A Comprehensive Study on Static and Dynamic Operational Efficiency in Major Korean Container Terminals Amid the Smart Port Development Context

Abstract

1. Introduction

2. Literature Review

2.1. Smart Port Efficiency

2.2. Port Efficiency Evaluation Methods

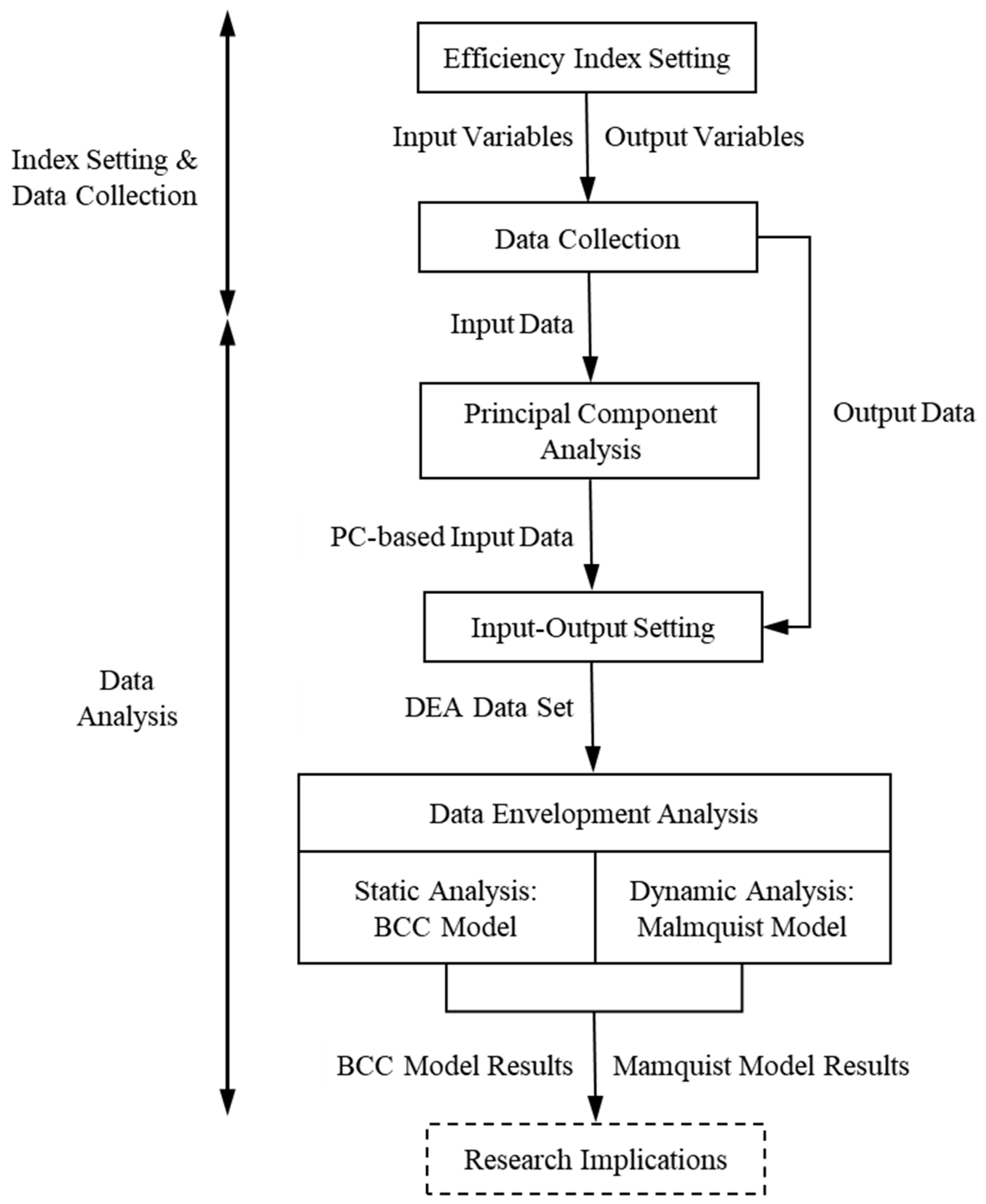

3. Methodology

3.1. Principal Component Analysis (PCA)

3.2. Data Envelopment Analysis (DEA)

3.2.1. BCC Model

3.2.2. Malmquist Model

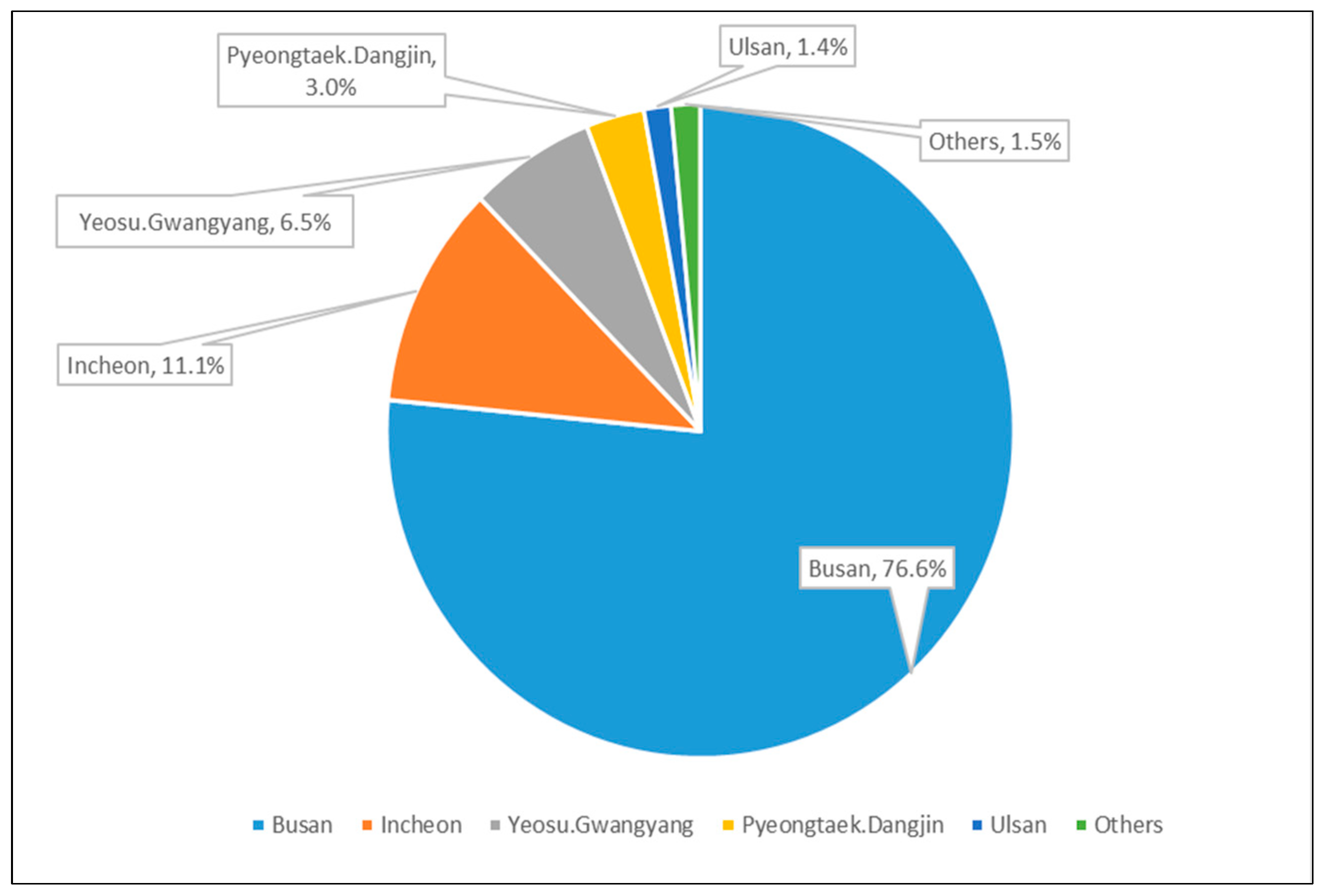

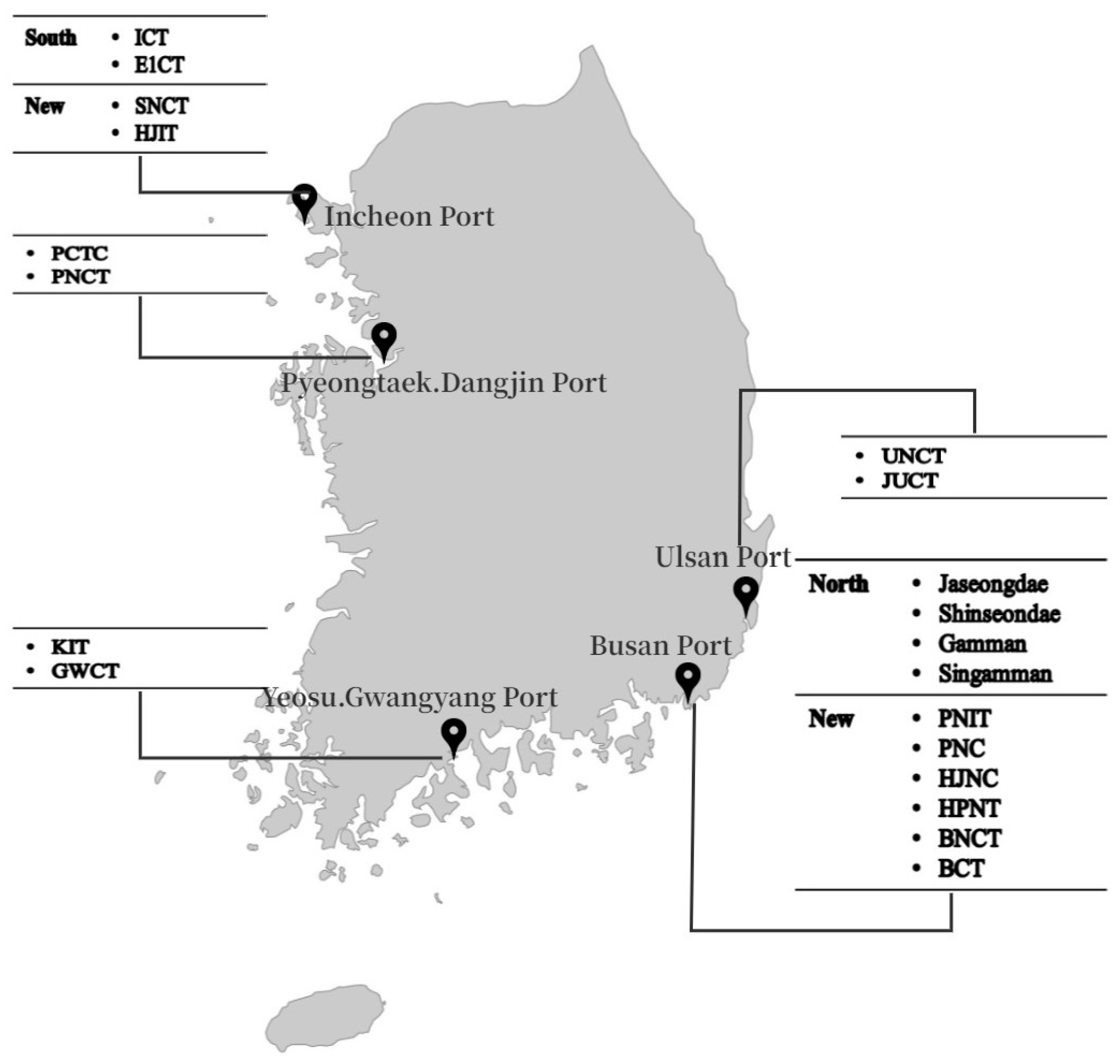

4. Index Setting and Data Collection

4.1. Efficiency Index Setting

4.2. Data Collection

5. Data Analysis

5.1. PCA Execution

5.2. Input–Output Setting

5.3. DEA Execution

5.3.1. Static Analysis: BCC Model

5.3.2. Dynamic Analysis: Malmquist Model

6. Discussion, Findings, and Implications

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Günther, H.O.; Kim, K.H. Container terminals and terminal operations. OR Spectr. 2006, 28, 437–445. [Google Scholar] [CrossRef]

- Felício, J.A.; Caldeirinha, V.; Dionísio, A. The effect of port and container terminal characteristics on terminal performance. Marit. Econ. Logist. 2015, 17, 493–514. [Google Scholar] [CrossRef]

- Humphrey, R. Why Ports Matter for the Global Economy. Available online: https://blogs.worldbank.org/transport/why-ports-matter-global-economy (accessed on 2 April 2024).

- Zheng, S.; Negenborn, R.R. Centralization or decentralization: A comparative analysis of port regulation modes. Transp. Res. E Logist. Transp. Rev. 2014, 69, 21–40. [Google Scholar] [CrossRef]

- de la Peña Zarzuelo, I.; Freire Soeane, M.J.; López Bermúdez, B. Industry 4.0 in the port and maritime industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100173. [Google Scholar] [CrossRef]

