Beneficial Use of Water Treatment Sludge with Stabilizers for Application in Road Pavements

Abstract

:1. Introduction

- -

- Few studies have evaluated the replacement of soil with sludge in combination with stabilizing materials;

- -

- Most research is limited to a single material, restricting analysis to comparisons between mixtures;

- -

- Many studies lack standardization or specifications for the pre-treatment of incorporated WTS;

- -

- There is no specific legislation governing the use of sludge.

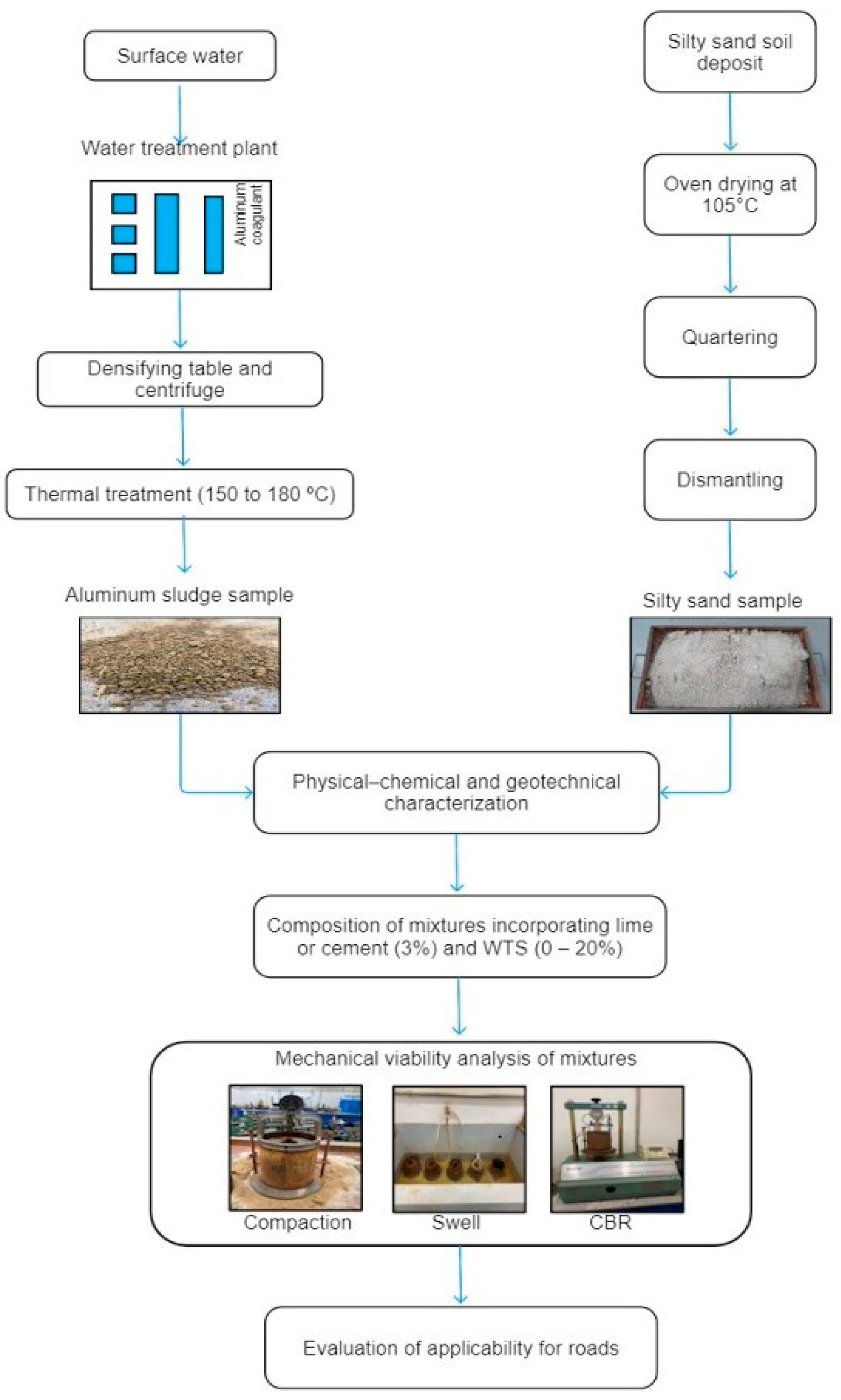

2. Materials and Methods

2.1. Sample Collection and Preparation

