Barriers and Enablers for Green Concrete Adoption: A Scientometric Aided Literature Review Approach

Abstract

:1. Introduction

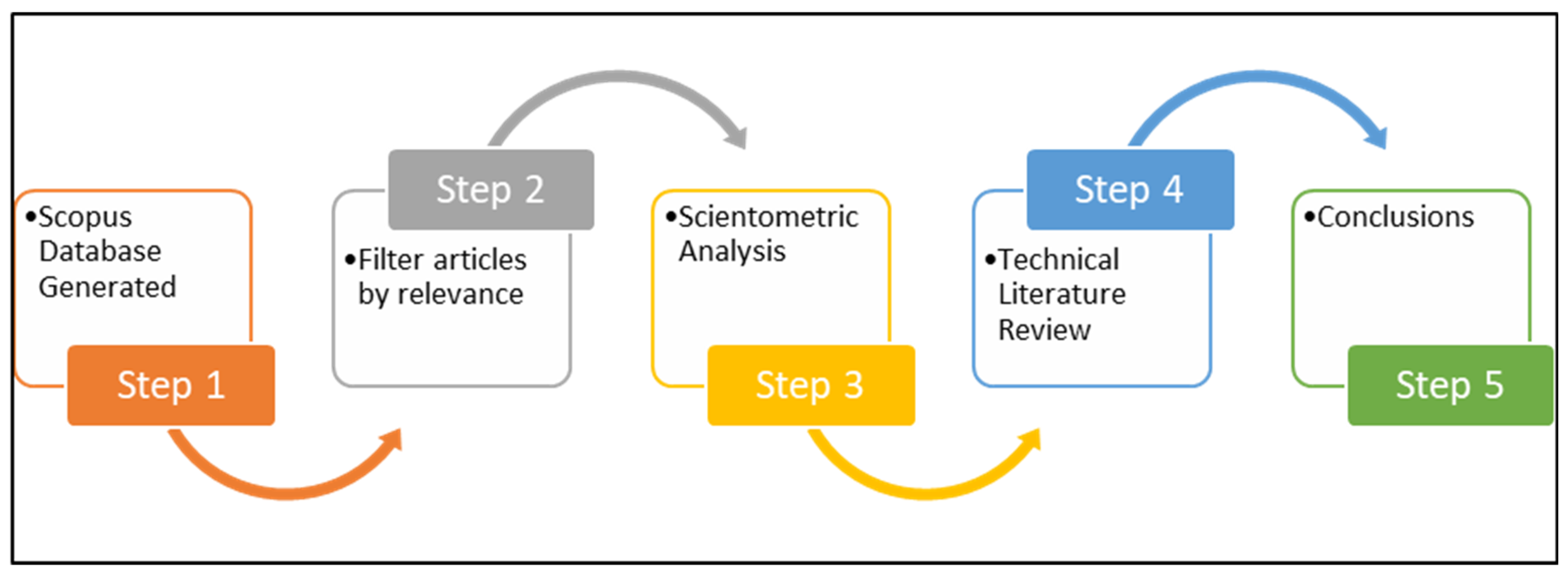

2. Methodology

2.1. Scientometric Analysis

Main Information

2.2. Annual Scientific Production

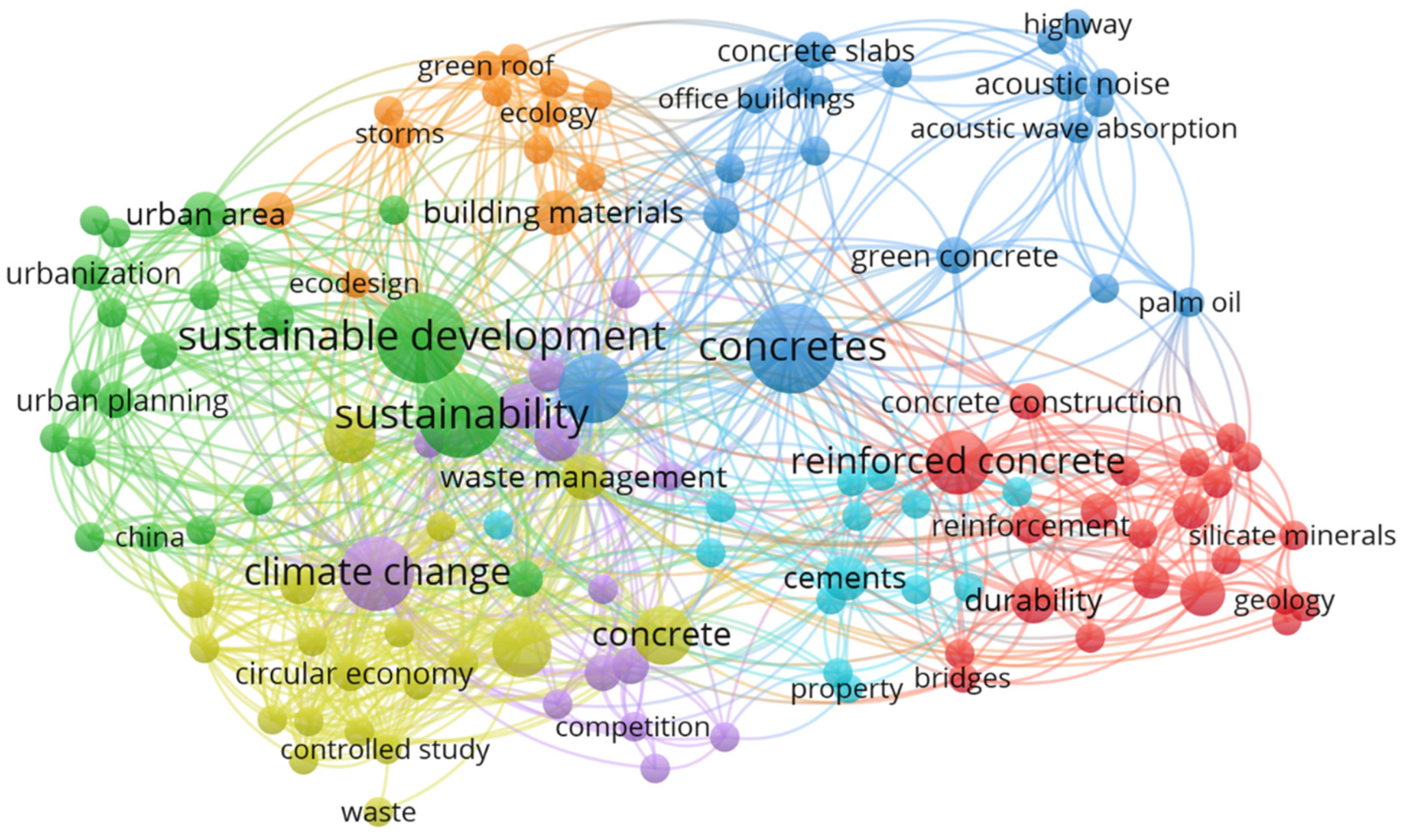

2.3. Most Frequent Words

3. Results and Discussions

3.1. Barriers and Their Analysis

3.1.1. Barrier’s Explanation

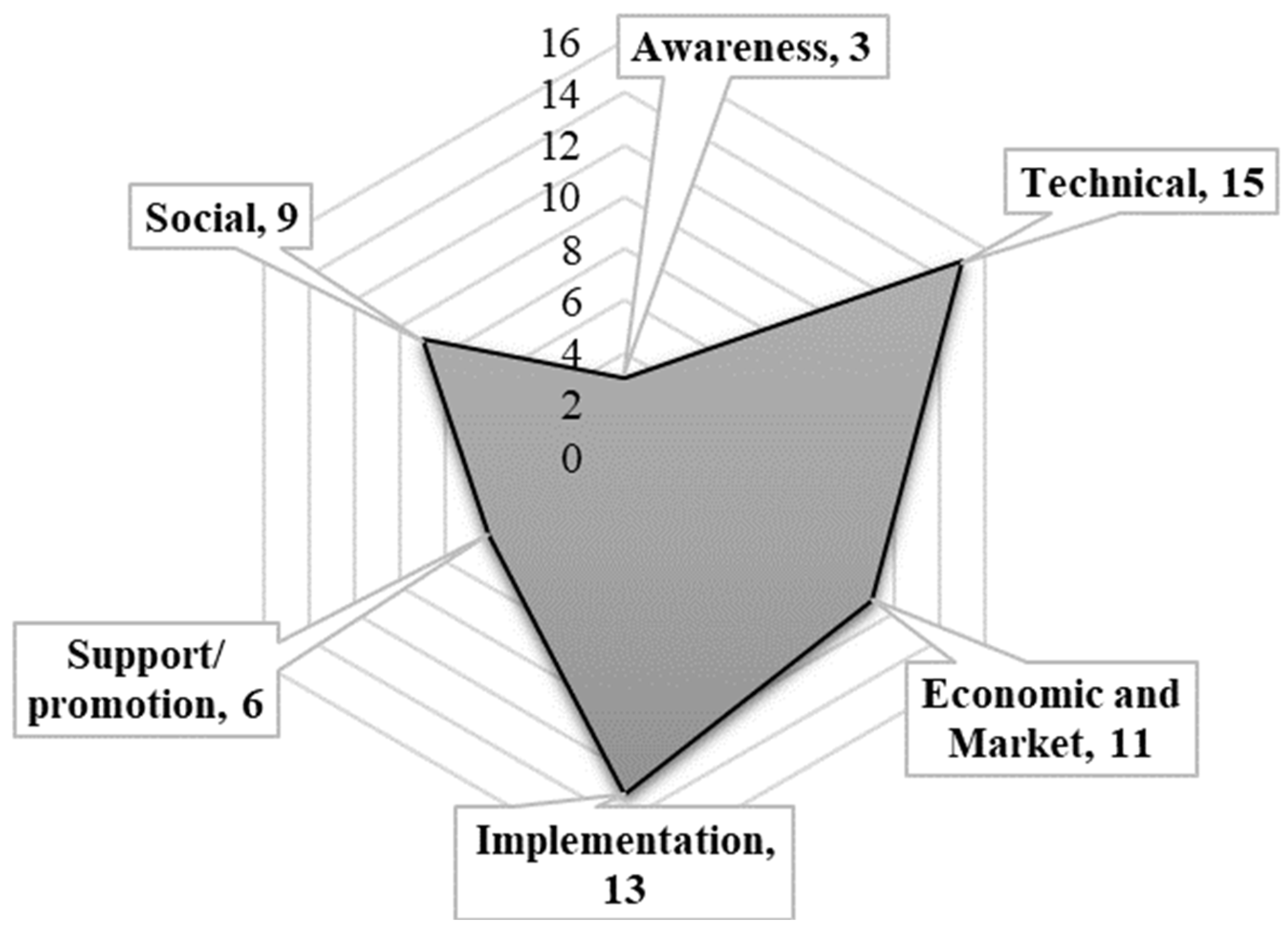