- Ferretti, M.; Schiavone, F. Internet of Things and business processes redesign in seaports: The case of Hamburg. Bus. Process Manag. J. 2016, 22, 271–284. [Google Scholar] [CrossRef]

- Jun, W.K.; Lee, M.K.; Choi, J.Y. Impact of the smart port industry on the Korean national economy using input-output analysis. Transp. Res. A Policy Pract. 2018, 118, 480–493. [Google Scholar] [CrossRef]

- Tongzon, J.; Heng, W. Port privatization, efficiency and competitiveness: Some empirical evidence from container ports (terminals). Transp. Res. A Policy Pract. 2005, 39, 405–424. [Google Scholar] [CrossRef]

- Castellano, R.; Fiore, U.; Musella, G.; Perla, F.; Punzo, G.; Risitano, M.; Sorrentino, A.; Zanetti, P. Do digital and communication technologies improve smart ports? A fuzzy DEA approach. IEEE Trans. Ind. Inform. 2019, 15, 5674–5681. [Google Scholar] [CrossRef]

- Molavi, A.; Lim, G.J.; Race, B. A framework for building a smart port and smart port index. Int. J. Sustain. Transp. 2020, 14, 686–700. [Google Scholar] [CrossRef]

- Lin, S.C.; Chang, H.K.; Chung, Y.F. Exploring the Impact of Different Port Governances on Smart Port Development Strategy in Taiwan and Spain. Sustainability 2022, 14, 9158. [Google Scholar] [CrossRef]

- ESCAP. Smart Ports Development Polices in Asia and the Pacific; ESCAP: Bangkok, Thailand, 2021. [Google Scholar]

- Intralink. Marine Industry 4.0 South Korea; Department for International Trade: Seoul, Republic of Korea, 2021. [Google Scholar]

- IAPH. The Study on Best Practices of Container Terminal Automation in the World; International Association of Ports and Harbors: Tokyo, Japan, 2015. [Google Scholar]

- CGTN. Ghost Port: Asia’s First Fully-Automated Port Begins Operations in Qingdao. Available online: https://news.cgtn.com/news/3d637a4e31677a4d/share_p.html (accessed on 5 June 2024).