2.2. Analysis Methods

2.2.1. Physical and Chemical Characterization

2.2.2. Geotechnical Characterization

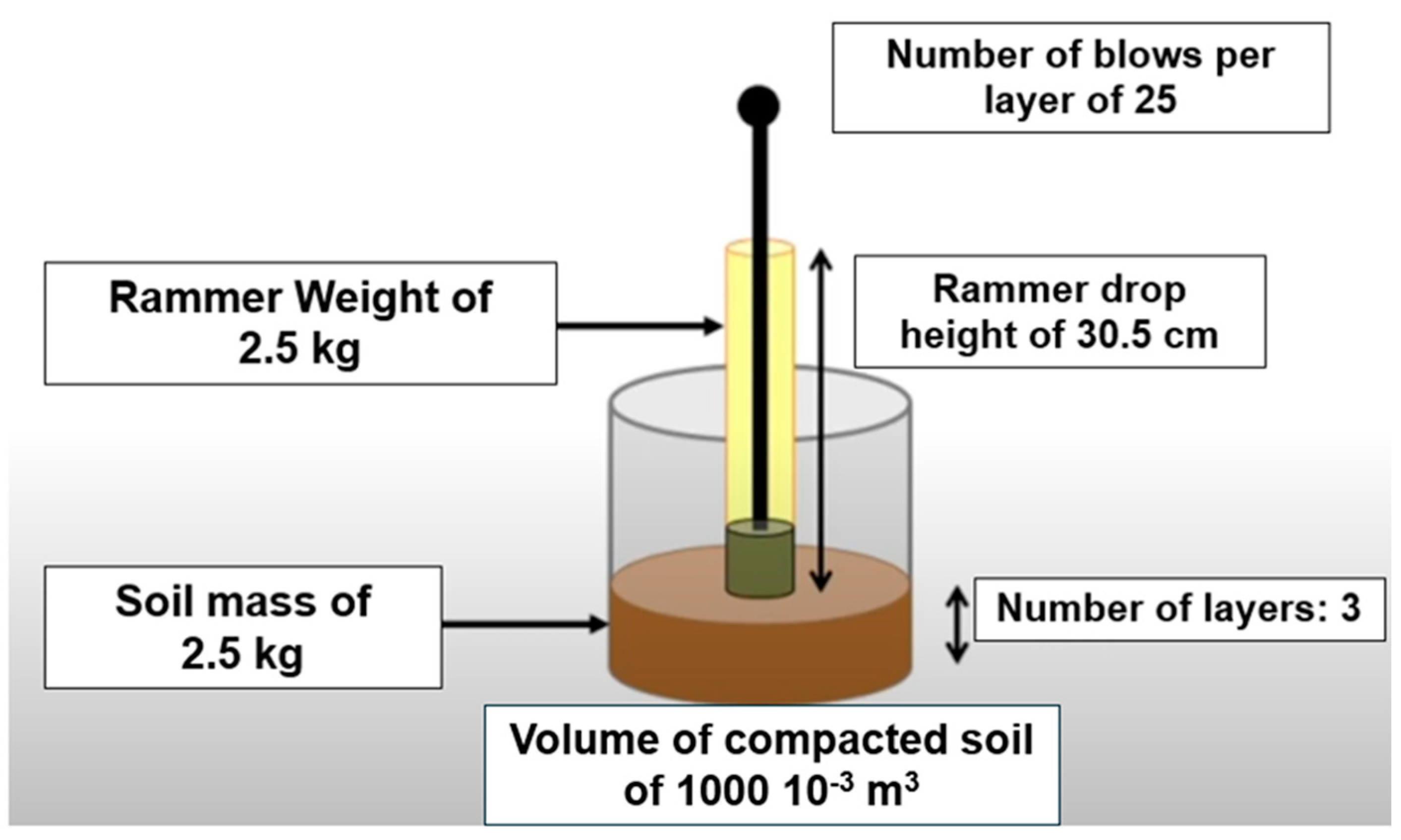

2.2.3. Mechanical Viability Analysis of Mixtures

- Subgrade materials must exhibit a swell of 2% or less, as measured in the CBR test, and have a CBR of at least 2%.

- Materials for subgrade reinforcement must have a CBR greater than that of the subgrade and a swell of 1% or less.

- Sub-base materials must have a CBR of at least 20% and a swell of 1% or less.

- Base materials must have a CBR of at least 80% and a swell of 0.5% or less.