3.1.2. Barrier Frequency Analysis

3.2. Enablers and Their Analysis

3.2.1. Enabler’s Explanation

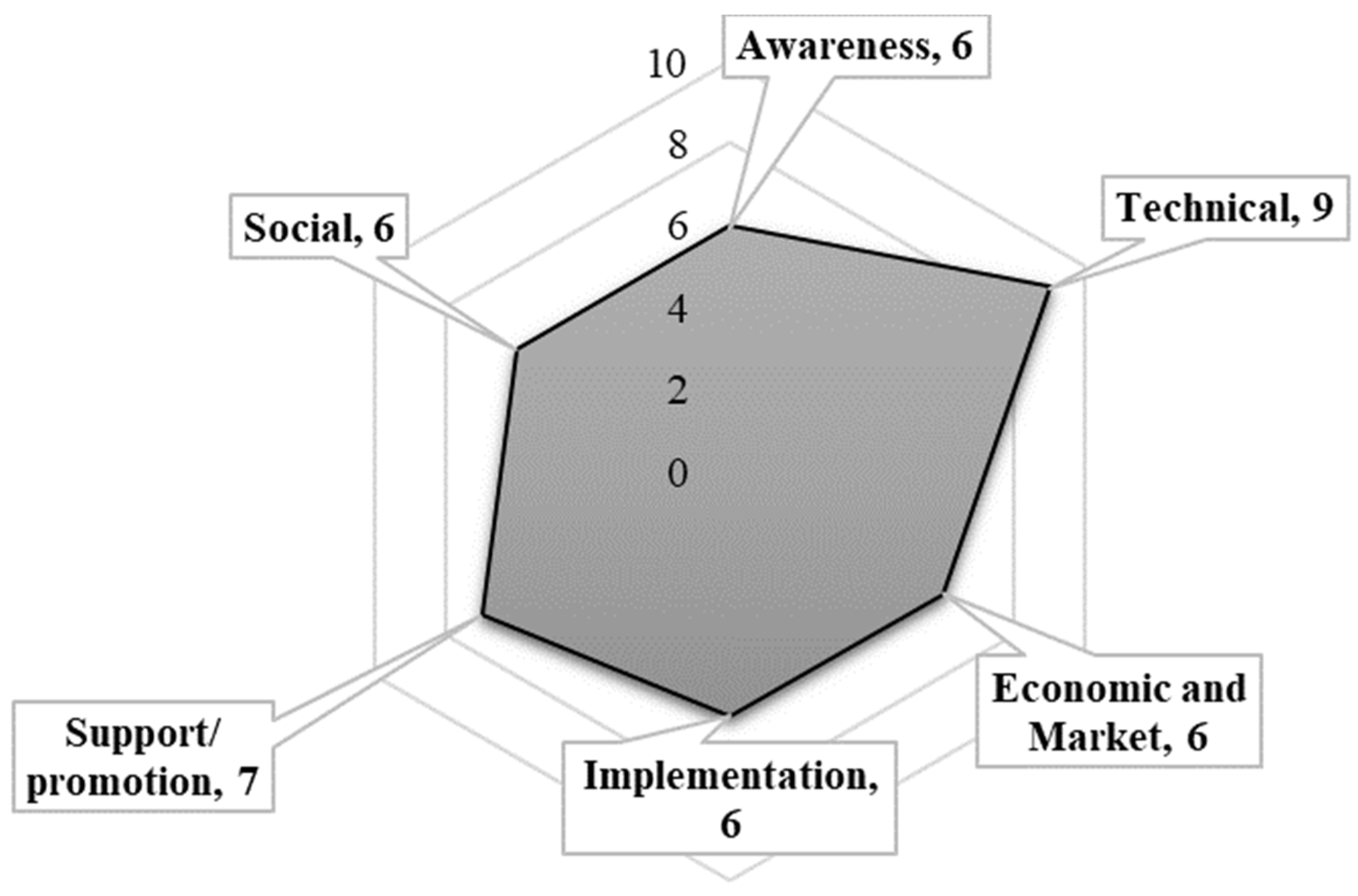

3.2.2. Enabler Frequency Analysis

4. Conclusions

- As a theoretical contribution to the body of knowledge, this study summarizes the main barriers and enablers related to green concrete implementation in the extant literature, providing insights into the nexus of green concrete and the building sector for subsequent empirical development.