- Seatrade Maritime News. Busan New Port Launches First Automated Container Terminal in South Korea; Seatrade Maritime News: Dubai, India, 2024; Available online: https://www.seatrade-maritime.com (accessed on 5 June 2024).

- Ministry of Land, Infrastructure and Transport. The National Logistics Master Plan (2016–2025); Ministry of Land, Transport and Maritime Affairs: Sejong, Republic of Korea, 2016. [Google Scholar]

- BPA. 2022 Port of Busan Container Statistics. Available online: https://www.busanpa.com/eng/Board.do?mode=view&mCode=MN0043&idx=30055 (accessed on 27 April 2024).

- World Shipping Council. The Top 50 Container Ports. Available online: https://www.worldshipping.org/top-50-ports (accessed on 1 March 2024).

- Yen, B.T.H.; Huang, M.J.; Lai, H.J.; Cho, H.H.; Huang, Y.L. How smart port design influences port efficiency—A DEA-Tobit approach. Res. Transp. Bus. Manag. 2023, 46, 100862. [Google Scholar] [CrossRef]

- Belmoukari, B.; Audy, J.F.; Forget, P. Smart port: A systematic literature review. Eur. Transp. Res. Rev. 2023, 15, 4. [Google Scholar] [CrossRef]

- Krmac, E.; Mansouri Kaleibar, M. A comprehensive review of data envelopment analysis (DEA) methodology in port efficiency evaluation. Marit. Econ. Logist. 2023, 25, 817–881. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Cooper, W.W.; Seiford, L.M.; Tone, K.; Zhu, J. Some models and measures for evaluating performances with DEA: Past accomplishments and future prospects. J. Prod. Anal. 2007, 28, 151–163. [Google Scholar] [CrossRef]

- Chen, J.; Wan, Z.; Zhang, F.; Park, N.k.; He, X.; Yin, W. Operational Efficiency Evaluation of Iron Ore Logistics at the Ports of Bohai Bay in China: Based on the PCA-DEA Model. Math. Probl. Eng. 2016, 2016, 9604819. [Google Scholar] [CrossRef]

- Mustafa, F.S.; Khan, R.U.; Mustafa, T. Technical efficiency comparison of container ports in Asian and Middle East region using DEA. Asian J. Shipp. Logist. 2021, 37, 12–19. [Google Scholar] [CrossRef]

- Fancello, G.; Serra, P.; Aramu, V.; Vitiello, D.M. Evaluating the efficiency of Mediterranean container ports using data envelopment analysis. Compet. Regul. Netw. Ind. 2021, 22, 163–188. [Google Scholar] [CrossRef]

- Haralambides, H.E. Containerization and the port industry. Int. Encycl. Transp. 2021, 5, 545–556. [Google Scholar] [CrossRef]

- Parola, F.; Risitano, M.; Ferretti, M.; Panetti, E. The drivers of port competitiveness: A critical review. Transp. Rev. 2017, 37, 116–138. [Google Scholar] [CrossRef]

- Figueiredo, A.E.P.; Carvalhal, R.d.D.; Hoeflich, S.; Figueiredo, L.; Pereira, S.L.; Dias, E.M. Port operation—Increase of automated systems, decline of workforce jobs? In Recent Advances in Computer Science, Proceedings of 19th International Conference on Circuits, Systems, Communications and Computers (CSCC 2015), Zakynthos Island, Greece, 16–20 July 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 259–266. ISBN 978-1-61804-320-7. [Google Scholar]

- Cullinane, K.; Wang, T.F. Chapter 23 Data Envelopment Analysis (DEA) and Improving Container Port Efficiency. Res. Transp. Econ. 2006, 17, 517–566. [Google Scholar] [CrossRef]

- Tongzon, J.L. Determinants of port performance and efficiency. Transp. Res. A Policy Pract. 1995, 29, 245–252. [Google Scholar] [CrossRef]

- Clark, X.; Dollar, D.; Micco, A. Maritime Transport Costs and Port Efficiency; World Bank: Washington, DC, USA, 2002. [Google Scholar]

- Sánchez, R.J.; Hoffmann, J.; Micco, A.; Pizzolitto, G.V.; Sgut, M.; Wilmsmeier, G. Port Efficiency and International Trade: Port Efficiency as a Determinant of Maritime Transport Costs. Marit. Econ. Logist. 2003, 5, 199–218. [Google Scholar] [CrossRef]

- Martinez Budria, E.; Diaz Armas, R.; Navarro Ibanez, M.; Ravelo Mesa, T. A study of the efficiency of Spanish port authorities using data envelopment analysis. Int. J. Transp. Econ./Riv. Internazionale Econ. Trasp. 1999, 26, 237–253. [Google Scholar]

- Cullinane, K.; Song, D.W.; Gray, R. A stochastic frontier model of the efficiency of major container terminals in Asia: Assessing the influence of administrative and ownership structures. Transp. Res. A Policy Pract. 2002, 36, 743–762. [Google Scholar] [CrossRef]

- Song, D.W. Port co-opetition in concept and practice. Marit. Policy Manag. 2003, 30, 29–44. [Google Scholar] [CrossRef]

- Cui, H.; Notteboom, T. A game theoretical approach to the effects of port objective orientation and service differentiation on port authorities’ willingness to cooperate. Res. Transp. Bus. Manag. 2018, 26, 76–86. [Google Scholar] [CrossRef]

- Rødseth, K.L.; Holmen, R.B.; Kuosmanen, T.; Schøyen, H. Market access and seaport efficiency: The case of container handling in Norway. J. Ship. Trade 2023, 8, 8. [Google Scholar] [CrossRef]

- Li, J.; Ren, J.; Ma, X.; Xiao, G. Environmental efficiency of ports under the dual carbon goals: Taking China’s Bohai-rim ports as an example. Front. Mar. Sci. 2023, 10, 1129659. [Google Scholar] [CrossRef]

- Philipp, R.; Gerlitz, L.; Moldabekova, A. Small and Medium-Sized Seaports on the Digital Track: Tracing Digitalisation across the South Baltic Region by Innovative Auditing Procedures. In International Conference on Reliability and Statistics in Transportation and Communication; Kabashkin, I., Yatskiv, I., Prentkovskis, O., Eds.; Springer: Cham, Switzerland, 2020; pp. 351–362. [Google Scholar]

- Yau, K.L.A.; Peng, S.; Qadir, J.; Low, Y.C.; Ling, M.H. Towards smart port infrastructures: Enhancing port activities using information and communications technology. IEEE Access 2020, 8, 83387–83404. [Google Scholar] [CrossRef]

- Makkawan, K.; Muangpan, T. A conceptual model of smart port performance and smart port indicators in Thailand. J. Int. Logist. Trade 2021, 19, 133–146. [Google Scholar] [CrossRef]