3. Results and Discussion

3.1. Soil and WTPS Characteristics

3.2. Geotechnical Characterization of Soil and WTPS

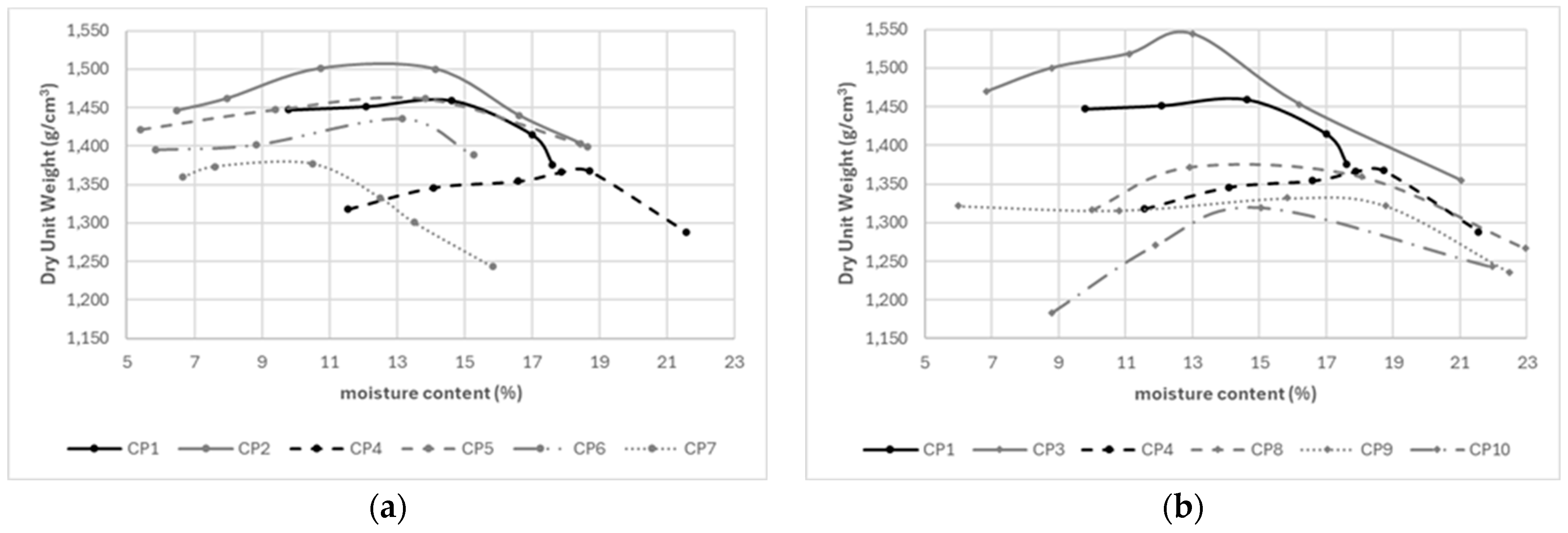

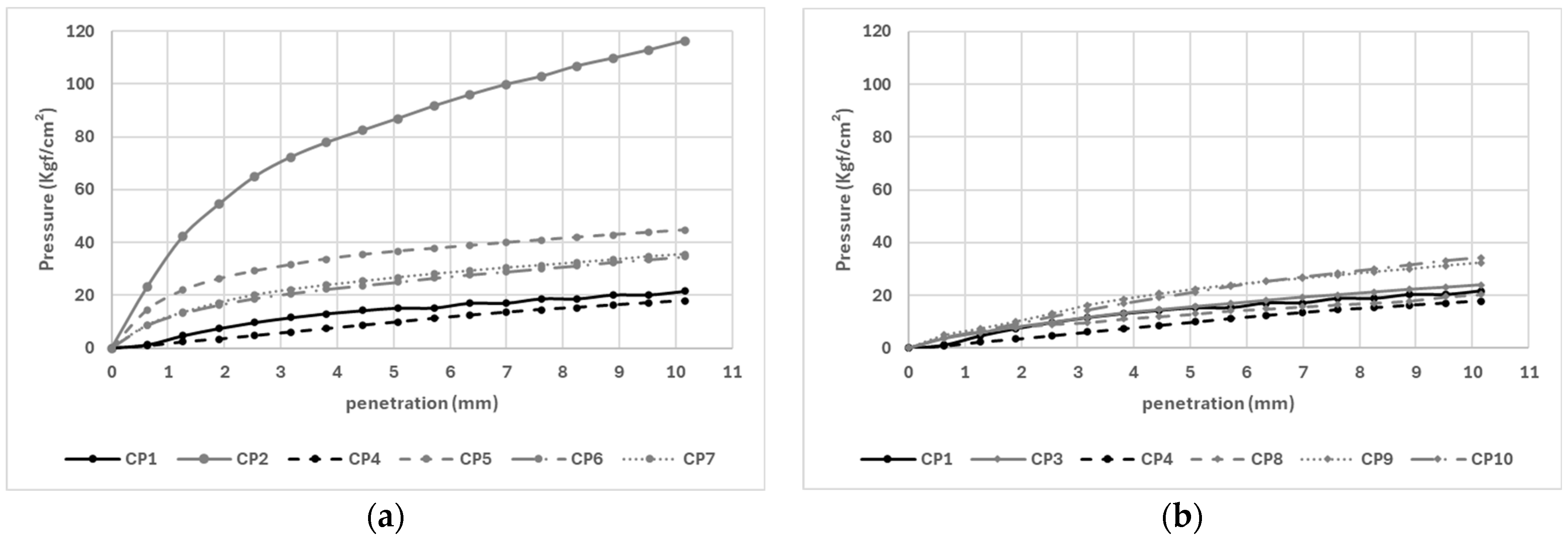

3.3. Mechanical Analysis of Mixtures

4. Conclusions

- -

- The physical and chemical analysis of the WTS and soil indicated that the resulting composites, when mixed for road construction, do not pose environmental risks.