- Six categories of factors are identified that affect green concrete implementation: awareness, technical, economic and market, implementation, support/promotion, and social as:

- ○

- Technical challenges: the study identifies technical issues as the primary obstacles to the development and implementation of green concrete. These include the availability of alternative energy sources, the efficiency of existing plants, and the lack of clear standards for recycled materials.

- ○

- Economic and market barriers: economic factors, such as the British Columbia carbon tax, affect the competitiveness of the cement industry. The cost of renewable energy and recycled materials also presents a challenge, alongside the lack of government grants and incentives.

- ○

- Implementation hurdles: the adoption of green concrete is hindered by implementation barriers such as restrictive cement standards, equipment and operational issues, and the need for appropriate staffing arrangements.

- ○

- Support and promotion: the study highlights a lack of policy support and incentives for the use of recycled materials in construction, something which is crucial for the promotion of green concrete.

- ○

- Social acceptance: consumer preferences and the environmental and social impacts of using recycled materials are social factors that influence the adoption of green concrete.

- It reveals that technical and operational aspects are the main barriers, while awareness and social acceptance are not major issues.

- Highlights the need for more research and innovation to overcome the technical and operational barriers and promote the adoption of green concrete.

- The study concludes that overcoming these barriers requires a comprehensive understanding of the challenges and a collaborative effort from all stakeholders involved in the construction industry. Future research directions include developing clear guidelines, improving technical standards, and fostering greater awareness and education about the benefits of green concrete.

- The study also concludes that green concrete is a promising solution for the sustainable development of the construction industry, but it requires more collaboration and coordination among the stakeholders and experts.

Limitations and Future Directions

- Geographical limitations: the research findings may be influenced by regional factors, and, thus, may not be universally applicable. The study is primarily relevant to the regions and countries represented in the dataset.

- Methodological constraints: the mixed-method approach, combining a scientometric analysis and a literature review, may have inherent limitations in capturing the nuanced perspectives of practitioners and experts in the field.

- Subjectivity in classification: the classification of barriers and enablers into six categories may introduce subjectivity, as certain factors could overlap or fit into multiple categories.

- Quantitative analysis: the current study focuses on quantitative analysis and might overlook the qualitative aspects of green concrete adoption, such as stakeholder perceptions and experiences.

- Economic and market dynamics: the current research may not fully capture the complex economic and market dynamics that influence the adoption of green concrete, such as policy changes or shifts in industry practices.

Funding

Acknowledgments

Conflicts of Interest

References

- Naik, T.R. Sustainability of Concrete Construction. Pract. Period. Struct. Des. Constr. 2008, 13, 98–103. [Google Scholar] [CrossRef]

- Meyer, C. The Greening of the Concrete Industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Aïtcin, P.-C. Cements of Yesterday and Today. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Tayebani, B.; Said, A.; Memari, A. Less Carbon Producing Sustainable Concrete from Environmental and Performance Perspectives: A Review. Constr. Build. Mater. 2023, 404, 133234. [Google Scholar] [CrossRef]

- Adesina, A. Recent Advances in the Concrete Industry to Reduce Its Carbon Dioxide Emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Mikulčić, H.; Cabezas, H.; Vujanović, M.; Duić, N. Environmental Assessment of Different Cement Manufacturing Processes Based on Emergy and Ecological Footprint Analysis. J. Clean. Prod. 2016, 130, 213–221. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K.; Biswas, W.K. Effect of Fly Ash on the Service Life, Carbon Footprint and Embodied Energy of High Strength Concrete in the Marine Environment. Energy Build. 2018, 158, 1694–1702. [Google Scholar] [CrossRef]

- Ansari, S.S.; Shariq, M.; Mohammad, Z.; Akhtar, S.; Masood, A. Effect of Elevated Temperature on the Structural Performance of Reinforced High Volume Fly Ash Concrete. Structures 2023, 57, 105168. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The Role of Inorganic Polymer Technology in the Development of ‘Green Concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Yap, S.P.; Lee, S.C. Green Concrete Partially Comprised of Farming Waste Residues: A Review. J. Clean. Prod. 2016, 117, 122–138. [Google Scholar] [CrossRef]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Dinkha, Y.Z.; Haido, J.H.; Ali, M.H.; Tayeh, B.A. Engineering Properties of Sustainable Green Concrete Incorporating Eco-Friendly Aggregate of Crumb Rubber: A Review. J. Clean. Prod. 2021, 324, 129251. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Ibrahim, S.M.; Ansari, S.S.; Hasan, S.D. Towards White Box Modeling of Compressive Strength of Sustainable Ternary Cement Concrete Using Explainable Artificial Intelligence (XAI). Appl. Soft Comput. 2023, 149, 110997. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Lee, Y.H.; Haruna, S.; Lee, Y.Y. Slag Uses in Making an Ecofriendly and Sustainable Concrete: A Review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Osial, M.; Pregowska, A.; Wilczewski, S.; Urbańska, W.; Giersig, M. Waste Management for Green Concrete Solutions: A Concise Critical Review. Recycling 2022, 7, 37. [Google Scholar] [CrossRef]

- Shamseldeen Fakhri, R.; Thanon Dawood, E. Limestone Powder, Calcined Clay and Slag as Quaternary Blended Cement Used for Green Concrete Production. J. Build. Eng. 2023, 79, 107644. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; He, Z.; Liu, Y.; Jiang, J.; Xiong, T.; Shi, J. A Green Ultra-Lightweight Chemically Foamed Concrete for Building Exterior: A Feasibility Study. J. Clean. Prod. 2021, 288, 125085. [Google Scholar] [CrossRef]

- Mohd Tahir, M.F.; Abdullah, M.M.A.B.; Abd Rahim, S.Z.; Mohd Hasan, M.R.; Saafi, M.; Putra Jaya, R.; Mohamed, R. Potential of Industrial By-Products Based Geopolymer for Rigid Concrete Pavement Application. Constr. Build. Mater. 2022, 344, 128190. [Google Scholar] [CrossRef]

- Ni, F.M.-W.; Oyeyi, A.G.; Tighe, S. The Potential Use of Lightweight Cellular Concrete in Pavement Application: A Review. Int. J. Pavement Res. Technol. 2020, 13, 686–696. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Bassey, D.E.; Olukanni, D.O.; Ngene, B.U.; Adegoke, D.; Odetoyan, A.O.; Kareem, M.A.; Enabulele, D.O.; Nworgu, A.T. Waste Materials in Highway Applications: An Overview on Generation and Utilization Implications on Sustainability. J. Clean. Prod. 2021, 283, 124581. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Ramachandran, D. Green Concrete Mix Using Solid Waste and Nanoparticles as Alternatives—A Review. Constr. Build. Mater. 2018, 162, 96–103. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental Impact and Life Cycle Assessment (LCA) of Traditional and ‘Green’ Concretes: Literature Review and Theoretical Calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G.; Singh, M. Recycle Option for Metallurgical By-Product (Spent Foundry Sand) in Green Concrete for Sustainable Construction. J. Clean. Prod. 2018, 172, 1111–1120. [Google Scholar] [CrossRef]

- AlJaber, A.; Martinez-Vazquez, P.; Baniotopoulos, C. Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review. Buildings 2023, 13, 2778. [Google Scholar] [CrossRef]