- Othman, A.; El-gazzar, S.; Knez, M. A Framework for Adopting a Sustainable Smart Sea Port Index. Sustainability 2022, 14, 4551. [Google Scholar] [CrossRef]

- Al Fatlawi, H.A.; Motlak, H.J. Smart ports: Towards a high performance, increased productivity, and a better environment. Int. J. Electr. Comput. Eng. (IJECE) 2023, 13, 1472–1482. [Google Scholar] [CrossRef]

- Odeck, J.; Schøyen, H. Productivity and convergence in Norwegian container seaports: An SFA-based Malmquist productivity index approach. Transp. Res. A Policy Pract. 2020, 137, 222–239. [Google Scholar] [CrossRef]

- Liu, Z. The Comparative Performance of Public and Private Enterprises: The Case of British Ports. J. Transp. Econ. Policy 1995, 29, 263–274. [Google Scholar]

- Notteboom, T.; Coeck, C.; Van Den Broeck, J. Measuring and Explaining the Relative Efficiency of Container Terminals by Means of Bayesian Stochastic Frontier Models. Int. J. Marit. Econ. 2000, 2, 83–106. [Google Scholar] [CrossRef]

- Cullinane, K.; Song, D.W. A stochastic frontier model of the productive efficiency of Korean container terminals. Appl. Econ. 2003, 35, 251–267. [Google Scholar] [CrossRef]

- Barros, C.P.; Chen, Z.; Wanke, P. Efficiency in Chinese seaports: 2002–2012. Marit. Econ. Logist. 2016, 18, 295–316. [Google Scholar] [CrossRef]

- Cook, W.D.; Tone, K.; Zhu, J. Data envelopment analysis: Prior to choosing a model. Omega 2014, 44, 1–4. [Google Scholar] [CrossRef]

- Roll, Y.; Hayuth, Y. Port performance comparison applying data envelopment analysis (DEA). Marit. Policy Manag. 1993, 20, 153–161. [Google Scholar] [CrossRef]

- Tongzon, J. Efficiency measurement of selected Australian and other international ports using data envelopment analysis. Transp. Res. A Policy Pract. 2001, 35, 107–122. [Google Scholar] [CrossRef]

- Barros, C.P.; Athanassiou, M. Efficiency in European Seaports with DEA: Evidence from Greece and Portugal. Marit. Econ. Logist. 2004, 6, 122–140. [Google Scholar] [CrossRef]

- Ng, A.S.F.; Lee, C.X. Productivity analysis of container ports in Malaysia: A DEA approach. J. East Asia Soc. Transp. Stud. 2007, 7, 2940–2952. [Google Scholar] [CrossRef]

- Jiang, B.; Li, J. DEA-based Performance Measurement of Seaports in Northeast Asia: Radial and Non-radial Approach. Asian J. Shipp. Logist. 2009, 25, 219–236. [Google Scholar] [CrossRef]

- Wanke, P.F.; Barbastefano, R.G.; Hijjar, M.F. Determinants of efficiency at major Brazilian port terminals. Transp. Rev. 2011, 31, 653–677. [Google Scholar] [CrossRef]

- Güner, S. Incorporating value judgments into port efficiency measurement models: Insights from Turkish ports. Marit. Econ. Logist. 2018, 20, 569–586. [Google Scholar] [CrossRef]

- Quintano, C.; Mazzocchi, P.; Rocca, A. A competitive analysis of EU ports by fixing spatial and economic dimensions. J. Ship. Trade 2020, 5, 18. [Google Scholar] [CrossRef]

- Park, R.k.; De, P. An Alternative Approach to Efficiency Measurement of Seaports. Marit. Econ. Logist. 2004, 6, 53–69. [Google Scholar] [CrossRef]

- Park, R.K. A Study on the Extracting the Core Input and Output Variables in Korean Seaports by DEA and PCA Approach. J. Navig. Port Res. 2006, 30, 793–800. [Google Scholar] [CrossRef][Green Version]

- Park, B.K.; Choi, M.S.; Song, J.Y. A Study on the Efficiency Analysis of Container Terminal. In Korean Institute of Navigation and Port Research Conference; Korean Institute of Navigation and Port Research: Yeosu, Republic of Korea, 2006; pp. 163–170. [Google Scholar]

- Min, H.; Park, B.I. A hybrid Data Envelopment Analysis and simulation methodology for measuring capacity utilisation and throughput efficiency of container terminals. Int. J. Logist. Syst. Manag. 2008, 4, 650–672. [Google Scholar] [CrossRef]

- Park, H.G. The data envelopment analysis of container terminals to transshipment cargo. J. Korea Port Econ. Assoc. 2010, 26, 1–19. [Google Scholar]

- Chang, Y.T. Environmental efficiency of ports: A data envelopment analysis approach. In Ports and the Environment; Routledge: London, UK, 2017; pp. 77–88. [Google Scholar]

- Seo, J.H.; Gong, J.M.; Nam, T.H.; Yeo, G.T. Analyzing Efficiency of Korean Automobile Ports. J. Navig. Port Res. 2017, 41, 127–136. [Google Scholar] [CrossRef]

- Chen, M.; Lee, H.; Yun, K. A Study on Efficiency Evaluation of Yeosu? Gwangyang Port. Korea Logist. Soc. 2021, 29, 13–24. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some Models for Estimating Technical and Scale Inefficiencies in Data Envelopment Analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Maćkiewicz, A.; Ratajczak, W. Principal components analysis (PCA). Comput. Geosci. 1993, 19, 303–342. [Google Scholar] [CrossRef]

- Pasini, G. Principal component analysis for stock portfolio management. Int. J. Pure Appl. Math. 2017, 115, 153–167. [Google Scholar] [CrossRef]

- Patro, S.; Sahu, K.K. Normalization: A preprocessing stage. arXiv 2015, arXiv:1503.06462. [Google Scholar] [CrossRef]

- Thanassoulis, E. Introduction to the Theory and Application of Data Envelopment Analysis; Springer: New York, NY, USA, 2001. [Google Scholar]

- Kumar, N.; Singh, A. Efficiency analysis of banks using DEA: A review. Int. J. Adv. Res. Innov. 2014, 1, 120–126. [Google Scholar] [CrossRef]

- Caves, D.W.; Christensen, L.R.; Diewert, W.E. The Economic Theory of Index Numbers and the Measurement of Input, Output, and Productivity. Econometrica 1982, 50, 1393–1414. [Google Scholar] [CrossRef]

- Farrell, M.J. The Measurement of Productive Efficiency. J. R. Stat. Soc. Ser. A Gen. 1957, 120, 253–281. [Google Scholar] [CrossRef]

- Firsova, A.; Chernyshova, G. Efficiency Analysis of Regional Innovation Development Based on DEA Malmquist Index. Information 2020, 11, 294. [Google Scholar] [CrossRef]

- Liang, L.; Huang, W.; Huang, S.; Weng, D. Combining SPSSAU and WJX. CN Analysis to Study the Status Quo of Online and Offline Blended Teaching Model. In Proceedings of the 2nd International Conference on Internet, Education and Information Technology (IEIT 2022), Zhangjiajie, China, 15–17 April 2022; Atlantis Press: Amsterdam, The Netherlands, 2022; pp. 379–389. [Google Scholar]

- Shrestha, N. Factor analysis as a tool for survey analysis. Am. J. Appl. Math. Stat. 2021, 9, 4–11. [Google Scholar] [CrossRef]

- An, N.; Xie, J.; Zheng, X.; Gao, X. Application of PCA in concrete infrared thermography detection. In Proceedings of the 2015 2nd International Workshop on Materials Engineering and Computer Sciences, Jinan, China, 10–11 October 2015; Atlantis Press: Amsterdam, The Netherlands, 2015; pp. 809–814. [Google Scholar]

- Zhang, S.; Wei, J.; Zhong, C.; Yang, Y.; Wei, W. The comprehensive evaluation of Wuhan’s urban ecological transportation development based on PCA-DEA. Highw. Automot. Appl. 2018, 189, 22–27. [Google Scholar] [CrossRef]

- HMM Co., Ltd. Terminal Operations. Available online: https://www.hmm21.com/company/service/terminalMain.do (accessed on 6 June 2024).