- -

- Geotechnical analysis revealed that WTS and silty sand soil share similar particle sizes. However, while the silty sand exhibited a liquid limit of 26.42% and a plasticity index of 2.68%, the WTS was classified as non-plastic.

- -

- Mechanical testing demonstrated that soil–sludge mixtures, when augmented with stabilizing agents, meet Brazilian standards for various pavement layers. The optimal composition was determined to be CP5 (92% soil + 5% WTS + 3% cement), achieving a CBR of 41.50%. With the addition of lime, the most favorable results were obtained for CP9 (82% soil + 15% WTS + 3% lime), yielding a CBR of 21.25%.

- -

- Increasing the WTS content in cement mixtures resulted in decreased CBR values due to the rise in fine particles, which hindered interaction with the cement.

- -

- Conversely, augmenting WTS content in lime mixtures led to increased CBR values, as lime exhibited a more effective interaction with fine particles.

- -

- This study solely assessed mixtures with dried WTPS, silty sand soil stabilizers, and stabilizers (cement and lime). Future research could explore the utilization of other soil types with stabilizers, incorporate fibers into the mixes, evaluate the long-term performance of the pavement structure, and examine the economic and environmental feasibility of this beneficial application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, M.; Thomas, M.; Surapaneni, A.; Moon, E.; Milne, N. Beneficial reuse of water treatment sludge in the context of circular economy. Environ. Technol. Innov. 2022, 28, 102651. [Google Scholar] [CrossRef]

- Ahmad, T.; Ahmad, K.; Alam, M. Sludge quantification at water treatment plant and its management scenario. Environ. Monit. Assess. 2017, 189, 453. [Google Scholar] [CrossRef]

- Zhao, W.; Xie, H.; Li, J.; Zhang, L.; Zhao, Y. Application of alum sludge in wastewater treatment processes: “Science” of reuse and reclamation pathways. Processes 2021, 9, 612. [Google Scholar] [CrossRef]

- Fiore, F.; Rodgher, S.; Ito, C.; Bardini, V.; Klinsky, L. Water sludge reuse as a geotechnical component in road construction: Experimental study. Clean. Eng. Technol. 2022, 9, 100512. [Google Scholar] [CrossRef]

- Montalvan, E.; Boscov, M. Geotechnical parameters of mixtures of a tropical soil with water treatment sludge. Environmental Science and Engineering. In Proceedings of the 8th International Congress on Environmental Geotechnics, Hangzhou, China, 28 October–1 November 2018; Volume 1, pp. 235–242. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, R.; Awe, O.; Yany, Y.; Shen, C. Acceptability of land application of alum-based water treatment residuals—An explicit and comprehensive review. Chem. Eng. J. 2018, 353, 717–726. [Google Scholar] [CrossRef]

- Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais Renováveis (IBAMA). Lista Brasileira de Resíduos Sólidos; Instrução Normativa No. 13, 18 de Dezembro de 2012; Diário Oficial da União: Brasília, Brazil, 2012.

- Ahmad, T.; Ahmad, K.; Alam, M. Sustainable management of water treatment sludge through ‘3R’ concept. J. Clean. Prod. 2016, 124, 1–13. [Google Scholar] [CrossRef]

- Silva, A.; Barboza, E.; Silva, M. Uso alternativo de lodo de estação de tratamento de água em pavimentação: Uma revisão. Res. Soc. Dev. 2020, 9, e786974458. [Google Scholar] [CrossRef]

- Siswoyo, E.; Qoniah, I.; Lestari, P.; Fajri, J.; Sani, R.; Sari, D.; Boving, T. Development of a floating adsorbent for cadmium derived from modified drinking water treatment plant sludge. Environ. Technol. Innov. 2019, 14, 100312. [Google Scholar] [CrossRef]

- Qiu, F.; Zhao, S.; Zhao, D.; Wang, J.; Fu, K. Enhanced nutrient removal in bioretention systems modified with water treatment residuals and internal water storage zone. Environ. Sci. Water Res. Technol. 2019, 5, 993–1003. [Google Scholar] [CrossRef]