- Hwang, B.; Tan, J.S. Green Building Project Management: Obstacles and Solutions for Sustainable Development. Sustain. Dev. 2012, 20, 335–349. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ji, X.; Liu, G.; Ulgiati, S. Evaluating the Transition towards Cleaner Production in the Construction and Demolition Sector of China: A Review. J. Clean. Prod. 2018, 195, 418–434. [Google Scholar] [CrossRef]

- Bui, T.T.P.; MacGregor, C.; Wilkinson, S.; Domingo, N. Towards Zero Carbon Buildings: Issues and Challenges in the New Zealand Construction Sector. Int. J. Constr. Manag. 2023, 23, 2709–2716. [Google Scholar] [CrossRef]

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 Abatement Strategies in Cement Industry: A Review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef]

- Golizadeh, H.; Hosseini, M.R.; Edwards, D.J.; Abrishami, S.; Taghavi, N.; Banihashemi, S. Barriers to Adoption of RPAs on Construction Projects: A Task–Technology Fit Perspective. Constr. Innov. 2019, 19, 149–169. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Berthelot, C.; Haichert, R.; Podborochynski, D.; Wandzura, C.; Taylor, B.; Guenther, D.; Cherry, D. Integrated Mechanistic-Based Framework for Sustainable “Green Street” Rehabilitation of Urban Low-Volume Roads. Transp. Res. Rec. J. Transp. Res. Board 2011, 2205, 103–110. [Google Scholar] [CrossRef]

- Foth, M.; Guenther, D.; Haichert, R.; Berthelot, C. City of Saskatoon’s Green Streets Program—A Case Study for the Implementation of Sustainable Roadway Rehabilitation with the Reuse of Concrete and Asphalt Rubble Materials. In Proceedings of the Green Streets and Highways 2010, Denver, CO, USA, 14–17 November 2010; pp. 337–348. [Google Scholar]

- Kumar, P.; Debele, S.E.; Sahani, J.; Rawat, N.; Marti-Cardona, B.; Alfieri, S.M.; Basu, B.; Basu, A.S.; Bowyer, P.; Charizopoulos, N.; et al. An Overview of Monitoring Methods for Assessing the Performance of Nature-Based Solutions against Natural Hazards. Earth Sci. Rev. 2021, 217, 103603. [Google Scholar] [CrossRef]

- Bintara, R.; Yadiati, W.; Zarkasyi, M.; Tanzil, N. Management of Green Competitive Advantage: A Systematic Literature Review and Research Agenda. Economies 2023, 11, 66. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Chang, C.-H. Enhance Environmental Commitments and Green Intangible Assets toward Green Competitive Advantages: An Analysis of Structural Equation Modeling (SEM). Qual. Quant. 2013, 47, 529–543. [Google Scholar] [CrossRef]

- Alam, S.M.S.; Islam, K.M.Z. Examining the Role of Environmental Corporate Social Responsibility in Building Green Corporate Image and Green Competitive Advantage. Int. J. Corp. Soc. Responsib. 2021, 6, 8. [Google Scholar] [CrossRef]

- Rehman, S.U.; Giordino, D.; Zhang, Q.; Alam, G.M. Twin Transitions & Industry 4.0: Unpacking the Relationship between Digital and Green Factors to Determine Green Competitive Advantage. Technol. Soc. 2023, 73, 102227. [Google Scholar] [CrossRef]

- Chiou, T.-Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The Influence of Greening the Suppliers and Green Innovation on Environmental Performance and Competitive Advantage in Taiwan. Transp. Res. E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Polas, M.R.H.; Kabir, A.I.; Sohel-Uz-Zaman, A.S.M.; Karim, R.; Tabash, M.I. Blockchain Technology as a Game Changer for Green Innovation: Green Entrepreneurship as a Roadmap to Green Economic Sustainability in Peru. J. Open Innov. Technol. Mark. Complex. 2022, 8, 62. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Ramsey, T.S.; Hewings, G.J.D. Will Researching Digital Technology Really Empower Green Development? Technol. Soc. 2021, 66, 101638. [Google Scholar] [CrossRef]

- Kraus, S.; Rehman, S.U.; García, F.J.S. Corporate Social Responsibility and Environmental Performance: The Mediating Role of Environmental Strategy and Green Innovation. Technol. Forecast. Soc. Change 2020, 160, 120262. [Google Scholar] [CrossRef]

- Fallahpour, A.; Yazdani, M.; Mohammed, A.; Wong, K.Y. Green Sourcing in the Era of Industry 4.0: Towards Green and Digitalized Competitive Advantages. Ind. Manag. Data Syst. 2021, 121, 1997–2025. [Google Scholar] [CrossRef]

- Zhai, X.; An, Y. The Relationship between Technological Innovation and Green Transformation Efficiency in China: An Empirical Analysis Using Spatial Panel Data. Technol. Soc. 2021, 64, 101498. [Google Scholar] [CrossRef]

- Umar, M.; Ahmad, A.; Sroufe, R.; Muhammad, Z. The Nexus between Green Intellectual Capital, Blockchain Technology, Green Manufacturing, and Sustainable Performance. Environ. Sci. Pollut. Res. 2024, 31, 15026–15038. [Google Scholar] [CrossRef]

- Kangmin, W.; Yuyao, Y.; Xiangyu, W.; Zhengqian, L.; Hong’ou, Z. New Infrastructure-Lead Development and Green-Technologies: Evidence from the Pearl River Delta, China. Sustain. Cities Soc. 2023, 99, 104864. [Google Scholar] [CrossRef]

- Anastasiades, K.; Dockx, J.; van den Berg, M.; Rinke, M.; Blom, J.; Audenaert, A. Stakeholder Perceptions on Implementing Design for Disassembly and Standardisation for Heterogeneous Construction Components. Waste Manag. Res. J. A Sustain. Circ. Econ. 2023, 41, 1372–1381. [Google Scholar] [CrossRef]

- Wijewickrama, M.K.C.S.; Chileshe, N.; Rameezdeen, R.; Ochoa, J.J. Information Sharing in Reverse Logistics Supply Chain of Demolition Waste: A Systematic Literature Review. J. Clean. Prod. 2021, 280, 124359. [Google Scholar] [CrossRef]

- Xia, B.; Ding, T.; Xiao, J. Life Cycle Assessment of Concrete Structures with Reuse and Recycling Strategies: A Novel Framework and Case Study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular Economy of Construction and Demolition Waste: A Literature Review on Lessons, Challenges, and Benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- van den Berg, M.; Voordijk, H.; Adriaanse, A. Recovering Building Elements for Reuse (or Not)—Ethnographic Insights into Selective Demolition Practices. J. Clean. Prod. 2020, 256, 120332. [Google Scholar] [CrossRef]

- Rameezdeen, R.; Chileshe, N.; Hosseini, M.R.; Lehmann, S. A Qualitative Examination of Major Barriers in Implementation of Reverse Logistics within the South Australian Construction Sector. Int. J. Constr. Manag. 2016, 16, 185–196. [Google Scholar] [CrossRef]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Moradhassel, A.; Masterson, B. Advancing the Cement Industry’s Climate Change Plan in British Columbia: Addressing Economic and Policy Barriers. In Proceedings of the Economic Implications of Climate Change Session of the 2009 Annual Conference of the Transportation Association of Canada, Vancouver, BC, Canada, 18–21 October 2009. [Google Scholar]

- Zębek, E.M.; Zięty, J.J. Effect of Landfill Arson to a “Lax” System in a Circular Economy under the Current EU Energy Policy: Perspective Review in Waste Management Law. Energies 2022, 15, 8690. [Google Scholar] [CrossRef]