- Valentine, V.F.; Gray, R. The measurement of port efficiency using data envelopment analysis. In Proceedings of the 9th World Conference on Transport Research, Seoul, Republic of Korea, 22–27 July 2001; Institute of Marine Studies, University of Plymouth: Plymouth, UK, 2001; p. 27. [Google Scholar]

- Duncombe, W.; Yinger, J. An analysis of returns to scale in public production, with an application to fire protection. J. Public Econ. 1993, 52, 49–72. [Google Scholar] [CrossRef]

- Fligstein, N.; Dauber, K. Structural change in corporate organization. Annu. Rev. Sociol. 1989, 15, 73–96. [Google Scholar] [CrossRef]

| Regional Type | Authors | DMU | Models | Primary Indicators | Second Indicators | |

|---|---|---|---|---|---|---|

| Abroad from Korea | Roll and Hayuh [52] | 20 hypothetical ports | CCR | Manpower; capital; cargo uniformity | The annual average number of longshore laborers; the total invested capital; the coefficient of variation (CV) of the types of cargo (3) | Cargo throughput; service level; users’ satisfaction; ship calls (4) |

| Martinez-Budria [35] | 26 Spanish ports | BCC | Port activity expenditures | Labor expenditures; depreciation expenditures; other expenditures (3) | Total cargo moved through the docks; revenue obtained from the rent of port facilities (2) | |

| Tongzon [53] | 4 Australian ports and 12 other container ports | CCR | Land; labor; capital | The number of port authority employees; the number of berths; the number of cranes; the number of tugs; the terminal area of the ports; the amount of delay time (6) | Cargo throughput; ship working rate (2) | |

| Barros and Athanassiou [54] | 20 Greek and 10 Portuguese seaports | CCR, BCC | Labor; capital | The number of workers; the book value of assets (2) | Ships; movement of freight; total cargo handled (dry and liquid cargo, unloaded and loaded); containers (loaded and unloaded) (4) | |

| Ng and Lee [55] | 6 Malaysian container ports | CCR | Land; infrastructure | Total yard area; number of yard; total berth length; number of quay cranes (4) | Container throughput; number of ship calls (2) | |

| Jiang and Li [56] | 12 Asian ports | Radial and Non-radial DEA | Trade volume; land; infrastructure | Import/export by customs; berth length; crane numbers (3) | Throughputs (1) | |

| Wanke et al. [57] | 25 major Brazilian port terminals | CCR, BCC | Land | Number of berths; terminal area; parking lot (3) | Aggregate throughput; loaded shipments (2) | |

| Chen et al. [25] | 7 ports of Bohai Bay in China | PCA-BCC | Natural conditions; infrastructure; scale and capacity; distribution capacity | Water depth of the navigation channel; width of the main navigation channel; average water depth of the berth; infrastructure related to iron ore logistic services; total length of the berth; the number of berths; the number of berths of over 150,000 tons; area of the iron ore storage yard; the volume of the iron ore stock; the number of loading and unloading machines; scale and capacity of the iron ore logistics; services of the port designed iron ore carrying capacity (11) | Iron ore throughput; growth of iron ore throughput; length of the railway line in the port; ship-loading efficiency of a single iron ore line; iron ore unloading efficiency (4) | |

| Guner [58] | 13 Turkish ports | CCR | Land; labor; infrastructure | Labor; total expenses; length of quay; terminal area; number of tugs; number of forklifts (5) | Freights handled; ship calls; total income (3) | |

| Quintano et al. [59] | 10 leading EU ports | BCC | Land; labor | Number of employees; terminal quay length (2) | Total gross weight of goods handled (1) | |

| Mustafa et al. [26] | 15 container ports each in both the South and Middle Eastern region and the East Asian region; i.e., the total is 30 | CCR, BCC | Land; infrastructure | Cranes; berth length; number of berths; draught (4) | Throughput (1) | |

| Domestic in Korea | Park and De [60] | 11 Korean ports | 4-stage DEA | Land | Bberthing capability; cargo handling capacity (2) | Cargo throughput; number of ship calls; revenue; customer satisfaction (4) |

| R.-K. Park [61] | 26 main ports in Korea | CCR, BCC | Infrastructure | Berthing ability; unloading capacity (2) | Export throughput; import throughput; the number of ships (3) | |

| B.-K. Park et al. [62] | 15 container terminals in Korea | CCR, BCC | Infrastructure | Length of berth; number of gantry cranes; number of yard equipment (3) | Container throughput (1) | |

| Min and Park [63] | 11 container ports in Korea | CCR | Land; infrastructure; labor | Number of gantry cranes; terminal quay length; size of yard areas; size of labor force (4) | Cargo throughput (1) | |

| H.-G. Park [64] | 8 container terminals in Korea | CCR, BCC | Labor; infrastructure | Number of employees; length of berth; CY (container yard) area; the number of gantry cranes (4) | Container throughput (1) | |

| Chang (2013) [65] | 23 Korean ports | SBM-DEA | Land; infrastructure; labor; energy | Labor; quay length; terminal area; energy consumption (4) | Vessel; cargo handled; emissions (3) | |

| Seo et al. [66] | 8 automobile terminals in Korea | CCR, BCC | Labor; infrastructure | Number of employees; terminal area (2) | Automobiles throughput (1) | |

| Chen et al. [67] | Oil/ore/coal/container terminals in Yeosu Gwangyang Port in Korea | CCR, BCC | Infrastructure | Length of berth, unloading capacity (2) | Oil throughput; coal throughput; ore throughput (3) | |

| DMU | Input | Output | |

|---|---|---|---|

| Busan Port (North): 1. Jaseongdae; 2. Shinseondae; 3. Gamman; 4. Singamman Busan Port (New): 5. PNIT; 6. PNC; 7. HJNC; 8. HPNT; 9. BNCT; 10. BCT Incheon Port (South): 11. ICT; 12. E1CT Incheon Port (New): 13. SNCT; 14. HJIT Yeosu Gwangyang Port: 15. KIT; 16. GWCT Ulsan Port: 17. UNCT; 18. JUCT Pyeontack Dangjin Port: 19. PCTC; 20. PNCT | Primary Indicator (3) | Second Indicator (11) | Container Throughput (Y) |