- Ren, B.; Lyczko, N.; Zhao, Y.; Nzihou, A. Alum sludge as an efficient sorbent for hydrogen sulfide removal: Experimental, mechanisms and modeling studies. Chemosphere 2020, 248, 126010. [Google Scholar] [CrossRef] [PubMed]

- Scalize, P.; Albuquerque, A.; Di Bernardo, L. Impact of alum water treatment residues on the methanogenic activity in the digestion of primary domestic wastewater sludge. Sustainability 2021, 13, 8783. [Google Scholar] [CrossRef]

- Muisa, N.; Nhapi, I.; Ruziwa, W.; Manyuchi, M. Utilization of alum sludge as adsorbent for phosphorus removal in municipal wastewater: A review. J. Water Process Eng. 2020, 35, 101187. [Google Scholar] [CrossRef]

- Lian, J.; Zhou, F.; Chen, B.; Yang, M.; Wang, S.; Liu, Z.; Niu, S. Enhanced adsorption of molybdenum(VI) onto drinking water treatment residues modified by thermal treatment and acid activation. J. Clean. Prod. 2020, 244, 118719. [Google Scholar] [CrossRef]

- Scalize, P.; Souza, L.; Albuquerque, A. Reuse of alum sludge for reducing flocculant addition in water treatment plants. Environ. Prot. Eng. 2019, 45, 57–70. [Google Scholar] [CrossRef]

- Wolowiec, M.; Komorowska-Kaufman, M.; Pruss, A.; Rzepa, G.; Bajda, T. Removal of heavy metals and metalloids from water using drinking water treatment residuals as adsorbents: A review. Minerals 2019, 9, 487. [Google Scholar] [CrossRef]

- Gadekar, M.; Ahammed, M. Use of water treatment residuals for colour removal from real textile dye wastewater. Appl. Water Sci. 2020, 10, 160. [Google Scholar] [CrossRef]

- Mansour, M.; Abdel-Shafy, H.; El Azab, W. Innovative reuse of drinking water sludge for the treatment of petroleum produced water to enhance oil recovery. Egypt. J. Pet. 2020, 29, 163–169. [Google Scholar] [CrossRef]

- Nayeri, D.; Mousavi, S. A comprehensive review on the coagulant recovery and reuse from drinking water treatment sludge. J. Environ. Manag. 2022, 316, 115649. [Google Scholar] [CrossRef] [PubMed]

- Scalize, P.; Neto, A.; Albuquerque, A. Water treatment sludge as potential soil amendment for native plants of the Brazilian Cerrado. Environ. Eng. Manag. J. 2018, 17, 1169–1178. [Google Scholar] [CrossRef]

- Ackah, L.A.; Guru, R.; Peiravi, M.; Mohanty, M.; Ma, X.; Kumar, S.; Liu, J. Characterization of Southern Illinois water treatment residues for sustainable applications. Sustainability 2018, 10, 1374. [Google Scholar] [CrossRef]

- Gomes, S.; Zhou, J.; Li, W.; Long, G. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A review. Resour. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Algamal, Y.; Khalil, N.; Saleem, Q. Usage of the sludge from water treatment plant in brick-making industry. J. Chem. Technol. Metall. 2018, 53, 504–510. Available online: https://journal.uctm.edu/node/j2018-3/14_17-72_p_504-510.pdf (accessed on 22 December 2023).

- Pokhara, P.; Ekamparam, A.; Gupta, A.; Rai, D.; Singh, A. Activated alumina sludge as partial substitute for fine aggregates in brick making. Constr. Build. Mater. 2019, 221, 244–252. [Google Scholar] [CrossRef]

- Heniegal, A.; Ramadan, M.; Naguib, A.; Agwa, I. Study on properties of clay brick incorporating sludge of water treatment plant and agriculture waste. Case Stud. Constr. Mater. 2020, 13, e00397. [Google Scholar] [CrossRef]

- Godoy, L.; Rohden, A.; Garcez, M.; Dalt, S.; Gomes, L. Production of supplementary cementitious material as a sustainable management strategy for water treatment sludge waste. Case Stud. Constr. Mater. 2020, 12, e00329. [Google Scholar] [CrossRef]

- Cremades, L.; Cusido, J.; Arteaga, F. Recycling of sludge from drinking water treatment as ceramic material for the manufacture of tiles. J. Clean. Prod. 2018, 201, 1071–1080. [Google Scholar] [CrossRef]

- Kaish, A.; Odimegwu, T.; Zakaria, I.; Abood, M.; Nahar, L. Properties of concrete incorporating alum sludge in different conditions as partial replacement of fine aggregate. Constr. Build. Mater. 2021, 284, 122669. [Google Scholar] [CrossRef]