- Del Zotto, L.; Tallini, A.; Di Simone, G.; Molinari, G.; Cedola, L. Energy Enhancement of Solid Recovered Fuel within Systems of Conventional Thermal Power Generation. Energy Procedia 2015, 81, 319–338. [Google Scholar] [CrossRef]

- Kusuma, R.T.; Hiremath, R.B.; Rajesh, P.; Kumar, B.; Renukappa, S. Sustainable Transition towards Biomass-Based Cement Industry: A Review. Renew. Sustain. Energy Rev. 2022, 163, 112503. [Google Scholar] [CrossRef]

- Gessinger, G. Lower CO2 Emissions through Better Technology. Energy Convers. Manag. 1997, 38, S25–S30. [Google Scholar] [CrossRef]

- Wu, P.; Low, S.P. Barriers to Achieving Green Precast Concrete Stock Management—A Survey of Current Stock Management Practices in Singapore. Int. J. Constr. Manag. 2014, 14, 78–89. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between Operational Practices and Performance among Early Adopters of Green Supply Chain Management Practices in Chinese Manufacturing Enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green Supply-chain Management: A State-of-the-art Literature Review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Lewis, H.; Gertsakis, J.; Grant, T.; Morelli, N.; Sweatman, A. Design + Environment; Routledge: London, UK, 2017; ISBN 9781351282208. [Google Scholar]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance Measurement for Green Supply Chain Management. Benchmarking 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Rock, S.; Hosseini, M.R.; Nikmehr, B.; Martek, I.; Abrishami, S.; Durdyev, S. Barriers to “Green Operation” of Commercial Office Buildings. Facilities 2019, 37, 1048–1065. [Google Scholar] [CrossRef]

- Ries, R.; Bilec, M.M.; Gokhan, N.M.; Needy, K.L. The Economic Benefits of Green Buildings: A Comprehensive Case Study. Eng. Econ. 2006, 51, 259–295. [Google Scholar] [CrossRef]

- Zuo, J.; Xia, B.; Chen, Q.; Pullen, S.; Skitmore, M. Green building rating for office buildings—Lessons learned. J. Green. Build. 2016, 11, 131–146. [Google Scholar] [CrossRef]

- Zuo, J.; Pullen, S.; Rameezdeen, R.; Bennetts, H.; Wang, Y.; Mao, G.; Zhou, Z.; Du, H.; Duan, H. Green Building Evaluation from a Life-Cycle Perspective in Australia: A Critical Review. Renew. Sustain. Energy Rev. 2017, 70, 358–368. [Google Scholar] [CrossRef]

- Islam, A.B.M.S.; Kutti, W.A.; Nasir, M.; Kazmi, Z.A.; Sodangi, M. Potential Use of Local Waste Scoria as an Aggregate and SWOT Analysis for Constructing Structural Lightweight Concrete. Adv. Mater. Res. 2022, 11, 147–164. [Google Scholar]

- Hosseinzadeh, N.; Ghiasian, M.; Andiroglu, E.; Lamere, J.; Rhode-Barbarigos, L.; Sobczak, J.; Sealey, K.S.; Suraneni, P. Concrete Seawalls: A Review of Load Considerations, Ecological Performance, Durability, and Recent Innovations. Ecol. Eng. 2022, 178, 106573. [Google Scholar] [CrossRef]

- Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Onuralp Özkılıç, Y.; Akeed, M.H. Application of Ultra-High-Performance Concrete in Bridge Engineering: Current Status, Limitations, Challenges, and Future Prospects. Buildings 2023, 13, 185. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging Building Materials in a Circular Economy: A BIM-Based Whole-Life Performance Estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing Waste to Landfill: A Need for Cultural Change in the UK Construction Industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- Alzoubi, Y.I.; Mishra, A. Green Blockchain—A Move towards Sustainability. J. Clean. Prod. 2023, 430, 139541. [Google Scholar] [CrossRef]

- Baxter, L. Biomass-Coal Co-Combustion: Opportunity for Affordable Renewable Energy. Fuel 2005, 84, 1295–1302. [Google Scholar] [CrossRef]

- Roh, T.; Noh, J.; Oh, Y.; Park, K.-S. Structural Relationships of a Firm’s Green Strategies for Environmental Performance: The Roles of Green Supply Chain Management and Green Marketing Innovation. J. Clean. Prod. 2022, 356, 131877. [Google Scholar] [CrossRef]

- Wang, T.; Foliente, G.; Song, X.; Xue, J.; Fang, D. Implications and Future Direction of Greenhouse Gas Emission Mitigation Policies in the Building Sector of China. Renew. Sustain. Energy Rev. 2014, 31, 520–530. [Google Scholar] [CrossRef]

- Tu, Y.; Wu, W. How Does Green Innovation Improve Enterprises’ Competitive Advantage? The Role of Organizational Learning. Sustain. Prod. Consum. 2021, 26, 504–516. [Google Scholar] [CrossRef]

- Kevin van Langen, S.; Vassillo, C.; Ghisellini, P.; Restaino, D.; Passaro, R.; Ulgiati, S. Promoting Circular Economy Transition: A Study about Perceptions and Awareness by Different Stakeholders Groups. J. Clean. Prod. 2021, 316, 128166. [Google Scholar] [CrossRef]

- Alotaibi, A.; Edum-Fotwe, F.; Price, A.D. Critical barriers to social responsibility implementation within mega-construction projects: The case of the Kingdom of Saudi Arabia. Sustainability 2019, 11, 1755. [Google Scholar] [CrossRef]

- Al-Otaibi, A.; Bowan, P.A.; Daiem, M.M.A.; Said, N.; Ebohon, J.O.; Alabdullatief, A.; Al-Enazi, E.; Watts, G. Identifying the Barriers to Sustainable Management of Construction and Demolition Waste in Developed and Developing Countries. Sustainability 2022, 14, 7532. [Google Scholar] [CrossRef]

- Han, H.; Ahn, S.W. Youth Mobilization to Stop Global Climate Change: Narratives and Impact. Sustainability 2020, 12, 4127. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green Concrete: Prospects and Challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Agrawal, Y.; Gupta, T.; Sharma, R.; Panwar, N.L.; Siddique, S. A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction. Constr. Mater. 2021, 1, 39–62. [Google Scholar] [CrossRef]

- Mena, Á.; López, F.; Framiñan, J.M.; Flores, F.; Gallego, J.M. XPDRL Project: Improving the Project Documentation Quality in the Spanish Architectural, Engineering and Construction Sector. Autom. Constr. 2010, 19, 270–282. [Google Scholar] [CrossRef]

- De Gaetani, C.I.; Mert, M.; Migliaccio, F. Interoperability Analyses of BIM Platforms for Construction Management. Appl. Sci. 2020, 10, 4437. [Google Scholar] [CrossRef]

- Gerbino, S.; Cieri, L.; Rainieri, C.; Fabbrocino, G. On BIM Interoperability via the IFC Standard: An Assessment from the Structural Engineering and Design Viewpoint. Appl. Sci. 2021, 11, 11430. [Google Scholar] [CrossRef]

