje Zemljin z Letečim Pepelom. European Committee for Standardization: Brussels, Belgium, 2006.

- SIST EN 14227-15; Hidravlično Vezane Zmesi—Specifikacije—15. Del: Stabiliziranje Zemljin s Hidravličnimi Vezivi. European Committee for Standardization: Brussels, Belgium, 2016.

- SIST EN 16907-4; Zemeljska Dela—4. Del: Tretiranje Zemljin z Apnom in/ali Hidravličnimi Vezivi. European Committee for Standardization: Brussels, Belgium, 2019.

- TSPI–PGV.06.325; Slovenian Technical Specification for Transport Infrastructure. Zgornji Ustroj Cest. Stabilizirane Nosilne Plasti Voziščne Konstrukcije Izvedene po hladnem Postopku. RS MZI, Slovenian Ministry of Infrastructure: Ljubljana, Slovenia, 2023.

- Justnes, H. Influence of SCMs on hydration and durability of blended cements: Chemical and physical principles. J. Chin. Ceram. Soc. 2015, 43, 1359–1371. [Google Scholar] [CrossRef]

- Win, T.T.; Prasittisopin, L.; Jongvivatsakul, P.; Likitlersuang, S. Investigating the synergistic effect of graphene nanoplatelets and fly ash on the mechanical properties and microstructure of calcium aluminate cement composites. J. Build. Eng. 2023, 78, 107710. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Zalar Serjun, V. (Latentno) hidravlična aktivnost različnih pepelov. In Proceedings of the Treatises, Reports: 26. Posvetovanje Slovenskih Geologov = 26th Meeting of Slovenian Geologists, Ljubljana, Slovenia, 1 December 2023; Rožič, B., Razprave, P., Eds.; Str. 210–211, ilustr. Geološki zbornik, 26/1; Univerza v Ljubljani, Naravoslovnotehniška Fakulteta, Oddelek za Geologijo: Ljubljana, Slovenia, 2023; ISSN 0352-3802. [Google Scholar]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Raasch, D. Magneto-optic Recording Materials: Chemical Stability and Life Time. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 5061–5063. [Google Scholar] [CrossRef]

- Shakespeare, W. Chapter 3—The Glass Transition Phenomenon. In Structural Chemistry of Glasses; Rao, K.J., Ed.; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2002; pp. 77–135. [Google Scholar] [CrossRef]

- Chancey, R.T.; Stutzman, P.; Juenger, M.C.; Fowler, D.W. Comprehensive phase characterization of crystalline and amorphous phases of a Class F fly ash. Cem. Concr. Res. 2010, 40, 146–156. [Google Scholar] [CrossRef]

- Wei, G.; Dong, B.; Hong, S.; Fang, G.; Xing, F.; Wang, Y. Deep insight into reactive chemical structures of Class F fly ash. Cem. Concr. Compos. 2023, 142, 105195. [Google Scholar] [CrossRef]

- Snellings, R.; Li, X.; Avet, F.; Scrivener, K. A Rapid, Robust, and Relevant (R3) Reactivity Test for Supplementary Cementitious Materials. ACI Mater. J. 2019, 116, 155–162. [Google Scholar] [CrossRef]

- NF P18-513; Addition for Concrete—Metakaolin—Specifications and Conformity Criteria. Association Française de Normalisation: La Plaine Saint-Denis, France, 2012.

- SIST EN 196-5; Metode Preskušanja Cementa—5. Del: Določanje Pucolanske Aktivnosti za Pucolanske Cemente. European Committee for Standardization: Brussels, Belgium, 2011.

- Aughenbaugh, K.L.; Stutzman, P.; Juenger, M.C.G. Identifying Glass Compositions in Fly Ash. Front. Mater. 2016, 3, 10. [Google Scholar] [CrossRef]

- SIST EN 196-2; Metode Preskušanja Cementa—2. Del: Kemijska Analiza Cementa. European Committee for Standardization: Brussels, Belgium, 2013.

- Win, T.T.; Wattanapornprom, R.; Prasittisopin, L.; Pansuk, W.; Pheinsusom, P. Exploring ASEAN Fly Ash for Enhancing Cement Hydration and Service Life Prediction of Portland Cement Mortar. Eng. J. 2023, 27, 1–13. [Google Scholar] [CrossRef]

- ASTM C1897; Standard Test Methods for Measuring the Reactivity of Supplementary Cementitious Materials by Isothermal Calorimetry and Bound Water Measurements. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Zalar Serjun, V.; Mladenovič, A.; Mauko Pranjić, A. Mineraloška karakterizacija pepelov iz industrijskih in termičnih procesov ter njihovih hidratacijskih produktov. In Proceedings of the Treatises, Reports. 23rd Meeting of Slovenian Geologists, Ljubljana, Slovenia, Marec 2017; Rožič, B., Razprave, P., Eds.; Str. 190–191. Geološki zbornik; Univerza v Ljubljani, Naravoslovnotehniška Fakulteta, Oddelek za Geologijo: Ljubljana, Slovenia, 2017. [Google Scholar]

- Zalar Serjun, V.; Mladenovič, A.; Oprčkal, P.; Čretnik, J. Paper ash as a raw material for the construction sector = Papirni pepeo kao sirovina za građevinski sektor. In Proceedings of the 14. Međunarodna Naučna Konferencija iNDiS 2018, Novi Sad, Srbija, 21–23. November 2018. = [14th] International Scientific Conference [iNDiS], with Subconference “Eco build”, Novi Sad, Serbia, 21–23 November 2018; Radonjanin, V., Folić, R., Eds.; Str. 1209–1220; Fakultet Tehničkih Nauka, Departman za Građevinarstvo i Geodeziju: Novi Sad, Serbia, 2018. [Google Scholar]

- Zalar Serjun, V.; Mladenovič, A. Characterization of mineral phases formed during of different recycled materials. In Book of Abstracts [and] Programme. Twenty-Fifth Slovenian-Croatian Crystallographic Meeting, 14–18 June 2017; Pevec, A., Počkaj, M., Eds.; Faculty of Chemistry and Chemical Technology, University of Ljubljana: Ljubljana, Slovenia, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).