- Buselatto, D.; Wenzel, M.; Rocha, G.; Webber, J.; Silva, S.; Andrade, J. Use of water treatment sludge (WTS) as fine aggregate in concretes: Evaluation of physical-mechanical properties. Rev. Mater. 2019, 24, 0645. [Google Scholar] [CrossRef]

- Liu, Y.; Chow, C.; Keegan, A.; Li, D.; Pham, P.; Huang, J.; Siddique, R. Utilization of drinking water treatment sludge in concrete paving blocks: Microstructural analysis, durability and leaching properties. J. Environ. Manag. 2020, 262, 110352. [Google Scholar] [CrossRef]

- Meert, R.; Hastenpflug, D.; Andrade, J. Contribution to the use of wet sludge water treatment plant fine aggregate in Portland cement concretes: Evaluation of consistency, density, porosity, absorption, strength and tensile strength. Rev. Mater. 2021, 26, 13025. [Google Scholar] [CrossRef]

- Guner, E. Experimental investigation of the feasibility of using drinking water treatment plant sludge in the improvement of sandy soils. J. Mater. Cycles Waste Manag. 2022, 24, 1923–1933. [Google Scholar] [CrossRef]

- Shaah, S.; Mahmood, Z.; Nisar, A.; Aamir, M.; Farid, A.; Waseem, M. Compaction performance analysis of alum sludge waste modified soil. Constr. Build. Mater. 2020, 230, 116953. [Google Scholar] [CrossRef]

- Boscov, M.; Tsugawa, J.; Montalvan, E. Beneficial use of water treatment sludge in geotechnical applications as a sustainable alternative to preserve natural soils. Sustainability 2021, 13, 9848. [Google Scholar] [CrossRef]

- Nazir, A.; Mahmoud, E.; Ali, M.; Ali, N. Safe and economic disposal of water treatment residuals by reusing it as a substitution layer in roads construction (spectroscopic and geotechnical study). Environ. Sci. Pollut. Res. 2020, 27, 30490–30501. [Google Scholar] [CrossRef] [PubMed]

- Marchiori, L.; Studart, A.; Albuquerque, A.; Pais, L.; Boscov, M.; Cavaleiro, V. Mechanical and chemical behaviour of water treatment sludge and soft soil mixtures for liner production. Open Civ. Eng. J. 2022, 16, e187414952211101. [Google Scholar] [CrossRef]

- Bagriacik, B.; Guner, E. An experimental investigation of reinforcement thickness of improved clay soil with drinking water treatment sludge as an additive. KSCE J. Civ. Eng. 2020, 24, 3619–3627. [Google Scholar] [CrossRef]

- Saldanha, R.; Rocha, C.; Caicedo, A.; Consoli, N. Technical and environmental performance of eggshell lime for soil stabilization. Constr. Build. Mater. 2021, 298, 123648. [Google Scholar] [CrossRef]

- Tan, E.; Zahran, E.; Tan, S. A review of chemical stabilisation in road construction. In Proceedings of the 2nd International Conference on Materials Technology and Energy, Miri, Malaysia, 6–8 November 2019; Volume 943, p. 012005. [Google Scholar] [CrossRef]

- Nguyen, V.; Phan, V.; Tran, H. Potential of fly ash, cement, and enzyme stabilized soil for road construction. Transp. Infrastruct. Geotechnol. 2023, 10, 1050–1071. [Google Scholar] [CrossRef]

- Mohamed, A.; Al-Ajamee, M.; Kobbail, A.; Dahab, H.; Abdo, M.; Alhassan, H. A study on soil stabilization for some tropical soils. Mater. Today Proc. 2022, 60, 87–92. [Google Scholar] [CrossRef]

- Williams, C. Research methods. J. Bus. Econ. Res. 2007, 5, 2532. [Google Scholar] [CrossRef]

- NBR 10007; Sampling of Solid Waste. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2004.

- M/MS Ordinance No. 588, of May 4, 2021. Amends Annex XX of GM/MS Consolidation Ordinance No. 5, of September 28, 2017, to Provide for Quality Control and Surveillance Procedures Water for Human Consumption and Its Potability Standard; Ministry of Health, Official Gazette of the Union, Section 1: Brasília, Brazil, 2021.

- Silva, J.; Menezes, A.; Fiore, F. Efficiency analysis of thermal drying of water treatment plant sludge: Case study carried out in the metropolitan region of São Paulo. In Proceedings of the 31st Congresso Brasileiro de Engenharia Sanitária e Ambiental, Curitiba, Brazil, 17–20 October 2021. [Google Scholar]

- US EPA. Method 3051A: “Microwave Assisted Acid Digestion of Sediments, Sludges, Soils, and Oils”, Revision 1; U.S. Environmental Protection Agency: Washington, DC, USA, 2007.