- Loo, B.P.Y.; Wong, R.W.M. Towards a Conceptual Framework of Using Technology to Support Smart Construction: The Case of Modular Integrated Construction (MiC). Buildings 2023, 13, 372. [Google Scholar] [CrossRef]

| Description | Results |

|---|---|

| Main information about data | |

| Timespan | 1977:2024 |

| Sources (Journals, Books, etc.) | 80 |

| Documents | 91 |

| Annual Growth Rate % | 3.48 |

| Document Average Age | 7.31 |

| Average citations per doc | 18.24 |

| References | 3467 |

| Document contents | |

| Keywords Plus | 769 |

| Author’s Keywords | 294 |

| Authors | |

| Authors | 292 |

| Authors of single-authored docs | 14 |

| Authors collaboration | |

| Single-authored docs | 14 |

| Co-Authors per Doc | 3.27 |

| International co-authorships % | 26.37 |

| Document types | |

| Article | 48 |

| Book | 2 |

| Book chapter | 1 |

| Conference paper | 17 |

| Conference review | 11 |

| Review | 10 |

| Year | Articles | Year | Articles | Year | Articles | Year | Articles |

|---|---|---|---|---|---|---|---|

| 1977 | 1 | 1989 | 0 | 2001 | 0 | 2013 | 6 |

| 1978 | 0 | 1990 | 0 | 2002 | 0 | 2014 | 10 |

| 1979 | 0 | 1991 | 0 | 2003 | 0 | 2015 | 4 |

| 1980 | 0 | 1992 | 0 | 2004 | 0 | 2016 | 5 |

| 1981 | 0 | 1993 | 1 | 2005 | 1 | 2017 | 5 |

| 1982 | 0 | 1994 | 0 | 2006 | 1 | 2018 | 2 |

| 1983 | 0 | 1995 | 0 | 2007 | 0 | 2019 | 8 |

| 1984 | 0 | 1996 | 0 | 2008 | 3 | 2020 | 4 |

| 1985 | 0 | 1997 | 0 | 2009 | 2 | 2021 | 6 |

| 1986 | 0 | 1998 | 0 | 2010 | 3 | 2022 | 8 |

| 1987 | 0 | 1999 | 0 | 2011 | 2 | 2023 | 13 |

| 1988 | 0 | 2000 | 0 | 2012 | 1 | 2024 | 5 |

| Category | Barrier | Description | References |

|---|---|---|---|

| Awareness | Lack of knowledge and education | Road agencies, contractors, sub-contractor, and the public may not be aware of the benefits and potential of recycled materials or may have misconceptions or negative perceptions about their quality and performance. | [32,33] |

| Lack of awareness, knowledge and benefits | Stakeholders and decision-makers may not be aware of the multiple benefits and co-benefits of nature-based solutions compared to grey solutions, or may have doubts about their efficiency, effectiveness, and reliability. | [34] | |

| Many companies are not fully aware of the benefits of the green competitive advantage or lack the necessary knowledge and skills to effectively adopt green innovation and environmental management practices. | [35,36,37] | ||

| Many managers and employees are not fully aware of the potential benefits that green and digital factors can bring to their organizations, such as improved efficiency, innovation, brand image, and competitiveness. | [38,39,40,41,42,43,44,45,46] | ||

| Resistance to change | Some stakeholders may perceive standardization and design for disassembly as a threat to their project uniqueness and architectural freedom. They may also lack the effective knowledge and practical skills to implement these principles in a good manner. | [47,48,49,50,51,52,53] | |

| Technical | Availability of alternative energy sources | The current waste management policies in the province and regions do not divert high-calorific materials from landfill, limiting the availability of waste-derived energy sources for the cement industry. | [54,55,56,57] |

| Some common substitute materials, such as steel slag and silica fume, are not available in the Pacific Northwest. The availability of fly ash, another substitute material, is uncertain due to the high pressures on the coal-fired electricity sector. | |||

| Energy efficiency improvements | The existing plants in British Columbia have limited potential for significant increases in fuel efficiency, and no new or modernized plants are planned in the near future due to the market conditions and investment climate. | [54,58] | |

| Lack of specifications and standards | There may not be clear and consistent guidelines for the production, testing, and quality control of recycled materials, or for the design and construction of road structures using recycled materials. | [32,33] | |

| There is no universally accepted framework or methodology for monitoring the performance and impact of nature-based solutions across different scales, hazards, and contexts. Different indicators may have different definitions, units, and data sources, making it difficult to compare and aggregate results. | [34] | ||

| Inappropriate battens | The use of incorrect or insufficient battens to support the precast concrete products during stacking can cause physical damage and waste. | [2,59,60,61,62,63] | |

| Unclear identification marks | The lack of clear and waterproof identification marks on the precast concrete products can lead to wrong delivery or double-handling. | ||

| Lack of computer stock control | The use of manual or simple software tools to manage the stock records can result in errors or inefficiencies. | ||

| Building age and condition | The limitations posed by the existing building design, structure, and services, all of which may not be compatible with new green technologies. | [64,65,66,67] | |

| Availability of space | The lack of adequate space for installing a new plant and equipment, such as solar panels or water tanks. | ||

| Building automation systems | The inefficiency or inadequacy of the systems that control the heating, cooling, lighting, and ventilation of the building. It can be a significant barrier due to the initial high investment costs and the complexity of integrating them with green concrete technologies, which often require new approaches for effective monitoring and control. | ||

| Metering systems | The lack of sufficient and accurate metering systems to monitor and measure the energy and water consumption of the building. It can pose challenges in accurately assessing the environmental benefits of green concrete, which is essential for its adoption and validation. | ||

| Large inventory in factory | The push production system adopted by most precasters leads to a high level of inventory, which increases storage costs and environmental impacts. | [59,61,62] | |

| Lack of sufficient care | The insufficient care provided by the vehicle drivers or crane operators during loading, unloading, and delivery can cause damage or loss of precast concrete products. | ||

| Reduced mechanical properties. | This barrier affects the performance and reliability of lightweight concrete structures, especially in seismic zones. | [68,69,70] | |

| Lack of skills, facilities, and technology | There is a severe lack of standards, both at the component level and at the procedure level, which can facilitate the reuse of components and design for disassembly. Moreover, there is a need for more research and development on reversible connection systems, especially for concrete elements, which are difficult to disassemble and reuse. Additionally, there is a need for better information management systems, such as material passports and Building Information Modelling (BIM), to store and share the data on the components’ quality and reusability. | [47,50,52,71,72] | |

| Many organizations lack the necessary technical skills and capabilities to adopt and implement green and digital factors, such as the Internet of Things (IoT), green human resource management, and investing in environmental management. They also face challenges in integrating these factors with their existing processes and systems. | [38,40,42,73] | ||

| High cost and risks | Implementing the green competitive advantage may require significant investments in green technologies, processes, products, or services, which may not be affordable or feasible for some companies, especially Small–Medium Enterprises (SME). Moreover, there may be uncertainties and risks associated with green innovation, such as market acceptance, customer preferences, regulatory changes, or technological obsolescence. | [35,36] | |

| Economic and Market | British Columbia carbon tax | The carbon tax increases the compliance costs and reduces the competitiveness of the British Columbia cement industry compared to other jurisdictions that do not have a similar price on greenhouse gas emissions. | [54,57,74] |

| Cost of renewable energy | The cost of woody biomass, a potential renewable energy source, is much higher than that of coal, the conventional fossil fuel used in cement manufacturing. | ||

| Cost and availability of materials | The cost of recycled materials may not be competitive with conventional materials, or there may not be enough supply or demand for recycled materials in the market. | [32] | |

| Access to capital | The difficulty of obtaining funds for green improvement works, especially when the payback period is longer than five years. | [64,75] | |

| Lack of government grants and incentives | The absence of financial support from the government to encourage building owners to invest in green measures. | ||

| Perceived split benefits | The imbalance between the costs borne by the building owners and the benefits enjoyed by the tenants. | ||

| Landlord priorities | The focus of property owners on financial returns and market competitiveness, rather than environmental performance. | ||