| Land | Terminal Area (X1) | ||

| C.F.S. Area (X2) | |||

| Length of Berth (X3) | |||

| Depth of Water (X4) | |||

| Number of Berths (X5) | |||

| Facility | No. of Quay Crane (X6) | ||

| No. Transfer Crane (X7) | |||

| No. of Other Mobile equipment (X8) | |||

| Container Handling Capacity (Annual) (X9) | |||

| Labor | No. of Employees (X10) Employee Salary (Annual) (X11) | ||

| 2022 | 2021 | 2020 | ||

|---|---|---|---|---|

| KMO | 0.733 | 0.780 | 0.763 | |

| Bartlett test | Approx. Chi-Square | 279.914 | 239.035 | 232.725 |

| df | 55 | 55 | 55 | |

| p value | 0.000 | 0.000 | 0.000 | |

| PCs | 2022 | 2021 | 2020 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Eigen Values | Proportion of Variance | Cumulative Variance | Eigen Values | Proportion of Variance | Cumulative Variance | Eigen Values | Proportion of Variance | Cumulative Variance | |

| PC 1 | 7.519 | 68.36% | 68.36% | 7.584 | 68.95% | 68.95% | 7.551 | 68.64% | 68.64% |

| PC 2 | 1.234 | 11.22% | 79.57% | 1.135 | 10.32% | 79.27% | 1.202 | 10.92% | 79.57% |

| PC 3 | 0.825 | 7.50% | 87.07% | 0.882 | 8.02% | 87.29% | 0.877 | 7.97% | 87.54% |

| PC 4 | 0.607 | 5.52% | 92.59% | 0.506 | 4.60% | 91.89% | 0.529 | 4.81% | 92.35% |

| 2022 | 2021 | 2020 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PC1 | PC2 | PC3 | PC4 | PC1 | PC2 | PC3 | PC4 | PC1 | PC2 | PC3 | PC4 | |

| X1 | 0.943 | 0.032 | −0.115 | 0.169 | 0.930 | 0.110 | −0.059 | 0.227 | 0.941 | 0.116 | 0.005 | 0.188 |

| X2 | 0.342 | 0.816 | −0.003 | 0.443 | 0.316 | 0.888 | −0.105 | 0.260 | 0.317 | 0.854 | −0.226 | 0.311 |

| X3 | 0.919 | −0.098 | −0.273 | 0.082 | 0.906 | −0.084 | −0.139 | 0.214 | 0.909 | −0.099 | −0.065 | 0.171 |

| X4 | 0.721 | −0.469 | 0.224 | 0.321 | 0.773 | −0.307 | 0.324 | 0.288 | 0.756 | −0.273 | 0.379 | 0.332 |

| X5 | 0.840 | −0.016 | −0.412 | 0.077 | 0.785 | −0.237 | −0.393 | 0.094 | 0.788 | −0.291 | −0.351 | 0.178 |

| X6 | 0.963 | −0.003 | 0.022 | −0.030 | 0.956 | −0.011 | 0.051 | −0.092 | 0.955 | −0.054 | 0.019 | −0.172 |

| X7 | 0.913 | −0.278 | 0.136 | −0.006 | 0.964 | −0.121 | 0.088 | −0.065 | 0.958 | −0.124 | 0.094 | −0.076 |

| X8 | 0.853 | 0.239 | −0.005 | −0.366 | 0.877 | 0.004 | −0.186 | −0.321 | 0.878 | −0.022 | −0.273 | −0.276 |

| X9 | 0.952 | −0.209 | −0.074 | −0.062 | 0.959 | −0.149 | −0.046 | 0.004 | 0.958 | −0.157 | 0.001 | −0.005 |

| X10 | 0.813 | 0.381 | 0.050 | −0.357 | 0.823 | 0.323 | −0.120 | −0.351 | 0.829 | 0.324 | −0.172 | −0.302 |

| X11 | 0.623 | 0.118 | 0.700 | 0.022 | 0.613 | 0.191 | 0.726 | −0.106 | 0.585 | 0.376 | 0.665 | −0.149 |

| 2022 | 2021 | 2020 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PC1 | PC2 | PC3 | PC4 | PC1 | PC2 | PC3 | PC4 | PC1 | PC2 | PC3 | PC4 | |

| X1 | 0.344 | 0.029 | −0.127 | 0.217 | 0.338 | 0.103 | −0.063 | 0.319 | 0.343 | 0.105 | 0.005 | 0.258 |

| X2 | 0.125 | 0.734 | −0.003 | 0.568 | 0.115 | 0.833 | −0.112 | 0.365 | 0.115 | 0.779 | −0.242 | 0.428 |

| X3 | 0.335 | −0.088 | −0.301 | 0.105 | 0.329 | −0.079 | −0.148 | 0.3 | 0.331 | −0.091 | −0.07 | 0.235 |

| X4 | 0.263 | −0.422 | 0.247 | 0.412 | 0.281 | −0.288 | 0.345 | 0.404 | 0.275 | −0.249 | 0.404 | 0.457 |

| X5 | 0.306 | −0.014 | −0.454 | 0.098 | 0.285 | −0.222 | −0.419 | 0.131 | 0.287 | −0.266 | −0.375 | 0.245 |

| X6 | 0.351 | −0.002 | 0.024 | −0.038 | 0.347 | −0.01 | 0.054 | −0.129 | 0.348 | −0.05 | 0.02 | −0.237 |

| X7 | 0.333 | −0.25 | 0.149 | −0.008 | 0.35 | −0.113 | 0.094 | −0.092 | 0.349 | −0.114 | 0.101 | −0.104 |

| X8 | 0.311 | 0.215 | −0.006 | −0.47 | 0.318 | 0.004 | −0.198 | −0.45 | 0.319 | −0.02 | −0.291 | −0.38 |

| X9 | 0.347 | −0.188 | −0.082 | −0.079 | 0.348 | −0.14 | −0.049 | 0.006 | 0.349 | −0.143 | 0.001 | −0.007 |

| X10 | 0.296 | 0.343 | 0.055 | −0.459 | 0.299 | 0.304 | −0.128 | −0.494 | 0.302 | 0.296 | −0.183 | −0.415 |

| X11 | 0.227 | 0.106 | 0.770 | 0.028 | 0.223 | 0.179 | 0.773 | −0.149 | 0.213 | 0.343 | 0.710 | −0.205 |

| Port | DMU | Input | Output | |||

|---|---|---|---|---|---|---|

| PC1 | PC2 | PC3 | PC4 | Container Throughput (Y) | ||

| Busan Port (North) | 1. Jaseongdae | 1.752 | 0.060 | 0.048 | 0.205 | 0.384 |

| 2. Shinseondae | 2.409 | 0.614 | 0.302 | 0.549 | 0.474 | |

| 3. Gamman | 1.520 | −0.202 | 0.381 | 0.271 | 0.280 | |

| 4. Singamman | 1.077 | −0.052 | 0.644 | 0.152 | 0.167 | |

| Busan Port (New) | 5. PNIT | 1.803 | −0.097 | 0.509 | 0.129 | 0.546 |

| 6. PNC | 3.071 | −0.195 | 0.213 | −0.239 | 1.000 | |

| 7. HJNC | 1.808 | −0.297 | 0.292 | 0.032 | 0.544 | |

| 8. HPNT | 1.575 | −0.424 | 0.281 | 0.249 | 0.456 | |

| 9. BNCT | 1.725 | −0.615 | 0.392 | 0.546 | 0.493 | |

| 10. BCT | 1.347 | −0.614 | 0.211 | 0.562 | 0.021 | |

| Incheon Port (South) | 11. ICT | 0.640 | −0.124 | 0.361 | 0.123 | 0.072 |

| 12. E1CT | 0.236 | 0.133 | 0.427 | 0.125 | 0.032 | |

| Incheon Port (New) | 13. SNCT | 1.169 | −0.214 | 0.588 | 0.314 | 0.178 |

| 14. HJIT | 1.220 | −0.348 | 0.603 | 0.429 | 0.207 | |

| Yeosu Gwangyang Port | 15. KIT | 1.180 | −0.249 | 0.081 | 0.401 | 0.139 |

| 16. GWCT | 1.389 | −0.268 | −0.059 | 0.369 | 0.212 | |

| Ulsan Port | 17. UNCT | 0.692 | −0.175 | −0.341 | 0.188 | 0.039 |

| 18. JUCT | 0.090 | 0.060 | 0.221 | 0.028 | 0.000 | |

| Pyeontack Dangjin Port | 19. PCTC | 0.892 | −0.136 | 0.068 | 0.315 | 0.075 |

| 20. PNCT | 0.539 | −0.004 | 0.063 | 0.197 | 0.35 | |

| Port | DMU | 2022 | 2021 | 2020 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TE | SE | OE | Efficiency | TE | SE | OE | Efficiency | TE | SE | OE | Efficiency | ||