- US EPA. Method 245.7: “Mercury in Water by Cold Vapor Atomic Fluorescence Spectrometry”, Revision 2; EPA-821-R-05-001; U.S. Environmental Protection Agency: Washington, DC, USA, 2005.

- APHA. Standard Methods for the Examination of Water and Wastewater. Method 2540 G, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- US EPA. SW-846 Test Method 6010D: “Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES)”, Revision 5; U.S. Environmental Protection Agency: Washington, DC, USA, 2018.

- NBR 10004; Solid Waste—Classification. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2004.

- CETESB. Board Decision No. 125/2021/E: Provides for the Approval of the Update of the List of Guiding Values for Soil and Groundwater; Companhia de Tecnologia de Saneamento Ambiental: São Paulo, Brazil, 2021.

- CONAMA. Resolution No. 420: Provides Criteria and Guiding Values for Soil Quality Regarding the Presence of Chemical Substances and Establishes Guidelines for the Environmental Management of Areas Contaminated by These Substances as a Result of Human Activities; Conselho Nacional do Meio Ambiente: Brasília, Brazil, 2009; 20p.

- NBR 7181; Grain Size Analysis. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018.

- NBR 6459; Liquid Limit Determination. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- NBR 7180; Plasticity Limit Determination. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2016.

- ASTM D4318; Standard Test Method for Liquid Limit, Plastic Limit and Plasticity Index of Soils. American Society for Testing and Materials: Washington, DC, USA, 2018; 20p.

- NBR 7182; Compaction Test. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2020.

- NBR 9895; Soil—California Bearing Ratio (CBR)—Testing Method. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- DNIT. Paving Manual; Departamento de Infraestrutura de Transportes: Rio de Janeiro, Brazil, 2006.

- Trang, N.; Ho, N.; Babel, S. Reuse of waste sludge from water treatment plants and fly ash for manufacturing of adobe bricks. Chemosphere 2021, 284, 131367. [Google Scholar] [CrossRef] [PubMed]

- Marchiori, L.; Albuquerque, A.; Cavaleiro, V. Water treatment sludge as geotechnical liner material—State-of-art. In Sustainable Earth and Beyond; Yukselen-Aksoy, Y., Reddy, K., Agnihotri, A., Eds.; Springer: Berlim, Germany, 2023; Volume 370, pp. 529–547. [Google Scholar] [CrossRef]

- Little, D. Evaluation of structural properties of lime stabilization soil and aggregates. In Mixture Design and Testing Procedure for Lime Stabilized Soils; National Lime Association: Arlington, VA, USA, 2000; Volume 3, 16p. [Google Scholar]

- Fadanelli, L.; Wiecheteck, G. Utilization of sludge from water treatment plant in soil cement for paving roads. Rev. Eng. E Tecnol. 2010, 2, 31–37. [Google Scholar]

- NLA. Lime Stabilization & Lime Modification; Bulletin 326; National Lime Association: Arlington, VA, USA, 2004; 41p.

- Jiang, P.; Chen, Y.; Wang, W.; Yang, J.; Wang, H.; Li, N.; Wang, W. Flexural behavior evaluation and energy dissipation mechanisms of modified iron tailings powder incorporating cement and fibers subjected to freeze-thaw cycles. J. Clean. Prod. 2022, 351, 131527. [Google Scholar] [CrossRef]

- Jiang, P.; Wang, Z.; Li, N.; Song, X.; Chen, Y.; Wang, W. Cumulative deformation and non-coaxial characteristics of fiber and cement-modified iron tailings under the rotation of principal stress. Transp. Geotech. 2023, 43, 101114. [Google Scholar] [CrossRef]

| Mixing Components with WTS | Type of Sludge Aluminum/Iron (A/I) | Pre-Treatment of Sludge | Evaluated WTS Incorporation Percentages (%) | Percentage of Most Suitable WTS (%) | Use for Geotechnical Applications | Reference |

|---|---|---|---|---|---|---|

| Clayey sand soil and sandy soil | A and I | Drying in thermal equipment (150 to 180 °C) | 25; 50 | 25 e 50 | Embankment | [4] |

| Sandy soil | I | N.S. | 2; 4; 6; 8; 10; 12; 14; 16; 18; 20; 22 | 18 | N.S. | [33] |

| Clayey soil | A | N.S. | 2; 4; 6; 8; 10 | 8 | Road infrastructure | [34] |

| Clayey sand soil, clayey soil, hydrated lime and granite–gneiss rock powder | A and I | N.S. | 3.4; 4.2; 4.5; 5.6; 5.7; 7.0; 7.4; 7.5; 8.5; 9.3; 10.0; 11.3; 13.9; 14.3; 20.0; 22.2; 25.0; 28.6 | 7.4 | Daily and intermediate covers of waste landfills, and other applications with low soliciting stresses | [35] |