| Lack of funding and incentives for nature-based solutions implementation and monitoring | Nature-based solutions projects may face financial constraints due to limited public budgets, lack of private investments, or high upfront costs. Nature-based solutions may also lack adequate incentives or regulations to encourage their adoption and maintenance. | [34] | |

| High costs and uncertain returns across different regions in Saudi Arabia. Astronomical costs of aggregate and storage facilities. | These barriers increase the production costs and reduce the competitiveness of lightweight concrete in the market. | [68,69] | |

| Many organizations face high costs and uncertain returns when investing in green and digital factors, such as technological innovation and environmental management. They also face market pressures and high competition from other organizations that may not adopt these factors. | [38,73] | ||

| Additional costs and time investment | The reuse of components may involve extra costs for transportation, storage, testing, certification, and maintenance. It may also require more time for logistics, disassembly, quality assurance measures, and method validation. These factors may discourage the stakeholders from adopting the reuse of components and design for disassembly. | [47,70,72] | |

| Lack of support and incentives | Some companies may face resistance or opposition from internal or external stakeholders, such as managers, employees, customers, suppliers, or competitors, who may not share the same vision or values of the green competitive advantage. Additionally, there may be a lack of adequate incentives, recognitions, or rewards for pursuing the green competitive advantage, such as tax breaks, subsidies, grants, or recognition. | [35,76,77] | |

| Implementation | Cement standards | The current Canadian Standards Association standards allow for a maximum of 5% limestone utilization, while, in Europe, the standards allow for up to 35%. This limits the potential contribution from limestone substitution unless the US standards are revised as well. | [54,74] |

| Equipment and operational issues | The use of recycled materials may require specialized equipment, training, or procedures that are not readily available or feasible for construction industry stakeholders. | [32] | |

| Inappropriate staffing arrangement | The lack of appropriate staffing arrangement for the lifting process can increase energy consumption and the risk of accidents. | [59,60,63] | |

| Unclear working instructions | The lack of well-written working instructions for the stacking and handling of precast concrete products can result in confusion or mistakes. | ||

| Lack of periodic stock checks | The lack of regular stock checks can lead to discrepancies between the actual and recorded stock levels, which can affect the delivery and production planning. | ||

| Tenant and staff education | The lack of awareness and knowledge among the building occupants about the benefits and practices of green operation. | [64,66] | |

| Tenant and staff priorities | The preference of the building occupants for their own comfort and convenience, rather than energy conservation. | ||

| Leasing agreements | The restrictions or conflicts caused by the terms and conditions of the short-term lease contracts, which may not align with the green operation goals. | ||

| Lack of coordination and integration of nature-based solutions across sectors and scales | Nature-based solution projects may involve multiple practitioners and stakeholders from different sectors and levels of governance, something which may pose challenges for coordination and integration. Nature-based solutions may also require long-term planning and a proactive management philosophy, which may not align with short-term objectives cycles or agendas. | [34] | |

| Client’s and end-user’s resistance to change and uncertainties due to durability and ductility issues of lightweight concrete. | This barrier hinders the adoption and acceptance of lightweight concrete as a viable alternative to normal weight concrete. | [68,70] | |

| Lack of a legal framework | This is the most significant barrier, as it prevents the stakeholders from operating safely and responsibly in the reuse of components. The article suggests that governments should take on their responsibility to create the necessary regulations and legislation for circular reuse. | [47,51,53] | |

| Lack of strategic alignment, integration, and collaboration | Achieving the green competitive advantage may require a holistic and systemic approach that integrates various aspects of the organization, such as strategy, culture, structure, processes, procedures, and performance. However, some companies may face difficulties or barriers in aligning and coordinating their green efforts across different functions, departments, or units. Furthermore, some companies may lack effective collaboration or partnership with other practitioners in the green supply chain, such as suppliers, distributors, customers, or regulators, who may have different needs, goals, interests, or expectations. Therefore, effective stakeholder management is highly recommended to gain shared value and reduce conflicts and disputes. | [35,37] | |

| Many firms lack a clear and coherent strategy and coordination for pursuing twin transitions. They also face difficulties in managing the change and resistance that may arise from different stakeholders, such as employees, customers, and suppliers. | [38,73,78] | ||

| Support/promotion | Policy support for the Cement Sector Climate Action Strategy | The provincial Climate Action Plan and the Climate Action Team Report do not include any specific measures that would directly support the implementation of the industry’s own greenhouse gas reduction strategy. | [54,74] |

| Lack of incentives and policies | There may not be sufficient financial, regulatory, or institutional incentives or policies to encourage or facilitate the use of recycled materials in road construction. | [32] | |

| Landlord education | The need to inform and persuade the property owners about the long-term advantages of green operations, such as lower operating costs, higher market value, and improved corporate image. | [64,66,67] | |

| Lack of communication and dissemination of nature-based solutions results and best practices | Nature-based solution projects may lack effective communication and dissemination strategies to share their results and best practices with relevant stakeholders, such as policymakers, practitioners, researchers, or the general public. This may limit the visibility and uptake of nature-based solutions as viable solutions for hydro-meteorological risks mitigation. | [34] | |

| Lack of government support | Some companies may not receive sufficient support or guidance from the government to implement the green competitive advantage, such as clear and consistent policies, regulations, standards, or law enforcement. The government may also lack the capacity or resources to monitor and evaluate the environmental performance and impact of the green competitive advantage. | [35,36] | |

| Many firms lack adequate institutional support and incentives for adopting and implementing green and digital factors, such as policies, regulations, standards, and subsidies. They also face barriers in accessing external resources and networks, such as financing, technology, and knowledge. | [38,78] | ||

| Social | Consumer preferences | The demand for cement and cement products is influenced by the consumer preferences for building materials, design, and construction practices. The industry needs to communicate the sustainability benefits of using green concrete products to the consumers and other stakeholders. | [54,55] |

| Environmental and social impacts | The use of recycled materials may have positive or negative impacts on the environment and society, such as reducing greenhouse gas emissions, saving landfill space, or affecting road safety and aesthetics. | [32] | |

| Lack of top management commitment | The lack of top management commitment to implement environmental management practices can hinder the adoption of green stock management. | [59,61] | |

| Lack of employee involvement | The lack of employee involvement and training in green stock management can reduce the awareness and motivation of the workers. | ||

| Occupational health and safety | The potential risks or hazards associated with the installation or operation of new green measures, which may affect the safety and well-being of the building users. | [64,66,67] | |

| Building compliance | The need to adhere to the existing building codes and standards, which may not be compatible with some green measures. | ||

| Architectural and aesthetic implications | The impact of new green measures on the appearance and ambience of the building, which may affect the satisfaction and preference of the building users. | ||

| Lack of stakeholder engagement and participation in nature-based solutions design and monitoring | Nature-based solution projects may not involve sufficient stakeholder engagement and participation in the design and monitoring of nature-based solutions, which may affect their acceptance, ownership, and sustainability. Stakeholders may have different preferences, values, and expectations of nature-based solutions, something which may need to be addressed and balanced. | [34] | |

| Lack of social responsibility, trust and awareness | Some companies may not have a strong sense of social responsibility or awareness of the environmental and social consequences of their actions. They may prioritize short-term profits over long-term sustainability and ignore the needs and expectations of their stakeholders and society at large. They may also lack the trust and legitimacy to engage in the green competitive advantage. | [35,36] | |

| Many firms face social barriers in adopting and implementing green and digital factors, such as negative perceptions, attitudes, and behaviors of customers, employees, and society. They also face ethical and legal issues, such as privacy, security, and accountability. | [38,73,78] |