| Busan Port (North) | 1. Jaseongdae | 0.847 | 0.874 | 0.741 | Non-Efficiency | 0.912 | 0.700 | 0.638 | Non-Efficiency | 0.954 | 0.659 | 0.629 | Non-Efficiency |

| 2. Shinseondae | 0.703 | 0.936 | 0.658 | Non-Efficiency | 0.830 | 0.742 | 0.616 | Non-Efficiency | 0.901 | 0.701 | 0.631 | Non-Efficiency | |

| 3. Gamman | 0.836 | 0.791 | 0.661 | Non-Efficiency | 0.827 | 0.657 | 0.543 | Non-Efficiency | 0.840 | 0.675 | 0.567 | Non-Efficiency | |

| 4. Singamman | 0.859 | 0.731 | 0.628 | Non-Efficiency | 0.904 | 0.563 | 0.509 | Non-Efficiency | 0.857 | 0.625 | 0.535 | Non-Efficiency | |

| Busan Port (New) | 5. PNIT | 0.965 | 0.994 | 0.959 | Non-Efficiency | 0.963 | 0.860 | 0.827 | Non-Efficiency | 0.997 | 0.878 | 0.875 | Non-Efficiency |

| 6. PNC | 1.000 | 1.000 | 1.000 | Efficiency | 1.000 | 1.000 | 1.000 | Efficiency | 1.000 | 1.000 | 1.000 | Efficiency | |

| 7. HJNC | 1.000 | 0.953 | 0.953 | Non-Efficiency | 1.000 | 1.000 | 1.000 | Efficiency | 1.000 | 1.000 | 1.000 | Efficiency | |

| 8. HPNT | 1.000 | 0.931 | 0.931 | Non-Efficiency | 1.000 | 0.864 | 0.864 | Non-Efficiency | 0.991 | 0.813 | 0.806 | Non-Efficiency | |

| 9. BNCT | 1.000 | 1.000 | 1.000 | Efficiency | 0.992 | 0.857 | 0.850 | Non-Efficiency | 0.965 | 0.778 | 0.751 | Non-Efficiency | |

| 10. BCT | 1.000 | 0.266 | 0.266 | Non-Efficiency | - | - | - | - | - | - | - | - | |

| Incheon Port (South) | 11. ICT | 0.995 | 0.623 | 0.620 | Non-Efficiency | 0.974 | 0.426 | 0.415 | Non-Efficiency | 0.946 | 0.475 | 0.449 | Non-Efficiency |

| 12. E1CT | 0.900 | 0.995 | 0.896 | Non-Efficiency | 0.951 | 0.43 | 0.408 | Non-Efficiency | 0.938 | 0.446 | 0.418 | Non-Efficiency | |

| Incheon Port (New) | 13. SNCT | 0.869 | 0.702 | 0.61 | Non-Efficiency | 0.866 | 0.546 | 0.473 | Non-Efficiency | 0.840 | 0.609 | 0.512 | Non-Efficiency |

| 14. HJIT | 0.911 | 0.714 | 0.65 | Non-Efficiency | 0.894 | 0.559 | 0.500 | Non-Efficiency | 0.869 | 0.582 | 0.506 | Non-Efficiency | |

| Yeosu Gwangyang Port | 15. KIT | 0.860 | 0.610 | 0.525 | Non-Efficiency | 0.868 | 0.510 | 0.443 | Non-Efficiency | 0.818 | 0.502 | 0.411 | Non-Efficiency |

| 16. GWCT | 0.908 | 0.650 | 0.591 | Non-Efficiency | 0.898 | 0.578 | 0.519 | Non-Efficiency | 0.843 | 0.562 | 0.474 | Non-Efficiency | |

| Ulsan Port | 17. UNCT | 1.000 | 0.820 | 0.820 | Non-Efficiency | 1.000 | 0.341 | 0.341 | Non-Efficiency | 1.000 | 0.364 | 0.364 | Non-Efficiency |

| 18. JUCT | 1.000 | 1.000 | 1.000 | Efficiency | 1.000 | 0.384 | 0.384 | Non-Efficiency | 1.000 | 0.414 | 0.414 | Non-Efficiency | |

| Pyeontack Dangjin Port | 19. PCTC | 0.863 | 0.565 | 0.488 | Non-Efficiency | 0.883 | 0.432 | 0.381 | Non-Efficiency | 0.842 | 0.444 | 0.374 | Non-Efficiency |

| 20. PNCT | 0.885 | 0.633 | 0.560 | Non-Efficiency | 0.931 | 0.385 | 0.358 | Non-Efficiency | 0.907 | 0.364 | 0.331 | Non-Efficiency | |

| Port | DMU | 2020–2021 | 2021–2022 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| EC | TC | PEC | SEC | TFP | EC | TC | PEC | SEC | TFP | ||

| Busan Port (North) | 1. Jaseongdae | 1.015 | 1.000 | 0.956 | 1.062 | 1.015 | 1.160 | 1.030 | 0.929 | 1.249 | 1.195 |

| 2. Shinseondae | 0.976 | 1.000 | 0.922 | 1.059 | 0.976 | 1.068 | 1.000 | 0.847 | 1.261 | 1.068 | |

| 3. Gamman | 0.959 | 1.000 | 0.984 | 0.975 | 0.959 | 1.217 | 1.000 | 1.011 | 1.203 | 1.217 | |

| 4. Singamman | 0.951 | 1.000 | 1.055 | 0.902 | 0.951 | 1.234 | 1.000 | 0.950 | 1.299 | 1.234 | |

| Busan Port (New) | 5. PNIT | 1.083 | 1.000 | 1.026 | 1.055 | 1.083 | 1.158 | 1.000 | 1.002 | 1.156 | 1.158 |

| 6. PNC | 1.000 | 1.018 | 1.000 | 1.000 | 1.018 | 1.000 | 1.617 | 1.000 | 1.000 | 1.617 | |

| 7. HJNC | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.953 | 0.820 | 1.000 | 0.953 | 0.781 | |

| 8. HPNT | 1.072 | 0.974 | 1.009 | 1.062 | 1.044 | 1.078 | 0.915 | 1.000 | 1.078 | 0.987 | |

| 9. BNCT | 1.133 | 0.991 | 1.028 | 1.102 | 1.123 | 1.176 | 1.037 | 1.008 | 1.167 | 1.220 | |

| 10. BCT | - | - | - | - | - | - | - | - | - | - | |

| Incheon Port (South) | 11. ICT | 0.924 | 1.000 | 1.030 | 0.897 | 0.924 | 1.493 | 1.000 | 1.023 | 1.459 | 1.493 |