| Collapsing soil | N.S. | Oven drying at 105 °C | 4; 8; 12; 16 | 10 | Road construction | [36] |

| Sandy silt | Al | N.S: | 5; 10; 15; 20 | 15 | Liner material | [37] |

| Clayey soil | I | Oven drying at 105 °C | 2; 4; 6; 8; 10; 12 | 10 | Construction of roads, particularly with lower-traffic loads, lowered airfields, and non-structural applications, such as subfloors, blocks, non-load bearing walls, sidewalks, and residential floors | [38] |

| Nomenclature | Composition | Description |

|---|---|---|

| CP1 | S | Soil (100%) |

| CP2 | S + 3%CEM | Soil (97%) + cement (3%) |

| CP3 | S + 3%LIME | Soil (97%) + lime (3%) |

| CP4 | S + 10%WTS | Soil (90%) + WTS (10%) |

| CP5 | S + 5%WTS + 3%CEM | Soil (92%) + WTS (5%) + cement (3%) |

| CP6 | S + 8%WTS + 3%CEM | Soil (89%) + WTS (8%) + cement (3%) |

| CP7 | S + 10%WTS + 3%CEM | Soil (87%) + WTS (10%) + cement (3%) |

| CP8 | S + 10%WTS + 3%LIM | Soil (87%) + WTS (10%) + lime (3%) |

| CP9 | S + 15%WTS + 3%LIM | Soil (82%) + WTS (15%) + lime (3%) |

| CP10 | S + 20%WTS + 3%LIM | Soil (77%) + WTS (20%) + lime (3%) |

| Parameter | WTS | Silty Sand Soil | QRV |

|---|---|---|---|

| Dry solids content (% w/w) | 78.1 | 95.7 | NE |

| Organic matter (% w/w) | 36.8 | 0.05 | NE |

| Iron (mg/kg) | 36,500 | 12,400 | NE |

| Aluminum (mg/kg) | 93,300 | 44,400 | NE |

| Cadmium (mg/kg) | <0.1 | <0.1 | <0.5 |

| Barium (mg/kg) | 57.2 | 62.0 | 75 |

| Lead (mg/kg) | 4.45 | 6.45 | 17 |

| Chromium (mg/kg) | 11.4 | 5.22 | 40 |

| Mercury (mg/kg) | <0.05 | <0.05 | 0.05 |

| Manganese (mg/kg) | 1330 | 1 | NE |

| Copper (mg/kg) | 366 | 1 | 35 |

| Nomenclature | OMC (%) | DUWmax (g/cm3) | Swell (%) | CBR (%) | Applicability in Paving [60] |

|---|---|---|---|---|---|

| CP1 | 14.40 | 1.68 | 0.88 | 14.44 | Subgrade reinforcement |

| CP2 | 14.20 | 1.72 | 0.36 | 92.33 | Base |

| CP3 | 13.00 | 1.74 | 0.39 | 8.11 | Subgrade reinforcement |

| CP4 | 18.60 | 1.42 | 0.24 | 14.87 | Subgrade reinforcement |

| CP5 | 11.00 | 1.66 | 0.22 | 41.50 | Subbase |

| CP6 | 13.20 | 1.62 | 0.64 | 26.65 | Sub-base |

| CP7 | 15.00 | 1.51 | 0.35 | 28.68 | Sub-base |

| CP8 | 18.10 | 1.60 | 0.40 | 12.89 | Subgrade reinforcement |

| CP9 | 19.30 | 1.58 | 0.22 | 21.25 | Sub-base |

| CP10 | 21.00 | 1.52 | 0.37 | 20.13 | Sub-base |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takao, T.W.; Bardini, V.S.; de Jesus, A.D.; Marchiori, L.; Albuquerque, A.; Fiore, F.A. Beneficial Use of Water Treatment Sludge with Stabilizers for Application in Road Pavements. Sustainability 2024, 16, 5333. https://doi.org/10.3390/su16135333

Takao TW, Bardini VS, de Jesus AD, Marchiori L, Albuquerque A, Fiore FA. Beneficial Use of Water Treatment Sludge with Stabilizers for Application in Road Pavements. Sustainability. 2024; 16(13):5333. https://doi.org/10.3390/su16135333

Chicago/Turabian StyleTakao, Túlio W., Vivian S. Bardini, Amanda D. de Jesus, Leonardo Marchiori, Antonio Albuquerque, and Fabiana A. Fiore. 2024. "Beneficial Use of Water Treatment Sludge with Stabilizers for Application in Road Pavements" Sustainability 16, no. 13: 5333. https://doi.org/10.3390/su16135333