| Category | Frequency |

|---|---|

| Awareness | 3 |

| Technical | 15 |

| Economic and Market | 11 |

| Implementation | 13 |

| Support/promotion | 6 |

| Social | 9 |

| Category | Barrier | Description | References |

|---|---|---|---|

| Awareness | Key practitioners, advocates, and champions | They initiate, mainstream, and sustain momentum for climate adaptation by raising awareness and mobilizing resources. | [54,57,74,81] |

| Scientific-based engineering methods | The use of advanced mechanistic laboratory tests and structural asset management techniques to quantify the benefits of recycled material systems and validate their end-product performance. | [32,33] | |

| Environmental awareness | The awareness of environmental issues and benefits of GSCM among precasters and their stakeholders. | [59,61] | |

| Circular economy | A concept that aims to reduce the environmental impact of production and consumption by minimizing resource extraction, waste generation and emissions, and maximizing the value retention of products and materials through reuse, recycling, and recovery. | [47,49,51,52,53] | |

| Green human resource management | Green human resource management is a set of practices that aim to promote and support employees’ green behavior and environmental awareness. | [38,40,42,43] | |

| Green innovation | This refers to the development of products, services, or processes that reduce environmental impacts and create value for customers and society. | [35,37] | |

| Technical | Technology development | It involves research and development activities to explore less CO2-intensive cementing materials and manufacturing processes and adopt proven CO2 control technologies and practices. | [54,55] |

| Impact crusher | A device that can process rubble materials into high-quality structural base course and substructure drainage aggregates with minimal waste and improved mechanical properties. | [32] | |

| Site layout design | The design of the site layout to align machinery in close proximity to the physical flow of production | [59,61,63] | |

| Substantial decrease in density and in building element self-weight. | This factor reduces the dead load, steel reinforcement, and foundation costs of the structures using lightweight concrete. | [68,82,83] | |

| Internet of things | The internet of things is a key technology that enables the interconnection of and communication among devices, machines, and products. | [38,40] | |

| Technological innovation | Technological innovation is the development and adoption of new or improved technologies that can create value for the company and its stakeholders. | ||

| Design for disassembly | An approach to the design of a product or constructed asset that facilitates disassembly at the end of its useful life in such a way that it enables components and parts to be reused, recycled, recovered for energy, or, in some other way, diverted from the waste stream. | [47,72,84,85,86,87] | |

| Standardization | The process of developing and implementing technical standards to ensure the compatibility, interoperability, and quality of construction components and connections, as well as procedures for information sharing, testing, certification, and legislation. | ||

| Environmental management | This refers to the adoption of practices and policies that minimize the negative effects of business activities on the environment and enhance the positive ones. | [35] | |

| Economic and market | Market demand | It refers to the need to maintain and grow the domestic and export market share of the cement industry in order to sustain its operations and investments in low-carbon solutions. | [54,57] |

| Reduced aggregate haul | The use of locally processed and recycled materials reduces the transportation costs and energy consumption associated with hauling virgin aggregates from distant sources. | [32] | |

| Incentive schemes | The schemes that provide financial or non-financial rewards for precasters to adopt green supply chain management practices. | [59,63] | |

| Cost savings of concrete elements | This factor is achieved by using local waste scoria as an aggregate, as it is cheaper and more sustainable than limestone aggregate. | [68,85] | |

| Investment in environmental management | Investment in environmental management is the allocation of resources and efforts toward environmentally friendly behaviors and strategies. | [38] | |

| Green intangible assets | These are the non-physical resources of a firm that contribute to its green competitive advantage, such as green reputation, green knowledge, green culture, and green capabilities. | [35,36] | |

| Implementation | Multilevel institutional coordination | It entails the coordination among different political and administrative levels in society to ensure effective and coherent implementation of climate adaptation measures. | [54,55] |

| Conventional road construction equipment | The use of standard road construction equipment to place and compact recycled materials in road structures, without requiring special modifications or adaptations. | [32] | |

| Stock control system | The system that helps precasters monitor and manage their inventory levels and reduce waste | [59] | |

| Structural flexibility | This factor allows the engineers to design smaller structural elements and greater span to depth ratio using lightweight concrete. | [68,83] | |

| Green work climate perception | Green work climate perception is the employees’ perception of the extent to which the company supports and encourages green behavior and sustainability. | [38,40,42] | |

| Green organizational identity | This is the extent to which a firm perceives itself as being environmentally responsible and committed to green values and goals. | [35] | |

| Support/Promotion | Policy support | It encompasses the provision of policy support from the government to address the competitiveness risks and leakage potential of the carbon tax and enable the industry to access alternative and renewable energy sources, supplementary cementing materials, and new technologies. | [54] |

| Green street program | A collaborative initiative between the City of Saskatoon and the University of Saskatchewan to investigate and demonstrate the use of recycled materials in urban road rehabilitation projects. | [32] | |

| Green labelling scheme | The scheme that certifies and promotes the products with low environmental impact. | [59,63] | |

| Enhanced energy dissipation | This factor improves the seismic performance of the structures using lightweight concrete, as they can withstand higher lateral forces and accelerations. | [68,81,83] | |

| Green human resource management | Green human resource management can help companies foster a green work climate, develop green skills and competencies, and motivate employees to engage in green initiatives. | [38] | |

| This entails a broad aspect of sustainable development as it fosters green innovation and enables organizations to gain a competitive advantage. | [35,36] | ||

| Investment in environmental management | Investment in environmental management can help companies comply with environmental regulations, improve their environmental performance, and gain a green competitive advantage. | [38] | |

| Stakeholder cooperation | The collaboration and communication among different practitioners in the construction sector, such as designers, contractors, manufacturers, clients, governments, knowledge institutions and federations, to create and support the necessary construction standards for component reuse. | [47,72] | |

| Social | Industry collaboration | It involves the collaboration with the global counterparts and other stakeholders of the cement industry to advance its climate action strategy and share best practices. | [54,56] |

| Environmental stewardship | The use of recycled materials reduces the landfilling of waste materials, conserves natural resources, and mitigates greenhouse gas emissions associated with road construction. | [32] | |

| Employee involvement | The involvement of employees in the decision-making and implementation of GSCM practices. | [59,63] | |

| Improved thermal insulation and sound absorption. | This factor enhances the comfort and quality of the buildings using lightweight concrete, as they can reduce heat loss and noise pollution. | [68,83] | |

| Green work climate perception | Green work climate perception can help companies enhance their green culture, increase their employees’ satisfaction and commitment, and strengthen their green reputation and image. | [38] | |

| Green human capital | This is the knowledge, skills, and abilities of employees that enable them to perform green tasks and activities effectively and efficiently. | [35,37] |

| Category | Frequency |

|---|---|

| Awareness | 6 |

| Technical | 9 |

| Economic and Market | 6 |

| Implementation | 6 |

| Support/promotion | 7 |

| Social | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Otaibi, A. Barriers and Enablers for Green Concrete Adoption: A Scientometric Aided Literature Review Approach. Sustainability 2024, 16, 5093. https://doi.org/10.3390/su16125093

Al-Otaibi A. Barriers and Enablers for Green Concrete Adoption: A Scientometric Aided Literature Review Approach. Sustainability. 2024; 16(12):5093. https://doi.org/10.3390/su16125093

Chicago/Turabian StyleAl-Otaibi, Ali. 2024. "Barriers and Enablers for Green Concrete Adoption: A Scientometric Aided Literature Review Approach" Sustainability 16, no. 12: 5093. https://doi.org/10.3390/su16125093