| 12. E1CT | 0.977 | 1.000 | 1.014 | 0.964 | 0.977 | 2.193 | 1.000 | 0.947 | 2.317 | 2.193 | |

| Incheon Port (New) | 13. SNCT | 0.924 | 1.000 | 1.031 | 0.896 | 0.924 | 1.290 | 1.000 | 1.018 | 1.268 | 1.290 |

| 14. HJIT | 0.988 | 1.000 | 1.029 | 0.961 | 0.988 | 1.300 | 1.000 | 1.053 | 1.235 | 1.300 | |

| Yeosu Gwangyang Port | 15. KIT | 1.077 | 1.000 | 1.061 | 1.015 | 1.077 | 1.185 | 1.000 | 1.010 | 1.173 | 1.185 |

| 16. GWCT | 1.095 | 1.000 | 1.066 | 1.027 | 1.095 | 1.138 | 1.047 | 1.011 | 1.126 | 1.191 | |

| Ulsan Port | 17. UNCT | 0.937 | 1.000 | 1.000 | 0.937 | 0.937 | 2.403 | 1.150 | 1.000 | 2.403 | 2.764 |

| 18. JUCT | 0.926 | 1.000 | 1.000 | 0.926 | 0.926 | 2.606 | 1.000 | 1.000 | 2.606 | 2.606 | |

| Pyeontack Dangjin Port | 19. PCTC | 1.020 | 1.000 | 1.049 | 0.972 | 1.020 | 1.280 | 1.000 | 0.998 | 1.284 | 1.280 |

| 20. PNCT | 1.083 | 1.000 | 1.026 | 1.055 | 1.083 | 1.564 | 1.000 | 0.958 | 1.633 | 1.564 | |

| Port | DMU | 2022 | 2021 | 2020 | |||

|---|---|---|---|---|---|---|---|

| λ | Type | λ | Type | λ | Type | ||

| Busan Port (North) | 1. Jaseongdae | 0.446 | irs | 0.451 | irs | 0.44 | irs |

| 2. Shinseondae | 0.527 | irs | 0.52 | irs | 0.529 | irs | |

| 3. Gamman | 0.352 | irs | 0.365 | irs | 0.381 | irs | |

| 4. Singamman | 0.25 | irs | 0.28 | irs | 0.292 | irs | |

| Busan Port (New) | 5. PNIT | 0.592 | irs | 0.584 | irs | 0.611 | irs |

| 6. PNC | 1 | crs | 1 | crs | 1 | csr | |

| 7. HJNC | 0.59 | irs | 1 | crs | 1 | csr | |

| 8. HPNT | 0.511 | irs | 0.716 | irs | 0.634 | irs | |

| 9. BNCT | 1 | crs | 0.7 | irs | 0.511 | irs | |

| 10. BCT | 0.2 | irs | - | - | - | - | |

| Incheon Port (South) | 11. ICT | 0.165 | irs | 0.189 | irs | 0.204 | irs |

| 12. E1CT | 0.129 | irs | 0.147 | irs | 0.151 | irs | |

| Incheon Port (New) | 13. SNCT | 0.26 | irs | 0.273 | irs | 0.286 | irs |

| 14. HJIT | 0.287 | irs | 0.294 | irs | 0.288 | irs | |

| Yeosu Gwangyang Port | 15. KIT | 0.225 | irs | 0.254 | irs | 0.235 | irs |

| 16. GWCT | 0.291 | irs | 0.322 | irs | 0.292 | irs | |

| Ulsan Port | 17. UNCT | 0.135 | irs | 0.156 | irs | 0.166 | irs |

| 18. JUCT | 1 | crs | 0.125 | irs | 0.134 | irs | |

| Pyeontack Dangjin Port | 19. PCTC | 0.167 | irs | 0.192 | irs | 0.187 | irs |

| 20. PNCT | 0.132 | irs | 0.151 | irs | 0.141 | irs | |

| Port | DMU | Average Structural Change (by Transition of Each Adjacent 2-Year Period) | Rank (by Port) | ||

|---|---|---|---|---|---|

| EC | TC | TFP | |||

| Busan Port (North) | 1. Jaseongdae | 1.088 | 1.015 | 1.105 | 7 |

| 2. Shinseondae | 1.022 | 1.000 | 1.022 | ||

| 3. Gamman | 1.088 | 1.000 | 1.088 | ||

| 4. Singamman | 1.092 | 1.000 | 1.092 | ||

| Average | 1.072 | 1.004 | 1.077 | ||

| Busan Port (New) | 5. PNIT | 1.121 | 1.000 | 1.121 | 6 |

| 6. PNC | 1.000 | 1.318 | 1.318 | ||

| 7. HJNC | 0.976 | 0.910 | 0.890 | ||

| 8. HPNT | 1.075 | 0.945 | 1.015 | ||

| 9. BNCT | 1.154 | 1.014 | 1.171 | ||

| 10. BCT | - | - | - | ||

| Average | 1.065 | 1.037 | 1.103 | ||

| Incheon Port (South) | 11. ICT | 1.208 | 1.000 | 1.208 | 2 |

| 12. E1CT | 1.585 | 1.000 | 1.585 | ||

| Average | 1.397 | 1.000 | 1.397 | ||

| Incheon Port (New) | 13. SNCT | 1.107 | 1.000 | 1.107 | 5 |

| 14. HJIT | 1.144 | 1.000 | 1.144 | ||

| Average | 1.125 | 1.000 | 1.125 | ||

| Yeosu Gwangyang Port | 15. KIT | 1.131 | 1.000 | 1.131 | 4 |

| 16. GWCT | 1.116 | 1.023 | 1.143 | ||

| Average | 1.124 | 1.012 | 1.137 | ||

| Ulsan Port | 17. UNCT | 1.670 | 1.075 | 1.851 | 1 |

| 18. JUCT | 1.766 | 1.000 | 1.766 | ||

| Average | 1.718 | 1.038 | 1.808 | ||

| Pyeontack Dangjin Port | 19. PCTC | 1.150 | 1.000 | 1.150 | 3 |

| 20. PNCT | 1.323 | 1.000 | 1.323 | ||

| Average | 1.237 | 1.000 | 1.237 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Suh, W. A Comprehensive Study on Static and Dynamic Operational Efficiency in Major Korean Container Terminals Amid the Smart Port Development Context. Sustainability 2024, 16, 5288. https://doi.org/10.3390/su16135288

Zhou L, Suh W. A Comprehensive Study on Static and Dynamic Operational Efficiency in Major Korean Container Terminals Amid the Smart Port Development Context. Sustainability. 2024; 16(13):5288. https://doi.org/10.3390/su16135288

Chicago/Turabian StyleZhou, Lele, and Woojong Suh. 2024. "A Comprehensive Study on Static and Dynamic Operational Efficiency in Major Korean Container Terminals Amid the Smart Port Development Context" Sustainability 16, no. 13: 5288. https://doi.org/10.3390/su16135288

APA StyleZhou, L., & Suh, W. (2024). A Comprehensive Study on Static and Dynamic Operational Efficiency in Major Korean Container Terminals Amid the Smart Port Development Context. Sustainability, 16(13), 5288. https://doi.org/10.3390/su16135288